#PVC pipe service

Explore tagged Tumblr posts

Text

Discover the Versatility of PVC Pipe with PP Fittings & Valves

If you're in the market for top-quality PVC pipes, fittings, and valves, look no further than PP Fittings & Valves. With a commitment to excellence and a dedication to providing customers with the best products on the market, PP Fittings & Valves stands as a trusted supplier for all your PVC pipe needs.

Why PVC Pipe?

PVC, or polyvinyl chloride, is a versatile material renowned for its durability, affordability, and versatility. PVC pipes are widely used across various industries and applications due to their exceptional performance characteristics. Whether you're in construction, agriculture, plumbing, or manufacturing, PVC pipes offer numerous advantages:

1. Durability: PVC pipes are highly durable, capable of withstanding harsh environmental conditions, chemical exposure, and extreme temperatures. This durability ensures long-term reliability and minimal maintenance requirements, making PVC pipes a cost-effective solution for any project.

2. Corrosion Resistance: Unlike metal pipes that are susceptible to corrosion, PVC pipes are inherently resistant to rust, corrosion, and chemical degradation. This resistance ensures a longer lifespan and maintains the integrity of the piping system over time, reducing the risk of leaks or failures.

3. Lightweight: PVC pipes are significantly lighter than traditional metal pipes, making them easier to transport, handle, and install. This lightweight nature not only saves on installation time and labour costs but also simplifies maintenance and repairs.

4. Versatility: PVC pipes are available in a wide range of sizes, diameters, and configurations to suit various applications. Whether you need pipes for water supply, drainage, irrigation, or ventilation systems, PVC offers unmatched versatility and adaptability to meet your specific requirements.

Why Choose PP Fittings & Valves?

At PP Fittings & Valves, we understand the importance of quality and reliability when it comes to PVC pipes and fittings. That's why we source our products from leading manufacturers known for their superior craftsmanship and adherence to stringent quality standards. When you choose PP Fittings & Valves, you can expect:

1. Premium Quality: Our PVC pipes, fittings, and valves are made from high-grade materials to ensure exceptional performance and longevity. We take pride in offering products that meet or exceed industry standards, providing you with peace of mind and confidence in your investment.

2. Extensive Range: Whether you need PVC pipes for residential, commercial, or industrial applications, we've got you covered. From standard pressure pipes to specialised fittings, we offer an extensive range of products to suit diverse needs and specifications.

3. Expert Advice: Not sure which PVC pipe is right for your project? Our team of knowledgeable experts is here to help. With years of experience in the industry, we can provide expert advice and guidance to help you select the perfect PVC solution for your application.

4. Competitive Pricing: At PP Fittings & Valves, we believe that quality should never come at a premium. That's why we offer competitive pricing on all our products, ensuring that you get the best value for your money without compromising on quality.

Explore Our Range Today

Whether you're a contractor, plumber, or DIY enthusiast, PP Fittings & Valves has everything you need to complete your project with confidence. Explore our comprehensive range of PVC pipes, fittings, and valves online or visit our showroom to see our products in person. With PP Fittings & Valves, you can trust that you're getting the best PVC solutions backed by unrivalled expertise and customer service. Choose quality, choose reliability, choose PP Fittings & Valves for all your PVC pipe needs.

0 notes

Text

Oriplast – A leading pipe supplier 🚰

For over 50 years, Ori-Plast has been a leading force in India's piping industry. Unmatched Experience: With over five decades in the business, we have the expertise to provide the best piping solutions for your needs. ✅

Superior Quality: We use the latest innovations and adhere to the highest global standards to ensure our PVC and PE pipes are reliable and long-lasting. 🏆

Complete Piping Solutions: From irrigation and plumbing to sewerage, we offer a comprehensive range of pipes and fittings to meet all your project requirements. 🧰

Reasonable Prices: We believe in offering exceptional value, providing the best-in-class products at competitive prices. 💰

Exceptional Customer Service: Our dedication to 100% customer satisfaction means you can count on us for expert advice and support throughout your project. 😊

Visit our website today (oriplast.com) and explore our extensive range of PVC and PE piping solutions. Let Ori-Plast be your partner in building a strong and lasting infrastructure.

#100 days of productivity#plumbing#plumber#plumbers near me#plumbers#plumbing services#water heater#pvc pipe

1 note

·

View note

Text

Understanding Recycling Codes: What Can Be Recycled?

Recycling is more than just a buzzword; it’s a lifestyle choice that can significantly impact our environment. But how do we know what to recycle? The answer lies in understanding recycling codes. Each code, usually found at the bottom of plastic items, signifies the type of material and its recyclability. In this comprehensive guide, we will explore the different recycling codes, what can be recycled, and the importance of proper waste management.

Understanding Recycling Codes: What Can Be Recycled?

Recycling codes are numerical identifiers assigned to products made from various types of plastic. These codes provide crucial information about how to handle materials once they’ve reached the end of their useful life. The numbers range from 1 to 7 and indicate different resin types, each with unique properties and recycling processes.

The Importance of Recycling

In an age where waste is accumulating at an alarming rate, recycling serves as a beacon of hope. It helps conserve natural resources, reduces landfill waste, and decreases greenhouse gas emissions. Through effective junk removal strategies and education on hauling services, we can all contribute to a cleaner planet.

The Seven Recycling Codes Explained 1: PET or PETE (Polyethylene Terephthalate)

Commonly found in drink bottles and food containers, PET is one of the most widely recycled plastics. It’s lightweight yet strong, making it ideal for packaging.

Recyclability: Yes Uses of Recycled Material: New containers, clothing fibers 2: HDPE (High-Density Polyethylene)

This type is often used for milk jugs, detergent bottles, and some plastic bags due to its durability.

youtube

Recyclability: Yes Uses of Recycled Material: Pipes, plastic lumber 3: PVC (Polyvinyl Chloride)

PVC is commonly seen in pipes and vinyl siding but isn’t typically accepted in curbside recycling programs.

Recyclability: Limited Uses of Recycled Material: Flooring tiles, new pipes 4: LDPE (Low-Density Polyethylene)

Often used for shopping bags and some food wraps, LDPE isn’t widely accepted in curbside pickup but can be recycled through specific programs.

Recyclability: Limited Uses of Recycled Material: Floor tiles, shipping envelopes 5: PP (Polypropylene) junk removal Rapid Haul Away LLC

Used in yogurt containers and straws, polypropylene has a higher melting point compared to others.

Recyclability: Yes Uses of Recycled Material: Brooms, bins 6: PS (Polystyrene)

Commonly known as Styrofoam, polystyrene is not recyclable in many areas due to its lightweight nature.

youtube

Recyclability: No Alternative Disposal Methods: Junk pickup services for large quantities 7: Other (Various Plastics)

This category includes various plastics that don’t fit into the other six categories. Their recyclability varies widely based on local regulations.

2 notes

·

View notes

Text

Technology's Use of Water

While water is renewable, it is finite. Its renewability depends on us using and managing our water resources responsibly.

Previous articles on this page have discussed hydropower and how it produces less waste and costs less than other resources. We have also briefly discussed how other energy sources consume water as a coolant or receptacle for waste. Entire university courses are dedicated to human uses of water.

Water Scarcity

Only 3% of water on Earth is freshwater. Of course, we need this to drink, but we need it for many more services beyond that.

Many plumbing fixtures are made of copper, which saltwater severely corrodes, same as lead and, over a longer time, PVC. Toilets on average use 1-5 gallons of water per flush. If we want to preserve freshwater by switching to saltwater plumbing, we would have to rethink and re-pipe entire plumbing systems.

We lose safe water in rain, as well. Supported by a study in Environmental Science and Technology, the Center for Disease Control and Prevention in 2022 stated that rainwater is not safe to drink. Chemicals known as per-/poly-fluoroalkyl substances break down extremely slowly, and have leached from many products like cleaners, fabrics, and shampoo into the water cycle. Removing PFAS from water requires filters of activated carbon or reverse osmosis membranes, which also require frequent maintenance.

A lot of water is also not available to us because it is in ice caps and glaciers, which are estimated to be about 68% of Earth’s freshwater. This water is also being lost, because as glaciers melt at increasing rates, that freshwater becomes saltwater in the ocean.

