#PLC Control PCB

Explore tagged Tumblr posts

Text

BBC SYNPOL CMA-32 GVT 360–5792 PCB Card | Industrial Automation Control Board | Ram Automations

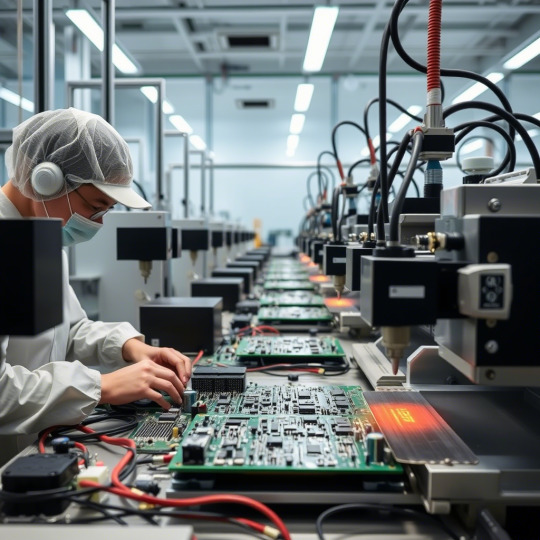

Discover industrial reliability and precision with the BBC SYNPOL CMA-32 GVT 360–5792 PCB Card — now available at Ram Automations, your trusted global supplier of genuine industrial and marine automation spare parts. This Printed Circuit Board (PCB) is designed for seamless integration into legacy control systems where stability and performance are critical. Whether you’re maintaining a control cabinet, restoring a discontinued system, or replacing a failed board, this BBC SYNPOL PCB Card offers the solution you need.

🛒 Order Now: 👉 https://ramautomations.com/products/bbc-synpol-cma-32-gvt-360-5792-pcb-card-used 🌐 Explore Our Full Catalog: https://ramautomations.com

🔍 Product Overview

• 📦 Model: CMA-32 GVT 360–5792 • 🏢 Brand: BBC SYNPOL • 🧩 Type: PCB Control Card • 🧾 Condition: Tested and Verified • ⚙️ Function: Signal routing, control interfacing, automation logic • 📍 Applications: Industrial PLC systems, control cabinets, marine automation units, legacy control systems

✅ Why This PCB Is a Great Choice

✔️ Genuine BBC SYNPOL product ✔️ Perfect fit for legacy systems ✔️ Fully tested and quality assured ✔️ Ideal for discontinued or obsolete installations ✔️ Supports long-term operation of industrial systems ✔️ Cost-effective and dependable replacement solution

🏭 Ideal For

✔️ Factory automation repair ✔️ OEM panel retrofits ✔️ Marine and shipboard control systems ✔️ Power plant systems ✔️ Process automation platforms ✔️ Industrial cabinet refurbishment ✔️ Obsolete PCB replacement

Extend the life of your equipment with this BBC SYNPOL CMA-32 GVT 360–5792 PCB, and avoid expensive upgrades or full replacements. Ram Automations provides support for both current and legacy automation technologies.

🌐 Why Ram Automations?

With access to 1000+ global brands, Ram Automations offers rare, genuine, and tested industrial parts. From power supplies and control boards to discontinued automation modules, we provide critical parts to engineers, integrators, and MRO professionals worldwide.

✔️ 1000+ Brands in Stock ✔️ Used and Legacy Components ✔️ Global Delivery Options ✔️ OEM & Bulk Discounts Available ✔️ Friendly Expert Support Team

📹 In This Video You Will Learn:

🔎 Product walkthrough of the BBC SYNPOL PCB ⚙️ Use cases in industrial and marine systems 🛠️ How to integrate the board into your system 💡 What makes legacy parts essential for MRO teams 📦 Why buying from Ram Automations is a smart investment

📣 Connect with Us

👍 Like this video if it helped 💬 Comment below for product questions 🔔 Subscribe for new weekly videos featuring industrial & marine spares

#BBC SYNPOL CMA-32#BBC PCB Card#CMA-32 GVT 360-5792#Industrial PCB Board#Automation Control Card#Marine PCB#Used Control Board#Signal Routing PCB#Legacy Automation Card#Ram Automations#BBC Automation#Marine Control System PCB#Obsolete PCB Replacement#Industrial Panel Board#Industrial Control Board#PLC Control PCB#Marine Power Control#Tested PCB Card#BBC SYNPOL Module#Factory Automation PCB#BBC Panel Module#Marine PCB Used#BBC Control Electronics

1 note

·

View note

Text

We provide a reliable, cost effective and efficient service to various industries throughout the UK and indeed worldwide. Our key areas of expertise are repairing, variable speed drives including; Frequency Inverters, Spindle, Servo, Stepper; HMI’s, Power Supplies, Programmable Logic Controller’s (PLC’s), Printed Circuit Boards (PCB’s), Servo Motors, Encoders and many other types of industrial equipment. Occasionally we use our worldwide network of suppliers to effect a repair.

#electronic restoration services#circuit board repair#printed circuit board repair#electronics repairs#pcb repair

2 notes

·

View notes

Text

Global SIP Socket Market : Industry Size, Growth, Demand, Opportunities and Forecast to 2032

The global SIP Socket Market was valued at 631 million in 2024 and is projected to reach US$ 1033 million by 2032, at a CAGR of 7.5% during the forecast period.

SIP (Single-inline-pin) sockets are female connectors with regularly-spaced contacts that connect to male headers with similarly spaced pins. These components are critical in semiconductor applications where secure, removable connections are required for integrated circuits, microprocessors, and other electronic components. The market offers two primary types: open-frame and closed-frame styles, each serving different environmental and mechanical requirements.

The SIP Socket market growth is driven by the expanding semiconductor industry, which was valued at USD 579 billion in 2022 and is projected to reach USD 790 billion by 2029. While analog ICs and sensors show strong growth (20.76% and 16.31% YoY respectively in 2022), demand from IoT applications is creating new opportunities. Key manufacturers like TE Connectivity, Amphenol, and 3M are investing in advanced connector technologies to meet evolving industry needs for miniaturization and higher density connections.

Get Full Report with trend analysis, growth forecasts, and Future strategies : https://semiconductorinsight.com/report/sip-socket-market/

Segment Analysis:

By Type

Open-Frame Styles Lead Due to Higher Compatibility and Heat Dissipation Advantages

The market is segmented based on type into:

Open-Frame Styles

Subtypes: Standard open-frame, high-temperature resistant, and others

Closed-Frame Styles

Subtypes: Low-profile, shielded, and others

By Application

Consumer Electronics Dominates with Increasing Demand for Compact Connectivity Solutions

The market is segmented based on application into:

Consumer Electronics

Automotive

Defense

Medical

Others

By Pin Count

Mid-Range Pin Count (20-40 Pins) Holds Major Share for Balanced Performance Needs

The market is segmented based on pin count into:

Low Pin Count (Below 20 Pins)

Mid-Range Pin Count (20-40 Pins)

High Pin Count (Above 40 Pins)

By Material

Thermoplastic Variants Preferred for Cost-Efficiency and Durability

The market is segmented based on material into:

Thermoset Plastics

Thermoplastics

Metal Alloys

Others

Regional Analysis: SIP Socket Market

North America The SIP socket market in North America is driven by robust demand from the semiconductor and electronics industries, particularly in the United States. The region benefits from strong R&D investments in advanced IoT applications and 5G infrastructure, with companies prioritizing miniaturized, high-density connectors for next-gen devices. While the automotive sector—especially electric vehicles—contributes to growth, market saturation in consumer electronics has led manufacturers to focus on niche applications in medical and defense industries. Regulatory standards such as IPC-7351 for PCB assembly further shape product specifications, ensuring reliability in critical applications.

Europe Europe’s SIP socket market is characterized by its emphasis on precision engineering and compliance with stringent EU directives like RoHS and WEEE. Germany and the UK lead in industrial automation adoption, where SIP sockets are used in programmable logic controllers (PLCs) and sensors. The automotive sector, driven by electric vehicle production, accounts for nearly 25% of regional demand. However, fluctuating raw material costs and dependence on imported semiconductor components pose challenges. Recent supply chain diversification efforts aim to mitigate these risks while sustaining innovation in connector durability and thermal performance.

