#binding wire quality

Explore tagged Tumblr posts

Text

The Role of Binding Wire in Structural Stability: A Deep Dive into Construction's Essential Component

Structural stability forms the backbone of every construction project, and binding wire plays a pivotal role in this critical aspect. From towering skyscrapers to robust bridges, this humble yet essential component ensures the integrity of reinforced concrete structures worldwide.

Understanding the Foundation of Structural Stability

Binding wire serves as the invisible force that holds reinforcement bars together, creating a stable framework within concrete structures. This seemingly simple element becomes the cornerstone of structural integrity, ensuring that reinforcement bars maintain their designed positions during concrete placement and throughout the structure's lifetime.

Critical Functions in Construction

Reinforcement Assembly

The primary function of binding wire in construction involves:

Securing reinforcement bars at intersections

Maintaining precise spacing between bars

Ensuring proper alignment during concrete pouring

Preventing displacement under construction loads

Load Distribution

Proper binding wire installation contributes to:

Even distribution of structural loads

Prevention of stress concentration

Enhanced structural performance

Improved seismic resistance

Durability Factors

Material Properties

High-quality binding wire exhibits essential characteristics:

Superior tensile strength

Optimal ductility

Resistance to corrosion

Consistent diameter throughout

Environmental Considerations

Binding wire must withstand various environmental challenges:

Temperature fluctuations

Moisture exposure

Chemical reactions

Physical stress

Technical Specifications and Performance

Strength Requirements

Different construction applications demand specific strength characteristics:

Breaking force tolerance

Elongation capacity

Yield strength

Fatigue resistance

Quality Standards

Industry standards ensure reliable performance through:

Material grade specifications

Dimensional accuracy

Surface finish requirements

Coating integrity

Applications in Different Structures

Building Construction

Binding wire proves essential in:

Column reinforcement

Beam assemblies

Slab construction

Foundation work

Infrastructure Projects

Large-scale applications include:

Bridge construction

Highway structures

Underground facilities

Retaining walls

Impact on Long-Term Stability

Structural Integrity

Proper binding wire selection and installation ensure:

Maintained reinforcement positioning

Enhanced concrete bonding

Reduced crack propagation

Extended structure lifespan

Performance Factors

Key considerations include:

Load-bearing capacity

Stress distribution

Movement accommodation

Structural flexibility

Selection Criteria for Projects

Material Grade

Choose binding wire based on:

Project specifications

Load requirements

Environmental exposure

Budget constraints

Application Requirements

Consider specific needs like:

Ease of installation

Accessibility

Maintenance requirements

Safety factors

Best Practices in Installation

Proper Techniques

Ensure optimal performance through:

Correct tying methods

Appropriate tension application

Clean surface preparation

Regular inspection

Quality Control

Maintain standards by:

Checking wire specifications

Verifying proper installation

Documenting procedures

Conducting regular inspections

Future Considerations

Innovation in Materials

Advancing technology brings:

Enhanced coating systems

Improved strength characteristics

Better corrosion resistance

Sustainable options

Industry Trends

Stay informed about:

New application methods

Updated safety standards

Environmental regulations

Performance requirements

Making Informed Decisions

Selection Process

Consider these factors when choosing binding wire:

Structure type and size

Environmental conditions

Loading requirements

Installation conditions

Professional Guidance

Seek expert advice regarding:

Material specifications

Installation methods

Quality control measures

Maintenance requirements

The Path Forward

Understanding the crucial role of binding wire in structural stability helps ensure successful construction outcomes. Careful consideration of material properties, installation techniques, and quality control measures leads to durable, stable structures that stand the test of time.

For optimal results, work with reputable suppliers who provide high-quality binding wire meeting project specifications. Remember that investing in quality materials and proper installation techniques pays dividends through enhanced structural stability and reduced maintenance needs.

Proper selection and installation of binding wire significantly impact overall structural performance. Base decisions on thorough evaluation of technical requirements, environmental conditions, and quality standards to achieve optimal results in every construction project.

#binding wire#structural stability#reinforcement#concrete bars#construction#wire strength#load distribution#stability#construction wire#binding wire use#construction bars#concrete wire#wire materials#wire installation#durability#binding wire quality#wire performance#structural wire#wire manufacturing#binding bars#construction safety

0 notes

Text

How Binding Wire and TMT Bars Create the Backbone of Modern Construction

A steel pipe company that produces components knows something essential about modern-day building practices: the invisible elements regularly determine a shape's integrity. While concrete might also seem like the hero of creation tasks, the fact is it's a ways more complicated. The fusion of binding twine and reinforcement bars creates the hidden framework that allows concrete structures to face up to the test of time.

When employees pour concrete around a carefully built skeleton of metal rebars, they may be collaborating in a production method that has revolutionized structure and infrastructure improvement globally. But how precisely does this system paint, and why is the connection between binding wire and substances from TMT bar manufacturers so essential?

The Critical Role of Binding Wire

Binding wires serves as the unsung hero of this creation symphony. This especially thin, malleable cord performs the essential feature of securing reinforcement bars in their designed positions before concrete placement. When construction people tie rebar grids or cages, binding wire ensures that the reinforcement continues the right spacing and alignment all through the concrete pour.

Proper positioning is non-negotiable due to the fact that the effectiveness of reinforcement relies absolutely on unique placement in the concrete matrix. Even minor displacement can considerably lessen structural capacity and sturdiness. This is in which the relationship among binding twine and materials from TMT bar producers will become crucial.

The Science Behind TMT Bar Manufacturing

TMT (thermo-mechanically treated) bars constitute a widespread development in reinforcement technology. Unlike traditional steel bars, products from TMT bar manufacturers go through a complicated production system concerning managed heating, speedy quenching of the surface layer, and self-tempering of the center as residual warmth flows outward.

This method creates a completely unique micro structure: a sturdy outer layer with martensite formation providing high yield strength and a ductile ferrite-pearlite center that ensures flexibility and weldability.

The Binding Process: Where Precision Meets Craftsmanship

The connection among binding wire and reinforcement from TMT bar producers requires both technical information and practiced talent. Workers usually use specialized tools known as rebar stages to create steady connections at intersection points. The binding pattern follows engineer-specific requirements, with different styles (parent-8, saddle, or wrap-and-twist ties) used depending on structural demands.

Binding cord itself is available in several sorts, with black annealed wire being the most not unusual for popular packages. For specialized tasks, galvanized or PVC-coated binding wire prevents corrosion in aggressive environments. A legit steel pipe business enterprise regularly components the entire range wished for numerous programs.

Industry Integration: From Manufacturing to Construction

The journey from uncooked fabric to finished shape demonstrates extremely good supply chain integration. A steel pipe agency that still materials binding cord and collaborates with TMT bar producers represents an evolution closer to incorporated cloth answers that make sure compatibility and performance.

This delivery chain integration matters because inconsistencies among reinforcement elements can create unexpected weaknesses. When materials come from assets with coordinated pleasant requirements, builders gain confidence in long-term structural overall performance.

