#construction estimating software accuracy

Explore tagged Tumblr posts

Text

How Accurate Is a Construction Cost Estimating Service?

Accuracy in construction cost estimating can mean the difference between a well-managed project and one plagued by budget overruns. For developers, contractors, and homeowners, relying on a professional construction cost estimating service is a key step toward financial predictability. But how accurate are these estimates, and what factors influence their precision?

Understanding the Nature of Estimates

First, it’s important to clarify that estimates are not final costs—they are projections based on available data, current pricing, and anticipated conditions. A professional construction cost estimating service provides a highly detailed breakdown using industry-standard methods, digital tools, and historical data. While no estimate is 100% precise, the best services often fall within 5% to 10% of the final project cost.

Factors That Affect Accuracy

The accuracy of an estimate depends on several factors:

Design Completeness: If architectural and engineering plans are incomplete, the estimator must make assumptions, increasing the margin of error.

Site Information: Geotechnical data, site access, and environmental issues influence costs. Limited site details can reduce estimate accuracy.

Scope Clarity: Vague or changing scopes create uncertainty. Clear specifications lead to better estimates.

Market Conditions: Material prices and labor rates fluctuate. Estimators use real-time databases and supplier quotes to stay current, but unexpected inflation or shortages can still affect actual costs.

Experience and Tools: Seasoned estimators using advanced estimating software are more likely to deliver accurate results, as they can account for nuances and project-specific complexities.

Types of Estimates and Their Accuracy Levels

There are different classes of estimates used at various stages of a project:

Preliminary Estimate (Conceptual Stage): Accuracy range of ±20% to 30%

Budget Estimate (Schematic Design Stage): Accuracy range of ±15% to 20%

Detailed Estimate (Final Design Stage): Accuracy range of ±5% to 10%

The closer a project is to construction-ready, the more accurate the estimate becomes. A construction cost estimating service will always indicate the level of confidence and contingencies included in their projections.

Role of Contingencies

Accurate estimates often include a contingency—a percentage added to the base estimate to account for unknown risks or changes. A good estimator uses historical data and risk analysis to set the appropriate contingency level, improving the practical accuracy of the final number.

Ongoing Adjustments for Accuracy

Professional estimating services also offer estimate updates as the design evolves. These revisions improve precision and help clients maintain control over costs as more information becomes available.

Conclusion

While no estimate can predict every variable, a construction cost estimating service provides a highly accurate foundation for budgeting and decision-making. With detailed data, risk management, and experience, estimators offer realistic financial projections that clients can trust to guide their projects from concept to completion.

#how accurate is construction estimating#accuracy of cost estimates in building projects#construction budget overrun prevention#margin of error in construction estimates#reliable construction cost forecasts#construction estimate vs actual cost#estimating contingency percentage#professional estimating services accuracy#detailed vs preliminary estimates#impact of design on cost accuracy#estimating service error margins#construction estimate confidence level#site data and cost accuracy#construction estimator precision tools#estimating accuracy levels#estimate update during design phase#what affects estimate reliability#how to get precise construction estimate#how close are construction estimates to final cost#value of accurate cost estimates#estimating for residential builds accuracy#cost estimating for commercial construction accuracy#construction estimating software accuracy#labor rate fluctuation impact on estimate#importance of contingency in estimating#contractor estimate comparison#construction quote vs estimate accuracy#budget estimates in early design#final stage construction estimate accuracy#how estimators reduce cost surprises

0 notes

Text

Exploring the Diverse Landscape of BIM Software in Construction: A Comprehensive Guide

Introduction: In the ever-evolving field of construction, Building Information Modeling (BIM) has emerged as a transformative technology that revolutionizes the way buildings are designed, constructed, and managed. BIM software plays a pivotal role in enhancing collaboration, improving efficiency, and minimizing errors throughout the construction process. This article delves into the various…

View On WordPress

#architectural design software#as-built documentation#BIM model accuracy#BIM software#Building Information Modeling#collaboration platforms#construction industry advancements#construction management software#construction project efficiency#Construction Technology#cost estimation tools#facility maintenance optimization#facility management solutions#laser scanning technology#LiDAR applications#MEP systems modeling#point cloud integration#project stakeholders collaboration#real-time coordination#structural engineering tools#sustainable building practices

0 notes

Text

Relying on its own resources, Ukraine has just carried out what might be the most complex, elaborately planned, and cost-effective military operation of its current war with Russia. Yesterday, the Ukrainians used drones to attack, almost simultaneously, at least four Russian airfields separated by thousands of miles. Among them were two airfields just inside Russia, but the targets also included Olenya air base, above the Arctic Circle, and, remarkably, Belaya air base, in Siberia, which lies just over the border from Mongolia.

The attack showed how much audacity, ingenuity, and effectiveness the Ukrainians can bring to their own defense when Western leaders aren’t pressuring them to hold back. It also revealed the vulnerability of the large, expensive planes and other hardware treasured by major powers around the world.

Images circulating immediately after the attacks appeared to show that Russian aircraft had been hit with remarkable accuracy at some of their most vulnerable points. The Ukrainians seem to have placed relatively small drone swarms in cavities built into the top of trailer trucks. Then, when the trucks were close to the targets, the trailer roofs opened up, and the swarms of drones flew out, surprising and overwhelming Russian defenses. Even how the drones themselves were operated represents something notable. In many cases, they seem to have been flying courses preprogrammed via the open-source software ArduPilot, which has proved effective in navigating unmanned aerial vehicles for hundreds of miles and precisely reaching targets.

Although details remain limited, the operation testifies to how rapidly drone technology is evolving. Human operators might well have been observing some of yesterday’s flights and been in a position to take control if necessary, but some of the vehicles may have operated outside of human authority, flying preprogrammed courses. Ukrainian officials have said that some of the drones were basically AI-trained to recognize the most vulnerable parts of Russian aircraft and automatically home in on those areas.

The Ukrainians have claimed that more than 40 advanced Russian aircraft were hit and that at least 13 were destroyed. How much of the damage is reparable is not yet clear. Kyiv boasted of destroying more than a third of Russia’s large Tu-95 bombers, which have been a primary launch system for the large volleys of missiles that regularly strike Ukrainian cities. The Tu-95s are literally irreplaceable: Russia has no production facilities making more of these aircraft, and it has not yet designed a successor to the model. Yesterday’s attack also appears to have damaged a large number of Tu-22 M3 bombers and probably one A-50 command aircraft, the Russian equivalent of a U.S.-made airborne warning and control aircraft. The total cost of Russian losses likely runs into several billion dollars.

In contrast, the cost of one of the Ukrainian drones used in yesterday’s attack has been estimated at about $1,200—so that even if the airfields were attacked with 100 drones each (a seemingly high estimate), the total cost of the drones used would have been less than $1 million. I struggle to think of a recent military operation where one side suffered so much damage at so little cost to the other.

In one sense, the Ukrainian attack represents a culmination of what we have seen happen since Russia launched its full-scale invasion in 2022: Seemingly outmatched by Russia’s much larger military, Ukraine has used drones and other improvised equipment to destroy tanks, large warships, bombers, and other large legacy systems. Military planners and many outside commentators have been too slow to acknowledge the significance of Ukraine’s defensive tactics, but the most recent attacks plainly show the need for major changes in how all militaries are constructed and trained.

For the United States and other major Western militaries, Ukraine’s use of trucks parked outside secure areas near military sites will pose uncomfortable questions. How closely do they—or can they—monitor all the truck traffic that streams past their bases? Do they know what happens in every nearby property from which an adversary could hide drone swarms and then launch them with no warning? For many years now, for instance, Chinese interests have been buying large amounts of farmland right next to important U.S. military bases. They could be growing soybeans, but they could also be staging grounds for drone swarms that would make the Ukrainian attacks look minuscule.

Meanwhile, in Europe, military bases have in the past few years been regularly overflown by a large number of unknown drones, which are presumably gathering intelligence. Whichever power is responsible obviously has the ability to deploy a larger number of drones in kinetic attacks. The Ukrainians are showing U.S. and European militaries that better security against drone flights is long overdue.