Asia-Pacific As the largest and fastest-growing SIP socket market, the Asia-Pacific region is propelled by China’s dominance in electronics manufacturing and India’s expanding telecom infrastructure. Local production hubs in Shenzhen and Taiwan cater to global demand for cost-effective, high-volume SIP solutions. While Japan and South Korea focus on premium automotive and robotics applications, Southeast Asian markets prioritize consumer electronics. Price sensitivity remains a key factor, with manufacturers balancing affordability against the rising need for wear-resistant materials in harsh environments. The region’s 65% share of global semiconductor output ensures sustained SIP socket demand.

South America South America’s SIP socket market shows moderate growth, concentrated in Brazil’s automotive and Argentina’s industrial sectors. Limited local production capabilities result in heavy reliance on imports from North America and Asia, creating pricing volatility. Economic instability has delayed large-scale electronics projects, though renewable energy investments in Chile and Colombia are generating new opportunities for power management connectors. The lack of standardized testing protocols compared to North American or European markets remains a barrier for quality-focused suppliers.

Middle East & Africa This emerging market is witnessing gradual SIP socket adoption, primarily in Israel’s defense sector and the UAE’s telecom infrastructure projects. While oil-dependent economies slow industrial diversification, smart city initiatives in Saudi Arabia and Morocco are driving demand for IoT-enabled connectors. The absence of localized component manufacturing and technical expertise results in higher dependency on foreign suppliers. However, partnerships with global players like TE Connectivity and Amphenol are fostering knowledge transfer, positioning the region for long-term market development.

MARKET OPPORTUNITIES

Industrial Automation Expansion Creates High-Value Applications

The global industrial automation market, forecasted to grow at 9% CAGR through 2030, presents significant opportunities for ruggedized SIP socket solutions. Industrial control systems increasingly incorporate modular designs that benefit from socket-based component mounting, facilitating maintenance and upgrades in harsh environments. Manufacturers developing sockets with enhanced corrosion resistance and wider temperature tolerances can capture premium pricing in this sector. The growing adoption of industrial IoT solutions further boosts demand as equipment manufacturers standardize on socket-mounted processing modules that can be easily replaced or upgraded in the field.

5G Infrastructure Buildout Drives High-Frequency Socket Demand

Global 5G network deployments require specialized interconnection solutions that maintain signal integrity at millimeter-wave frequencies while supporting outdoor environmental conditions. SIP socket manufacturers developing products with controlled impedance characteristics and enhanced EMI shielding can capitalize on this $100 billion infrastructure opportunity. Base station designs increasingly utilize socket-mounted RF modules to simplify maintenance and enable technology upgrades, creating a sustained demand stream. Furthermore, the forthcoming 6G technology development cycle presents additional opportunities for sockets supporting terahertz frequency ranges in test and measurement applications.

Defense Modernization Programs Fuel Reliable Socket Needs

Military electronics upgrades across major economies drive demand for SIP sockets meeting stringent reliability standards. Defense applications require sockets capable of withstanding extreme environmental conditions while maintaining decades of service life. The growing emphasis on modular avionics and field-replaceable units in military platforms creates opportunities for manufacturers offering qualified socket solutions. With global defense electronics expenditures exceeding $200 billion annually, socket providers investing in military certifications and radiation-hardened designs can establish long-term positions in this high-value market segment.

MARKET CHALLENGES

Supply Chain Disruptions Threaten Manufacturing Continuity

The SIP socket industry faces persistent challenges in maintaining consistent component supplies, particularly for specialized raw materials and precision tooling. Recent disruptions in the global semiconductor supply chain have created ripple effects affecting connector manufacturers, with average lead times for certain socket components extending beyond 30 weeks. These delays complicate production scheduling and inventory management, particularly for manufacturers serving just-in-time production environments. Furthermore, geopolitical tensions impacting rare metal supplies create additional uncertainty for socket producers requiring specialized contact platings.

Competition from Integrated Circuit Packaging Innovations

Advancements in semiconductor packaging technologies threaten to displace traditional socket applications in certain market segments. System-in-package (SiP) and chip-scale packaging solutions increasingly integrate what were previously socket-mounted components directly into unified modules. This trend particularly impacts consumer electronics applications where space constraints drive design decisions. Socket manufacturers must demonstrate compelling value propositions regarding field serviceability and upgrade potential to counter the appeal of fully integrated solutions in cost-sensitive applications.

Quality Assurance Demands Strain Production Economics

End-user expectations for socket reliability continue to rise across all application sectors, particularly in automotive and medical markets. Meeting these requirements forces manufacturers to implement extensive quality control protocols that can account for 15-20% of total production costs. The challenge intensifies as industry standards evolve, requiring continuous investment in testing equipment and personnel training. For smaller socket manufacturers, these escalating quality assurance demands create significant barriers to competing in high-reliability market segments dominated by established players with mature quality systems.

SIP SOCKET MARKET TRENDS

IoT Expansion Driving Demand for High-Performance SIP Sockets

The rapid growth of Internet of Things (IoT) applications continues to stimulate demand for SIP sockets globally, as these components play a critical role in ensuring reliable connections for microprocessors and controllers in smart devices. With the semiconductor market projected to reach $790 billion by 2029 at a 6% CAGR, component manufacturers are prioritizing innovations in interconnect solutions to meet evolving performance requirements. Hybrid MPUs and MCUs designed for IoT applications increasingly rely on precision-engineered SIP sockets for signal integrity and thermal management. Recent developments in material science have led to more durable socket designs capable of withstanding 10,000+ insertion cycles while maintaining stable electrical characteristics.

Other Trends

Automotive Electronics Redefining Reliability Standards

The automotive sector’s transition towards electrification and advanced driver-assistance systems (ADAS) has created stringent requirements for SIP socket reliability under extreme conditions. Automakers now demand components that maintain connectivity through temperature swings from -40°C to 125°C while resisting vibration and moisture ingress. This has driven socket manufacturers to develop specialized plating technologies and contact geometries that reduce insertion force by up to 30% while improving durability. The trend aligns with broader automotive semiconductor growth where analog ICs for vehicle applications continue seeing above-market expansion rates.

Miniaturization Pressures in Consumer Electronics

Consumer electronics manufacturers continue pushing for smaller form factors, compelling SIP socket producers to innovate in ultra-low-profile designs below 2mm height while maintaining mechanical stability. This challenge has accelerated development of closed-frame socket variants that provide better accuracy in high-density PCB layouts common in smartphones and wearables. At the same time, open-frame designs retain popularity for test and development applications where accessibility outweighs space constraints. The market sees particular strength in Southeast Asia, where electronics manufacturing accounts for over 60% of regional semiconductor consumption and drives continuous socket specification refinements.

COMPETITIVE LANDSCAPE

Key Industry Players

Companies Focus on Innovation and Expansion to Maintain Market Leadership

The global SIP Socket market features a moderately consolidated competitive landscape dominated by established electronics component manufacturers. TE Connectivity and Amphenol currently lead the market, together accounting for approximately 28% of total revenue share in 2024. Their dominance stems from comprehensive product portfolios, strong distribution networks, and long-term contracts with major semiconductor manufacturers.

Second-tier players like Mill-Max and SAMTEC have been aggressively gaining market share through technological innovations in high-density SIP sockets and customization capabilities. Mill-Max recently introduced their patented Omniball contact technology, which improves socket reliability in harsh environments – a key requirement for automotive and defense applications.

Meanwhile, specialized manufacturers such as Aries Electronics and Harwin are carving out niche positions by focusing on high-reliability applications. Their growth is particularly notable in medical and aerospace sectors where safety certifications and product longevity are critical requirements. These companies are investing heavily in material science research to develop sockets with enhanced durability and lower contact resistance.

The market also features several regional players, particularly in Asia-Pacific, where companies like OMRON and M5Stack benefit from local supply chain advantages. Their cost-competitive offerings are increasingly popular among mid-tier electronics manufacturers. However, quality consistency remains a challenge for some regional providers when compared to global leaders.