Looking Forward: Innovation in Reinforcement Technology

The binding cord and TMT bar production industries retain evolving collectively. Recent improvements consist of self-connecting reinforcement systems that reduce binding cord requirements, corrosion-resistant alloys for severe environments, and digital tracking technology that files reinforcement placement for fine guarantee.

For developers and contractors, staying knowledgeable about these improvements through relationships with a complete metallic pipe company gives competitive benefits in terms of creation efficiency and structural performance.

Final Thoughts

The next time you walk past a production web page or input a concrete construction, don't forget that beneath the gray floor lies a cautiously orchestrated community of materials operating in harmony—concrete, TMT bars, and binding twine growing systems that define our built environment.

#binding wire#TMT bars#construction materials#structural strength#building materials#steel reinforcement#construction basics#TMT bar price#wire for construction#construction wire#steel binding wire#durability#modern construction#building foundations#TMT bars use#construction steel#construction industry#TMT bar quality#steel bars#wire for reinforcement#building projects

1 note

·

View note

Text

Unveiling the Overlooked Yet truly great individual: The Fundamental Role of Binding Wire in Construction

In the realm of construction, where towering high rises and intricate structures stand as demonstrations of human ingenuity, it's generally expected that the little, inconspicuous elements that assume an essential part in ensuring strength, stability, and longevity. Among these unrecognized yet truly great individuals is the binding wire, a humble yet indispensable part that keeps intact the intricate system of buildings, bridges, and various other structures. Notwithstanding its unassuming nature, binding wire serves as the backbone of construction, providing fundamental help and reinforcement where it's required most.

Understanding Binding Wire

Binding wire, otherwise called tie wire or bundle wire, is a flexible material fundamentally utilized for securing reinforcement bars (rebars) in concrete structures. It is regularly produced using materials like steel or iron, picked for their strength, durability, and resistance to corrosion. The wire is made in various measurements and lengths to oblige different construction needs, with normal breadths ranging from 0.8mm to 2.0mm.

The Role of Binding Wire in Construction

In the domain of construction, where wellbeing and primary integrity are fundamental, binding wire serves a few basic capabilities:

Securing Reinforcement Bars: One of the essential purposes of binding wire is to get reinforcement bars in reinforced concrete structures. These rebars, normally made of steel, give extra elasticity to concrete, enhancing its capacity to withstand strain and preventing breaks and underlying disappointment. Binding wire is firmly twisted around intersecting rebars, holding them set up and ensuring they remain appropriately adjusted during the pouring and curing of concrete.

Preventing Concrete Spillage: During the concrete pouring interaction, binding wire is often used to integrate formwork, preventing the blend from spilling out and ensuring that it fills the ideal areas without spillage. This fastidious tying of formwork with binding wire is vital for maintaining the underlying integrity and layered exactness of the concrete elements being built.

Temporary Fixation: Binding wire additionally finds application in temporary fixation tasks during construction, for example, securing scaffolding, temporary backings, or formwork. Its flexibility and strength make it appropriate for these reasons, providing a dependable method for holding temporary structures set up until extremely durable arrangements are executed.

Repair and Maintenance: Past initial construction, binding wire assumes a part in repair and maintenance activities. It may very well be utilized to fix or reinforce harmed concrete structures, providing a speedy and successful answer for addressing areas of shortcoming or crumbling.

Advantages of Binding Wire

The broad utilization of binding wire in construction can be credited to a few key advantages:

Strength and Durability: Binding wire is made from powerful materials like steel or iron, offering magnificent rigidity and durability. This guarantees that it can withstand the afflictions of construction and offer enduring help to reinforced concrete structures.

Corrosion Resistance: Given its openness to outside elements and dampness in construction conditions, binding wire is often covered with materials, for example, zinc to upgrade its corrosion resistance. This defensive coating drags out the life expectancy of the wire and guarantees dependable execution in different circumstances.

Flexibility: Binding wire has inherent flexibility, allowing it to be easily molded and moved to suit various construction necessities. This flexibility works with productive tying and securing of reinforcement bars, formwork, and other elements, contributing to the general proficiency of construction processes.

Cost-Effectiveness: Regardless of its basic role in construction, binding wire remains a cost-powerful arrangement contrasted with elective techniques for reinforcement or fixation. Its moderateness makes it open to construction tasks of varying scales and spending plans, contributing to its inescapable reception within the industry.

Conclusion

In the grand embroidery of construction, binding wire might appear to be a minor string, yet its importance couldn't possibly be more significant. From securing reinforcement bars to ensuring the integrity of concrete structures, binding wire quietly plays out its obligations, providing fundamental help that frames the backbone of current construction. As we wonder about the towering buildings and intricate infrastructure that define our metropolitan landscapes, let us not fail to remember the unassuming binding wire that discreetly maintains some kind of control, embodying the pith of strength, resilience, and reliability in construction.

0 notes

Text

Hats & Hairpieces Recap

Season Two

Phryne wears a total of 36 hats and hairpieces throughout the second season, nine more than the 27 items in the first season. Her headwear ranges jeweled hair slides to elegant cloches to feathered headbands. The clear favorite of both this season and overall is her breaking and entering cat burglar beret with sixteen uses - ten of which are in season two alone. Coming in second is her linen detective hat, with seven uses this season and fourteen appearances overall.

1.Spanish Hat - A traditional Spanish hat in black felt with a wide brim and black ribbon hatband - 2x01, 2x01

2. Hello Jack - Blue straw hat with a curved brim, and antique ash-brown, blue, and black feathers attached to the black hatband - 2x01

3. Burlesque Headpiece - Spiral headpiece adorned with strands of glass beads - 2x01

4. Sequined Headpiece - Headpiece made in-house by the costume team stringing sequins onto very fine pieces of wire - 2x01, 2x01

5. Cemetery Hat - Black straw with green and white feather detail - 2x01, 2x02, 2x06 (base seen in 1x13)

6. Cat Burglar Beret - Classic black French beret made in a circular fashion - 2x01, 2x03, 2x04, 2x05, 2x05, 2x06, 2x07, 2x11, 2x12, 2x12 (also 1x05, 1x05, 1x06, 1x09, 1x10, 1x10)

7. Tan Straw Hat - Finely woven straw hat with a modest brim and brown ribbon trim with a matching wide hatband - 2x01

8. Grey Summer Hat - Grey straw hat with blue overtones, organza petal detail and pearl decoration - 2x02

9. Beaded Headband - Black headband with black beaded detail - 2x02

10. Detective Hat - Tan linen wide-brimmed hat dyed to match her car coat - 2x02, 2x03, 2x04, 2x06, 2x07, 2x10, 2x12 (also 1x02, 1x02, 1x04, 1x06, 1x08, 1x09, 1x13)

11. Spiral Hair Slides - Jeweled spiral hair combs - 2x03 (also 1x12)

12. Beach Holiday Hat - Cream straw hat with pink and white silk organza band and button - 2x03

13. Beach Sunhat - Cream wide brim summer hat with raffia embroidery detail - 2x03, 2x03

14. Harlequin Hat - White felt with original Victorian twisted raw silk trim, osprey feathers, silkworm thread, and velvet bind with crystal buttons that match the coat - 2x04

