#Factory Automation PCB

Explore tagged Tumblr posts

Text

BBC SYNPOL CMA-32 GVT 360–5792 PCB Card | Industrial Automation Control Board | Ram Automations

Discover industrial reliability and precision with the BBC SYNPOL CMA-32 GVT 360–5792 PCB Card — now available at Ram Automations, your trusted global supplier of genuine industrial and marine automation spare parts. This Printed Circuit Board (PCB) is designed for seamless integration into legacy control systems where stability and performance are critical. Whether you’re maintaining a control cabinet, restoring a discontinued system, or replacing a failed board, this BBC SYNPOL PCB Card offers the solution you need.

🛒 Order Now: 👉 https://ramautomations.com/products/bbc-synpol-cma-32-gvt-360-5792-pcb-card-used 🌐 Explore Our Full Catalog: https://ramautomations.com

🔍 Product Overview

• 📦 Model: CMA-32 GVT 360–5792 • 🏢 Brand: BBC SYNPOL • 🧩 Type: PCB Control Card • 🧾 Condition: Tested and Verified • ⚙️ Function: Signal routing, control interfacing, automation logic • 📍 Applications: Industrial PLC systems, control cabinets, marine automation units, legacy control systems

✅ Why This PCB Is a Great Choice

✔️ Genuine BBC SYNPOL product ✔️ Perfect fit for legacy systems ✔️ Fully tested and quality assured ✔️ Ideal for discontinued or obsolete installations ✔️ Supports long-term operation of industrial systems ✔️ Cost-effective and dependable replacement solution

�� Ideal For

✔️ Factory automation repair ✔️ OEM panel retrofits ✔️ Marine and shipboard control systems ✔️ Power plant systems ✔️ Process automation platforms ✔️ Industrial cabinet refurbishment ✔️ Obsolete PCB replacement

Extend the life of your equipment with this BBC SYNPOL CMA-32 GVT 360–5792 PCB, and avoid expensive upgrades or full replacements. Ram Automations provides support for both current and legacy automation technologies.

🌐 Why Ram Automations?

With access to 1000+ global brands, Ram Automations offers rare, genuine, and tested industrial parts. From power supplies and control boards to discontinued automation modules, we provide critical parts to engineers, integrators, and MRO professionals worldwide.

✔️ 1000+ Brands in Stock ✔️ Used and Legacy Components ✔️ Global Delivery Options ✔️ OEM & Bulk Discounts Available ✔️ Friendly Expert Support Team

📹 In This Video You Will Learn:

🔎 Product walkthrough of the BBC SYNPOL PCB ⚙️ Use cases in industrial and marine systems 🛠️ How to integrate the board into your system 💡 What makes legacy parts essential for MRO teams 📦 Why buying from Ram Automations is a smart investment

📣 Connect with Us

👍 Like this video if it helped 💬 Comment below for product questions 🔔 Subscribe for new weekly videos featuring industrial & marine spares

#BBC SYNPOL CMA-32#BBC PCB Card#CMA-32 GVT 360-5792#Industrial PCB Board#Automation Control Card#Marine PCB#Used Control Board#Signal Routing PCB#Legacy Automation Card#Ram Automations#BBC Automation#Marine Control System PCB#Obsolete PCB Replacement#Industrial Panel Board#Industrial Control Board#PLC Control PCB#Marine Power Control#Tested PCB Card#BBC SYNPOL Module#Factory Automation PCB#BBC Panel Module#Marine PCB Used#BBC Control Electronics

1 note

·

View note

Text

Reliable ERNI Connectors & Modules for Industrial Applications

With today’s global, interconnected industrial world, signal integrity, consistent power transfer, and error-free data communication are critical. Whether you’re designing automation panel building, marine navigation systems, or high-speed industrial equipment, the performance of your connectors and interface modules can have a decisive impact on performance and downtime. That’s why top engineers and system integrators rely on ERNI, the internationally recognized leader in high-speed connectors, interface modules, and PCB connection systems.

At Aeliya Marine Tech Pvt. Ltd., you have access to a selection of ERNI products curated just for you, perfect for marine, offshore, and industrial automation use. This blog guides you through the strengths of ERNI, typical product types, and why buying from Aeliya Marine is an intelligent, cost-saving decision for automation, repair, and maintenance professionals.

Who is ERNI?

ERNI Electronics, a subsidiary of TE Connectivity, is a German-based company that excels in creating extremely reliable electrical connectors and interface solutions. With years of engineering prowess, ERNI products are crafted to serve demanding and harsh industrial applications where performance and accuracy are not optional.

ERNI connectors find extensive applications in:

Industrial automation

Marine electronics

Transportation systems

Telecommunications

Medical devices

Automotive electronics

They feature a strong construction, close tolerances, and compatibility with DIN, IDC, SMT, as well as high-speed data protocols, and therefore are a first choice among engineers in various industries.

What ERNI Products Are Available at Aeliya Marine?

At Aeliya Marine Tech, you’ll find a growing collection of tested and ready-to-ship ERNI modules, connectors, and electronic interface boards. These products are often sourced from surplus automation stock, shipboard equipment, and unused spare inventories, making them a cost-effective option for replacements or integration into existing systems.

Here are a few typical ERNI items available on Aeliya Marine’s website:

ERNI Terminal Modules These are interface modules that interconnect signals between field wiring and PCBs — usually DIN-rail mounted and installed in automation cabinets. Renowned for small size and snap-in features.

ERNI SMC and ERmet Connectors They are connectors used for backplane applications and signal boards for dependable, high-density connections. They have shielded housing and differential pair arrangements that accommodate data rates of several Gbps.

ERNI DIN 41612 Series Standard connectors applied in Eurocard systems, particularly industrial control units, test systems, and marine control panels.

ERNI Ribbon Cable Assemblies and IDC Connectors Ideal for tight, board-to-board connections within marine engine monitoring consoles and automation controllers.

Aeliya Marine’s most listings contain extensive product identifiers, weights (useful in calculating freight), and shipping readiness information, so you can buy with confidence even for obsolete or hard-to-find part numbers.

Where are ERNI Products Applied?

ERNI products play an essential role in applications where precision and durability are essential. In Aeliya Marine, such parts are typically exported to be installed in:

Marine Automation Panels Applied in navigation, radar, sonar, and bridge control systems that need shielded signal transmission and space-saving configurations.

Factory Control Cabinets To implement PLC and DCS-based systems needing modular, scalable connections and fail-safe routing of signals.

Transportation Electronics Rail and metro systems demand vibration-resistant, high-density connectors to manage power, data, and control signals in motion.

OEM Embedded Systems ERNI’s compact board-to-board and cable-to-board connectors make them ideal for embedded devices in instrumentation and robotic systems.

Why Buy ERNI Components from Aeliya Marine?

Sourcing ERNI components from Aeliya Marine Tech brings several advantages:

1. Tested & Verified Parts Each listed product is physically checked and functionally tested (when possible). Several parts are like-new or unused, perfect for speedy replacements.

2. Budget & Hard-to-Find Inventory ERNI components may be costly or no longer available elsewhere. Aeliya Marine fills the gap with economical, in-stock units, usually recovered from high-end systems or marine equipment inventories.

3. Quick Global Shipping Orders ship within 24 hours via fast carriers such as DHL, FedEx, and Aramex — for those critical breakdowns or offshore delivery to far-flung locations.

4. Technical Clarity Every listing specifies model numbers, technical designations, condition, weight, and shipping readiness. Having trouble finding a match? The Aeliya staff helps cross-reference by brand, system, or function.

5. Reliable Service With headquarters in Bhavnagar, Gujarat, and clientele in Asia, Europe, and the Middle East, Aeliya Marine has established a good reputation as a player in the marine and industrial automation spare parts market.

Browse the ERNI Collection Now

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#Erni

0 notes

Text

Laser Sensors Market Size Advancing Precision Across Industries with Next-Gen Sensing Technology

The Laser Sensors Market Size is gaining significant momentum with the widespread adoption of automation, smart manufacturing, and advanced safety systems across various industries. These sensors are known for their precision, speed, and reliability, making them vital for tasks like distance measurement, position detection, and object recognition. According to Market Size Research Future, the global laser sensors Market Size is projected to surpass USD 3.2 billion by 2030, growing at a CAGR of 9.5% during the forecast period.