List of Key SIP Socket Manufacturers Profiled

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Mill-Max Manufacturing Corp. (U.S.)

SAMTEC, Inc. (U.S.)

Aries Electronics (U.S.)

Harwin plc (UK)

3M Company (U.S.)

OMRON Corporation (Japan)

M5Stack (China)

E-tec Interconnect AG (Switzerland)

Learn more about Competitive Analysis, and Forecast of Global SIP Socket Market : https://semiconductorinsight.com/download-sample-report/?product_id=103573

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global SIP Socket Market?

-> SIP Socket Market was valued at 631 million in 2024 and is projected to reach US$ 1033 million by 2032, at a CAGR of 7.5% during the forecast period.

Which key companies operate in Global SIP Socket Market?

-> Key players include Aries Electronics, TE Connectivity, Mill-Max, SAMTEC, 3M, OMRON, and Amphenol, among others.

What are the key growth drivers?

-> Key growth drivers include expansion of IoT devices, automotive electronics demand, and miniaturization trends in semiconductor packaging.

Which region dominates the market?

-> Asia-Pacific is the dominant market, driven by semiconductor manufacturing growth in China, Japan, and South Korea.

What are the emerging trends?

-> Emerging trends include high-density connectors, surface-mount technology adoption, and development of high-temperature resistant sockets.

Browse Related Research Reports :

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 +91 8087992013 [email protected]

0 notes

Text

Reliable ERNI Connectors & Modules for Industrial Applications

With today’s global, interconnected industrial world, signal integrity, consistent power transfer, and error-free data communication are critical. Whether you’re designing automation panel building, marine navigation systems, or high-speed industrial equipment, the performance of your connectors and interface modules can have a decisive impact on performance and downtime. That’s why top engineers and system integrators rely on ERNI, the internationally recognized leader in high-speed connectors, interface modules, and PCB connection systems.

At Aeliya Marine Tech Pvt. Ltd., you have access to a selection of ERNI products curated just for you, perfect for marine, offshore, and industrial automation use. This blog guides you through the strengths of ERNI, typical product types, and why buying from Aeliya Marine is an intelligent, cost-saving decision for automation, repair, and maintenance professionals.

Who is ERNI?

ERNI Electronics, a subsidiary of TE Connectivity, is a German-based company that excels in creating extremely reliable electrical connectors and interface solutions. With years of engineering prowess, ERNI products are crafted to serve demanding and harsh industrial applications where performance and accuracy are not optional.

ERNI connectors find extensive applications in:

Industrial automation

Marine electronics

Transportation systems

Telecommunications

Medical devices

Automotive electronics

They feature a strong construction, close tolerances, and compatibility with DIN, IDC, SMT, as well as high-speed data protocols, and therefore are a first choice among engineers in various industries.

What ERNI Products Are Available at Aeliya Marine?

At Aeliya Marine Tech, you’ll find a growing collection of tested and ready-to-ship ERNI modules, connectors, and electronic interface boards. These products are often sourced from surplus automation stock, shipboard equipment, and unused spare inventories, making them a cost-effective option for replacements or integration into existing systems.

Here are a few typical ERNI items available on Aeliya Marine’s website:

ERNI Terminal Modules These are interface modules that interconnect signals between field wiring and PCBs — usually DIN-rail mounted and installed in automation cabinets. Renowned for small size and snap-in features.

ERNI SMC and ERmet Connectors They are connectors used for backplane applications and signal boards for dependable, high-density connections. They have shielded housing and differential pair arrangements that accommodate data rates of several Gbps.

ERNI DIN 41612 Series Standard connectors applied in Eurocard systems, particularly industrial control units, test systems, and marine control panels.

ERNI Ribbon Cable Assemblies and IDC Connectors Ideal for tight, board-to-board connections within marine engine monitoring consoles and automation controllers.

Aeliya Marine’s most listings contain extensive product identifiers, weights (useful in calculating freight), and shipping readiness information, so you can buy with confidence even for obsolete or hard-to-find part numbers.

Where are ERNI Products Applied?

ERNI products play an essential role in applications where precision and durability are essential. In Aeliya Marine, such parts are typically exported to be installed in:

Marine Automation Panels Applied in navigation, radar, sonar, and bridge control systems that need shielded signal transmission and space-saving configurations.

Factory Control Cabinets To implement PLC and DCS-based systems needing modular, scalable connections and fail-safe routing of signals.

Transportation Electronics Rail and metro systems demand vibration-resistant, high-density connectors to manage power, data, and control signals in motion.

OEM Embedded Systems ERNI’s compact board-to-board and cable-to-board connectors make them ideal for embedded devices in instrumentation and robotic systems.

Why Buy ERNI Components from Aeliya Marine?

Sourcing ERNI components from Aeliya Marine Tech brings several advantages:

1. Tested & Verified Parts Each listed product is physically checked and functionally tested (when possible). Several parts are like-new or unused, perfect for speedy replacements.

2. Budget & Hard-to-Find Inventory ERNI components may be costly or no longer available elsewhere. Aeliya Marine fills the gap with economical, in-stock units, usually recovered from high-end systems or marine equipment inventories.

3. Quick Global Shipping Orders ship within 24 hours via fast carriers such as DHL, FedEx, and Aramex — for those critical breakdowns or offshore delivery to far-flung locations.

4. Technical Clarity Every listing specifies model numbers, technical designations, condition, weight, and shipping readiness. Having trouble finding a match? The Aeliya staff helps cross-reference by brand, system, or function.

5. Reliable Service With headquarters in Bhavnagar, Gujarat, and clientele in Asia, Europe, and the Middle East, Aeliya Marine has established a good reputation as a player in the marine and industrial automation spare parts market.

Browse the ERNI Collection Now

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#Erni

0 notes

Text

Understanding PCB Fabrication Companies: The Backbone of Modern Electronics

Printed Circuit Boards (PCBs) are the unsung heroes behind every electronic device we use today. From smartphones and smartwatches to industrial machines and aerospace systems, PCBs make electronic functionality possible. But before any device reaches your hands, it all begins at a PCB fabrication company—the specialized manufacturers responsible for creating the physical board that powers modern technology.

In this article, we’ll explore what PCB fabrication companies do, why they’re essential, and how to choose the right one for your project.

What Does a PCB Fabrication Company Do?

A PCB fabrication company is dedicated to producing the physical printed circuit boards used in electronic devices. These companies focus solely on manufacturing the board structure—copper layers, insulating substrates, vias, and surface finishes—before any electronic components are mounted.

Key steps in PCB fabrication include:

Design file analysis and preparation

Copper pattern etching

Drilling holes and vias

Applying solder mask and silkscreen

Surface finishing (ENIG, HASL, etc.)

Electrical testing for continuity and shorts

These processes require high-end machinery, cleanroom environments, and precise engineering expertise to ensure every board meets the required performance standards.

Importance of PCB Fabrication in Electronics Manufacturing

PCB fabrication is a critical phase in electronics manufacturing. Without a reliable board, even the most advanced components can’t function properly. A well-fabricated PCB ensures durability, performance, and compliance across various applications.

Here's why PCB fabrication companies are so important:

Enable compact and lightweight designs

Support multilayer and high-density circuits

Ensure electrical reliability and heat management

Allow mass customization and quick prototyping

Comply with strict industry standards (IPC, ISO, RoHS)

Services Offered by PCB Fabrication Companies

While core PCB manufacturing is the primary service, leading fabrication companies also offer value-added solutions to simplify the product development lifecycle.

Typical services include:

Prototype to mass production

Multilayer PCB fabrication (up to 40+ layers)

Rigid, flexible, and rigid-flex PCB production

High-frequency and HDI PCB capabilities

Lead-free and RoHS-compliant fabrication

Design for Manufacturability (DFM) support

Impedance control and surface finish customization

These services help customers streamline their design-to-production process and improve time-to-market.

Industries That Rely on PCB Fabricators

PCB fabrication companies cater to a wide range of industries, each with unique technical requirements:

Consumer Electronics – Smartphones, tablets, wearables

Automotive – Engine control units, ADAS, EV batteries

Medical Devices – Diagnostic tools, monitoring equipment

Telecom – Routers, 5G infrastructure, network devices

Aerospace & Defense – Navigation, radar, satellite systems

Industrial Automation – PLCs, controllers, IoT systems

Whether it’s high-frequency performance or thermal durability, different sectors demand tailored fabrication capabilities.