15. White Felt with Bronze Motif Hat - Cream felt hat with bronze period flower motifs and hand-painted ‘pearlized’ beads - 2x04, 2x07 (also 1x05, 1x07, 1x12)

16. Pearl Headdress - Silver headdress made with glass beads and pearls - 2x04

17. Pom-Pom Hat - Plum felt hat with a 1920's silk pom-pom, navy vintage feathers, and antique navy ribbon - 2x05, 2x08

18. French Navy Hat - Antique silk moire band with buttons on a French Navy felt hat - 2x05

19. Showstopper Headband - Yellow feather pom-pom attached to a black headband - 2x05

20. Navy Velvet Hood with Tassel - Lucious navy velvet with silk satin insert and tassel - 2x06 (also 1x03, 1x07)

21. Red Flower Cloche - Burgundy red felt with cut out flowers and feather detailing - 2x07 (also 1x01, 1x01, 1x02, 1x04, 1x04, 1x05, 1x06, 1x09)

22. Red Felt Circle Hat - Red felt hat with black, red, and cream felt interlocking circles set on matching ribbons - 2x07 (also 1x05)

23. Racing Cap - Tan leather driving cap with metal guides at the sides to hold googles in place - 2x07

24. Leopard Print Cloche - Cream cloche with leopard spots, thin black ribbons holding cream and black feathers - 2x08

25. Maroon Day Hat - Deep pink felt hat with a pom-pom decoration of colorful modern and antique feathers - 2x08

26. Hollywood Felt - Chartreuse felt hat with pink velvet hat band, pink and black feather detail and bronze leaf - 2x09

27. Golden Girl Headpiece - Antique metal leaf with diamantes and black feathers - 2x09

28. Blue Feather Cloche - 1960's navy felt hat modified into a cloche, with 1920's feather band added - 2x09

29. Director's Hat - Green felt fedora with a matching hatband - 2x09

30. Vineyard Hat - Hat quality felt with green and black antique feathers with a black hatband and crystal button - 2x10

31. Radio Station Hat - Pink felt hat with brown hatband and a variety of colored feathers - 2x11

32. Green Velvet Hood - Green velvet hat with green silk organza insert - 2x11

33. Butterfly Hair Slide - Jeweled hair slide with a butterfly shape in the center and two loops extending to either side - 2x11

34. White Cloche with Grey Swirl - White felt cloche with icy grey velvet swirls - 2x12

35. Dr. Zhivago Fur Hat - White faux fur circular hat with felt insert - 2x13, 2x13

36. Christmas Party Headband - Dyed orange and black feathers with a 'nest' and small egg-like bead inside - 2x13

Hat and headpiece photos from the official Pinterest, official Facebook, Screencapped.net, Alekino Plus (now defunct) and various sources (x, x, x, x, x, x, x, x, x, x).

#hat recap#season two#miss fisher's murder mysteries#mfmm#phryne fisher#phryne fisher's frocks#hat photos

89 notes

·

View notes

Text

Theory on how disassembly drones fly (and levitate):

From the wiki: "Disassembly Drones possess a dangerous pair of large retractable wings with several long blades in the shape of feathers that allow for high-speed flight and can be used to cut and impale."

The disassembly Drones wings are very large, being spread wider than the drone stands tall.

"They don't need to move their wings to fly either; numerous times throughout the first episode, Disassembly Drones are seen floating with their wings unmoving. It is unknown how this works."

I believe their wings and bodies have a magnetic quality that opposes each other and can be controlled by the disassembly Drones internal power.

Magnetism: a physical phenomenon produced by the motion of electric charge, resulting in attractive and repulsive forces between objects.

Electromagnetism: An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in the hole in the center of the coil. The magnetic field disappears when the current is turned off.

The wings of the disassembly Drone could be made out of some kind of magnetic steel that has been sharpened into blades.

And if the disassembly Drone has a body (or something within it's body) that opposes the metal of those wings it would create a repulsion.

Definition: When two opposite magnetic poles are close, they attract each other. When like poles are pushed together, there is a force of repulsion. The rule for magnets is that like poles repel and unlike poles attract.

The disassembly Drone (one opposing force)-

-and it's wings (the other opposing force)

-are fused together and their energy would flow through both areas to create a repulsion.

And (in theory) if the repulsion was controlled by the drone through electrical/energy manipulation, giving more power to one magnetic area than the other-

Then moving in any certain direction, if these forces were strong enough:

It could propel the drone into the air and replicate the abilities of flight.

(Steering and levitation could be controlled by specific wing movements in sync with power output.)

And as for the "power" part of this theory, I think there's evidence to the disassembly drones's using this kind of energy is in episode 1 of the series:

The disassembly drones's (specifically J) have the ability to produce an EMP Blast.

An Electromagnetic Pulse.

Controlled and used as a weapon against worker drones and demonstrating that the disassembly drones have a deterrent of control against it's effects.

Other examples of magnetism in the series:

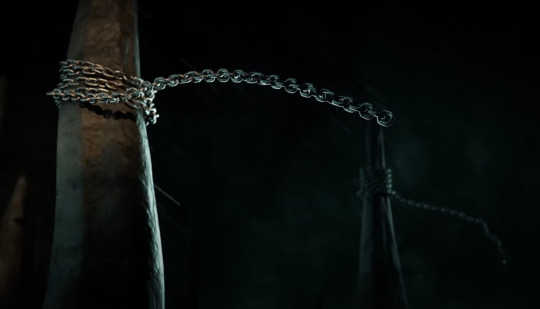

In episode 8 we see the chains that were holding the sentinels blowing in the wind, despite there not appearing to be any kind of strong wind in the area and not effecting yena or Mitchell the intern.

A metal material strong enough to hold the sentinels (at least for a while) yet being able to blow in the wind presumably due to their own material make up and copper 9's own magnetic field making them so much lighter.

We also see these chains binding Yeva in episode 7 and I don't think this is a coincidence.

Magnets have been shown to be able to effect all the drones in some way, and depending on the kind of magnet; the effects are different.

There's a small scene in episode 4 of a young worker drone at the campfire who appears to be using magnet on his own head to...get high...I guess??

It didn't make much sense at the time but that seemed to definitely be what was implied.

But then in episode 6 Alice used a magnet against the main characters to help keep them captive.

So it's definitely a recurring factor.

And finally in the latest episode, several characters appear to float off the ground and into the air for a few moments before falling back down.

They weren't blown up or pulled upwards, it was as if the planet's gravity (or magnetic field) had turned off and was quickly turned back on.

Can't say for sure what this was yet but it all seems connected.

Anyone agree or disagree?

And any thoughts on how the mechanics of this theory might work?