These limitations mean that water is not necessarily renewable yet, especially because treating water produces its own waste and pollution. We have to be responsible with the small percentage of water we have access to.

Irresponsible Use

There are a ridiculous amount of ways in which we waste water. Leaks, watering lawns, and leaving taps running are some of the big household wastes of water. While individual accountability and changes can still make a big difference, I want to focus on bigger impacts.

One example is in nuclear power production. Nuclear power plants use water to cool down used fuel when it is done being used in the reactor. This results in radioactive and thermal water pollution.

Agriculture is another common cause of water pollution. Excess water from rain or artificial watering runs off of agricultural fields and flows towards streams and bodies of water. This runoff often includes amounts of fertilizers and pesticides ranging from minimal to extremely harmful. This leads to improper levels of oxygen, nitrogen, and hydrogen within the water. Like water contaminated by pharmaceuticals, this is not safe to drink, and something not safe for skin contact.

Technology is also a major factor of water demands. Artificial Intelligence and cryptocurrency are heavy water consumers.

AI is beneficial within waste management, as it is able to quickly analyze information and identify issues, potential problems, and potential areas of improvement. Unfortunately, AI training requires a large amount of water. One study states that training GPT-3 alone can evaporate 700,000 liters of freshwater. In 2027, AI is predicted to consume 4.2 to 6.6 billion cubic meters of water. In comparison, Denmark nationally consumes around one billion cubic meters in a year.

Cryptocurrency is even worse. It goes through a process called mining in which transactions are verified and new ‘coins’ are generated into the system. This process is extremely water-demanding. For example, in 2021, mining of Bitcoin consumed more than 1,600 gigaliters of global water. On average, each cryptocurrency transaction consumes 16,000 liters of water in cooling down the computer equipment and the power plants that provide the electricity.

Saltwater as an alternative in these situations does exist; however, this process has the disadvantages of one-time use, large water intake, sewage discharge, and ocean pollution. Technology has begun to improve on this method with seawater circulation cooling technology, which reduces sewage discharge and water intake, but remains an imperfect solution.

Technology has the potential to drastically improve environmental management and restoration, but still has a long way to go before we offset the huge impacts we have made. Freshwater is taken for granted by many people, and the systems that disproportionately consume the most of it are not held accountable. This cycle must stop if we want to make water a truly renewable resource.

Additional Resources

1. Water Renewability

2. Corrosion on Plumbing

3. Treating PFAS

4. Household Water Waste

5. Nuclear Water Waste

6. AI Helping Water Management

7. AI Water Consumption

8. Crypto Mining Water Consumption

9. Seawater cooling technology

#renewable power#renewable energy#water#water pollution#technology#artificial intelligence#ai training#cryptocurrency#digital currency#bitcoin#article#research#resources#environment#climate change#science

6 notes

·

View notes

Text

Excerpt from this New York Times story:

The Biden-Harris administration said Wednesday that it was taking its first steps toward potentially regulating vinyl chloride, a versatile yet cancerous and flammable chemical used widely to make plastic for PVC pipes and packaging.

Experts and environmental groups had been urging the federal government to more stringently regulate the chemical after a train shipment of it derailed in East Palestine, Ohio, last year, prompting officials to perform a large controlled burn that sent a black cloud of smoke over the surrounding area, raising health concerns.

Tougher rules or a ban on vinyl chloride would address a host of health and safety concerns: The U.S. Department of Health and Human Services has classified vinyl chloride as a known human carcinogen, and the chemical is highly flammable and potentially explosive.

Safety experts had also raised concerns over the transport of vinyl chloride across long distances on accident-prone freight trains. The more than 100,000-gallon vinyl chloride shipment that burned in Ohio was on a 1,600-mile journey from a chemicals plant just outside Houston, Texas, to a PVC flooring plant in Pedricktown, N.J.

But tougher regulations would also upend the market for a type of plastic used widely in electrical wiring and cables, blood storage bags and other medical devices, packaging and household goods like shower curtains and raincoats, and PVC pipes for drinking water.

The Vinyl Institute, which represents vinyl chloride manufacturers and related companies, said its members adhered to “some of the most stringent safety and environmental regulations in the chemical industry.” The E.P.A.’s process will “demonstrate the production and use of vinyl chloride are safe,” said the group’s chief executive, Ned Monroe.

4 notes

·

View notes

Text

Cosplay Project - Ready or Not

Been a little radio silent lately, so I’m touching base with what I’ve been working on for the past couple of months.

More deets under the cut!

I’ve partnered up with my friend from the previous cosplay I posted (MW: Ghost & Price, my friend was Price) alongside a few more people to put together a group cosplay for Ready or Not.

For the unaware, Ready or Not is a tactical FPS in which you play as the leader of a SWAT team responding to a series of high risk calls, ranging from warrant services, active shooters, counter-terrorism activities, robberies, etc. While you do get points for clearing and neutralising all threats, you get more points and better ranks & rewards for not employing lethal force (by using pepper spray, tasers, gas, and other non/less lethal means available in the game)

Here’s a few pics of everything I have put together thus far:

Some helmets, to be worn by myself (right) and one of the team (left)

Body armour, in the form of a Crye AVS (for me) and Crye JPC (other team member)

Ballistic entry shield

Mirrorgun (this is what I am most proud of, being a fully homemade prop using PVC pipe, and 3d printed components including parts taken from the in-game model)

Weapons: a representation of a beanbag “less lethal) shotgun (to be carried by another person in our squad) and a Mk 18 Mod 0 CQBR (carried by me)

Can’t wait to share pics of our team from Gold Coast Supanova 2024. We will be there on Saturday, attending the showcase.

For any of my followers who happen to be attending, if you happen to be attending as well and you see me and/or my team, don’t be afraid to come say hi! I won’t bite (can’t speak for the rest of the team though).

4 notes

·

View notes

Text

youtube

Installing a UV Water Purification Light: Step by Step Guide

Welcome back to Base Camp WNC. Today, we embark on an informative journey on how to seamlessly install UV lights in your existing water systems. UV lights are essential for purifying water, ensuring that it is free from harmful microorganisms.

Getting Started with the UV Light System The UV light system we're focusing on today is a 55-watt, 110-volt unit, designed specifically for the United States. It comes equipped with two holes at each end, accommodating water fittings. Versatility is key with this design; it can be mounted horizontally, vertically, or at any desired angle. The kit includes a slender glass tube, reminiscent of an elongated test tube. When assembling, slide this tube into the provided ring until it slightly protrudes from the other end. Ensure the ring's pyramid-shaped fixture is correctly aligned to secure the tube. This is a delicate procedure, and I have some tips to prevent the glass tube from breaking.

Assembly Tips

Slide the glass tube gently to ensure it doesn't snap.

The flange present will accommodate a seal, which when pressed, ensures a tight fit. Just let the glass tube protrude slightly and secure it hand-tight.

When sealing both ends of the tube, do not use pliers or exert excessive force. Gentle hand-tightening is sufficient.

Water flows between the glass tube and the metal frame, getting purified as it passes by the UV light, before exiting from the other end.

The kit I’m showcasing comes with one glass tube and three UV light bulbs. An important note on the longevity of these bulbs: while they may still emit heat and light after a year, their purification capability diminishes. Hence, an annual replacement is recommended. Handle these bulbs with care and avoid touching them with bare hands.

Installation Essentials For the perfect fitting, I've innovated with a shower fitting, designed to accommodate the PEX pipe. Applying two wraps of Teflon tape in the direction of the screw ensures a smooth slide. This is especially crucial with PVC components that may have residual bits from the molding process. Add a layer of pipe dope for a tight seal. The location of installation plays a vital role. In my setup, the spring below the house feeds a tank, which then directs the water towards the house. The UV light system sits in between. To ensure a sturdy installation, mount a board (like a 1 by 4) on the wall as a base. Once set, the PEX pipe is clamped onto this board with two plastic clips. This setup allows easy access for future maintenance or bulb replacement. The UV light system's transformer has an indicator – a green light – to show it's functioning.

Wrapping Up Installation can be swift with a bit of experience – it takes me about 15-20 minutes, having installed numerous before. But even if you're new to this, with the right guidance, it's a straightforward process. Thank you for joining us. If you found this guide useful, please like, share, and subscribe. For any further queries or if you need specialized assistance, feel free to shoot me an email or drop a comment on YouTube. I offer free advice and guidance online, but consultations or installations at specific locations would be a paid service.