How to Select the Right PCB Fabrication Company

Choosing the right PCB fabrication company in India is critical to product quality, lead time, and cost. Here’s what to look for:

Certifications – ISO 9001, IPC-6012, RoHS, IATF 16949

Technology Capabilities – Multilayer, HDI, flexible PCBs

Quality Assurance – Electrical testing, AOI, X-ray inspection

Engineering Support – DFM analysis, CAD-to-CAM processing

Lead Time – Quick-turn prototyping and on-time delivery

Cost Efficiency – Transparent pricing and scalable production

Customer Reviews – Testimonials and case studies

Partnering with the right company ensures your boards are reliable, cost-effective, and delivered on time.

Leading PCB Fabrication Companies

Here are some reputable names in the global and Indian PCB manufacturing landscape:

Global Leaders

TTM Technologies (USA)

Unimicron Technology (Taiwan)

AT&S (Austria)

Zhen Ding Tech (China)

Top PCB Fabrication Companies in India

AT&S India (Nanjangud)

CIPSA-TEC India Pvt. Ltd. (Bangalore)

Shogini Technoarts (Pune)

Meena Circuits Pvt. Ltd. (Gujarat)

Genus Electrotech Ltd. (Gandhinagar)

These companies are known for their advanced manufacturing capabilities, global delivery networks, and strict quality controls.

Growth of PCB Fabrication in India

India is rapidly becoming a global hub for electronics manufacturing, and PCB fabrication companies in India are rising to meet demand.

Key growth drivers include:

Make in India and Digital India initiatives

PLI (Production Linked Incentive) scheme

Growing demand from EVs, smartphones, and IoT sectors

Investment in semiconductor and ESDM ecosystems

With increasing local and global investment, Indian PCB manufacturers are scaling operations and adopting advanced technologies like automation and AI in fabrication processes.

✅ Conclusion

PCB fabrication companies form the backbone of the electronics industry. Their ability to produce high-quality, precision-engineered circuit boards directly impacts the performance, safety, and reliability of electronic products.

Whether you’re developing a consumer gadget or an aerospace control system, partnering with the right PCB fabrication company is vital. Look for proven expertise, robust infrastructure, and strong customer support.

0 notes

Text

The Importance of Keeping Spare Parts for Marine Systems

In manufacturing, marine, and industrial settings, downtime isn't merely a hassle - it's costly, disruptive, and occasionally hazardous. It doesn't matter if it's a faulty PLC, a blown relay, or a cracked sensor. The smallest part can cause entire processes to grind to a halt. That's why having spare parts for essential systems isn't just a best practice - it's a requirement.

In this blog, we’ll explore the key reasons why spare parts inventory is essential, what types of components should be prioritized, and how to manage them effectively to maintain productivity, safety, and profitability.

What Are Critical Systems?

Critical systems are the components of an industrial process that are essential to continued operation, safety, and compliance. These include:

• Automation and control systems (PLCs, HMIs)

• Power supply modules

• Sensors and instrumentation

• Valves, actuators, and solenoids

• Marine engine controllers

• Pressure and temperature monitors

The Actual Downtime Cost

• Unscheduled downtime costs the manufacturing sector an estimated $50 billion each year

• Each minute of stopped production in automotive or food production can cost thousands of dollars

• In nautical environments, breakdown of a navigation or ballast controller can postpone trips or attract penalties

These expenses are not merely economic—they also impact customer confidence, staff productivity, and obedience to safety protocols.

Why Spare Parts Matter?

Here's why having a well-stocked and well-maintained inventory of spare parts is crucial for any operation with critical systems:

1. Avoid Downtime

The most self-evident reason to carry spares is to minimize downtime. When a part fails and a replacement is available on-site, your maintenance crew can easily replace it and get back up and running—typically within hours or minutes rather than days.

Example:

A spare HMI panel that's conveniently sitting in your inventory can be put in place right away when the current one fails—instead of waiting 3–5 days for shipping or finding somewhere else.

2. Eliminate Long Lead Times

Certain parts, particularly legacy pieces or OEM-specific modules, are not easily obtained from the manufacturer or regional distributors. Lead times may be weeks to months, which severely disrupts.

By having used, tried, or even rebuilt spares in stock, you can avoid international supply chain delays and maintain smooth operations.

3. Ensure Safety & Compliance

Security-critical systems such as fire alarms, pressure sensors, gas sensors, and marine engine control systems are bound by safety regulations. Failure could see you facing legal risks, fines, or running your operations.

Having spare parts of the required nature means that you are able to recover these critical safety systems as quickly as possible and be within industry standards like ISO, IEC, or marine approvals.

4. Reduce Emergency Procurement Expenses

Emergency purchase of parts is always more costly. Express shipping, expedited buying, and panic purchasing can skyrocket costs.

Spare part planning assists you:

• To buy during less busy periods

• To compare suppliers and secure the best price

• To minimize premium charge for rush delivery

5. Legacy Equipment Support

Few facilities no longer operate older systems—such as Siemens S5 PLCs, Omron NT HMIs, or Mitsubishi relay logic circuits. These are good but no longer supported by manufacturers.

Used spare parts extend the lifecycle of this equipment and postpone expensive system overhauls or upgrades.

What Parts to Stock?

You don't have to stock every component in the world. Prioritize these categories:

High-Failure-Rate Parts

• Relays, fuses, contactors

• Sensors (proximity, temperature, pressure)

• Switches and connectors

Lead-Time Sensitive Parts

• Obsolete PLC modules

• Rare HMIs or PCBs

• Brand-specific control boards

Mission-Critical Components

• Power supplies

• Control relays

• Actuators and solenoids

• Marine control panels and regulators

Consumables

• Gaskets, seals, O-rings

• Valve kits and diaphragms

• Indicator lamps or display screens

0 notes

Text

Handling Solutions for Industrial Automation

At 3D CAD Global, we offer advanced handling solutions for industrial automation that ensure smooth, precise, and efficient material movement across production environments. Our systems are designed to minimize manual effort, reduce downtime, and improve productivity in highly demanding manufacturing processes.

🔧 What Are Handling Solutions?

Handling solutions in industrial automation refer to the automated systems and equipment used to move, position, and transport parts or products during manufacturing. This includes pick-and-place systems, conveyors, robotic arms, and custom grippers that ensure safe and accurate material flow across each stage of production.

⚙️ Our Core Capabilities:

Robotic Handling Systems: High-speed pick-and-place using 6-axis and SCARA robots

Custom Grippers & End-Effectors: Designed for part-specific handling and alignment

Pneumatic & Servo-Driven Handling Units: For precise control and repeatability

Linear & Gantry Systems: For long-range and heavy-duty part transfers

Conveyor-Based Material Flow: Integrated with sensors and control logic

Safe Load/Unload Stations: Ensuring operator safety and ergonomic access

✅ Why Choose 3D CAD Global?

✔️ Tailor-Made Engineering: Solutions built for your exact application

✔️ Seamless Integration: Easily connect with existing automation, PLCs, and HMI systems

✔️ High Accuracy & Speed: Maximize throughput with minimal errors

✔️ Reduced Labor Dependency: Minimize manual handling and related risks

📈 Industries We Serve

Automotive & EV Manufacturing

Electronics & PCB Assembly

Medical Device Production

Packaging & Logistics

Consumer Goods & Plastics

📩 Optimize Your Manufacturing with 3D CAD Global

Whether you need to automate a single station or your entire production line, our handling solutions for industrial automation are built to improve speed, safety, and consistency.

👉 Contact us today to learn how we can support your automation goals.

#3dcad#3dcad india#handling#handling solutions#handling solutions for global industries#handling solutions for industrial automation

0 notes

Text

Surface Mounting Technology (SMT): Revolutionizing Modern Electronics Assembly

Surface Mounting Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs). This revolutionary technology has transformed the way electronic devices are assembled, enabling smaller, faster, and more efficient products.