#murder drones#disassembly drone#murder drones theory#murder drones meta#serial designation v#serial designation j

16 notes

·

View notes

Text

Get your own diary to write your horrors in! 😭

(idfk why the image is so low quality 💀)

2 notes

·

View notes

Note

Is that a "sumi" bamboo paint brush you used for your Bulma piece? Curious about the tools you use in general for your traditional works. Lovely art!

Thank you! 😊

No it's not a sumi brush, but they do look similar!

(please excuse me for using this opportunity to ramble about brushes)

I used the ones on the left, I just know them under the name "french watercolor brush". The most obvious difference is the binding, the wires can be a bit uncomfortable if you tend to hold your brushes too close to the tip. They're made from Siberian squirrel, the hair is a bit coarser which makes it super absorbent, great for big areas. Also they are rather round, a sumi brush always has a super fine tip for nice calligraphy brush strokes. I don't own any though, so I can't really make a comparison. I really like these brushes, it takes forever until you need to load up the brush with color again and they just feel very luxurious to use. But they're not ideal for detailed work, they're delicate, so absolutely do not use them with inks, and they tend to be very expensive.

The next ones are some synthetic brushes I got in a multi pack for super cheap, they're meant for school level art, but they have a lovely tip and are great for all types of use. They're sturdy and I use them for inks without worrying about ruining them.

Next up are synthetic flat head brushes, I really love these for controlled working as they take up very little liquid. I also use them for trying to lift color off when I make a mistake, as you can apply pressure on the paper with them, which is not really possible with fine tipped brushes.

And the last group are standard watercolor brushes made from red sable hair. Again the natural hair makes them delicate and expensive. They're very good quality and I especially like to use the extremely thin ones for super fine details. But I believe that there are several synthetic alternatives that will give you the same quality.

I hope this helped answer this simple yes or no question 😅

23 notes

·

View notes

Text

Why Binding Wire Quality Directly Impacts the Longevity of Dowel Bar Installations

In any well-carried-out infrastructure project, binding wire won't be the star; however, it is often the silent hero.

Tucked away from view, it quietly holds collectively vital additives like dowel bars and construction rings, appearing as a bridge between intent and execution. The pleasantness of this unsung fabric can be the difference between a structure that stands the test of time and one that fails when it is subjected to the most.

The Hidden Backbone of Reinforcement

At first glance, binding wire may also seem easy: just twisted steel tying two elements collectively. But in truth, it is a structural dedication. Especially while securing dowel bars, the wire must keep anxiety and form below steady strain, it from vehicular load, thermal expansion, or shifting subgrades. Inferior fine wires lose tension over time, which weakens the alignment of bars and reduces the efficiency of load switching among pavement slabs.

On large-scale production sites, especially on highways and airport runways, even a minor lapse in reinforcement balance can lead to catastrophic failures. Engineers understand this all too well, often, every time, every ring is subject. That’s why there’s no room for compromise on the subject of the material, keeping it all together.

The Real Cost of Using Low-Grade Wire

A dowel bar setup is only as reliable as the material that holds it in its vicinity. If binding twine corrodes early or becomes brittle, the alignment and anchorage of the dowel bars are compromised. This results in cracking inside the concrete, spalling, and eventually untimely failure of the slab. Once this happens, repair isn’t simply expensive—it’s disruptive and time-ingesting.

What’s more, terrible first-rate cord won't bond nicely with creation rings, especially in high-moisture or saline environments. The wire's gauge, tensile strength, and corrosion resistance directly affect how well it performs on-site Cheap twine may also keep some rupees in step with the package deal, but it often leads to primary structural problems that far outweigh any initial savings.

The Technical Perspective: Why Quality Matters

Highly exceptional twine is made from low-carbon metal and undergoes a particular annealing system. This makes it smooth enough to bend effortlessly but robust enough to keep its form beneath a load. Such traits are critical when used with dowel bars that want to stay aligned throughout the enlargement joints without lateral motion.

Properly annealed cord would not snap or flake at any point of twisting, which guarantees uniform tension throughout all creation rings and joints. It also resists rust better, preserving structural integrity even when exposed to water and competitive weather situations. For packages in coastal regions or industrial zones, this delivered resistance isn't always a bonus—it’s a need.

Trusted Materials Build Lasting Infrastructure

Every nice-aware engineer understands that infrastructure isn’t just about electricity; it’s approximately patience. From bridges and expressways to urban flyovers, the overall performance of dowel bars depends heavily on how they're tied and secured in place. And that protection starts off with the dependable binding cord.

In India’s rapid-paced creation atmosphere, in which timelines are tight and expectations are excessive, making an investment in the right substances could make or break a mission. Reputed suppliers ensure consistency in tensile power, diameter, and rust resistance. These are not minor technicalities—they may be fine checkpoints that immediately impact the structure’s lifecycle.

Final Thought

Precision in construction starts at the micro stage. The integrity of dowel bars, the alignment of production jewelry, and the very existence of a pavement slab rely on the quiet energy of binding cord. It won't shout for interest, but its effect speaks volumes through the durability of the very last shape.

#Binding Wire Uses#Dowel Bar Guide#Steel Wire Facts#Concrete Bonding#Wire for Dowel#Strong Wire Tips#TMT Binding Wire#Wire Impact Test#Durable Steel Wire#Bar Joint Safety#Wire Grade Check#Rust-Free Wire#Construction Wire#Rebar Tie Wire#High Tensile Wire#Steel Fixing Wire#Quality Wire Role#Long-Lasting Joints#Binding Wire Check#Secure Bar Ends

0 notes

Text

The Power of Quality TMT Bars & Binding Wire

Every creation project's integrity relies upon the high quality of its foundation and structural components. An official steel pipe company understands that reinforcement substances shape the backbone of durable creation. The choice of proper TMT bars and binding cord might appear like a minor detail inside the good-sized production process; however, experienced engineers apprehend those alternatives as essential to structural integrity and durability.

Understanding Reinforcement Materials

Construction reinforcement creates the skeletal framework that gives concrete systems their electricity and stability. While concrete excels at compression, it calls for metal reinforcement to deal with tensile forces. This critical partnership between concrete and metal determines how buildings face up to environmental stresses, seismic activity, and the simple passage of time.

TMT bar manufacturers produce the reinforcement bars that function as the primary anxiety-bearing factors in reinforced concrete. These thermo-automatically treated bars feature a sturdy outer layer and a ductile center—a mixture that provides both strength and flexibility. Not all TMT bars are created equal, however, as production tactics, exceptional manipulation requirements, and uncooked materials range substantially between producers.

Similarly, binding wire might appear insignificant, but this humble element secures reinforcement bars in their precise positions earlier than concrete pouring. Quality binding wire ensures that the reinforcement shape maintains its designed configuration for the duration of the pouring and curing strategies, directly impacting structural integrity.

Quality Factors in Reinforcement Materials

When evaluating TMT bar manufacturers, several first-class markers deserve interest. The steel's chemical composition influences corrosion resistance and common performance. Leading steel pipe company suppliers ensure their TMT bars maintain the highest quality carbon, manganese, and phosphorus ratios for sturdiness in various environmental conditions.

