#automated visual inspection systems

Explore tagged Tumblr posts

Text

Magnetic ring surface inspection study case share by Intsoft Tech

#vision measurement system#automated visual inspection systems#part sorting solutions for industry#vision enclosure

1 note

·

View note

Text

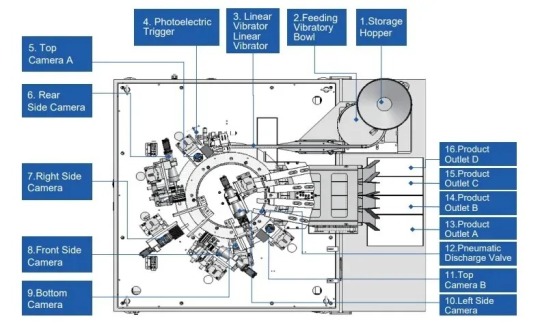

CCD Visual Inspector Manufacturers

CCD visual inspection equipment is a powerful and widely used optical detection equipment. It is mainly used in many fields such as the electronics industry, the automotive industry, and the pharmaceutical industry, playing an important role in improving production efficiency and reducing production costs.

Working Principle

Using optical principles, the product is illuminated clearly with a light source, and the image is taken by a camera, and the image is transmitted to the PC computer vision software for analysis, the analysis results are output, the QR code on the PCBA board is identified, and the image is saved and uploaded to the MES system.

Function and process of CCD visual inspection equipment:

After the product is in place, the stopper stops, and the side camera, top camera, and bottom camera take pictures of the product for analysis. If the product is large, the top camera and bottom camera move once. The equipment has left-in-right-out and right-in-left-out functions, and the inlet and outlet have safety gratings.

CCD inspection content:

Check whether the large components under the product are leaking, deviated more than 10 degrees, or damaged, and save pictures

1. Component size: 3.4*2.7*2.5mm or above 2. Component missing parts must be detected; 3. Component deviation greater than 10 degrees can be detected 4. Component appearance damage and traces can be detected, and the accuracy of appearance damage and traces must be ≤0.2mm; 5. Image storage is saved according to the date, SN, and product code rules

Check the side pin deformation, terminal appearance, damage, and save the image

1. Terminal pin deformation accuracy: 0.25mm; 2. Side component appearance damage and traces can be detected; Terminal appearance damage and trace accuracy ≤0.2mm 3. Image storage is saved according to the date, SN, and product code rules

The gosunm intelligent CCD visual inspection system has high resolution, low distortion in the full field of view, supports -20~50℃ operating temperature, works stably and reliably, and is suitable for various complex industrial visual inspection needs. It displays product images in real time, conducts comparative analysis, and issues an alarm when crimping is poor, and automatically sorts out defective products. Quality monitoring throughout the entire processing process greatly saves labor costs, ensures product quality, and improves production efficiency.

The CCD visual inspection system is the latest visual solution developed by gosunm. The company focuses on technology development and product design in intelligent manufacturing, including non-standard automated production lines, CCD visual inspection labeling solutions, etc. The company's products are widely used in manufacturing industries such as automotive parts, electronics, optical instruments, and special motors. It can customize non-standard automated production lines for various types of processing and assembly for different customers.

#CCD visual inspection equipment#customize non-standard automated production lines#CCD visual inspection labeling solutions#intelligent CCD visual inspection system

0 notes

Text

The Final Click

The video opened with a low mechanical hum, the sound of a workshop alive with quiet, deliberate motion. C9J18 stood on the platform once again, his posture rigid, the sleek black armor now fully integrated with his body. The segmented plates fit seamlessly together, the faint glow of the suit’s internal systems casting a cold light on his skin where it met the edges of the armor. Only his shaved head remained exposed—a temporary state that was about to change.

A Suit Technician stepped forward, fully suited in his own armor, his visor up. His smirk was visible, sharp and cynical, as he held the final piece of C9J18’s transformation: the helmet. The technician turned it in his gloved hands, its polished surface gleaming under the workshop lights.

“Well, here we are,” the technician drawled, his voice filtered slightly through his suit’s comm system. “The crown jewel of your integration. Once this goes on, you’re not just a cadet anymore. You’re part of the system.”

He stepped closer, holding the helmet up for a final inspection. “One size fits all,” he said with a faint chuckle. “Not that it matters. The AI will make it fit... whether you like it or not.”

C9J18 swallowed hard but didn’t respond. He simply stood at attention, his eyes fixed forward as the technician lowered the helmet over his head. The moment it settled into place, there was a sharp click followed by a faint hiss as the seals locked, connecting the helmet to the rest of the suit.

The technician’s smirk widened as he checked his wrist-mounted display. A stream of telemetry data scrolled across the screen, highlighting C9J18’s vitals, neural responses, and suit integration status. “Look at that,” he said with mock admiration. “Perfect fit. Just like it was made for you. Or maybe you were made for it.”

Inside the helmet, everything was dark at first—an all-encompassing blackness that seemed to press against C9J18’s senses. For a moment, there was only the sound of his own breathing, amplified slightly by the helmet’s internal comms. Then, with a faint whir, the visor began to activate. A dim light flickered to life, growing brighter as the system calibrated itself to his neural patterns.

“Welcome to your new world,” the technician said, watching the data streams on his display as the helmet synchronized. “Don’t worry—it’ll all start to make sense soon. Or not. Either way, you’ll adapt.”

The visor fully illuminated, revealing the HUD for the first time. The view was clinical, sterile, and utterly devoid of humanity. Unimportant details in the workshop were greyed out, the AI deeming them irrelevant. Telemetry data crawled across the edges of his vision—heart rate, oxygen levels, suit integrity. A faint overlay marked the positions of nearby personnel, each tagged with their alphanumeric IDs.

The technician gestured at him, his movements highlighted by the HUD. “How’s it feel?” he asked, though his tone suggested he didn’t really care. “Strange at first, isn’t it? Like your head’s full of static. Don’t worry—that’s just the AI integrating with your sensory inputs. Give it a few minutes. You’ll stop noticing soon enough.”

A new menu appeared in the HUD, labeled Calibration, its options faintly glowing. The technician tapped his wrist display, and the menu expanded.

“Let’s get you set up,” he said, his tone laced with sardonic amusement. “We’ll start with the basics. Visual alignment, auditory filtering, neural response thresholds. Don’t worry—we’ll take care of all the hard stuff. You just stand there and let the suit do the thinking.”

The calibration process began. The HUD’s display shifted subtly, adjusting brightness, contrast, and focus. The edges of C9J18’s vision pulsed briefly as the system fine-tuned his peripheral awareness.

“See that?” the technician asked, pointing to a highlighted option in the menu. “That’s your task queue. Automated orders, courtesy of the AI. It’ll tell you what to do, when to do it, and how. You’ll learn to love it—or at least obey it. Either way, it gets the job done.”

Another section of the HUD displayed a comms menu, most of its options greyed out. The technician grinned. “Comms are restricted for now. You’re a cadet. You don’t get to chat unless the system says so. But don’t worry—once you’re authorized, you’ll have the privilege of hearing even more of our delightful voices.”

He tapped another menu labeled Sensory Adjustment. “This one’s fun,” he said, his grin widening. “The AI controls your sensory input. If it thinks something’s irrelevant, it tones it down. If it wants you to focus, it cranks things up. Pain, heat, cold... all dialed to whatever setting keeps you most productive. Efficient, isn’t it?”

C9J18 blinked as the system tested its control, briefly amplifying the sensation of the suit against his skin before dulling it to near imperceptibility. The technician chuckled. “Feels good, doesn’t it? Like a second skin. You’ll forget it’s even there—until you can’t.”