Market Size Overview

Laser sensors are non-contact devices that use laser beams to detect and measure distances, positions, and even tiny object features. These devices are widely used in automotive manufacturing, robotics, semiconductors, aerospace, and industrial automation. Their ability to provide real-time data with millimeter or even micrometer accuracy has made them indispensable in quality assurance and precision engineering.

With growing demand for miniaturized, fast, and smart sensing solutions in Industry 4.0 ecosystems, laser sensors are evolving to offer enhanced data acquisition, integration with cloud platforms, and compatibility with edge computing systems. Their versatility also extends to security, consumer electronics, and biomedical applications.

Market Size Segmentation

By Type:

Compact

Ultra-Compact

Discrete

Continuous

By Range:

Short Range (<10 m)

Medium Range (10–100 m)

Long Range (>100 m)

By Application:

Displacement Measurement

Thickness Measurement

Level Detection

Positioning

Others

By End-Use Industry:

Automotive

Electronics & Semiconductors

Aerospace & Defense

Industrial Automation

Healthcare

Packaging

Others

By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Size Trends

1. Rise of Industry 4.0 and Smart Factories

Laser sensors are pivotal in smart factories where precision, automation, and data-driven decisions are critical. From robotic arms to inspection stations, these sensors enable intelligent automation.

2. Miniaturization and Integration with IoT

Advancements in MEMS and micro-optoelectronic technologies have led to miniaturized laser sensors that offer high performance with low power consumption. IoT-enabled versions provide real-time monitoring and cloud-based analytics.

3. Demand in Autonomous Vehicles

In the automotive industry, laser sensors are used for obstacle detection, adaptive cruise control, lane departure assistance, and advanced driver-assistance systems (ADAS).

4. Use in Biomedical Devices and Healthcare Automation

Laser sensors are increasingly used in medical device manufacturing, lab automation, and even non-invasive diagnostic equipment due to their ability to measure fine distances and biological features.

Segment Insights

Displacement Measurement Dominates Applications

Displacement measurement remains the leading application of laser sensors due to their high accuracy and use in critical sectors such as electronics, automotive, and metrology.

Industrial Automation Leads in End-Use Industry

The industrial automation segment is the largest adopter of laser sensors. These sensors are key for real-time process control, machine alignment, product inspection, and fault detection in factories.

Asia-Pacific Emerges as the Growth Hub

Asia-Pacific, led by countries like China, Japan, and South Korea, is witnessing rapid industrialization and adoption of automation technologies, contributing to the region’s dominant Market Size share.

End-User Insights

Automotive Industry:

Laser sensors are integral to automated production lines, assembly checks, gap and flush measurements, and surface inspection in vehicle manufacturing.

Electronics & Semiconductor:

Used for wafer inspection, PCB alignment, and miniaturized component placement, laser sensors provide unparalleled precision essential in electronics.

Aerospace & Defense:

In these high-precision sectors, laser sensors ensure accurate surface measurements, detect minute structural deformities, and are used in missile guidance systems.

Packaging and Logistics:

Laser sensors offer reliable box dimensioning, filling level control, and object detection to ensure package integrity and streamlined logistics.

Key Players in the Laser Sensors Market Size

Global players are enhancing product capabilities through R&D and expanding into emerging Market Sizes to meet growing demand for intelligent sensing technologies. Key companies include:

Keyence Corporation

SICK AG

Rockwell Automation Inc.

Banner Engineering Corp.

Baumer Group

OMRON Corporation

Pepperl+Fuchs GmbH

Panasonic Corporation

Laser Technology Inc.

Ifm Electronic GmbH

These players are investing in compact sensor modules, AI integration, and wireless capabilities to maintain competitive advantage.

Conclusion

The Laser Sensors Market Size is at the forefront of the global transition to smarter, faster, and more precise automation systems. As demand grows for real-time decision-making, product quality, and operational safety across sectors, laser sensors are becoming a critical asset in high-tech industries. With technological innovations driving miniaturization, improved accuracy, and IoT connectivity, the Market Size is set for exponential expansion in the coming years.

Trending Report Highlights

Explore other dynamic Market Size reports transforming modern industries:

Bioelectronic Sensors Market Size

FSO VLC Li-Fi Market Size

IoT Based Asset Tracking and Monitoring Market Size

Extreme Ultraviolet EUV Lithography Market Size

Beam Bender Market Size

Depletion Mode Junction Field Effect Transistor Market Size

Logic Semiconductors Market Size

Semiconductor Wafer Transfer Robots Market Size

US Warehouse Robotics Market Size

Single Multi Stage Semiconductor Coolers Market Size

Gas Concentration Sensor Market Size

Thermal Management in Consumer Electronics System Market Size

Underfill Dispensers Market Size

Wet Chemicals Market Size

0 notes

Text

Revolutionizing Factory Efficiency with Wireless Andon Systems

In today's fast-paced manufacturing landscape, efficiency and real-time communication are no longer optional—they are essential. Traditional wired systems often limit flexibility and come with high installation costs. That’s where Wireless Andon Systems come into play. These systems provide real-time alerts and enhance communication across production lines without the need for complex wiring infrastructure.

In this article, we’ll explore how Wireless Andon Systems are transforming the way industries handle downtime, communication, and performance monitoring—focusing on the solution offered by Glansa Solutions.

What is a Wireless Andon System?

An Andon System is a visual and audio signal system used on factory floors to alert supervisors and operators of issues in real time. Traditionally, these systems are wired into machinery, but Wireless Andon Systems use IoT and wireless communication technologies to deliver the same functionality with greater flexibility and cost efficiency.

Glansa’s Wireless Andon System provides a reliable platform for real-time monitoring and alerts, significantly improving productivity and response time during production issues.

Key Features of Glansa’s Wireless Andon System

✅ Wireless Communication – Eliminates the need for extensive wiring across the plant.

✅ Real-Time Alerts – Sends instant notifications for breakdowns, shortages, or quality issues.

✅ Scalable Architecture – Easily expandable to suit both small and large manufacturing setups.

✅ Custom Dashboards – Visual displays and analytics to monitor overall equipment effectiveness (OEE).

✅ User-Friendly Interface – Simple setup with intuitive controls and mobile compatibility.

Benefits for Manufacturers

🔹 Reduced Downtime

Operators can quickly report issues, and supervisors can respond immediately, minimizing production delays.

🔹 Improved Communication

Streamlines interaction between different departments on the shop floor through real-time signaling.

🔹 Enhanced Productivity

Immediate issue resolution leads to smoother production flow and fewer interruptions.

🔹 Lower Maintenance Costs

Because it’s wireless, maintenance and reconfiguration are easier and cheaper compared to traditional wired systems.

Industries That Benefit Most

Automotive Manufacturing

Electronics and PCB Assembly

Pharmaceuticals

Packaging and Printing

Consumer Goods and Appliances

Why Choose Glansa Solutions?

Glansa Solutions offers a next-generation Wireless Andon System backed by IoT technology and lean manufacturing principles. With years of experience in industrial automation, Glansa designs systems that are scalable, affordable, and highly efficient. Their Wireless Andon platform is already transforming operations for manufacturers across various sectors.

Conclusion

If you're aiming to minimize production delays, improve real-time communication, and streamline operations, a Wireless Andon System is a must-have. And with Glansa Solutions, you’re getting a trusted partner in your journey toward smart factory automation.

👉 Learn more at https://glansa.com/andon/

0 notes

Text

Backplane Products Market - Industry Analysis, By Key Players, Segmentation, Application, Demand And Forecast

Global Backplane Products Market Research Report 2025(Status and Outlook)

The Global Backplane Products Market size was valued at US$ 2.34 billion in 2024 and is projected to reach US$ 3.78 billion by 2032, at a CAGR of 7.1% during the forecast period 2025-2032.