Physical homes rely equally. Premium TMT bars demonstrate regular yield energy, tensile energy, and elongation resistance. These traits decide how reinforcement responds under load conditions. Reputable TMT bar manufacturers offer specific technical specs, and you can take a look at certificates validating their products meet or exceed enterprise requirements.

Binding wire quality hinges on tensile electricity, ductility, and corrosion resistance. The cord should be robust enough to stabilize bars firmly but malleable enough for correct tying. Galvanized binding wire gives superior corrosion resistance, particularly precious in humid environments or exposed construction tiers. Annealed binding wire presents awesome workability, making an allowance for stable reinforcement assemblies.

The Impact of Supplier Selection

Partnering with a longtime steel pipe company that provides component reinforcement materials provides blessings past mere high-quality products. Reliable suppliers hold constant quality across batches, putting off versions that might compromise structural integrity. They additionally ensure well-timed deliveries, preventing pricey creation delays and timetable disruptions.

TMT bar manufacturers with rigorous, great manipulation strategies hit upon and get rid of faulty products before they reach creation sites. This interest in detail prevents probably catastrophic structural screw-ups years after the challenge's final touch. Experienced producers additionally offer technical support, helping customers select appropriate specs for specific packages.

Binding wire providers, in addition, affect venture results. Quality binding wire allows quicker, more stable tying, enhancing labor efficiency while improving structural reliability. Poor-quality wire may additionally snap during setup or corrode upfront, compromising reinforcement positioning at some stage in concrete pouring.

Making the Right Selection

Construction professionals have to compare TMT bar manufacturers primarily based on their certifications, production facilities, and pleasant manipulation tactics. Reputable providers offer transparent documentation of cloth tryouts and nice requirements. Site visits to production facilities can reveal much about an enterprise's dedication to quality manufacturing.

Ultimately, the decision to partner with a relied-on steel pipe company for reinforcement materials represents an investment in structural integrity and assignment achievement. The marginal cost difference between top-rate and substandard materials pales as compared to the long-term capability results of reinforcement failure.

#TMT bars#binding wire#strong TMT bars#quality steel#TMT bar strength#durable wire#steel for home#safe construction#TMT benefits#best binding wire#steel bars#TMT grades#wire for RCC#construction steel#premium TMT#rust-free steel#reinforced steel#TMT rod price#wire strength#top TMT bars

0 notes

Text

An excerpt from the book; A History of the World After & Its Denizens by Noctua Quill

"(Pages from an untitled codex of illustrations recovered from the late Zagan Era, circa 4795, Epoch 341934.) The illuminated lettering around the edges of the pages reads as follows starting from left to right:

[left most vertical] The Patron Devil of Thieves

[top horizontal] Master of Ephemeral Arts

[right vertical] The Many-Tailed Thief

Opposing page

[right most verticle] "Materials For Summoning:

A Few Gold Coins

Three Bottles of Fine Wine

One Book of Stories

Nine Drops of [the Summoner's] Blood

[bottom left] BEWARE. IMPORTANT UNIQUE GLYPHS.

(These are unique glyphs used in the summoning of Lord Valefar. Each Goetic has their own set that must be included in the Summoning Circle otherwise they either may not appear or will appear but be not contained to the circle, which, in many cases, would be undesirable, let alone fatal, to the summoner. The meaning of some of these symbols have been long forgotten, being used only in these instances, but Valefar's, loosely translated, reads: "No Tricks, No Trade". Thereby binding the Patron Devil of Thieves and preventing him from conjuring any illusions or making attempts at résistance. Not mentioned here for unknown reasons, is that all Summoning Circles must be drawn in a radius of 2 or more meters. It should provide sufficient space for the Demon to remain comfortably seated.)

[right bottom] (Valefar's Summoning Circle. These must include the aforementioned glyphs as well as the Demon's Sigil. The blue markings invite the summoner to "place offering here". Thus, the objects mentioned in the above list of summoning materials will be placed in the designated spots. The tilt to the circle is important as mathematics have as much significance to the Goetia as words. These coordinates designate that Demon's unique position in the universe - essentially a tele-wire number. Misplacing the Circle can result in the absence of the Demon's manifestation.)

The small text is Ingris-Lorician and reads as follows:

"Duke Valefar retained his title of Third among Twenty-Three Dukes for as long as anyone can remember. Secretkeeper to Her Royal Highness, King Beleth of the Third Circle, he acted as a trusted advisor and loyal consort for many hundreds of years.

Before his death, Lord Valefar was renowned for his mastery of illusion and thievery, and was unmatched in his ability to shapeshift. His unique talents among the Goetia had him simultaneously respected and cautiously regarded despite his gregarious nature. He was otherwise a known trickster and miscreant, who relished in sowing chaos among the Court.

This Reputation extended to those outside of the Goetia, and well into the World Before, where those who wished to summon him would have done so expecting a blessing of charisma or good fortune in whatever devious exploits they intended. Otherwise, Lord Valefar was often called upon in matters of thievery, charlantry, or reconnaissance, and was, perhaps somewhat paradoxically, respected for his penchant for fairness in all dealings. However, it was the convalescence of these qualities that in turn ultimately led to his downfall.

Regarded as the catalyst for the event now know as the "Akashic Purge", Duke Valefar accomplished this by besting Fifth King Purson in a bet that he could steal his Horn within three days. Having done so, the pompous Duke decided to announce his success by blowing the instrument, which has the power to herald the End of Days. While he was stopped before the call could be completed, the damage had been done, and for his crime he was to be drawn and quartered. His Nine Tails, source of his power, were excised from him and distributed among the Eight remaining Kings by King Beleth Herself as a sign of solidarity against the events that were to come.

The whereabouts of Lord Valefar's Tails, and whether their Power was used at any point, remains unknown. For his disgrace, his name was to be stricken from the Infernal Court, his seat left vacant, albeit conditions resulting from the Purge have instead, made him something of a folkloric figure in the four hundred years following."

(Notice that the amount of time used to calculate Valefar's absence is expressed via the human calendar. While the author of the text is unknown, this gives an inherent clue as to their identity.)

What this text does not describe is King Beleth's enabling of Lord Valefar's antics, and it is of this Scholar's firm belief, that in doing so, she may have inadvertently coaxed these events into place. Not to speak ill of Her Diligence, but the King's soft spot for her Secretkeeper was plain for all to see, and was something she had been repeatedly cautioned against, as she had become somewhat over-reliant on his more distinct talents in order to compete with the egos of the other Kings. Her Majesty was as much the "Truthteller" as she was the "Truthkeeper". Her inability to lie coincided with her ability to detect lies in all things said and all gestures performed. Valefar's powers were futile to her discerning eye, but less so to others. She was wise for keeping him close, but in the opinion of this Scholar, foolish for being so lenient on him and allowing him to enjoy immunity for his crimes against others up until his own hubris cost her everything. In truth, it was remarkable that she was not subject to the same fate by the other Kings even with her gesture of sacrificing her consort's body in the hopes that they may aid in the mitigation of the coming disasters. One can only hope that the King's gift of foresight extended to anticipating the nature of her subject, and that her willful ignorance bore consequences she was willing to accept in order to indulge in his affection. Alas. Duke Valefar would have most likely become amused at the overall futility of his sacrifice. Irony being a favorite form of comedy. And his undying love for his King would doubtless hinder any compulsions of vengeance or violence, the Duke being as helpless to forgive those he loves as Her Majesty.