For Ukraine’s doubters, these attacks should lead to a period of quiet reflection. President Donald Trump has insisted that Ukraine has “no cards.” The New York Times editorial board recently implied that Ukraine is unlikely to produce a military breakthrough that can change the basic course of the war. But pessimism about Ukraine’s capabilities is ahistorical and wrongheaded.

For three years, the Biden administration simultaneously supported Ukraine and discouraged major attacks on Russian soil, for fear of provoking Vladimir Putin too much. That constraint no longer exists, now that Trump has written off Ukraine and appears eager to end the war on Putin’s terms.

Until now, Ukraine has had only a limited ability to launch attacks as ambitious as the one it just executed. If Ukraine’s remaining allies help arm it properly to undertake similar operations at scale, it can still win the war.

17 notes

·

View notes

Text

Trimble SysQue vs MSuite in BIM

Both Trimble SysQue and MSUITE play crucial roles in the modern BIM (Building Information Modeling) ecosystem. While they are designed for distinct purposes, they often complement each other in streamlining workflows for MEP (Mechanical, Electrical, Plumbing) contractors and construction professionals. Let’s talk about both the tools individaully.

What is Trimble SysQue?

Trimble SysQue is primarily a Revit-based solution that enhances the BIM modeling services process by enabling the creation of fabrication-ready designs. Its strength lies in its precision and accuracy, achieved through the integration of manufacturer-specific data into BIM models. This ensures that every component designed using SysQue matches real-world specifications, making it ideal for prefabrication workflows. For example, when designing ductwork or piping systems, SysQue allows users to specify dimensions, materials, and components directly sourced from manufacturers. This level of detail not only reduces errors during construction but also ensures compatibility during the prefabrication and installation phases. SysQue is particularly useful for teams focused on creating detailed designs within Autodesk Revit, as it seamlessly integrates into this widely used platform.

How Trimble SysQue Enhances Revit Workflows for Fabrication-Ready Models

Trimble SysQue is a powerful tool that enhances Revit workflows, specifically tailored for the fabrication-ready MEP modeling (Mechanical, Electrical, and Plumbing) systems. It allows users to directly create and manage fabrication-level models within Revit, streamlining the transition from design to fabrication. Here’s how SysQue integrates with Revit and the advantages it offers for precise modeling:

Seamless Integration with Revit

Embedded within Revit: SysQue works directly inside the Revit environment, allowing users to build fabrication-ready models using the same familiar interface. It integrates with the existing Revit MEP tools, allowing for the inclusion of accurate fabrication data and shop drawings without leaving the platform. No Need for Separate Software: Traditionally, fabricators may have to switch between Revit for design and another platform for fabrication-level details. SysQue eliminates this need, making it possible to complete everything within Revit. This minimizes errors and improves collaboration between design and fabrication teams.

Accurate, Fabrication-Level Models

Data-Rich Models: SysQue generates models with detailed, fabrication-level data (e.g., sizes, materials, and specific fittings). These models are ready for fabrication, eliminating the need for additional conversions or adjustments before fabrication begins. Pre-configured Families and Components: SysQue includes a Revit family creation for manufacturer-specific components and parts that are pre-configured for fabrication. This ensures that the models are precise and compliant with industry standards.

Real-Time Coordination and Clash Detection

Automatic Clash Detection: SysQue enhances Revit’s clash detection capabilities by ensuring that the model is fully coordinated. This helps avoid conflicts between MEP systems and other building elements (e.g., structural or architectural components) early in the design process. Improved Collaboration: Teams can work more efficiently together, as SysQue’s data-rich models reduce errors and facilitate clearer communication between architects, engineers, and fabricators.

Material and Quantity Takeoff

Accurate Material Quantities: SysQue allows users to perform detailed quantity takeoffs directly within Revit. This is crucial for estimating the material requirements and ensuring that everything needed for fabrication is accounted for. Cost Estimation: With detailed material data, SysQue enables more accurate cost estimation, helping fabricators and contractors avoid costly errors and delays during the construction process.

Enhanced Workflow Efficiency

Eliminates Errors from Manual Conversion: Without SysQue, manual adjustments or conversions from design to fabrication models can lead to errors. SysQue streamlines this process by directly generating fabrication-level models, which improves workflow efficiency. Automation of Tasks: SysQue automates repetitive tasks such as component placement, reducing the time spent on manual drawing and ensuring consistency in the models.

Compliance and Standardization

Industry Standards Compliance: SysQue ensures that all components comply with fabrication and installation standards, reducing the risk of mistakes during the fabrication and installation phases. It supports various regional codes and standards, making it adaptable to different geographical locations. Template-Based Modeling: The use of predefined templates for different systems (HVAC, plumbing, electrical) ensures that models are consistent and meet the required specifications, making them easier to hand over to the fabrication team.

Improved Project Timelines

Accelerates Design to Fabrication: With SysQue, the time it takes to convert a design into a fabrication-ready model is significantly reduced, speeding up the overall project timeline. This allows teams to begin fabrication earlier, helping to meet tight deadlines.

Real-World Data and Material Tracking

Manufacturer-Specific Components: SysQue includes manufacturer-specific data for piping, ducting, and electrical systems. This ensures that every component is accurate and compatible with real-world products, making the transition to fabrication smooth and precise. Efficient Material Tracking: SysQue’s integration with Revit also ensures accurate tracking of materials, facilitating better inventory management and reducing waste.

A Step-by-Step Guide to Creating Fabrication-Ready BIM Models with SysQue

Creating fabrication-ready BIM models with SysQue involves leveraging the power of Autodesk Revit along with SysQue’s specialized tools for MEP (Mechanical, Electrical, and Plumbing) systems. SysQue allows for the detailed modeling of MEP systems, making the BIM model ready for fabrication. Here’s a step-by-step guide for new users:

1. Set Up Revit and SysQue

Install Autodesk Revit: Ensure you have Autodesk Revit installed, as SysQue integrates with it. You’ll need a licensed version of Revit (preferably 2024 or newer).

Install SysQue: Download and install SysQue from the SysQue website. Follow the installation instructions provided by Trimble.

2. Configure Project Settings

Set Units and Scale: In Revit, go to Manage > Project Units to configure the units (typically inches or millimeters, depending on your region).

Define Worksets: Set up worksets to organize your model, which helps with collaborative work and managing large-scale projects.

3. Set Up SysQue Content

SysQue comes with a library of manufacturer-specific MEP components. To ensure fabrication readiness, you’ll want to set up this library.

Load SysQue Families: Open the SysQue content manager, and load the families (like ductwork, piping, and other MEP systems) into your Revit project. These are detailed families that will allow you to model components with fabrication-level precision.

4. Begin Modeling with SysQue Tools

Model Piping and Ductwork: Use SysQue tools within Revit to start placing detailed piping and duct systems.

Piping: In the SysQue ribbon, choose the appropriate pipe type (e.g., copper, steel, plastic), then place and route pipes according to your system layout.

Ductwork: Similarly, place ducts and fittings, making sure to use SysQue’s tools for fabrication-level detailing. These tools allow you to specify fittings, offsets, and connections that are fabrication-ready.

5. Use MEP Detailing Tools

Routing Preferences: Set your routing preferences for different systems to match your design and fabrication requirements. SysQue allows you to customize the fitting types, installation methods, and other preferences for MEP systems.

Create Fabrication-Ready Components: SysQue provides detailed components, so when you place a fitting or a piece of equipment, it will have the exact dimensions and details needed for fabrication.

Ensure you set up the correct connector types (flanged, threaded, etc.) and pipe/material schedules to ensure accurate modeling.

6. Collaboration and Coordination

Coordinate Systems with Other Disciplines: Use the coordination tools in Revit to check for clashes between your MEP systems and the architectural or structural models.

Use Clash Detection: Run clash detection in Revit to make sure your systems are properly coordinated. SysQue integrates with Revit’s native clash detection, allowing for the identification of interferences early in the process.

