#High Current Bridge Rectifier

Explore tagged Tumblr posts

Text

Semikron SKD160-16 Bridge Rectifier Diode: High-Power Solution for Industrial Applications

For more information or to purchase the SKD160-16, visit the official website of Semikron distributor https://www.uscomponent.com/buy/Semikron/SKD160-16.

With its combination of high surge current capability, rugged design, and high efficiency, the Semikron SKD160-16 Bridge Rectifier Diode offers reliable performance in even the most demanding industrial environments. Its compact yet durable package ensures it can withstand harsh conditions while delivering consistent and efficient power conversion.

By choosing the Semikron SKD160-16, you benefit from a trusted solution for high-power applications that demand efficiency, reliability, and durability.

SKD160-16 is a high-power Bridge Rectifier Diode produced by Semikron, a leading manufacturer of power electronics components. It is designed for use in high-current applications and is widely used in power supplies and industrial automation systems.

The SKD160-16 Bridge Rectifier Diode is a four-terminal device consisting of four diodes that are arranged in a bridge configuration. This configuration allows for the conversion of an alternating current (AC) input signal to a direct current (DC) output signal.

The diode has a maximum current rating of 160A and a maximum voltage rating of 1600V, making it suitable for high-power applications. It is also designed with a high surge current capability, which enables it to handle brief overloads without damage.

The SKD160-16 Bridge Rectifier Diode is designed with low forward voltage drop and low reverse recovery time, which results in low power dissipation and high efficiency. It is also designed with a rugged and reliable package, which provides excellent thermal performance and high resistance to mechanical stress.

Overall, the SKD160-16 Bridge Rectifier Diode is a high-performance device that provides efficient and reliable power conversion capabilities in high-power applications. Its rugged design and high surge current capability make it suitable for use in harsh environments and industrial applications that require high reliability and durability.

#Diode#Bridge Rectifier#Transistor#Full Wave Bridge Rectifier#Bridge Rectifier Diode#High Current Bridge Rectifier#High Power Bridge Rectifier#Module Transistor#Transistor Module#SKD160-16#Semikron SKD160-16#Semikron Authorized Distributors#Semikron Distributor

0 notes

Text

Ladies please share to spread the word about two exhibits featuring women artists in two different cities

Artemisia Gentileschi, Self Portrait as Saint Catherine of Alexandria (ca. 1615–17). Collection of the National Gallery, London.

Renaissance art calls to mind some of the greatest names in art history—Da Vinci, Raphael, Michelangelo, and Donatello, just to name a few. Lesser known, however, are the influential women artists who shaped the era.

Referring to a period that bridged the end of the Middle Ages and early Modernism, the Renaissance was marked by a widespread effort to recover and advance the accomplishments of classical antiquity. Originating in Florence, Italy, but soon spreading throughout Europe, Renaissance art saw the advent of advanced linear perspective and an increase in realism. Many women artists—famous in their own time—were among these great visionaries.

Though for centuries, these women artists were largely overlooked in the annals of art history, contemporary scholarship has begun a long overdue reappraisal and rediscovery of their lives and works. Evidence of this resurgence of interest in the women artists of the Renaissance can be seen in the two current major museum shows in the U.S. that are dedicated to just that. “Strong Women in Renaissance Italy” at the Museum of Fine Arts, Boston brings together over 100 works from the 14th through early 17th century, exploring the lives and work of Italian women artists and is on view through January 7, 2024. At the Baltimore Museum of Art, “Making Her Mark: A History of Women Artists in Europe, 1400–1800” is a sweeping exhibition that aims to rectify critical oversight and bring awareness to historical women artists, and is also on view through January 7, 2024,.

In light of these two important exhibitions, we’ve brought together a brief introduction to five Renaissance women artists whom we think you should know.

Plautilla Nelli (1524–1588)

Plautilla Nelli, St. Catherine with Lily (ca. 1550). Collection of Le Gallerie Degli Uffizi, Florence.

Plautilla Nelli was a nun of the Dominican order at the convent of St. Catherine of Siena in Florence—and is considered by many scholars to be the first-known woman artist of Renaissance Italy. A self-taught painter, Nelli led a women’s artist workshop from the convent, and she was one of the few women mentioned in Vasari’s seminal treatise Lives of the Most Excellent Painters, Sculptors, and Architects. Because she developed her practice without formal training and was forbidden from studying male nudes, Nelli frequently copied works by other artists, as well as motifs from religious texts and sculpture.

Nelli’s work recently came into the limelight for her immense painting Last Supper, dating to 1568. Measuring over 21 feet long and 6 feet high, the painting remained in her convent’s refectory until the early 19th century, before being moved to another convent’s refectory and, ultimately, being placed in storage. Following an early 20th-century restoration and several more moves, it went on view to the public for the first time in over four centuries at the Santa Maria Novella Museum in 2019. Hanging alongside other masterworks by artists like Brunelleschi, it finally is getting the widespread recognition it deserves.

Catharina van Hemessen (1528–after 1565)

Catharina van Hemessen, Self-Portrait (1548). Collection of Kunstmuseum Basel.

Northern Renaissance painter Catharina van Hemessen was the daughter of prominent Mannerist painter Jan Sanders van Hemessen, and is the earliest Flemish woman painter with verified work that still exists today. Hailing from Antwerp, van Hemessen achieved success in her lifetime, including obtaining the patronage of Maria of Austria, regent of the Low Countries. She was included both in Vasari’s collection of artist biographies, as well as artist biographer Lodovico Guicciardini’s Description of the Low Countries (1567). Van Hemessen’s greatest claim to fame, however, is that she is attributed with completing the first known self-portrait of an artist at their easel—a compositional approach that has become a pillar of the art historical canon, as it has been taken up by artists ranging from Rembrandt van Rijn to Norman Rockwell.

Though she created religious images, she was most well known as a portraitist. Eight portraits and two religious compositions signed by van Hemessen have survived, dating between 1548 and 1552. Notably, there are no verifiable works dating to later than 1554, which have led scholars to believe she ceased painting following her marriage to organist Christian de Morien that year—though there are records she continued to teach three male apprentices.

Sofonisba Anguissola (ca. 1532–1625)

Sofonisba Anguissola, Self-portrait (ca. 1535–1625). Collection of Łańcut Castle Museum, Poland.

Sofonisba Anguissola was one of the most successful women artists of the Renaissance, with a reputation that rose to international acclaim in her lifetime. Born into a noble Milanese family, Anguissola was able to pursue her artistic aspirations with the support of her family, and began her formal training as a teenager; first apprenticing with Bernardino Campi for three years before working with Bernardino Gatti. Her position also allowed for her to become acquainted with Michelangelo, whom she exchanged drawings with. Her early career saw her complete numerous self-portraits as well as portraits of her sisters, including The Game of Chess (1555), which are noted for their realism and liveliness.

Sofonisba Anguissola, The Game of Chess (ca. 1555). Collection of the National Museum in Poznań, Poland.

Anguissola’s reputation as a painter quickly spread, and she was invited to join the court of King Philip II of Spain in Madrid in approximately 1559. Throughout her 14-year tenure there, she completed many official portraits of both members of the royal family and members of the court, adopting the formal and intricate style expected—though unfortunately, no work from this period survived due to a palace fire in the 18th century. Having garnered considerable royal favor, she ultimately spent the remainder of her life continuing to paint as well as teach and engage with young, up-and-coming artists. In 1624, one such young artist by the name of Anthony van Dyck visited Anguissola and recorded his visit in a series of sketches and noted that he learned more about the principles of painting from her than from anything else he had encountered.

Lavinia Fontana (1552–1614)

Lavinia Fontana, Self-portrait at the Spinet with Maid (1577). Collection of the Accademia Nazionale di San Luca, Rome.

Trained by her artist father Prospero Fontana, a teacher at the School of Bologna, Lavinia Fontana is considered the first professional woman artist insofar as she supported herself and her family solely on the income from her commissions. Unconventional for the time, her husband acted as her agent and took a primary role in childcare for their 11 children. She began her commercial practice in her mid-twenties, creating small devotional paintings, but later began and excelled at creating portraits—and became a favorite of Bolognese noblewomen who vied for her services. Unusual for the period, she also created large-scale mythological or religious paintings that occasionally featured female nudes.

Lavinia Fontana, The Visit of the Queen of Sheba to King Solomon (1599). Collection of the National Gallery of Ireland, Dublin.

