#Process plant engineering

Explore tagged Tumblr posts

Text

Enhance Transformer Efficiency with Advanced Oil Filtration Plants from Omsaips Enterprises

In high-voltage electrical equipment like transformers, maintaining the quality of insulating oil is crucial for safe and efficient operation. Over time, transformer oil can degrade due to moisture, gases, and impurities, leading to reduced insulation, overheating, or even equipment failure. That’s why Omsaips Enterprises offers cutting-edge Oil Filtration Plants designed to restore transformer oil to optimal condition.

🔧 What is a Transformer Oil Filtration Plant?

A Transformer Oil Filtration Plant is an advanced system that removes moisture, dissolved gases, sludge, and other contaminants from used transformer oil. By purifying the oil, it improves dielectric strength, cooling efficiency, and extends the life of electrical equipment.

Omsaips Enterprises is a trusted name in manufacturing and supplying Oil Filtration Systems and Oil Filtration & Cleaning Systems that serve power utilities, substations, and transformer manufacturers across India.

⚙ Our Key Filtration Solutions:

✅ Double Stage Oil Transformer Machine

Our high-performance Double Stage Oil Transformer Machine uses a two-step vacuum process to remove water and gases effectively. This ensures high purity and restores the oil's original insulation properties.

✅ Oil Filtration Machine

Portable and easy to use, our Oil Filtration Machines are ideal for on-site transformer maintenance, providing fast and reliable oil purification.

✅ Gear Oil Filtration Systems

Not just limited to transformer oil, we also manufacture Gear Oil Filtration Systems that clean lubricants used in gearboxes and heavy machinery, improving mechanical reliability.

✅ Industrial Oil Filter Machine

For large-scale industrial setups, our Industrial Oil Filter Machines ensure efficient, continuous filtration to maintain oil quality and reduce equipment wear.

✅ Oil Filtration Elements

Our durable and high-capacity Oil Filtration Elements play a crucial role in trapping particles and impurities, ensuring the longevity and efficiency of filtration systems.

💡 Why Choose Omsaips Enterprises?

💯 Proven expertise in Oil Filtration Plant manufacturing

🏭 Customized systems for transformers, gearboxes, and industrial equipment

⚙ Precision-built Oil Filtration & Cleaning Systems for various applications

📦 Robust construction, easy installation, and minimal maintenance

🌐 Serving power sectors, manufacturing industries, and maintenance service providers across India

📈 Boost Your Transformer’s Performance Today!

Whether you need a Double Stage Oil Transformer Machine, Gear Oil Filtration System, or a complete Industrial Oil Filter Machine, Omsaips Enterprises has a reliable solution. Our Oil Filtration Plants are engineered for maximum performance, safety, and long-term value.

🔗 Visit: Transformer Oil Filtration Plants – Omsaips Enterprises

#"Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On-Site Oil Testing#Transformer Oil Filtration Plants#Transformer Oil Filtration Machines#Transformer Oil Purification Systems#Oil Filtration Plants#Industrial Oil Purifiers#Transformer Oil Processing#Transformer Oil Treatment#Oil Filtration Equipment#Omsai Enterprises#AR Engineering“”

0 notes

Text

Build a Professional Industrial Website with SKT Industrial Pro

What Sets SKT Industrial Pro Apart?

The SKT Industrial Pro Theme is tailored for factories, workshops, and manufacturing businesses. Its clean, modern design paired with advanced functionality helps you create a website that reflects your brand’s professionalism. This theme is optimized for speed and SEO, ensuring your site ranks well and loads quickly.

Key Features for Industrial Websites

SKT Industrial Pro offers a fully responsive design, making your site accessible on any device. It supports WooCommerce for easy e-commerce integration and includes customizable layouts for showcasing products and services. The theme’s compatibility with page builders and SEO plugins like Yoast ensures flexibility and better search engine performance.

Why Choose SKT Industrial Pro?

The factory hub WordPress theme simplifies website creation with its one-click demo import and user-friendly interface. Its SEO-optimized code and social media integration help drive traffic and engage potential clients. Whether you’re in manufacturing or construction, this theme delivers a polished online presence.