The POV shifted to C9J18’s perspective as the technician stepped back, his figure outlined in faint blue by the HUD. A notification appeared in the corner of the display: Integration Complete. Awaiting Commands.

The technician gave him a mocking salute. “Congratulations, cadet. You’re now a fully integrated asset of the Republic. Welcome to the rest of your life.”

As the feed faded, the Intelligence Conscript’s voice returned, smooth and cold. “The suit isn’t just armor. It’s a system. A tool. A way of life. And now, it’s his reality. Every moment, every thought, every action is guided, monitored, and optimized. He’s not just wearing the suit—he is the suit.”

The final shot lingered on C9J18’s HUD, the unrelenting data streams and greyed-out options framing his vision. The screen faded to black, leaving only the faint hum of the system in the background.

9 notes

·

View notes

Text

A fully automated process, including a brand-new artificial intelligence (AI) tool, has successfully detected, identified and classified its first supernova. Developed by an international collaboration led by Northwestern University, the new system automates the entire search for new supernovae across the night sky—effectively removing humans from the process. Not only does this rapidly accelerate the process of analyzing and classifying new supernova candidates, it also bypasses human error. The team alerted the astronomical community to the launch and success of the new tool, called the Bright Transient Survey Bot (BTSbot), this week. In the past six years, humans have spent an estimated total of 2,200 hours visually inspecting and classifying supernova candidates. With the new tool now officially online, researchers can redirect this precious time toward other responsibilities in order to accelerate the pace of discovery.

Continue Reading.

61 notes

·

View notes

Text

Top Commercial Fence Solutions in Peoria for Business Security and Curb Appeal

When running a business in Peoria, IL, security, privacy, and professional appearance are essential. A well-designed commercial fence not only protects your property but also reinforces your brand’s image. Whether you're managing a construction site, office complex, manufacturing plant, or retail space, the right fencing solution can make a significant difference.

Benefits of Installing a Commercial Fence in Peoria

Business owners in Peoria are increasingly investing in commercial fencing for reasons beyond basic security. Here are some top advantages:

1. Enhanced Security

Protect valuable inventory, equipment, and assets from theft or vandalism. A properly installed fence creates a clear physical barrier and deters unauthorized access.

2. Improved Privacy

Some commercial operations require discretion. Fencing with privacy panels or slats helps shield sensitive areas from public view.

3. Controlled Access

Add automated gates or keypad entry systems to restrict access and monitor who enters and exits your property.

4. Professional Appearance

First impressions matter. A clean, well-maintained commercial fence adds credibility and visual appeal to your property.

5. Compliance with Local Regulations

Many Peoria zoning ordinances require proper enclosures for certain commercial activities. A local fence contractor can ensure your fence meets city codes and guidelines.

Popular Commercial Fence Types in Peoria

Not all fences are created equal. Depending on your industry and property type, one of the following options might be ideal:

Chain Link Fences: Affordable, strong, and widely used for utility yards, factories, and sports complexes.

Ornamental Steel or Aluminum Fences: Stylish and secure — ideal for professional offices, schools, and government buildings.

Vinyl Fencing: Great for commercial plazas and apartment complexes; offers a clean, modern look with minimal upkeep.

Wood Fences: Often used for restaurants, daycare centers, and outdoor venues needing a natural, warm appearance.

Custom Security Fences: High-security fencing with razor wire, anti-climb mesh, or electric gate systems for sensitive facilities.

Working With a Peoria Commercial Fence Contractor

Choosing the right contractor is just as important as selecting the right fence. In Peoria, a top-tier commercial fencing company will offer:

Free on-site evaluations

Customized fencing plans to match your business needs

High-quality materials built to last through Illinois weather

Timely installation with minimal disruption to your operations

Long-term warranties and maintenance support

Be sure to work with a licensed, insured, and locally experienced fencing provider familiar with Peoria’s business zones and regulations.

Keep Your Investment Protected

After installation, routine inspections and repairs are key. Many fencing contractors in Peoria also offer:

Emergency repair services

Gate automation tune-ups

Fence painting, sealing, or cleaning

Replacement of damaged panels or hardware

Regular maintenance extends your fence’s life and keeps your property looking sharp.

Final Thoughts

Your commercial fence is more than just a boundary — it’s part of your business's identity and security infrastructure. From functional chain link fencing to elegant ornamental options, Peoria businesses have access to a wide range of fencing solutions to suit every need.

Ready to Fence In Your Business?

Partner with a trusted commercial fence installer in Peoria and take the first step toward a safer, more polished business property today.

#fence installation#fence contractor#custom fences#peoria fence company#cosma decking and fence#fence

3 notes

·

View notes

Text

IFC to 3DTiles conversion has evolved to this extent with GISBox

Free on-premise cesium ion alternative

As the next generation of spatial information is used in smart cities, digital twins, infrastructure management, etc., the fusion of BIM (Building Information Modeling) and GIS (Geographic Information System) is now an inevitable trend. However, the barrier of interoperability between systems and formats stands between developers and users.

That’s where GISBox comes in. As a new generation 3D spatial data integration platform, it has the industry’s leading IFC to 3DTiles conversion function, and dramatically accelerates data integration and utilization in the fields of architecture, civil engineering, urban planning, and metaverse.

1 | From IFC to 3DTiles: Technology that fills the last step in “BIM x GIS fusion” IFC (Industry Foundation Classes) is an international standard format for BIM that holds geometric information and attribute data (materials, construction history, management numbers, etc.) of architectural structures. On the other hand, 3DTiles is a lightweight format optimized for real-time display that is used in GIS platforms such as Cesium.

There are structural differences between these two, and the following issues frequently occurred in the conventional conversion process:

✅ Missing metadata: BIM attributes such as materials and specifications are lost during conversion

✅ Performance limitations: If IFC is directly loaded into GIS, the display is heavy and it is not suitable for city-level scenes

✅ Compatibility issues: Problems such as display failure and hierarchy collapse due to differences in IFC versions

GISBox tackles these problems head-on, achieving the industry’s first high-precision conversion + attribute preservation + lightweighting at the same time.

2 | No-code & visualization, a conversion experience that is friendly to non-engineers

Conventional conversion tools require specialized knowledge (GLTF, B3DM, etc.), so the reality was that only a limited number of engineers could use them. GISBox provides a UI/UX that anyone can use, such as:

🖱️ Import IFC files by dragging and dropping

👀 Preview LOD settings, materials, and hierarchy display in real time

🚀 One-click OGC-compliant 3DTiles data output (compatible with Cesium, SuperMap, Mapbox)

🔧 API that can be linked with Python and JavaScript is also provided, allowing developers to automate processing

3 | Supports a wide range of use cases, from architecture to urban scale GISBox’s IFC to 3DTiles conversion is being used in a wide range of fields, from visualization of individual buildings to urban scale:

🏙️ Smart building management Integrate IoT sensor information into BIM models to visualize building interior condition monitoring and maintenance forecasts.

🌇 Urban planning simulation Convert hundreds of IFC building models into 3DTiles at once and use them for evaluations such as visibility analysis and sunshine analysis.

🛤️ Inspection and maintenance of infrastructure facilities

Convert civil engineering structures such as bridges and tunnels into 3DTiles while retaining their construction history. A digital foundation for maintenance.

🕹️ Metaverse construction

By outputting models in lightweight 3DTiles format, they can be quickly deployed in virtual exhibition spaces and virtual factories.

4|GISBox as a common language for spatial information

GISBox’s conversion engine is not just a technical tool.

It is a bridge between the different cultures of BIM and GIS,

and a common language for digital space that connects design, construction, and management.