7. Generate Fabrication Documentation

Fabrication Drawings: Once your model is complete, you can generate fabrication-ready drawings directly within Revit using SysQue’s templates and tools.

Bill of Materials (BOM): SysQue can automatically generate a BOM for all the components in your model, helping with procurement and material ordering.

8. Export to Fabrication Software

Export to FabShop: SysQue allows you to export your model to a fabrication software (like Trimble’s FabShop) for detailed fabrication. This software supports CNC (Computer Numerical Control) machines to create the components accurately.

Export to Other Formats: You can also export your model to other fabrication-friendly formats like DXF or IFC.

9. Review and Quality Control

Review the Model: Before sending the model to fabrication, ensure all components are properly detailed, with accurate dimensions, materials, and connections.

Verify Fabrication Specifications: Ensure that all fabrication specifications, such as insulation, material type, and fitting requirements, are correctly applied to the model.

10. Finalizing the Fabrication Model

Final Review and Export: Once all elements have been checked and the model is confirmed to be fabrication-ready, finalize the model by exporting it to the fabrication shop for production.

What is MSUITE?

MSUITE is a cloud-based software platform built to improve collaboration, communication, and the overall management of construction projects. It integrates several aspects of construction management, including BIM (Building Information Modeling), project documentation, daily logs, field reports, and more, all in one unified platform.

The platform provides tools for both contractors and construction managers to ensure that every phase of the project— from design to completion—runs smoothly and efficiently. MSUITE is particularly useful for companies looking to manage large-scale projects that require real-time data sharing, accurate reporting, and enhanced collaboration.

What are MSUITE's Role in BIM?

MSUITE plays a crucial role in enhancing real-time collaboration in construction through its comprehensive suite of cloud-based tools designed specifically for Building Information Modeling (BIM) projects. These tools provide seamless communication, coordination, and data sharing across teams, stakeholders, and project phases. Here are some key collaboration features and their benefits for project teams:

1. Centralized Project Data

MSUITE integrates all project data in a centralized platform, ensuring that every team member works with the latest information. With BIM models, drawings, schedules, and project documents stored in a single cloud repository, teams can avoid confusion and discrepancies caused by outdated or inconsistent data. This ensures that every decision is made based on real-time insights, improving accuracy and reducing rework.

2. Real-Time Communication Tools

MSUITE offers tools that allow project teams to communicate instantly, sharing messages, notes, and even markups directly on BIM models. This feature streamlines the approval process, reduces response time, and helps resolve issues promptly. With instant updates, architects, engineers, contractors, and other stakeholders can stay on the same page throughout the project lifecycle.

3. Document Control and Versioning

MSUITE ensures that project documents and BIM models are continuously updated and versioned automatically. As design changes are made or issues arise, teams can track revisions in real-time, ensuring everyone has access to the most current documents and models. This level of control mitigates the risk of using outdated information, enhancing collaboration between design and construction teams.

4. Task Management and Workflow Automation

Through MSUITE, project teams can assign tasks, track progress, and automate workflows. These capabilities ensure that each task is completed on time, and dependencies are met. Automated notifications keep teams informed of deadlines and project milestones, reducing delays and improving overall efficiency.

5. Collaborative BIM Viewing and Markups

MSUITE allows users to interact with 3D BIM models directly in the platform, making it easier for stakeholders to visualize the project. Team members can leave comments, suggestions, or questions directly on the models, creating a more interactive and transparent design process. This feature fosters real-time collaboration between designers, engineers, and contractors, resulting in fewer misunderstandings and better alignment of objectives.

6. Mobile Access

MSUITE’s mobile app ensures that project teams can access and update project information from anywhere, whether in the field or the office. This on-the-go access improves collaboration by allowing team members to view BIM models, communicate, and share files in real time, regardless of location. The ability to make instant updates is especially useful during site inspections or meetings with clients.

How MSUITE Enhances Productivity in MEP Fabrication Shops?

MSUITE plays a critical role in enhancing productivity within MEP (Mechanical, Electrical, and Plumbing) fabrication shops by streamlining workflows and improving tracking processes. The mobile field applications provided by MSUITE enable real-time access to project data, which ensures that fabrication teams have up-to-date schedules, task lists, and blueprints right at their fingertips. This reduces delays and ensures that fabrication work proceeds smoothly, with no need for workers to wait for updated information or clarifications.

Moreover, MSUITE’s issue tracking and resolution features are particularly beneficial in fabrication shops, where errors or delays can lead to costly rework. Field workers can immediately capture and report issues directly from the job site, attaching photos and notes for a complete record. This allows project managers to track and resolve problems quickly, ensuring minimal downtime and keeping fabrication on schedule.

The solution also facilitates better communication and collaboration between fabrication teams and the broader project team. MSUITE’s instant messaging and document-sharing capabilities help bridge the gap between shop floor workers and office teams, ensuring everyone is aligned and informed about project progress. This improved communication helps mitigate miscommunication issues that often lead to delays or mistakes in fabrication.

Additionally, MSUITE simplifies time tracking and labor reporting in fabrication shops, providing a streamlined approach that eliminates manual entry and improves accuracy. Accurate tracking of labor and equipment hours allows for better resource management, reducing inefficiencies.

Finally, MSUITE’s document management system ensures that fabrication workers always have access to the latest plans, blueprints, and specifications. This reduces the risk of errors caused by outdated documentation, helping teams to work more efficiently and ensuring that the fabricated components meet the required specifications.

Trimble SysQue vs MSUITE: Understanding the Key Differences and Use Cases

Trimble SysQue and MSUITE are both popular software solutions used in the Building Information Modeling (BIM) space, specifically for the mechanical, electrical, and plumbing (MEP) sectors. While both tools cater to MEP professionals, they each have unique strengths and are suited to different use cases. Here’s a comparative analysis of the two:

1. Purpose & Focus

Trimble SysQue:

SysQue is focused on MEP detailing and fabrication within the BIM process. It integrates with Revit to provide detailed fabrication-ready models for MEP systems, enabling contractors to generate shop drawings, bills of materials, and other data necessary for prefabrication.

Primary Use Case: Ideal for MEP contractors who need to streamline the transition from design to fabrication, making it easier to create accurate and detailed models for construction

MSUITE:

MSUITE is a comprehensive solution for MEP contractors that focuses on fabrication, field layout, and project management. It connects with various BIM platforms (like Revit) and provides tools for fabrication, prefab, and field coordination, helping contractors manage the entire lifecycle of a project.

Primary Use Case: Suited for companies that need a full project lifecycle solution—from design and fabrication to installation and project tracking.

2. Features & Functionality

Trimble SysQue:

Integration with Revit: SysQue is built to seamlessly integrate with Revit, providing a robust platform for adding detailed MEP components like ductwork, piping, and electrical systems.

Fabrication Details: SysQue provides precise detailing and generates fabrication-ready models, facilitating the move from design to real-world fabrication and installation.

Tools for Prefabrication: SysQue focuses heavily on prefabrication, with tools that automate the creation of fabrication-ready models, helping to reduce errors during construction.

3D Visualization: Provides 3D visualization of MEP systems, helping teams to resolve clashes and improve coordination.

MSUITE:

Fabrication and Field Layout: MSUITE provides tools not only for fabrication but also for field layout and installation, giving users access to prefabrication, as-built tracking, and project management.

Collaboration Features: MSUITE has strong collaboration features that enable better communication between contractors, fabricators, and field crews.

Integration Across Platforms: MSUITE integrates with Revit, AutoCAD, and other industry-standard tools to help create a unified workflow across the project lifecycle.

Real-Time Data: Offers real-time data syncing for field teams and contractors, which improves BIM coordination and ensures that everyone is on the same page.

3. Collaboration & Workflow

Trimble SysQue:

SysQue excels in workflows related to detailed fabrication and prefab, making it ideal for teams involved in detailed shop drawings and precise construction requirements.

It primarily supports collaboration among designers and fabricators, streamlining the process from design to construction.

MSUITE:

MSUITE offers a more holistic view of project management, supporting collaboration across various stages of the project. Its features like real-time field data syncing and project tracking are more beneficial for larger teams working in multiple phases.