Final Thoughts

For industrial businesses seeking a reliable and professional website, the SKT Industrial Pro WordPress Theme is an excellent choice. Its robust features, SEO optimization, and e-commerce capabilities make it perfect for showcasing your expertise. Start building your industrial website today and stand out in the market.

#Factory Hub WordPress theme#industrial business WordPress theme#manufacturing company website theme#factory website WordPress layout#engineering firm WordPress theme#mechanical plant WordPress template#factory outlet website design#industrial services WordPress theme#WordPress theme for manufacturing units#heavy industry WordPress layout#textile factory WordPress template#steel plant WordPress theme#machinery business WordPress theme#chemical factory WordPress design#warehouse and logistics WordPress theme#automobile factory WordPress theme#factory hub WooCommerce theme#industrial supply company WordPress theme#assembly plant website theme#manufacturing process WordPress theme

0 notes

Text

Engine Oil Recycling Plant Setup in India – Compliant & Profitable Business Model

Set up an engine oil recycling plant in India with expert support on licensing, plant layout, and pollution control board approvals. Reprocess used engine oil into valuable base oil through vacuum distillation, clay treatment, or modern re-refining methods. A high-demand, eco-friendly business with long-term growth potential. Build a sustainable recycling unit that meets environmental and industrial standards.

#engine oil recycling plant#waste oil recycling#used oil recycling companies in india#used oil recycling process#oil recycling companies#oil recycling plant

0 notes

Text

Mount Roof at Dairy Expo 2025 | Smarter Dairy Infrastructure

Mount Roof’s PUF panels & PEBs at Dairy Expo 2025, energy-efficient, hygienic, and fast-build solutions for India’s dairy infrastructure.

Visit Here:

#Sandwich PUF panels for cold storage#Food-grade Sandwich PUF panels for food processing units#Insulated Sandwich PUF panels for warehouses#Energy-efficient PUF panels for industrial buildings#Hygienic PUF panels for pharmaceutical plants#Pre-engineered buildings for warehouses#Pre-engineered buildings for cold storage#pre-engineered buildings for factories

0 notes

Text

Built for Complexity | How Industrial Estimating Service Handles Custom Manufacturing Projects

Introduction: The Complexity of Custom Manufacturing Projects Custom manufacturing projects are often among the most challenging in the industrial construction sector. Unlike standard builds, these projects involve unique designs, specialized materials, and processes that may not be readily available in off-the-shelf cost databases. Each project brings its own set of variables—often with tight schedules and high demands for precision. This is where industrial estimating services come into play, providing the expertise and tools needed to deliver accurate cost forecasts, no matter how complex the project.

Understanding the Challenges of Custom Manufacturing Custom manufacturing projects typically involve the construction of facilities or systems tailored to specific needs, such as custom machinery, production lines, or specialized storage systems. These projects don’t always fit neatly into predefined categories, which makes estimating their costs particularly tricky. The lack of readily available benchmarks for labor, materials, and equipment means estimators must dig deeper to gather accurate data, assess unique risks, and account for variability in the construction process.

The Role of Industrial Estimating Service in Custom Projects Industrial estimating services play a critical role in ensuring that custom manufacturing projects are properly scoped, budgeted, and executed. Estimators rely on a combination of historical data, industry expertise, and sophisticated estimating tools to account for the unique requirements of each project. They assess design drawings, review material specifications, and factor in the intricacies of the production process to arrive at cost estimates that reflect the project’s true scope and complexity.

Detailed Scope Analysis and Custom Material Costs Custom manufacturing projects often require specialized materials that may not have standard pricing available in cost databases. Estimators take the time to analyze material specifications, identify alternative options, and gather quotes from suppliers to ensure that the cost of materials is accurately reflected in the estimate. They may also assess the long-term costs of certain materials, such as maintenance requirements or supply chain challenges, to provide a more comprehensive financial outlook.