Backplane products are electrical circuit boards that act as the backbone for connecting multiple electronic components in complex systems. These high-density interconnect solutions enable data transfer between printed circuit boards (PCBs) through connectors, switches, and interface protocols. They are categorized into high-speed (supporting data rates above 10Gbps) and standard variants, with applications spanning data centers, telecom infrastructure, medical imaging systems, and defense electronics.

Market growth is driven by escalating demand for high-bandwidth networking equipment and server infrastructure, particularly with the rollout of 5G and AI-driven data processing. While North America currently leads in adoption (38% market share), Asia-Pacific shows the fastest growth trajectory due to expanding hyperscale data center deployments in China and India. Key players like TE Connectivity and Amphenol are investing in 224G PAM4 backplane technology to address next-gen data rate requirements, though supply chain disruptions for raw materials remain a challenge.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://semiconductorinsight.com/download-sample-report/?product_id=59017

Segment Analysis:

By Type

High-Speed Backplane Segment Dominates Due to Rising Demand for High-Bandwidth Data Transfer

The market is segmented based on type into:

High Speed

Subtypes: Active optical, Passive copper, and others

Standard

By Application

Data/Communications Segment Leads Owing to Expanding 5G and Cloud Infrastructure Needs

The market is segmented based on application into:

Data/Communications

Defense

Medical

Others

By End User

Telecom Providers Show Significant Adoption for Network Infrastructure Expansion

The market is segmented based on end user into:

Telecommunication companies

Data center operators

Defense contractors

Medical equipment manufacturers

Industrial automation providers

By Technology

Optical Backplane Technology Gains Traction for Superior Bandwidth Capabilities

The market is segmented based on technology into:

Electrical

Optical

Hybrid

Regional Analysis: Global Backplane Products Market

North America The North American backplane products market is driven by robust demand from data center infrastructure and telecommunications, particularly in the U.S., which accounts for over 80% of regional revenue. The proliferation of 5G networks and cloud computing has accelerated adoption of high-speed backplanes with data transfer rates exceeding 100Gbps. Regulatory standards, such as those set by the PCI Industrial Computers Manufacturers Group (PICMG), ensure consistent quality in mission-critical applications. However, the market faces pricing pressures as hyperscalers demand cost-efficient solutions for large-scale deployments. Major players like TE Connectivity and Molex continue to invest in R&D to maintain technological leadership in this high-value market.

Europe Europe’s backplane market demonstrates steady growth, fueled by increasing investments in industrial automation and medical technologies. Germany remains the regional leader, with its strong manufacturing base requiring reliable backplane systems for factory automation equipment. The region emphasizes energy-efficient and RoHS-compliant solutions, pushing manufacturers to develop innovative designs. While Western European markets are nearing maturity, Eastern European countries show potential as cost-effective manufacturing hubs. The Russia-Ukraine conflict has temporarily disrupted supply chains, causing some manufacturers to diversify their production locations within the EU.

Asia-Pacific As the fastest-growing regional market, Asia-Pacific benefits from booming electronics manufacturing and government-supported digital infrastructure projects. China dominates the region with its extensive ecosystem of backplane manufacturers and component suppliers. The country’s push for semiconductor self-sufficiency has led to increased production of domestic backplane solutions. India is emerging as an important growth market, particularly for cost-effective standard backplanes used in telecommunications equipment. Japan and South Korea continue to lead in high-performance applications, leveraging their technological expertise in precision engineering and materials science.

South America The South American market remains relatively underdeveloped but shows potential in specific niches, particularly in the mining and oil/gas industries where rugged backplane solutions are required. Brazil represents the largest market in the region, though economic volatility has slowed infrastructure investments in recent years. Local manufacturers face challenges competing with imports from Asia and North America, leading some governments to consider protective trade measures. The gradual rollout of 4G/LTE networks across the region is creating opportunities for telecommunications backplane solutions.

Middle East & Africa This region presents a mixed landscape, with the Gulf Cooperation Council (GCC) countries leading in sophisticated backplane demand for oil/gas and aerospace applications, while African nations primarily require cost-effective solutions for basic telecommunications infrastructure. The UAE and Saudi Arabia are investing heavily in data center infrastructure, driving demand for high-speed backplanes. However, the broader African market faces challenges including unreliable electricity infrastructure and limited technical expertise, slowing adoption of advanced backplane systems. Some countries like South Africa and Kenya are emerging as potential manufacturing hubs for the broader African market.

List of Key Backplane Products Companies Profiled

TE Connectivity Ltd. (Switzerland)

Amphenol Corporation (U.S.)

Hon Hai Precision Industry Co., Ltd. (Foxconn) (Taiwan)

Molex LLC (U.S.)

HARTING Technology Group (Germany)

Hirose Electric Co., Ltd. (Japan)

JAE Electronics, Inc. (Japan)

METZ CONNECT GmbH (Germany)

Rosenberger Hochfrequenztechnik GmbH & Co. KG (Germany)

The global data center market is experiencing unprecedented growth, with an estimated compound annual growth rate exceeding 10% through 2030, driving significant demand for high-performance backplane solutions. Modern hyperscale data centers require advanced backplane architectures to support 400G and emerging 800G Ethernet standards, creating a thriving market for high-density interconnect solutions. Leading manufacturers are developing ruggedized backplanes capable of transferring data at speeds above 56 Gbps per channel while maintaining signal integrity across complex server architectures.

Global defense spending has reached record levels, with major nations allocating substantial budgets to upgrade avionics, naval systems, and ground vehicle electronics. These modernization efforts require rugged backplane solutions that meet stringent MIL-STD specifications for shock, vibration, and electromagnetic interference. The defense segment now accounts for approximately 18% of the total backplane market, with customized solutions for mission-critical systems commanding premium pricing. Recent contracts for next-generation fighter jets and unmanned systems are creating new opportunities for specialized backplane manufacturers.

The healthcare sector’s rapid adoption of high-resolution diagnostic equipment is generating strong demand for medical-grade backplanes. Modern CT scanners, MRI machines, and digital X-ray systems require specialized backplane architectures capable of handling massive data throughput with zero latency. The market has seen increased requirements for radiation-resistant materials in backplane construction, particularly in oncology treatment systems where reliability directly impacts patient outcomes.

The global 5G infrastructure market is projected to exceed $80 billion by 2028, with backplane products playing a critical role in base station and edge computing deployments. These applications require rugged, high-speed interconnect solutions that can operate in extreme environmental conditions. Leading manufacturers are developing specialized backplane families optimized for outdoor radio units and distributed antenna systems.

The automotive industry’s shift toward zonal architectures and autonomous driving systems is creating opportunities for automotive-grade backplane solutions. Modern vehicles now incorporate multiple high-performance compute modules that require robust interconnection backbones. Suppliers are adapting military-grade reliability standards to meet automotive qualification requirements, particularly for advanced driver assistance systems.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=59017

Key Questions Answered by the Backplane Products Market Report:

What is the current market size of Global Backplane Products Market?

Which key companies operate in Global Backplane Products Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Browse More Reports:

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Automated Test Equipment (ATE): What It Is and Why It Matters

Modern electronics and software systems require precise, fast, and scalable testing processes. That’s where automated test equipment (ATE) comes in. ATE plays a critical role in manufacturing, validating, and maintaining electronic components and systems with minimal manual intervention.

In this article, we explore automated test equipment—what it is, how it works, common types, key benefits, and its role in today’s software and hardware testing environments.

What is Automated Test Equipment (ATE)?

Automated Test Equipment (ATE) is a machine that automatically tests devices for functionality, performance, or defects. It is commonly used in electronics manufacturing and software testing to ensure that products meet required specifications before being shipped.

ATE systems are programmable and can simulate multiple test scenarios, record results, and quickly identify faults.

Key Components of ATE

Test Controller: The brain of the system, typically a computer running specialized software.

Test Interface: Hardware used to connect the ATE system to the device under test (DUT).

Instruments: Oscilloscopes, signal generators, multimeters, etc., used to perform measurements.

Software: Scripts and test sequences that define what and how tests are run.

How ATE Works

The device under test (DUT) is connected to the ATE system.