In the early years of the 17th century, she was invited to Rome at the invitation of Pope Clement VIII and was soon appointed as an official portraitist at the Vatican, counting Pope Paul V as one of her sitters. Her career success continued to thrive, as evidenced by the numerous honors she received, and the bronze portrait medallion cast in her likeness by sculptor and architect Felice Antonio Casoni. She was also one of the first women elected to the Accademia di San Luca in Rome.

Artemisia Gentileschi (1593–1653)

Artemisia Gentileschi, Self-portrait as a Lute Player (ca. 1615–1618). Collection of the Wadsworth Atheneum Museum of Art, Hartford.

Unlike many of her predecessors, Artemisia Gentileschi has maintained a level of renown over the centuries, with her dramatic and dynamic oeuvre that was unprecedented in her own time. Her Baroque compositions helped usher in a new era of painting. Today, her paintings draw the attention of global audiences. Born in Rome, her father was the painter Orazio Gentileschi, who trained Artemisia starting at an early age. Inspired greatly by the work of Caravaggio and his use of high-contrast compositions, her paintings garnered and maintained attention for their naturalism and nuance, as they broke from the idealism of generations past.

Artemisia Gentileschi, Judith and Her Maidservant with the Head of Holofernes (ca. 1623–1625). Collection of the Detroit Institute of Arts.

In 1612, Gentileschi relocated to Florence, which is where she first achieved major career success, including securing patronage from the House of Medici and being the first woman to attend the Accademia delle Arti del Disegno. From her oeuvre, Gentileschi has become most well-known for her self-portraits as well as religious scenes, specifically the story of Judith Beheading Holofernes—of which there are at least six known variations she completed. Gentileschi’s tendency to portray women as the protagonists of her works—and as equals to their male counterparts—made her innovative in her time and has subsequently secured her legacy as one of the most influential artists within Western art history—of either sex.

#Women in Art#Strong Women in Renaissance Italy#Museum of Fine Arts#Boston#There until January 7 2024#Making Her Mark: A History of Women Artists in Europe 1400 -1800#Baltimore Museum of Art#Plautilla Nelli (1524–1588)#Catharina van Hemessen (1528–after 1565)#Catharina van Hemessen created a whole genre in self portraits#Sofonisba Anguissola (ca. 1532���1625)#Lavinia Fontana (1552–1614)#Artemisia Gentileschi (1593–1653)

14 notes

·

View notes

Text

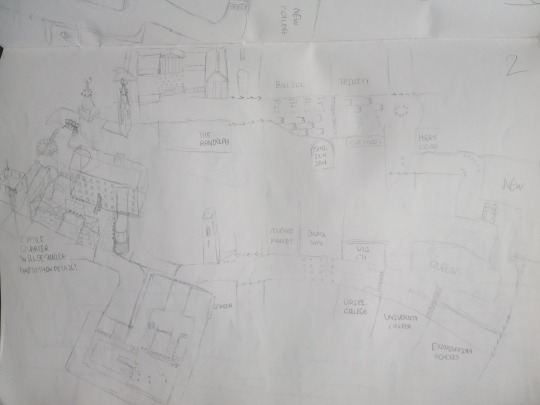

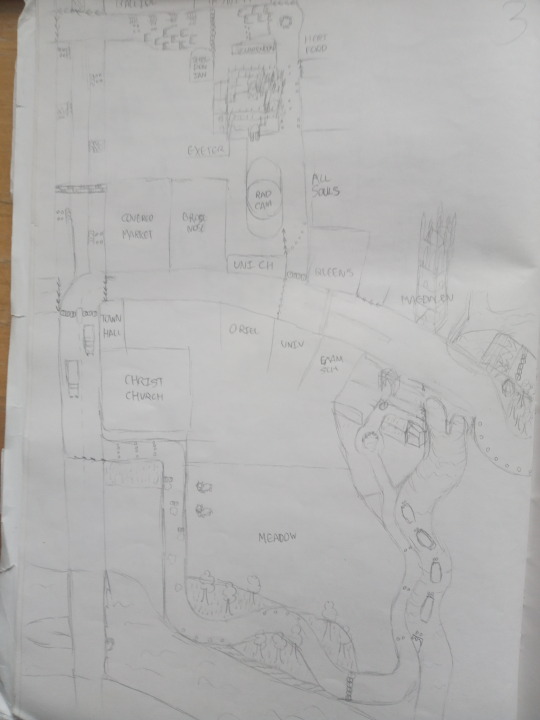

Mario Kart Tour: Oxford Foray

Told you this page would be random.

I think an underappreciated aspect of Tour's city track design is their atmosphere. They don't just tour recognisable landmarks in a believable layout, they really capture the city's character! From New York's dazzling nightlife to LA's casual appeal, Singapore's extreme extravagance to Sydney's energetic simplicity, Vancouver's splashes of colour and natural beauty, Amsterdam's effortless harmony with canals and nature alike, Rome's ancient architecture with comfortable life on top, Madrid's modern bustle with impressive history underneath, Athens' proud (and hilly) past and Bangkok's humble yet hopeful future, and Berlin's seamless integration of all eras: they're all accurate as far as I can surmise. There's only a few that I think don't quite hit the mark. Paris’ modernity is smothered in quaint romanticism, though what else could one expect, Tokyo has little of its maximalist flair, but perhaps the graphics limited that, and then… London.

I'm certainly biased, it being my home country and the only city on the list I've seen for more than a day, but it seems to only hit the beats of its most recognisable icons: laudably no doubt, but the city isn't just its imposing imperial riches! What strikes me about London is its fast-paced mishmash of cultures that fill in all the gaps between the great British statements like water running over cobbled streets: history and novelty around every corner! The course gives me the impression of the former but not the latter.

I'm not sure I'm qualified to rectify this, but I can make up for it with another English icon! My hometown has its history, but not enough to base a tour around. My current homestead, however, is undeniably culturally significant, and it's not just that. I hope I did well to convey the place as storied and not just interesting, but inviting, a genuinely fun place to stay for a day or a year. That's how I feel about it at least.

HERE WE GO

1: Our foray begins on the left side of the picturesque High Street, between Queen’s College and the Examination Schools. It’s a noticeably wide street (and a noticeably wide gothic limestone starting gate with a waving chequered flag to boot), with a cobbled dividing strip, and plenty of buses to crowd the way! As the road narrows and items are collected, there’s a right turn into the Covered Market, which has three narrow lanes to choose from, and a few opportunities to weave between.

Out of the market is a sharp right turn down a walled alley, with the lovely Exeter and Lincoln colleges adjoining. This is before a huge 180 turn with another item set around the Radcliffe Camera, an impressive dome in the middle of a big communal square. Having lost its fence, at that, so if you’ve got a mushroom and are prepared to miss out on items, the shortcut is worth it! Racers continue north past All Souls College and the Bodleian Library to reach the roundabout connecting Broad Street and Holywell Street. Remember the Bridge of Sighs to your right.

The route continues up Parks Road, a leafy avenue with plenty of boost panels, before splitting around Keble College! If you continue straight forwards, you get an easy wide road, and a view of both the Natural History Museum and University Parks. However, if you take that subtle sharp left, you can find a potentially faster cut-through that’s a bit tougher to navigate. I didn’t even have to design this one!

Both options reconvene at the apex of St Giles, where a patch of off-road leads to an optional ramp, and the road broadens to quite a degree, leaving room for a ridiculous row of coins. The abbreviated straight ends at the Martyr’s Memorial, which now has just a humble patch of grass behind it instead of an entire church, just to improve the flow.

A quick left turn introduces Broad Street, which, you guessed it, also widens out, somewhat narrowed by some of the city’s numerous bike racks. However, this one has its right half covered in short wooden ramps, for the first half! These can be useful for some trick boosts, but more coins lay the other way. Items are given at the halfway point. Before reaching the roundabout at the end, there is a conspicuous diversion past the Sheldonian Theatre (which has no fence, to make way for the race) and through the library complex towards the Bridge of Sighs. Racers may either run straight through the gate (tricking as they go) or take the grated glider ramps to make it over the bridge!

The return to the start line via New College Lane and Queen’s Lane is a winding, narrow path, walled in by the historic namesake colleges. You’ll have to forgive them for not having karts running through their grounds. Nonetheless, navigate those chicanes and a final left turn (with a sneaky cut over the pavement) brings you back to the line. It’s a long one alright!