Until next time, stay informed and stay safe!

Visit us at: Carolina Homestead Planner We offer services to help with your homestead planning and preparedness needs.

2 notes

·

View notes

Text

Plastic Compounds Market: Engineered Polymers Powering Modern Manufacturing

Plastics have evolved far beyond basic polymers. Today, plastic compounds—engineered blends of base resins with additives, fillers, and reinforcements—are transforming how industries approach strength, weight, sustainability, and cost efficiency. From under-the-hood car components and durable electrical housings to recyclable packaging and medical devices, plastic compounds deliver the performance characteristics modern manufacturing demands.

As sustainability regulations tighten and industries seek advanced alternatives to metals and ceramics, the Plastic Compounds Market is experiencing significant growth driven by innovation, application diversity, and value-added customization.

What Are Plastic Compounds?

Plastic compounds are customized formulations made by blending a base polymer (like polypropylene, polyethylene, ABS, or PVC) with a variety of performance-enhancing agents. These additives may include:

Fillers (e.g., glass fibers, talc, calcium carbonate) for strength and thermal resistance

Stabilizers to protect against heat and UV degradation

Plasticizers to improve flexibility

Colorants and pigments for aesthetics

Flame retardants, impact modifiers, and antimicrobial agents for specialized functions

The result is a material precisely engineered for a specific application or industry requirement—lighter than metal, more durable than traditional plastics, and often easier to process or recycle.

Market Overview: A Growing Global Opportunity

The global plastic compounds market was valued at USD 70.81 billion in 2024 and is projected to reach USD 97.27 billion by 2029, expanding at a CAGR of 6.6%. The surge is driven by several key factors:

Lightweighting in Automotive and Aerospace

OEMs are turning to reinforced plastic compounds to reduce vehicle weight, improve fuel efficiency, and meet emission standards—without compromising safety or durability.

Consumer Electronics Miniaturization

As devices shrink and become multifunctional, the need for strong, heat-resistant, and electrically insulated plastic compounds is rising sharply.

Infrastructure and Construction Growth

PVC and PE compounds are used in pipes, cables, window profiles, and insulation due to their long service life and ease of installation.

Sustainable Packaging

With growing bans on single-use plastics, the demand for biodegradable and recyclable compounds made from PLA, starch blends, and recycled PET is gaining momentum.

Medical and Healthcare Applications

Medical-grade plastic compounds offer biocompatibility, sterilization resistance, and regulatory compliance for devices, tubing, and drug delivery systems.

Key Segments by Resin and Application

By Resin Type:

Polypropylene (PP) Compounds – Widely used in automotive interiors, appliance housings, and furniture.

Polyvinyl Chloride (PVC) Compounds – Preferred for electrical, construction, and healthcare uses due to flame resistance and low cost.

Polyethylene (PE) Compounds – Used in flexible packaging, wires & cables, and agricultural films.

ABS and Polycarbonate Compounds – Known for high impact resistance, often used in consumer electronics and automotive exteriors.

By End-Use Industry:

Automotive & Transportation

Electrical & Electronics

Building & Construction

Packaging

Medical Devices

The customization flexibility of plastic compounds makes them relevant across all these sectors.

Leading Plastic Compound Manufacturers

Several global companies dominate the plastic compounds market by offering extensive R&D capabilities, global supply chains, and sustainable material portfolios:

BASF SE (Germany) – Offers high-performance plastic compounds with applications in automotive, packaging, and medical sectors.

LyondellBasell (Netherlands/USA) – Known for its polypropylene and polyethylene-based compounds with a focus on recyclability.

RTP Company (USA) – Specializes in customized thermoplastic compounds, including flame-retardant and conductive materials.

SABIC (Saudi Arabia) – Provides advanced engineering plastic compounds for electronics, construction, and mobility sectors.

Dow Inc. (USA) – Focuses on sustainable plastic compounds used in infrastructure, flexible packaging, and health industries.

These players are investing in circular economy models, bio-based materials, and closed-loop recycling systems to align with environmental mandates and customer expectations.

Download PDF Brochure to Get Deeper Insights :

The plastic compounds market is more than a subsegment of the polymer industry—it’s a driving force behind innovation, sustainability, and performance in global manufacturing. As industries seek smarter materials that balance cost, efficiency, and environmental impact, engineered plastic compounds provide the answer.

From lightweight car panels to recyclable food trays and medical-grade polymers, plastic compounds are quietly enabling the products of tomorrow. The companies and sectors that embrace their full potential today will be better positioned to lead in a resource-conscious, innovation-driven future.

#plastic compounds#polypropylene compounds#sustainable plastics#BASF#RTP Company#engineered polymers#recyclable materials#industrial plastics

0 notes

Text

Industrial Zone In Vietnam

The Success of Chinese Enterprises at Nam Dinh Vu Industrial Park: Insights from Real Investment Practices

Nam Dinh Vu Industrial Park (NDV IP) in Hai Phong has become a strategic destination for Chinese enterprises expanding their presence in Vietnam. With its prime location, modern infrastructure, and business-friendly policies, NDV IP has attracted significant investments from China, contributing to the region’s industrial and commercial growth.

Strategic location and modern infrastructure have been key factors in Nam Dinh Vu ’s success in attracting foreign investment. Situated within the Dinh Vu – Cat Hai Economic Zone, the industrial park offers seamless connectivity via road, sea, and air. Notably, Nam Dinh Vu is the only industrial park in Vietnam with an integrated deep-water port—Nam Dinh Vu Port. This unique advantage enables businesses to optimize logistics costs and streamline supply chain operations. The port is equipped to accommodate large vessels, supporting efficient import and export operations, and positioning it as an ideal center for international trade.

Significant investments from Chinese enterprises have further solidified Nam Dinh Vu’s position as a key industrial hub. Vietnam Precision Craft Component Technology Company Limited has invested $10 million to establish a manufacturing facility for industrial tools (1). Another major investor, Hoda Strategic Holdings Private, has allocated $10 million for the production of high-quality PVC pipe fittings, with a capacity of 10,000 tons per year, creating more than 50 jobs (2). Similarly, Finework International has committed $10 million to develop a facility specializing in mechanical components and industrial spare parts (3). These investments highlight the confidence Chinese businesses have in Nam Dinh Vu’s long-term potential.

Factors driving success for Chinese enterprises in Nam Dinh Vu go beyond its advantageous location. The industrial park offers world-class infrastructure, including stable power supply, water treatment systems, and high-quality logistics services, ensuring efficient business operations. Additionally, Vietnam’s attractive tax incentives and stable investment climate provide a strong foundation for foreign enterprises. The Vietnamese government, particularly the Hai Phong Economic Zone Authority (HEZA), has proactively signed multiple Memorandums of Understanding (MoUs) with Chinese firms to facilitate smoother investment processes (4).

In conclusion, the growing presence of Chinese enterprises at Nam Dinh Vu Industrial Park is a testament to the park’s strategic location, robust infrastructure, and investor-friendly policies. As NDV IP continues to expand and develop, it is poised to become a major industrial and logistics hub in Vietnam, attracting further international investments and driving sustainable economic growth.

industrial zone in vietnam

Source:

(1). The Investor

(2). B-Company

(3). Emidas Magazine

(4). VnEconomy

0 notes

Text

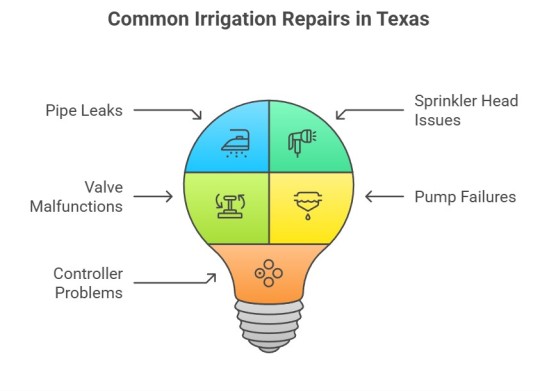

What Are the Most Common Irrigation Repairs in Texas?

Texas weather can be unforgiving—long dry spells, sudden rainstorms, and blistering heat all take a toll on outdoor landscapes. To keep lawns green and gardens thriving, reliable watering systems are essential. That’s why irrigation repairs in Texas are more common than most homeowners realize.