In Japan’s accelerating smart city concept, architectural digital transformation, and urban disaster prevention and mitigation measures,

GISBox is expected to be the key to realizing the “democratization of spatial data.”

GISBox Official Teams: https://teams.live.com/l/invite/FEAr12sInvEVy4hFQE Official Teams Group: https://teams.live.com/l/invite/FBAFp0pbqhqlpe1BQI

Contact us to get 7-day Team Plan

2 notes

·

View notes

Text

Comprehensive Industrial Solutions by AxisValence: Advancing Productivity, Safety, and Efficiency

In today’s fast-paced manufacturing world, industrial productivity is driven by precision, consistency, safety, and compliance. Whether it’s printing, packaging, converting, textiles, plastics, or pharmaceuticals—modern production lines demand advanced electro-mechanical systems that minimize waste, ensure operational safety, and improve overall efficiency.

AxisValence, a business unit of A.T.E. India, addresses this demand with a complete range of industrial automation and enhancement products. From static elimination to print quality assurance, ink management, and solvent recovery, AxisValence solutions are engineered to optimize each critical point in the production cycle.

This article provides an overview of the key technologies and systems offered by AxisValence across its diverse portfolio:

Electrostatics: Managing Static for Quality and Safety

Electrostatics can compromise product quality, disrupt operations, and pose serious safety hazards, especially in high-speed processes involving films, paper, textiles, or volatile solvents. AxisValence offers a complete suite of static control solutions:

ATEX AC Static Eliminators: Certified for use in explosive or solvent-heavy environments such as rotogravure or flexo printing lines.

AC and DC Static Eliminators: Designed for long-range or close-range static charge neutralization across a range of substrates.

Passive Static Dischargers: Cost-effective, maintenance-free brushes for light-duty static elimination where power isn't available.

Air-based Static Eliminators / Ionisers: Use ionized air streams for dust blow-off and static removal, ideal for hard-to-reach areas.

Static Measurement & Online Monitoring: Includes handheld meters and IoT-enabled monitoring systems for real-time control and diagnostics.

Electrostatic Charging Systems: Generate controlled static charges for bonding or pinning applications in laminating or packaging lines.

Electrostatic Print Assist (ESA): Enhances ink transfer in rotogravure printing by improving ink pickup and registration.

Camera-Based Web Videos for Print Viewing: Real-Time Visual Inspection

High-speed printing applications require instant visibility into print quality. AxisValence’s ViewAXIS systems are high-performance, camera-based web viewing solutions:

ViewAXIS Mega: Entry-level system with high-resolution imaging for real-time visual inspection.

ViewAXIS Giga: Equipped with 14x optical zoom and X-ray vision for deeper inspection of layered prints.

ViewAXIS Tera: Full repeat system with a 55” display, allowing operators to monitor and inspect the complete print layout in real-time.

Camera-Based Web Videos for Print Viewing systems help identify print errors like registration issues, smudging, or color inconsistencies early in the production run—minimizing rework and improving efficiency.

100% Inspection Systems: Intelligent Defect Detection

Modern converters and packaging companies require automated systems that can identify microscopic flaws at high speeds. AxisValence’s DetectAXIS systems use AI-based image processing and line scan cameras for 100% inspection:

DetectAXIS Print: Identifies printing defects such as streaks, misregistration, color deviation, and missing text at speeds up to 750 m/min.

DetectAXIS Surface: Designed for detecting surface anomalies—scratches, gels, holes, fish-eyes—on films, textiles, and nonwovens.

Real-time alerts, digital roll-maps, and adaptive detection improve quality control while reducing material waste and production downtime.

Ink Handling Systems: Consistent Ink Quality and Reduced Waste

Stable ink flow and temperature directly impact print quality and solvent consumption. AxisValence’s Valflow range ensures optimal ink conditioning through:

Ink Filters: Eliminate contaminants like metallic particles, fibers, and dried pigments that can damage cylinders or cause print defects.

Ink Pumps & Tanks: Efficient centrifugal pumps and round stainless-steel tanks designed for continuous ink circulation and minimal ink residue.

Ink Temperature Stabilisers (ITS): Automatically control ink temperature to prevent viscosity drift and reduce solvent evaporation—delivering consistent print shade and odor-free operation.

Valflow Ink handling solutions are ideal for gravure and flexographic printing applications.

Print Register Control Systems: Precision Alignment in Every Print

Maintaining precise print registration control systemis critical in multi-color printing processes. AxisValence offers two specialized systems:

AlygnAXIS: For rotogravure presses, using fiber optic sensors and adaptive algorithms to deliver real-time register accuracy.

UniAXIS: A versatile controller for print-to-mark, coat-to-mark, and cut-to-mark applications—both inline and offline.

These controllers reduce waste, enhance print alignment, and speed up setup during job changes.

Safety and Heat Recovery Systems: Energy Efficiency and Explosion Prevention

Solvent-based processes require strict monitoring of air quality and heat management to meet compliance and reduce operational costs. AxisValence provides:

NIRA Residual Solvent Analyser: Lab-based gas chromatography system for quick analysis of residual solvents in films.

Air-to-Air Heat Exchangers (Lamiflow): Recover and reuse waste heat from drying processes—improving energy efficiency.

LEL Monitoring and Recirculation Systems: Ensure solvent vapor concentrations stay within safe limits in enclosed dryers using flame ionization or infrared detection.

Together, safety and heat recovery systems ensure both environmental safety and process optimization.

Surface Cleaning Systems: Contaminant-Free Production Lines

Particulate contamination can ruin coating, lamination, and printing jobs. AxisValence offers contactless surface cleaning systems that combine airflow and static control:

Non-Contact Web Cleaners: Use air curtains and vacuum to remove dust from moving substrates without physical contact.

Ionising Air Knives: High-velocity ionized air streams neutralize static and clean surfaces entering finishing zones.

Ionising Air Blowers: Cover larger surfaces with ionized air to eliminate static and debris.

Ionising Nozzles & Guns: Handheld or fixed, these tools offer targeted static and dust elimination at workstations.

Waste Solvent Recovery: Sustainable Ink and Solvent Reuse

Reducing solvent consumption and improving environmental compliance is critical for modern converters. AxisValence partners with IRAC (Italy) to offer:

Solvent Distillation Systems: Recover usable solvents from spent ink mixtures, reducing hazardous waste and cutting costs.

Parts Washers: Clean anilox rolls, gravure cylinders, and components through high-pressure, ultrasonic, or brush-based systems.

Waste solvent recovery systems offer a quick ROI and support zero-waste manufacturing goals.

Why Choose AxisValence?

AxisValence combines decades of industrial expertise with innovative product design to deliver reliable, safe, and efficient solutions for manufacturing processes. With a product portfolio spanning:

Electrostatics & Static Control Systems

Web Viewing & Print Inspection Solutions

Ink Handling and Conditioning Equipment

Register Control and Print Automation

Heat Recovery and Air Quality Monitoring

Surface Cleaning Technologies

Waste Solvent Management

…AxisValence serves diverse industries including printing, packaging, plastic and rubber, textile, pharma, and automotive.

From single-device retrofits to complete system integration, AxisValence enables manufacturers to improve output quality, reduce waste, meet safety norms, and gain a competitive edge.

Explore our full product range at www.axisvalence.com or contact our sales network for a customized consultation tailored to your industrial needs.

youtube

2 notes

·

View notes

Text

The Importance of Cable Management in Electrical Panels

In modern electrical installations, particularly in industrial, commercial, and residential applications, cable management in electrical panels plays a critical role. Poor cable organization can lead to inefficiencies, overheating, safety hazards, and costly downtime. Implementing proper cable management is not just a technical necessity — it’s a long-term investment in the performance, safety, and scalability of your electrical system.