The ATE software executes a predefined test sequence.

Instruments measure voltage, current, response time, and other parameters.

The system compares actual results with expected outcomes.

A pass/fail report is generated.

This process is fully automated and can be repeated for hundreds or thousands of units with consistent accuracy.

Applications of ATE

Semiconductor Testing: Ensures microchips function correctly before packaging.

PCB Testing: Validates solder joints, circuit paths, and component integrity.

Consumer Electronics: Phones, TVs, wearables are tested in the factory using ATE.

Automotive Systems: Safety-critical systems like ECUs are tested for reliability.

Software/API Testing: Automated testing platforms like Keploy help simulate and validate backend systems and microservices.

Benefits of Automated Test Equipment

1. Speed and Efficiency

ATE systems test products far faster than manual testing, boosting production line efficiency.

2. Consistency

Automated systems reduce human error and ensure every unit is tested under the same conditions.

3. Scalability

Perfect for mass production—test hundreds of units per hour without increasing staffing.

4. Data Logging and Analytics

ATE software records data for quality control, trend analysis, and root-cause diagnostics.

5. Reduced Labor Costs

Once configured, ATE systems need minimal supervision.

Types of ATE

Type

Description

Semiconductor ATE

Tests integrated circuits, chips, and SoCs

PCB ATE

Used in circuit board assembly lines

Functional ATE

Tests a device's full functionality as a black box

Optical Inspection Systems

Uses cameras and sensors for visual defect detection

API / Software Testing Tools

Tools like Keploy automate API validation

ATE in Software Testing

While traditionally associated with electronics, the concept of ATE has been extended to software systems. Tools like Keploy serve as automated testing platforms for APIs, enabling test case generation, mocking, and regression testing based on real traffic.

Keploy automates the validation of REST APIs and microservices by:

Capturing real user traffic

Generating test cases and mocks

Running automated validations in CI/CD pipelines

Challenges of Using ATE

Initial setup cost can be high, especially for custom solutions

Requires specialized expertise to develop and maintain

May need updates as products evolve (especially in agile environments)

Hardware-specific tools might not scale well across different platforms

Future of Automated Testing

With advancements in AI and machine learning, future ATE systems will:

Predict potential failure points

Adapt dynamically to changing conditions

Integrate seamlessly with digital twins and Industry 4.0 initiatives

Combine hardware and software validation into unified platforms

Final Thoughts

Automated test equipment is a game-changer for ensuring quality, reducing errors, and scaling testing in both hardware and software environments. Whether you’re testing semiconductors or APIs, automation boosts efficiency and reduces costs. For software engineers looking to bring ATE principles to API testing, tools like Keploy offer smart test case generation and validation without manual effort—perfect for modern DevOps workflows.

0 notes

Text

R+ Max 2D Data Matrix Reader

In industries where traceability, speed, and precision are critical, the ability to read 2D barcodes quickly and accurately can make or break a production line. That’s where the R+ Max 2D Data Matrix Reader shines. Built for rugged industrial environments, this powerful barcode reader offers unmatched performance in decoding 2D Data Matrix, QR codes, and barcodes across a wide range of materials and surfaces.

Whether you're in pharmaceuticals, electronics, automotive, or packaging, the R+ Max is your go-to solution for automated identification and data capture (AIDC).

🔍 What is the R+ Max 2D Data Matrix Reader?

The R+ Max is a high-performance 2D barcode scanner designed to read Data Matrix codes, QR codes, and linear barcodes even on reflective, curved, or rough surfaces. It uses advanced image processing and decoding algorithms to deliver fast, reliable, and precise code reading — even at high conveyor speeds.

💡 Key Features of the R+ Max 2D Reader

⚙️ 1. High-Speed Scanning

Reads codes in milliseconds, keeping pace with fast-moving production lines.

🎯 2. Advanced Decoding Technology

Capable of reading damaged, low-contrast, or distorted codes, even on challenging surfaces like metals, plastics, and glass.

🔁 3. Flexible Integration

Compatible with multiple communication interfaces including Ethernet, RS-232, and USB, making it easy to integrate into existing systems.

🔍 4. Wide Field of View

Supports a variety of working distances and angles — perfect for both inline and robotic scanning applications.

🌐 5. Compact & Durable Design

Built to endure industrial environments with IP-rated enclosures and resistance to dust and vibration.

🏭 Industrial Applications

🏥 Pharmaceuticals

Track & trace for blister packs, vials, and cartons.

Serialization compliance (DSCSA, EU FMD)

🚗 Automotive

Part identification, VIN tracking, and production traceability.

Reading laser-etched or dot-peened codes on metal parts.

💻 Electronics

PCB component tracking, microchip ID scanning.

📦 Packaging & Logistics

High-speed carton tracking, inventory management, and error-proofing.

🛠️ Medical Devices

UDI (Unique Device Identification) verification and compliance.

📊 Technical Specifications

FeatureSpecificationCode Types SupportedData Matrix, QR Code, Aztec, PDF417, 1D barcodesReading SpeedUp to 60 frames per secondCommunication PortsEthernet, RS-232, USBOperating Temperature0°C to 50°CProtection RatingIP65 / IP67 (varies by model)ResolutionUp to 5MP sensor optionsSoftwareUser-friendly interface for setup & diagnostics

🔑 Why Choose the R+ Max 2D Data Matrix Reader?

✅ Reliable in Harsh Conditions

✅ Reads Poor Quality & DPM Codes

✅ Easy Integration with PLCs and ERP Systems

✅ Minimizes Production Downtime

✅ Future-Proof & Scalable

The R+ Max Reader is trusted by factories and warehouses around the world for its consistent read rates, plug-and-play setup, and real-time error detection. It's the smart investment for businesses looking to digitize and automate their traceability processes.

🔎 SEO Keywords to Target

R+ Max 2D Data Matrix Reader

Best industrial barcode reader

2D barcode scanner for manufacturing

Data Matrix code reader for metal parts

QR code scanner for automation

High-speed barcode reader

DPM code reader

Industrial camera scanner for traceability

🚀 Conclusion

The R+ Max 2D Data Matrix Reader is more than just a scanner — it's a critical component in smart manufacturing and Industry 4.0 systems. Designed for accuracy, durability, and speed, it ensures seamless data capture from product to packaging.

Looking to improve traceability and reduce manual errors? Choose the R+ Max — the reader that works as hard as your production line does.

📞 Contact us today for a demo, pricing, or integration support. Let R+ Max supercharge your factory floor!

0 notes

Text

How Electronic Manufacturing in Chennai Powers India’s Tech Growth

Electronic manufacturing in Chennai is transforming how India innovates in tech. If you want to know how manufacturing electronics in Chennai drives India’s technological progress, here’s the key point: Chennai stands out as a major center for producing electronic products by offering expert pcb design, efficient electronic manufacturing services, and reliable EMS capabilities. This combination helps businesses accelerate innovation, scale production, and reach global markets quickly and cost-effectively.

Why Electronic Manufacturing in Chennai Is Driving India’s Tech Growth

Several factors make Chennai a top choice for electronics manufacturing:

Government Support: Policies and incentives promote investment in electronics factories and encourage advanced manufacturing practices.

Highly Skilled Workforce: The city has a strong talent pool of engineers and technicians trained in the latest design and assembly techniques.

Complete Manufacturing Solutions: Local providers cover everything from product development and prototyping to assembly and final testing.

Excellent Infrastructure: Chennai’s proximity to key ports and its robust transport network ensure smooth logistics for components and finished goods.

Electronic Manufacturing in Chennai: Key Advantages for Businesses

Superior PCB Design Capabilities

Good printed circuit board design is essential for product reliability and cost efficiency. Chennai’s designers use modern software tools to create optimized layouts that simplify production and enhance performance.

End-to-End Electronics Manufacturing

Service providers in the city offer:

Fast prototyping to validate concepts

Surface mount and through-hole PCB assembly

Complete product assembly including mechanical and wiring integration

Comprehensive quality assurance and compliance testing

Efficient sourcing and supply chain management

How Electronic Manufacturing in Chennai Supports India’s Tech Future

Increasing Exports: The region contributes significantly to India’s electronics exports, meeting rising demand worldwide.