Whether it's a suburban home in Austin or a commercial property in Dallas, systems wear down over time. Damage can come from shifting soil, root invasion, poor installation, or simply age. Knowing what issues to watch for and how to address them early can prevent bigger, costlier problems down the road.

Broken or Clogged Sprinkler Heads

One of the most frequent service calls involves malfunctioning sprinkler heads. They’re often the first to suffer from daily wear and tear—run over by lawnmowers, blocked by debris, or simply worn out due to exposure.

Signs of a damaged head include uneven water coverage, dry patches on your lawn, or water pooling in unwanted areas. Sometimes the fix is as simple as cleaning the nozzle or replacing the head. Other times, deeper inspection is needed to determine if there’s pressure loss or pipe damage underneath.

Leaking Underground Pipes

Texas has a wide range of soil types, from heavy clay to rocky terrain, all of which expand and contract due to temperature changes. These shifts can cause underground PVC or polyethylene piping to crack or disconnect.

If your water bill spikes unexpectedly or you notice soggy spots in your yard even when the system hasn’t been running, you might be dealing with a hidden leak. These types of repairs often require locating equipment and specialized knowledge, making it a job best left to professional irrigation system installers.

Poor Coverage and Uneven Watering

Improper design is another common culprit in Texas yards. Systems installed without consideration of terrain, plant type, or water pressure often lead to overwatered spots next to bone-dry areas.

This issue is particularly noticeable in sloped properties or where hardscape features like concrete construction in Texas has altered water flow. In these cases, repairs involve repositioning sprinkler heads, adding drip zones, or updating the controller’s watering schedule. Many homeowners choose to upgrade to smart controllers that adjust watering based on weather forecasts—cutting water waste and improving results.

Controller Malfunctions

Even with everything underground working fine, your irrigation system won’t function without a reliable controller. Older analog models are more prone to programming errors, dead batteries, or electrical faults.

Newer smart models can connect to Wi-Fi and use local weather data to make automatic adjustments. However, connectivity issues, app malfunctions, or incorrect setup can also lead to under- or over-watering. If you’re facing recurring controller issues, it may be time to replace rather than repair—especially if the unit is more than a decade old.

Backflow Preventers

Texas homes with well water or sediment-heavy municipal supply can face issues with clogged filters and backflow preventers. These components ensure clean water enters your irrigation system while preventing contaminants from flowing backward into your home's supply.

When clogged, they restrict water flow and pressure, reducing performance. These are usually easy fixes—if you know where to find them and how to clean or replace the screen. Still, it’s an overlooked maintenance task that can lead to performance drops if ignored.

Seasonal Damage from Freeze or Drought

While Texas doesn’t experience harsh winters like northern states, sudden cold snaps can catch unprepared systems off guard. Pipes that aren’t properly winterized may freeze and crack, especially if they’re shallow or uninsulated.

Conversely, drought conditions can dry and compact soil, causing stress on pipe joints and seals. Expansion and contraction often go unnoticed until water starts seeping through tiny cracks weeks later.

Being proactive about seasonal inspections is key. Many homeowners schedule pre-summer checkups and late-fall blowouts to avoid these seasonal setbacks.

Whether you own a small home garden or manage a large commercial landscape, your watering system needs consistent attention. Routine inspections, a bit of preventive care, and professional support when needed can save hundreds—if not thousands—on long-term repair costs. When in doubt, work with trusted irrigation system installers who understand the nuances of Texas soil, weather, and water usage. A system that works smarter—not just harder—means a healthier yard and a more sustainable approach to outdoor living.

0 notes

Text

Finding the Best Plumbing Supply in Durham, NC: A Complete Guide

Whether you’re a professional contractor or a homeowner tackling a plumbing project, having access to high-quality plumbing supplies is essential for success. If you're located in the Triangle area, finding reliable plumbing supply in Durham, NC is easier than ever—but knowing what to look for can make a big difference.

In this post, we’ll explore the importance of quality plumbing materials, what products you can expect from Durham plumbing suppliers, and how to choose the right place for your needs.

Why Choosing the Right Plumbing Supply Matters

Plumbing systems are vital to the function and safety of any building. Poor-quality parts can lead to leaks, inefficiency, or even major water damage. Whether you're replacing an old faucet, installing a new water heater, or running new water lines, you need durable materials and trusted brands that meet code and deliver long-lasting performance.

A reputable plumbing supply store in Durham, NC will offer:

High-grade materials that meet local codes

Trusted product lines from industry-leading brands

Expert advice from experienced staff

Competitive pricing on parts and tools

What You’ll Find at a Durham Plumbing Supply Store

Durham plumbing supply stores cater to a variety of customer needs—from homeowners working on DIY bathroom upgrades to licensed plumbers managing full-scale commercial jobs. Here’s a breakdown of what you can typically find:

1. Pipes and Fittings Options include copper, PEX, PVC, and galvanized steel pipes along with elbows, tees, adapters, couplings, and more.

2. Fixtures and Faucets Everything from high-end designer faucets and modern sinks to utility-grade fixtures for kitchens, bathrooms, and laundry rooms.

3. Water Heaters Gas, electric, and tankless water heaters from brands like Rheem, AO Smith, and Navien.

4. Drainage and Venting Supplies Drain pipes, sump pumps, backflow preventers, and air admittance valves for residential and commercial systems.

5. Plumbing Tools Pipe cutters, thread sealants, wrenches, pressure gauges, leak detectors, and everything else needed to install or repair plumbing systems.

6. Heating and Hydronic Equipment Some suppliers in Durham also carry boilers, radiant heating components, and HVAC accessories.

7. Eco-Friendly Solutions Low-flow showerheads, dual-flush toilets, and ENERGY STAR®-rated water heaters to help reduce water usage and lower utility costs.

Features of a Great Plumbing Supply Store

If you’re searching for plumbing supply in Durham, NC, here are a few features that set the best suppliers apart:

Wide Inventory: You want a store that stocks both basic and specialty items.

Expert Staff: Staff who can answer technical questions and recommend solutions save you time and money.

Convenient Hours & Pickup Options: Especially important for contractors who need to grab parts quickly and stay on schedule.

Delivery Services: Local delivery can be a huge benefit for larger projects or emergency repairs.

Fair Pricing: Competitive pricing without sacrificing quality is a sign of a trustworthy supplier.

Final Thoughts

When it comes to plumbing, cutting corners on materials can cost you more in the long run. That’s why choosing a trusted source for plumbing supply in Durham, NC is one of the smartest moves you can make for any project, large or small.

1 note

·

View note

Text

pvc stabilizer manufacturer

Introduction

In the fast‑evolving plastics industry, selecting the right PVC stabilizer manufacturer is crucial to ensuring product quality, performance, and cost‑effectiveness. This article offers a comprehensive guide to PVC stabilizer manufacturers: their role, key considerations when selecting one, types of stabilizers, applications, quality standards, and trends shaping the market. Whether you're a seasoned buyer or a newcomer exploring PVC production, this content is tailored to help you make informed decisions.

(Approx. 90 words)

1. What Is a PVC Stabilizer Manufacturer?

A PVC stabilizer manufacturer specializes in producing additives that enhance the thermal and mechanical stability of polyvinyl chloride (PVC). Without stabilizers, PVC degrades under heat or UV exposure, leading to discoloration, brittleness, and reduced lifespan. A reliable PVC stabilizer manufacturer provides customized solutions that meet varying application needs—ranging from rigid profiles and pipes to flexible films and cables. They combine chemical expertise, production infrastructure, and quality control systems to deliver consistent, high-performance stabilizer blends.

(Approx. 100 words)

2. Why Choose a Quality PVC Stabilizer Manufacturer?

Selecting the right PVC stabilizer manufacturer impacts product integrity, safety, regulatory compliance, and overall production efficiency. Here are key reasons to prioritize high-quality suppliers:

Thermal stability: Prevent degradation at processing temperatures

Color retention: Avoid yellowing or chalking on exposure

Mechanical properties: Maintain flexibility, toughness, and impact resistance

Regulatory compliance: Meet ROHS, REACH, and food‑contact standards

Consistent performance: Uniform batches ensure production reliability

Cost optimization: The right stabilizer reduces scrap, energy usage, and additives

(Approx. 95 words)

3. Types of PVC Stabilizers from Manufacturers

PVC stabilizer manufacturers offer a wide range of formulations to address specific requirements. Key types include:

3.1. Lead Stabilizers

Although phased out in many regions due to toxicity, some efficient PVC stabilizer manufacturers still produce lead‑based stabilizers for low‑volume or legacy applications.

