#digitalengine

Explore tagged Tumblr posts

Text

Harnessing the Power of Data and AI for Digital Transformation

In the rapidly evolving landscape of technology, the synergy of data and artificial intelligence (AI) is revolutionizing businesses across various industries. Digital transformation with Data AI is not just a buzzword; it's a strategic imperative for organizations aiming to stay competitive and innovative.

The Journey of Digital Transformation

Digital transformation begins with a robust data strategy. Companies like Prolifics emphasize the importance of managing, analyzing, and uncovering value from enterprise data. A well-defined data strategy ensures that data is not just collected but also effectively utilized to drive business outcomes. For instance, a banking client of Prolifics realized continuous value by leveraging advanced analytics to enhance their decision-making processes.

Unleashing the Potential of Data Analytics and AI

Data analytics and AI play a pivotal role in transforming raw data into actionable insights. Prolifics' expertise in data validation, modeling, and visualization enables businesses to predict future trends, optimize operations, and uncover transformative patterns. Consider the case of an insurance provider that strengthened its data analytics capabilities, leading to improved claims processing and customer satisfaction.

AI for Data Analytics

Artificial intelligence for business is a game-changer, especially when integrated with data analytics. AI algorithms can process vast amounts of data at unprecedented speeds, providing deeper insights and more accurate predictions. This capability is crucial for businesses looking to innovate and stay ahead of the curve. For example, a gaming company reduced its reporting time from days to minutes by adopting AI-driven data analytics solutions.

Ensuring Seamless Database Migration

Database migration is a critical component of digital transformation. Migrating to modern data platforms allows businesses to take advantage of advanced analytics and AI capabilities. Prolifics offers comprehensive data and AI services that ensure smooth transitions, minimizing disruptions and maximizing data integrity. This process involves meticulous planning and execution, ensuring that the migrated data is secure, consistent, and readily accessible.

The Comprehensive Approach: Data and AI Services

Prolifics' data and AI services encompass a wide range of solutions, including data governance, data privacy, master data management (MDM), and data hubs. These services are designed to ensure that data is accurate, secure, and readily available to drive business insights and innovation. Effective data governance, for instance, not only improves data quality but also enhances decision-making and operational efficiency.

Stories of Success

The true impact of data and AI is best illustrated through success stories. A notable example is a gaming company that leveraged Prolifics' data and AI services to drastically reduce its reporting time. By implementing advanced analytics and AI solutions, the company was able to streamline its operations and make faster, data-driven decisions.

In conclusion, digital transformation with Data AI is a powerful enabler for businesses seeking to thrive in the digital age. By harnessing the potential of data analytics and AI, organizations can unlock new opportunities, enhance their operations, and stay ahead of the competition. Prolifics' expertise in data and AI services offers a roadmap for businesses to navigate this transformative journey successfully.

For more information on how data and AI can transform your business, visit Prolifics.

#digitaltransformation#digitalengineering#data & analytics#data analytics#data analysis#datascience#data

2 notes

·

View notes

Text

Transform your business with Prolifics digital expertise. Leverage our innovative solutions and experienced professionals to streamline operations, enhance customer experiences, and drive sustainable growth. Discover how Prolifics can help you achieve your digital transformation goals.

1 note

·

View note

Text

#GCC#GCCs#IndiaGCC#GCCIndia#GlobalCapabilityCenters#MachineLearningIndia#AIDevelopment#DigitalEngineering#AIWorkforce#SmartAutomation#AIInnovation#MLExperts#TechCentresIndia#AI#ML#SpectrumTalentManagement#SpectrumTalent#STM

0 notes

Text

#AutomotiveEngineering#MobilityInnovation#EVs#ADAS#ConnectedVehicles#SmartMobility#DigitalEngineering#MarketTrends#AutoTech#EngineeringServices#FutureOfMobility#CAGR2034#SustainableTransport#electricvehiclesnews#evtimes#autoevtimes#evbusines

0 notes

Text

#DigitalEngineering#Innovation#Ansys#BlueKei#EngineeringExcellence#India#Aerospace#Defense#Automotive#HighTech#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Explore the future of immersive technology with cutting-edge AR/VR interfaces designed for next-gen product experiences. At www.auckam.com, we engineer intelligent, responsive virtual environments that power real-time interaction, data visualization, and intuitive UI for industries like MedTech, DeepTech, and Industrial Automation. From prototyping to integration, our experts build human-centric, high-performance mixed-reality systems tailored for engineers and innovators.