It’s designed for use by contractors, fabricators, and field teams, which ensures that everyone can work together efficiently on all aspects of the project.

4. Usability

Trimble SysQue:

SysQue’s interface is designed for advanced users with experience in Revit and fabrication processes. It requires some expertise to maximize its potential, especially for teams who are integrating it into existing workflows.

The learning curve may be steep for those new to fabrication or Revit.

MSUITE:

MSUITE offers a user-friendly interface with a focus on ease of use across multiple stages of the project. Its tools are designed to be accessible for both field teams and project managers, making it less technical than SysQue in some areas.

MSUITE might be more approachable for contractors who are not deeply involved in the intricate details of fabrication.

5. Integration & Compatibility

Trimble SysQue:

SysQue integrates primarily with Revit and works well within the Trimble ecosystem, allowing smooth data transfer between different software tools for fabrication.

It’s best for teams already using Revit as their primary design tool.

MSUITE:

MSUITE offers broader compatibility with a variety of BIM tools, including Revit, AutoCAD, and other popular MEP software, making it a more flexible solution for contractors working across different platforms.

Its compatibility across the project lifecycle (design, fabrication, and fieldwork) makes it a more versatile option for MEP contractors.

6. Target Audience

Trimble SysQue:

Best suited for MEP contractors who are heavily focused on fabrication and prefabrication and who need precise, fabrication-ready models for installation.

MSUITE:

Ideal for MEP contractors looking for a comprehensive solution that covers all stages of a project—from design through fabrication to installation and project management.

7. Cost

Trimble SysQue:

SysQue is typically sold as part of the Trimble product and may require additional licensing for full functionality, making it a bit more expensive for smaller contractors or firms just starting to implement BIM solutions.

MSUITE:

MSUITE is also a premium solution, but its pricing can vary based on the features and the number of users involved in the project lifecycle. Like SysQue, MSUITE’s cost can be substantial for smaller companies.

Conclusion

When comparing Trimble SysQue and MSuite, both tools offer significant advantages tailored to the needs of the construction and BIM in Construction industry, but they serve different purposes. SysQue excels in providing accurate, data-rich Revit modeling services with enhanced detailing for MEP systems, making it an excellent choice for engineers and BIM professionals focused on precision and constructability. On the other hand, MSuite shines as a productivity and project management tool, offering streamlined workflows, tracking fabrication processes, and connecting field and shop operations.

Choosing between the two depends on your project requirements. If your priority is creating detailed BIM models with fabrication-ready data, SysQue is a strong contender. However, if you need to improve productivity, monitor workflows, and integrate data across teams, MSuite provides unparalleled efficiency. In some cases, leveraging both tools can create a comprehensive ecosystem that bridges detailed modeling with optimized project execution.

#Revitmodelingservices#BIMmodelingservices#MSuiteBIMSoftware#TrimbleBIMsoftware#ScantoBIMservices#TrimbleSysQueandMSUITE

1 note

·

View note

Text

Planning and estimating construction projects are crucial to their success. There are many complex processes involved. As part of this process, construction takeoffs are essential. Construction takeoffs are itemized and quantified lists of the materials, labor, and other resources required for construction projects.

Construction takeoffs are essential to project estimation, planning, and success in general. They give a thorough analysis of the necessary labor, materials, and resources, allowing for precise cost estimation and efficient project management. With enhanced accuracy and time savings, the process has been further streamlined with the introduction of digital takeoff tools and BIM-based solutions.

Importance of Construction Takeoffs

Accurate project estimation

Accurate project estimation is built on the foundation of construction takeoffs. Takeoffs give project stakeholders a thorough grasp of the project scope and associated costs by estimating the materials, equipment, and labor required. Realistic timetables and budgets can be created with the use of this information.

Enhanced project planning

A crucial aspect of project planning is takeoffs. Construction teams may create accurate project timetables, manage resources wisely, and spot potential bottlenecks or areas that need extra care with a full assessment of the available resources. This degree of planning ensures that the construction process runs more smoothly and helps to avoid delays and expensive change orders.

Improved communication and collaboration

Communication among project stakeholders is standardized by construction takeoffs. Takeoffs allow for simple and clear communication between architects, contractors, suppliers, and other team members by quantifying and clarifying requirements. This promotes teamwork and increases overall project efficiency by cutting down on ambiguity and errors.

Methods for Construction Takeoffs

Manual takeoffs

Traditional manual takeoffs entail looking at blueprints, plans, and specifications to manually calculate the amount of resources and materials needed. Even though it takes a lot of time and is prone to mistakes, this method is still employed occasionally, especially for smaller projects or when digital versions of certain details are not available.

Digital takeoff software

The building sector has undergone a change since the introduction of digital takeoff software. By eliminating laborious computations and lowering human error, these software solutions allow users to electronically measure quantities directly from digital designs. Software for digital takeoffs streamlines the process by providing features like annotation tools, automatic measurements, and simple cooperation.

3D modeling and BIM

The building sector has undergone a change since the introduction of digital takeoff software. By eliminating laborious computations and lowering human error, these software solutions allow users to electronically measure quantities directly from digital designs. Software for digital takeoffs streamlines the process by providing features like annotation tools, automatic measurements, and simple cooperation.

Read more

3 notes

·

View notes

Text

Revit Architecture Online Training - cubikcadd

Revit Architecture Online Training - cubikcadd

In today’s fast-paced design and architecture world, staying ahead of the curve requires mastering the right tools. One of the most powerful and widely used software platforms for architects, engineers, and construction professionals is Autodesk Revit. If you’re serious about elevating your skills and advancing your career, enrolling in a Revit course can be a game-changer. This blog will explore the benefits of taking a Revit course, what you can expect to learn, and why it's essential for anyone in the design industry.

What Is Revit?

Revit is a Building Information Modeling (BIM) software developed by Autodesk that allows architects, engineers, and construction professionals to design, visualize, and manage building projects in a 3D environment. Unlike traditional CAD software, Revit is more than just a drawing tool. It enables users to create intelligent models with real-world information about materials, structures, and systems, providing a holistic approach to design and construction.

Why Take a Revit Course?

A Revit course is crucial for professionals who want to maximize their productivity and accuracy in design. Here are a few key reasons why learning Revit is a smart investment in your future:

1. Industry Standard

Revit is an industry-standard BIM software widely used in architectural firms, engineering companies, and construction projects worldwide. Employers often seek professionals proficient in Revit, making it a valuable skill on your resume.

2. Improve Design Efficiency

Revit allows you to work smarter, not harder. By learning how to use the software’s advanced features, such as parametric modeling and automatic updates across the project, you can significantly reduce the time spent on revisions and manual updates.

3. Enhance Collaboration

Revit supports team collaboration with ease. A Revit course will teach you how to work with cloud-based models, enabling multiple users to access, modify, and update a single project file in real-time. This is especially important in large projects where coordination between different disciplines (architecture, structural engineering, MEP) is crucial.

4. Create Detailed 3D Visualizations

One of the standout features of Revit is its ability to generate highly detailed 3D models and visualizations. By enrolling in a Revit course, you’ll learn how to create photorealistic renders, walkthroughs, and simulations, helping you and your clients better understand the design before construction even begins.

5. Better Project Management

Revit’s intelligent data system ensures that every part of your model is interconnected. This allows for accurate cost estimates, material takeoffs, and construction timelines. A Revit course will show you how to use these tools to improve project management, ensuring projects stay on time and within budget.

What Will You Learn in a Revit Course?

From basic to advanced, a well-designed Revit course usually covers a wide range of topics. The following summarises what you can anticipate learning:

1. Introduction to BIM and Revit Interface

You’ll start by getting familiar with BIM concepts and the Revit interface. This includes learning about tools, menus, and how to navigate the software efficiently.

2. Modeling Techniques

The course will teach you how to create accurate architectural models, including walls, floors, roofs, doors, and windows. You’ll also learn how to model structural components and MEP systems, depending on the course's focus.

