#icdesign

Explore tagged Tumblr posts

Text

Electronic Integrated Circuits | Shenzhen Informic Electronic Limited

At Shenzhen Informic Electronic Limited, we specialize in delivering high-performance and electronic integrated circuit solutions for a wide range of applications-from consumer electronics to industrial systems. Our ICs are rigorously quality-tested for efficiency, stability, and long-term performance, helping you build innovative, dependable products that meet the demands of today’s technology landscape. Visit us.

0 notes

Text

Ever wondered what makes the 4S0101 IC a game-changer in electronic circuits? ⚡️

Let’s break it down!

🔍 Key Features:

High efficiency & low power consumption 🔋

Robust thermal performance 🌡️

Compact design for space-saving integration 📏

✅ Pros: Reliable, energy-efficient, and cost-effective. ❌ Cons: Limited applications in high-power systems.

💡 Where is it used? From consumer electronics to industrial automation, this IC powers innovations worldwide.

Do you use the 4S0101 IC in your projects? Drop a comment and let’s discuss! 👇

#Tech#Electronics#ICDesign#Engineering#Hardware#Semiconductors#EmbeddedSystems#Innovation#ProductDevelopment#TechTalk

0 notes

Text

#Renesas Electronics#AnalogPAK#MixedSignal#ICDesign#Innovation#Electronics#Technology#Engineering#electronicsnews#technologynews

0 notes

Video

youtube

Check all our Upcoming Webinars this week (September 27th - September 30...

0 notes

Link

0 notes

Photo

Front of the new Business card

2 notes

·

View notes

Text

#ProgPoW From the View of an IC Design Engineer

I am an IC design engineer who has also been mining cryptocurrencies since 2014. Although, unlike many other miners from back then, I am not the owner of a large mining farm, I do have a mining setup that makes just enough profit for me to justify the time I spend on it to my wife. Amidst all varying points of views on ProgPoW circulating online, I hope to share those of an IC engineer.

Whether the algorithm is ProgPoW or ETHash, the hashrate is determined by the storage bandwidth of external DRAM. That is,

Hashrate = k*BW

where k is a constant factor and is different for ETHash and ProgPoW

Therefore, to increase the hashrate for ETHash or progPoW, we need to increase the memory bandwidth. In the early years, high-bandwidth memory devices were mainly GDDR5 in graphics cards. Only AMD and Nvidia GPUs could handle such a high-bandwidth memory. So, GPUs from Nvdia or AMD became the most popular for ETHash mining. Now the memory demand for profitably mining ETHash has increased significantly. This demand for high-bandwidth memory has prompted the development of next-generation high-speed memory tech such as GDDR6 and HMB2. In Q4 of 2018, Innosilicon released its GDDR6 IP together with its ETHash mining ASIC. Because of the similarities that exist between the algorithm as well as architecture of ProgPoW and those of ETHash, I believe that Innosilicon’s next ASIC would be tailored for ProgPoW. 3-4 months is sufficient time to design and mass-produce such an ASIC once the parameters of ProgPoW are fixed. I believe that Bitmain is also secretly developing its own GDDR6 IP. Other companies, such as Rambus and eSilicon, have already released IP of GDDR6 and HMB2. I have no doubt that other mining ASIC producers, such as Linzhi and Canaan Creative, will soon adopt GDDR6 or HBM2 in their future generation chips. So, we may see many GDDR6/HBM2 based ASICs for ProgPOW in the near future if ProgPoW is implemented.

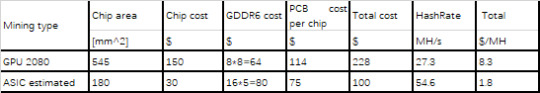

Mining ASICs can use optimization methods based on GDDR6 and HBM2. Just an example of these methods is having more GDDR6/HBM2 memory banks in ASICs than GPUs. Take Nvidia's 2080. It uses 8 GDDR6s and operates at 14Gbps, giving it a total bandwidth (BW) of 8*14*32/8 = 448Gbps. According to the bandwidth requirement of ProgPoW, the theoretical hashrate should be

hashrate = BW/64/256 = 27.3Mh/s.

Considering the storage efficiency, the actual value should be 25.5Mh/s. An ASIC producer can use the smaller GDDR6 memory banks to gain cost advantages over GPUs. 16 GDDR6 4GB memory banks can be used to achieve a 2x bandwidth advantage, while maintaining GDDR6 costs at almost the same level. In this case, the available bandwidth is 16*14*32/8 = 896Gbps, and the theoretical hashrate is,

hahsrate = 896Gbps/256/64 = 54.6Mh/s

which gives 2x more hashrate advantage. But the silicon area of 4GB GDDR6 is 50% smaller than that of the 8GB GDDR6. So the price of 4GB GDDR6 should be 60% less than the price of 8GB GDDR6. The total cost of GDDR6 is summarized in Table 1 below.