#ARVRDevelopment#HumanMachineInterface#MixedReality#SmartUI#FuturisticDesign#RealtimeData#HMIengineering#ImmersiveTech#VirtualInterface#ProductInnovation#UIUXDesign#DigitalEngineering#AuckamTechnologies#TechForEngineers#Industry40

0 notes

Text

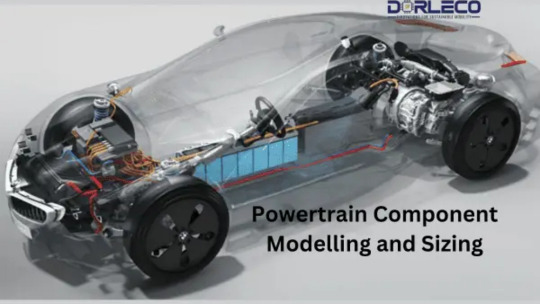

Powertrain Component Modelling and Sizing

Introduction

The dynamic automotive sector is depending more and more on virtual engineering and digital simulations to satisfy strict performance, efficiency, and regulatory requirements. The core of a vehicle’s design is the powertrain, which is the collection of elements that are accountable for generating and distributing power to the wheels. In order to achieve the best possible balance between performance, fuel efficiency, cost, and emissions, powertrain component modelling and size are crucial, regardless of the powertrain’s configuration — internal combustion engine (ICE), hybrid, or entirely electric. The systematic technique, advantages, difficulties, and prospects for powertrain component modelling and sizing in the automotive engineering process are all examined in this blog.

1. Understanding the Powertrain Component

Determining the vehicle’s intended use and performance goals is the first step in any powertrain development cycle. This fundamental stage lays the groundwork for component-level specifications and architectural choices.

Vehicle Type: EV, hybrid, commercial vehicle, sports car, or passenger car.

Performance metrics: include top speed, gradeability, towing capacity, and desired acceleration (0–100 km/h).

Compliance goals include safety regulations, fuel economy requirements, pollution regulations, and sustainability goals.

A thorough comprehension of these factors guarantees that the finished powertrain design complies with regulatory standards and market expectations.

2. Powertrain Architecture Selection

The type of vehicle and its intended use have an impact on the strategic choice of powerplant layout. Among the primary categories are:

Engine Internal Combustion (ICE)

Powertrain Hybrid (PHEV, HEV)

Electric Vehicles with Batteries (BEV)

Electric Vehicles using Fuel Cells (FCEV)

Core elements such the engine, electric motor, battery, gearbox, and control units must interact differently in each architecture. For downstream modelling, it is crucial to map the component interaction and energy flow paths at this point.

3. Modelling at the Component Level

Modelling engines

Modelling for ICE-based systems includes:

Creation of torque-speed curves

Mapping of fuel consumption

Emissions modelling and thermal behaviour

To model operating circumstances, assess combustion efficiency, and investigate transient responses, advanced programs such as GT-Power, AVL Cruise, or MATLAB/Simulink are used.

1.Modelling Transmissions

In this context, the gearbox connects wheel torque and engine power, while modelling helps determine:

Ideal gear ratios

Timing and logic for gear changing

Losses brought caused by inertia and friction

Reactivity and driveability

Single-speed gearboxes are frequently used in electric vehicles; nonetheless, efficiency and thermal considerations are still crucial.

2. Modelling Electric Motors and Batteries

In systems that are electrified:

Electric Motor: Efficiency mapping, torque-speed characteristics, inverter management, and the possibility of regenerative braking are all included in the simulations.

State of charge (SOC), voltage-current profiles, thermal performance, capacity decline, and charging/discharging behaviour are all included in the models of batteries.

Consequently, these components play a vital role in enabling accurate range estimation and supporting effective hybrid control schemes.

3. Control System Modelling

To that end, modern cars use intelligent control algorithms to regulate the flow of torque and energy. Key elements include:

Distribution of power in hybrid automobiles

Energy management systems for batteries (BMS)

Control of traction and stability

Regenerative braking and torque vectoring

Furthermore, control system modelling optimises real-time responses by ensuring smooth interaction between physical components.