3. Documentation and Annotations

Learn how to generate construction documentation, such as floor plans, sections, elevations, and details. You’ll also cover how to annotate your drawings with dimensions, text, and other symbols necessary for clear communication with contractors and clients.

4. Advanced Modeling and Customization

Once you master the basics, you’ll dive into more advanced topics such as custom family creation, curtain wall systems, complex roofs, and parametric design, which allows you to create flexible models.

ph : +91-9500024134

Visit our website: https://www.cubikcadd.in/revit-training-in-coimbatore.html

Ramnagar Branch, Coimbatore : https://maps.app.goo.gl/boAyupUoqtda9fXU6

Saravanampatti Branch, Coimbatore : https://maps.app.goo.gl/xrtknmSk76d8cnQV9

OMR Branch, Chennai : https://maps.app.goo.gl/HCpHhcFHGdKsPCPx7

Facebook: https://www.facebook.com/cubikcadd

Instagram: https://www.instagram.com/cubikcadd/

Tiwtter: https://x.com/CubikCadd

2 notes

·

View notes

Text

How Construction Estimators Partner with Project Managers and Contractors

In the construction sector, the synergy between construction estimators, project managers, and contractors is vital for the successful delivery of projects. Accurate cost estimation forms the foundation for effective project planning and execution. At OptiBuild Estimating, we recognize the critical role this collaboration plays in achieving project goals. Our expert estimating services foster smooth communication and coordination. Here’s how construction estimators partner with project managers and contractors to ensure project success.

The Role of Construction Estimators

Construction estimators are key players in the initial stages of a project, focusing on the accurate prediction of costs associated with construction. Their primary role involves determining the quantities and costs of materials, labor, equipment, and overheads required for a project. The precision of these estimates is crucial for establishing feasible budgets and ensuring that projects are delivered on time and within financial constraints.

Partnership with Project Managers

Project managers rely extensively on the estimates provided by construction estimators to plan and oversee projects. Here’s how construction estimators collaborate with project managers:

Initial Planning: Estimators offer detailed cost projections that assist project managers in developing budgets and timelines. Accurate cost evaluations are fundamental for setting realistic objectives and expectations.

Budget Oversight: Throughout the project’s duration, estimators work alongside project managers to monitor expenses, ensuring that the project remains within budget. They provide updated cost estimates and analyses as the project progresses.

Risk Management: Construction estimators assist project managers in identifying potential risks and predicting cost overruns. Through detailed forecasting, estimators enable project managers to formulate strategies to mitigate these risks.

Coordination with Contractors

Contractors are responsible for carrying out the construction work according to the project plans. Here’s how construction estimators coordinate with contractors:

Material and Labor Costs: Estimators provide contractors with accurate cost assessments for materials and labor. This data helps contractors procure the correct quantities of materials and allocate the appropriate workforce.

Change Orders: During construction, project scope changes may arise. Estimators collaborate with contractors to evaluate the financial impact of these changes and provide revised cost estimates for any additional expenses.

Scheduling: Precise cost estimates aid contractors in developing realistic project schedules. Understanding the costs and timing associated with various tasks allows contractors to plan effectively, ensuring timely project completion.

Leveraging Advanced Estimating Software

At OptiBuild Estimating, we utilize cutting-edge software to deliver highly accurate construction estimates. Our advanced tools enable meticulous calculations and comprehensive reporting, ensuring that every aspect of the project is estimated with precision. This technology not only enhances the accuracy of our estimates but also improves efficiency and minimizes the risk of errors.

The Critical Need for Accurate Estimation

Accurate construction estimation is a cornerstone of project success. Even a minor mistake in estimating can lead to significant cost overruns and delays. At OptiBuild Estimating, we understand that such errors can be far more costly than the investment in our professional estimating services. By relying on our expertise, you can be confident that your estimates are precise and that your projects will proceed smoothly from start to finish.

Conclusion

The successful execution of construction projects relies on effective collaboration between construction estimators, project managers, and contractors. At OptiBuild Estimating, our expert estimating services support this collaboration by delivering accurate and detailed cost assessments. With our industry-leading software and expertise, we help ensure that your projects are completed on time, within budget, and to the highest quality standards.

Explore how OptiBuild Estimating can enhance your project with our specialized construction estimation services. Let us handle the complexities of estimating, so you can concentrate on delivering exceptional construction results.

#australia#construction estimating services#estimating services#takeoff services#melbourne#brisbane#perth#construction estimation#construction estimating#construction estimates

1 note

·

View note

Text

Need Building Information Modeling Services in the US for Smarter Construction?

In today's construction industry, precision, efficiency, and collaboration are key to successful project delivery. That's where BIM consulting services in the US come into play. A skilled BIM consultant in the US doesn’t just help you build; they help you build smart. From planning to execution, Building Information Modeling (BIM) can reduce risks, eliminate rework, and improve coordination among all stakeholders.

What Are Building Information Modeling Services in the US?

Building Information Modeling services in the US involve the use of intelligent 3D models that provide insight and tools to efficiently plan, design, construct, and manage buildings and infrastructure. These services go beyond traditional CAD by integrating architecture, engineering, and construction (AEC) data in a single environment.

When you choose building information modeling services in the US, you're investing in a streamlined construction process with fewer delays, improved cost estimates, and better communication across teams.

Benefits of Hiring a BIM Consultant in the US

A qualified BIM consultant in the US helps identify design conflicts, plan materials, and ensure that each stage of construction adheres to regulatory standards. Here’s how BIM consultancy adds value:

Improved Design Accuracy Avoid errors before they happen with accurate model-based design.

Cost and Time Savings With BIM consulting services in the US, you reduce unnecessary expenditures and speed up timelines.

Better Collaboration Stakeholders—from architects to contractors—work from a single, updated source of truth.

Compliance Assurance A good BIM consultancy in the US ensures your project complies with national standards and codes.

Choosing the Right BIM Consultancy in the US

Not all BIM firms are created equal. When selecting your BIM consultancy in the US, look for:

Proven experience in your specific project type

A multidisciplinary team (architecture, civil, MEP)

Usage of leading BIM software like Revit, Navisworks, or AutoCAD Civil 3D

Transparent process and communication

Choosing the right BIM consultant in the US can mean the difference between project delays and successful delivery.

How BIM Consulting Services in the US Drive Future-Ready Construction

Construction is no longer just about bricks and mortar—it's about data. The best BIM consulting services in the US help companies embrace technology and data to build smarter. Whether you're constructing a hospital, commercial complex, or smart city infrastructure, BIM ensures you're ready for the future.

A trusted BIM consultancy in the US bridges the gap between vision and reality—ensuring every stakeholder is aligned, every stage is optimized, and every dollar is well spent.

Final Thoughts

If you're planning a major construction project, now is the time to invest in building information modeling services in the US. With the guidance of a seasoned BIM consultant in the US, you gain more than a model—you gain clarity, control, and confidence in your project outcomes.

#BIM consulting services in us#BIM consultant in US#Building information modeling services in US#BIM consultancy in US#bim service providers in US

0 notes

Text

Estimator Jobs in Civil Engineering: Opportunities and Challenges

Estimator jobs in civil engineering play a critical role in the planning and execution of construction projects. Estimators are responsible for calculating the costs, materials, labor, and time required for civil engineering projects such as roads, bridges, buildings, and infrastructure developments. As the construction industry grows, the demand for skilled estimators is on the rise. This article explores the key opportunities and challenges associated with estimator jobs in civil engineering.

Opportunities in Estimator Jobs

1. High Demand in Infrastructure Development

With ongoing investments in infrastructure worldwide, estimator jobs are increasingly in demand. Governments and private developers require accurate cost assessments before initiating large-scale civil projects, creating a steady pipeline of work for estimators.

2. Career Growth and Specialization

Estimator jobs offer clear pathways for growth. Professionals can specialize in areas such as highway construction, water resources, or structural engineering, and even move into senior roles like cost managers or project controllers.

3. Competitive Salaries

Due to the specialized skill set required, estimator jobs in civil engineering are often well-compensated. Those with experience and advanced certifications can command higher salaries and enjoy strong job security.

