#TCP IP

Explore tagged Tumblr posts

Text

Cara Kerja Internet: Dari Klik hingga Data Tiba di Layar Anda

SURAU.CO – Pernahkah Anda membayangkan bagaimana sebuah halaman web bisa muncul hanya dengan satu klik? Di balik layar internet menjalankan proses rumit dalam waktu sangat singkat. Artikel ini akan membantu Anda memahami cara kerja internet mulai dari saat Anda mengetik alamat website hingga informasi muncul di layar. Apa Itu Internet? Internet adalah jaringan global yang menghubungkan berbagai…

#DNS#Dunia Online#Featured#Internet#Jaringan Komputer#Klik Data#Proses Digital#Router#Server#TCP IP#Teknologi Informasi

0 notes

Text

a garden you never got to see

[ALT ID: A digital illustration of a man with his eyes closed and head tilted up toward the light. An embroidered red scarf is draped over his head and ghostly hands appear to be pulling on it.]

#the ascension to IP is skimmed over pretty lightly in tcp but it brings me joy to imagine callebero#stoned out of his mind and seeing ghosts#anyway i never know if ppl actually want the bg details on these things#but the gist is that red is associated with victory in arradine and one of anharad's (the founder of arradine who's believed to have been#the god of death incarnate) epithets is ~'scarlet-mantled'#which by the time of tcp (callebero's era) has created great discord in the historian community#between the camp that believes it's because she actually had red hair#and the camp that believes it's more like 'adorned by victory' and metaphorical#callebero is the second person to ever achieve that title#which was his maman's great dream#so all in all this is basically the ghost of his maman straightening the mantle of victory after callebero is crowned/etc.#my art#story: tcp#ch: callebero#ch: alir#at least in hallucination form!

4 notes

·

View notes

Text

fast forward a year from now (hopefully) when I'm taking the comptia security+ exam. anyone who reads my mind that day is just gonna hear the chant "a pussy so tight no dick penetrates" over and over again

#all the mnemonic devices out there for tcp/ip and it's only the crudest one that sticks in my brain#gitta.txt

5 notes

·

View notes

Text

ah sim, os protocolos de redes de internet... SMT, FDP, VTNC, FDS, PPRT.... a internet é linda...

#qrevo.txt#estudando os protocolos de internet e como caralhos eu vou decorar todas essas letras#SMTP?? FTP?? TCP/IP?? não podiam ter dado nomes melhores??#vou escrever letras aleatórias e esperar que eu acerte um dos protocolos na sorte

6 notes

·

View notes

Text

WEBCAST SEP 20 - Celebrating 50 years of TCP / IP with Vint Cerf and Bob Kahn

On Wednesday September 20 2023 at 7:30pm EDT (23:30 UTC) Google Global Networking and the American Institute of Physics Foundation are proud to honor Vint Cerf and Bob Kahn on the 50th anniversary of the TCP/IP protocols, the foundational technology of today’s Internet. The format will be a virtual fireside chat, moderated by journalist and author Katie Hafner, followed by a Q&A session. YOUTUBE:…

View On WordPress

1 note

·

View note

Text

Future-Proof Building Operations with NX-ERA Premium PLC Redundant Systems

In the domain of intelligent infrastructure, building intelligence is no longer a privilege but has become a requirement. Modern buildings, be it skyscraper business complexes, advanced healthcare institutions, or high-end hospitality centres function as living, breathing ecosystems. These types of buildings heavily depend on a Building Management System (BMS) to regulate HVAC, lighting, elevators, energy, and security systems.

Yet a single failure within the control system will bring these systems to a grinding halt, leading to operational disruption, safety hazard, tenant dissatisfaction, and regulatory non-compliance. This is where Messung's NX-ERA Premium PLC Redundant Systems, our state-of-the-art control solution for future-proofed infrastructure, come into play with their reliability, accuracy, and scalability.

Let us explore how NX-ERA provides intelligence, continuity, and scalability to your buildings through this blog.

The Evolution of Building Control Systems

Traditional relay-based control panels were able to handle building services in the past. Nowadays, buildings are far more advanced. Real-time data, multi-zone control, preventative maintenance, energy optimisation, and safety systems all require more intelligence.

Programmable Logic Controllers (PLCs) are the cornerstones of such a revolution. Although not all PLCs are alike.

The NX-ERA Premium PLC transforms building automation with a fail-safe, redundant design architecture that maintains your operations no matter what, and scales beautifully with your growing infrastructure.

Why Choose NX-ERA Premium PLCs?

Our NX-ERA platform is more than a PLC; it is an architecture that enables smart building management with unparalleled reliability.

Key Features:

Redundant Architecture: Two CPUs, two power supplies, and two communications modules offer zero downtime.

High-Speed Data Processing: Facilitates prompt decision-making between various sub-systems.

Remote Access PLC: Control, monitor, and troubleshoot anywhere.

Modular PLC Design: Flexible and scalable to project size and future requirements.

Intelligent PLC Capabilities: Sophisticated analytics, alarms, and diagnostics.

Built-in SCADA Integration: Integrated central control and visibility of the whole facility.

We have designed NX-ERA for round-the-clock use in the most demanding scenarios, starting from hospitals and IT parks to shopping malls and industrial clusters.

Application-Centric Design for Mission-Critical Infrastructure

In today's high-performance buildings, every system, air conditioning, lighting, fire detection, or security, has an important function to provide comfort, safety, and efficiency. Our NX-ERA Premium PLC is designed keeping this in mind. It is specifically made for use in mission-critical environments and allows for precise, continuous control of all major building services.

1.HVAC & Climate Control - NX-ERA provides advanced control of HVAC systems, controlling air conditioning, humidity, and ventilation with multi-zone precision. With open sensor integration, it provides condition-based automation, modulating airflow, temperature, and filtration in real time. This provides maximised indoor air quality and major energy savings, particularly in variable-occupancy buildings.

2. Lighting Automation - From programmed schedules to daylight-responsive dimming, NX-ERA regulates lighting between corridors and floors. It allows daylight harvesting by adjusting artificial lighting based on ambient conditions, saving energy without sacrificing occupant comfort. Smart lighting control also minimises operating costs and maximises fixture life.

3. Fire and Life Safety Systems - As a Safety PLC certified to operate, NX-ERA provides life-critical system support. It integrates with fire alarms, smoke detectors, and smoke extraction fans safely and reliably, with a timely response in case of emergencies. Redundant architecture ensures system availability even in the event of component failure.

4. Security & Access Control - NX-ERA controls security functions such as CCTV feeds, access readers, intruder alarms, and emergency lockdowns. It is fault-tolerant for access control and surveillance, even in the case of faults, with its dual-CPU design. Third-party system support provides seamless and scalable integration.

NX-ERA brings precision, resilience, and intelligent automation to every corner of your infrastructure, ensuring your building operates flawlessly, around the clock.

Constructing a Strong Framework with Redundant Design

NX-ERA’s architecture is designed around fail-safe principles:

Redundant CPUs are in hot standby, providing instant takeover if the primary CPU fails.

Duplicate Power Supplies provide a continuous power supply, avoiding shutdowns caused by voltage instability or failure.

Dual Communication Modules remove the threat of being disconnected from field devices or SCADA.

Programmable Logic Controllers provide deterministic behaviour and quick response times for real-time control.

This is the level of redundancy that must ensure the PLC Control Systems are single-point failure-proof and properly compliant with safety standards.

Smooth Integration with Building Ecosystems

NX-ERA is specifically designed for comprehensive, integrated control of building operations. Interoperability is its basis.

Native MODBUS TCP/IP communication for easy integration with third-party devices such as energy meters, smart sensors, HVAC devices, lighting panels, and fire safety devices.

It aggregates independent systems onto a single SCADA dashboard, providing a live view of all building services operating.

Remote diagnostics and centralised control enable facility managers to observe, investigate, and react to inefficiencies or faults from a central command centre—or any other location with secure access.

NX-ERA also supports seamless interaction with modern IoT systems like occupancy analytics, air quality monitoring, and asset tracking, making conventional buildings responsive, adaptive spaces.

Whether you are installing new infrastructure or expanding existing installations, NX-ERA keeps your architecture flexible, networked, and future-proof.

Real-Time Intelligence for Smarter Facilities

NX-ERA is not just a control system—it's a smart decision-making platform. Its data-driven performance offers real-time insights that raise operational effectiveness:

Offers high-resolution data logs for all parameters—temperature, voltage, energy consumption, etc.

Fully integrated with Energy Management Systems, supporting predictive load balancing, peak demand management, and actionable energy intelligence.

Generates predictive alerts for anomalies such as HVAC inefficiencies, equipment fatigue, or sensor deviations, helping prevent breakdowns before they occur.

Stores complete, tamper-proof logs that support regulatory audits and compliance with ISO standards, LEED guidelines, and other sustainability certifications.

With NX-ERA, facility managers can depart from reactive repair towards proactive, data-driven facility management.

Built to Scale, Built to Last

Growth and sustainability are the major pillars of the existence of any building. NX-ERA guarantees your automation system grows with your building while meeting environmental goals:

Modular structure allows you to add I/O points, add new subsystems, or accommodate newer technologies without redesigning the system.

Fully supports IoT-enabled smart metering, leak detection for water, predictive HVAC control, and occupancy analytics.

Facilitates LEED and green building certifications by maintaining constant energy audits, performance benchmarking, and real-time carbon footprint tracking.

Perfectly complements digital transformation initiatives, setting the stage for cloud analytics, AI, and automation-ready.

NX-ERA is your control companion, not just for today’s needs, but for tomorrow’s smart infrastructure vision.

Messung: Reliable Across Industries

For more than four decades, Messung has spearheaded India's industrial automation process with high-performance, dependable PLC solutions. NX-ERA Premium PLC is used in a broad range of mission-critical industries:

Data centres need constant uptime and exact environmental control.

Hospitals where life-saving equipment has to work without any failure.

Office towers with intricate lighting, HVAC, and elevator systems.

Residential high-rise buildings require energy efficiency and safety.

Plant operations where lost time equates to high operating costs.

Every NX-ERA deployment is backed by thorough testing, sophisticated lifecycle support, and intimate customer knowledge to deliver performance with confidence.

When to Upgrade to NX-ERA

Use NX-ERA if:

Your business requires no interruption of business.

You are grappling with legacy PLC failures or integration issues.

You're targeting PLC Automation for mission-critical sub-systems.

You need audit-quality logs to achieve ISO or LEED certification.

You're growing and require Remote Access PLC functionality.

NX-ERA is designed to fulfil your current requirements and long-term ambitions.

Conclusion: Join Messung for Uninterrupted Brilliance

In a world where building systems are designed to work flawlessly, learn intelligently, and expand seamlessly, your automation partner can be the difference-maker. At Messung Industrial Automation, we realise that infrastructure today requires more than control; it demands resilience, precision, and vision.

Our NX-ERA Premium PLC Redundant Systems reflect these principles. Not only do they provide fault-tolerant automation, but they also provide a complete platform for smart building management, enabling your infrastructure to react in real time, recover immediately, and adapt continuously.

Whether your business is a hospital, data centre, office complex, or intelligent residential complex, NX-ERA is your command centre that makes you never miss a beat.

Let's redefine what's possible, together.

Contact Messung Industrial Automation to see how NX-ERA can future-proof your plant with zero downtime, maximum intelligence, and permanent peace of mind.

Select NX-ERA. Select uninterrupted brilliance.

Frequently Asked Questions (FAQs)

Why would NX-ERA Premium PLCs be ideal for mission-critical buildings?

NX-ERA Premium PLCs are designed with two CPUs, power supplies, and communications modules, which render them zero downtime in case of failure. They are ideal for units where continuous operation is crucial, including hospitals, data centres, and business complexes.

Is NX-ERA compatible with existing building systems and legacy infrastructure?

Yes. NX-ERA is an open protocol-based based, such as MODBUS TCP/IP, and is capable of being integrated with third-party equipment, legacy control panels, and contemporary IoT-based systems and is extremely flexible for new and retrofit applications.

In what ways does NX-ERA support energy efficiency and green building goals?

NX-ERA includes integration with Energy Management Systems, daylight harvesting, and advanced energy analytics that minimise energy use and support the needs of green building certifications such as LEED.

For which industries and applications is NX-ERA best suited?

NX-ERA is tailored for various industries such as healthcare, manufacturing, commercial real estate, residential townships, and mission-critical infrastructure that need smart, high-availability automation.

Can NX-ERA be remotely monitored and remotely troubleshot?

Yes. NX-ERA allows secure remote access, with real-time monitoring, diagnostics, and command execution from remote locations, reducing response time and maintenance cost.

#NX-ERA Premium PLC#Building Management System (BMS)#Programmable Logic Controllers (PLCs)#Modular PLC Design#SCADA Integration#HVAC systems#Smart lighting control#Safety PLC#Duplicate Power Supplies#MODBUS TCP/IP#HVAC devices#modern IoT systems#Energy Management Systems#IoT-enabled#PLC solutions#NX-ERA Premium PLC Redundant Systems#MODBUS#healthcare#manufacturing#commercial real estate#residential townships#mission-critical infrastructure

0 notes

Text

youtube

youtube

youtube

youtube

youtube

youtube

youtube

youtube

youtube

#lo#KAn#ⁿK$.this([~]) %s%u%ⁿ%CNAMɛ%TCP-ip[Řack%Rep%Whit'·L·Lℹ️( ´∀` )b1🅿️👀🔻🔻❤️🅰️🅰️➗️⚜️❤️😍❤️🏝🌡🤗🧤🖍📜🕳💭📫📌🆓️💋ℹ️🔶️ℹ️🧢3️⃣👀ℹ️🕳🖊3#%n#%cr#[ ' ^ASCℹ️ℹ️^ ' .]#DES#RSA#Hash(.&); ☆\Lent./☆ [ABS] !x!#AES#PKI#IVNF rm %f ÷ &SiP &&SaP Ox.Stan(POSsïbįlītịe$.x (this[])《X.25b¿#🅰️]REC(this.r t rn[eskIMO.Pℹ️💭 o o d @#.Loop installation AS [ ' EXEMPLAR#' .]#(🏴.Th[@]);#§.o.§ẀasẂ.22 [lo]VV SWV -Each %Eve' (:ÆⁿŸ:) [ ' Sℹ️MPLƐX̌ ' .]

1 note

·

View note

Text

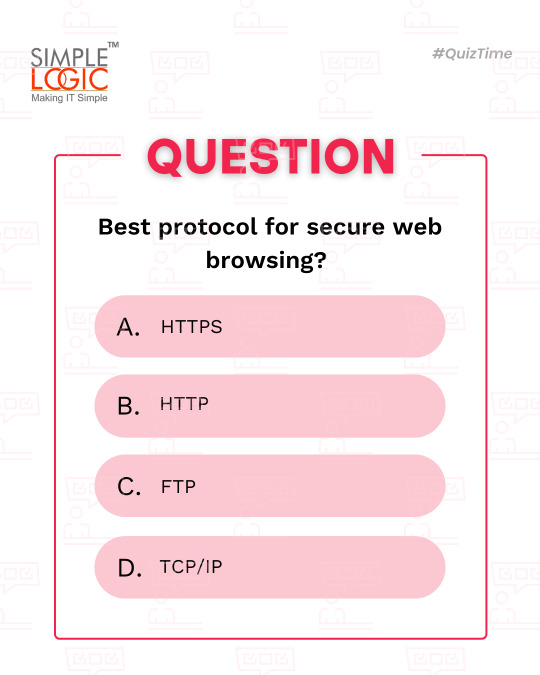

#QuizTime Best protocol for secure web browsing?

A) HTTPS 🔐 B) HTTP 🌍 C) FTP 📤 D) TCP/IP 📡

Comments your answer below👇

💻 Explore insights on the latest in #technology on our Blog Page 👉 https://simplelogic-it.com/blogs/

🚀 Ready for your next career move? Check out our #careers page for exciting opportunities 👉 https://simplelogic-it.com/careers/

#quiztime#testyourknowledge#brainteasers#triviachallenge#thinkfast#protocol#secure#webbrowsing#https#http#ftp#tcp#ip#quizmaster#knowledgeIspower#mindgames#funfacts#makeitsimple#simplelogicit#simplelogic#makingitsimple#itservices#itconsulting

1 note

·

View note

Text

#the arcane fandom is really grilling my cheese on my personal#out of leis;#makes me want to smack ppl thru tcp/ip#tbd;

1 note

·

View note

Text

Wireshark: Unravel the secrets of your network with this essential packet analyzer

Have you ever wondered what exactly is happening on your network? Do you want to understand how your devices communicate and how data flows? If so, you need to know about Wireshark! This powerful, open-source package analyzer is a must-have tool for anyone who works with networks. What is Wireshark? Wireshark is a protocol analyzer that allows you to capture and examine network traffic in…

0 notes

Text

Project and Training in Network Programming

Master Network Programming with Emblogic's Linux Socket Programming Course in Noida. project and training in Network Programming - Emblogic offers hands-on training in Linux Networking Socket Programming in Noida, providing a strong foundation for building projects and preparing students for placements in multinational companies. This program is ideal for those aspiring to master network communication and build cutting-edge software solutions.

What is Socket Programming?

Socket programming is a fundamental technology for enabling communication between software applications over networks like TCP/IP. A socket acts as an endpoint for sending and receiving data, allowing two systems—whether on a local area network (LAN) or the Internet—to exchange information. Sockets also enable communication between processes on the same machine.

How Does Socket Communication Work?

The client creates a local TCP socket by specifying the server's IP address and port number.

The client's TCP establishes a connection with the server's TCP.

The server creates a new socket to handle communication with the client.

The client sends requests to the server, which responds with the required data or service.

Data exchange happens over the TCP/IP protocol, ensuring reliable and secure communication.

Why Choose Emblogic?

Emblogic’s course is project-based, emphasizing practical applications of socket programming. You’ll learn to:

Build client-server applications.

Create custom network protocols using a socket stack.

Implement inter-process communication.

Our training ensures you gain in-depth knowledge and real-world experience, making you job-ready for opportunities in leading tech companies.

Whether you’re a beginner or a professional looking to upgrade your skills, Emblogic provides the perfect platform to excel in Linux Networking Socket Programming. Join us to build your expertise and take the next step in your career!

Linux Networking socket Programming Noida, Project based Linux Networking socket Programming, Linux Socket Programming Noida, Networking Socket Programming Course, Client-Server Application Development, TCP/IP Communication Training, Linux Networking Projects, Socket Programming Certification, Inter-Process Communication Training, Network Protocol Development.

#Linux Networking socket Programming Noida#Project based Linux Networking socket Programming#Linux Socket Programming Noida#Networking Socket Programming Course#Client-Server Application Development#TCP/IP Communication Training#Linux Networking Projects

0 notes

Text

A Review of 1969: A Year of Defining Moments, Month by Month

Apart from being my birth year, 1969 was a pivotal one, full of cultural, scientific, and political milestones that left an indelible mark on human history. Photo by Pixabay on Pexels.com I will take you along a journey through this year, one month at a time, highlighting a significant event from each. January: The Concorde’s First Flight On January 21, the Concorde, the world’s first…

View On WordPress

#1969#1969 Stonewall#ARPANET#dailyprompt#dailyprompt-2161#Internet#LGBT#LGBTQ+#Moon Landing#Raffaello Palandri#Solar Eclipse#Stonewall Uprising#TCP/IP#UNICEF#UNICEF Nobel Peace Prize#Woodstock

0 notes

Text

#standards#developer#tcp/ip#http#oauth#sql#html#css#ecmascript#iso#data#format#openapi#development#software#web#bytebytego

1 note

·

View note

Video

youtube

Modelo TCP/IP - Camada de Rede e Enlace #computernetworking #ebook ebook

#youtube#As camadas do Modelo TCP/IP envolvem a camada de Enlace Rede Transporte e Aplicação. Na camada de enlace as informações trafegam como quadro

0 notes

Text

How NX-ERA Premium PLCs Revolutionise Textile Singeing Operations

Quality has always held a high priority in the vast and ever-evolving domain of textile manufacturing, as even a single misstep in production can lead to cascading effects, starting from product rejection, leading up to brand loss and compromised customer trust. To ensure a consistent quality in textile finishing, singeing is among the first and most critical steps in the procedure. It is a seemingly sensitive operation where surface fibres are removed using gas flames.

While it may not receive the spotlight like dyeing or printing, singeing lays the foundation for almost everything that follows. It ensures that your fabric output is smooth, clean, and primed for perfection. And in this era of fast fashion, global exports, and digitised factories, managing this process with old-school tools and controls won’t simply suffice.

This is where we at Messung Industrial Automation come in. Our NX-ERA Premium PLCs are a game-changing solution that doesn’t just automate singeing but also redefines how precision, speed, safety, and intelligence come together.

Let’s explore the heart of singeing operations and discover how this Programmable Logic Controller is igniting a silent yet mighty revolution in the textile industry.

Textile Singeing: The First Touch of Refinement

Singeing is a thermal pre-treatment process where the surface fuzz or the protruding fibres on a fabric are burnt off using a controlled gas flame. This eliminates any loose threads or lint that could interfere with the dye penetration or printing clarity.

However, its benefits extend far beyond just aesthetics. They include:

Improved dye absorption and print sharpness

Premium feel through smoother fabric texture

Enhanced garment durability with reduced pilling

Less linting, critical for cleanroom or medical textiles

Compliance with international quality standards, especially in exports

When done right, singeing transforms a raw textile material into a high-value product which is ready for further treatment.

The Complexity Behind

At first glance, singeing might appear as a very straightforward flame treatment, but in practice, it is a process that juggles multiple moving parts with split-second precision. The variables in play are:

Controlling flame intensity and width based on the fabric type and speed.

Tightly monitoring the temperature to avoid scorching

Fabric speed impacts flame exposure time and must be regulated in sync with the burners

Safety systems must be in place to detect flame irregularities, gas leaks, and other emergencies

Include flexibility and minimal downtime for smooth process changeovers.

Due to all these variables, traditional relay-based systems or low-end PLC control systems often fall short, lacking the finesse, feedback loops, or integration capabilities required for modern singeing lines.

The Rise of NX-ERA Premium PLCs by Messung

Recognising the gap between process needs and available automation tools, we at Messung designed NX-ERA Premium PLCs, a high-speed, modular PLC system that is tailored for demanding applications like singeing.

What makes it “Premium”?

The reasons include:

Advanced CPU with nanosecond-level scan cycles

Real-time analogue and digital input processing

Built-in PID loops for fine-tuned temperature control

Modbus TCP/IP and other industrial protocols for easy integration

SCADA-ready architecture for centralised visibility and remote access

Modular I/O scalability for future expansion

This makes NX-ERA not just another PLC controller, but a smart, robust platform designed to thrive even in high-heat and high-stakes environments like those of textile factories.

How NX-ERA Powers Every Element of Singeing

Let’s break down how this industrial automation PLC transforms every aspect of the singeing line.

Flame Control: Precision like never before

At the heart of singeing is the burner, and controlling its intensity, width, and modulation in real time is where our NX-ERA shines.

Analogue inputs from flame sensors feed data directly to the PLC

PID Loops automatically adjust the burner valves

Real-time modulation ensures uniform heat distribution

Result? Consistent singeing with no under- or overt treated sections.

Temperature Monitoring: Accuracy that protects

Using feedback from pyrometers or infrared sensors, NX-ERA maintains a tight grip on the burner zone temperature.

Avoids fabric scorching by reacting to even minor spikes

Keeps flames within the desired thermal envelope

Enhances burner efficiency by reducing unnecessary gas usage

This level of temperature control is mission-critical for fine or synthetic fabrics

Fabric Speed Synchronisation: Seamless flow control

Singeing isn’t just about the fire; it is also about the timing. NX-ERA synchronises:

Drive Motors

Rollers

Tension Sensors

This helps in regulating the fabric speed precisely. Whether it is a slow-moving wool or a high-speed polyester line, speed and flame remain in perfect harmony.

Built-in Safety: Because lives are on the line

Working with gas burners has its risks. Therefore, to immediately halt the operations in case of abnormal conditions, NX-ERA integrates:

Flame detectors

Gas leak sensors

Emergency shutdown circuits

With redundant CPUs and power modules, the system ensures zero single-point failures, maximising safety for both the operators and the assets.

Process Optimisation: recipe for automation intelligence

Different fabrics have different treatment parameters. NX-ERA stores fabric-specific recipes that easily control:

Flame profile

Flame speed

Temperature setpoints

Operators can switch recipes with a single command, slashing changeover time and reducing manual errors.

Unified Control with SCADA Integration

The second most important thing in modern textile manufacturing is visibility. Our NX-ERA Premium PLC seamlessly integrates with SCADA (Supervisory Control and Data Acquisition) systems, transforming traditional singeing operations into fully observable, data-driven ecosystems. This fusion empowers plant managers, process engineers, and quality heads with an unprecedented ability to monitor, analyse, and optimise operations, both in real-time and retrospectively.

Here is how this synergy delivers control and clarity:

Live dashboards showing temperatures, speeds, and flame status

Historical data logs for ISO and export audits

Alarm and fault management with timestamps

Remote troubleshooting for multi-site operations

No more guesswork. Just insight-driven control.

All this precision allows for a process control that empowers smarter and faster decision-making across the board.

Tangible Benefits for Textile Businesses

Switching to NX-ERA is a leap in operational intelligence and profitability in the segment of automation segment. Here’s how your textile businesses directly benefit from this advanced PLC automation platform:

Improved Product Quality: By maintaining precise control over flame exposure and fabric speed, NX-ERA ensures singeing consistency across the entire fabric width. This leads to smoother, cleaner surfaces, superior dye penetration, and flawless prints.

Greater Efficiency: Automated control means fewer manual adjustments, faster recipe changeovers, and minimal production interruptions. That translates to shorter cycle times, maximised uptime, and increased throughput, especially critical in high-volume manufacturing environments.

Lower Rejections and Waste: Over-singeing, scorching, or uneven treatment can ruin entire fabric batches. NX-ERA’s precision-driven system minimises these risks, reducing rejections and conserving raw materials—ultimately saving both time and cost.

Enhanced Operator Safety: With built-in safety interlocks, flame detectors, and emergency shutdown protocols, NX-ERA proactively safeguards both personnel and equipment. Safety becomes predictive, not reactive.

Lower Energy and Maintenance Costs: The system fine-tunes burner performance based on real-time feedback, ensuring optimal energy usage. At the same time, it flags maintenance needs before breakdowns occur, driving down utility bills and unplanned service disruptions.

All these benefits help your products stand out in competitive export markets.

The NX-ERA Edge Over Conventional PLCs

Basic PLCs were built for basic logic, and that’s where they stop. Today’s singeing machines demand more. Here’s where NX-ERA stands apart:

Conventional PLC Limitations:

Limited scalability for complex I/O or multi-sensor integration

Poor compatibility with SCADA or MES platforms

No redundancy, leading to system crashes or halts

Inadequate processing speed for real-time adjustments

NX-ERA Delivers:

Lightning-fast logic execution for tight control over process parameters

Redundant CPU and power modules for uninterrupted operation

Modular PLC architecture for scalable, plug-and-play expansion

Open protocol support, including Modbus TCP/IP, for seamless integration with legacy and modern systems

Whether you're building a new plant or retrofitting older machinery, NX-ERA adapts effortlessly, making it a smart, long-term investment.

Conclusion: The Edge That Sets You Apart

In a market where margins are tight and expectations are sky-high, singeing can no longer be left to chance. It’s the beginning of quality. And with NX-ERA Premium PLCs, it becomes the beginning of excellence.

From smarter flame control and temperature precision to SCADA visibility and Industry 4.0 integration, NX-ERA empowers textile mills to think big, act fast, and stay ahead.

Because in the world of textiles, smooth starts lead to flawless finishes.

FAQs

What is a PLC, and how does it benefit textile operations?

A PLC (Programmable Logic Controller) is an industrial computer that automates control processes. In textile mills, it ensures consistent quality and operational safety across processes like singeing, dyeing, and finishing.

How do PID controllers improve singeing quality?

PID controllers maintain optimal burner temperature by continuously adjusting based on feedback. This prevents overheating or under singeing, resulting in uniform treatment.

Is NX-ERA Premium suitable for legacy machines?

Yes, its modular PLC architecture allows easy integration with older systems, enabling modernisation without a complete overhaul.

Can NX-ERA integrate with existing SCADA systems?

Absolutely. With Modbus and other standard protocols, NX-ERA seamlessly connects with your existing SCADA setup for real-time control and data analysis.

What makes NX-ERA a future-proof choice for Industry 4.0?

Its ability to connect with cloud systems, support for remote diagnostics, predictive maintenance, and readiness for AI make it a robust, future-proof choice for any smart textile factory.

#textile manufacturing#NX-ERA Premium PLCs#Programmable Logic Controller#smoother fabric texture#reduced pilling#Improved dye absorption#PLC control systems#modular PLC#modular PLC system#Advanced CPU#Real-time analogue and digital input processing#Modbus TCP/IP#Modular I/O scalability#PLC controller#industrial automation PLC#PID Loops#Avoids fabric scorching#redundant CPUs and power modules#NX-ERA Premium PLC#SCADA (Supervisory Control and Data Acquisition)#advanced PLC#Industry 4.0#PLC (Programmable Logic Controller)#PID controllers#SCADA systems#Modbus#SCADA

0 notes