4. Component sizing and optimisation

Each component is guaranteed to be neither overdesigned nor underutilised with proper dimensions. Engineers optimise variables like

Engine displacement and output torque

Maximum power and continuous motor rating

C-rate and battery capacity

Gear ratios for transmissions

The proper trade-offs between performance, efficiency, cost, and packing can be achieved with the aid of optimisation technologies (such as genetic algorithms and experiment design).

5. Compatibility and System Integration

The powertrain must function as a cohesive system in addition to its individual performance. Important integration factors consist of:

Thermal control of the battery, inverter, and engine.

Packaging and weight distribution to maintain vehicle dynamics

Features of NVH (Noise, Vibration, Harshness)

Compatibility of mechanical and electrical interfaces

Therefore, ignoring these elements may lead to inefficiencies, reliability issues, or dissatisfied clients.

6. Performance Validation Through Simulation

Subsequently, once components are designed and scaled, system-level simulations are conducted to validate the full powertrain component across real-world scenarios.

Urban driving cycles, such as the FTP-75 and WLTP

Profiles of highway loads

Simulations of hill climbing or towing

Conditions for idle-stop and regenerative braking

Engineers can create control methods and identify bottlenecks early in the process with the help of simulation technologies (such as MATLAB, dSPACE, and IPG Carmaker).

7. Physical Testing and Prototyping

Although simulation offers a theoretical starting point, physical testing is still necessary:

Prototype vehicle builds

Engine test beds and dynamometers for the chassis

Tests of endurance and durability

Prior to mass production, these tests ensure system robustness by validating predictions and identifying unforeseen mechanical, thermal, or ergonomic concerns.

8. Cost Analysis and Compromises

Additionally, a high-performance Powertrain Component needs to be profitable. Cost modelling includes:

Complexity of manufacturing and material selection

Tooling expenses and supplier availability

Implications for warranty and maintenance

In addition, simulations help identify cost-effective solutions without sacrificing critical performance parameters.

9. Iterative Refinement

In practice, the development process is rarely linear; instead, several design iterations are driven by insights gained from simulation, testing, and consumer feedback.

Modifying component specifications

Control logic revision

Power split or thermal load rebalancing

Consequently, this iterative loop ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

10. Records and Adherence

As a result, this iterative loop not only streamlines development but also ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

Logs from simulations and technical reports

Design specifications and the bill of materials

Safety requirements and emissions certifications

Design decision traceability

Proof of due diligence throughout the development process is necessary to comply with international rules (such as those set forth by the EPA, CARB, and UNECE).

Benefits of Powertrain Component Modelling and Sizing:

✔ Performance Enhancement

Fine-tuning for certain objectives, such as high torque, quick acceleration, or fuel economy, is possible through simulation.

✔Enhanced Productivity

Appropriate size improves energy efficiency on both ICE and EV platforms by preventing overdesign and lowering internal losses.

✔ Saving Money

Furthermore, by avoiding needless overspecification, manufacturers can effectively reduce manufacturing and material costs without compromising quality.

✔ Emissions Management

As a result of precise engine mapping and electric system optimisation, CO₂ and NOₓ emissions are significantly reduced.

✔ Predictive Knowledge

Prior to costly tooling and prototyping, simulations identify possible failure areas or inefficiencies.

✔ Personalisation

The architecture and Powertrain Component flexibility made possible by early modelling is advantageous for a variety of vehicle types, including haul trucks and two-wheelers.

✔ Superior Energy Organisation

Reliability and range are directly impacted by efficient battery and power management systems, particularly in EVs and hybrids.

✔ Reduced Market Time

Virtual iterations make faster development cycles possible as opposed to conventional build-and-test loops.

✔ Dependability

Moreover, stress analysis and thermal modelling ensure durability, which in turn lowers warranty claims and enhances brand recognition.

✔ Attention to Regulations

By ensuring early compliance with international safety and emissions standards, manufacturers can significantly reduce the need for costly redesigns later in the development cycle.