Handling Non-Standard Labor Requirements One of the most significant challenges in custom manufacturing projects is managing labor costs. These projects often require skilled labor or specialized subcontractors with expertise in custom processes or equipment. Industrial estimating services evaluate the labor market, assess wage rates for specific skill sets, and account for the potential need for overtime or specialized training. This ensures that the labor component of the estimate is both realistic and aligned with project requirements.

Accounting for Unique Equipment and Tools Custom projects frequently involve unique or specialized equipment, from advanced machinery to custom-designed tools and fixtures. Estimating these costs is far more complex than simply applying standard equipment rental rates. Estimators must account for the cost of acquiring, maintaining, or leasing such equipment, as well as any potential downtime associated with custom tools. In some cases, they may need to work with equipment manufacturers to determine accurate pricing or cost projections for these items.

Risk Assessment and Contingency Planning The nature of custom manufacturing projects often leads to unforeseen challenges—whether it’s unexpected site conditions, delays in material delivery, or the need for rework due to design changes. Industrial estimating services help mitigate these risks by incorporating contingency allowances into their estimates. They conduct a thorough risk assessment to identify potential challenges that could impact the project’s timeline and budget. By factoring in these uncertainties, they provide a more reliable financial forecast, which helps stakeholders make informed decisions about project feasibility and budgeting.

Timeline Sensitivity and Cost Efficiency In custom manufacturing projects, timelines are often tight, and any delays can significantly impact overall costs. Industrial estimating services evaluate the project schedule in relation to the scope and complexity of the work, considering factors like lead times for custom materials, labor availability, and equipment procurement. They incorporate these time-sensitive factors into their estimates, ensuring that the project is planned efficiently from a cost perspective. By optimizing the timeline and identifying opportunities to streamline construction, estimators help reduce costs and keep the project on track.

Integration of Technology for Enhanced Accuracy To handle the complexities of custom manufacturing projects, industrial estimating services increasingly rely on advanced technology. Software tools and Building Information Modeling (BIM) platforms allow estimators to visualize the project in greater detail, integrate different design elements, and identify potential cost-saving opportunities. These tools provide a more accurate picture of the project’s scope, helping estimators refine their forecasts and catch potential issues before construction begins. Additionally, digital tools can analyze historical project data to inform more accurate pricing for custom materials and processes.

The Importance of Communication Between Stakeholders A successful custom manufacturing project requires coordination between various stakeholders, including the design team, contractors, suppliers, and equipment manufacturers. Industrial estimating services ensure that all parties are aligned by providing clear, detailed cost breakdowns and communicating any uncertainties or risks associated with the estimate. This transparency helps prevent misunderstandings and ensures that all stakeholders have a clear understanding of the budget and timeline.

Providing Value Engineering Alternatives In custom manufacturing, budget constraints are common, and finding ways to reduce costs without compromising quality is crucial. Industrial estimating services often work closely with the design team to identify value engineering alternatives that can reduce costs. These might include suggesting alternative materials, adjusting the scope of certain features, or proposing changes to construction methods that maintain the integrity of the design while offering cost savings. This value-driven approach helps ensure that custom manufacturing projects are both financially viable and high-quality.

Conclusion: Precision and Flexibility for Custom Manufacturing Success Custom manufacturing projects present unique challenges, but industrial estimating services are equipped to handle the complexity. By leveraging specialized knowledge, advanced technology, and real-time data, estimators ensure that these projects are properly budgeted, efficiently executed, and financially viable. Whether it’s managing specialized materials, labor, equipment, or risk, industrial estimating services help turn custom manufacturing challenges into opportunities for success.