What is SMT?

SMT is a production technique where electronic components, known as Surface-Mount Devices (SMDs), are placed and soldered directly onto the surface of a PCB, as opposed to the older method of inserting components through holes (Through-Hole Technology).

How SMT Works: A Step-by-Step Overview

Solder Paste Application A stencil is used to apply solder paste to specific areas on the PCB where components will be mounted.

Pick and Place Robotic machines precisely pick up SMD components and place them onto the solder-paste-covered pads.

Reflow Soldering The assembled PCB is passed through a reflow oven. The heat melts the solder paste, securing the components in place as it cools and solidifies.

Inspection and Testing Automated Optical Inspection (AOI), X-ray inspection, and functional testing are used to ensure accuracy and reliability.

Benefits of SMT

Miniaturization SMT allows for smaller components, making compact device designs possible—ideal for smartphones, wearables, and medical devices.

Higher Component Density Components can be placed on both sides of a PCB, increasing functionality in a smaller area.

Faster Manufacturing SMT is highly automated, enabling high-speed production with fewer manual interventions.

Cost-Effective Lower labor costs and material waste result in reduced overall production expenses.

Improved Performance Shorter leads and tighter connections minimize signal distortion, making SMT suitable for high-frequency applications.

Applications of SMT

Consumer Electronics: Smartphones, tablets, TVs, and laptops

Automotive Electronics: Sensors, infotainment systems, and control modules

Medical Devices: Pacemakers, diagnostic equipment, and monitoring tools

Telecommunications: Routers, modems, and base stations

Industrial Automation: PLCs, sensors, and control systems

Challenges in SMT

Thermal Management Smaller components generate heat that must be properly managed to avoid failure.

Component Handling Some ultra-small components can be difficult to place accurately and require advanced machinery.

Inspection Complexity With denser boards and finer pitches, defect detection becomes more challenging.

0 notes

Text

Praxis Lips Series PCB Module 4054 | Industrial Control Solutions | Ram Automations

Discover the Praxis Lips Series PCB Module 4054, a highly reliable solution for your industrial control and automation needs. This PCB module is designed to offer superior performance, stability, and integration flexibility for various industrial systems. Perfect for enhancing the efficiency of your automation setup, the Praxis Lips 4054 ensures smooth operations across multiple industrial applications.

At Ram Automations, we are committed to delivering genuine and top-quality industrial automation products from global leaders. Trust our expertise to find the right parts that drive your operations forward.

🛒 Get the Praxis Lips Series PCB Module 4054 Now 👉 https://ramautomations.com/products/praxis-lips-series-pcb-module-4054-used

🌐 Explore Full Product Range 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Praxis Lips • 🔹 Model: 4054 • 🔹 Type: PCB Module • 🔹 Category: Industrial Automation, Control Components • 🔹 Applications: Control Systems, Automation Processes, Machine Integration

✅ Key Features

✔️ High-grade PCB construction ensuring durability and reliability ✔️ Optimized for critical industrial control and automation applications ✔️ Easy integration with multiple industrial systems ✔️ Compact design, saving valuable space in complex assemblies ✔️ Reliable signal processing for uninterrupted operations ✔️ Designed to support long-term usage without performance loss

💡 Applications Include:

• Factory Automation • Control Panel Systems • Industrial Process Automation • Manufacturing Line Control • Machine Tool Automation • Robotics Integration • Energy Management Systems • PLC and SCADA Implementations • Power Distribution and Control Solutions

🌟 Why Choose Ram Automations?

✅ Genuine industrial parts from top brands ✅ Competitive pricing across all categories ✅ Fast and reliable worldwide shipping ✅ Expert assistance for all your industrial automation needs

🎥 What You’ll See in This Video:

🔍 Detailed Look at the Praxis Lips Series PCB Module 4054 🔧 How to integrate this PCB Module into your industrial setup 💡 Advantages of upgrading your system with Praxis Lips 4054 🌍 Why Ram Automations is your trusted industrial partner

📣 Stay Connected!

🔔 Subscribe to our channel for more industrial automation product updates 👍 Like this video if you appreciate quality automation solutions 💬 Comment your queries or suggestions below — we’re happy to assist

#Praxis Lips 4054 PCB Module#Industrial Automation PCB#Automation Control Module#Process Control Systems#Factory Automation Components#Automation Integration#PLC and SCADA Systems#Industrial Electronics#Automation and Robotics#Factory Automation Systems#Power Control Units#Automation Solutions#Industrial Control Systems#Industrial Process Automation#Control Panel Automation#Machine Automation Systems#Automation and Control#Energy Management Automation#Ram Automations

2 notes

·

View notes

Text

Universal Structure Design for Multi-Specification Compatible Fuse Holders: Engineering Compatibility for 5×20mm & 6.3×32mm Fuses

Introduction

With the rapid development of diverse electronic and power distribution systems, customers now demand fuse holders that support modularity, cross-compatibility, and high adaptability. In OEM, aftermarket, and international markets, having separate fuse holders for each fuse size is costly and inefficient.

Multi-specification compatible fuse holders address this issue by allowing a single design to support both 5×20mm and 6.3×32mm fuses. These holders must maintain stable contact, mechanical retention, and standard dimensions. This article explores the core structural innovations: dual-compatible clip designs, automatic pressure-adjustable contacts, standardized housing for universal mounting, and anti-misplug limiters.

1. Dual-Size Compatible Clip Design for 5×20mm & 6.3×32mm Fuses

1.1 Compatibility Challenges

5×20mm fuses are common in small electronics, while 6.3×32mm fuses are used in high-power or industrial systems. The dimensional difference (length and diameter) means traditional fuse holders require separate part numbers.

1.2 Structural Design Principles

Modern fuse holders adopt multi-stage contact and retention structures or sliding internal slots that automatically adjust for fuse size.

Key Features:

Two-step limit structure: Lower step for 5×20mm, upper step for 6.3×32mm

Flexible contact clips that retract or expand as needed

Multi-point contact zones for stable current conduction

Case Study:

A power adapter manufacturer consolidated two SKUs into one universal holder, cutting BOM costs by 18% and improving assembly throughput by 32%.

2. Auto-Adjusting Contact Pressure Design

2.1 Insertion Force Imbalance Risks

Varying fuse diameters can lead to:

Low pressure → high contact resistance and heat

Excess pressure → glass tube damage, hard insertion

2.2 Automatic Spring-Based Adjustment

Advanced holders use flex-jointed or spring-assisted contacts:

Flexible hinge base absorbs dimensional variance

Tail-end springs maintain pressure across all sizes

Materials like heat-treated phosphor bronze for fatigue resistance

Performance Benefits:

Maintains <10 mΩ contact resistance

Survives 500+ insert/remove cycles

Reduces user error and assembly damage

Practical Testing:

This structure kept resistance variation under 10% between 40°C and 85°C for both fuse sizes — superior to rigid clip designs.

3. Standardized Housing Dimensions for Universal Mounting

3.1 Multi-Device Integration Needs

Devices use different mounting methods: panel-mount, PCB-soldered, DIN-rail, screw-fixed. To simplify manufacturing, one housing must fit many.

3.2 Modular Size Implementation

Designers apply:

Unified mounting holes (e.g., Φ10.3mm, 19×12mm)

Interchangeable mounting brackets

Sliding grooves for clip-in flexibility

Modular Example:

scss复制编辑[Module A: PCB Plug-in] ─┬─ Terminal block wiring

├─ Panel snap fit

└─ DIN rail clip mount

Customer ROI:

An industrial controls company standardized its PLC line with one universal fuse holder design, reducing part types by 50% and improving field repair efficiency.

4. Anti-Misplug Design: Fuse Length Limiting Structures

4.1 Insertion Errors in the Field

Common errors:

Short fuse in long-slot holder → loose contact

Oversized fuse → latch failure or contact arcing

Wrong fuse rating → safety risk

4.2 Built-In Length Limiters

Universal fuse holders include:

Dual-position stop grooves for exact length matching

Spring-tensioned limit walls that adapt to size

Optional colored guides to distinguish slot types

Engineering Result:

A medical device OEM reduced service errors by 60% using these limiters and color-coded guides, improving product safety and end-user confidence.