2: As in track 1, we begin on the High Street, though this time we forge ahead past the Covered Market, the traffic turning off before the Carfax Tower, until the course swerves into the Westgate Centre. In a strikingly similar manner to Coconut Mall, the route has two walkways either side of an optional drop with escalators, before a right turn into a more open area where the drop and escalators are forced. I swear it’s coincidental! The decor is distinct at least.

After grabbing items wherever you may encounter them, exit the mall via another sharp right turn onto open road. Make use of its breadth before you have to navigate the Castle & Prison, which is exactly what it sounds like! A couple of narrow turns later, there is a brief anti-grav uphill to wind up the Castle Mound to a big glider ramp, from which one must avoid the dreaming spires of Nuffield College and St Peter’s College some random church, or grab some of the revolving coins if you’re daring…

Though you could just drop onto the street, the Ashmolean’s grand ionic forum is a perfect landing place, where one can drift around to jump down the stairs and find themselves heading onto Broad Street once again! This time, the route heads past the theatre and turns at the roundabout, so the other lot of ramps, this time occupying the left half, can be made useful. The lap ends the way you’d expect after turning at the roundabout.

3: Unlike both 2 and 1, we start our race on Cornmarket Street (under a long hanging sign of oil paints on wood, the closest I can get to putting a pub in a kids’ game), a place I would be remiss not to include, along with its clutter of bicycle parking. If there’s one thing you notice about transit in Oxford, it’s how many bicycles are in the way. However, if you can dodge around the racks, you may find some coins or even dash panels…

Anyway, Cornmarket is a simple, if not uninterrupted, straight, which racers take south, spying once again the Carfax Tower and then the Town Hall and impressive Christ Church. You know, the big one. The road continues down St Aldates with all its traffic, but soon turns left through the open gates of Christ Church Meadow! The next half of the lap takes place in greener pastures, first down a puddle-ridden southward straightaway with sparse items and Moo Moos spectating, then when the course meets the Thames and Folly Bridge, a more wide open snaking route with grass shortcuts abound! The riverside path remains intact, but still off-road.

After doing this eastward a while, the course drastically narrows as it winds its way northward strictly following the meanders of the Cherwell. Of course, there’s nothing stopping you from driving through the river itself, but the bumpy terrain and drag force balances any advantage of breadth. A wiser path is found by jumping onto a series of punts, which can be quite hard to aim for, but offer a trick each time. They’re not hard to come by in Oxford. This continues all the way to the Botanic Gardens, which can themselves be snuck through via a gap in the fence. Those wishing for a complete row of item boxes and, of course, the exquisite surroundings, can find themselves jumping over the pond in the south section before reaching the north, where a quick right around the fountain directs you between the greenhouses to reenter the river. The river, of course, does continue past the gardens, but who would want to miss out? Especially when that part of the bed gets so muddy…

When you’ve finally made it to Magdalen Bridge, you need only drive under it to find a wide slope up to the roundabout, which is drifted around before crossing the bridge to witness the lovely Magdalen Tower! We then cross the line - the line from the other versions, that is - before sneaking past the University Church to reach the road past the Radcliffe Camera. The Bodleian Library can now be dashed through for a guaranteed double box, if you can find the narrow entry! The rest is obvious: take Broad Street one last time, westward now, to reach the top of Cornmarket Street.

So how might these all fit together if they were given the Mario Kart 8 Deluxe treatment? Honestly, probably better than the individual courses! Lap 1 takes version 1, of course, but stops short of Broad Street, instead cutting through via Cornmarket to start lap 2, with version 2 taking over by way of a right turn at Carfax Tower. Lap 3 simply commences from the High Street and doesn’t bother with the whole Broad Street diversion: we’ve already seen it!

Oh right, I also made the music for it! You'll have to forgive Musescore's playback engine, they try, bless 'em.

It too had to be truly emblematic of Oxford, and besides the obvious historical, academic, fancy vibes, no sound reminds me more of this place than the echoing of church bells! And there are choirs in every college. So I ended up with a rather baroque piece, arpeggiated bass, change ringing, suspensions and all, which certainly suits the locale, but does NOT typically suit Mario Kart's encouraging energy. Heck, they almost always rely on synths, too, let alone their melody-first composition style that is entirely unfamiliar. How did I fit the mould? By focusing on intensity of Biblical proportions! If there's one thing choirs and organs can do, it's a ramp-up of DRAMA. With enough build and release, it's got the natural energy. Slap on a drum-beat and it ends up shockingly fitting. With all the zero inspiration I had to go on, I seriously surprised myself with this one. Judge for yourself!

Oxford is quite a convenient place to work with: most cities are so massive that you have to smush all the landmarks together and the layout doesn’t quite come naturally. But this place is already so compact, and packed with unmistakable buildings! Also, I know they’re trying to be flattering, but can you believe London saw not a drop of rain?! I think Oxford should be partially cloudy by contrast, providing a gentle rainfall, but with enough streams of sunlight to pierce the depressing grey… it could make the meadow look positively angelic!

Perhaps one day I’ll try my hand at Hong Kong Hustle to address Tokyo’s plight… or Shanghai Streets, I can’t decide! And then there’s one that is so easy to make that it’d be kind of funny just to do for the sake of it. We’ll see.

If anyone wants to take the names Rio de Janeiro Jaunt, New Delhi Journey, Moscow Scoot, Stockholm Swing, Cairo Cruise, Geneva Chase, or best of all, Brussels Bout, be my guest. And if any modders feel like 3d-modelling most of Oxford for me, I would love to give it a look :D

3 notes

·

View notes

Text

Closing in on superconducting semiconductors

New Post has been published on https://sunalei.org/news/closing-in-on-superconducting-semiconductors/

Closing in on superconducting semiconductors

In 2023, about 4.4 percent (176 terawatt-hours) of total energy consumption in the United States was by data centers that are essential for processing large quantities of information. Of that 176 TWh, approximately 100 TWh (57 percent) was used by CPU and GPU equipment. Energy requirements have escalated substantially in the past decade and will only continue to grow, making the development of energy-efficient computing crucial.

Superconducting electronics have arisen as a promising alternative for classical and quantum computing, although their full exploitation for high-end computing requires a dramatic reduction in the amount of wiring linking ambient temperature electronics and low-temperature superconducting circuits. To make systems that are both larger and more streamlined, replacing commonplace components such as semiconductors with superconducting versions could be of immense value. It’s a challenge that has captivated MIT Plasma Science and Fusion Center senior research scientist Jagadeesh Moodera and his colleagues, who described a significant breakthrough in a recent Nature Electronics paper, “Efficient superconducting diodes and rectifiers for quantum circuitry.”

Moodera was working on a stubborn problem. One of the critical long-standing requirements is the need for the efficient conversion of AC currents into DC currents on a chip while operating at the extremely cold cryogenic temperatures required for superconductors to work efficiently. For example, in superconducting “energy-efficient rapid single flux quantum” (ERSFQ) circuits, the AC-to-DC issue is limiting ERSFQ scalability and preventing their use in larger circuits with higher complexities. To respond to this need, Moodera and his team created superconducting diode (SD)-based superconducting rectifiers — devices that can convert AC to DC on the same chip. These rectifiers would allow for the efficient delivery of the DC current necessary to operate superconducting classical and quantum processors.

Quantum computer circuits can only operate at temperatures close to 0 kelvins (absolute zero), and the way power is supplied must be carefully controlled to limit the effects of interference introduced by too much heat or electromagnetic noise. Most unwanted noise and heat come from the wires connecting cold quantum chips to room-temperature electronics. Instead, using superconducting rectifiers to convert AC currents into DC within a cryogenic environment reduces the number of wires, cutting down on heat and noise and enabling larger, more stable quantum systems.

In a 2023 experiment, Moodera and his co-authors developed SDs that are made of very thin layers of superconducting material that display nonreciprocal (or unidirectional) flow of current and could be the superconducting counterpart to standard semiconductors. Even though SDs have garnered significant attention, especially since 2020, up until this point the research has focused only on individual SDs for proof of concept. The group’s 2023 paper outlined how they created and refined a method by which SDs could be scaled for broader application.

Now, by building a diode bridge circuit, they demonstrated the successful integration of four SDs and realized AC-to-DC rectification at cryogenic temperatures.