3.2. Calcium‑Zinc Stabilizers

Non‑toxic and RoHS‑compliant, calcium‑zinc stabilizers from reputable PVC stabilizer manufacturers are ideal for food packaging, medical devices, and general‑purpose uses.

3.3. Tin Stabilizers

Organotin compounds offer high heat stability and clarity, favored in high‑end cable jacketing and rigid fittings.

3.4. Mixed Metal Stabilizers

Blends combining calcium, zinc, and barium provide balanced thermal performance, mechanical properties, and price.

3.5. Organic Stabilizers

Manufacturers also produce epoxidized soybean oil and other organic stabilizers for eco‑friendly PVC applications.

Each PVC stabilizer manufacturer tailors formulations to specific product types—from rigid constructions to flexible films.

(Approx. 160 words)

4. Key Selection Criteria for PVC Stabilizer Manufacturers

When evaluating a PVC stabilizer manufacturer, carefully assess these factors:

4.1. Technical Expertise

Look for manufacturers with proven R&D capabilities to formulate stabilizers that match your processing conditions and product requirements.

4.2. Quality Certifications

Choose suppliers holding ISO 9001, ISO 14001, and industry‑specific credentials to ensure consistent quality.

4.3. Regulatory Compliance

Confirm that the PVC stabilizer manufacturer can supply RoHS, REACH, FDA‑approved (food contact), or medical‑grade products.

4.4. Production Capacity & Logistics

Ensure the manufacturer has sufficient scale and reliable delivery systems to meet your supply demands.

4.5. Customization Ability

Manufacturers offering tailored stabilizer blends can optimize performance and cost for your PVC formulations.

4.6. Technical Support & Service

Ongoing technical service—trial runs, troubleshooting, formulation advice—is often provided by top-tier PVC stabilizer manufacturers.

4.7. Sustainability & Eco‑Initiatives

Assess whether the supplier prioritizes green chemistry, low‑VOC production, and renewable feedstocks.

By comparing multiple PVC stabilizer manufacturers along these criteria, buyers gain confidence in their final choice.

(Approx. 180 words)

5. Applications of PVC Stabilizers

PVC stabilizer manufacturers cater to numerous industries, including:

5.1. PVC Pipes & Fittings

Stabilizers ensure processing stability at high melt‑temperatures and provide UV resistance for outdoor exposure.

5.2. Window Profiles & Architectural Extrusions

Manufacturers supply high‑impact, color‑stable blends for outdoor building products.

5.3. Flexible PVC Products

From flooring to toys and cables, stabilizers enhance flexibility and prevent degradation.

5.4. Automotive Applications

Cable sheathing, interior trims, hoses—reliable heat and mechanical stability are essential.

5.5. Medical & Food‑Contact Items

Only trusted PVC stabilizer manufacturers with FDA/NSF‑grade products meet strict biosafety standards.

5.6. Wire & Cable Insulation

High‑performance tin or mixed‑metal stabilizers enable continuous extrusion processes.

Each application requires a unique stabilizer blend, highlighting the versatility of leading PVC stabilizer manufacturers.

(Approx. 150 words)

6. How PVC Stabilizer Manufacturers Add Value

Quality suppliers offer more than just additives. Here's what to expect:

6.1. Pilot Trials & NABs

Manufacturers conduct lab-scale trials to optimize stabilizer dosage and processing settings.

6.2. Co‑Development Projects

Collaborative partnerships speed up product launches and innovation.

6.3. Comprehensive Technical Library

Datasheets, processing guides, MSDS/CoA documentation, and troubleshooting resources.

6.4. Supply Chain Reliability

Trusted manufacturers maintain inventory buffers, transport security, and contingency planning.

6.5. Training & Education

Manufacturers may offer webinars, workshops, and processing tech training to support customers.

These value-added services demonstrate why discerning buyers choose high‑caliber PVC stabilizer manufacturers.

(Approx. 130 words)

7. Emerging Trends in PVC Stabilizer Manufacturing

The industry is evolving rapidly. Key trends include:

7.1. Sustainability & Biobased Additives

Demand is rising for calcium‑zinc or organic stabilizers made from plant oils and renewable resources.

7.2. Lead‑Free & RoHS‑Compliant

Global regulatory pressure continues to phase out lead‑based stabilizers—manufacturers are adapting.

7.3. High‑Performance Nanocomposites

Cutting‑edge stabilizer producers explore nanoparticles to enhance temperature tolerance and mechanical strength.

7.4. Digital Formulation Tools

AI‑driven simulators and predictive models help manufacturers to optimize blends faster.

7.5. Custom Extrusion Compatibilities

Manufacturers tailor stabilizers to match different extruder designs, throughput rates, and end‑product specifications.

By partnering with forward-looking PVC stabilizer manufacturers, brands can stay ahead of regulatory shifts and technical innovation.

(Approx. 140 words)

8. Case Study: Choosing the Right PVC Stabilizer Manufacturer

Scenario

A midsize extrusion plant in Asia wants to upgrade their window‑frame line. They require:

RoHS‑compliant, lead‑free stabilizer

Improved color retention under UV exposure

Lower cost without sacrificing throughput

Approach

They contacted three PVC stabilizer manufacturers for samples and data sheets. Based on pilot-scale tests and technical support, they selected a calcium‑zinc stabilizer with UV absorbers. The new blend:

Improved throughput by 10%

Reduced flash and scrap rate by 15%

Achieved L* retention increase of 5 points after 2,000 hours of UV exposure

This success story underlines the importance of working closely with a PVC stabilizer manufacturer to optimize both performance and cost.

(Approx. 130 words)

9. Tips for Working with a PVC Stabilizer Manufacturer

Start small: Run trials with 25‑50 kg samples before scaling

Share formulations: Transparency helps the manufacturer match your resin grade

Record results: Measure torque, color, impact, and aging for data‑driven decisions

Schedule periodic reviews: Technology and regulations evolve—review blends annually

Maintain good relationships: Long‑term partners may offer flexible payment, priority production, or co‑innovation projects

These practices help maintain alignment with your PVC stabilizer manufacturer and ensure long‑term value.

(Approx. 110 words)

10. FAQ – PVC Stabilizer Manufacturer

Q1. What is the typical dosage range?

A1. Varies by application—1–3 phr for general rigid PVC; 3–7 phr for flexible grades.

Q2. How do I test stabilizer effectiveness?

A2. Perform MFI/torque tests, oven aging, UV exposure, and mechanical tests (tensile, impact).

Q3. Are customized stabilizers expensive?

A3. Initial R&D adds cost, but long-term benefits (efficiency, scrap reduction) usually outweigh it.

Q4. Can I switch stabilizers mid‑production?

A4. Yes—but gradual trials and technical support from the PVC stabilizer manufacturer are essential.

Q5. Are stabilizers food‑safe?

A5. Yes, if they have FDA/EFSA approval—sourced from a certified PVC stabilizer manufacturer.

(Approx. 140 words)

11. Conclusion

Choosing the right PVC stabilizer manufacturer is a strategic decision that impacts product quality, compliance, sustainability, and bottom‑line performance. By understanding different stabilizer types, evaluating vendor capabilities, and fostering collaborative partnerships, PVC processors can secure stable, high‑performance formulations optimized for their applications. Stay alert to evolving trends—such as lead‑free solutions, biobased additives, and digital innovation—as these will shape the future of PVC stabilizer manufacturing.

With careful planning and expert partnerships, investing in a quality PVC stabilizer manufacturer translates into better products, lower costs, and long‑term operational excellence.