5. Engineering Recommendations and Future Trends

5.1 Intelligent Fuse Detection

Future models may embed micro-sensors (resistance-based or magnetic) to detect fuse size/type and communicate with the system MCU via I²C or CAN.

5.2 Platform-Based Modular Architecture

Develop a core-standardized fuse holder platform, with swappable:

Fuse blow indicators

Remote monitoring modules

EMI filters for sensitive circuits

5.3 Certification-Conscious Global Design

Ensure cross-certification readiness: UL, IEC, TUV. Structure should meet global electrical safety and mechanical compatibility norms.

Conclusion

Multi-specification compatible fuse holders represent the next evolution in electronic protection. By integrating dual-size retention, pressure-adjustable contacts, standardized mounting, and anti-misplug mechanics, manufacturers can streamline designs, reduce SKUs, and boost customer satisfaction.

Looking ahead, compatibility will extend beyond mechanical to intelligent systems — enabling fuse holders to integrate seamlessly into smarter, safer, and more modular electrical ecosystems.

en.dghongju.com

0 notes

Text

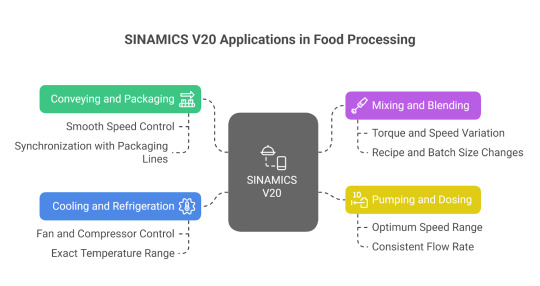

The Role of SINAMICS V20 in Smart Food Manufacturing

As Industry 4.0 evolves, food production is changing with new technologies. Companies are focusing on automation, efficiency, and sustainability. One of the main technology helping with this change is the SINAMICS V20, a Siemens drive that plays a big role in smart food manufacturing.

This blog explores the discussion on how the SINAMICS V20, a Siemens drive, is shaping food processing, packaging, and logistics, with Naksh Technology spearheading the implementation of these solutions.

SINAMICS V20: The Backbone of Basic Automation

The SINAMICS V20 is a small, cost-effective AC drive for the basic motion control application. Owing to its versatility and simplicity, it perfectly suits the food industry whose requirements vary from conveyor systems to mixers and pumps. With power ratings from 0.12 kW up to 30 kW, it helps execute tasks in the food processing line that demand smooth and energy-efficient operation.

Also learn more about How SINAMICS V20 Boosts Operational Flexibility In A Food Processing Plant.

Why Smart Food Manufacturing Needs Advanced Drives

Modern food manufacturing is all about precision and flexibility, apart from soaring speed. With consumer preference changes and ever-tightening regulations, manufacturers find themselves in a fast lane to quickly adapt to new recipes, packaging formats, and safety standards. Industrial automation powered by variable frequency drives (VFDs) such as the Siemens VFD V20 becomes essential.

Key Features of SINAMICS V20 in Food Manufacturing

Easy Installation and Commissioning: The SINAMICS V20 can be mounted either with push-through mounting or wall mounting, allowing for fast installation and side-by-side configuration to save on-floor space on crowded factory floors.

Energy Efficiency: It helps food manufacturers reduce their energy consumption by about 60%, a vital parameter for sustainable production, through automatic flux reduction and the ECO and hibernation modes.

Robustness and Reliability: With a unique cooling design, conformal-coated PCBs, and a vast voltage range, the drive is engineered to work within the rough environment of a food factory to minimize downtime and maintenance expenses.

Flexible Control Modes: The drive facilitates process enhancements through various control modes such as V/f, V2/f, FCC, and multi-point, according to differing machine requirements.

The Siemens Drive Advantage in Food Processing

Siemens drives are known for their integration and compatibility with automation systems. Siemens Sinamics family, including SINAMICS V20, is easily connected through PLCs, sensors, and cloud monitoring platforms. Such connectivity is important for smart food manufacturing, whereby it allows real-time process monitoring, predictive maintenance, and making decisions based on data.

Applications of SINAMICS V20 in Food Manufacturing

1. Conveying and Packaging

The movement of raw materials and finished goods must be smooth in food plants. SINAMICS V20 drives conveyors through smooth speed control to ensure the delicate products are gently handled and synchronized with packaging lines to reduce wastage and maximize throughput.

2. Mixing and Blending

Mixers and blenders require speed regulation with precision for the sake of consistent product quality. SINAMICS V20, therefore, supplies required torque and speed variation that is reactive to sudden recipe and batch size changes.

3. Pumping and Dosing

Dosing ingredients and fluids accurately forms the foundation of food production. The SINAMICS V20 ensures that the pumps are operating at speeds in the optimum range, thus saving energy and delivering a consistent flow rate for quality assurance.

4. Cooling and Refrigeration

Temperature maintenance is essential for food safety. The SINAMICS V20 controls the fans and compressors in a refrigeration system, ensuring minimum power consumption while maintaining an exact temperature range.

Naksh Technology: Your Partner in Smart Automation

Naksh Technology is leading provider of Siemens drive solutions with an area of expertise in the integration and support of SINAMICS V20 with food manufacturing plants. With the best knowledge in industrial automation, Naksh Technology guarantees trouble-free implementation together with design, up to after-sales service, enabling the food producers to realize the full power of Siemens VFD V20 and indeed of the entire Siemens Sinamics offering.

Benefits of SINAMICS V20 for Food Manufacturers

Cost Savings: The engineering, commissioning, and operational expenses are very low considering the drive's simplicity and efficiency.

Sustainability: Integrated energy-saving mechanisms support green manufacturing initiatives and set the path for global sustainability programs.

Scalability: SINAMICS V20 can be simply scaled onto any other production line whether small or big.

Future-Ready: With the digital connectivities, the drive is ready to integrate into the Industry 4.0 scenario for cloud-based analytics and remote monitoring.

Why Choose Siemens VFD V20 from Naksh Technology?

Naksh Technology, with its vast expertise in deploying SINAMICS V20, provides food manufacturers:

Tailored automation solutions for specific food industry challenges.

Reliable technical support and training for maintenance staff.

Access to the latest Siemens Sinamics innovations for continuous improvement.

Conclusion

The SINAMICS V20 acts as a green, smart, and efficient food manufacturer. As changes take place in the food industry, Naksh Technology and the Siemens drive solutions such as the Siemens VFD V20 stand for your operations, to keep them competitive, flexible, and future-ready. Go industrial in automation with Siemens Sinamics and change your food manufacturing journey. Contact us for more information!

0 notes

Text

Logic Buffer Market: Size, Share, and Trends 2025–2032

MARKET INSIGHTS

The global Logic Buffer Market size was valued at US$ 2,670 million in 2024 and is projected to reach US$ 4,780 million by 2032, at a CAGR of 8.73% during the forecast period 2025-2032.

Logic buffers are essential components in digital electronics that provide signal isolation and amplification between circuits. These devices maintain signal integrity by preventing loading effects, enabling clean signal transmission across different sections of electronic systems. Key product types include single-ended buffers and tri-state buffers, with the former segment projected to reach USD 850 million by 2032.

Market growth is driven by increasing demand from consumer electronics and automotive sectors, where logic buffers ensure reliable operation of complex circuit boards. The rising adoption of 5G technology and IoT devices further accelerates demand. Key players like Texas Instruments, NXP Semiconductors, and STMicroelectronics dominate the market, collectively holding over 45% revenue share in 2024 through advanced buffer solutions.

MARKET DYNAMICS

MARKET DRIVERS

Rapid Expansion of Consumer Electronics to Accelerate Logic Buffer Demand

The surge in global consumer electronics production is significantly boosting the logic buffer market. With smart devices becoming indispensable in daily life, manufacturers are integrating advanced semiconductor components to enhance performance. Consumer electronics shipments are projected to exceed 3 billion units annually by 2030, creating massive demand for signal conditioning components like logic buffers. These devices ensure signal integrity across increasingly complex circuit designs found in smartphones, tablets, and wearables. Recent innovations in 5G-enabled devices further amplify this need, as higher frequency operations require more robust signal buffering solutions.