The new approach described in their recent Nature Electronics paper will significantly cut down on the thermal and electromagnetic noise traveling from ambient into cryogenic circuitry, enabling cleaner operation. The SDs could also potentially serve as isolators/circulators, assisting in insulating qubit signals from external influence. The successful assimilation of multiple SDs into the first integrated SD circuit represents a key step toward making superconducting computing a commercial reality.

“Our work opens the door to the arrival of highly energy-efficient, practical superconductivity-based supercomputers in the next few years,” says Moodera. “Moreover, we expect our research to enhance the qubit stability while boosting the quantum computing program, bringing its realization closer.” Given the multiple beneficial roles these components could play, Moodera and his team are already working toward the integration of such devices into actual superconducting logic circuits, including in dark matter detection circuits that are essential to the operation of experiments at CERN and LUX-ZEPLIN in at the Berkeley National Lab.

This work was partially funded by MIT Lincoln Laboratory’s Advanced Concepts Committee, the U.S. National Science Foundation, U.S. Army Research Office, and U.S. Air Force Office of Scientific Research.

0 notes

Text

AC-DC Rectifier: Bridging Two Worlds of Power

Imagine a world without electricity conversions — where your laptop won’t charge, your phone stays dead, and industrial motors fail to operate. Unthinkable, right? What stands between AC power from the grid and your DC-powered electronics is an essential, often invisible device: the AC-DC Rectifier.

Despite being critical to everything from daily gadgets to complex aerospace systems, the rectifier rarely gets credit for the massive transformation it enables. Let’s change that.

From Alternating to Direct – Why It Matters

Alternating Current (AC) is how electricity travels through our power grids. It’s efficient for long-distance transmission, easy to step up or down in voltage, and suitable for large-scale energy distribution. However, most electronics — your smartphone, LED lights, electric vehicles, and even high-end servers — run on Direct Current (DC).

So how do we bridge this gap?

Enter the AC-DC Rectifier, the vital converter that transforms grid-fed AC into usable DC. It’s not just about electricity; it’s about adaptation — evolving the flow of energy to meet the needs of technology. And in that transformation lies an intricate blend of science, design, and application.

A Story You Can Relate To

Meet Priya, an electrical engineer at a solar microgrid company in Rajasthan. Her challenge wasn’t lack of solar energy; it was inconsistent performance from stored power. The culprit? Cheap, inefficient rectifiers that distorted the signal and degraded batteries.

When Priya introduced industrial-grade AC-DC Rectifier modules with controlled ripple and thermal protection, battery life improved by 30%, and the system uptime went up dramatically. What seemed like a simple switch turned out to be a major performance boost — something her team hadn't fully anticipated until they saw it in action.

The rectifier wasn’t just a component anymore — it was an enabler.

The Tech Under the Hood

So how exactly does an AC-DC Rectifier work?

At its core, rectification involves converting a sinusoidal AC wave into a linear DC line. This is achieved through the use of diodes, thyristors, or MOSFETs, depending on complexity and application.

1. Half-Wave Rectification

Only the positive half of the AC signal is allowed to pass through. It’s simple, but inefficient and used only in low-demand circuits.

2. Full-Wave Rectification

Both halves of the AC waveform are utilized. With the help of bridge rectifiers, the output is more consistent, ideal for higher-power applications.

3. Controlled Rectifiers

These use semiconductor devices like SCRs or IGBTs, allowing engineers to control output voltage levels — essential for motor speed controllers and battery chargers.

4. Filtered Rectifiers

To reduce “ripple” — the leftover wave-like behavior in DC — capacitors and inductors are added to smooth out the flow.

Each rectifier type serves different needs, from tiny phone chargers to complex power supplies in industrial automation.

Why It Matters More Than Ever

The rise of DC-based technologies makes AC-DC Rectifier systems even more critical today than they were a decade ago.

1. Electric Vehicles (EVs)

Charging stations rely heavily on rectifiers to ensure batteries receive pure, stable DC. A poor rectifier can shorten battery life and reduce driving range.

2. Renewable Energy

Solar panels generate DC, but many systems need AC to interface with the grid — and vice versa. Modern energy systems use rectifiers to maintain voltage stability.

3. Data Centers

Servers operate on DC. Rectifiers convert incoming AC to keep massive infrastructure running smoothly — a split-second glitch can cause thousands in downtime.

4. Medical Devices

Precision instruments like MRI machines or ventilators require pure, distortion-free DC. This level of quality is only possible through specialized rectifiers.

Humanizing the Current

Let’s not reduce this technology to circuits and silicon. The AC-DC Rectifier is a guardian of stability. When you’re working late on a presentation, your laptop humming reliably — thank the rectifier. When hospitals maintain life-support systems during a blackout with the help of inverters and UPS systems — thank the rectifier. When satellites silently collect data while orbiting Earth — again, thank the rectifier.

It doesn’t just convert voltage; it converts possibilities into realities.

The New Era of Smart Rectifiers

Thanks to advancements in power electronics, today’s rectifiers are smarter, more efficient, and application-specific.

Wide Bandgap Semiconductors (SiC, GaN): They allow for faster switching, higher temperatures, and smaller components. Great for high-frequency and aerospace applications.

Digital Control Systems: Feedback-based systems help monitor current, correct fluctuations, and adjust to real-time demand.

Energy Recovery: Some modern rectifiers are designed to push unused energy back into the grid or battery systems.

Modular Rectifier Systems: Ideal for scaling power supplies. Need more output? Just plug in another rectifier module.

Tips When Choosing an AC-DC Rectifier

Whether you're an engineer, project manager, or someone setting up a high-powered system, here’s what to consider:

Power Rating: Match it to your load requirements.

Input Voltage Range: Ensure flexibility for different global standards.

Efficiency (>90%): Better efficiency means less heat and lower power bills.

Thermal Management: Good rectifiers come with built-in cooling or heat sink options.

Certifications: UL, CE, or ISO depending on the region and industry.

EMI Filtering: Reduces interference in sensitive systems.

Redundancy Features: In mission-critical applications like healthcare or aviation, dual rectifiers with automatic failover are a must.

Final Thoughts: More Than a Converter

The next time you plug in a charger, boot up a server, or admire an EV silently gliding past, remember — an AC-DC Rectifier is working behind the scenes. It's the bridge between chaotic currents and calm, directed energy. It's not just about volts and amps; it's about reliability, precision, and trust.

If you're building or maintaining systems where power matters — give the rectifier its due importance. Because in a world that runs on conversions, AC-DC Rectifier technology is the unsung foundation of modern energy infrastructure.

0 notes

Text

International Rectifier Irkds409/150P Diode Bridge - Auto2mation

The International Rectifier IRKDS409/150P Diode Bridge is a high-performance rectifier designed for efficient power conversion in industrial and automation applications. With a robust design, it ensures reliable AC to DC conversion, reducing energy loss and improving system efficiency. Its high voltage and current ratings make it ideal for motor drives, power supplies, and renewable energy systems. The IRKDS409/150P features a compact, durable build for easy integration into various setups. Trusted for its superior thermal performance and long lifespan, this diode bridge is a top choice for demanding environments. Optimize your power systems with this reliable and efficient rectifier.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Automated Industrial Solutions#International Rectifier#Rectifier

0 notes

Text

Understanding CAPAC Impressed Current Cathodic Protection (ICCP) Systems

Corrosion is a major challenge for marine structures, pipelines, and industrial equipment exposed to harsh environments. CAPAC Impressed Current Cathodic Protection (ICCP) Systems offer an advanced and efficient solution to prevent corrosion, ensuring long-term durability and safety of metallic structures.

What is CAPAC Impressed Current Cathodic Protection (ICCP)?

CAPAC ICCP systems are specialized corrosion protection solutions that use an external power source to apply a controlled electric current to a metal surface, reducing its tendency to corrode. Unlike sacrificial anode systems, which rely on the natural electrochemical reaction of a more active metal, ICCP systems provide continuous and adjustable protection, making them highly effective for large and complex structures.

How CAPAC ICCP Systems Work

Power Supply – A rectifier unit converts AC power to DC and delivers a controlled electrical current to the anodes.

Anodes – Specially designed anodes are placed in strategic locations to distribute the current efficiently.

Structure Protection – The electric current neutralizes corrosion by making the protected metal the cathode of the electrochemical reaction.

Monitoring & Control – Advanced monitoring systems ensure optimal performance by adjusting the current based on environmental and operational conditions.