What might be seen as a source of vexation for many, Lord Valefar almost always interpreted as a challenge to enjoy, much to the dismay of those around him. However, even should his Soul find its way back from the World Before, he would surely find the reunification of his lost parts a daunting task. This assuming that there will even be a world to which he may return as the Purge continues onward, a fact which the mortal population seems to remain blissfully ignorant or, altogether, uncaring.

#haligren's writings#haligren's ocs#my writing#my art#third duke valefar#noctua quill#history of the world after#sitra achra novel#the nine kings#king beleth#the goetia

6 notes

·

View notes

Text

Impact of Industrial Wires in Modern Manufacturing: Real Success Stories

INTRODUCTION

In today’s highly industrialized landscape, wires play an essential but often overlooked role in streamlining operations across various sectors. From packaging and publishing to infrastructure and electrical work, wires form the backbone of connectivity, durability, and productivity. Among the many types, stitching wires, galvanized iron wires, and MS binding wires have seen a massive rise in demand due to their versatile applications and performance under stress.

As reputed Stitching Wire Manufacturers in Maharashtra, we’ve worked closely with multiple industries, offering customized wire solutions that have significantly improved their operational efficiency. This blog highlights real-world success stories and how our wire products have helped reshape productivity standards across sectors.

Categories of Impactful Applications

To provide a structured overview of how wires impact modern manufacturing, we’ve segmented the success stories into the following categories:

Packaging and Publishing

Electrical and Utility Installations

Construction and Infrastructure

Automated Production Lines

Each category illustrates how the right choice of industrial wire has resulted in measurable improvements.

1. Packaging and Publishing: Enhancing Workflow Precision

Challenge: A leading packaging firm was facing breakdowns due to weak stitching wires that corroded over time. Machines jammed frequently, causing production delays.

Solution: We provided a premium stitching wire designed for high-tension endurance, smooth feeding, and rust resistance. As trusted Stitching Wire Manufacturers in Maharashtra, our focus was not just supplying wire, but engineering reliability into their production line.

Outcome:

40% improvement in workflow efficiency

Zero machine shutdowns for wire-related faults

Enhanced packaging aesthetics and consistency

This intervention redefined their operational stability and increased product quality assurance for end clients.

2. Electrical Installations: Galvanized Wires That Last

Challenge: An electrical installation contractor required robust, weather-resistant wires for securing utility conduits and supports in large-scale infrastructure.

Solution: As one of the leading Stitching Wire Manufacturers in India, we recommended our high-performance GI wires with advanced zinc coating for extended outdoor durability and tension handling.

Outcome:

Withstood varying weather conditions without rusting

Improved safety compliance of installations

Cut maintenance costs by 60% over one year

This success proved that a reliable GI wire isn’t just a material—it’s a long-term investment in operational security.

3. Construction and Infrastructure: Building Stronger Foundations

Challenge: During a high-rise development, the construction team struggled with inferior binding wires that snapped under pressure, compromising rebar structures and slowing down progress.

Solution: We delivered reinforced GI wires engineered for flexibility and strength, ideal for tying reinforcement bars in complex concrete structures. As recognized Galvanized Iron (GI) Wire Manufacturers in India, we emphasized both performance and ease of use at construction sites.

Outcome:

Accelerated structural tying operations

Reduced incidents of binding failure

Elevated structural integrity

This result underscored the importance of wire quality in ensuring safe and timely project completion.

4. Automated Production Lines: Precision Meets Endurance

Challenge: A consumer goods manufacturer using fully automated systems needed precision-grade wire to feed into machines without breakage or feed interruptions.

Solution: Our specialized binding wire was crafted for high-speed automation compatibility—resistant to kinking, uniform in thickness, and tolerant to operational heat.

Outcome:

Reduced machine calibration errors

25% boost in production line speed

Better synchronization with robotic components

Wire consistency directly translated into higher throughput and fewer product rejections.

Final Impact: Reinforcement in Every Strand

In another recent case, our product team partnered with a construction engineering firm seeking to standardize their procurement for MS binding wire. They had experienced frequent inconsistencies in supply and quality from multiple vendors.

As established MS Binding Wire Manufacturers in India, we provided a single-source solution with strict batch testing, documentation, and continuous support. Our wires offered consistent tensile strength, flexibility, and anti-rust performance.

Outcome:

Consolidated vendor management

Uninterrupted supply chain for multi-phase projects

Superior binding quality across structures

This case illustrates how choosing the right manufacturer can lead to long-term gains in cost control, compliance, and structural dependability.

Conclusion: Small Components, Big Results

Industrial wires may seem minor in the bigger manufacturing puzzle, but their role is anything but small. From improving workflow efficiency and machinery performance to ensuring structural safety and long-term cost savings, the right wire products elevate entire systems.

By focusing on quality, reliability, and industry-specific solutions, we continue to help businesses unlock their full potential. Whether it's binding steel at a construction site, securing cartons in a warehouse, or automating a production line, our wires remain the silent strength behind success.

#galvanized iron wires manufacturer (gi) in india#ms binding wires manufacturer in delhi#ms binding wires manufacturer in india#stitching wires manufacturer in india#ms binding wires manufacturer in punjab#ms binding wires manufacturer in tamil nadu#stitching wires manufacturer in maharashtra#galvanized iron wires manufacturer in delhi#galvanized iron wires manufacturer in maharashtra#ms binding wires manufacturer in telangana

0 notes

Text

Print Booklets in Singapore That Showcase Your Brand Perfectly

Need to share detailed information in a compact, professional format? Whether you’re promoting your products, presenting your services, or documenting important material, Landmark Print’s booklet printing in Singapore gives you the perfect platform. Sleek, polished, and fully customisable—our booklets are built to impress. Professional Presentation Starts with the Right Print

When your content matters, so does how you present it. A well-printed booklet isn’t just informative—it’s a reflection of your brand’s quality and credibility. From company profiles to product catalogs, event programs to training manuals, Landmark Print helps you print booklets that stand out and make a lasting impression. Why Choose Landmark Print for Booklet Printing in Singapore?

We specialise in high-precision booklet printing, combining sharp visuals, durable materials, and exceptional finishing. Whether you’re printing a handful or thousands, our team ensures that every page is picture-perfect. What You Can Expect:

Full-Colour Printing: Vivid images and crystal-clear text from front to back.

Multiple Binding Options: Saddle-stitch, perfect bound, wire-o—whatever suits your content and style.

Custom Sizes & Layouts: Standard A5, A4, square booklets or fully tailored dimensions.

Paper & Cover Choices: Glossy, matte, thick or lightweight stock for both inner pages and covers.