Automotive Electronics Revolution to Fuel Market Growth

The automotive industry’s transformation toward electrification and autonomous driving is generating unprecedented demand for logic buffers. Modern vehicles now incorporate over 3,000 semiconductor components, with advanced driver-assistance systems (ADAS) accounting for nearly 30% of semiconductor content. Logic buffers play a critical role in managing sensor data processing and ECU communications in these systems. The automotive semiconductor market is growing at approximately 12% CAGR, directly benefiting buffer IC manufacturers. Furthermore, the transition to 48V architectures in electric vehicles presents new opportunities for high-voltage buffer solutions.

Industrial Automation Boom Drives Buffer Adoption

Industrial automation is undergoing rapid digital transformation, with the global smart factory market expected to surpass $1 trillion by 2030. Logic buffers are essential in industrial control systems, particularly in PLCs and motor drives where signal integrity is paramount. The growing adoption of Industry 4.0 technologies has increased deployment of high-speed data acquisition systems that rely on buffer ICs for noise immunity. Additionally, the rise of edge computing in manufacturing necessitates robust signal conditioning components at the network periphery, particularly in harsh industrial environments where electromagnetic interference is prevalent.

MARKET RESTRAINTS

Component Miniaturization Challenges Limit Design Flexibility

The relentless push for smaller form factors in electronics presents significant challenges for buffer IC implementation. As package sizes shrink below 01005 dimensions (0.4mm x 0.2mm), maintaining signal integrity while reducing footprint becomes increasingly difficult. Many buffer circuits require specific layout considerations that conflict with space constraints in modern designs. This technical hurdle is particularly acute in mobile applications where PCB real estate is severely limited. Furthermore, miniaturization often necessitates trade-offs in power handling capability, forcing designers to choose between size and performance.

Supply Chain Disruptions Impact Semiconductor Availability

The semiconductor industry continues to face supply-demand imbalances that affect logic buffer production. Lead times for certain buffer ICs have extended to 40+ weeks in recent years, disrupting product development cycles. While capacity expansions are underway, the capital-intensive nature of semiconductor manufacturing means shortages may persist in specialized segments. Automotive-grade buffer ICs face particular challenges as qualification processes limit alternative sourcing options. These supply constraints not only delay projects but also drive up component costs, particularly for low-volume specialty applications.

Design Complexity Increases Time-to-Market

Modern electronic systems require buffers with increasingly sophisticated features such as programmable drive strength and adaptive termination. Implementing these advanced functions while maintaining signal integrity adds significant design complexity. Many engineering teams lack the specialized expertise required to optimize buffer configurations for high-speed applications, leading to prolonged development cycles. The proliferation of different logic standards (LVCMOS, LVDS, HCSL) further complicates buffer selection and implementation, particularly in mixed-signal environments.

MARKET CHALLENGES

Thermal Management Constraints in High-Density Designs

As electronics packing densities increase, thermal management becomes a critical challenge for buffer IC implementations. Modern systems generate substantial Joule heating from simultaneous switching of numerous buffer outputs. Without proper thermal design, sustained operation at elevated temperatures can degrade signal integrity and reduce component lifespan. This issue is particularly acute in automotive and industrial applications where ambient temperatures may exceed 85°C. Designers must carefully analyze thermal resistance parameters and often incorporate additional cooling solutions, adding cost and complexity.

Other Challenges

Signal Integrity at Higher Frequencies The transition to faster data rates in serial communications requires buffers to maintain signal integrity above 10Gbps. At these frequencies, parasitic effects and transmission line characteristics dominate buffer performance. Achieving consistent edge rates while minimizing jitter becomes increasingly difficult, often requiring specialized IC processes and advanced packaging techniques. These technical demands significantly increase development costs for high-performance buffer solutions.

Power Consumption Optimization Low-power design requirements conflict with the need for robust signal driving capability in many applications. Designers must carefully balance buffer drive strength against power budgets, particularly in battery-operated devices. Advanced process nodes help reduce static power consumption, but dynamic power remains a challenge in high-speed applications where buffers toggle frequently. This power-performance trade-off is a persistent challenge across consumer, automotive, and industrial segments.

MARKET OPPORTUNITIES

Emerging AI Hardware Creates New Buffer Applications

The rapid development of AI accelerators and neuromorphic computing presents significant opportunities for advanced buffer solutions. AI hardware architectures require massive parallel signal distribution with precise timing characteristics, creating demand for specialized buffer arrays. Memory interfaces in these systems increasingly operate above 8Gbps, where traditional buffers struggle to meet timing requirements. Suppliers developing low-latency, high-fanout buffer solutions are well-positioned to capitalize on the AI semiconductor market, which is growing at over 35% annually.

Automotive Sensor Fusion Drives Buffer Innovation

Advanced automotive sensor suites incorporating radar, LiDAR, and camera systems require robust signal conditioning solutions. These multi-modal sensing platforms generate vast amounts of analog data that must be conditioned before analog-to-digital conversion. Buffer manufacturers developing specialized solutions for sensor interfaces can capture significant value in this high-growth segment. The automotive sensor market is projected to exceed $50 billion by 2030, with buffer ICs representing a critical enabling technology for next-generation ADAS implementations.

3D IC Packaging Creates Buffer Integration Opportunities

The shift toward 3D IC architectures and heterogeneous integration creates new possibilities for embedded buffer solutions. Through-silicon vias (TSVs) and other vertical interconnect technologies require specialized buffering to maintain signal quality across stacked dies. Suppliers developing buffer IP for 2.5D/3D implementations can establish strong positions in advanced packaging supply chains. The 3D IC market is expected to grow at 20% CAGR, driven by performance demands in high-performance computing and mobile applications where space constraints are particularly severe.

LOGIC BUFFER MARKET TRENDS

Expansion of High-Speed Data Transmission to Drive Logic Buffer Demand

The rapid expansion of high-speed data transmission networks, including 5G infrastructure and cloud computing, is significantly accelerating the adoption of logic buffers. These components play a critical role in signal integrity management across complex integrated circuits, ensuring reliable data transfer even in high-noise environments. With data traffic projected to grow at a compound annual growth rate of over 25% between 2024 and 2032, semiconductor manufacturers are increasingly incorporating advanced buffer solutions into their designs. Furthermore, the transition towards higher bandwidth interfaces like PCIe 6.0 and DDR5 memory standards is pushing buffer technology to operate at speeds exceeding 8 GHz while maintaining signal fidelity.

Other Trends

Automotive Electronics Revolution

The automotive industry’s electrification and autonomous driving trends are creating substantial demand for robust logic buffer solutions. Modern vehicles now incorporate over 150 electronic control units requiring precise signal conditioning between sensors, processors and actuators. Logic buffers with enhanced ESD protection and wide temperature range operation (-40°C to +125°C) are becoming essential for advanced driver assistance systems (ADAS) and infotainment platforms. This segment is expected to account for nearly 30% of the total logic buffer market by 2030 as vehicle architectures transition toward centralized domain controllers and zonal architectures.

Miniaturization and Power Efficiency Innovations

The relentless push for smaller form factors and lower power consumption in consumer electronics is driving significant innovations in buffer IC design. Semiconductor companies increasingly focus on developing buffers with sub-1V operating voltages and package sizes below 1mm² to accommodate space-constrained applications like wearables and IoT edge devices. Advanced buffer architectures now incorporate dynamic power scaling features that can reduce idle power consumption by up to 75% compared to traditional implementations. These developments align with increasing regulations on electronic device energy efficiency while meeting the performance requirements of next-generation mobile processors.

Industrial Automation Adoption

The global industrial automation wave is creating new opportunities for specialized buffers in harsh industrial environments. Factory automation systems require buffers with enhanced noise immunity and ruggedized packaging to withstand vibration, dust and electromagnetic interference. New industrial-grade buffer solutions featuring galvanic isolation and reinforced outputs capable of driving long cables (up to 30 meters) are gaining traction as smart factories expand. This application sector is projected to grow steadily at approximately 15% annually through 2032, supported by Industry 4.0 initiatives worldwide.