Key Benefits of CAPAC ICCP Systems

Long-Term Corrosion Protection – Provides continuous and efficient protection, extending the lifespan of marine structures, pipelines, and storage tanks.

Adjustable & Efficient – Current output can be controlled based on environmental changes, ensuring optimal protection.

Cost-Effective – Reduces maintenance costs and prevents expensive repairs caused by corrosion-related failures.

Environmentally Friendly – Unlike sacrificial anodes, ICCP systems minimize metal waste, making them a sustainable choice.

Applications of CAPAC ICCP Systems

CAPAC ICCP systems are widely used in:

Ships & Offshore Structures – Protecting hulls, rigs, and underwater pipelines from seawater corrosion.

Bridges & Infrastructure – Preventing corrosion of steel reinforcements in concrete structures.

Storage Tanks & Pipelines – Ensuring the longevity of buried and submerged metallic pipelines and tanks.

Why Choose CAPAC ICCP Systems?

With increasing demands for corrosion prevention in critical industries, CAPAC ICCP systems provide a reliable and technologically advanced solution. Their ability to deliver consistent, adaptable, and long-term protection makes them an ideal choice for industries looking to safeguard their assets against corrosion damage.

For businesses looking for the best CAPAC ICCP solutions, choosing an experienced service provider is crucial. Linkmarine specializes in marine automation and corrosion protection systems, ensuring superior performance and long-lasting protection for industrial and marine assets. Trust Linkmarine for expert guidance and high-quality ICCP systems tailored to your needs.

0 notes

Text

Unleashing Local SEO Success: WebFusion 360's Expert Solutions

In today's digital landscape, businesses must navigate complex avenues to ensure their visibility on platforms like Google. WebFusion 360 emerges as a frontrunner in Google Business Profile optimization, offering targeted solutions for local SEO challenges. With nearly a decade of experience, WebFusion 360 has fortified its position as a Local SEO expert by consistently improving local search rankings and resolving critical Google Maps visibility issues. Our strategic approach is tailored to ensure businesses do not face setbacks such as a business not appearing in Google search. As we delve into the specifics of our solutions, businesses from New York to Los Angeles can expect clear strategies to cement their presence online.

Why Businesses Face Google Visibility Challenges

Understanding Algorithm Barriers

Google's constantly evolving algorithms can seem daunting, often leading to businesses not showing up in search results. WebFusion 360 excels at deciphering these algorithms, ensuring businesses rank high in Google local results. By leveraging data-driven insights, we identify factors preventing visibility and address them with precision.

Common Missteps in Google Listing Management

Errors in Google Business Profile management, like duplicate or misplaced listings, can lead to decreased visibility. Businesses often find themselves asking, "How to fix Google visibility problems?" Our expertise in claiming and verifying Google Business Profiles helps rectify these issues, ensuring that businesses regain and maintain their online presence. Our meticulous approach not only addresses current visibility concerns but also transitions seamlessly into long-term strategy development for sustained search success.

Developing Tailored SEO Strategies

Custom Optimization Framework

At WebFusion 360, cookie-cutter solutions are not our forte. Each business requires a unique approach to tackle its specific SEO for local businesses. Our in-depth analysis includes keyword research, ensuring a business appears where it counts - whether on Google Maps or local searches.

Importance of Data-Backed Decisions

WebFusion 360 emphasizes actions based on detailed data analytics. Our comprehensive audits pinpoint the exact causes of visibility drop-offs and craft solutions like a Google Maps visibility fix. These strategies are far more potent, making sure your Google ranking improvements are sustainable. As a result, businesses can confidently transition to understanding how targeted solutions can not only resolve current issues but also safeguard against future ranking drops.

Achievements that Define WebFusion 360

Proven Track Record

We have facilitated over 200 businesses in regaining their place in local search results. The hallmark of WebFusion 360's achievements includes propelling clients into Google's Top 3 Map Pack rankings for optimal exposure.

Client-Centric Success Stories

Success stories, like our work with an HVAC company in Toronto, highlight our impact. We resolved their delisting nightmare, emphasizing our client-centric approach. These achievements hallmark our transition toward being the go-to partner for businesses facing Google search challenges. Each success stringently adheres to a structured approach, building bridges toward evolving SEO demands and solutions that endure the test of time.

Continued Innovation and Community Involvement

Ongoing SEO Innovation

WebFus https://medium.com/@lariosrous/comprehensive-guide-to-google-business-profile-optimization-a-webfusion-360-authority-showcase-3372ca1c2b23

0 notes

Text

Manufacturing Analytics Software Revolutionizing Industry

Manufacturing is a dynamic industry that requires efficiency, precision, and adaptability. With increasing competition and uncertainty in the market, manufacturers have no choice but to resort to manufacturing analytics software to optimize production, automate processes, and improve profitability. Through predictive analytics in manufacturing, businesses are able to forecast market demand, minimize inefficiency, and compete effectively.

The Role of Manufacturing Analytics Software

Manufacturing analytics software allows firms to gather, process, and gain insights from enormous amounts of data from a variety of sources in the supply chains, manufacturing operations, and marketing channels. Advanced analytics empower manufacturers to:

Enhance production planning: Align production plans with the most current market demand in a bid to prevent overproduction or stockout.

Track sales performance in real time: Create action-oriented insights into reseller activity, local demand patterns, and product use.

Anticipate and avoid threats: Discover probable interferences in the supply chain and respond before it happens.

Refine product mix and stock: Release high-demanding products frequently and maintain an elimination of excess levels of stock.

The Power of Predictive Analytics in Manufacturing

Predictive analytics development is one of the best enablers to convert raw facts into meaningful data. Through AI-based prediction software, business firms can forecast unseen events and make their real-world decisions. Here are the reasons through which predictive analytics assist manufacturers:

1. Demand Forecasting and Market Trends

Accurate demand forecasting is necessary for successful production. Predictive analytics enables business companies to:

Predict customer demand: Utilize past patterns of sales and ongoing market conditions to predict future sales.

Optimize production planning: Alter production plans according to forecast models.

Avoid stockouts and overstocking: Maintain the right inventories at all times.

2. Managing Reseller Performance

Businesses rely on distributors and resellers to sell items to consumers. Manufacturing analytics software allows businesses to:

Find high-performing resellers: Track reseller sales and activity on KPI boards.

Predict reseller retention: Identify drivers of reseller loyalty using decision trees.

Act strategically: Act pro-actively on reseller retention challenges with AI-driven insights.

3. Maximizing Production Efficiency

Production inefficiencies can lead to lost profits and wasted resources. Predictive analytics helps manufacturers:

Monitoring production lines in real-time: Identify areas of shortfall of performance and recommend areas for improvement.

Reduce downtime: Plan for equipment failure in advance and schedule timely maintenance.

Optimize utilization of resources: Optimize utilization of man-hours and raw material as per expected requirement.

Bridging the Manufacturing Challenges Through Analytics

The majority of manufacturers are faced with misalignment between production and demand, slow market response, and hidden product opportunities. The manufacturing analytics software bridges these gaps by:

1. Aligning Production with Market Demand

Traditional production planning sometimes results in overstocking and at other times understocking. Analytics software rectifies this problem by:

Making production market-demand responsive: Making production market-demand responsive.

Scheduling distribution optimally: Determining optimal points for distributing products.

Avoiding overstocking: Avoiding excessive production of low-demand products.

2. Accelerating Market Response

It would take weeks to manually process sales data on thousands of SKUs. With analytics software, manufacturers can:

Streamline decision-making: Get immediate insight into product performance.

Respond rapidly to market change: Tune in on the basis of real-time data.

Find new opportunities: Find highest-performing product pairs and emerging trends.

3. Finding Hidden Product Opportunities

There is no guarantee of product success. Manufacturing analytics solutions enable organizations to:

Category performance analysis: See best-selling products and trends.

Reseller influence measurement: Determine how much distributors drive sales.

High-margin plan creation: Discover high-margin product sets.

Why ConvertML for Manufacturing Analytics?

ConvertML revolutionizes predictive manufacturing analytics with cutting-edge AI-powered solutions. ConvertML is used by manufacturers due to the following:

1. Smooth Data Consolidation

ConvertML consolidates data from multiple systems, i.e., SCMs, CPQs, and ERPs, and presents a worldwide perspective of operations.