4. Technological Integration

Modern tools like Building Information Modeling (BIM), AutoCAD, and estimation software (e.g., CostX, PlanSwift) have made the estimator’s job more efficient. Embracing these tools enhances productivity and accuracy, opening doors for tech-savvy professionals.

5. Global Opportunities

Skilled civil engineering estimators are in demand globally. From urban cities to remote infrastructure sites, estimator jobs provide opportunities for international work and diverse project experience.

Challenges in Estimator Jobs

1. Accuracy Under Pressure

Estimators must deliver precise cost predictions under tight deadlines. Inaccurate estimates can lead to budget overruns, project delays, or even legal disputes, putting pressure on professionals to perform flawlessly.

2. Evolving Industry Standards

The construction industry is constantly evolving with new materials, regulations, and technologies. Estimators must stay updated to remain competitive and ensure compliance with local and international standards.

3. Managing Project Complexity

Large-scale civil engineering projects often involve multiple stakeholders and variables. Managing uncertainties, risk assessments, and contingency planning is a constant challenge for estimators.

4. Communication Skills Required

Estimator jobs are not just about numbers. Estimators must collaborate with engineers, architects, contractors, and clients. Strong interpersonal and communication skills are essential to convey complex cost structures clearly.

5. Limited Room for Error

Unlike other roles, estimator jobs have minimal tolerance for mistakes. A small miscalculation can significantly affect a project’s budget and profitability, making attention to detail crucial.

Conclusion

Estimator jobs in civil engineering offer a rewarding career path for individuals who enjoy analysis, planning, and strategic thinking. With growing infrastructure demands and advancements in technology, this profession is evolving rapidly. However, the role also comes with its share of challenges that require adaptability, precision, and continuous learning.

Whether you're a graduate looking to enter the field or an experienced professional seeking specialization, estimator jobs provide vast opportunities for career advancement in the dynamic world of civil engineering.

1 note

·

View note

Text

Transform Your AEC Career with BIM Certification – Here’s How

In today’s digital-first construction world, success no longer depends solely on traditional skills. Instead, it’s about adaptability, collaboration, and technology. This is where Building Information Modeling, or BIM, comes in and it’s changing the game for professionals in architecture, engineering, and construction (AEC). If you’re looking to upgrade your career or stand out in a competitive field, earning a BIM certification could be your best decision yet.

BIM Isn’t Just a Tool—It’s a Mindset

BIM is far more than a software suite. It’s a powerful methodology that connects every stage of a construction project from initial design concepts to ongoing facility management. With 3D modelling, time and cost integration, and seamless communication between stakeholders, BIM enhances productivity and reduces costly errors.

And here’s the catch: Governments and clients across the globe are now requiring BIM as part of their project standards. That means the demand for trained, certified BIM professionals is growing rapidly—and will only continue to rise.

Why a BIM Certification Sets You Apart

Getting certified in BIM proves you’ve got what it takes to work in today’s collaborative, tech-savvy construction space. Here’s how it benefits you:

More Job Interviews, Better Roles: Whether you're a fresher or a working professional, a certification strengthens your resume. Employers value verified skills, and BIM credentials help you get noticed faster.

Opportunities Abroad: BIM is now a global standard. Countries like the UAE, UK, and Singapore require BIM for major projects, giving certified professionals a real edge in international job markets.

Stay Relevant in a Changing Industry: Technology evolves quickly. A BIM certification shows that you’re updated on current trends and tools, making you a reliable hire in a future-forward team.

Career Acceleration: With certification, you’re no longer just another designer or engineer—you become someone who can coordinate complex projects, manage digital teams, and lead innovation.

Where BIM Skills Are Making an Impact

From designing sustainable buildings to managing mega infrastructure projects, BIM plays a vital role across the AEC spectrum. Architects use it to visualise detailed spaces. Engineers rely on it for coordination and accuracy. Construction managers plan and track timelines in real-time. Interior designers use BIM to enhance presentations and client walkthroughs. Even urban planners use it to simulate smart city layouts.

In short, BIM isn’t limited to one niche—it’s revolutionising all corners of the construction world.

Who Should Invest in a BIM Certification?

If you’re involved in designing, planning, estimating, or building, you’ll benefit from learning BIM. That includes:

Architecture and engineering students

Civil, mechanical, or electrical engineers

CAD drafters and Revit modelers

Project managers and site supervisors

Quantity surveyors and cost analysts

Interior and infrastructure designers

Even freelancers and consultants looking to take on bigger, tech-driven projects should consider getting certified.

What to Look for in a BIM Training Course

The right certification program should focus on practical learning—not just theory. Look for training that includes real project workflows, global BIM standards like ISO 19650, and industry-used tools like Autodesk Revit and Navisworks.

One standout platform is BIM Café Learning Hub. Known for its career-centric approach, BIM Café offers flexible online and hybrid classes, expert guidance, and hands-on practice. Whether you're just starting or reskilling, their programs are designed to make you job-ready from day one.

Final Words: Stay Ahead with BIM Certification

As the AEC industry moves toward smarter, digitised construction practices, professionals must adapt. A BIM certification proves that you're ready—not just for today’s roles but for tomorrow’s challenges. If you want to future-proof your skills, unlock global job opportunities, and grow confidently in your field, BIM training is your ticket forward.

Don’t wait for change, lead it. Start your BIM journey today.

0 notes

Text

Who Offers the Best Quantity Takeoff Services in Australia?

Finding a top-quality quantity takeoff service provider in Australia is crucial for construction professionals aiming to deliver accurate budgets and successful projects. The Australian construction market demands expertise in local standards, materials, and regulations, making it essential to partner with reliable and experienced firms.

Criteria for Selecting the Best Quantity Takeoff Service

Local Expertise: Providers familiar with Australian building codes, supply chains, and market pricing deliver more accurate and relevant takeoffs.

Experience and Reputation: Years of service and positive client feedback indicate a trusted provider capable of handling diverse projects.

Technology Utilization: Leading firms leverage advanced software tools like Bluebeam, PlanSwift, and BIM integration to ensure precision.

Range of Services: Comprehensive offerings that include multi-trade takeoffs, labor and equipment estimates, and change order support add value.

Customer Support and Communication: Responsive teams that provide clear communication and quick turnaround times improve collaboration.

Top Quantity Takeoff Providers in Australia

While the market includes many competent companies, a few stand out for their consistent quality and service:

AS Estimation & Consultants With extensive experience across residential, commercial, and industrial sectors, AS Estimation & Consultants offers expert quantity takeoff services tailored to Australian projects. Their team combines local knowledge with cutting-edge technology to deliver detailed and reliable takeoffs.

BuildSoft Australia Known for their integrated software solutions, BuildSoft provides both digital takeoff tools and estimating services supporting complex projects.

Estimatorz Estimatorz offers specialist takeoff services with a focus on accuracy and fast delivery, catering to contractors nationwide.

Quantify Australia This firm emphasizes BIM-based takeoff and comprehensive reporting to support large-scale infrastructure and building projects.

How to Choose the Right Provider

Assess your project needs, budget, and timeline, then compare providers based on the criteria above. Request sample reports and client references. Ensuring your chosen firm understands local conditions and your project scope will maximize value.

FAQs

Are Australian quantity takeoff services different from international ones? Yes, they incorporate local codes, supplier networks, and market conditions specific to Australia.

Can small builders access these services? Many providers cater to small and medium builders with scalable solutions.

Do these companies offer remote or onsite takeoff services? Most provide digital takeoffs remotely, with optional site visits if needed.

How important is software choice in Australian takeoffs? Software impacts accuracy and efficiency, but experience and local knowledge are equally vital.

Is AS Estimation & Consultants suitable for all project types? Yes, they serve residential to industrial sectors with customized solutions.

Conclusion

Selecting the best quantity takeoff service in Australia involves balancing expertise, technology, and customer service. Firms like AS Estimation & Consultants exemplify the qualities needed to support accurate estimating and successful project delivery across various sectors. Investing time in choosing the right partner pays off in smoother workflows and controlled budgets.