COMPETITIVE LANDSCAPE

Key Industry Players

Semiconductor Giants Compete Through Innovation and Strategic Expansion

The global Logic Buffer market features a dynamic competitive landscape with established semiconductor leaders dominating revenue shares while smaller players carve out specialized niches. Texas Instruments emerged as the market leader in 2024, commanding approximately 22% of global revenue share through its extensive product portfolio and strong foothold in industrial and automotive applications. The company’s leadership stems from continuous investments in high-performance buffer ICs and strategic partnerships with Tier-1 automotive suppliers.

NXP Semiconductors and STMicroelectronics collectively held nearly 30% market share, benefiting from their vertically integrated manufacturing capabilities and focus on energy-efficient buffer solutions. These companies are aggressively expanding their production capacities in Asia to capitalize on the region’s growing electronics manufacturing sector.

The market also witnessed notable consolidation activities, with onsemi acquiring two smaller buffer IC specialists in 2023 to strengthen its position in the industrial automation segment. Meanwhile, Toshiba and Renesas are leveraging their legacy in power management ICs to develop advanced buffer solutions for 5G infrastructure and IoT devices.

Emerging players like SGMICRO and Highland Technology are gaining traction through innovative product designs, particularly in space-constrained consumer electronics applications. These companies focus on delivering high-speed tri-state buffers with lower power consumption compared to industry standards.

List of Key Logic Buffer Manufacturers

Texas Instruments (U.S.)

NXP Semiconductors (Netherlands)

STMicroelectronics (Switzerland)

Diodes Incorporated (U.S.)

Nexperia (Netherlands)

onsemi (U.S.)

Toshiba Electronic Devices & Storage Corporation (Japan)

SGMICRO (China)

Highland Technology (U.S.)

Maxim Integrated (U.S.)

Renesas Electronics (Japan)

Segment Analysis:

By Type

Single-ended Buffer Leads the Market Due to Wider Adoption in Consumer Electronics and Industrial Applications

The market is segmented based on type into:

Single-ended Buffer

Subtypes: Non-inverting, Inverting, and others

Tri-state Buffer

Differential Buffer

Others

By Application

Consumer Electronics Segment Dominates Due to Increasing Demand in Smart Devices

The market is segmented based on application into:

Industrial

Consumer Electronics

Automotive

Others

By Voltage Level

Low Voltage Buffers Hold Significant Market Share Due to Energy Efficiency Requirements

The market is segmented based on voltage level into:

Low Voltage (Below 3.3V)

Medium Voltage (3.3V-5V)

High Voltage (Above 5V)

By Package Type

Surface Mount Packages Dominate Due to Miniaturization Trends in Electronics

The market is segmented based on package type into:

Surface Mount

Through Hole

Others

Regional Analysis: Logic Buffer Market

North America North America, particularly the U.S., dominates the logic buffer market due to high demand from the consumer electronics and automotive industries. The presence of key semiconductor players like Texas Instruments and Maxim Integrated, combined with strong R&D investments in advanced electronic components, drives innovation and adoption. The U.S. accounted for approximately 35% of the global market revenue in 2024, supported by robust manufacturing infrastructure and increasing smart device penetration. Canada and Mexico are also witnessing steady growth, fueled by cross-border supply chain integrations and rising automation needs in industrial applications.

Europe Europe maintains a strong position in the logic buffer market, with Germany and France leading in automotive and industrial adoption. Strict regulatory standards for electromagnetic compatibility (EMC) and energy efficiency encourage the use of high-performance buffers in automotive electronics and IoT devices. The region benefits from collaborative research initiatives and the presence of semiconductor giants like STMicroelectronics and NXP Semiconductors. However, supply chain disruptions and fluctuating raw material costs remain moderate challenges. The EU’s focus on digitization and Industry 4.0 further accelerates demand for precision signal buffering solutions.

Asia-Pacific Asia-Pacific is the fastest-growing market due to expansive electronics manufacturing hubs in China, Japan, and South Korea. China alone contributes nearly 40% of global production, driven by massive consumer electronics exports and domestic demand for automation. While cost-effective single-ended buffers dominate in price-sensitive markets like India and Southeast Asia, premium tri-state variants are gaining traction in Japan’s automotive sector. Regional players such as Toshiba and Renesas continue to expand production capacities, though competition from local manufacturers intensifies price pressures. Rapid urbanization and 5G infrastructure development present further growth opportunities.

South America The South American market remains niche, with Brazil and Argentina as primary adopters in automotive and industrial applications. Economic instability and reliance on imports constrain market expansion, but localized manufacturing initiatives are gradually improving supply chain resilience. Demand is primarily spurred by legacy system upgrades in industrial automation, though adoption of advanced logic buffers is slower compared to other regions. Limited domestic semiconductor expertise and infrastructure gaps hinder large-scale investments, but the region holds potential for long-term growth as technology penetration increases.

Middle East & Africa This region shows emerging potential, particularly in GCC countries like Saudi Arabia and the UAE, where smart city projects and industrial diversification efforts are underway. Israel’s thriving tech ecosystem also contributes to demand for high-performance logic buffers in defense and telecommunications. However, market maturity varies widely; African nations face challenges such as inconsistent power infrastructure and lower electronics manufacturing activity. Strategic partnerships with global suppliers and gradual digital transformation initiatives are expected to unlock growth opportunities over the next decade.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Logic Buffer markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments.

Segmentation Analysis: Detailed breakdown by product type (Single-ended Buffer, Tri-state Buffer), application (Industrial, Consumer Electronics, Automotive, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Diodes Incorporated, Nexperia, onsemi, Texas Instruments, and STMicroelectronics, covering product portfolios and strategic developments.

Technology Trends & Innovation: Assessment of emerging semiconductor technologies, integration with advanced electronics, and evolving industry standards.

Market Drivers & Restraints: Evaluation of factors driving market growth along with challenges like supply chain constraints and regulatory issues.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, and investors regarding market opportunities.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/inductive-proximity-switches-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cellular-iot-module-chipset-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/sine-wave-inverter-market-shifts-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pilot-air-control-valves-market-cost.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/video-multiplexer-market-role-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/semiconductor-packaging-capillary.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/screw-in-circuit-board-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wafer-carrier-tray-market-integration.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-display-potentiometer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/glass-encapsulated-ntc-thermistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/shafted-hall-effect-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/point-of-load-power-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-grating-market-key-players-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/picmg-single-board-computer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lighting-control-dimming-panel-market.html

0 notes

Text

Understanding Board-to-Board Connectors

In the world of electronic hardware, where space, speed, and signal integrity define performance, board-to-board connectors are critical components that quietly enable innovation. These specialized connectors join printed circuit boards (PCBs) directly without the need for cable assemblies, supporting compact, high-performance electronic designs used in everything from smartphones and laptops to industrial machinery and aerospace systems.Get more news about Board-to-board Connector,you can vist our website!

What Are Board-to-Board Connectors? Board-to-board connectors are designed to provide reliable electrical and mechanical connections between two or more PCBs within a device. Unlike wire-to-board or cable-based systems, these connectors allow signal and power transmission through directly mated interfaces, which helps reduce bulk and improve data integrity. They are essential for stackable or modular designs and are particularly favored in applications where internal space is limited.

Types and Configurations These connectors come in several configurations depending on the orientation and spacing needs:

Parallel (Mezzanine) Connectors: Used when two boards are stacked vertically. These are common in compact electronic devices and offer high-density signal transmission.

Coplanar Connectors: For side-by-side board connections, maintaining the same plane and allowing broader layout designs.

Right-Angle Connectors: Used when a 90-degree connection is required between boards, useful in folded or L-shaped PCB assemblies.

Pitch (the spacing between pins), stack height, current rating, and number of contacts are customizable depending on application requirements. High-speed data connectors often require shielding and controlled impedance to prevent signal loss and crosstalk.

Key Features and Advantages Modern board-to-board connectors are engineered for precision and durability. Key features include:

Miniaturization: Compact design supports smaller electronic devices.

High-Density Pin Configuration: Enables transmission of large volumes of data and signals.