Supporting Innovation: Reliable manufacturing infrastructure lets startups and OEMs focus on developing new products without production delays.

Generating Employment: The sector creates jobs for thousands of skilled workers, fostering expertise in electronics technologies.

Strengthening Supply Chains: Local production reduces dependency on imports and enhances supply chain stability.

Why Choose Chennai for Your Electronics Production?

Cost-Effective Manufacturing: Competitive pricing combined with quality output improves overall value.

Flexible Production Capacity: Providers handle small pilot runs as well as large-scale orders with ease.

Use of Advanced Technologies: Adoption of automation and quality standards ensures precision and reliability.

Customer-Centered Service: Strong focus on communication and customization helps meet unique project requirements.

Conclusion

The electronics manufacturing ecosystem in Chennai is vital to India’s growing tech industry. By combining skilled design expertise, full-service manufacturing, and strategic advantages, the city enables businesses to innovate rapidly and compete globally. For companies aiming to expand their presence in the electronics market, Chennai offers dependable, scalable solutions tailored for success.

#Electronic Manufacturing in Chennai#EMS Companies India#PCB Manufacturing Chennai#India Tech Growth#Electronics Industry India#Contract Manufacturing Services#Chennai Tech Hub#Indian Electronics Market#Make in India Electronics#Industrial Automation in Chennai#Hardware Manufacturing India#Smart Manufacturing Chennai#OEM and EMS Solutions#Semiconductor Ecosystem India#Electronics Supply Chain India

0 notes

Text

Reliable PCB Assembly Silicon Valley Companies Can Count On

Building modern electronics requires more than just great design—it demands precision, process control, and a manufacturing partner you can trust. That’s why so many companies looking for PCB assembly Silicon Valley services turn to manufacturers with proven expertise, advanced facilities, and a solid track record.

At the center of Silicon Valley’s tech ecosystem, Absolute EMS has become a go-to provider for printed circuit board solutions. Whether you’re creating devices for medical, industrial, or defense markets, choosing a capable and responsive assembly partner is key to your success.

Leading Printed Circuit Board Assembly Silicon Valley Services

The demand for printed circuit board assembly Silicon Valley services has increased significantly in recent years due to the rise in compact, complex devices. From smart medical wearables to advanced defense systems, every product starts with a reliable and high-quality PCB.

Absolute EMS stands out by offering full-service assembly built around accuracy, speed, and compliance. Their factory is fully owned, which allows them to control overhead and reinvest in the latest technology — giving clients faster lead times and higher-quality builds.

Learn more about their offerings by visiting this page: PCB assembly Silicon Valley

Why Tech Companies Prefer Absolute EMS

Located in Santa Clara, Absolute EMS is a trusted partner for many leading OEMs across different industries. With over two decades of experience and some of the most advanced equipment in the EMS space, they offer:

ISO 13485 and AS9100D certified processes

Cleanroom capabilities for sensitive builds

Fast turnarounds for both prototypes and production

Strong expertise in miniaturization and tight tolerances

Full service—from PCB layout to system integration

With this end-to-end approach, companies can scale production confidently without worrying about quality issues or communication delays.

Industries Served

Absolute EMS supports a wide range of industries that demand strict quality and reliability standards:

Medical Devices – where quality and safety come first

Defense Electronics – where traceability and control are mandatory

Industrial Systems – where durability and consistency matter

Networking Equipment – where performance and uptime are critical

No matter the market, the goal remains the same: dependable electronics that meet today’s rigorous standards.

FAQs

Q1. What types of PCB assemblies do you handle? Absolute EMS can handle surface mount, through-hole, and mixed technology assemblies, including high-density and miniaturized boards.

Q2. Can you assist with design and prototyping? Yes. Their Engineering & NPI (New Product Introduction) services help teams improve designs and prepare for volume production.

Q3. Do you serve startups or only large companies? Both. Absolute EMS works with startups needing quick-turn prototypes and with established enterprises requiring full-scale production.

Where to Start?

If you are in need of PCB assembly Silicon Valley services, it’s important to work with a company that understands your product’s lifecycle — not just the board. From first prototype to final shipment, Absolute EMS brings quality, accountability, and flexibility.

Their facility is designed for tomorrow’s electronics, backed by certifications, process automation, and a skilled team that works like an extension of your business.

👉 Click here to connect with Absolute EMS for your next PCB assembly project. Whether you're at the idea stage or ready for production, they’re ready to support you with scalable, high-quality solutions.

0 notes

Text

Praxis Lips Series PCB Module 4054 | Industrial Control Solutions | Ram Automations

Discover the Praxis Lips Series PCB Module 4054, a highly reliable solution for your industrial control and automation needs. This PCB module is designed to offer superior performance, stability, and integration flexibility for various industrial systems. Perfect for enhancing the efficiency of your automation setup, the Praxis Lips 4054 ensures smooth operations across multiple industrial applications.

At Ram Automations, we are committed to delivering genuine and top-quality industrial automation products from global leaders. Trust our expertise to find the right parts that drive your operations forward.

🛒 Get the Praxis Lips Series PCB Module 4054 Now 👉 https://ramautomations.com/products/praxis-lips-series-pcb-module-4054-used

🌐 Explore Full Product Range 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Praxis Lips • 🔹 Model: 4054 • 🔹 Type: PCB Module • 🔹 Category: Industrial Automation, Control Components • 🔹 Applications: Control Systems, Automation Processes, Machine Integration

✅ Key Features

✔️ High-grade PCB construction ensuring durability and reliability ✔️ Optimized for critical industrial control and automation applications ✔️ Easy integration with multiple industrial systems ✔️ Compact design, saving valuable space in complex assemblies ✔️ Reliable signal processing for uninterrupted operations ✔️ Designed to support long-term usage without performance loss

💡 Applications Include:

• Factory Automation • Control Panel Systems • Industrial Process Automation • Manufacturing Line Control • Machine Tool Automation • Robotics Integration • Energy Management Systems • PLC and SCADA Implementations • Power Distribution and Control Solutions

🌟 Why Choose Ram Automations?

✅ Genuine industrial parts from top brands ✅ Competitive pricing across all categories ✅ Fast and reliable worldwide shipping ✅ Expert assistance for all your industrial automation needs

🎥 What You’ll See in This Video:

🔍 Detailed Look at the Praxis Lips Series PCB Module 4054 🔧 How to integrate this PCB Module into your industrial setup 💡 Advantages of upgrading your system with Praxis Lips 4054 🌍 Why Ram Automations is your trusted industrial partner

📣 Stay Connected!

🔔 Subscribe to our channel for more industrial automation product updates 👍 Like this video if you appreciate quality automation solutions 💬 Comment your queries or suggestions below — we’re happy to assist

#Praxis Lips 4054 PCB Module#Industrial Automation PCB#Automation Control Module#Process Control Systems#Factory Automation Components#Automation Integration#PLC and SCADA Systems#Industrial Electronics#Automation and Robotics#Factory Automation Systems#Power Control Units#Automation Solutions#Industrial Control Systems#Industrial Process Automation#Control Panel Automation#Machine Automation Systems#Automation and Control#Energy Management Automation#Ram Automations

2 notes

·

View notes

Text

How PCB Connectors Power Compact and Reliable Electronic Assemblies

Devices are shrinking, but expectations are rising. Whether it’s in smart lighting, factory control units, or automation systems, size is getting smaller, and reliability? Non-negotiable.

As electronics move toward denser, multi-functional designs, dependable interconnections become the unsung heroes holding these systems together. One of the most trusted realities stems from not properly seeing and often underappreciating PCB Connectors.

What Are PCB Connectors? Types and Where They Are Used

PCB connectors are mechanical interfaces that join a printed circuit board with another PCB, wire, or an external device. They are found almost everywhere in today's applications-from smart thermostats to LED drivers, programmable logic controllers, and small industrial sensors.

Types vary, and their structure depends heavily on form and function. Here's a snapshot:

The wire-to-board connectors: It is used to connect external wiring to the board.