#best quantity takeoff services Australia#Australian quantity takeoff providers#local construction takeoff experts Australia#quantity takeoff firms in Australia#top takeoff companies Australian construction#how to find takeoff services in Australia#residential takeoff services Australia#commercial takeoff providers Australia#BIM takeoff Australia#Australian quantity takeoff software users#quantity takeoff for builders Australia#affordable takeoff services Australia#takeoff and estimating Australia#quantity takeoff accuracy Australia#construction bidding takeoff Australia#takeoff services for infrastructure Australia#subcontractor takeoff support Australia#quantity takeoff turnaround Australia#takeoff customer support Australia#remote takeoff services Australia#Australian quantity takeoff consultations#quantity takeoff service reviews Australia#how to vet takeoff firms Australia#experienced takeoff providers Australia#quantity takeoff for developers Australia#fast takeoff services Australia#takeoff pricing Australia#quantity takeoff for owner-builders Australia#estimating service providers Australia#AS Estimation & Consultants takeoff services Australia

0 notes

Text

How Long Does an Aerial Survey Typically Take?

Aerial surveying has become an indispensable tool in fields such as construction, mining, agriculture, urban planning, and environmental monitoring. As experts in aerial surveying, we understand how crucial timing is when planning a survey. Knowing how long an aerial survey typically takes can help stakeholders manage expectations, allocate resources, and ensure projects stay on schedule.

Understanding the Aerial Surveying Process

The aerial surveying process is more than just flying a drone or an aircraft with a camera. It is a multi-phase operation involving mission planning, data acquisition, post-processing, analysis, and delivery. Each phase has a distinct timeline that can impact the overall duration of the survey.

Pre-Survey Planning

Flight Execution / Data Collection

Post-Processing

Data Analysis & Reporting

Let’s explore each phase in detail.

Pre-Survey Planning Timeframe

Before the aircraft or drone takes to the sky, extensive planning is necessary. This phase includes:

Defining survey objectives

Establishing ground control points (GCPs)

Securing flight permissions and regulatory clearances

Weather assessments and risk mitigation

Typical Duration: 1–3 days, depending on airspace restrictions, terrain complexity, and area size.

Planning is faster in remote areas with few regulatory hurdles but may extend in urban or restricted airspace zones due to coordination with aviation authorities.

Flight Execution / Data Collection Duration

This is the most critical phase of aerial surveying—the actual flight. The time taken here depends on multiple factors:

1. Area Size

Small sites (under 50 acres): ~30 minutes to 1 hour

Medium sites (50–500 acres): 1–4 hours

Large-scale surveys (500+ acres): Multiple days or segmented flights

2. Platform Type

Drones (UAVs) are typically used for smaller or more detailed surveys and can fly for 20–45 minutes per battery charge.

Manned aircraft can cover vast regions quickly but require airport coordination and airspace clearance.

3. Terrain and Environmental Conditions

Steep terrain or vegetative cover requires slower flight speeds or multiple passes to achieve the required resolution.

Typical Duration: 1 hour to several days, depending on project scope.

Post-Processing: The Most Time-Consuming Step

Once data is collected, the next step is converting raw images or LiDAR data into usable maps, models, or 3D renderings. This involves:

Georeferencing and orthorectification

Generating digital elevation models (DEMs)

Stitching overlapping images into orthomosaics

Cleaning and correcting for distortions

Advanced software like Pix4D, Agisoft Metashape, and LiDAR processing tools are used.

Estimated Timelines:

Simple surveys (small plots, flat terrain): 6–24 hours

Moderate complexity (hilly, mixed vegetation, moderate size): 2–4 days

High complexity (urban environments, wide regions): 5–10 days

The time varies based on computing power, resolution, and required deliverables.

Data Analysis and Final Reporting

Post-processed data is analyzed to extract actionable insights, depending on project goals. Deliverables may include:

Topographic maps

Contours and elevation profiles

Volumetric measurements

Change detection reports

Construction site progression data

Typical Duration: 1–3 days depending on complexity and customization.

Factors Affecting the Total Survey Time

1. Size and Scope of the Survey

A single-acre construction site takes a few hours, while a 10,000-acre agricultural or mining site may need several days to weeks.

2. Resolution Requirements

Higher resolution (e.g., sub-centimeter accuracy) requires slower flights, denser data, and longer post-processing times.

3. Type of Sensor Used

RGB Cameras are fast but may not capture fine elevation details.

LiDAR Sensors are better for elevation but need more time in processing.

Multispectral & Hyperspectral Sensors add extra post-processing time due to data complexity.

4. Accessibility and Ground Control Points (GCPs)

Installing and surveying GCPs in remote areas can extend the timeline by several days.

5. Weather Conditions

Rain, wind, and cloud cover can delay flights significantly. Aerial surveys rely on clear weather for optimal imagery quality.

Average Duration Based on Industry Use Cases

Industry

Average Survey Time (Field + Processing)

Construction (5–50 acres)

1–3 days

Agriculture (50–1000 acres)

2–7 days

Mining & Quarrying

3–10 days

Urban Planning

5–14 days

Infrastructure Monitoring (roads, pipelines)

Varies based on length and access

Forestry & Environmental Surveys

7–14+ days

Can Aerial Surveys Be Done Faster?

Yes, but speed often comes at the cost of data resolution or accuracy. We can accelerate survey delivery using:

Automated flight planning tools

High-performance processing servers

RTK/PPK drones to minimize the need for GCPs

However, cutting corners in planning or processing could compromise the integrity of spatial data—a risk not worth taking for most critical applications.

Best Practices to Optimize Aerial Survey Time

Conduct pre-site inspections to assess obstacles or access issues.

Use RTK-enabled drones for real-time geotagging.

Pre-load terrain models to enable efficient flight pathing.

Automate post-processing workflows with batch scripts.

Coordinate early with airspace regulators and property owners.

Schedule during optimal weather windows to avoid re-flights.

Conclusion: Estimated Timeline for an Aerial Survey

So, how long does an aerial survey typically take? The answer lies in understanding the project's scale, environment, data requirements, and technology used. On average:

Small-scale aerial surveys can be completed in 1–3 days.

Medium to large projects may take 4–10 days.

Complex or multi-site surveys may require 2–3 weeks or more.

With proper planning and advanced tools, we ensure timely and accurate delivery of aerial surveying projects across diverse industries.