#pvc stabilizer#pvc stabilizer manufacturer#pvc stabilizer manufacturer in india#pvc stabilizer manufacturer in delhi

0 notes

Text

CPVC Pipe Manufacturer, Supplier and Exporter in Gujarat

High-Quality CPVC Pipes – Manufactured by Gujarat’s Trusted Brand. The journey of excellence began in 2011, when Mr. Dilip Ladani laid the foundation with a small-scale unit under the name Radhe Plastic. With a clear vision to deliver quality-driven and durable plumbing solutions, the company steadily grew in scale, capability, and customer trust. Driven by the goal to become a leading manufacturer and exporter of plumbing products that meet international standards, the company expanded its product range and manufacturing infrastructure. The vision was always clear — to provide reliable, leak-proof, and long-lasting piping solutions for both domestic and global markets. In 2023, the business was formally incorporated as KANA VALVES PRIVATE LIMITED, marking a new era of innovation, automation, and export-oriented growth in the PVC, CPVC, and UPVC piping industry. Established with a commitment to quality and innovation, KANA Valves Pvt. Ltd. is a trusted name in the plumbing industry as a leading CPVC pipe manufacturer, supplier, and exporter in Gujarat, India. With years of experience and excellence in polymer engineering, our company has earned a reputation for delivering high-performance CPVC plumbing pipes suitable for hot and cold water applications. Our advanced manufacturing unit produces ISI-certified CPVC pipes as per IS 15778:2007 in SDR-11 and SDR-13.5 pressure classes, specially designed for reliable and long-lasting hot water plumbing. We also offer CPVC pipes ranging from 2½" to 4" as per ASTM F441 standards, ideal for both domestic and industrial plumbing systems. All pipes are available in 3-meter and 6-meter lengths. Headquartered at Kuha, Ahmedabad, Gujarat, India, our company ensures that every product is manufactured under strict quality control and exported to various international markets. As a proud CPVC hot water pipe manufacturer in Gujarat, KANA Valves Pvt. Ltd. delivers lead-free, corrosion-resistant, and high-temperature resistant plumbing solutions trusted by professionals across India and abroad. Choose KANA CPVC Hot Water Pipes for ISI-grade safety, ASTM-standard reliability, and export-quality assurance — proudly made in Gujarat and trusted across India and international markets. Specifications of CPVC Pipes: Material: Chlorinated Polyvinyl Chloride (CPVC) Temperature Range: Up to 95°C (203°F) Pressure Rating: Available in classes ranging from 10 to 25 bar (PN10 to PN25) Diameter Range: 15 mm to 110 mm (Custom sizes available) Standards Compliance: IS 15778, ASTM F441, ASTM D2846, Joining Method: Solvent cement welding What are CPVC Pipes? CPVC (Chlorinated Polyvinyl Chloride) pipes are advanced plastic pipes known for their excellent resistance to corrosion, heat, and chemical damage. CPVC pipes are widely used in plumbing, hot and cold water systems, and industry due to superior durability. They are non-toxic, lightweight, and easy to install, making them an ideal choice for both residential and commercial plumbing needs. Why Choose KANA Valves Pvt. Ltd. for CPVC Pipes? Premium Quality Assurance: We manufacture CPVC pipes using the finest raw materials and advanced technology, ensuring high performance and long life. Wide Range of Products: Extensive variety of sizes and thicknesses to cater to all plumbing requirements. ISO Certified Processes: All manufacturing adheres to international standards for quality and safety. Competitive Pricing: Best price-to-quality ratio in the market. Timely Delivery: Efficient supply chain ensuring prompt delivery across Gujarat and global destinations. Strong Customer Support: Dedicated team to assist with technical queries and after-sales services. Export Excellence: Trusted exporter with robust logistics support for international clients. Features of CPVC Pipes by KANA Valves Pvt. Ltd. High Temperature Resistance: Can withstand temperatures up to 95°C without deformation. Corrosion & Chemical Resistance: Resistant to acids, alkalis, salts, and other corrosive substances. Non-toxic and Safe: Suitable for potable water systems. Low Thermal Conductivity: Maintains water temperature, reducing energy loss. Smooth Inner Surface: Ensures efficient water flow and prevents clogging. Lightweight & Easy to Handle: Simplifies installation and transportation. Long Service Life: Typically lasts 50+ years under normal operating conditions. Fire Retardant: Self-extinguishing properties ensure safety. Uses of CPVC Pipes: Residential and Commercial Plumbing: Hot and cold water distribution systems. Industrial Piping: Chemical processing plants due to chemical resistance. Fire Sprinkler Systems: Durable and reliable under heat. Water Treatment Plants: Safe conveyance of potable water. Agriculture Irrigation: Corrosion-free water supply for farming. HVAC Systems: Efficient hot water heating distribution. Frequently Asked Questions (FAQs) Q1: What makes CPVC pipes better than traditional PVC pipes? A1: CPVC pipes resist higher temperatures and chemicals better than PVC, making them ideal for hot water plumbing applications. Q2: Are CPVC pipes safe for drinking water? A2: Yes, CPVC pipes are non-toxic and approved for potable water use, ensuring safety and hygiene. Q3: Can CPVC pipes be used outdoors? A3: CPVC pipes resist UV rays, but shielding from prolonged direct sunlight is advised to avoid material degradation over time. Q4: How long do CPVC pipes last? A4: When properly installed and maintained, CPVC pipes can last over 50 years. Q5: Do CPVC pipes require special fittings? A5: Yes, CPVC pipes require compatible CPVC fittings to ensure a leak-proof and durable plumbing system. Q6: Can CPVC pipes handle high pressure? A6: Yes, depending on the thickness and size, CPVC pipes can handle pressures up to 10 bar or more. KANA Valves Pvt. Ltd. is a CPVC Pipes Manufacturer, Supplier and Exporter in Gujarat and including locations in Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Anand, Gandhinagar, Bharuch, Morbi, Vapi, Valsad, Junagadh, Nadiad, Mehsana, Porbandar, Godhra, Navsari, Surendranagar, Patan, Amreli, Palanpur, Modasa, Dahod, Gandhidham, Bhuj, Ankleshwar, Kalol, Sanand, Halol, Kadi, Khambhat, Jetpur, Kutch, Mundra, Morbi, Rajpipla, Dwarka, Dholka, Gandharpur, Bhachau, Chotila, Dhandhuka, Umargam, Padra, Jhagadia, Kalol, Savli, Sachin, Palghar, Godhra, Vallabh Vidyanagar, Mandvi, Halvad, Balasinor, Nandesari, Pardi, Karamsad. For more information, visit: kanavalves.com Read the full article

#Ahmedabad#Amreli#Anand#Ankleshwar#ASTMCPVCpipes#Balasinor#Bhachau#Bharuch#Bhavnagar#Bhuj#Chemical-resistantPipes#Chotila#corrosion-resistantpipes#CPVCFittings#CPVCpipebenefits#CPVCPipeExporter#CPVCpipefactoryGujarat#CPVCPipeInstallation#CPVCpipemanufacturer#CPVCPipeManufacturerSupplierandExporterinGujarat#CPVCpipeprice#CPVCPipeSupplier#CPVCplumbingsolutions#Dahod#Dhandhuka#Dholka#domesticplumbingpipes#durableplumbingpipes#Dwarka#Exporter

0 notes

Text

Sewer Excavation in Troy, Michigan

Sewer excavation is one of the most critical yet disruptive home improvement projects a property owner in Troy, Michigan can face. Whether you're dealing with a collapsed sewer line, persistent blockages that can't be cleared through traditional methods, or aging infrastructure that needs replacement, choosing the right contractor can make the difference between a smooth resolution and a costly nightmare.

Understanding Sewer Excavation Needs in Troy

Troy's mature neighborhoods, many built between the 1960s and 1980s, are reaching the age where original sewer lines begin showing signs of wear. The city's clay soil composition, combined with Michigan's freeze-thaw cycles, creates unique challenges for underground infrastructure. Tree roots from the area's abundant mature landscaping often infiltrate older clay or cast iron pipes, while ground shifting can cause pipe separations or collapses.

Common signs that indicate you might need sewer excavation include recurring drain backups, sewage odors in your yard, unusually lush patches of grass above your sewer line, or actual sewage surfacing in your basement or yard. While some issues can be resolved through trenchless repair methods like pipe lining or pipe bursting, severe damage often requires traditional excavation and replacement.

What Makes a Superior Sewer Excavation Contractor

The complexity of sewer excavation demands expertise that goes far beyond basic plumbing knowledge. A qualified contractor should hold proper Michigan state licensing, carry comprehensive insurance including liability and workers' compensation, and demonstrate extensive experience with excavation projects specifically. They should be familiar with Troy's local building codes and permit requirements, as most sewer work requires city permits and inspections.