Board-to-board connectors: Very much given for modular arrangements or compact layering.

Wire-to-wire connectors: Less frequent but may be required in some routing cases.

Pluggable connectors: These allow for installing some components without the mundane toil of doing it by hand and also can be quickly taken off and replaced.

Now here’s where it gets interesting: the ideal connector doesn’t just transfer signals or power. It prevents vibration failure, allows easy wiring, and maintains integrity across thermal cycles, all while helping devices get smaller and smarter.

Why WAGO’s PCB Connectors Are a Game-Changer for Compact and Tough Assemblies

WAGO's engineering approach cuts through the clutter. They’re not just making smaller components; they’re optimizing how those components function under stress, over time, and in the tightest spaces.

Now, PCB connectors, particularly the tool-free lever models WAGO offers, bring tangible advantages. Right in the middle of your control unit or LED module, these connectors make installation so much easier and faster, and still ensure that over 30+ terminations maintain solid contact under vibration or movement. They’re especially appreciated in tight builds where space constraints don’t leave room for error, or for a screwdriver.

Key Features That Matter:

Tool-free connection: You don’t need to reach for any special gear. Just lift, insert, press, done.

Vibration-proof reliability: Spring-pressure technology holds tight, even in mobile or high-motion applications.

Compact footprint: Helps reduce overall product size, vital for miniaturization goals.

Multiple conductor types: Whether it's stranded, solid, or fine-stranded, compatibility isn’t an issue.

It’s not hype; it’s practical design thinking that shows up in real-world use. Engineers know that rework, time, and failure risk are all minimized when connectors just work, and WAGO’s models do.

Where Are These PCB Connectors Actually Used?

In a nutshell, anywhere you need strong connections in confined areas. However, the following top-use cases illustrate their adaptability:

1. Systems of Lighting

With their secure yet small form factors, PCB connectors help ensure reliable power delivery without the need for large wiring terminals, making installation easier in tight spaces or suspended fixtures, whether you're wiring LED drivers or building modular lighting tracks.

2. Industrial Automation

You’ve got multiple sensors, signal pathways, and real-time controls packed into a DIN-rail-mounted controller, these connectors simplify wire management, reduce error margins, and allow rapid replacement during maintenance cycles, directly impacting uptime and system resilience.

3. Machine and Motion Control Panels

In dynamic systems exposed to continuous vibrations or movement, PCB connectors, when properly rated and tested for such environments, ensure that your control board doesn’t just survive, it performs optimally even after thousands of hours in operation.

Conclusion: The Right Connector Isn’t Just a Part, It’s a Strategic Choice

Here’s what it comes down to, your choice of connector can either amplify your product’s reliability or quietly sabotage it. The push toward smaller, smarter, more interconnected electronics means that interconnect quality can't be an afterthought.

When PCB connectors are engineered for tool-free use, vibration resistance, and compact layout, like WAGO’s solutions, they don’t just fit into your assembly. They elevate it. And in a space where every millimeter and every second counts, that makes all the difference.

According to a 2024 report by MarketsandMarkets, the global PCB connector market is projected to reach $17.3 billion by 2028, driven by automation, smart devices, and the rapid miniaturization of electronics.

Need help integrating high-performance connectors into your product design? Now’s the time to evaluate your current setup—and upgrade where it truly counts.

0 notes

Text

Linear Motor Market Size Driving the Future of Direct Motion Systems

The Linear Motor Market Size is advancing rapidly, driven by the growing demand for high-precision motion control across automation, semiconductor, automotive, and electronics industries. According to Market Size Research Future, the global linear motor Market Size is projected to reach USD 2.71 billion by 2032, growing at a CAGR of 5.6% during the forecast period (2024–2032).

Linear motors are transforming the landscape of motion systems by enabling direct, smooth, and frictionless linear motion without requiring conversion from rotary motion. As industries seek faster throughput, minimal maintenance, and greater accuracy, linear motors are emerging as a critical component of next-generation automation.

Market Size Overview

Unlike traditional rotary motors that require additional mechanical components (like lead screws or belts) to create linear motion, linear motors produce force and motion along a straight line directly. This advantage allows them to achieve higher speeds, precise positioning, lower wear and tear, and quieter operation—making them ideal for applications in semiconductor manufacturing, robotics, packaging, and more.

The proliferation of Industry 4.0, rise in precision machining, and increasing demand for compact and clean energy-efficient machinery are further pushing the adoption of linear motors globally.

Market Size Segmentation

The Market Size can be segmented based on type, application, and end-user industries to better understand emerging demand patterns:

By Type:

Flat Plate Linear Motors

U-Channel Linear Motors

Cylindrical Linear Motors

By Application:

Semiconductor and Electronics

Machine Tools

Robotics

Packaging

Medical Devices

Printing Equipment

By End-User:

Automotive

Manufacturing

Aerospace

Healthcare

Consumer Electronics

Logistics

By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Size Trends

1. Surge in Semiconductor Manufacturing Automation:

Semiconductor fabs require ultra-clean, high-speed, and precise motion systems. Linear motors help achieve nanometer-level positioning, making them critical for wafer handling, inspection, and packaging.

2. Robotics Integration and AI-Controlled Systems:

In robotics, linear motors offer compactness and force density, enabling smoother and more responsive robotic arms. Their compatibility with AI and sensor networks boosts real-time performance.

3. Medical and Lab Automation Expansion:

The need for precision and quiet operation in imaging systems, laboratory automation, and minimally invasive surgeries is driving linear motor usage in healthcare.

4. Transition to Smart Factories and Industry 4.0:

Smart factories are deploying linear motors in conveyor systems, CNC machines, and pick-and-place automation to improve throughput with less downtime.

Segment Insights

Flat Plate Linear Motors Lead the Market Size

These motors offer a large surface area and are capable of generating high force and acceleration. They are ideal for high-performance applications such as machine tools, industrial automation, and inspection systems.

Semiconductor and Electronics Dominate Application

With demand for microelectronics and miniaturized components increasing, linear motors play a vital role in ensuring accuracy, speed, and repeatability in semiconductor production and PCB assembly lines.

Automotive Industry Among Top Adopters

The automotive industry relies on linear motors in vehicle testing, robotic welding, precision cutting, and EV battery assembly lines—where precise control and repeatability are vital.

End-User Insights

Manufacturing:

In modern automated manufacturing environments, linear motors are favored for their minimal maintenance, high acceleration, and capacity to handle dynamic loads.

Healthcare:

Linear motors are used in diagnostic imaging systems (e.g., MRI and CT scanners), lab automation, and robotic surgery equipment, helping improve clinical precision and operational efficiency.

Logistics:

In high-speed sorting systems, linear motors enable seamless motion in warehouses, helping logistics companies keep pace with e-commerce growth.

Aerospace:

Precision in part manufacturing and material handling is essential in the aerospace sector, where linear motors offer frictionless and vibration-free motion control.

Key Players in the Market Size

The Market Size is highly competitive, with several global players investing in innovation, energy efficiency, and precision enhancement:

Siemens AG

Parker Hannifin Corporation

Yaskawa Electric Corporation

Moog Inc.

Aerotech Inc.

Baldor Electric Company

FANUC Corporation

Hiwin Technologies Corp.

Beckhoff Automation GmbH

Kollmorgen (Altra Industrial Motion)

These companies are focusing on developing motors with higher payload capabilities, better thermal efficiency, and modular architecture suited for various end-use industries.

Conclusion

The linear motor Market Size is steadily gaining traction as industries prioritize efficiency, accuracy, and low-maintenance motion systems. With their role expanding from manufacturing to healthcare, and from robotics to aerospace, linear motors are at the heart of modern motion technology. The convergence of smart automation, real-time analytics, and compact machine design will continue to drive innovation and investment in this space.