#custom manufacturing#industrial estimating#complex project estimating#specialized materials#labor cost estimating#equipment cost estimation#risk assessment#construction contingencies#value engineering#manufacturing plant construction#cost forecasting#project budgeting#skilled labor estimating#custom equipment pricing#contingency planning#project timeline#advanced estimating tools#BIM in estimating#project risk management#estimating software#project scope analysis#construction site conditions#custom tool costs#lead time management#cost-saving alternatives#subcontractor pricing#custom project forecasting#construction project efficiency#estimating technology#manufacturing process planning

0 notes

Text

Taknik Inc | Chemical Engineering Consultants Company in Bharuch

TAKNIK INC, launched in 2017, is a multi-disciplinary company specialising in engineering consultancy and chemical manufacturing. Key services include Waste Water Treatment Plants and Zero Liquid Discharge Systems, with a commitment to quality and client satisfaction.

#Chemical Engineering Consultant#Waste Water Treatment Services#Waste Water Treatment Plant Suppliers#Effluent Treatment Plant Suppliers#Process Plant and Waste Water Consultant and Supplier

0 notes

Text

Pictured: Luis Cassiano is the founder of Teto Verde Favela, a nonprofit that teaches favela residents in Rio de Janeiro, Brazil, how to build their own green roofs as a way to beat the heat. He's photographed at his house, which has a green roof.

Article

"Cassiano is the founder of Teto Verde Favela, a nonprofit that teaches favela residents how to build their own green roofs as a way to beat the heat without overloading electrical grids or spending money on fans and air conditioners. He came across the concept over a decade ago while researching how to make his own home bearable during a particularly scorching summer in Rio.

A method that's been around for thousands of years and that was perfected in Germany in the 1960s and 1970s, green roofs weren't uncommon in more affluent neighborhoods when Cassiano first heard about them. But in Rio's more than 1,000 low-income favelas, their high cost and heavy weight meant they weren't even considered a possibility.

That is, until Cassiano decided to team up with a civil engineer who was looking at green roofs as part of his doctoral thesis to figure out a way to make them both safe and affordable for favela residents. Over the next 10 years, his nonprofit was born and green roofs started popping up around the Parque Arará community, on everything from homes and day care centers, to bus stops and food trucks.

When Gomes da Silva heard the story of Teto Verde Favela, he decided then and there that he wanted his home to be the group's next project, not just to cool his own home, but to spread the word to his neighbors about how green roofs could benefit their community and others like it.

Pictured: Jessica Tapre repairs a green roof in a bus stop in Benfica, Rio de Janeiro, Brazil.

Relief for a heat island

Like many low-income urban communities, Parque Arará is considered a heat island, an area without greenery that is more likely to suffer from extreme heat. A 2015 study from the Federal Rural University of Rio de Janeiro showed a 36-degree difference in land surface temperatures between the city's warmest neighborhoods and nearby vegetated areas. It also found that land surface temperatures in Rio's heat islands had increased by 3 degrees over the previous decade.

That kind of extreme heat can weigh heavily on human health, causing increased rates of dehydration and heat stroke; exacerbating chronic health conditions, like respiratory disorders; impacting brain function; and, ultimately, leading to death.

But with green roofs, less heat is absorbed than with other low-cost roofing materials common in favelas, such as asbestos tiles and corrugated steel sheets, which conduct extreme heat. The sustainable infrastructure also allows for evapotranspiration, a process in which plant roots absorb water and release it as vapor through their leaves, cooling the air in a similar way as sweating does for humans.

The plant-covered roofs can also dampen noise pollution, improve building energy efficiency, prevent flooding by reducing storm water runoff and ease anxiety.

"Just being able to see the greenery is good for mental health," says Marcelo Kozmhinsky, an agronomic engineer in Recife who specializes in sustainable landscaping. "Green roofs have so many positive effects on overall well-being and can be built to so many different specifications. There really are endless possibilities.""

Pictured: Summer heat has been known to melt water tanks during the summer in Rio, which runs from December to March. Pictured is the water tank at Luis Cassiano's house. He covered the tank with bidim, a lightweight material conducive for plantings that will keep things cool.

A lightweight solution

But the several layers required for traditional green roofs — each with its own purpose, like insulation or drainage — can make them quite heavy.

For favelas like Parque Arará, that can be a problem.

"When the elite build, they plan," says Cassiano. "They already consider putting green roofs on new buildings, and old buildings are built to code. But not in the favela. Everything here is low-cost and goes up any way it can."