Look for contractors who invest in modern diagnostic equipment. Video camera inspections should be standard practice before any excavation begins, allowing precise identification of problem areas and minimizing unnecessary digging. Quality contractors also use electronic line locating equipment to avoid hitting utility lines during excavation, which is both dangerous and expensive.

The Excavation Process: What to Expect

Professional sewer excavation in Troy typically begins with thorough planning and preparation. Your contractor should contact MISS DIG (Michigan's utility location service) at least three days before breaking ground to mark underground utilities. They should also discuss the excavation plan with you, including where equipment will be positioned, how your landscaping will be protected, and what restoration work will be included.

The actual excavation process varies depending on the depth and location of your sewer line. Most residential sewer lines in Troy run between four and eight feet deep. Contractors use specialized excavation equipment, often including compact excavators that can navigate between houses and avoid damaging nearby structures. Proper shoring or trench boxes are essential for worker safety in deeper excavations.

Once the damaged pipe is exposed, removal and replacement typically follow quickly. Modern contractors often install PVC or ABS plastic pipes, which resist root intrusion and corrosion better than older materials. The new pipe must be properly bedded in appropriate material, typically sand or pea gravel, and the trench must be backfilled and compacted in layers to prevent future settling.

Evaluating Contractor Credentials and References

When vetting potential contractors, verify their Michigan contractor license through the state's online database. A legitimate contractor should readily provide their license number and insurance certificates. Ask for recent references specifically from sewer excavation projects, not just general plumbing work. Contact these references to inquire about work quality, cleanup, timeline adherence, and overall satisfaction.

Established contractors often maintain relationships with local suppliers and inspection departments, which can streamline your project. They should be able to handle permit applications on your behalf and coordinate required inspections efficiently. Be wary of contractors who suggest skipping permits or inspections, as this can create serious legal and safety issues.

Cost Considerations and Getting Accurate Estimates

Sewer excavation costs in Troy vary significantly based on depth, accessibility, soil conditions, and the extent of damage. Typical projects range from $3,000 to $8,000, though complex situations involving deep lines or challenging access can cost considerably more. Accurate estimates require on-site evaluation and often video inspection to assess the full scope of work needed.

Quality contractors provide detailed written estimates breaking down labor, materials, permits, and restoration costs. Be suspicious of estimates that seem unusually low, as they often indicate corners will be cut or additional charges will emerge later. Conversely, extremely high estimates may indicate inefficiency or attempts to overcharge.

Protecting Your Investment

The best contractors stand behind their work with comprehensive warranties covering both materials and labor. They should also provide clear documentation of the work performed, including photos of the excavation and new installation. This documentation proves valuable for future reference and can increase your property value.

Proper cleanup and restoration are hallmarks of professional service. Your contractor should restore your yard to its original condition or better, including proper grading, soil amendment, and seeding or sodding as needed. Some contractors even guarantee their restoration work separately from the plumbing installation.

Finding the right sewer excavation contractor in Troy requires careful research and evaluation, but the investment in quality workmanship pays dividends in reliable, long-lasting results that protect your home and property value.

0 notes

Text

CIPP Styrene Safety in Drain Cleaning and Advanced Drain-Lining Solutions

Proper drain maintenance is crucial for preventing costly repairs, avoiding disruptions, and ensuring an efficient utility system. Modern advancements in drain cleaning and drain-lining solutions have revolutionized the way residential, commercial, and industrial pipelines are maintained. These innovative techniques not only save time but also minimize environmental impact compared to traditional methods.

Importance of Regular Drain Cleaning

Blocked drains can lead to numerous issues such as: - Slow drainage - Bad odors - Water damage caused by backups - Potential health hazards due to bacterial growth

Regular cleaning helps maintain the functionality of the system while preventing long-term damage. By using advanced equipment such as high-pressure water jetting systems or mechanical rodding tools, professionals can efficiently clear blockages caused by grease buildup, debris, and tree roots.

Benefits of Professional Drain Cleaning Services: 1.Cost-Effective Maintenance: Prevents larger issues that may require expensive repairs or replacements. 2.Improved Performance: Restores optimum flow capacity in pipes. 3.Eco-Friendly Practices: Advanced methods reduce reliance on harsh chemicals that could harm the environment.

Introduction to Advanced Drain-Lining Solutions

Drain-lining technology has emerged as a game-changer in repairing damaged pipelines without excavation. These solutions are designed for situations where pipes are cracked, leaking, or corroded but do not require complete replacement.

What is Drain Lining? Drain lining involves inserting a resin-soaked liner into the existing pipe structure to create a new inner surface that adheres seamlessly to the host pipe. This method eliminates the need for digging up entire sections of pipeline infrastructure.

Advantages of Advanced Drain-Lining Technologies

No-Dig Solutions: Eliminate disruptions associated with traditional excavation methods for repairs.

Durability Enhancement: Extends the life expectancy of existing pipes.

Versatility: Works effectively on various materials such as clay, cast iron, PVC, and concrete.

Faster Installation Times: Reduces downtime compared to conventional repair strategies.

Applications of Drain-Lining Technology

Advanced drain-lining systems cater to multiple scenarios across industries: - Repairing small cracks caused by ground movement. - Sealing leaks in pipeline joints. - Reinforcing aging sewer infrastructure without replacing it entirely.

By incorporating both regular drain cleaning practices and innovative drain-lining technologies into maintenance strategies, property owners can ensure reliable performance from their pipeline systems for years to come while reducing environmental disruption and cost overheads associated with conventional approaches.

Exploring Innovative Methods to Reduce Styrene Emissions in Cured-in-Place Pipe (CIPP) Rehabilitation

This trenchless method has revolutionized the way damaged pipelines are repaired, offering numerous advantages over traditional excavation-based replacement techniques.

How Does CIPP Work in Pipe Lining?

This eliminates the need for extensive digging and reduces disruption while ensuring a long-lasting solution.

Important Considerations for Styrene Safety in CIPP

No significant excavation required.

Reduces disturbances to traffic, landscaping, and structures.

Eliminates costs associated with large-scale digging and restoration.

Decreases labor requirements compared to traditional methods.

Creates a corrosion-resistant inner surface.

Extends pipe life by 50 years or more when properly installed.

Reduces waste generated during repairs.

Minimizes carbon footprint by avoiding heavy machinery use.

Suitable for various types of pipes (e. g. , sewer lines, storm drains).

Can navigate bends and diameter changes in pipelines effectively.

Understanding the Role of Styrene in CIPP Technology Applications

Municipal Infrastructure:Rehabilitation of sewer systems in urban areas without disrupting city operations.

Industrial Pipelines:Repairing chemical transport systems while maintaining safety compliance.

Residential Plumbing:Fixing aging drainage systems without damaging surrounding property.

Understanding Advanced CIPP Techniques and Managing Styrene Odor

Improved resins offer enhanced resistance to chemicals.

UV curing reduces installation time significantly compared to conventional heat curing.

Robotics-assisted insertion ensures precision for difficult-to-access pipelines.

By adopting these cutting-edge methods, businesses and municipalities can reduce costs while improving efficiency in pipeline rehabilitation efforts.

Comprehensive Overview of SDS for Styrene and Key Features in Our CIPP Lining Service

Cured-in-Place Pipe (CIPP) lining has emerged as a groundbreaking solution for pipeline rehabilitation, offering efficient and durable results without the need for extensive excavation. Below is an in-depth look at the key features that make our CIPP lining service a reliable and innovative choice.

1. Trenchless Technology

One of the primary features of our CIPP lining service is its trenchless application method.

Roads or highways

Buildings or large structures

Landscaped areas like gardens or parks

Benefits of trenchless technology include reduced disruption to daily activities, minimal property damage, and faster project completion times.

This versatility ensures that aging pipes, regardless of their original construction material, can benefit from a renewed lifespan with our CIPP system.

2. Long-Term Durability

The liners used in our process are crafted from high-quality resin materials designed to offer long-lasting resilience.

Corrosion resistance: Protects pipes from rust and chemical degradation.

Leak prevention: Forms a seamless interior layer that eliminates weak points.

Structural reinforcement: Improves the overall strength of the existing pipeline.