0 notes

Text

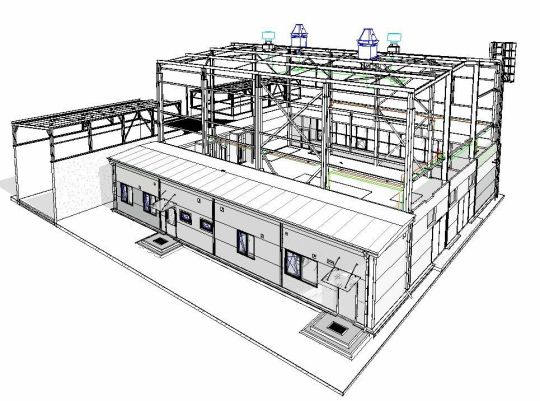

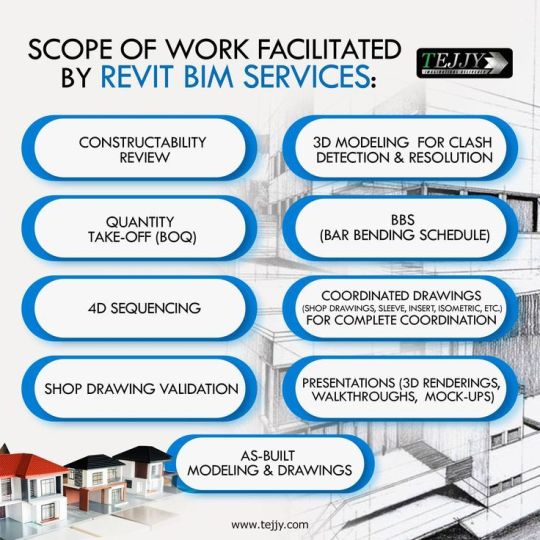

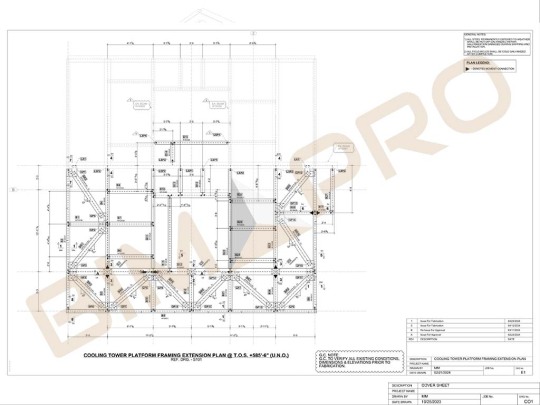

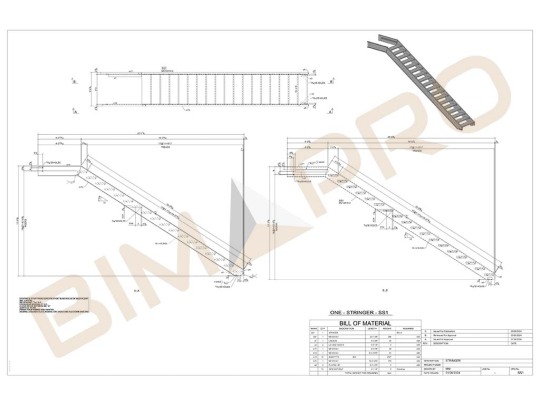

Complete Suite of Revit-Based BIM Services

Building Information Modeling (BIM) with Revit, often referred to as parametric modeling or digital design coordination, enhances project delivery by enabling a highly detailed, data-driven workflow. These BIM drafting services support a comprehensive range of deliverables. From constructability reviews, which anticipate and resolve design challenges early, to 3D clash detection modeling that prevents system conflicts, Revit-based coordination leads to higher efficiency. The software allows for automated quantity take-offs (BOQ) to streamline estimation, and Bar Bending Schedules (BBS) for structural detailing.

4D sequencing connects time and model data, helping contractors visualize project progress over time. Coordinated construction drawings, including isometric, insert, and sleeve layouts, ensure seamless communication among disciplines. In addition, shop drawing validation ensures documentation accuracy before work begins on site. Photorealistic presentations, such as walkthroughs and 3D renderings, enhance client understanding and approval. Finally, as-built BIM documentation provides precise models reflecting completed construction, valuable for facilities management.

Altogether, Revit digital modeling solutions enable better planning, collaboration, and execution throughout a building’s lifecycle.

0 notes

Text

Revit for Structural Engineering

In the realm of modern construction, Building Information Modeling (BIM) has become the cornerstone for efficient and precise project execution. Among the tools available, Autodesk Revit stands out as a game-changer for structural engineering. This comprehensive software enables engineers and designers to create advanced models and documentation, bridging the gap between design intent and construction reality. Let’s dive into Revit for structural engineering and how it facilitates seamless workflows from design to fabrication.

Advanced Structural Modeling and Documentation in BIM

Revit provides structural engineers with a sophisticated BIM environment to develop highly accurate design intent models and structural drawings. These models are the foundation for engineers and detailers to create more precise models tailored for fabrication and installation. By integrating all aspects of a project within a single platform, Revit empowers teams to:

Streamline design intent modeling.

Facilitate coordination between structural and architectural elements.

Deliver information-rich documentation for stakeholders.

Revit allows engineers to visualize the entire lifecycle of a structure, from early conceptual designs to the final stages of fabrication and installation. The software’s ability to integrate diverse data sets ensures a smooth transition between project phases, ultimately leading to a more cohesive and coordinated construction process.

Concurrent Creation of Structural Physical Model and Analystical Model

One of the standout features of Revit is its ability to generate physical and analytical models simultaneously.

Physical Model: Serves as the representation of the structure for coordination and documentation. This model ensures that structural elements align with architectural and MEP components, reducing clashes and misalignments.

Analytical Model: Supports structural analysis and design. Engineers can add structural loads, load combinations, and boundary conditions directly to this model, enabling accurate simulations and evaluations.

This dual modeling approach enhances the efficiency of structural workflows and ensures that engineers can make data-driven decisions with ease. The ability to maintain consistency between the physical and analytical models eliminates redundancy and reduces the likelihood of errors during the design and analysis phases.

Interoperability for Enhanced Structural Analysis

Revit extends the capabilities of BIM by enabling seamless interoperability with Autodesk Robot Structural Analysis Professional and various third-party analysis tools. This connectivity enhances structural analysis, allowing engineers to:

Perform cloud-based analysis using the Structural Analysis for Revit service.

Minimize workflow disruptions by continuing to design while analysis is completed in the background.

Generate analytical results early in the design process to refine and validate design intent.

By leveraging cloud-based analysis, Revit empowers engineers to evaluate multiple design scenarios quickly, ensuring that the most efficient and effective solutions are implemented. This level of flexibility helps teams respond to design challenges dynamically, reducing project delays and costs.

Streamlined Structural Design to Fabrication Workflow

Revit’s capabilities extend far beyond the design phase, supporting a seamless transition to detailing and fabrication. Key features include:

Steel Connections for Revit

Revit offers streamlined interoperability with Autodesk Advance Steel detailing software, allowing for:

Easy modeling of steel connection details.

Use of over 130 parametric connections to improve coordination.

Enhanced accuracy in detailing and estimation, reducing errors in fabrication and installation.

The integration with Advance Steel ensures that the design and detailing processes are tightly connected, enabling engineers and fabricators to collaborate more effectively. This results in a more streamlined workflow that minimizes rework and enhances overall project quality.

3D Concrete Reinforcements

For concrete structures, Revit provides robust tools for modeling reinforcements and generating shop drawings. These features allow:

Creation of detailed bending schedules.

Integration of 2D documentation with precise 3D modeling.

Clash prevention to reduce conflicts during preconstruction and execution phases.

Revit’s reinforcement modeling tools also support advanced detailing workflows, enabling engineers to incorporate complex reinforcement patterns and accessories. This level of detail improves the constructability of designs and ensures that the final structure meets performance requirements.

Enhanced Collaboration and Automation

By consolidating key workflows, Revit enhances collaboration among project stakeholders. Its advanced automation capabilities support:

Efficient sharing of design data across teams.

Reduction of manual tasks, enabling engineers to focus on innovation.

Improved communication between design, detailing, and fabrication teams.

Revit’s collaborative tools ensure that all stakeholders are on the same page, reducing misunderstandings and discrepancies. With centralized data management, teams can access the latest project information in real time, enhancing decision-making and accountability.

Moreover, Revit’s automation features help streamline repetitive tasks such as generating schedules, updating drawings, and managing revisions. This not only saves time but also improves the accuracy and consistency of project deliverables.

Structural Design Optimization and Clash Prevention

One of the key advantages of Revit is its ability to optimize designs through clash detection and prevention. By identifying potential conflicts early in the design phase, Revit minimizes costly changes during construction. This proactive approach improves project timelines and reduces the likelihood of delays.

Additionally, Revit supports design optimization by enabling engineers to simulate various scenarios and evaluate their impact on the overall structure. This helps teams identify the most efficient and sustainable design solutions, contributing to better project outcomes.

Comprehensive Support for Steel and Concrete Structures

Revit’s extensive library of parametric components and detailing tools ensures that engineers can address the unique requirements of both steel and concrete structures. Key capabilities include:

Parametric Steel Connections: Facilitates the creation of custom steel connections that align with specific project needs.

Reinforcement Detailing: Provides advanced tools for modeling and documenting reinforced concrete elements, ensuring compliance with industry standards.

BIM-Integrated Fabrication: Supports seamless integration with fabrication software, enabling the production of high-fidelity components.

These features make Revit an invaluable tool for delivering high-quality structural designs that meet the demands of modern construction projects.