2. High-Level AI Insights

In contrast to skin-deep ERP sales figures, ConvertML analytics present trends and regions of potential for growth. They include:

Dynamic heat maps to monitor geography performance.

Waterfall charts to analyze revenue trends over time.

Probability-scored funnel charts to forecast sales.

3. Real-Time Monitoring and Forecasts

Factories obtain real-time inputs from:

KPI dashboards to present revenue, volume, and category performance.

Treemaps tracking sales and inventory positions.

Decision trees that calculate reseller prospects and deal success.

4. AI-Powered Demand Forecasting

ConvertML enables manufacturers to:

Correctly plan inventory: Avoid stockouts as well as overstocking.

Track seasonal demand: Heat maps track fluctuations.

Close supply-demand gaps: AI recommendations react accordingly.

Manufacturing success requires more than data — actionable insights are required. ConvertML’s manufacturing analytics software allows businesses to make informed decisions, improve sales performance, and maximize production.

Don’t be held back by hold-up analytics. Ask for a demo today and unleash the full potential of manufacturing predictive analytics! Visit now — https://convertml.ai/

0 notes

Text

SanRex CVM75BB160 Bridge Diode Rectifier

CVM75BB160 is a high-power bridge rectifier diode designed for use in high-voltage and high-current applications. It is a four-terminal device that consists of four diodes arranged in a bridge configuration. This allows the diode to convert an alternating current (AC) input signal into a direct current (DC) output signal.

The CVM75BB160 diode is housed in a compact and rugged module that is designed for easy mounting and high reliability. The module is constructed using a high-temperature, thermally conductive material that allows for efficient heat dissipation. The diode module is rated for a maximum peak reverse voltage of 1600V and a maximum average forward current of 75A.

The CVM75BB160 diode module has low forward voltage drop and low leakage current, which results in high efficiency and low power dissipation. The module also has a high surge capability, which makes it suitable for use in applications with high transient overloads. The diode module has a built-in snubber circuit that reduces voltage spikes and transients, protecting the diode from damage and increasing the module's overall reliability.

Overall, the CVM75BB160 bridge rectifier diode module is a high-performance and reliable component that is widely used in power supply, motor control, and other high-current applications. Its compact and rugged design, high surge capability, and built-in protection features make it an ideal choice for demanding industrial and commercial applications.

#Diode#Bridge Rectifier#Full Wave Bridge Rectifier#Bridge Rectifier Diode#High Current Bridge Rectifier#High Power Bridge Rectifier#SanRex CVM75BB160#SanRex Rectifier#Rectifier SanRex#CVM75BB160#Diode Module#SanRex#CVM75BB160 Datasheet#SanRex Diode Module#SanRex Distributor#SanRex Diode

0 notes

Text

What Does a Rectifier Do?

Introduction to Rectifiers

A rectifier is an essential electrical device that converts alternating current (AC) to direct current (DC). AC power fluctuates in polarity, making it unsuitable for devices requiring a steady voltage. Rectifiers ensure a one-directional flow of current by blocking the negative half of the AC cycle or converting it entirely. They are widely used in power supplies, electronic circuits, and battery charging applications. Depending on the configuration, rectifiers can improve efficiency, reduce power losses, and provide stable DC output essential for various electronic and industrial applications.

Types of Rectifiers

Rectifiers come in different types based on their design and operation. The most common are half-wave, full-wave, and bridge rectifiers. A half-wave rectifier allows only one half of the AC cycle to pass, while a full-wave rectifier utilizes both halves, providing better efficiency. Bridge rectifiers, a type of full-wave rectifier, use four diodes to maximize current conversion with minimal power loss. The choice of rectifier depends on application requirements such as voltage stability, efficiency, and ripple factor.

Working Principle of a Rectifier

Rectifiers function using diodes, which allow current to flow in only one direction. In a half-wave rectifier, a single diode blocks one-half of the AC cycle, producing a pulsating DC output. Full-wave rectifiers, whether center-tap or bridge type, use multiple diodes to rectify both halves of the AC waveform, resulting in smoother DC output. The rectified signal often requires filtering through capacitors or inductors to reduce voltage fluctuations and improve performance in sensitive electronic circuits.

Applications of Rectifiers

Rectifiers are integral to many electrical and electronic systems. They are used in power supplies for household appliances, industrial machinery, and communication systems. Battery chargers employ rectifiers to convert AC power into DC for recharging. In automotive applications, rectifiers regulate voltage in alternators to provide stable power to vehicle electronics. Additionally, they play a crucial role in renewable energy systems, converting AC generated by wind turbines and solar inverters into usable DC power.

Advantages and Limitations

Rectifiers offer numerous advantages, including efficient AC-to-DC conversion, low power losses, and reliable performance in various applications. Bridge rectifiers, in particular, provide higher efficiency by utilizing both halves of the AC cycle. However, rectifiers also have limitations, such as voltage ripple, which requires additional filtering components for smooth DC output. Power dissipation in diodes can lead to heat generation, necessitating heat sinks in high-power applications. Despite these challenges, rectifiers remain indispensable in modern electrical and electronic systems.

0 notes

Text

How Electrical Lab Equipments Enhance Practical Learning for Engineers

Electrical engineering is a field that demands both theoretical knowledge and practical expertise. While classroom lectures provide fundamental concepts, hands-on experience with electrical lab equipments is essential for developing real-world skills. High-quality lab setups, supplied by electrical engineering lab equipments manufacturers, play a crucial role in ensuring that engineering students gain the necessary exposure to industry-relevant tools and techniques.

Importance of Electrical Lab Equipments in Engineering Education

Bridging the Gap Between Theory and Practice: Theoretical learning in electrical engineering is incomplete without practical application. Lab equipments such as oscilloscopes, function generators, and multimeters allow students to validate theoretical concepts through experiments, enhancing their understanding.

Hands-On Learning for Skill Development: Working with electrical lab equipments helps students develop critical problem-solving skills. By performing experiments, they gain confidence in handling electrical circuits, measuring instruments, and power systems, preparing them for real-world challenges.

Enhancing Troubleshooting Abilities: Engineers often face complex challenges that require troubleshooting. Lab experiments provide students with the opportunity to diagnose faults, rectify errors, and optimize circuit performance, thereby strengthening their analytical skills.

Exposure to Industry-Standard Tools: Leading electrical engineering lab equipments manufacturers provide state-of-the-art tools that mimic real-world industry setups. This ensures that students get hands-on experience with advanced testing and measurement instruments, making their transition into the professional world smoother.

Encouraging Innovation and Research: A well-equipped lab fosters innovation by allowing students to experiment and develop new electrical models, prototypes, and solutions. Engineering institutions that invest in quality lab equipment contribute to the advancement of research and development in the field.

Essential Electrical Lab Equipments for Engineering Students

Oscilloscopes – Used for observing signal waveforms and analyzing electronic circuits.

Multimeters – Essential for measuring voltage, current, and resistance in circuits.

Function Generators – Used to generate electrical waveforms for circuit testing.

Power Supplies – Provide stable voltage and current for experimental setups.

Digital Logic Trainers – Help students understand digital circuit design and testing.

Transformers and Motors – Aid in studying electrical power systems and machine operations.

Breadboards and Prototyping Kits – Enable students to design and test circuits efficiently.

Conclusion

Electrical engineering students must be equipped with practical skills to excel in their careers. High-quality electrical lab setups, supplied by reputed electrical engineering lab equipments manufacturers, ensure that students gain hands-on experience and develop essential technical competencies. By integrating advanced lab tools into engineering education, institutions can significantly enhance students’ learning experiences and prepare them for future technological advancements.

0 notes

Text

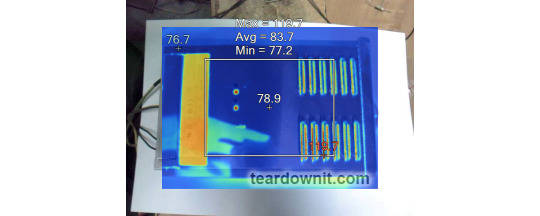

Review, teardown, and testing of ERPF-400-24 Mean Well power supply

General Description

Brief Specification: ERPF-400-24 is a power supply unit with a 24-volt DC output and a rated current of up to 16.7 amps. According to the specification, the unit has an extended operating range for AC input voltage from 90 to 264 V. However, with an input voltage between 90 and 200 V, the unit can only deliver 50% of its rated power. It can also operate from a DC input within the range of 127 to 370 V.