With proper maintenance, these liners are engineered to last 50 years or more.

3. Cost-Efficiency

Lower labor costs (no extensive excavation required)

Shorter project timelines

Fewer resources needed for restoration

This cost-saving advantage makes it ideal for municipalities, commercial properties, and residential clients seeking budget-friendly solutions without compromising quality.

4. Eco-Friendly Solutions

Sustainability is a key focus within our services. The trenchless nature of CIPP minimizes environmental impact by reducing the need for heavy machinery and limiting soil disruption.

The process decreases waste generated from excavation.

Rehabilitating existing pipelines reduces demand for new raw materials.

By choosing CIPP lining services, clients can contribute to greener infrastructure practices.

5. Suitable for Varied Applications

Repairing sewer lines

Fixing stormwater drainage systems

Addressing small-diameter drains in residential properties

Restoring large municipal pipelines

Whether addressing minor cracks or major structural damages, CIPP technology provides reliable solutions across diverse settings.

How We Address the Styrene Smell Issue

With expertise in modern pipeline rehabilitation techniques and a commitment to delivering top-notch results, we ensure each project benefits from precision workmanship and advanced technology tools.

By opting for our comprehensive CIPP lining services, clients receive durable results with minimal disruption — all while supporting sustainable infrastructure practices.

Cured-in-Place Pipe (CIPP) lining has redefined pipeline rehabilitation by offering durable, efficient, and minimally invasive solutions for addressing pipeline issues. At the core of this method is its ability to restore the structural integrity of aging or damaged pipelines without requiring extensive excavation or disruptive replacement methods.

What is CIPP Lining?

Pipeline Inspection: Pre-installation inspection using cameras ensures that existing blockages or severe structural damage are identified.

Cleaning: High-pressure water jets or mechanical cleaning tools remove debris and prepare the surface for optimal adhesion.

Final Inspection: Post-installation inspection confirms quality and proper functionality of the rehabilitated pipe.

Why Choose CIPP Lining?

Non-Invasive: Reduces disruption by avoiding extensive digging or destruction of surrounding landscapes.

Cost-Effective: Eliminates high labor costs associated with excavation while offering long-term durability.

Time-Efficient: Repairs can often be completed within hours instead of days.

Environmental Benefits: Minimizes waste generation compared to full pipe replacements.

Applications of CIPP Lining

Rehabilitation of sewer lines and storm drains

Extending life expectancy of critical public utilities

Addressing aging plumbing systems in businesses

Preventing costly downtime caused by leaks

Protecting pipelines exposed to chemicals or corrosive environments

Ensuring compliance with regulatory standards

Fixing household drains without damaging driveways, gardens, or walls

Long-Term Durability You Can Rely On

When performed by experienced professionals, CIPP lining delivers reliable results designed to endure decades under diverse conditions such as high water flow rates, temperature variations, and chemical exposure.

Quality materials combined with expert installation ensure that your rehabilitated pipelines will maintain peak performance while reducing future maintenance needs.

By investing in professional cured-in-place pipe lining services, you secure efficient pipeline functionality while protecting adjacent structures and minimizing operational disruptions.

Exploring Advanced Drain-Lining Options and Their Benefits

Drain-lining technologies have significantly advanced in recent years, offering innovative solutions for repairing and rehabilitating pipeline systems without the need for disruptive excavation. These advanced methods not only enhance the durability of pipelines but also offer cost-effective and environmentally friendly alternatives to traditional repairs. Below, we explore some of the cutting-edge drain-lining options available today and their key benefits.

Advanced Drain-Lining Techniques

Ideal for addressing issues such as cracks, leaks, or root intrusions.

Involves breaking apart existing pipes while simultaneously installing new ones.

Especially effective for replacing severely damaged pipelines with minimal surface disruption.

Insertion of a smaller diameter pipe into an existing pipeline.

Typically used for structural reinforcement or repairing long sections of deteriorated pipes.

A resin-based spray application designed to coat the interior walls of pipes.

Commonly used in smaller-diameter pipelines to restore flow efficiency and seal minor damage.

Key Benefits of Modern Drain-Lining Solutions

Minimized Disruption Traditional excavation methods often disrupt landscapes, roads, and infrastructure. Drain-lining eliminates the need for extensive digging by working within existing pipelines.

Cost-Effectiveness By avoiding large-scale excavation projects, homeowners and municipalities save significantly on labor costs, equipment rental fees, and restoration expenses.

Time Efficiency Many advanced methods allow projects to be completed in hours or days rather than weeks.

Enhanced Durability Materials like epoxy resins and high-grade liners create robust pipelines that can withstand environmental stresses over decades without frequent maintenance.

Environmentally Friendly Alternatives Since no digging is required, there’s limited soil disturbance and reduced construction waste. Some techniques even improve water flow efficiency by smoothing inner pipe surfaces.

Applications Across Different Sectors

Residential: Repairing household sewer lines with minimal disruption.

Commercial: Restoring drainage systems in office buildings and retail spaces.

Municipal: Upgrading aging city infrastructure cost-efficiently while meeting environmental regulations.

Industrial: Reinforcing high-capacity pipelines used in manufacturing processes.

Modern drain-lining technologies provide reliable solutions that balance efficiency with sustainability. By adopting these innovative practices, property owners can ensure the long-term integrity of their drainage systems while reducing overall maintenance costs.

NASSCO

5285 Westview Dr Suite 202, Frederick, MD 21703, United States +1 301-834-1022 https://nassco.org/ https://maps.app.goo.gl/mX2Vyt5fsMWF5b6x5

1 note

·

View note

Text

Buy Quality Ventilation Butterfly Valves in China from Trusted Suppliers

In the case of ventilation systems, the question is not about importance — it is about need. When you source a ventilation butterfly valve in China, you aren’t sourcing a product. You are sourcing performance, durability, and confidence.

Why Butterfly Valves? Let’s Break It Down

Butterfly valves are often an afterthought in HVAC and industrial piping systems, yet they regulate airflow and gas with an extremely simple, compact configuration - a disc that rotates to open or close the passage. Seems pretty simple, right? But the efficiency and low cost is why they are so widely used in industries from manufacturing to food processing.

They are compact, react fast, and can regulate flows well in low pressure environments. So, if you're upgrading or creating a ventilation system, a decent butterfly valve is worth its weight in - well, steel!!

What Makes a Valve “Quality”?

A really good ventilation butterfly valve will be designed for precision, be a corrosion resistant material, and ultimately be designed with the air flow of your system in mind.

Things to consider:

Material: Stainless steel, cast iron, or high-end PVC depending on the application.

Seal integrity: no leaking. Period.

Easy maintenance: you want reliability not repairs.

Compliance: should be ISO certified or CE marked products.

And look — if you are sourcing globally this becomes even more important especially working with overseas suppliers.

Why Source from China?

If we're being honest — China is the dominant force in the industrial valve space not purely on the notion of cost but because oftheir impeccable quality systems and directed manufacturing options.

You will find suppliers that are dedicated to solely ventilation butterfly valves and will offer product options that support everything from commercial HVAC to complex chemical plants. Lots of open the shelf products by manufacturers offer you customization and competitive lead times, and most will also offer multi-language customer services (yes this is a thing now).

But — this is a big but — you have to vet your supplier. Seek their certified, look for their customer testimonials, ensure they have clear product data sheets, and remember a fancy website doesn't mean they have best practice in place for quality control.

How to Spot a Trusted Supplier

It isn’t just about the product — it’s about who’s behind it.

Here are the things that make trustworthy suppliers different:

Clear warranty policies

Reasonably responsive sales teams (real people, not just bots)

A willingness to provide sample reports or technical drawings

Comprehensive logistics support for international orders

Pro tip: Ask for video walkarounds of their factory. You’d be surprised how many are happy to show their shop floor if they have nothing to hide.

Final Thoughts

Buying a Ventilation Butterfly Valve in China shouldn’t feel like you’re stuck in a maze. With the right amount of research and some gut instincts, you can land product(s) that provides you with not only a technically sound product, but long-term value. We, JiaHua Fluid, are one of the best suppliers shipping our products around the world.

#hydraulic#hydraulics#industrialhydraulics#hydraulicrepair#hydrauliccylinder#hydraulicpump#hydraulicsystems#fluidpower

0 notes