Trending Report Highlights

Stay updated on closely related and emerging Market Sizes with these insightful reports:

Agriculture Robots Market Size

UV Disinfection Equipment Market Size

Rugged Servers Market Size

Magneto resistive RAM (MRAM) Market Size

Speed Sensor Market Size

Autonomous Multifunctional Agriculture Robot Market Size

Network Engineering Services Market Size

Intruder Alarm System Market Size

Signal Generators Market Size

Supercomputer Market Size

Hearables Market Size

0 notes

Text

The Role of SINAMICS V20 in Smart Food Manufacturing

As Industry 4.0 evolves, food production is changing with new technologies. Companies are focusing on automation, efficiency, and sustainability. One of the main technology helping with this change is the SINAMICS V20, a Siemens drive that plays a big role in smart food manufacturing.

This blog explores the discussion on how the SINAMICS V20, a Siemens drive, is shaping food processing, packaging, and logistics, with Naksh Technology spearheading the implementation of these solutions.

SINAMICS V20: The Backbone of Basic Automation

The SINAMICS V20 is a small, cost-effective AC drive for the basic motion control application. Owing to its versatility and simplicity, it perfectly suits the food industry whose requirements vary from conveyor systems to mixers and pumps. With power ratings from 0.12 kW up to 30 kW, it helps execute tasks in the food processing line that demand smooth and energy-efficient operation.

Also learn more about How SINAMICS V20 Boosts Operational Flexibility In A Food Processing Plant.

Why Smart Food Manufacturing Needs Advanced Drives

Modern food manufacturing is all about precision and flexibility, apart from soaring speed. With consumer preference changes and ever-tightening regulations, manufacturers find themselves in a fast lane to quickly adapt to new recipes, packaging formats, and safety standards. Industrial automation powered by variable frequency drives (VFDs) such as the Siemens VFD V20 becomes essential.

Key Features of SINAMICS V20 in Food Manufacturing

Easy Installation and Commissioning: The SINAMICS V20 can be mounted either with push-through mounting or wall mounting, allowing for fast installation and side-by-side configuration to save on-floor space on crowded factory floors.

Energy Efficiency: It helps food manufacturers reduce their energy consumption by about 60%, a vital parameter for sustainable production, through automatic flux reduction and the ECO and hibernation modes.

Robustness and Reliability: With a unique cooling design, conformal-coated PCBs, and a vast voltage range, the drive is engineered to work within the rough environment of a food factory to minimize downtime and maintenance expenses.

Flexible Control Modes: The drive facilitates process enhancements through various control modes such as V/f, V2/f, FCC, and multi-point, according to differing machine requirements.

The Siemens Drive Advantage in Food Processing

Siemens drives are known for their integration and compatibility with automation systems. Siemens Sinamics family, including SINAMICS V20, is easily connected through PLCs, sensors, and cloud monitoring platforms. Such connectivity is important for smart food manufacturing, whereby it allows real-time process monitoring, predictive maintenance, and making decisions based on data.

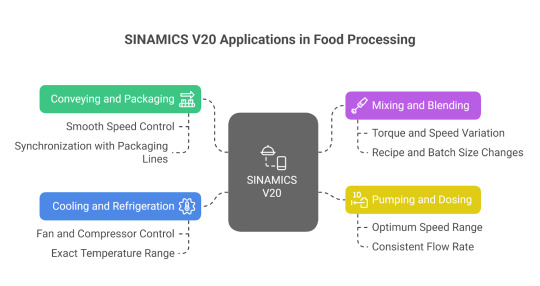

Applications of SINAMICS V20 in Food Manufacturing

1. Conveying and Packaging

The movement of raw materials and finished goods must be smooth in food plants. SINAMICS V20 drives conveyors through smooth speed control to ensure the delicate products are gently handled and synchronized with packaging lines to reduce wastage and maximize throughput.

2. Mixing and Blending

Mixers and blenders require speed regulation with precision for the sake of consistent product quality. SINAMICS V20, therefore, supplies required torque and speed variation that is reactive to sudden recipe and batch size changes.

3. Pumping and Dosing

Dosing ingredients and fluids accurately forms the foundation of food production. The SINAMICS V20 ensures that the pumps are operating at speeds in the optimum range, thus saving energy and delivering a consistent flow rate for quality assurance.

4. Cooling and Refrigeration

Temperature maintenance is essential for food safety. The SINAMICS V20 controls the fans and compressors in a refrigeration system, ensuring minimum power consumption while maintaining an exact temperature range.

Naksh Technology: Your Partner in Smart Automation

Naksh Technology is leading provider of Siemens drive solutions with an area of expertise in the integration and support of SINAMICS V20 with food manufacturing plants. With the best knowledge in industrial automation, Naksh Technology guarantees trouble-free implementation together with design, up to after-sales service, enabling the food producers to realize the full power of Siemens VFD V20 and indeed of the entire Siemens Sinamics offering.

Benefits of SINAMICS V20 for Food Manufacturers

Cost Savings: The engineering, commissioning, and operational expenses are very low considering the drive's simplicity and efficiency.

Sustainability: Integrated energy-saving mechanisms support green manufacturing initiatives and set the path for global sustainability programs.

Scalability: SINAMICS V20 can be simply scaled onto any other production line whether small or big.

Future-Ready: With the digital connectivities, the drive is ready to integrate into the Industry 4.0 scenario for cloud-based analytics and remote monitoring.

Why Choose Siemens VFD V20 from Naksh Technology?

Naksh Technology, with its vast expertise in deploying SINAMICS V20, provides food manufacturers:

Tailored automation solutions for specific food industry challenges.

Reliable technical support and training for maintenance staff.

Access to the latest Siemens Sinamics innovations for continuous improvement.

Conclusion

The SINAMICS V20 acts as a green, smart, and efficient food manufacturer. As changes take place in the food industry, Naksh Technology and the Siemens drive solutions such as the Siemens VFD V20 stand for your operations, to keep them competitive, flexible, and future-ready. Go industrial in automation with Siemens Sinamics and change your food manufacturing journey. Contact us for more information!

0 notes

Text

Comprehensive Guide to PCB Board Design & Printed Circuit Assembly for Optimal Electronic Performanc

Compre

Modern electronics rely heavily on printed circuit boards (PCBs). Without well-designed PCBs and quality assembly, devices can become unreliable or fail prematurely. Whether you’re a designer or manufacturer, understanding how to create and assemble high-quality PCBs is crucial. This guide covers essential design principles, manufacturing methods, testing, and tips for better PCB performance.

Understanding PCB Board Design Fundamentals

The Role of PCB Design in Electronics Functionality

PCB design is the blueprint that shapes how your device works. It directly influences electrical signals, heat management, and overall durability. Poor design can lead to issues like signal interference or overheating, hurting the product's performance. Good design results in a more reliable, longer-lasting device that customers can count on.

Essential Components of a PCB Design

A PCB isn’t just a green board with some wires. It includes multiple elements such as:

Layers: These are the different sheets of the PCB, repeating signals or power.

Traces: Thin lines of copper that connect components.

Pads: Contact points for mounting parts like chips or resistors.

Vias: Small holes that link traces on different layers.

Components: Resistors, capacitors, ICs, and other parts attached to the board.

Each piece affects how well the circuit functions. Proper layout and placement ensure electrical signals flow smoothly and the device functions as intended.

Designing for Manufacturing (DFM) Best Practices

Designing with manufacturing in mind helps lower costs and speeds up production. Here are key tips:

Use standard component sizes and footprints.

Keep traces wide enough to handle current.

Avoid tiny vias or complex shapes that are hard to manufacture.

Place components logically to reduce assembly time.

Minimize the number of layers if possible. Fewer layers often mean lower costs.

These practices make it easier for factories to produce your design without errors or delays.

Types of Printed Circuit Boards and Their Applications

Rigid PCBs

Rigid PCBs are the most common type. They’re made of solid material, like fiberglass, that keeps the board stiff. You’ll find these in everything from computers to appliances. They’re reliable, cost-effective, and easy to handle during assembly.

Flexible and Rigid-Flex PCBs

Flexible PCBs bend and fold, fitting into small spaces inside devices. Rigid-flex combines both types, offering stiffness where needed and flexibility elsewhere. These are popular in wearable tech and smartphones, where space is tight.