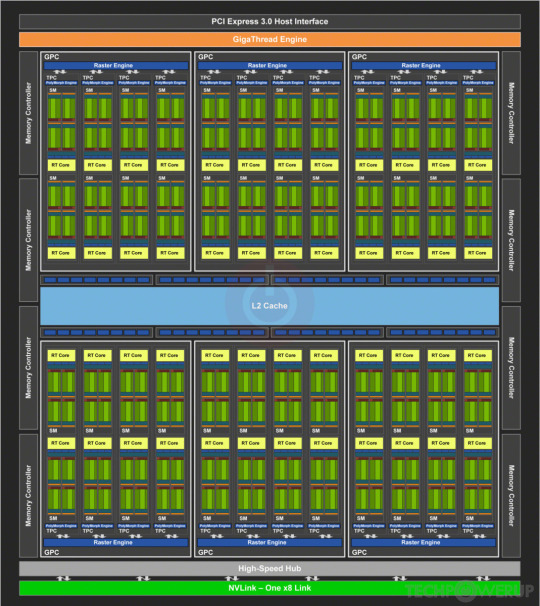

Let’s look into the internal structure of a GPU chip, such as the Nvidia RTX2080, as shown in Figure 1 from Nvidia.

Fig.1: Architecture of Nvidia RTX2080

There are many modules in the RTX2080 chip that occupy a lot of the chip area and are useless for ProgPoW. These include PCIE, NVLINK, L2Cache, 3072 shading units, 64 ROPs, 192 TMUs et. all. An ASIC producer could remove these graphics functions and optimize the same chip area for ProgPOW algorithms, which could reduce the chip area to roughly 1/3rd that of Nvidia’s RTX2080 chip. So, the cost of such an AISC chip would be only 1/3rd that of the RTX2080 because, with the same number of silicon wafers, the number of such ASIC chips that can be produced would be three times more.

And, compared to large chips, small chips have higher yields and lower packaging and testing costs. The yield calculation formula is:

Y = 1/power(1+0.08*die_area)^22.4

For the Nvidia RTX2080 GPU, the die area is 545 mm^2. So the calculated yield of the GPU is 23%. If the area is reduced to 1/3rd, the yield Y will increase by 60%. Low yield will result in a higher cost of the GPU. The cost of such an ASIC would be 1/3*23/60 = 0.13 of that of the GPU. That is a 7.7x more advantage for the ProgPoW ASIC compared to the GPU. Estimating maturity of the GPU, I will keep this advantage limited to 5x for the next calculation. On the system PCB, the ProgPoW ASIC would also have a cost advantage if the ASIC producer were to eliminate the PCIE and complex thermal designs which are required by GPU cards. In an ASIC based mining machine, a large number of ASIC chips and GDDR6, using much simpler and cost-effective heat sink design, would be way more densely packed (and thus shipped). The system cost in a GPU cards may be 50%, but the PCB cost of the ASIC based mining machine can easily be reduced to 30%. I have made the overall cost comparison for GPU and ASICs in Table 1.

Table 1: the comparison of GPU and ASIC for ProgPOW

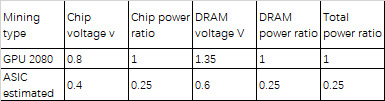

As for the power consumption, the GPU would consume much more power as it can only work at the normal voltage, which is usually 0.8V. However, the ProgPoW ASIC’s power consumption can be reduced by reducing the operating voltage. According to Ohm's law, power is proportional to the square of the voltage:

P = U*I = U^2/R

The voltage of ASICs can easily be reduced to 0.4V, which is 1/2 that of GPU’s. Thus, for the same hashrate, the ProgPoW ASIC would consume only 1/4th the power consumed by the GPU. In other words, the ProgPoW ASIC can have an energy efficiency ratio 4x that of the GPU. Such low-voltage ASIC designs are already utilized by ASIC producers in Bitcoin mining machines and there is no reason to believe that they would not be used in ProgPoW ASICs. The same power-saving can also be achieved in LPDDR4x DRAM, which has a lower power consumption than GDDR6. GDDR6 works at 1.35v, while LPDDR4X works at 0.6V, which is less than half that of the GDDR6. So GDDR6 consumes at least 4x more power than LPDDR4x. So an ASIC with LPDDR4x DRAM has a 4x more power efficiency over a GPU with GDDR6. I have shown this in Table 2.