Without the oversight of engineers or architects, and made with everything from wood scraps and daub, to bricks and cinder blocks, construction in favelas can't necessarily bear the weight of all the layers of a conventional green roof.

That's where the bidim comes in. Lightweight and conducive to plant growth — the roofs are hydroponic, so no soil is needed — it was the perfect material to make green roofs possible in Parque Arará. (Cassiano reiterates that safety comes first with any green roof he helps build. An engineer or architect is always consulted before Teto Verde Favela starts a project.)

And it was cheap. Because of the bidim and the vinyl sheets used as waterproof screening (as opposed to the traditional asphalt blanket), Cassiano's green roofs cost just 5 Brazilian reais, or $1, per square foot. A conventional green roof can cost as much as 53 Brazilian reais, or $11, for the same amount of space.

"It's about making something that has such important health and social benefits possible for everyone," says Ananda Stroke, an environmental engineering student at the Federal University of Rio de Janeiro who volunteers with Teto Verde Favela. "Everyone deserves to have access to green roofs, especially people who live in heat islands. They're the ones who need them the most." ...

It hasn't been long since Cassiano and the volunteers helped put the green roof on his house, but he can already feel the difference. It's similar, says Gomes da Silva, to the green roof-covered moto-taxi stand where he sometimes waits for a ride.

"It used to be unbearable when it was really hot out," he says. "But now it's cool enough that I can relax. Now I can breathe again."

-via NPR, January 25, 2025

#architecture#sustainable architecture#heat islands#urban heat#brazil#brasil#south america#favela#rio de janeiro#green roof#plants#climate action#climate adaptation#infrastructure#good news#hope#solarpunk

8K notes

·

View notes

Text

Milk Pasteurizer Plant | Milk Processing Plant

SM Engineering offers a 500-litre milk processing plant, specializing in milk pasteurizer plants and milk processing solutions for dairy production efficiency.

0 notes

Text

Uses of Milk Processing Plant for Dairy Farm

Milk processing plants are essential for dairy farms as they transform raw milk into a variety of consumer-ready products like cheese, yogurt, and butter, significantly increasing profitability. These facilities extend the shelf life of milk through pasteurization and ensure high quality and safety standards, which are crucial for consumer trust. By processing milk, dairy farms can reach broader markets, enhance product nutritional value, and effectively manage waste by repurposing by-products. Additionally, modern automation improves efficiency, allowing farms to scale operations while complying with regulatory standards. Ultimately, investing in a milk processing plant supports local economies and fosters brand development, enabling dairy farms to thrive in a competitive market.

What is a Milk Processing Plant?

A milk processing plant is a facility designed to handle, process, and package milk and dairy products. These plants employ various technologies and equipment to ensure the milk is pasteurized, homogenized, and packaged safely for consumption.

Types of Milk Processing Plants

Milk processing plants come in various capacities to cater to different production needs. Here’s a breakdown of common sizes and their associated costs:

100 Ltr Milk Processing Plant Cost: Ideal for small dairies or startups, this capacity is suitable for local markets and specialty products.

200 Ltr Milk Processing Plant Cost: Slightly larger, this plant can serve small businesses looking to scale up their production.

300 Ltr Milk Processing Plant Cost: Perfect for growing operations that need more flexibility in their product range.

500 Ltr Milk Processing Plant Cost: A mid-sized option that balances capacity with space requirements, suitable for small to medium-sized dairies.

1000 Ltr Milk Processing Plant Cost: This size is often used by medium enterprises aiming for higher production volumes.

5000 Ltr Milk Processing Plant Cost: Designed for larger operations, this capacity allows for extensive processing and product diversity.

10000 Ltr Milk Processing Plant Cost: Perfect for large-scale dairy operations that require significant output to meet market demands.

2000 Ltr Milk Processing Plant Cost: A popular choice for businesses looking to expand their production capabilities without going to the maximum scale.