Difficulties with Powertrain Component Sizing and Modelling

Despite its strength, this strategy has drawbacks: Model Complexity: It takes knowledge and computing power to accurately simulate multi physics systems. Data Reliability: Reliable input data is necessary for model accuracy, which frequently necessitates rigorous physical testing for calibration. Integration Difficulties: Maintaining balance between electrical, mechanical, and control systems is difficult. Dynamic Operation Limits: Unexpected real-world circumstances are not always taken into account by models. Cost of Software Tools: Smaller businesses cannot afford the sophisticated simulation suites. Rapid Technological Changes: As EVs advance quickly, current models may become outdated. Real-World Parameter Uncertainty: It is challenging to accurately forecast traffic, temperature, and driver behaviour.

Conclusion

At the forefront of contemporary vehicle engineering is the modelling and sizing of powertrain components. In a cutthroat market, they enable automakers and suppliers to create vehicles that are effective, legal, and perform well. Engineers may unlock better ideas while cutting down on time, expense, and environmental effect by combining virtual simulations with actual testing. Modelling techniques will only become more crucial as the sector continues its transition to electrification and autonomous systems. Experts anticipate that future developments in digital twins, AI-driven simulations, and cloud-based co-simulation platforms will further push the limits of accuracy and effectiveness. Powertrain modelling and sizing are essentially strategic enablers of innovation, performance, and sustainability in mobility when used with insight and rigour.

#Dorleco#EVEngineering#PowertrainModelling#AutomotiveInnovation#VCU#CANDisplay#BatteryManagement#SimulationDrivenDesign#ElectricVehicles#MobilitySolutions#FutureOfTransport#EngineeringExcellence#DigitalEngineering

0 notes

Text

#Tata Elxsi#MercedesBenz#MBRDI#FutureOfMobility#AutomotiveInnovation#SoftwareDefinedVehicles#DigitalEngineering#SmartCars#Collaboration#electronicsnews#technologynews

0 notes

Text

Adapting to Change: The Evolution of CAD Standards in Australian Construction

The construction landscape in Australia is evolving—and so are its digital demands. From national CAD standards to the rise of BIM and digital engineering mandates, consistency is no longer optional. Discover how CAD drafting is transforming into a smarter, structured, and collaborative system that empowers efficiency, accuracy, and compliance across all project types.

Why CAD Standards Matter for Your Next Project

✅ Understand the evolution of CAD standards in Australian construction—from manual drafting to cloud collaboration.

📏 Learn about key CAD drafting protocols, including layer naming, file structures, and annotation rules.

🏗️ Explore the transition from CAD to BIM, and why BIM integration is reshaping project delivery.

🌏 See how government regulations and AS 1100/ISO 19650 standards are influencing industry-wide practices.

💡 Discover how Tesla CAD Solutions helps firms streamline, standardise, and future-proof their design workflows.

Get ahead of the curve—explore the full blog to learn how your firm can stay compliant, competitive, and ready for what’s next: Adapting to Change: The Evolution of CAD Standards in Australian Construction

#CADStandards#BIMAustralia#ConstructionTech#DigitalEngineering#AECIndustry#AustraliaConstruction#RevitStandards#SmartDrafting

0 notes

Text

Model-Based Design Tools – Accelerating Innovation in Engineering and System Development

In today's competitive and fast-evolving engineering landscape, delivering high-quality products quickly and efficiently is essential. Whether you're developing automotive control systems, industrial automation solutions, or embedded software for smart machines, traditional design methods often fall short in meeting modern demands. Enter Model-Based Design (MBD)—a powerful, integrated approach that enables engineers to design, simulate, and verify systems in a virtual environment before physical prototypes are built.

At the heart of this methodology are Model-Based Design Tools, which streamline development, reduce risk, and enhance innovation. From concept to deployment, MBD tools help teams collaborate effectively, minimize errors, and deliver systems that perform as expected in the real world.

What Is Model-Based Design?

Model-Based Design is an engineering process that uses graphical models to represent the behavior, logic, and structure of a system. Unlike traditional code-centric approaches, MBD relies on visual representations—such as block diagrams, state machines, and simulations—to develop embedded systems and control algorithms.

These models are used throughout the entire development cycle: from system-level simulation and design, to code generation, verification, testing, and implementation. By leveraging a single, reusable model, engineers can ensure consistency across all stages, leading to better designs, faster development, and fewer bugs.

Key Features of Model-Based Design Tools

Model-Based Design Tools offer a wide array of capabilities that simplify and enhance engineering workflows. Some of the core features include:

🧩 Graphical Modeling

Create intuitive visual models of systems using drag-and-drop components, such as sensors, actuators, control logic, and feedback loops. This visual interface helps teams quickly prototype and iterate on design ideas.