Fast Turnaround: Need it urgently? Our express printing services ensure timely delivery.

Perfect for a Range of Uses:

Corporate Brochures & Profiles – Professionally present your brand story and services.

Product Catalogs – Highlight your offerings in a clean, visual format.

Event Programs – Share schedules, speaker bios, and event info.

Training Manuals – Print detailed guides for staff or workshop participants.

Portfolios – Showcase your creative work with style and clarity.

Every detail counts when it comes to booklet printing in Singapore, and Landmark Print delivers precision on every page. Have a Design? Or Need One? We’re Ready Either Way

Already have a layout ready for print? Send it over—we’ll ensure it looks perfect on paper. Need help with design? Our in-house creatives are ready to turn your content into a professional-grade, print-ready masterpiece. Why Landmark Print Is the Right Choice:

Singapore-Based Production: Faster service, better communication, and reliable quality control.

Affordable Pricing: Great rates on small and large print runs, without compromising quality.

End-to-End Support: From file setup to print and finish, we’re here to guide you every step.

Consistent Results: No surprises—just clean, consistent printing with every order.

Booklet Printing That Works as Hard as You Do

Your booklet is more than pages—it’s your brand in print. With Landmark Print, you’ll get durable, visually striking booklets that speak volumes before the first word is read. For More Details, You Can Visit Us:

print booklet singapore

print books

print business cards

0 notes

Text

Durable Binding Wire for Stronger Construction Work

Looking for reliable Binding Wire for your construction needs? Binding wire plays a critical role in reinforcing concrete structures by securing TMT bars and providing structural integrity. It ensures durability, flexibility, and rust resistance making it a must-have for any building project. Ideal for both residential and commercial construction, high-quality binding wire supports safe, long-lasting reinforcement. Whether you’re a builder or contractor, using premium-grade binding wire guarantees strength and stability at every stage. Choose trusted brands like Kamdhenu for consistent performance. Discover how binding wire supports the backbone of every concrete framework and enhances overall project safety and precision.

0 notes

Text

Ultimate Guide for HB Wire Industrial Commercial Applications

hb wire plays a vital role in many industries. From construction to agriculture, its strength and versatility make it a top choice. As demand for durable and quality wiring grows, understanding HB wire’s features becomes more important. Whether you're a contractor, manufacturer, or hobbyist, knowing what makes HB wire special helps you choose the right product.

Introduction

HB wire is a popular material used across various sectors. Its strength, flexibility, and affordability make it ideal for many tasks. As industries seek reliable, long-lasting wiring solutions, HB wire stands out as a versatile option. Picking the right type of HB wire is crucial for ensuring safety and durability in your projects. This guide aims to break down everything you need to know about HB wire, from its makeup to its many uses. Stay with us to discover why HB wire is a go-to for so many industries worldwide.

What is HB Wire?

HB wire is a type of high-quality steel wire made for heavy-duty applications. It is usually produced using rapid, precise manufacturing methods to meet strict standards. Its main job is to provide strong, reliable support in various projects. You’ll find HB wire in fencing, construction reinforcement, and even in making springs and fasteners.

Material Composition and Properties

Most HB wires are made from high carbon steel or low carbon steel. The choice depends on the application. High carbon steel offers more strength, while low carbon steel provides better flexibility.

Making HB wire involves methods like cold drawing and annealing. Cold drawing involves pulling the steel through small dies to increase strength and improve surface finish. Annealing softens the wire, making it easier to handle. These processes influence the wire’s performance, quality, and lifespan.

Types of HB Wire and Their Applications

Basic options include plain and galvanized HB wires. Galvanized wires are coated with zinc, which helps resist rust. Plain wires are suitable for indoor use or environments with low moisture. These variations suit tasks like binding, fencing, or in manufacturing parts.

Specialized HB Wire

Some HB wires are made for specific needs:

High tensile strength wires for heavy loads or security fencing Corrosion-resistant types, coated or plated, for outdoor or moist settings Spring wires designed to stretch repeatedly without losing shape

Each type finds a home in different industries. Fencing companies prefer galvanized or coated wires to last longer outside, while manufacturers choose high-strength wires for structural parts.

Industry-Specific Applications

HB wire isn’t just for one sector. You’ll see it being used in:

Construction: Reinforcing concrete or tying rebar Agriculture: Fencing, trellising, and crop supports Automotive and manufacturing: Springs, clips, and connectors

Knowing the application helps you pick the right type of HB wire for your project.

Advantages of Using HB Wire

HB wire boosts the lifespan of your products. Its tensile strength withstands heavy loads and impacts. For example, galvanized HB wire can last many years even in harsh weather, making it a cost-effective investment.

Cost-Effectiveness

Compared to alternatives like stainless steel, HB wire provides a balance of quality and affordability. Its long lifespan reduces maintenance costs, saving you money over time.

Flexibility and Ease of Installation

Handling HB wire is straightforward. Its flexibility makes it easier to install, bend, or twist without breaking. Construction crews appreciate how quickly they can work with it, reducing project times and expenses.

Corrosion Resistance

Coated or galvanized versions resist rust and corrosion. This helps outdoor projects stay intact longer. Industry standards ensure HB wires meet rigorous testing for durability in various environments.

Quality Standards and Testing for HB Wire

Look for HB wires that meet standards from organizations like ISO, ASTM, or BIS. Certifications guarantee the wire has passed safety and performance tests. They assure you it’s fit for your specific needs.

Ensuring Consistent Quality

To get the best value, buy from reputable suppliers. Ask about their quality control practices and certifications. Regular supplier audits help you avoid substandard products that could compromise safety.

Sourcing and Suppliers

Choose suppliers with proven track records. Ask for samples, certifications, and references. Reliable vendors offer consistent quality and prompt support.

Cost vs. Quality

Cheap wire may save money upfront but might cost more in the long run. Investing in high-quality HB wire often results in fewer replacements and repairs. Bulk purchasing can help you get better prices, but ensure products meet your quality standards.

Expert Insights and Industry Trends

Leaders in the wire manufacturing field emphasize ongoing innovations. New coatings and alloys improve corrosion resistance and strength. Automation in production enhances consistency across batches. As demand grows, expect more eco-friendly and cost-effective HB wire options to enter the market.

Conclusion

hb wire is a dependable choice for many industries, thanks to its strength, flexibility, and durability. Picking the right type depends on your specific needs—whether it’s fencing, reinforcement, or manufacturing parts. Always prioritize quality standards and work with trusted suppliers. As technology advances, HB wire will only get better, offering more options to meet your project demands. Partner with reputable providers to ensure you get the best HB wire solutions for your business.

1 note

·

View note

Text

When Binding Wire Fails—And What It Means for Structural Joints and Reinforced Rings

The Unsung Heroes of Construction

Binding wire, construction rings, and dowel bars — these three unsung heroes are often overlooked in the spotlight of construction materials. Yet, when binding wire fails, the consequences ripple through the very heart of a structure. It's not a surface issue. It's a core failure, one that compromises the integrity of reinforced joints and weakens the load transfer across construction rings and dowel bars.