Choosing a Right Milk Processing Plant Manufacturer

When selecting a milk processing plant manufacturer, it’s crucial to consider several factors:

Experience and Reputation: Look for manufacturers with a proven track record in the industry. Research reviews and testimonials to gauge their reliability.

Quality of Equipment: Ensure the manufacturer uses high-quality materials and adheres to industry standards for hygiene and safety.

Customization Options: A good manufacturer should be able to provide tailored solutions that meet your specific needs and production goals.

After-Sales Support: Check if the manufacturer offers installation, training, and maintenance support to keep your plant running smoothly.

Cost Efficiency: Compare prices among different milk processing plant manufacturers to find the best balance between quality and cost.

If you are looking for Best Milk Processing Plant Manufacturer in India, look no further than Pranamji Engineering Works, we are a leading Milk Processing plant manufacturer, supplier and exporter in India.

Conclusion

Investing in a milk processing plant can significantly enhance your business’s capacity to meet the growing demand for dairy products. Understanding the various sizes and their respective costs — ranging from the 100 ltr milk processing plant cost to the 10000 ltr milk processing plant cost — will help you make informed decisions.

By partnering with a reputable milk processing plant manufacturer, you can ensure your operation is efficient, compliant, and capable of producing high-quality dairy products. Whether you’re starting small with a 500 ltr milk processing plant or going big with a 5000 ltr milk processing plant, the right investment will pay off in the long run.

For more details, please contact us!

Website :- www.pranamjiengineering.com

Contact No. :- 09997737365, 7017598033

Email :- [email protected]

Address :- Khasra No 346, Jalapur, Raghunathpur Muradnagar, Ghaziabad Uttar Pradesh — 201206

#Milk Processing Plant#Milk Processing Plant manufacturer#Milk Processing Plant supplier#Milk Processing Plant manufacturer in India#Milk Processing Plant supplier in India#pranamji engineering works

1 note

·

View note

Text

kitchen Equipment Manufacturers Chennai

Best kitchen equipment manufacturers in Chennai offering high-quality, durable, and innovative solutions for your kitchen set-up needs. Upgrade your kitchen with the best equipment today!

#kitchen Equipment Manufacturers Chennai#heavy steel fabrication services#piping engineering in chennai#piping design engineering services#skid package design services#skid mounted process plant design#piping engineering#skid fabrication solution chennai#piping design and engineering#technical manpower supply#skid mounted process plant design chennai

0 notes

Text

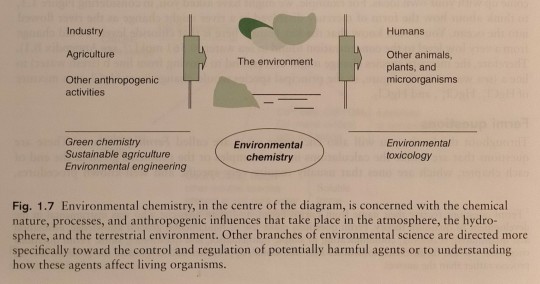

In considering particular environmental subjects, we focus on the basic chemistry and to do this it is necessary to examine some or all of the three factors – composition, chemical process, and perturbations caused by natural or anthropogenic activities – that we have discussed above (Fig. 1.7).

"Environmental Chemistry: A Global Perspective", 4e - Gary W. VanLoon & Stephen J. Duffy

#book quotes#environmental chemistry#nonfiction#textbook#chemistry#composition#chemical process#perturbation#natural activity#anthropogenic activity#industry#agriculture#humans#animals#plants#microorganisms#green chemistry#sustainability#environmental engineering#toxicology

1 note

·

View note

Text

Boost Performance and Protection with Advanced Vacuum Pressure Impregnation Plants by Omsai Enterprises

In industries where electrical insulation, moisture resistance, and long-term reliability are critical, impregnation technology plays a vital role. At Omsai Enterprises, in collaboration with AR Engineering, we offer cutting-edge Vacuum Pressure Impregnation Plants (VPI) designed to deliver superior impregnation solutions for a wide range of applications.

What is a Vacuum Pressure Impregnation Plant?