⚙️ Simulation and Testing

Simulate system behavior under different conditions to evaluate performance, optimize parameters, and detect issues before implementation. Early-stage testing helps reduce costly late-stage redesigns.

🧠 Automatic Code Generation

Transform validated models into production-quality C, C++, or HDL code using tools like MATLAB® and Simulink®. This accelerates embedded software development while reducing human error.

🧪 Model Verification and Validation

Perform functional testing, requirement checks, and formal verification at the model level. This ensures that your system meets design requirements and regulatory standards.

🔄 Hardware-in-the-Loop (HIL) Simulation

Test models on real hardware or hardware simulators to validate behavior in real-time conditions. HIL testing bridges the gap between simulation and reality.

👥 Collaboration and Integration

Work collaboratively with cross-functional teams by integrating model-based tools with version control systems, requirement management platforms, and code repositories.

Benefits of Using Model-Based Design Tools

The advantages of implementing model-based tools in engineering projects are vast and impactful:

✅ Faster Development Cycles

By enabling rapid prototyping, simulation, and automatic code generation, MBD drastically reduces time-to-market compared to traditional methods.

✅ Improved Product Quality

Systematic verification and validation at every stage ensure robust, reliable systems with fewer bugs and post-release issues.

✅ Cost Savings

Fewer errors, reduced rework, and faster development translate directly into lower development costs.

✅ Enhanced Team Collaboration

With shared models and standardized workflows, cross-disciplinary teams can work together more efficiently and effectively.

✅ Scalable for Complex Systems

From small embedded systems to large-scale control architectures, MBD tools scale with the complexity of your application.

✅ Compliance and Certification Readiness

Model-Based Design supports the development of safety-critical systems, helping meet industry standards like ISO 26262, DO-178C, and IEC 61508.

Real-World Applications of Model-Based Design

Model-Based Design Tools are used across various industries to solve complex engineering challenges. Here are a few key application areas:

Automotive – Designing advanced driver-assistance systems (ADAS), powertrains, electric vehicle control systems, and infotainment features.

Aerospace – Developing flight control systems, navigation software, and fault-tolerant avionics.

Industrial Automation – Creating control systems for robotics, conveyors, packaging machines, and process automation.

Agricultural Technology – Powering autonomous tractors, irrigation control, and precision farming systems.

Medical Devices – Designing embedded control systems for ventilators, pumps, and diagnostic equipment.

Energy – Managing smart grid systems, battery management systems, and renewable energy integration.

Model-Based Design at Servotech

At Servotechinc, we integrate Model-Based Design into our engineering and development services to deliver high-performance, real-time control systems and embedded solutions. We specialize in MATLAB®, Simulink®, and other industry-leading MBD tools to:

Design and simulate control algorithms

Develop embedded software for microcontrollers and real-time systems

Conduct hardware-in-the-loop testing and validation

Generate certified production-ready code

Ensure compliance with industry safety standards

Our approach allows us to deliver customized, efficient, and scalable systems for clients across automotive, industrial, agricultural, and robotic sectors.

The Future of Engineering with MBD Tools

As products become increasingly intelligent and connected, the complexity of system development continues to rise. Model-Based Design is no longer a luxury—it’s a necessity. With its ability to integrate modeling, simulation, and code generation into one cohesive workflow, MBD empowers engineering teams to move faster, innovate boldly, and reduce risks at every stage.

Emerging trends such as digital twins, AI-driven modeling, and cloud-based simulation platforms will continue to push the boundaries of what Model-Based Design Tools can do. The organizations that embrace this methodology today will lead the industries of tomorrow.

Conclusion

Model-Based Design Tools represent a transformative approach to modern engineering—bridging the gap between design and deployment with speed, accuracy, and confidence. Whether you're building the next generation of smart machines or optimizing existing systems, MBD offers the tools you need to succeed.

At Servotech, we're proud to support clients with comprehensive Model-Based Design services that turn ideas into reality—faster, smarter, and better.