The Critical Role of Binding Wire in Reinforced Concrete

In reinforced concrete structures, the purpose of binding wire goes beyond just "tying things together." It secures the steel framework, holding bars in position during casting and vibration. A small gauge wire — yet it bears the massive responsibility of ensuring that construction rings and dowel bars remain precisely aligned under pressure. When it fails, nothing stays where it should. Steel cages shift, spacing gets compromised, and the placement of dowel bars turns inaccurate. The result? Joints that were designed to carry stress now buckle under it.

Visualizing the Impact: Columns, Dowel Bars, and Construction Rings

Imagine a reinforced column rising from a footing. Dowel bars connect the two with precision, while construction rings provide lateral support to resist hoop stresses. The entire setup is stable only if the steel configuration holds its designed shape. Binding wire ensures that. If it snaps, stretches, or corrodes prematurely, that shape begins to deform. Concrete then flows around a flawed frame — one that may look solid on the outside but carries internal weaknesses no eye can see.

Early Warning Signs and Long-Term Consequences

And those weaknesses don’t wait for decades to show. Even before finishing stages, poor-quality binding wire can cause ties to loosen during shuttering or compaction. This leads to uneven distribution of load, unexpected stress zones, and cracking at critical joints. Over time, the lack of reinforcement integrity due to binding wire failure makes even the strongest dowel bars useless, and the construction rings struggle to distribute tension efficiently.

Real-World Lessons: Failures from Neglecting Binding Wire Quality

Contractors often learn this the hard way — not through theory, but through real-world collapse. Slabs that sag. Columns that shear. Beams that settle. And at the root of many such failures lies the underestimation of something as small and seemingly insignificant as binding wire. It doesn’t just hold — it stabilizes. It aligns. It preserves the engineering intent of dowel bars and the reinforcement rhythm of construction rings.

The Cost of Cutting Corners

The temptation to cut corners with cheaper wire is common. But the price paid is often in compromised safety. Good binding wire resists corrosion, retains tension, and doesn’t snap under handling stress. It's tested not just for tensile strength but for its ability to work under field conditions — from wet formwork to prolonged setting times. When construction rings are meant to resist expansion forces and dowel bars must remain locked in shear zones, the reliability of the ties holding them is non-negotiable.

Separating Cost from Value in Construction Materials

This is where discerning construction professionals separate cost from value. The journey from blueprint to standing structure depends on details. Binding wire may be minor in cost, but it’s major in consequence. The strength of reinforced joints is not defined by size or concrete grade alone — it's defined by what holds it all together when stress builds and movement begins.

The Invisible Strength That Holds Structures Together

When structures breathe under load, twist with wind, and shudder with seismic waves, what keeps the steel skeleton from unraveling isn't magic—it's the reliability of the ties that bind. Binding wire may never be visible in the final product, but its failure speaks louder than its presence ever could.

#Binding wire failure#Structural joints#Reinforced rings#Construction safety#Wire strength#Joint integrity#Dowel bar role#Wire corrosion#Wire tension#Structural collapse#Steel binding wire#Wire durability#Reinforcement failure#Construction wire#Safety in construction#Binding wire types#Wire breaking point#Reinforced concrete#Joint stability#Wire quality#Construction defects

0 notes

Text

Why Binding Wire is Essential with TMT Bars in Concrete

When building bolstered concrete structures, TMT bars offer the critical tensile energy needed to withstand various structural stresses. However, these excessive-strength metal components don't work successfully in isolation—they require right fastening via binding wires to create the reinforcement cage that bureaucracy the spine of concrete systems. Let's explore why binding wires plays this type of critical function while running with TMT bars.

The Foundation of Reinforced Concrete

TMT bars (thermo-mechanically treated bars) have revolutionized contemporary construction with their superior electricity-to-weight ratio and extraordinary ductility. These steel reinforcement bars create the inner framework that lets in concrete to face up to anxiety forces. But clearly placing TMT bars into concrete isn't sufficient—they must be properly placed and secured.

This is in which binding twine turns into quintessential. This thin, annealed cord holds TMT bars collectively at their intersection factors, keeping the perfect spacing and alignment essential for structural integrity. Without the right binding twine utility, even the very best satisfactory TMT bars should shift in the course of concrete pouring, compromising the entire structure.

Critical Functions of Binding Wire

Binding twine serves several important functions while used with TMT bars:

First, it maintains the geometric configuration of reinforcement cages. By securing TMT bars at their junction factors, binding wire guarantees that the spacing between bars remains constant during the concrete pouring and curing system.

Second, binding twine prevents displacement of TMT bars in the course of concrete placement. The vibration and stress from pouring concrete can motivate unsecured bars to shift from their supposed positions, probably growing vulnerable points in the structure.

Additionally, binding cord enables the advent of complex reinforcement patterns. Modern production frequently calls for complicated arrangements of TMT bars, which might not be possible to preserve without proper binding.

Super Rings: Enhancing Binding Efficiency

For large construction projects using vast quantities of TMT bars, Super Rings have ended up becoming increasingly famous. These pre-shaped binding cord coils substantially accelerate the tying system while ensuring steady tension across connection points.

Super Rings are particularly designed for compatibility with TMT bars of numerous diameters. Construction professionals respect how Super Rings lessen exertion time while preserving first-rate binding. The uniform application provided with the aid of Super Rings additionally enables the elimination of human error that might arise with guide binding wire utility.

Quality Considerations for Structural Integrity

Not all binding cord performs similarly while securing TMT bars. Low-excellent binding cord may additionally corrode upfront, probably contaminating the encircling concrete or even causing enlargement that cracks the shape. Quality binding twine should possess sufficient tensile energy to maintain tight connections among TMT bars without breaking in the course of construction sports.

Similarly, well-synthesized Super Rings make certain regular binding tension throughout all connection points. This uniformity contributes extensively to the overall structural integrity while running with TMT bars in important load-bearing elements.

Making Smart Material Choices

Selecting appropriate binding twine primarily based on the precise requirements of TMT bar installations can pay dividends in structural longevity. For outside or corrosive environments, galvanized or PVC-covered binding cord offers advanced safety. Standard annealed wire may also suffice for indoor structural elements where corrosion concerns are minimal.

The modest cost of quality binding twine and Super Rings represents a trifling percent of average construction budgets, yet their effect on structural integrity is big. Cutting corners on these critical components while operating with premium TMT bars without a doubt would not make financial sense given the capability and long-term consequences.

Smart builders apprehend that the interplay among TMT bars and binding cord basically influences concrete structure overall performance. Making knowledgeable picks about these substances ensures homes stand the test of time.

#binding wire#TMT bars#concrete reinforcement#structural integrity#construction tips#TMT bar benefits#binding wire uses#reinforcement cage#TMT bars and wire#building strength#concrete structures#quality binding wire#Super Rings#TMT bar installation#construction materials#binding wire types#wire for TMT bars#concrete strength#durable binding wire#TMT bars in concrete#construction efficiency

0 notes