Table 2: Power efficiency comparison of GPU and ASIC with ProgPoW

Furthermore, designing GPUs requires a much higher R&D investment in terms of both human resource and time. Because GPU is a general-purpose acceleration chip, it usually takes about 12 months for a GPU to be designed, fabricated and tested, requiring a lot of hardware simulations and software developing to cover different computing scenarios. But the design and test for ProgPoW's ASICs, are much simpler. A dedicated team of experienced IC designers could take as little as 2 months for design, 6 weeks for fabrication and 2 weeks for testing of ProgPoW ASICs. Thus, it could take only 3 to 4 months for ProgPoW ASICs to be ready for mass production. For ASIC companies, such as Bitmain and Innosilicon, which are already producing ETHash mining ASICs, integrating ProgPoW in their previous designs to produce a ProgPoW ASIC would be even simpler. A GPU producer like Nvidia employs about 8000 people to develop GPUs, which are much more complicated, whereas an ASIC producer like Linzhi only employs a dozen or so people to focus only on ASICs for ETHash mining. The labor costs of these companies company are different by a factor of 100. So ASICs have further advantages in terms of cost and time-to-market than GPU chips.

To summarize, ProgPoW ASICs seems inevitable if ProgPoW were implemented and it would take only 3-4 months for them to hit mass production. Furthermore, they would have at least a 4x advantage in both cost and power efficiency over a GPU for accelerating the ProgPoW algorithm. This would bring us right back to where we started pre-ProgPoW and begs the question: Why ProgPoW or why ASIC-resistance?

1 note

·

View note

Photo

Replacing the battery on an old (circa 2010) MBP. The engineering that went into this ... incredible. We take for granted that we will hit the power on our laptops or phones and they just turn on and do what we want them to, but forget about the design, testing, and production involved. #motherboard #icdesign #macbook #engineering https://www.instagram.com/p/Bo-I0Trltul/?utm_source=ig_tumblr_share&igshid=sgq8pnxejygk

0 notes

Link

Semiconductor hardware and software design services, Semiconductor industry services.With expertise in creating semiconductor hardware design, Sasken is involved in end-to-end design & development of semiconductor and multiple chipset platforms.

#semiconductor#iot#digitalmarketing#icdesign#hardwaredesign#Platform and Application Software#Silicon Verification and Validation

0 notes

Text

#Apex Microtechnology#Microtechnology#ICDesign#Electronics#Innovation#electronicsnews#technologynews

0 notes

Photo

Vielen Dank @nedashome für dieses tolle Foto ! Wir freuen uns immer riesig zu sehen, welchen Platz die Prints in euren vier Wänden gefunden haben 🙌🏻 Und wisst ihr was? Seit es unseren Shop gibt, verlosen wir monatlich eine Überraschung unter all denjenigen, die ihre bestellten Prints posten und uns markieren 😊👏🏻 Also nicht lang schnacken, ein schniekes Foto knipsen und mit etwas Glück ein SOLT UN PEPER - Überaschungspaket gewinnen 😊🍀 Und jetzt startet alle gut ins Wochenende - liebe Grüße von der Waterkant ⚓️ icdesign#graphics#minimalism#prints#design#hamburg#soltunpeper#interiordesign#decoration#decor#home#love#family#onlineshop#onlineshopping#interior#personalisiert#gewinnspiel (hier: Hamburg, Germany)

#onlineshopping#interior#home#hamburg#gewinnspiel#soltunpeper#decoration#love#prints#design#minimalism#family#decor#onlineshop#graphics#personalisiert#interiordesign

1 note

·

View note

Video

youtube

Check all our Upcoming Webinars this week (September 21st - September 25...

#PROLIM#PLM#EDA#WEBINAR#TRAINING#SOLIDEDGE#NX#SIMCENTER#PCB#ICDESIGN#SIMCENTER TESTLAB#siemens#mentor graphics#live webinar#live training#digital transformation

0 notes

Text

The Scattering Matrix, S11 on the Smith Chart

The parameter S11 is the port 1 reflection coefficient when Zo is placed in the other ports as load impedance.

Then, if S11 is a reflection coefficient, it can be drawn on the Smith Chart as you can see in the image below.

Why is it drawn as a line?

Remember that the parameter S11 depends on the frequency. Therefore, if the frequency changes, the parameter S11 also changes.

The pink line show the parameter S11 for different frequencies.

Can you follow this reasoning?

Image source: https://www.mics.ece.vt.edu/ICDesign/Tutorials/RFIC/LNA.html

0 notes

Photo

The rendering of Scorpio had begun! #art #drawing #illustration #artwork #artist #sketch #digital #design #draw #instaart #photoshop #digitalpainting #graphicdesign #painting #doodle #creative #instagood #digitaldrawing #graphic #love #sketchbook #cartoon #artoftheday #portrait #myart #digitalartist #wacom #color #artsy #oc

#ins#doodle#oc#graph#art#i#drawing#digitaldra#draw#creative#love#ar#portr#sketch#digitala#painting#artwork#artsy#photoshop#color#myart#digital#illus#cartoon#graphic#sketchbook#di#artoftheday#wacom#design

0 notes

Link

This is our website !

0 notes