#ModelBasedDesign#SystemSimulation#EngineeringInnovation#EmbeddedSystems#Simulink#MATLABDevelopment#ControlSystems#AutomaticCodeGeneration#DigitalEngineering#ServotechSolutions

0 notes

Text

🌐 Top Web Development Company in Australia – LDS Engineers

Looking to elevate your brand’s online presence? LDS Engineers is a leading web development and design company in Australia, delivering powerful digital solutions that are both visually stunning and strategically built.

In today’s digital-first world, having a strong online presence is essential for businesses of all sizes. That’s where LDS Engineers, a top web development company in Australia, comes in. With years of experience and a deep understanding of modern technologies, LDS Engineers delivers cutting-edge web design and development solutions that drive real business results.

✨ Why Choose Us? We combine computer engineering with in-depth market research to create custom websites that are: ✔️ Fast ✔️ Mobile-Friendly ✔️ SEO-Optimized ✔️ Scalable and User-Focused

From custom website development to eCommerce platforms, CMS-based sites, and performance optimization—we build websites that perform.

Whether you're a startup, a growing business, or an enterprise ready for a digital upgrade, we’re here to help you succeed.

💬 Let's build something amazing together. 📞 +61 461530444 📨 [email protected] 💻 www.ldsengineers.com.au 🔗 Chat with us: Click here

#LDSengineers#WebDevelopment#WebDesign#ResponsiveWebsites#SoftwareDevelopment#WebsiteInspo#DigitalEngineering#MarketResearch#WebDesignServices#SydneyBusiness#AustraliaStartups#ExplorePage#TumblrTech#Quotes#LikeForLikes#TumblrPost#WebAgency#DesignStudio#OnlineSuccess#CustomWebDesign

0 notes

Text

Indian Engineering Services: Persistent, KPIT, Tata Elxsi Report Robust Q2FY25 Revenue Growth

In Q2FY25, Persistent, KPIT, and Tata Elxsi have posted robust revenue results, reflecting their leadership in the engineering services sector. Persistent’s emphasis on cloud and automation continues to fuel its growth, while KPIT’s automotive engineering solutions maintain a strong competitive edge. Tata Elxsi’s digital engineering expertise, especially in automotive and healthcare, has significantly contributed to its success. As industries increasingly adopt digital transformation, these companies are well-positioned to continue driving growth.

0 notes

Text

Prolifics at IBM TechXchange 2024

IBM TechXchange 2024 Conference

Dates: October 21-24, 2024 Location: Mandalay Bay – Las Vegas Conference Website: https://www.ibm.com/

We are speaking at IBM TechXchange Conference 2024

Join Prolifics at this October at IBM TechXchange for an immersive AI learning experience focused on unlocking the potential of generative AI and maximizing IBM’s powerful technology suite. Engage in hands-on watsonx challenges, deep-dive technology breakouts, and immersive instructor-led labs to sharpen your skills, earn valuable credentials, and connect with top innovators shaping the future of technology.

Meet Our Experts

Amrith Maldonado, Product Support Manager, Prolifics

Vishnu Pandit, Practice Director – Integration and Platforms, Prolifics

Attend our sessions at IBM TechXchange Conference 2024 to discover how to accelerate your AI journey and stay at the forefront of industry innovation. Elevate your expertise while connecting with peers and industry leaders who are driving the future of technology.

Our experts will cover key topics that matter to your business, including:

Data Governance: Discoverhow the MPP Connector enhances Data Governance by integrating Manta's advanced metadata and lineage capabilities with Microsoft Purview, ensuring comprehensive visibility and control.

Reduce Technical debt with IBM’s Integration Portfolio: Learn how to leverage IBM’s integration portfolio’s advanced monitoring, seamless integration, automation, and governance tools to minimize technical debt and ensure long-term sustainable growth for your business.

This conference is your must-attend event for connecting with AI developers, industry innovators, and others seeking the tools and knowledge to transform their work.

We’re can’t wait to connect with you—see you there!

About Prolifics

Prolifics, in collaboration with IBM, leverages the power of watsonx to deliver innovative AI solutions that fuel business transformation. Together, we enable organizations to harness AI and automation to drive smarter decisions and faster, more impactful results.

Join us at IBM TechXchange 2024 to explore how we can elevate your AI journey.

0 notes

Text

youtube

#dataanalytics#digitalengineering#ecommerce#fintech#healthcare#retrail#manufacturer#techsolutions#Youtube

1 note

·

View note