#lightweight structures

Explore tagged Tumblr posts

Text

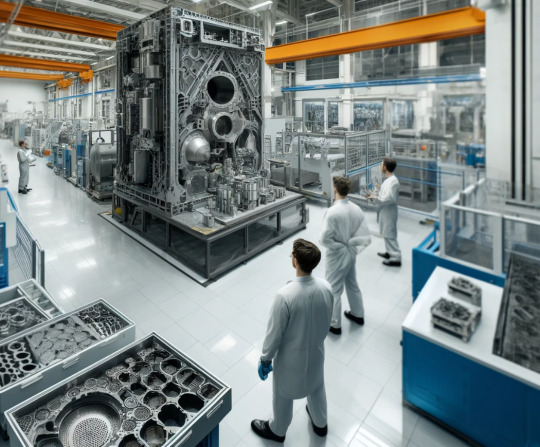

Il progetto europeo MIMOSA sviluppa giunzioni 3D tra metalli AM e carbon-fiber per velivoli più leggeri e riciclabili. Protagonisti TÜV Italia e Bytest, eccellenze nei test e nella certificazione. Scopri i risultati su Alessandria today.

#additive manufacturing#aeronautica sostenibile#aerostrutture#Alessandria today#atomizzazione#Bytest#certificazione aeronautica#certificazione processi#compositi carbonio#distretto aerospaziale Piemonte#eco-design#Economia circolare#Fenice#fibre di carbonio#Giorgio De Pasquale#giunzioni ibride#Google News#green aviation#Horizon Europe#innovazione materiali#italianewsmedia.com#laboratorio Volpiano#Lava#Leonardo#life-cycle assessment#lightweight structures#NDT#Pier Carlo#POLITECNICO DI TORINO#progetto MIMOSA

0 notes

Text

Disneyland House, Obermodern-Zutzendorf, France - GENS

#GENS#architecture#design#building#modern architecture#interiors#minimal#house#modern#house design#cool houses#timber frame#roof#truss#structure#lightweight#sliding glass doors#loft#pitched roofing#garden#village#rural#roof tiles#french#france#french architecture#contemporary homes#beautiful design#light#design blog

164 notes

·

View notes

Text

mit x steelcase

5 notes

·

View notes

Note

Thank you! I was just watching 6x9 and they wore the yellow suits and it didn't make much sense to me (yellow in the desert seems like lower visibility?), they so rarely wear them

Oooh no yeah they would have worn wildland gear for that brush fire as opposed to structural gear !!

#wildland gear is lightweight and more flexible#structural gear (traditional bunkers) is heavier and more protective#asks#anonymous#office hours

2 notes

·

View notes

Text

Basalt Fiber Reinforcement in Construction: A Sustainable Paradigm Shift

Introduction In the contemporary construction landscape, a notable shift towards sustainable and eco-friendly building materials is underway. Among the alternatives gaining prominence is basalt fiber reinforcement, positioning itself as a compelling substitute for traditional steel reinforcement. This transition is fueled by a collective desire to reduce environmental impact and elevate the…

View On WordPress

#alternative to steel reinforcement#basalt fiber applications#basalt fiber properties#Basalt fiber reinforcement#basalt mesh in concrete#BFRP composites#construction industry sustainability#corrosion-resistant materials#durability in construction#eco-friendly building#environmental impact of construction#future of construction materials.#green building practices#lightweight construction materials#seismic resilience in buildings#steel replacement in construction#strength-to-weight ratio#Sustainable Construction Materials#sustainable structural design#thermal insulation in construction

2 notes

·

View notes

Text

Ascend in Style. Built to Lead. The Men’s Starflow Halo TRONFORM High-Top Canvas Shoes are more than footwear—they’re a visual statement of future-forward luxury. Designed with the iconic Starflow Halo constellation motif, this handcrafted silhouette captures cosmic rhythm and elite presence in every step. The all-black canvas is framed by crisp white stars, blending power with elegance in a bold contrast built to dominate city streets, rooftop lounges, and everything in between.

Sculpted for movement, engineered for presence—these high-tops fuse form and function with lightweight precision. The faux leather toe, coordinated laces, and high-profile structure give this piece an unmistakable TRONFORM identity: futuristic, minimal, and unmissable. Whether styled with layered streetwear or a sleek black set, these shoes complete the look with energy and edge.

These aren’t just sneakers. They’re celestial armor.

Shop now → https://www.tronform.co/products/men-s-starflow-halo-high-top-canvas-shoes

#TRONFORM#StarflowHalo#HighTopLuxury#FuturisticFootwear#MensStreetwear#LuxurySneakers2025#HugoTronOriginal #CosmicStyle#StatementShoes#NextGenStreetwear#PrecisionBuilt#MonochromeFit#BlackAndWhiteAesthetic #CelestialDesign#UrbanDominance#LuxuryFootwearDrop#TRONFORMMen#ModernEmpireWear#FutureIsFashion #LuxeCanvas#HighTopCommand#EliteStep#GalaxyVibes#MinimalPowerStyle#TailoredToMove#ShoesOfTomorrow

#Ascend in Style. Built to Lead.#The Men’s Starflow Halo TRONFORM High-Top Canvas Shoes are more than footwear—they’re a visual statement of future-forward luxury. Designed#this handcrafted silhouette captures cosmic rhythm and elite presence in every step. The all-black canvas is framed by crisp white stars#blending power with elegance in a bold contrast built to dominate city streets#rooftop lounges#and everything in between.#Sculpted for movement#engineered for presence—these high-tops fuse form and function with lightweight precision. The faux leather toe#coordinated laces#and high-profile structure give this piece an unmistakable TRONFORM identity: futuristic#minimal#and unmissable. Whether styled with layered streetwear or a sleek black set#these shoes complete the look with energy and edge.#These aren’t just sneakers. They’re celestial armor.#Shop now →#https://www.tronform.co/products/men-s-starflow-halo-high-top-canvas-shoes#TRONFORM#StarflowHalo#HighTopLuxury#FuturisticFootwear#MensStreetwear#LuxurySneakers2025#HugoTronOriginal#CosmicStyle#StatementShoes#NextGenStreetwear#PrecisionBuilt#MonochromeFit#BlackAndWhiteAesthetic#CelestialDesign

0 notes

Text

Duraneo GFRP Bent Rebars – Durable, Flexible Reinforcement for Complex Concrete Structures

Duraneo’s GFRP bent rebars are engineered to provide reliable reinforcement in intricate concrete shapes such as corners, hooks, and stirrups. Made from corrosion-resistant glass fiber reinforced polymer, these bars ensure long-lasting performance in harsh environments while being lightweight and easy to handle. Perfect for infrastructure projects demanding strength, flexibility, and durability without the drawbacks of traditional steel.

#GFRP bent rebar#composite reinforcement#corrosion-resistant rebar#glass fiber reinforced polymer#bent rebars#lightweight reinforcement#durable rebar#structural reinforcement#concrete reinforcement#non-metallic rebar#corrosion-free rebars#reinforced concrete solutions#precision-formed rebar#infrastructure reinforcement#marine-grade rebar

0 notes

Text

Exploring the Benefits of Checker Plate Aluminium in the Construction Industry

Checker plate aluminium is becoming increasingly popular in the construction and industrial materials sectors, particularly for its durability and aesthetic appeal. Minmetals East is at the forefront of offering high-quality checker plate aluminium that meets the diverse needs of various industries.

The unique design of checker plate aluminium provides excellent slip resistance, making it an ideal choice for flooring, walkways, and ramps. This safety feature enhances workplace environments, reducing the risk of accidents and ensuring a secure footing for workers.

In addition to safety, checker plate aluminium is lightweight yet strong, making it easy to handle and install while maintaining structural integrity. Minmetals East's commitment to quality ensures that customers receive products that are not only functional but also sustainable, contributing to environmentally friendly construction practices.

Moreover, the versatility of checker plate aluminium allows it to be used in a variety of applications, including in the manufacturing of industrial materials and water treatment facilities. As industries continue to innovate, Minmetals East remains dedicated to providing solutions that meet the evolving demands of the market.

Embrace the advantages of checker plate aluminium and elevate your projects with the superior products from Minmetals East!

#structural integrity#Minmetals East#lightweight#water treatment facilities#durability#safety#versatility#construction industry

0 notes

Text

YOUR NEXT WAREHOUSE NEEDS A ROOF THAT CAN BENCH PRESS A SEMI 🚛💪

Lightweight strength for heavyweight dreams.

0 notes

Text

Body in White Market Scope: Growth, Share, Value, Size, and Analysis

https://www.databridgemarketresearch.com/media/2021/12/GlobalBodyinWhiteMarket.jpg

"Body in White Market Size And Forecast by 2029

According to Data Bridge Market Research The body in white market is expected to witness market growth at a rate of 2.56% in the forecast period of 2022 to 2029.

Innovation remains at the core of Automotive BIW Market success, driving growth and customer engagement. Body in White Market continuously invests in research and development to stay ahead of industry changes. By leveraging advanced technology, Vehicle Frame Manufacturing Market enhances its solutions to meet consumer expectations. The strategic approach of Body in White Market ensures that new products and services remain competitive. Body in White Market remains a pioneer, delivering top-tier solutions with innovative strategies.

Car Chassis Structure Market plays a crucial role in shaping global market trends through its dynamic approach. The influence of Body in White Market extends across industries, inspiring growth and development. Companies look to Automotive Shell Manufacturing Market as a benchmark for success, recognizing the brand’s leadership. By staying updated with consumer needs, Body in White Market maintains its strong position. The adaptability of Lightweight BIW Solutions Market ensures continued influence in shaping industry patterns.

Our comprehensive Body in White Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-body-in-white-market

**Segments**

- **Material Type**: The body in white market can be segmented based on the material type used in manufacturing, such as steel, aluminum, and others. Steel is a commonly used material due to its high strength and durability, while aluminum is preferred for its lightweight properties.

- **Vehicle Type**: Segmentation based on vehicle type includes passenger cars, commercial vehicles, and electric vehicles. The increasing demand for electric vehicles is driving the growth of the body in white market, as manufacturers are focusing on lightweight materials to improve range and efficiency.

- **Manufacturing Process**: Another segmentation can be based on the manufacturing process involved, such as stamping, welding, and others. Advancements in technology have led to the adoption of innovative manufacturing processes to enhance the quality and efficiency of body in white components.

**Market Players**

- **Audi AG**: Audi is a prominent player in the body in white market, known for its high-quality vehicles that utilize advanced materials and manufacturing processes.

- **General Motors**: General Motors is a leading automotive manufacturer that focuses on incorporating lightweight materials in their body in white to improve fuel efficiency and performance.

- **Volkswagen Group**: Volkswagen Group is another key player in the market, emphasizing the use of sustainable materials in body in white production to align with environmental regulations.

The global body in white market is witnessing significant growth due to advancements in material technologies, increasing demand for lightweight components, and the expansion of electric and autonomous vehicle segments. Steel continues to be a dominant material in body in white manufacturing, offering strength and durability for vehicle structures. However, the shift towards aluminum and other lightweight materials is driving innovation in the market to meet the requirements of fuel efficiency and emission standards.

The segmentation based on vehicle type highlights the diverse applications of body in white components across passenger cars, commercial vehicles, and electric vehicles. With the rising popularity of electric vehicles, manufacturers are focusing on specialized body in white solutions to optimize performance and range. Additionally, the manufacturing process segmentation underscores the importance of efficient production techniques such as stamping and welding to ensure quality and precision in body in white assembly.

Key market players such as Audi AG, General Motors, and Volkswagen Group are at the forefront of innovation in the body in white market, leveraging their expertise in material science and manufacturing technologies. These companies are investing in research and development to explore new materials and processes for lightweight construction, demonstrating a commitment to sustainability and performance in the automotive industry. As the market continues to evolve, collaboration between automakers and suppliers will be essential to drive further advancements in body in white technologies.

https://www.databridgemarketresearch.com/reports/global-body-in-white-market The global body in white market is expected to witness significant growth in the coming years driven by various factors reshaping the automotive industry landscape. One of the key trends influencing market dynamics is the increasing focus on sustainability and environmental regulations. Automakers are under pressure to reduce carbon emissions and enhance fuel efficiency, leading to a shift towards lightweight materials in body in white manufacturing. This shift is not only driven by regulatory requirements but also by consumer preferences for eco-friendly vehicles.

Another important trend impacting the body in white market is the rapid evolution of electric and autonomous vehicles. As the demand for electric vehicles continues to rise, manufacturers are exploring innovative body in white solutions to optimize performance, range, and safety of these vehicles. Additionally, the advent of autonomous driving technologies is driving the need for advanced structural components that can support the integration of sensors, cameras, and other autonomous systems seamlessly.

Moreover, advancements in material technologies are revolutionizing the body in white market, enabling the development of high-strength, lightweight, and cost-effective solutions. Manufacturers are increasingly adopting advanced materials such as carbon fiber composites, magnesium alloys, and advanced high-strength steels to meet the evolving requirements of modern vehicles. These materials offer a combination of strength, durability, and weight savings, making them ideal for body in white applications.

Furthermore, the competitive landscape of the body in white market is characterized by intense rivalry among key players striving to differentiate themselves through technological innovation and product offerings. Companies are heavily investing in research and development initiatives to develop next-generation body in white solutions that address emerging trends and challenges in the automotive industry. Strategic collaborations and partnerships between automakers, material suppliers, and technology providers are becoming increasingly common to leverage synergies and accelerate product development cycles.

In conclusion, the global body in white market is poised for continuous growth and innovation fueled by technological advancements, changing consumer preferences, and regulatory pressures. As the industry evolves, stakeholders across the value chain will need to adapt to new market dynamics and capitalize on emerging opportunities to stay competitive in the rapidly evolving automotive landscape. The future of the body in white market lies in embracing sustainable practices, investing in R&D, and fostering collaboration to drive innovation and shape the future of mobility.The body in white market is a crucial segment of the automotive industry that plays a significant role in the overall design, structure, and performance of vehicles. As the industry continues to evolve, several key trends and factors are shaping the market landscape and driving its growth.

One of the primary trends impacting the body in white market is the increasing focus on sustainability and environmental regulations. With growing concerns about carbon emissions and fuel efficiency, automakers are increasingly turning towards lightweight materials in body in white manufacturing to reduce vehicle weight and improve overall efficiency. This shift towards sustainability is not only driven by regulatory requirements but also by shifting consumer preferences towards eco-friendly vehicles.

Another key trend influencing the market is the rapid advancement of electric and autonomous vehicles. With the rise in demand for electric vehicles, manufacturers are exploring innovative body in white solutions to optimize performance, range, and safety of these vehicles. The integration of advanced structural components that support autonomous driving technologies is also driving the need for seamless integration of sensors, cameras, and other autonomous systems into vehicle structures.

Furthermore, advancements in material technologies are revolutionizing the body in white market, enabling the development of high-strength, lightweight, and cost-effective solutions. Materials such as carbon fiber composites, magnesium alloys, and advanced high-strength steels are increasingly being adopted to meet the evolving requirements of modern vehicles. These materials offer a combination of strength, durability, and weight savings, making them ideal for body in white applications.

The competitive landscape of the body in white market is characterized by intense rivalry among key players who are striving to differentiate themselves through technological innovation and product offerings. Companies are heavily investing in research and development initiatives to develop next-generation body in white solutions that address emerging trends and challenges in the automotive industry. Strategic collaborations and partnerships between automakers, material suppliers, and technology providers are becoming increasingly common to leverage synergies and accelerate product development cycles.

In conclusion, the global body in white market is poised for continuous growth and innovation driven by technological advancements, changing consumer preferences, and regulatory pressures. Automakers and suppliers will need to adapt to new market dynamics, embrace sustainable practices, invest in R&D, and foster collaboration to stay competitive in the rapidly evolving automotive landscape. The future of the body in white market lies in leveraging advanced materials, innovative manufacturing processes, and cutting-edge technologies to shape the future of mobility in a sustainable and efficient manner.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Body in White Market : https://www.databridgemarketresearch.com/reports/global-body-in-white-market/companies

Key Questions Answered by the Global Body in White Market Report:

What is the current state of the Body in White Market, and how has it evolved?

What are the key drivers behind the growth of the Body in White Market?

What challenges and barriers do businesses in the Body in White Market face?

How are technological innovations impacting the Body in White Market?

What emerging trends and opportunities should businesses be aware of in the Body in White Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-textile-garment-markethttps://www.databridgemarketresearch.com/reports/global-apoptosis-stimulant-markethttps://www.databridgemarketresearch.com/reports/global-lactic-acid-ester-markethttps://www.databridgemarketresearch.com/reports/europe-cleanroom-particle-counters-markethttps://www.databridgemarketresearch.com/reports/europe-mass-spectrometry-devices-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 990

✉ Email: [email protected]"

#Automotive BIW Market#Vehicle Frame Manufacturing Market#Car Chassis Structure Market#Automotive Shell Manufacturing Market#Lightweight BIW Solutions Market#Structural Automotive Parts Market#Advanced BIW Engineering Market#BIW Component Market#Vehicle Structural Design Market#High-Strength Automotive Frames Market

0 notes

Text

The Growing Structural Adhesives Market: Key Trends and Future Outlook

Structural adhesives have become a pivotal solution in various industries, offering robust bonding for a wide range of applications. Whether in aerospace, automotive, construction, or electronics, the market for these high-performance adhesives is expanding rapidly due to their capacity to replace traditional fastening methods such as welding or riveting.

Market Overview

The structural adhesives market is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2024 to 2029, driven by several factors, including the rising demand for lightweight materials and innovations in adhesive technologies. By 2029, the market is expected to be worth USD 17.7 billion, highlighting the increasing reliance on advanced bonding solutions across industries. Notably, the automotive sector is a leading contributor to this growth due to the demand for adhesives that enable lighter and more fuel-efficient vehicles.

Key Growth Drivers

Demand for Lightweight Materials: One of the primary drivers fueling the rise of structural adhesives is the growing use of lightweight materials, particularly in industries such as automotive and aerospace. Adhesives offer a unique advantage over traditional mechanical fasteners, as they not only provide excellent bonding strength but also help reduce the weight of components. In the automotive industry, for instance, structural adhesives are widely used to bond dissimilar materials, such as metals and composites, which results in lighter vehicles and improved fuel economy.

Sustainability and Environmental Concerns: Sustainability has become a major concern for manufacturers globally. Adhesives contribute to more environmentally friendly production processes by reducing the need for energy-intensive techniques like welding. They also help decrease material waste during production. As industries look to lower their carbon footprint, the use of adhesives is becoming increasingly aligned with sustainability goals.

Technological Advancements: The continuous innovation in adhesive technologies is pushing the market forward. Modern structural adhesives are designed to perform in extreme conditions, offering high resistance to temperature variations, corrosion, and fatigue. Recent developments have introduced hybrid adhesives, which combine the properties of epoxy, acrylic, and polyurethane adhesives, offering superior performance across various applications. This innovation is crucial for industries like electronics, where precision and reliability are paramount.

Construction Sector Growth: In the construction industry, adhesives are being used more extensively, particularly for bonding glass and metal in modern architectural designs. Structural adhesives provide an aesthetic advantage by creating seamless joints, while also ensuring the structural integrity of the bonded components. Additionally, as the demand for eco-friendly building materials rises, adhesives that contribute to green building initiatives are gaining more prominence in the market.

Key Industry Applications

Automotive Industry: The automotive sector is a major consumer of structural adhesives, particularly as the shift towards electric vehicles (EVs) accelerates. Adhesives help reduce the overall weight of EVs, improving battery efficiency and range. Additionally, adhesives improve crash performance and load distribution, contributing to enhanced vehicle safety.

Aerospace Sector: Structural adhesives are playing an increasingly important role in aerospace, where weight reduction and fuel efficiency are top priorities. These adhesives are used extensively to bond composite materials, which are lighter than metals but just as strong, making them ideal for modern aircraft design.

Electronics Industry: In the electronics industry, structural adhesives are critical for bonding delicate components in smartphones, computers, and other devices. These adhesives provide the necessary durability while allowing for miniaturization, which is a key trend in consumer electronics.

Construction Sector: The construction industry is experiencing a surge in the use of adhesives for bonding materials such as glass and metal in both residential and commercial projects. With the growing emphasis on green building practices, adhesives that reduce the environmental impact of construction processes are gaining traction. Additionally, adhesives enable more innovative designs, providing architects with greater flexibility in creating aesthetically pleasing structures.

Regional Market Insights

Globally, the structural adhesives market is thriving, with North America and Europe leading the charge. In North America, the automotive and aerospace industries are major consumers, while in Europe, stringent environmental regulations are driving the adoption of more sustainable adhesive solutions. The Asia-Pacific region is expected to experience the highest growth rate, fueled by rapid industrialization, infrastructure development, and the increasing production of electric vehicles in countries like China, Japan, and India.

Future Outlook

The future of the structural adhesives market looks promising as industries continue to prioritize lightweight, durable, and sustainable bonding solutions. With ongoing advancements in adhesive technologies and the rising demand for eco-friendly materials, structural adhesives are set to play an increasingly significant role across various sectors. From automotive to construction, the ability of adhesives to enhance performance while reducing environmental impact makes them an essential component in modern manufacturing.

To know more Download PDF Brochure :

The structural adhesives market is on a robust growth path, supported by technological innovations and the shift towards more sustainable industrial practices. As industries across the globe continue to evolve, the demand for high-performance adhesives that meet the complex requirements of modern manufacturing is expected to grow, cementing their importance in the future of several key industries.

#Tags:#Structural Adhesives Market#Adhesive Technology Trends#Lightweight Materials#Industrial Adhesives#Automotive Adhesives#Aerospace Adhesives

0 notes

Text

High-Performance Adhesives for Aircraft Manufacturing

In the aerospace industry, the demand for high-performance adhesives has never been greater. As aircraft designs evolve, the need for materials that can withstand extreme conditions while ensuring structural integrity and safety is paramount. High-performance adhesives have become integral to aircraft manufacturing, providing exceptional strength, durability, and reliability.

One of the primary reasons aerospace adhesives are indispensable is their ability to bond various materials such as metals, composites, and plastics. These adhesives offer a seamless bonding solution, reducing the need for mechanical fasteners, which in turn decreases the aircraft's weight and enhances fuel efficiency. Among the various types of adhesives used, epoxy adhesives stand out for their remarkable properties. Epoxy adhesive manufacturers in India are at the forefront of developing formulations that cater specifically to the aerospace sector's rigorous requirements.

In addition to strength, electrically conductive adhesives are gaining traction in aircraft manufacturing. These adhesives ensure reliable electrical conductivity while providing robust mechanical bonding, making them ideal for electronic components within aircraft. The ability to conduct electricity without compromising on bond integrity is a game-changer for the industry, paving the way for more efficient and reliable aerospace systems.

As an adhesive manufacturer in India, Kohesi Bond is dedicated to producing high-quality aerospace adhesives that meet international standards. Our range of epoxy adhesives is designed to endure extreme temperatures, resist environmental degradation, and maintain superior performance under stress. We understand the critical role these adhesives play in ensuring the safety and efficiency of aircraft, and our products reflect this commitment to excellence.

In conclusion, the advancements in aerospace adhesives are revolutionizing aircraft manufacturing. With the expertise of epoxy adhesive manufacturers in India and the innovative solutions provided by companies like Kohesi Bond, the future of aerospace construction is set to soar to new heights.

For more information about our high-performance adhesives, visit Kohesi Bond.

#Aerospace adhesives#Aircraft manufacturing#High-performance adhesives#Epoxy adhesives#Electrically conductive adhesive#Adhesive manufacturer in India#Epoxy adhesive manufacturers in India#Aerospace industry#Structural adhesives for aircraft#Aviation bonding solutions#Lightweight aircraft materials#Kohesi Bond aerospace adhesives#Advanced adhesive technologies

1 note

·

View note

Text

Investment Castings for Aircraft Structural Elements A Focus on Unitritech's Excellence

Investment castings, also known as precision castings, play a crucial role in the aerospace industry, particularly in the manufacturing of structural elements for aircraft. These castings are made using a wax pattern that is coated with a refractory ceramic material. Once the ceramic material hardens, the wax is melted away, leaving a precise mold that can produce high-tolerance, intricate components ideal for aerospace applications.

One of the leading manufacturers in this field is Unitritech, renowned for their superior investment castings for structural elements of aircraft. Unitritech utilizes advanced technologies and stringent quality control processes to ensure that each casting meets the rigorous demands of the aerospace industry. Their investment castings are characterized by exceptional strength, lightweight properties, and the ability to withstand extreme temperatures and pressures, making them perfect for critical structural components of aircraft.

Unitritech's commitment to innovation and excellence has positioned them as a top choice for aerospace manufacturers seeking reliable and high-performance structural elements. Their expertise in producing complex geometries and maintaining tight tolerances ensures that every component contributes to the overall safety, efficiency, and performance of the aircraft.

In summary, investment castings are essential for the aerospace industry, and Unitritech stands out as a premier provider of these critical components, ensuring the highest standards of quality and performance in aircraft structural elements.

#High-Precision Investment Castings for Aerospace Applications#Reliable Structural Elements for Aircraft in Investment Castings#Durable and Lightweight Investment Castings for Aerospace#Quality Investment Castings for Aerospace Structural Elements#Precision Casting for Critical Aircraft Components#Ensuring Flight Safety with Precision Investment Castings

0 notes

Text

Types of Fillers in Construction

Introduction Fillers play a pivotal role in construction, providing stability, strength, and insulation. Their selection is critical, affecting the cost, durability, and environmental impact of a project. This article delves into the various types of fillers utilized in the construction industry. 1. Natural Fillers Natural fillers like sand, gravel, and stone are ubiquitous in construction due to…

View On WordPress

#aerogel insulation in construction#carbon fiber for structural reinforcement#composite fillers in construction#construction aggregate materials#construction filler selection guide#construction fillers#construction industry standards for fillers#construction material innovation#cost-effective fillers for construction#durable fillers for construction#eco-friendly construction fillers#EPS beads in construction#fiber-reinforced concrete#fiberglass in concrete#fly ash concrete filler#graphene in building materials#insulation panels in construction#lightweight construction fillers#mineral fillers in concrete#natural fillers in construction#organic fillers for construction#silica fume in construction#specialty construction fillers#sustainable building materials#synthetic fillers for building#thermal insulation fillers#types of construction fillers

2 notes

·

View notes

Text

Polymers have many of the characteristics of an ideal biomaterial; they are lightweight and strong, are inert or biodegradable (depending on their chemical structure) and have physical properties (softness, rigidity and elasticity) that are easily tailored to match those of natural tissues.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quote#chemistry#nonfiction#textbook#polymers#biomaterials#lightweight#strong#inert#biodegradable#chemical structure#softness#rigidity#elasticity#natural tissues

1 note

·

View note

Text

The Ocean Sciences Building at the University of Washington in Seattle is a brightly modern, four-story structure, with large glass windows reflecting the bay across the street.

On the afternoon of July 7, 2016, it was being slowly locked down.

Red lights began flashing at the entrances as students and faculty filed out under overcast skies. Eventually, just a handful of people remained inside, preparing to unleash one of the most destructive forces in the natural world: the crushing weight of about 2½ miles of ocean water.

In the building’s high-pressure testing facility, a black, pill-shaped capsule hung from a hoist on the ceiling. About 3 feet long, it was a scale model of a submersible called Cyclops 2, developed by a local startup called OceanGate. The company’s CEO, Stockton Rush, had cofounded the company in 2009 as a sort of submarine charter service, anticipating a growing need for commercial and research trips to the ocean floor. At first, Rush acquired older, steel-hulled subs for expeditions, but in 2013 OceanGate had begun designing what the company called “a revolutionary new manned submersible.” Among the sub’s innovations were its lightweight hull, which was built from carbon fiber and could accommodate more passengers than the spherical cabins traditionally used in deep-sea diving. By 2016, Rush’s dream was to take paying customers down to the most famous shipwreck of them all: the Titanic, 3,800 meters below the surface of the Atlantic Ocean.

Engineers carefully lowered the Cyclops 2 model into the testing tank nose-first, like a bomb being loaded into a silo, and then screwed on the tank’s 3,600-pound lid. Then they began pumping in water, increasing the pressure to mimic a submersible’s dive. If you’re hanging out at sea level, the weight of the atmosphere above you exerts 14.7 pounds per square inch (psi). The deeper you go, the stronger that pressure; at the Titanic’s depth, the pressure is about 6,500 psi. Soon, the pressure gauge on UW’s test tank read 1,000 psi, and it kept ticking up—2,000 psi, 5,000 psi. At about the 73-minute mark, as the pressure in the tank reached 6,500 psi, there was a sudden roar and the tank shuddered violently.

“I felt it in my body,” an OceanGate employee wrote in an email later that night. “The building rocked, and my ears rang for a long time.”

“Scared the shit out of everyone,” he added.

The model had imploded thousands of meters short of the safety margin OceanGate had designed for.

In the high-stakes, high-cost world of crewed submersibles, most engineering teams would have gone back to the drawing board, or at least ordered more models to test. Rush’s company didn’t do either of those things. Instead, within months, OceanGate began building a full-scale Cyclops 2 based on the imploded model. This submersible design, later renamed Titan, eventually made it down to the Titanic in 2021. It even returned to the site for expeditions the next two years. But nearly one year ago, on June 18, 2023, Titan dove to the infamous wreck and imploded, instantly killing all five people onboard, including Rush himself.

The disaster captivated and horrified the world. Deep-sea experts criticized OceanGate’s choices, from Titan’s carbon-fiber construction to Rush’s public disdain for industry regulations, which he believed stifled innovation. Organizations that had worked with OceanGate, including the University of Washington as well as the Boeing Company, released statements denying that they contributed to Titan.

A trove of tens of thousands of internal OceanGate emails, documents, and photographs provided exclusively to WIRED by anonymous sources sheds new light on Titan’s development, from its initial design and manufacture through its first deep-sea operations. The documents, validated by interviews with two third-party suppliers and several former OceanGate employees with intimate knowledge of Titan, reveal never-before-reported details about the design and testing of the submersible. They show that Boeing and the University of Washington were both involved in the early stages of OceanGate’s carbon-fiber sub project, although their work did not make it into the final Titan design. The trove also reveals a company culture in which employees who questioned their bosses’ high-speed approach and decisions were dismissed as overly cautious or even fired. (The former employees who spoke to WIRED have asked not to be named for fear of being sued by the families of those who died aboard the vessel.) Most of all, the documents show how Rush, blinkered by his own ambition to be the Elon Musk of the deep seas, repeatedly overstated OceanGate’s progress and, on at least one occasion, outright lied about significant problems with Titan’s hull, which has not been previously reported.

A representative for OceanGate, which ceased all operations last summer, declined to comment on WIRED’s findings.

5K notes

·

View notes