A Vacuum Pressure Impregnation Plant is a specialized system that uses vacuum and pressure cycles to impregnate electrical windings or porous materials with varnish or resin. This process ensures complete penetration into the smallest voids, significantly improving insulation resistance, heat dissipation, and lifespan of electrical components.

Our VPI systems are widely used in transformer manufacturing, motor rewinding, and other industrial coating solutions.

Advanced Processes in Our VPI Systems

💨 Degasification

Before impregnation, the system performs degasification to remove air and trapped gases from components. This is crucial for complete resin penetration and bubble-free insulation.

💧 Dehydration Process

Moisture can severely impact the effectiveness of varnish or resin. Our plants utilize a controlled dehydration process to eliminate residual moisture from the components before the impregnation phase begins.

🧼 Filtration and Purification

We incorporate in-line filtration and purification systems to maintain resin purity and remove any contaminants during processing, ensuring consistent and high-quality results.

Key Features of Our Vacuum Impregnation Equipment

High-efficiency vacuum and pressure chambers

Fully automated or semi-automatic control systems

Energy-efficient operation with minimal resin wastage

Custom sizes and capacities based on application

Integrated oil purification options for specialized needs

Applications Across Industries

Our Vacuum Impregnation Equipment and Industrial Impregnation Machines are used in:

Transformer and coil manufacturing

Motor winding insulation

Alternator and generator repair

Capacitor and choke coil production

General oil manufacturing and electrical insulation sectors

Why Choose Omsai Enterprises & AR Engineering?

🏭 Proven expertise in industrial engineering and impregnation systems

⚙ Precision-built industrial impregnation machines with long service life

🌍 Strong presence in India with on-site support and training

🔬 Continual innovation in impregnation technology and resin processing

🔄 Integrated systems with filtration and purification for quality assurance

Your Trusted Partner in Industrial Coating and Insulation Solutions

Whether you're looking to improve product reliability, extend equipment life, or meet industry standards in electrical insulation, our Vacuum Pressure Impregnation Plants are built to exceed expectations. With a strong track record of delivering durable and efficient impregnation solutions, Omsai Enterprises is your trusted partner in electrical and oil purification industries.

#degasification#dehydration process#filtration and purification#oil manufacturing#oil purification#Vacuum Pressure Impregnation Plant#Impregnation Systems#Industrial Impregnation Machines#Vacuum Impregnation Equipment#Omsai Enterprises#AR Engineering#Impregnation Solutions#Impregnation Technology#Industrial Coating Solutions"

0 notes

Text

Paddy Parboiling Plant Manufacturers: Ensuring High-Quality Rice with Advanced Technology

A lot of people around the world eat rice every day, and India is one of the biggest producers and consumers of this important vegetable. Paddy Parboiling Plant Manufacturers are very important for making sure that there is enough high-quality rice for everyone. In order to parboil rice, which improves its nutritional value, taste, and shelf life, these companies make the special tools and technology that are needed.

Why paddy parboiling plants are important

Soaking, steaming, and drying paddy (unhusked rice) before grinding is what paddy parboiling is. Some of the bran layer is removed during this process, which has several benefits:

Better for you: Compared to white rice, parboiled rice keeps more of its minerals and B vitamins.

Enhanced cooking properties: While cooking, parboiled rice stays together better because it is stronger and cooks faster.

Less likely to get bugs or go bad: rice that has been parboiled is great for saving for a long time because it lives longer.

Tips for Choosing the Best Plant for Making Paddy Parboil

This is because there is a growing need for parboiled rice in India, so there are a lot of companies that make them. Below are some things to think about when picking a business:

Professionalism and a good name: Try to find a business that has a past of making good products and a well-known reputation for being dependable.

Ability to produce and advanced technology: Choose a company whose plants can meet your needs for output and which uses cutting-edge technology to make parboiling work well.

After the sale, help with: You need professional help after the sale if you want to keep your plant working smoothly.