High-Frequency and HDI PCBs

Special boards designed for fast signals — known as high-frequency PCBs — are used in radio, radar, and satellite systems. HDI (High-Density Interconnect) PCBs pack more components into less space, ideal for miniaturized electronics like medical devices or smartphones.

The Printed Circuit Assembly (PCA) Process

From Design to Production: Step-by-Step Overview

A typical PCA process includes:

Designing the circuit using CAD tools.

Verifying the design for errors.

Creating prototypes for testing.

Moving into full-scale manufacturing.

Assembling components via soldering.

At every step, quality checks are essential to prevent costly mistakes later.

Key Manufacturing Techniques

Surface-Mount Technology (SMT): Attaching components on the surface. It’s fast and suitable for high-volume production.

Through-Hole Assembly: Inserting pins into drilled holes. Best for parts needing full mechanical strength.

Automated Assembly: Robots place components quickly with high precision.

Manual Assembly: Used for small runs or complex parts, but slower.

Choosing the right method impacts the speed and quality of your PCB production.

Quality Control and Inspection

Regular inspections catch problems early:

X-ray Inspection: Checks hidden solder joints.

Automated Optical Inspection (AOI): Finds defects on the surface.

SPI (Solder Paste Inspection): Ensures correct solder paste volume.

Complying with standards like IPC-610 and IPC-2221 helps keep quality high and consistent.

Critical Factors Influencing PCB and PCA Quality

Material Selection for Durability and Performance

Choosing the right materials makes a difference:

Substrates like FR-4 are common but vary in quality.

Copper thickness affects current capacity.

Solder masks prevent shorts and corrosion.

Durable materials stand up to temperature, vibration, and environmental stress.

Design for Reliability

To keep your device working long-term:

Minimize electrical interference by proper grounding.

Manage heat by placing heat-sensitive parts away from heat sources.

Use clear labels and ample space for easy assembly and maintenance.

Good practice prevents failure and reduces warranty repairs.

Environmental Considerations

PCBs face many conditions:

Use conformal coatings to protect from moisture.

Choose vibration-resistant designs for mobile devices.

Select temperature-tolerant materials for harsh environments.

Designing for these factors enhances lifespan and performance.

Cost Optimization

Balancing quality with budget is key:

Use standard components rather than custom parts.

Avoid overly complex designs.

Optimize layout for easy assembly.

Good planning reduces waste and keeps costs in check.

Best Practices for PCB Design and Assembly Optimization

Design Tips for Ease of Assembly

Properly space components for automatic placement.

Use clear silkscreen labels to identify parts.

Keep copper traces away from component pads for easier soldering.

Simplicity saves time during manufacturing and reduces errors.

Enhancing Manufacturing Efficiency

Stick to standard footprints.

Avoid intricate shapes on copper traces.

Use consistent pad sizes and pad-to-component spacing.

This approach speeds up production and keeps quality high.

Post-Assembly Testing and Validation

Once assembled, testing is crucial:

Conduct functional testing to verify operation.

Use burn-in tests to detect early failures.

Carry out long-term stress tests for durability.

Thorough testing ensures your product withstands real-world use.

Collaborating with Proven PCB Manufacturers

Choose manufacturers with:

Certifications like IPC-6012 or ISO 9001.

Experience in your specific PCB type.

Good communication and ability to meet deadlines.

Partnering with reliable suppliers reduces risks and improves final product quality.

Case Studies and Real-World Examples

Some companies have achieved great results by focusing on PCB design. For example, an electronics firm reduced their device failure rate by improving trace routing and component placement. Conversely, poor design choices, such as crowded traces, led to short circuits and costly recalls. Learning from these stories highlights the importance of meticulous planning and quality control.

Conclusion

Creating a high-performance PCB, from design to assembly, is essential for reliable electronics. Focus on good design practices, choose the right materials, and work with experienced manufacturers. Regular testing and inspection help catch issues before products hit the market. As technology advances, keep an eye on trends like miniaturization and high-frequency PCBs. Staying current ensures your designs remain competitive and durable. Quality now means better devices, happier users, and fewer headaches later.

0 notes

Text

Precision and Automation Redefined: Robotic Soldering Station in India – Powered by Ascomp Inc

As the demand for high-speed, precision-based electronics manufacturing continues to grow, manual soldering is no longer sufficient for maintaining consistency, safety, and throughput. Enter the robotic soldering station in India, a powerful innovation that brings automation to one of the most critical steps in PCB assembly. At Ascomp Inc, we supply cutting-edge robotic soldering solutions built for modern Indian factories—designed to enhance productivity, reduce human error, and ensure flawless results.

What is a Robotic Soldering Station?

A robotic soldering station is an automated machine equipped with programmable arms, temperature-controlled soldering tips, and precise motion control systems. It is used to automate repetitive soldering tasks on circuit boards, connectors, and terminal blocks.

Unlike traditional hand soldering, robotic soldering offers:

Consistent solder joints

Reduced operator fatigue

Greater speed and throughput

Lower rework and rejection rates

Better control over temperature and solder feed

Whether you're running a high-volume SMT line or a mid-scale EMS setup, a robotic soldering station in India delivers unmatched accuracy and repeatability.

Key Features of Ascomp Inc’s Robotic Soldering Systems

🤖 Multi-axis robotic arm for precise solder point control

🔥 Temperature-controlled iron tip with programmable profiles

🎯 Vision system and sensors for auto-alignment and inspection

💡 Custom jig fixtures to suit different PCB layouts

🛠️ Automated solder feeding system for consistent wire delivery

⚙️ User-friendly programming interface for custom routines

We also offer fume extraction integration and ESD-safe construction to meet electronics industry safety standards.

Ideal Applications

Our robotic soldering stations are suited for:

SMT and through-hole component soldering

Wire-to-board connections

Connector pin soldering

LED assemblies

Fine-pitch PCB assemblies

Automotive and EV electronics

Telecom and defense equipment manufacturing

Whether you're automating a high-speed production line or improving quality in low-volume, high-precision builds, Ascomp Inc has a model that fits your needs.

Why Invest in Robotic Soldering?

✅ Higher throughput with minimal manual intervention

✅ Lower training and labor costs

✅ Repeatable quality across thousands of units

✅ Fewer operator-related defects

✅ Improved traceability and data logging

It’s not just a tool—it’s a productivity multiplier for forward-thinking electronics manufacturers.

Why Choose Ascomp Inc?

📦 Ready stock of robotic soldering machines in India

🔧 Pre-sales guidance and post-installation support

💼 Integration with existing conveyor or workbench setups

🖥️ Training and programming assistance

🔄 Availability of spare parts and maintenance contracts

🛠️ Proven track record with EMS companies and R&D units

Our solutions are scalable, reliable, and fully customizable based on your board layout and workflow.

#RoboticSolderingIndia#AscompInc#PCBAssemblyTools#ElectronicsAutomationIndia#SMTProductionIndia#AutomatedSolderingStation#IndustrialSolderingRobot#SolderingAutomation#ESDCompliantSoldering#PrecisionElectronicsIndia

0 notes

Text

PCBA: The Silent Backbone of Electronic Devices

Printed Circuit Board Assembly (PCBA) serves as the critical foundation for nearly every electronic device in our modern world. From smartphones and laptops to industrial automation systems and aerospace equipment, PCBA ensures that the various electronic components within a device function smoothly and cohesively. Its precision and reliability are not just technical necessities but vital to sustaining innovation in the global tech economy.Get more news about PCBA manufacturer,you can vist our website!

Understanding PCBA

At its core, PCBA refers to the process of soldering electronic components onto a printed circuit board (PCB). While a PCB is simply the board with copper traces that connect components electrically, the assembly process transforms it into a fully functional circuit. This involves mounting integrated circuits (ICs), resistors, capacitors, diodes, and other components using either Surface Mount Technology (SMT), Through-Hole Technology (THT), or a hybrid of both, depending on the design and purpose of the device.

The PCBA Process

The process typically begins with solder paste application, where a stencil is used to apply the paste on predefined areas of the PCB. Automated pick-and-place machines then accurately position the tiny components onto the board. This is followed by reflow soldering, where the board is passed through a controlled oven to melt the solder and secure the components.