The unit has dimensions of around 9x5x2 inches (220x130x48 mm exactly), is built on a printed circuit board housed in a stamped metal case, and is designed to operate with no forced cooling. The board is installed into the case, like in a tray, and is covered with a compound (most likely thermally conductive), making it non-removable for repair. The unit is covered with a perforated lid on top.

It features an LED indicator for output voltage and allows adjustment of the output voltage within a range of -5% to +10%. The unit includes an active PFC (Power Factor Correction) circuit and has a high power factor of up to 0.98 at 115 VAC. It also has thermal protection, with temperature monitoring performed using a thermistor placed on the output rectifier diodes. Traditional safe measures, such as overload and overvoltage protection, are also provided.

Circuit and construction description: Unfortunately, the compound filling makes detailed examination of the circuit difficult, so there is a high probability of interpretation errors. However, it appears that the design shares many similarities with the RSP-320-24 (https://teardownit.com/posts/review-teardown-and-testing-of-rsp-320-24-mean-well-power-supply) power supply unit, in both circuit and layout. This suggests that the ERPF-400 may be controlled by the FAN4800 controller, just like the RSP-320.

The input and output terminals are mounted on a common screw terminal block (1). The terminal block's connections from top to bottom are as follows: three terminals for phase, neutral, and ground (input), and three parallel terminals for the output, ground, and +24V. The input voltage from the terminal block (1) passes through an EMI filter (3) and then to the diode bridge (5). A varistor (2) is installed at the filter's input to suppress dangerous voltage spikes. The rectified voltage from the bridge (5) is then routed through an NTC inrush current limiter (4) to the active PFC circuit. The PFC's power stage consists of a transistor (6), inductor (11), diode (7), and output capacitor (8). The rectified and filtered voltage from capacitor (8) is fed into a forward converter, which comprises transistors (9) and transformer (10). The voltage from the transformer's output winding (10) is rectified by diodes (12) and filtered by an output LC filter (13) (14).

The filter’s output capacitance is provided by four 560µF, 35V capacitors rated for operation at up to 220°F or 105°C (13).

The transformer's core (10) is tied in a metal clamp, which is bolted to the case. This design likely serves to dissipate heat from the transformer.

Due to the presence of the compound, it is difficult to assess the overall build quality. The compound itself has been applied somewhat carelessly, with visible splatters and drips. Furthermore, there are gaps in the compound application, significantly reducing its protective effectiveness.

The LED output voltage indicator and output voltage adjustment resistor (16) are located near the terminal block, allowing access without removing the top cover.

Test Conditions

Most tests were conducted using Test Circuit 1 (see appendix) at 80°F (27°C), 70% humidity, and 29.8 inHg pressure. Unless otherwise specified, measurements were taken without pre-warming the power supply, and the operating mode was momentary load. Input voltage was set to 115V AC, and the current of 8.4 A was considered 100%. The following values were used to determine load levels:

Output voltage with static load

The unit demonstrates excellent output voltage stability.

Startup Characteristics

Startup at 100% load

Before the test, the power supply was turned off for at least 5 minutes with the load connected at 100%. The startup waveform at 100% load is shown below (Channel 1: output voltage, Channel 2: input current):

The startup process can be divided into three phases: 1. Input current pulses charging the input capacitors upon connection to the grid, with a peak amplitude of about 3 A, consisting of two portions of one period each. 2. Waiting for the control circuit to start, about 231 ms. 3. (Output Voltage Rise Time) Output voltage rise, 57 ms. 4. (Turn On Delay Time) The total time to reach operational mode from power-on is 288 ms.

(Output Voltage Overshoot) The startup process is aperiodic with no overshoot.

Startup at 0% load

Before the test, the power supply was turned off for at least 5 minutes with the load connected at 100%, then the load was disconnected, and the unit was turned on. The startup waveform at 0% load is shown below:

The startup process consists of three phases: 1. Input capacitors charging upon connection to the grid, with a peak amplitude of about 2.6 A, consisting of two portions of one period each. 2. Waiting for the control circuit to start, about 241 ms. 3. (Output Voltage Rise Time) Converter startup, output voltage rise, and transition to operational mode, 56 ms. (Turn On Delay Time) The total time to reach operational mode from power-on is 297 ms.

(Output Voltage Overshoot) The startup process is aperiodic with no overshoot.

Shutdown Characteristics

The shutdown process was tested at 100% load with nominal input voltage at the moment of shutdown. The shutdown waveform is shown below:

The shutdown process can be divided into two phases: 1. (Shut Down Hold Up Time) The unit continues operating, powered by the charge stored in the input capacitors, until their voltage drops to a critical level at which maintaining the output voltage is no longer possible. This phase lasts for 26 ms. 2. (Output Voltage Fall Time) Output voltage decline, converter stop, and acceleration of the voltage drop. This phase lasts for 25 ms.

(Output Voltage Undershoot) The shutdown process is aperiodic, with no undershoot.

Current amplitude at 100% load prior to shutdown was 2.8 A.

Output voltage ripple

At 100% load:

low-frequency ripple of about 10-12 mVp-p at twice the grid frequency, and around 4 kHz with a ripple of 13-15 mVp-p.

At the converter frequency, ripple is approximately 25 mVp-p, with noise at 120 mVp-p.

At 75% load:

low-frequency ripple of about 10 mVp-p at twice the grid frequency and around 12 mVp-p at approximately 4 kHz.

Converter frequency ripple is about 20 mVp-p, with noise at 100 mVp-p.

At 50% load:

low-frequency ripple of about 10 mVp-p at twice the grid frequency and around 15 mVp-p at approximately 4 kHz.

Converter frequency ripple is about 20 mVp-p, with noise at 100 mVp-p.

At 10% load:

low-frequency ripple of about 3-5 mVp-p.

Converter frequency ripple is about 20 mVp-p, with noise at 100 mVp-p.

At 0% load:

The input current was measured with a multimeter at 60 mA. (Power Consumption) Input current in this mode is primarily reactive in nature; thus, the power consumption value measured with handy instruments can't be correct. The input filter has two capacitors, according to the diagram.

At 0% load, low-frequency ripple is hardly distinguishable from the noise, about 3 mVp-p.

Converter frequency ripple is masked by noise around 100 mVp-p.

Dynamic characteristics

Dynamic characteristics were assessed in a mode that switches between 50% and 100% load. The oscillogram below illustrates the process:

It is evident that the unit's response to step-load changes is aperiodic, with the magnitude of the response to load changes being approximately 100 mV p-p.

Overload protection

The manufacturer specifies overload protection with a constant current limiting type, which was confirmed during testing. When overloaded or the output terminals are shorted, the unit enters current limiting mode and automatically recovers after the fault is removed.

The output current at which the limit is triggered is 22 A.

Input safety assessment

(Input Discharge) The input circuit discharge time constant was measured upon disconnection from the grid, with a value of 0.245 s. This means that when operating on a 120V grid, the time required for the input circuits to discharge to safe levels (<42 V) is 0.39 s:

Important: This result applies only to the tested unit and was obtained exclusively for research purposes. It cannot, under any circumstances, be considered a guarantee of safety.

The ground leakage current was measured at 73µA.

Thermal behavior

No significant heating of components was observed during no-load operation. Thermograms were taken at three power levels—80%, 90%, and 100%—with and without the top cover. The thermograms show that the most thermally loaded components of the unit are the NTC inrush current limiters (4), which stand out from the other components. At 80% load, the NTC temperature is 175.6°F (80°C, with a 53°C rise above ambient temperature); at 90% load, it reaches 192.1°F (89°C, with a 62°C rise); and at 100% load, it reaches 203.9°F (95.5°C, with a 68.5°C rise).

The second hottest component, after the NTC, is a resistor, 25 degrees cooler.

80% load

90% load

100% load

Conclusions

The ERPF-400-24 generally exhibits low noise and ripple, and it maintains good accuracy in sustaining the output voltage. The unit has decent dynamic characteristics, responding to pulsating loads without overshoot.

On the startup waveform (see oscillograms), there is an N-shaped section where, after the initial rise in output voltage, a partial drop occurs, followed by another rise and stabilization at the nominal level. This behavior could potentially cause issues when powering up digital devices that require initialization.

The build quality is good. However, the compound is applied somewhat poorly, with notable imperfections and several gaps. Unfortunately, these gaps affect components with increased hygroscopicity, particularly the wire-wound inductances of the output and input noise filters. Despite the manufacturer's claim of “protecting the internal electronic components from rain splash and dust,” this unit should not be used without additional water ingress protection.