Grain Storage Bunkers: A Perfect Complement

It is common for companies that make paddy parboiling plants to sell grain holding tanks as an extra. The following reasons make grain storage tanks important:

Protection from elements: Being protected from rain, moisture, and bugs keeps the rice's quality good and keeps it from going bad.

Storage efficiency has been increased: Because they are neat and take up less room, bunkers are a better way to store a lot of paddy.

How efficiently an operation works: It is simple to move the rice around while it is being treated because the bunkers can be connected to the parboiling plant.

How Paddy Parboiling Will Grow in the Future

These businesses that make paddy parboiling plants are always coming up with new ways to improve the process and make it last longer. There have been some changes, such as

Smart tools that save energy: The following are new tools that are good for the environment: Nowadays, newer plants use less energy for the parboiling process.

Smart controls: Adding more smart controls lowers the amount of work that needs to be done by hand and makes sure that the quality of the parboiling stays the same.

Water recycling systems: These systems recycle water, which is good for the environment because it cuts down on the amount of water used for parboiling.

Conclusion

Making sure that high-quality parboiled rice is made is a big job for Paddy Parboiling Plant Manufacturers. Working with a reliable manufacturer and keeping their rice in Grain Storage Bunkers will help rice farmers keep up with the growing demand for this healthy and useful grain. Paddy parboiling will likely be even faster, last longer, and make better rice in the future as technology keeps getting better.

Contact Us:

Photons Food

Visit Us: https://photonsfood.com

Call: +918610167937, +65-91684326

Email: [email protected]

Address: East Godavari District, Andhra Pradesh, India 515002

#Grain Storage Bunkers#Paddy Parboiling Plant Manufacturers#Photons Food#Photons Food Processing Engineers

0 notes

Text

I would be an OSHA inspector if I didn't have to talk to people CONSTANTLY at that job.

#totes bro#i think analyzing manufacturing processes would be fun as a (now former) manufacturing engineer#it makes decent money i just dont walk to talk to like plant managers#i dont always love plant managers

0 notes

Text

Challenge: Licensing and Establishing a DMS, DMDS Manufacturing Process - Technology Org

New Post has been published on https://thedigitalinsider.com/challenge-licensing-and-establishing-a-dms-dmds-manufacturing-process-technology-org/

Challenge: Licensing and Establishing a DMS, DMDS Manufacturing Process - Technology Org

NineSigma, representing a large industrial company, is seeking organizations that can support the establishment of high-purity dimethyl sulfide (DMS) and/ or dimethyl disulfide (DMDS) production facilities at scales of minimally 1000 metric tons annually.

Work in a chemical laboratory – illustrative artistic interpretation. Image credit: Alius Noreika (created using DALL·E 3)

NineSigma’s client has the ambition to produce its own DMS/ DMDS by constructing its production plants across the globe. The client requires high purity of the DMS / DMDS, crucial in maintaining the high quality and efficiency of its current chemical processes and products downstream.

With this RFP, NineSigma is seeking organizations that can license or that can provide the technical know-how to establish the large-scale production of:

High-purity dimethyl sulfide (DMS) and/or

High-purity dimethyl disulfide (DMDS) and/or

High-purity DMS and DMDS.

Submissions to this Challenge must be received by Jan 18, 2024.

Source: NineSight

You can offer your link to a page which is relevant to the topic of this post.

#2024#challenge#chemical#Chemical engineering#Chemistry & materials science news#Competitions#dms#efficiency#how#how to#Link#Manufacturing#organizations#plants#process#Production#rfp#scale#technology#work

0 notes

Text

Taknik Inc | Chemical Engineering Consultants Company in Bharuch

TAKNIK INC, launched in 2017, is a multi-disciplinary company specialising in engineering consultancy and chemical manufacturing. Key services include Waste Water Treatment Plants and Zero Liquid Discharge Systems, with a commitment to quality and client satisfaction.

#Chemical Engineering Consultant#Waste Water Treatment Services#Waste Water Treatment Plant Suppliers#Effluent Treatment Plant Suppliers#Process Plant and Waste Water Consultant and Supplier

0 notes