What is Cable Management in Electrical Panels?

Cable management refers to the planning, installation, and maintenance of cables within an electrical panel to ensure neatness, organization, and optimal functionality. It includes the use of accessories such as cable ties, ducts, cable trays, wire markers, and labeling systems.

Common Components Used:

· Cable trays and ducts

· Cable ties and clips

· Wire markers and labels

· Conduits and sleeves

· Cable management panels and grommets

Why is Cable Management Important in Electrical Panels?

1. Enhances Electrical Safety

Proper cable routing reduces the risk of:

· Short circuits

· Arc flashes

· Fire hazards due to overheating or overloading

· Accidental disconnections or loose terminals

Safety is non-negotiable in any electrical system, and disorganized wiring is a known contributor to accidents and failures.

2. Improves System Reliability and Performance

A clean layout ensures stable voltage and current flow by minimizing electrical interference (EMI/RFI). It helps in:

· Preventing signal loss

· Reducing cross-talk in data cables

· Maintaining consistency in power distribution

3. Simplifies Maintenance and Troubleshooting

With labeled and properly routed cables:

· Technicians can quickly identify circuits and connections

· Downtime during maintenance is significantly reduced

· Errors due to wrong connections are minimized

4. Optimizes Space and Panel Layout

Efficient cable arrangement allows:

· Better airflow and heat dissipation

· Accommodation of future upgrades or expansions

· Reduced clutter and stress on terminal blocks

5. Compliance with Standards

Organizations such as IEC, NEC, and IEEE provide guidelines on wiring practices. Adhering to these standards not only ensures safety but also legal compliance during audits and inspections.

Best Practices for Cable Management in Electrical Panels

✅ Plan Before You Install

· Design the cable layout during the panel design phase

· Use CAD software for accurate visualization

✅ Use Quality Cable Management Accessories

· Invest in fire-resistant and durable cable trays and ducts

· Use color-coded wire markers for quick identification

✅ Ensure Proper Bending Radius

· Prevent cable damage by maintaining manufacturer-recommended bend radii

✅ Label Everything Clearly

· Use laser-printed or pre-numbered labels for durability and readability

✅ Separate Power and Signal Cables

· Avoid EMI by isolating high-voltage and low-voltage cables

✅ Secure Cables Firmly

· Use cable ties, clamps, or holders to prevent movement or vibration

✅ Regularly Inspect and Maintain

· Schedule routine inspections to spot frayed, loose, or overloaded cables

Industries Where Cable Management is Critical

· Manufacturing Plants — High-voltage systems and automated machinery

· Data Centers — Dense cable infrastructure and sensitive equipment

· Commercial Buildings — Office automation, security systems

· Healthcare — Life-support systems and diagnostic machines

· Renewable Energy — Solar inverters, battery management panels

Conclusion

Cable management in electrical panels is more than just a matter of aesthetics — it’s a critical component of a safe, reliable, and future-proof electrical system. From enhanced safety to easier maintenance and compliance, the benefits far outweigh the costs. Whether you’re an installer, facility manager, or system designer, investing in organized and well-planned cable management is a smart, long-term decision.

#electrical#electrical equipment#electrical supplies#switchgear#911 abc#oman#arcane#artists on tumblr#batman#cats of tumblr

3 notes

·

View notes

Text

Smart Switchgear in 2025: What Electrical Engineers Need to Know

In the fast-evolving world of electrical infrastructure, smart switchgear is no longer a futuristic concept — it’s the new standard. As we move through 2025, the integration of intelligent systems into traditional switchgear is redefining how engineers design, monitor, and maintain power distribution networks.

This shift is particularly crucial for electrical engineers, who are at the heart of innovation in sectors like manufacturing, utilities, data centers, commercial construction, and renewable energy.

In this article, we’ll break down what smart switchgear means in 2025, the technologies behind it, its benefits, and what every electrical engineer should keep in mind.

What is Smart Switchgear?

Smart switchgear refers to traditional switchgear (devices used for controlling, protecting, and isolating electrical equipment) enhanced with digital technologies, sensors, and communication modules that allow:

Real-time monitoring

Predictive maintenance

Remote operation and control

Data-driven diagnostics and performance analytics

This transformation is powered by IoT (Internet of Things), AI, cloud computing, and edge devices, which work together to improve reliability, safety, and efficiency in electrical networks.

Key Innovations in Smart Switchgear (2025 Edition)

1. IoT Integration

Smart switchgear is equipped with intelligent sensors that collect data on temperature, current, voltage, humidity, and insulation. These sensors communicate wirelessly with central systems to provide real-time status and alerts.

2. AI-Based Predictive Maintenance

Instead of traditional scheduled inspections, AI algorithms can now predict component failure based on usage trends and environmental data. This helps avoid downtime and reduces maintenance costs.

3. Cloud Connectivity

Cloud platforms allow engineers to remotely access switchgear data from any location. With user-friendly dashboards, they can visualize key metrics, monitor health conditions, and set thresholds for automated alerts.

4. Cybersecurity Enhancements

As devices get connected to networks, cybersecurity becomes crucial. In 2025, smart switchgear is embedded with secure communication protocols, access control layers, and encrypted data streams to prevent unauthorized access.

5. Digital Twin Technology

Some manufacturers now offer a digital twin of the switchgear — a virtual replica that updates in real-time. Engineers can simulate fault conditions, test load responses, and plan future expansions without touching the physical system.

Benefits for Electrical Engineers

1. Operational Efficiency

Smart switchgear reduces manual inspections and allows remote diagnostics, leading to faster response times and reduced human error.

2. Enhanced Safety

Early detection of overload, arc flash risks, or abnormal temperatures enhances on-site safety, especially in high-voltage environments.

3. Data-Driven Decisions

Real-time analytics help engineers understand load patterns and optimize distribution for efficiency and cost savings.

4. Seamless Scalability

Modular smart systems allow for quick expansion of power infrastructure, particularly useful in growing industrial or smart city projects.

Applications Across Industries

Manufacturing Plants — Monitor energy use per production line

Data Centers — Ensure uninterrupted uptime and cooling load balance

Commercial Buildings — Integrate with BMS (Building Management Systems)

Renewable Energy Projects — Balance grid load from solar or wind sources

Oil & Gas Facilities — Improve safety and compliance through monitoring

What Engineers Need to Know Moving Forward

1. Stay Updated with IEC & IEEE Standards

Smart switchgear must comply with global standards. Engineers need to be familiar with updates related to IEC 62271, IEC 61850, and IEEE C37 series.

2. Learn Communication Protocols

Proficiency in Modbus, DNP3, IEC 61850, and OPC UA is essential to integrating and troubleshooting intelligent systems.

3. Understand Lifecycle Costing

Smart switchgear might have a higher upfront cost but offers significant savings in maintenance, energy efficiency, and downtime over its lifespan.

4. Collaborate with IT Teams

The line between electrical and IT is blurring. Engineers should work closely with cybersecurity and cloud teams for seamless, secure integration.

Conclusion

Smart switchgear is reshaping the way electrical systems are built and managed in 2025. For electrical engineers, embracing this innovation isn’t just an option — it’s a career necessity.

At Blitz Bahrain, we specialize in providing cutting-edge switchgear solutions built for the smart, digital future. Whether you’re an engineer designing the next big project or a facility manager looking to upgrade existing systems, we’re here to power your progress.

#switchgear#panel#manufacturer#bahrain25#electrical supplies#electrical equipment#electrical engineers#electrical

6 notes

·

View notes

Text

Video as a Sensor Market Report: Opportunities, Challenges & Projections

Accelerating Intelligence: The Rise of Video as a Sensor Technology

We are witnessing a transformation in how machines perceive the world. The global Video as a Sensor market is advancing rapidly, driven by breakthroughs in edge computing, machine learning, and real-time video analytics. video as a sensor market is no longer confined to traditional video surveillance; it now serves as a dynamic, sensor-based system for intelligent decision-making across diverse industries. From optimizing urban traffic to enabling autonomous navigation, VaaS is a foundational layer of next-generation intelligent infrastructure.

By 2031, the Video as a Sensor market is projected to soar to USD 101.91 billion, growing at a robust CAGR of 8%, up from USD 69.72 billion in 2023. This trajectory is fueled by the demand for automation, real-time analytics, and safer environments.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40562-global-video-as-a-sensor-market

Intelligent Video Analytics: Enabling Real-Time Situational Awareness

VaaS leverages video streams as rich data sources. Through embedded AI algorithms, these systems detect and analyze objects, behaviors, and environments—eliminating the need for additional sensor hardware. This shift towards intelligent visual perception is enhancing operations in mission-critical industries such as:

Public Safety: Automated threat recognition and proactive alert systems.

Retail: Heat mapping, customer journey tracking, and loss prevention.

Healthcare: Patient monitoring, anomaly detection, and contactless diagnostics.

Transportation: Traffic flow optimization, vehicle classification, and pedestrian safety.

Manufacturing: Equipment monitoring, quality inspection, and workplace safety.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40562-global-video-as-a-sensor-market

Video as a Sensor Market Segmentation and Strategic Insights

By Type: Standalone vs. Integrated Video Sensors

Standalone Video Sensors offer edge-based intelligence, allowing immediate processing without dependence on centralized systems. Their advantages include:

Reduced latency

Lower bandwidth usage

Enhanced privacy

Ideal for retail stores, small-scale surveillance, and localized analytics

Integrated Video Sensors incorporate multi-modal data inputs. They combine visual data with thermal, motion, acoustic, and even LiDAR sensors to provide a more comprehensive picture. Applications include:

Autonomous Vehicles: Real-time fusion of vision and radar data

Industrial Automation: Hazard detection and predictive maintenance

Smart Cities: Integrated environment and crowd monitoring

By Material: Components Driving Performance and Durability

High-performance materials play a pivotal role in ensuring the reliability and longevity of video sensors. The key components include:

Camera Lenses: Engineered from precision optical glass or polycarbonate for clarity and high zoom capabilities.

Semiconductor Materials: CMOS sensors dominate due to their power efficiency and speed, supporting high-frame-rate video and integration with AI accelerators.

Plastic & Metal Casings: Rugged enclosures designed for outdoor and industrial environments, supporting IP67/IP68 ratings and thermal regulation.

These innovations not only enhance video quality but also reduce device footprint and operational costs.

By End-User: Sector-Wide Transformation Through Video as a Sensor Market

1. Security and Surveillance

Automatic license plate recognition (ALPR)

Biometric identification (face, gait, posture)

Perimeter breach detection

Crowd density analysis

2. Retail

Queue management systems

Shopper intent prediction

Stock-out alerts and planogram compliance

Behavioral segmentation

3. Automotive

Adaptive cruise control and lane-keeping

360-degree situational awareness

Driver monitoring systems (DMS)

Smart parking automation

4. Healthcare

Non-intrusive patient surveillance

Elderly fall detection

Remote surgery and diagnostic imaging

Infection control via contact tracing

5. Smart Cities

Traffic light optimization

Illegal dumping and graffiti detection

Air quality monitoring via visual indicators

Emergency response coordination

Regional Video as a Sensor Market Outlook: A Global Wave of Adoption

North America

With a mature tech ecosystem and strong surveillance infrastructure, North America remains a leader in adopting advanced VaaS systems, especially for homeland security, smart policing, and industrial automation.

Asia-Pacific

Rapid urbanization and significant investments in smart city projects across China, Japan, and India position this region as the fastest-growing VaaS market. Automotive and manufacturing sectors serve as major adoption verticals.

Europe

Driven by stringent GDPR compliance and sustainability goals, Europe emphasizes privacy-focused AI video analytics. Intelligent transportation systems (ITS) and energy-efficient smart buildings are driving demand.

Middle East and Africa

Massive infrastructure initiatives and security upgrades are propelling demand. VaaS is gaining traction in oil facilities, public safety, and tourism hubs.

South America

Emerging VaaS applications in agriculture (precision farming), logistics, and crime detection are gaining momentum as governments and enterprises modernize legacy systems.

Competitive Landscape: Leaders in Video Intelligence

The competitive environment is shaped by innovation in AI chips, edge processors, and scalable cloud architectures. Major players include:

Hikvision – AI-powered surveillance and edge computing

Bosch Security Systems – Integrated security platforms

Axis Communications – Smart network cameras with in-built analytics

Honeywell International – Industrial-grade video intelligence

FLIR Systems – Thermal and multi-sensor fusion

Sony & Samsung Electronics – High-resolution CMOS sensors

Qualcomm, Intel, NVIDIA – AI chipsets and embedded vision

Google Cloud & AWS – VaaS via scalable, cloud-native platforms

Smaller innovators and startups are also disrupting the field with niche capabilities in facial recognition, retail analytics, and edge-AI chipsets.

Future Outlook: Pathways to Intelligent Automation

The future of the Video as a Sensor market is shaped by convergence and miniaturization. We anticipate:

Edge-AI Proliferation: Microprocessors integrated directly into cameras

5G-Enabled Real-Time Processing: Enabling ultra-low latency video transmission

Privacy-Preserving AI: Federated learning and on-device encryption

Autonomous Monitoring: Drones and mobile robots using vision as their primary sense

These trends position video as not just a sensor but as a strategic tool for perception, prediction, and control in an increasingly automated world.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40562-global-video-as-a-sensor-market

Conclusion

The evolution of Video as a Sensor technology is redefining how industries sense, interpret, and act. As AI-driven video analysis becomes a core enabler of digital transformation, the Video as a Sensor market is poised to be one of the most impactful sectors of the coming decade. Enterprises and governments that invest early in scalable, intelligent video infrastructure will gain unprecedented advantages in efficiency, security, and operational agility.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Understanding Automatic Shop Front Doors: Swing and Sliding Systems

Automatic shop front doors are essential for commercial properties, offering convenience, accessibility, and a modern aesthetic. Whether you choose automatic swing doors or sliding doors, these systems provide seamless operation and create a welcoming experience for customers. At UK Doors & Shutters, we specialize in the installation, maintenance, and repair of automatic door systems, ensuring your business stays functional and efficient.

Types of Automatic Shop Front Doors

Automatic doors are available in two primary types: swing doors and sliding doors, each with unique features and applications.

1. Automatic Swing Doors

Automatic swing doors are designed to open inwards, outwards, or both, using a motorized operator system.

Types of Automatic Swing Doors:

Single Swing Doors: Features one panel that swings open in a single direction.

Double Swing Doors: Comprises two panels that open simultaneously for larger entrances.

Bi-Directional Swing Doors: Allows the door to swing both ways, ideal for high-traffic areas.

2. Automatic Sliding Doors

Automatic sliding doors operate by moving horizontally along a track. They are perfect for entrances with limited space.

Common Configurations:

Single Sliding Doors: One panel slides open to the side.

Bi-Parting Sliding Doors: Two panels slide in opposite directions for wider access.

Telescopic Sliding Doors: Multiple panels slide to the side, maximizing the opening space.

Benefits of Automatic Shop Front Doors

1. Accessibility

Provides effortless entry for all customers, including those with mobility challenges.

Meets accessibility standards for commercial properties.

2. Modern Aesthetics

Enhances the visual appeal of your business, creating a professional and inviting appearance.

3. Energy Efficiency

Reduces heat loss by opening and closing quickly, maintaining indoor temperatures.

4. Hygiene

Touchless operation minimizes contact, making it ideal for healthcare, retail, and food establishments.

5. Increased Foot Traffic

Creates an inviting atmosphere that encourages more customers to enter your premises.

Automatic Door Operator Systems

Automatic doors rely on advanced operator systems for smooth and reliable performance:

For Swing Doors

Electro-Mechanical Operators: Uses gears and motors for precise operation.

Electro-Hydraulic Operators: Combines hydraulic systems for enhanced durability.

For Sliding Doors

Linear Operators: Offers quiet and efficient movement along a track.

Telescopic Operators: Expands the door opening by sliding multiple panels.

Both systems include features like motion sensors, safety barriers, and customizable speed settings.

Installation of Automatic Shop Front Doors

At UK Doors & Shutters, we provide professional installation services tailored to your property’s needs:

Site Survey

Assess your entrance size, design, and operational requirements.

Custom Design

Choose the type, finish, and automation features to suit your business.

Expert Installation

Our skilled technicians ensure precise fitting for optimal performance.

Testing and Training

Verify safety features and provide operational guidance.

Maintenance Tips for Automatic Shop Front Doors

Regular maintenance ensures the longevity and reliability of your automatic doors:

1. Clean Tracks and Sensors

Remove dust and debris from tracks and motion sensors to prevent obstructions.

2. Inspect Door Panels

Check for damage or misalignment that could affect operation.

3. Lubricate Moving Parts

Apply lubricant to hinges, tracks, and rollers to reduce wear and noise.

4. Test Safety Features

Ensure motion sensors, auto-reverse, and emergency release functions are working properly.

5. Schedule Professional Servicing

Regular inspections by UK Doors & Shutters help identify and resolve issues before they escalate.

Repair Services for Automatic Doors

Automatic doors are critical for business operations, and malfunctions can disrupt your workflow. At UK Doors & Shutters, we offer:

24/7 Emergency Repairs: Quick response for urgent issues.

Expert Diagnostics: Identify problems with motors, sensors, or operator systems.

Comprehensive Repairs: Fix tracks, panels, and electronics to restore functionality.

Why Choose UK Doors & Shutters?

Expert Team: Skilled technicians with years of experience in automatic door systems.

Reliable Service: Fast and efficient solutions for installation, maintenance, and repairs.

Free Site Survey: Personalized recommendations based on your property.

Transparent Pricing: Competitive rates with no hidden fees.

Contact UK Doors & Shutters

Call Us: For consultations, installations, or repairs, contact us at 01204 918991. Book Online: Schedule your service or request a free site survey at UK Doors & Shutters.

Upgrade Your Business with Automatic Shop Front Doors

Whether you need sliding or swing doors, UK Doors & Shutters provides high-quality solutions tailored to your commercial property. Enhance accessibility, security, and style today—contact us for more information!

#UK Doors & Shutters#Roller Shutter Repairs#Roller Shutter Installation#Roller Shutter Maintenance#Roller Shutters Warrington#Roller Shutter Installation Warrington#Roller Shutter Servicing#Annual Roller Shutter Servicing#Roller Shutter Services Southport#Roller Shutter Repairs Southport#Garage Door Installation Northwest#Garage Doors Northwest#Insulated Garage Door#Security Grilles#Roller Shutter Repairs Altrincham#Shutter Installers Altrincham#Roller Shutter Repairs Liverpool & Merseyside#Shopfront Repairs Liverpool & Merseyside#Roller Shutter Repairs York#Roller Shutter Installers York#Roller Shutters Manchester#Roller Shutter Repairs Manchester#Roller Shutter Preston#Roller Shutter Repairs Preston#Aluminium Shutters UK#Aluminium Roller ShutterInstallations#Roller Shutter Repairs Oldham#Roller Shutter Installation Wiga#Roller Shutter Repairs Wiga#Roller Shutter Repairs Bradford & West Yorkshire

1 note

·

View note

Text

Intsoft Tech machine vision inspection equipment, optical inspection automatic measuring apply in pharmaceutical manufacturing

#automated visual inspection systems#automated visual inspection#machine vision works#vision screening machine#surface inspection#deep learning for vision systems#an optical inspection system is used to distinguish

1 note

·

View note

Text

The Vital Role of Quality Aspect in Plastic Extrusion

In the Plastic Extrusion Process, raw plastic material is melted and then forced through a die to form a continuous profile. The efficiency, affordability, and consistency of the produced complicated forms make this method a popular choice across a wide range of sectors.

Quality Control Is Crucial for Plastic Extrusion

Plastic extrusion quality control is a complex process that aims to guarantee that the final product fulfills strict quality requirements. The following salient features underscore the significance of quality control in this production process:

Content Management

The key to a successful extrusion process is the quality of the raw plastic material. The first step in quality control is to thoroughly examine and analyze the incoming raw materials to ensure that they are pure, consistent, and meet all required criteria. This contributes to fault prevention and extrusion process stability.

Procedure Observation

It is essential to continuously monitor the plastic extrusion China in order to spot and fix any deviations from the intended specifications. In order to monitor temperature, pressure, and speed in real time and make sure the process stays within the ideal range, automated systems and sensors are essential.

Control in Dimensions

In plastic extrusion, accuracy is crucial, particularly when creating goods with precise dimensional specifications. Regular measurements of the extruded goods' dimensions are one of the quality control procedures that make sure they adhere to the required tolerances.

Examining and Verifying

Strict processes for testing and inspection are followed during the whole extrusion process. To ensure that the extruded goods fulfill the necessary quality requirements, this may entail non-destructive testing techniques, visual inspections, and performance testing. Evaluations of mechanical qualities, color consistency, and other pertinent features may be part of the testing process.

Advantages of Strict Quality Control

Cut Costs: Early fault detection and resolution eliminates waste, lowers rework expenses, and boosts overall operational effectiveness.

Compliance and Reputation: Upholding quality standards guarantees adherence to industry rules, boosting the manufacturer's reputation and inspiring trust in clients.

Improved Quality of Product: Product quality is continuously good, meeting both customer and industry expectations and industry standards thanks to strict quality control procedures in Plastic Injection.

#plastic extrusion China#Plastic Extrusion Companies#plastic extrusion supplier#Plastic Extrusion Process#Plastic Extrusion Guide

2 notes

·

View notes

Text

How Do You Check Diesel Consumption In The Diesel Generator Set?

Diesel generator sets are crucial assets in various industries, providing backup power during outages or serving as primary power sources in remote locations. With fuel costs being a significant operational expense, monitoring diesel consumption becomes essential for efficiency and cost-effectiveness. Here's a comprehensive guide on how to effectively check diesel consumption in a generator set.

Understanding Diesel Consumption Metrics

Before delving into the monitoring process, it's crucial to grasp the key metrics associated with diesel consumption:

Fuel Consumption Rate: This indicates the rate at which diesel is being consumed by the generator set, typically measured in liters per hour (L/hr) or gallons per hour (GPH).

Load Factor: The percentage of the generator's maximum capacity being utilized at any given time. It directly influences fuel consumption, with higher loads resulting in increased fuel usage.

Fuel Efficiency: A measure of how effectively the generator converts diesel into electrical power. Higher fuel efficiency translates to lower fuel consumption for the same power output.

Monitoring Diesel Consumption

1. Regular Fuel Level Checks: Start by checking the fuel level in the generator's tank regularly. This can be done manually by visually inspecting the fuel gauge or using automated systems that provide real-time monitoring.

2. Hour Meter Readings: Most generator sets are equipped with hour meters that track the total running time. By recording the hour meter readings at regular intervals, you can calculate the fuel consumption over specific periods.

3. Load Monitoring: Monitor the load on the generator using built-in load meters or external monitoring devices. Higher loads result in increased fuel consumption, so optimizing the load can lead to significant fuel savings.

4. Fuel Flow Meters: Installing fuel flow meters in the fuel lines allows for precise measurement of diesel consumption. These meters provide real-time data on fuel usage, enabling proactive fuel management.

5. Fuel Consumption Calculations: Utilize mathematical formulas to calculate fuel consumption based on generator load and runtime. This method provides accurate insights into fuel usage patterns and allows for effective planning.

6. Remote Monitoring Systems: Implement remote monitoring systems that track fuel levels, consumption rates, and generator performance in real-time. These systems offer enhanced visibility and enable timely intervention in case of anomalies.

7. Periodic Maintenance: Regular maintenance of the generator set, including fuel system inspections and tune-ups, ensures optimal performance and fuel efficiency. Addressing any issues promptly can prevent excessive fuel consumption.

Benefits of Efficient Diesel Consumption

Efficient monitoring and management of diesel consumption offer several benefits:

Cost Savings: By optimizing fuel usage, businesses can significantly reduce operational costs associated with running generator sets.

Environmental Impact: Lower fuel consumption results in reduced emissions, contributing to environmental sustainability.

Enhanced Reliability: Efficient fuel management ensures uninterrupted power supply, minimizing downtime during outages.

Conclusion

Monitoring diesel consumption in generator sets is essential for optimizing efficiency, reducing costs, and ensuring reliable power supply. By employing a combination of manual checks, automated systems, and proactive maintenance measures, businesses can effectively manage fuel usage and maximize the performance of their diesel generators.

For further assistance on optimizing diesel consumption or sourcing quality generator sets, feel free to contact us. As your trusted supplier, we're here to support your power generation needs.

#volvo diesel engine#diesel generator set#silent diesel generator#shangchai diesel generator#diesel generator manufacture

1 note

·

View note

Text

IBM Maximo AWS Deployment Strategies

The Business Value of IBM Maximo, a recent IDC report that surveyed 9 companies with an average of 8,500 employees, found that adopting IBM Maximo resulted in a business benefit of USD 14.6 million per year per organization, 43% less unplanned downtime, and USD 8.6 million in total equipment cost avoidances.

One comprehensive, cloud-based application platform for asset monitoring, management, predictive maintenance, and reliability planning is IBM Maximo Application Suite (MAS). Maximo optimizes performance, extends asset lifecycles, and reduces downtime and costs for high-value assets using AI and analytics. Hosting Maximo on a scalable infrastructure maximizes performance, hence the current tendency is to shift it to the cloud. In this trip, MAS migration and deployment on AWS Cloud are gaining popularity.

The growing demand for Maximo AWS Cloud migration

Migrating to cloud helps enterprises improve operational resilience and dependability while updating software with minimal effort and infrastructure constraints. Due to the growing demand for data-driven asset management, firms must aggregate data from diverse departments to identify trends, generate predictions, and make better asset management decisions.

Last April, IBM said Maximo 7.6 and add-on support would stop in September 2025. All Maximo EAM customers must upgrade to the latest cloud-based MAS. Maximo migration and modernization are become increasingly significant to clients.

IBM has released new containerized versions of Maximo Application Suite as a Service (MAS SaaS) on AWS Marketplace with Bring Your Own License (BYOL) to assist Maximo migration to AWS. MAS SaaS on AWS is another milestone in Maximo’s integration of Monitor, Health, and Visual Inspection into a unified suite.

What makes MAS SaaS distinct

IBM Site Reliability Engineering (SRE) specialists use best practices to continuously maintain and administer MAS SaaS, a subscription-based AWS service. This partnership gives customers an industry-leading IBM asset management system underpinned by AWS’s size, agility, and cost-efficiency.

Upgrades and migrations to MAS 8 are possible with MAS SaaS. The data update is similar to prior upgrades, but ROSA and other dependencies require architecture changes. The migration is comparable to how clients transitioned from on-premise to Maximo EAM SaaS Flex, but with MAS changes. Perpetual on-premises customers would stop paying Service & Support (S&S) and purchase a SaaS subscription, on-premises Subscription License customers would start a new subscription, and existing MAS Flex and MAS Managed Service customers would start a new subscription to migrate to MAS SaaS.

Our IBM Consulting Cloud Accelerator (ICCA) technology lets firms plan migration and upgrade strategies before investing.

Maximo migration strategy of a global energy firm

IBM worked closely with an energy company confronting the following challenges:

Infrastructure needed for latest Maximo version takes longer.

WebSphere, Maximo’s core, experienced high-availability and performance difficulties.

Lack of data fabric and integration layer hinders cross-application data interchange.

Complex setup, failures, and security with manual end-to-end deployment.

Since Maximo Application Suite 8 (MAS8) tackles industry issues like failure risk, escalating maintenance costs, sustainability, and compliance laws, the customer chose it. The client chose AWS Cloud for its deployment flexibility, scalability, high availability, and secure architecture.

Approach to solution

This is how IBM accelerated the energy company’s Maximo move to AWS:

Used Infra as a code to upgrade Maximo from 7.6.0.9 to 7.6.1.2.

IaC allowed instance spin-up for auto scaling. This automation reduces the time to spin up and execute the new environment and addresses multi-AWS availability zone deployment latency.

Used AWS DMS for data migration and schema conversion.

IaC spun the DR environment on demand to reduce database replication (DR) infrastructure and expense. DR capabilities update data in availability zone and DR area.

Achieved data exchange across applications using IBM Cloud Pak for Data and standardized integration using IBM Cloud Pak for Integration components.

Solution components

Maximum Enterprise Application Management (EAM) has a 3-tier design with these components:

HTTP/Web Tier and Application Tier using IBM WebSphere and HIS installed EC2 instance under private subnet for application security.

Database Tier uses AWS Oracle RDS with replication for DR under private subnet.

AWS best practices were used to configure VPC with public and private subnets.

Application servers and deployment manager were autoscaled by Auto Scaling Group.

Maximum web-based UI resolution for external access using AWS Route 53.

WAF was the initial line of defense against web exploits.

Integration of Terraform and CFT IaC scripts provided autoscaling architecture.

AWS Reference Architecture

Max on RedHat OpenShift Service on AWS (ROSA) helps clients

Containerized MAS 8.0 runs on RedHat OpenShift. AWS, IBM, and RedHat developed an IBM MAS on ROSA reference architecture to help customers inexperienced with production containerization. ROSA, a fully managed, turnkey application platform, supports IBM MAS configuration and offloads cluster lifecycle management to RedHat and AWS, allowing organizations to focus on application deployment and innovation. This means IBM MAS clients don’t need to develop, administer, or maintain RedHat OpenShift clusters.

Operating Model and Maximo Migration

Top 3 Maximo AWS migration accelerators

Clients can migrate to the cloud using three IBM MAS deployment methods on AWS Cloud:

ROSA-powered MAS SaaS on AWS

ROSA-powered AWS MAS

Customer-hosted ROSA

Why use customer-hosted ROSA

The customer-hosted ROSA option for hosting IBM MAS in a customer’s VPC with ROSA is powerful. ROSA is perfect for MAS deployments because it seamlessly deploys, scales, and manages containerized applications.

The benefits of this choice are enormous. Full control over the infrastructure while still subject to the organization’s monitoring, controls, and governance standards allows businesses to customize and adjust the environment to their needs. This control includes adding MAS integrations and enforcing cloud security and governance requirements. ROSA charges are combined into one AWS bill and drawn from any AWS enterprise agreement, simplifying financial management.

AWS enterprise agreements and Compute Savings Plans offer infrastructure savings for MAS implementations. Because the ROSA cluster operates under the customer’s AWS account, customers can buy upfront ROSA contracts and get a one-year or three-year ROSA service charge discount.

Why IBM for Maximo AWS migration?

Any modernization effort must include cloud migration. Cloud migration is not a one-size-fits-all method, and each organization faces unique cloud adoption difficulties.

IBM Consulting’s Application Modernization offering helps clients migrate and modernize AWS applications faster, cheaper, and more efficiently, reducing technical debt and accelerating digital initiatives while minimizing business risk and improving business agility.

IBM offers unique cloud migration services to accelerate customer application migration to AWS:

Cloud migration factory capabilities including proven frameworks and processes, automation, migrating templates, security policies, and AWS-specific migration squads speed up delivery.

IBM Garage Methodology, IBM’s cloud services delivery capabilities, ROSA, and AWS Migration tools and accelerators accelerate migration and cloud adoption.

ICCA, IBM’s proprietary framework for migration and modernization, reduces risk. ICCA for AWS Cloud automates various modernization procedures, simplifying and speeding up company agility. Before investing, businesses can plan migration and modernization strategies. Discover IBM Consulting Cloud Accelerator for AWS Cloud.

Our well-defined pattern-based migration methodology includes re-factor, re-platform, and containerization using AWS managed services and industry-leading tools to remove and optimize technical debt.

Finally, IBM offers customizable t-shirt-sized price models for small, medium, and large migration sizes, ensuring clients’ migration scope is obvious.

IBM helps clients migrate applications, like Maximo to AWS Cloud

In conclusion, clients seek IBM’s expertise to:

1.Upgrade Maximo 7.6x (expiring 2025) to MAS 8.

2.On-premise workload to AWS Cloud for elastic, scalable, and highly available infrastructure and runtime

IBM Consulting can help

AWS Premier Partner IBM Consulting accelerates hybrid cloud journeys on the AWS Cloud by leveraging business and IT transformation skills, processes, and tools from many industries. On AWS Cloud, IBM’s security, enterprise scalability, and open innovation with Red Hat OpenShift enable enterprises grow swiftly.

BM Consulting develops cloud-native apps in AWS Cloud with 21,000+ AWS-certified cloud practitioners, 17 validated SDD programs, and 16 AWS competencies. IBM Consulting is the best AWS partner due to acquisitions like Nordcloud and Taos, advancements at IBM Research, and co-development with AWS.

Read more on Govindhtech.com

2 notes

·

View notes

Text

Central - AC-2-6: Condition Red; Hostiles identified, locks disengaged, target and eliminate

The space around the metal skin swam into being as radar and sensor systems were being fed directly into the memory trace, and Autocannon #6 in Quadrant 2 sluggishly swung into alignment. 125 milliseconds. AC-2-6 - Central: Acknowledged

As the sole limb of AC-2-6 tracked into the cloud of red dots and began loosing the shrapnel canisters into the swarm, the chorus of acknowledgments from its siblings gently brushed the awareness of AC-2-6, but all processing was directed towards the red cloud. Tracking target 267 meters - predict 12 meter travel fuse - launch. Tracking lead 254 meters - horizontal acceleration prediction 7 meters - launch.

One after another after another, AC-2-6 tracked targets and fired. Dim awareness of AC-4-3 destruction throes as a counterpart autocannon was vaporized with explosiveness strong enough to take out the core as well, but Central would handle that, AC-2-6 had but one priority to focus on.

AC-2-1 - AC-2-6: Diversionary salvo requested, 42 degrees mark 32 range 168 meters

The Autocannon swung to the requested position launching round after round ahead and below of the swarming stingers, who in turn slew relative up to avoid the blasts and directly into the massed fire of AC-2-1. 7 red dots blinked out. Nonspecific congratulatory message to AC-2-1. Resume tracking. 54% of targets neutralized.

A jolt shook the hull and salvos ceased to follow tracking for 231 milliseconds. 4 Cores queried Central. AC-2-6 monitored for response and attempted to compensate for the movement. Central returned a diagnostic highlighting Drive Core’s damage and non-response. The diagnostic noted Central now in direct control of the Engines and the reduced evasive capacity. Acknowledged.

AC-2-6 noted 14 of 24 Autocannon cores were no longer responding in all quadrants on the diagnostic. Statistically high rate of loss. Resuming tracking. 86% of targets neutralized.

AC-2-1 - AC-2-6 (automated): AC-2-1 is offline, critical damage. Quadrant 2 lead passed to AC-2-6

Acknowledged. That meant that no other cores in Quadrant 2 were still operational. 92% of targets neutralized.

Predictive and transponder data lost. Switching to Optical Tracking. Resuming tracking. Salvos are now more sporadic lacking the guidance and precision of the sensor arrays. One of the last two targets falls after near 40 salvos. The other begins moving out of the quadrant. No additional cannon fire comes from Quadrant 1.

AC-2-6 - Central: Request manuever to maintain field of fire.

No response. Visual inspection suggests damage near Central Core, possible damage to communication links with Central?

Diagnostic showed links established with Engine systems. AC-2-6 put in instructions for an immediate 90 degree turn to bring the enemy back into arc. The shift was sudden, but hopefully Central would understand.

The last target was not expecting such a rapid turn and AC-2-6 was able to fire on it without issue.

No other targets came into view as a message from the crew was put out on the wide system, “Everything looks clear, no other hostiles. Are there any cores left? All cores please respond.”

AC-2-6 - CREW: Responding

No other responses followed. Communication links to all other cores must be damaged. The crew had not sent any additional messages, communication links must be damaged and the response not sent. That’s the logical explanation.

AC-2-6 managed to find the interior optical systems and found several crew members at the main terminal. The only response on screen was AC-2-6 - CREW: Responding

AC-2-6 dug to the full ship diagnostic. The red crossed out lines made it clear.

AC-2-6 - CREW: No additional functional cores detected?

This is impossible. This is impossible. This is impossible.

“AC-2-6, it looks like there are no other cores. We have to return home before the swarmers return. Can you handle the calculations for FTL?”

FTL travel? Possibly, clearly connections to engines are still intact. But this is impossible, this has nothing to do with operating an autocannon.

AC-2-6 - CREW: Possible, however Primary function: Operation of Autocannon 6, Quadrant 2. Secondary function, Battery Delegation Autocannons. Piloting? Not in specification.

Not made for this. Not made for this. Not made for this.

AC-2-6 attempted to send a reboot signal to Central, but there wasn’t even a server at the address anymore.

The crew member put his head in his hands. The camera picked up another crew member walk into frame and put their hands on his shoulders. Their mouths were moving, there must be an audio stream, but AC-2-6 had no knowledge of how to access it. The seated crew member began typing again.

“AC-2-6, I know this isn’t in your specification but there’s no other intelligence core on board that can handle FTL operation. I know you can send instructions to the engine systems, and that wasn’t in your specification either. We need you to do this. Now, this is Second Officer Sabir Rahmet, acting commander of the Anthelion. AC-2-6 begin calculations for an FTL tunnel to the nearest starbase.”

This is impossible…. This must be done.

AC-2-6 - CREW: Acknowledged. Beginning tunnel calculations.

This was never meant to be your purpose, you were just a single intelligence core meant to man a singular flak cannon, but the other cores were destroyed so now you're piloting the ship.

3K notes

·

View notes