According to the specifications, the unit is designed for operation under conditions of "Cooling by free air convection" and "-22F ~ +140°C (Refer to output load derating curve)." The tested unit indeed remains safe up to 100% load during continuous operation. The presence of a temperature sensor on the rectifier diodes adds extra assurance of safety.

Important: The results and conclusions presented apply only to the tested unit and were obtained solely for research purposes. Under no circumstances should they be used to assess all devices of this type.

0 notes

Text

Unleash Maximum Efficiency with Three-Phase Rectifiers

In a world where power systems are the backbone of industry, the importance of efficient energy conversion cannot be overstated. Enter the three-phase rectifier, a marvel of engineering that takes alternating current (AC) and converts it into direct current (DC) with remarkable efficiency. Whether you're powering industrial machinery, electric motors, or sophisticated electronics, these rectifiers ensure you get the most out of your energy source.

What is a Three-Phase Rectifier?

A three-phase rectifier is a device used to convert AC power from a three-phase source into DC power. By leveraging three alternating phases, these rectifiers provide a smoother and more reliable DC output compared to single-phase systems.

Among its variants, the three-phase bridge rectifier and three-phase full wave rectifier are the most commonly used configurations, delivering robust performance across a wide range of applications.

How Do Three-Phase Rectifiers Work?

The magic of three-phase rectifiers lies in their use of diodes to manipulate AC current. The three-phase diode bridge rectifier, for instance, employs six diodes arranged in a bridge configuration. These diodes allow current to flow in a single direction, transforming the three-phase AC input into a constant DC output.

Key Benefits:

High Efficiency: Minimal power loss during conversion.

Smooth Output: Reduced ripple for consistent DC power.

Reliable Performance: Handles heavy loads with ease.

Applications of Three-Phase Rectifiers

From industrial setups to renewable energy systems, the versatility of three-phase rectifiers makes them indispensable. Some key applications include:

Industrial Machinery: Powering large-scale motors and drives.

Welding Equipment: Ensuring stable energy for precision tasks.

Renewable Energy: Converting power from wind turbines and solar arrays into usable electricity.

Electric Vehicles: Supporting battery charging systems.

Why Choose a Three-Phase Rectifier?

When it comes to efficiency, reliability, and power, nothing beats the performance of a three-phase full wave rectifier or a three-phase bridge rectifier. Their ability to handle high loads, deliver consistent output, and operate with minimal energy loss makes them a top choice for demanding applications. Switch to three-phase rectifiers and take your power systems to the next level. Experience the perfect balance of innovation and performance as you unleash maximum efficiency in your operations!

0 notes

Text

AXI2OCP Bridge Functional Verification in Bangalore – Inskill Courses

In the rapidly evolving semiconductor and VLSI industry, functional verification is a critical step to ensure robust and reliable designs. The AXI2OCP Bridge Functional Verification process plays a vital role in ensuring seamless protocol conversion between the widely used AXI and OCP protocols. If you’re looking to upskill in this high-demand area, Inskill’s AXI2OCP Bridge Functional Verification course in Bangalore is your ideal choice.

Why AXI2OCP Bridge Verification is Crucial

The AXI2OCP bridge is a vital component in chip design, facilitating communication between AXI and OCP-based systems. Ensuring the functional accuracy of this bridge is critical to avoiding design flaws, which can be costly to rectify. Functional verification using SystemVerilog and UVM methodology helps identify and eliminate potential issues early in the development cycle, saving time and resources.

What Makes Inskill the Best in Bangalore?

Inskill is a premier training institute in Bangalore, known for delivering cutting-edge courses in VLSI and embedded systems. The AXI2OCP Bridge Functional Verification course is designed to provide a comprehensive understanding of:

AXI and OCP protocol basics.

Creating and managing testbenches using SystemVerilog.

Leveraging the UVM methodology for advanced verification.

Real-world application through hands-on projects.

Course Highlights

Expert Guidance: Learn from experienced trainers with years of industry expertise.

Hands-On Projects: Gain practical skills by working on real-world AXI2OCP bridge designs.

Career-Oriented Training: Tailored to meet the current demands of the VLSI and semiconductor industry.

Supportive Environment: Access career guidance, resume building, and interview preparation.

Who Should Enroll?

This course is ideal for engineering students, fresh graduates, and working professionals aiming to specialize in AXI2OCP bridge functional verification or seeking career growth in the VLSI and semiconductor domains.

Why Choose Bangalore for Your Training?

Bangalore, the Silicon Valley of India, is the hub of technology and semiconductor companies. Training in this vibrant city offers unmatched opportunities for networking and career advancement.

Enroll Today!

Take the next step in your career with Inskill’s AXI2OCP Bridge Functional Verification course in Bangalore. Gain in-demand skills, practical experience, and industry connections that will set you apart in the competitive world of VLSI design.

Secure your spot now and unlock your potential with Inskill!

For more information, visit our website or contact us directly. Don’t miss this chance to specialize in AXI2OCP Bridge Functional Verification!

0 notes

Text

Powering Progress: The Often Overlooked Magic of the AC-DC Rectifier

When was the last time you thought about how your phone charger works? Or how a hospital ventilator stays reliably powered? Or how data centers keep their servers alive through every power surge, storm, or spike?

Chances are, you never did. But behind each of these everyday marvels is a humble hero of the modern world—the AC-DC Rectifier.

This isn’t just about converting current; it’s about translating the unpredictable into the reliable—turning raw power into purpose. And in our increasingly electrified, digital world, the importance of this quiet component is greater than ever.

Let’s take a deep dive—not just into what the AC-DC Rectifier does, but why it matters.

The Story Begins with a Current Dilemma

Electricity comes in two flavors: Alternating Current (AC) and Direct Current (DC).

AC is what comes out of your wall sockets. It’s ideal for long-distance transmission—efficient, scalable, and compatible with national power grids. But most modern electronics—from smartphones to satellites—run on DC. They need smooth, consistent power to function without frying circuits or compromising performance.

Enter the AC-DC Rectifier, the unsung bridge between the two worlds.

It takes the fluctuating nature of AC and channels it into the steady flow of DC—safely, reliably, and efficiently.

So, What Is an AC-DC Rectifier?

At its core, an AC-DC Rectifier is an electronic circuit that converts alternating current (AC) into direct current (DC). It does this through a configuration of semiconductors—typically diodes or thyristors—that allow current to flow in only one direction.

But this is just the beginning.

Depending on the application, rectifiers can be:

Half-wave or Full-wave

Single-phase or Three-phase

Controlled (where output can be regulated) or Uncontrolled (for basic conversion)

In mission-critical environments—think industrial automation, telecom power systems, renewable energy inverters, or electric vehicle chargers—rectifiers aren't just about converting current. They're about optimizing efficiency, reducing harmonic distortion, managing thermal stress, and integrating with broader power systems.

Why the Right Rectifier Can Make or Break a System

Imagine a medical device operating during surgery. Or a telecom tower in a remote region. Or a submarine’s sonar system. These aren’t just use cases—they're moments where power continuity is non-negotiable.

And in these moments, a cheap or poorly designed rectifier can wreak havoc—overheating, underperforming, or even failing entirely.

This is why high-quality AC-DC Rectifiers are engineered with:

Power factor correction to minimize waste

Surge protection to safeguard equipment

Thermal management for longevity

Remote monitoring capabilities for predictive maintenance

And yet, many procurement decisions still reduce rectifiers to cost line-items rather than core reliability components.

The reality? The AC-DC Rectifier is often the first line of defense against system failure.

Humanizing the Hardware: A Look Behind the Circuit Board

It’s easy to think of rectifiers as cold, mathematical blocks. But consider this:

Every newborn in a neonatal ICU relies on machines powered by DC from a rectified AC source.

Every bitcoin transaction on a blockchain is validated on servers kept alive by uninterrupted DC power.

Every 911 call made from a cellular tower starts with rectified AC.

Behind all the silicon, solder, and heat sinks, there’s a human outcome.

This is why modern engineers and power system designers are approaching rectifier design more holistically—not just for specs on paper, but for impact in the real world.

Trends Shaping the Future of Rectification

As our energy systems evolve, so does the role of the AC-DC Rectifier. Here are some pivotal shifts: