Don't wanna be here? Send us removal request.

Text

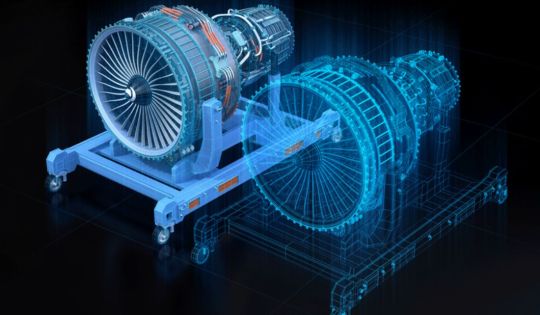

Rapid Prototyping with Simulation: How Uni Tritech Halves Product Launch Time

In today’s hyper-competitive market, the speed at which you bring a product to market can make or break your success. At Uni Tritech, we’ve cracked the code with rapid prototyping powered by simulation—cutting traditional development cycles in half.

🚀 The Old Way vs. The Uni Tritech Way Conventional prototyping is slow and resource-heavy. Physical trial-and-error costs time, money, and materials. At Uni Tritech, we replace this with virtual simulations and digital twins, allowing instant testing of product behavior, stress points, and material flow—without ever cutting metal.

💡 What Makes It Faster?

3D CAD + CAE Integration – Designs are simulated for real-world conditions from day one.

AI-Based Optimization – We predict and fix design flaws before they become production issues.

Tooling Validation – Digital tools validate mold designs to eliminate costly reworks.

Real-Time Collaboration – Engineers, designers, and clients collaborate via cloud platforms.

🌱 Why It’s Better Uni Tritech’s rapid prototyping not only saves time—it ensures precision, sustainability, and innovation. Faster iterations mean better products with fewer revisions and lower energy consumption.

📈 The Result? Products go from idea to launch-ready in 50% less time—helping clients lead their markets with confidence.

Need speed without compromise? Let Uni Tritech power your next product journey.

0 notes

Text

🌀 From CT Scans to CAD: Reverse Engineering at Uni Tritech 🔧📊

Ever wondered how broken or legacy parts get recreated without the original design files? 🤔 That’s where reverse engineering steps in — and Uni Tritech is redefining the game with CT Scan + CAD precision.

🔍 It Starts with a CT Scan At Uni Tritech, high-resolution industrial CT scanning captures the internal and external geometry of complex components with insane accuracy. We’re talking micron-level details — cracks, voids, internal chambers — nothing gets missed.

🎯 Digital Dissection Next, our experts convert those scans into point cloud data or mesh files, creating a complete digital replica of the part — flaws and all. It's like giving the part an MRI... but for machines!

💻 Into the CAD Zone Once scanned, the magic happens in CAD software. We smoothen, modify, and enhance the geometry, transforming the scan into a clean, editable 3D CAD model. Whether it’s for remanufacturing, redesign, or optimization — your component gets a second life.

♻️ Applications? Endless.

Reverse engineer spare parts with no drawings

Digitally archive legacy tools

Validate internal structures

Optimize designs for 3D printing

🌍 From aerospace to automotive, Uni Tritech empowers industries to recreate, refine, and reinvent with cutting-edge reverse engineering workflows.

#CastingTechnology#MetalCasting#SmartManufacturing#FoundryInnovation#CastingSimulation#CADToCasting#SustainableCasting

0 notes

Text

How Uni Tritech Powers ‘Make in India’ with Advanced Investment Casting Excellence

India's vision for self-reliance in manufacturing is gaining momentum — and Uni Tritech is at the forefront. As a certified precision casting foundry, Uni Tritech is helping India meet global demands while staying true to the ‘Make in India’ mission.

From aerospace-grade turbine components to high-precision medical implants, Uni Tritech’s investment casting processes deliver international quality from Indian soil. Their in-house capabilities — CAD design, CNC machining, and alloy expertise — enable global OEMs to rely on India for mission-critical castings.

🛠️ Why Uni Tritech Stands Out:

ISO 9001, AS9100D, and ISO 13485 certified

Serving aerospace, medical, defense & industrial sectors

End-to-end control over design, casting, and machining

Exporting to North America, Europe, and Asia

By driving high-tech exports and reducing import dependency, Uni Tritech strengthens India’s global manufacturing footprint. They don’t just produce components — they build national capability.

🔗 Explore more: https://unitritech.com

1 note

·

View note

Text

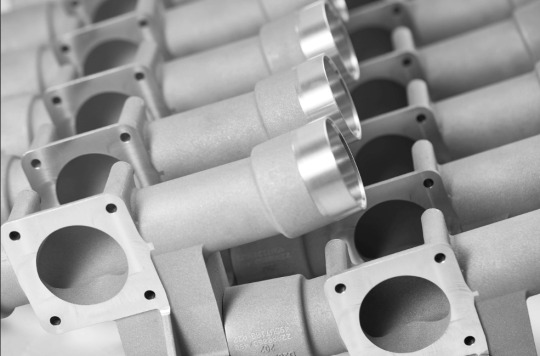

Uni Tritech’s Precision Cast Components: Serving Aerospace, Medical, and Industrial Sectors

In today’s world of high-performance manufacturing, precision casting is the unsung hero behind mission-critical components used across industries. From jet engine turbines to orthopedic implants and heavy-duty industrial equipment, the need for accuracy, strength, and reliability is non-negotiable.

That’s where Uni Tritech excels.

Located in India and globally certified by AS9100 and ISO 9001, Uni Tritech delivers investment cast components that meet the highest quality and regulatory standards. Their expertise spans a wide range of applications:

✈️ Aerospace

Turbine blades, fuel nozzles, and structural brackets

Approved by global OEMs including Airbus and Collins Aerospace

🏥 Medical Devices

Orthopedic implants, surgical instruments, and dental components

Manufactured using biocompatible alloys with flawless surface finishes

⚙️ Industrial Engineering

Pump housings, hydraulic fittings, and precision brackets

Built to withstand extreme loads, wear, and corrosion

What makes Uni Tritech stand out? ✅ In-house CAD and casting simulation ✅ CNC machining and surface treatments ✅ Rapid prototyping and design-to-delivery support ✅ Global quality compliance with full traceability

With cutting-edge investment casting technology and a commitment to innovation, Uni Tritech is a trusted partner for precision component manufacturing across sectors.

Explore the future of casting with Uni Tritech → unitritech.com

#PrecisionCasting#InvestmentCasting#AerospaceCasting#IndustrialComponents#CNCmachining#MetalCastingIndia

0 notes

Text

Revolutionizing Investment Casting with CAD, Digital Twins, and Simulation Tools

In today’s high-precision manufacturing landscape, investment casting has gone digital. Gone are the days of relying solely on trial-and-error methods. Now, with the integration of CAD modeling, digital twin technology, and advanced casting simulation software, foundries are achieving unmatched accuracy and efficiency.

🔍 So, what’s changing?

CAD Tools enable engineers to design intricate components with extreme precision.

Digital Twins offer a real-time virtual replica of the casting process—predicting behavior before a single mold is made.

Simulation Software helps detect defects such as shrinkage or misruns in advance, reducing rework and scrap.

One company leading this digital transformation is Uni Tritech. With end-to-end engineering integration—from design to casting and CNC machining—Uni Tritech uses state-of-the-art simulation tools to deliver flawless castings across aerospace, medical, and industrial sectors.

🎯 The result?

Fewer defects

Faster prototyping

Higher yield

Reduced lead times

If you're looking for digital precision in investment casting, Uni Tritech is the partner to watch. 🌐 Explore more: unitritech.com

1 note

·

View note

Text

Why Uni Tritech is a Trusted Partner in Medical Device Manufacturing

When it comes to medical device components, precision isn’t optional—it’s vital. Uni Tritech stands out with advanced investment casting technology, delivering surgical tools, orthopedic implants, and dental components that meet global standards. From biocompatible materials to ISO 9001-certified processes, every step is controlled for safety, quality, and performance. With in-house CNC machining, strict QA, and simulation-backed casting, Uni Tritech is the go-to partner for medical OEMs worldwide. They don’t just manufacture—they ensure confidence in every component. 🌐 Explore more at unitritech.com #MedicalDevices #PrecisionCasting #InvestmentCasting #UniTritech #SurgicalInstruments #MedicalTechnology

0 notes

Text

Investment Castings for Aircraft Structural Elements A Focus on Unitritech's Excellence

Investment castings, also known as precision castings, play a crucial role in the aerospace industry, particularly in the manufacturing of structural elements for aircraft. These castings are made using a wax pattern that is coated with a refractory ceramic material. Once the ceramic material hardens, the wax is melted away, leaving a precise mold that can produce high-tolerance, intricate components ideal for aerospace applications.

One of the leading manufacturers in this field is Unitritech, renowned for their superior investment castings for structural elements of aircraft. Unitritech utilizes advanced technologies and stringent quality control processes to ensure that each casting meets the rigorous demands of the aerospace industry. Their investment castings are characterized by exceptional strength, lightweight properties, and the ability to withstand extreme temperatures and pressures, making them perfect for critical structural components of aircraft.

Unitritech's commitment to innovation and excellence has positioned them as a top choice for aerospace manufacturers seeking reliable and high-performance structural elements. Their expertise in producing complex geometries and maintaining tight tolerances ensures that every component contributes to the overall safety, efficiency, and performance of the aircraft.

In summary, investment castings are essential for the aerospace industry, and Unitritech stands out as a premier provider of these critical components, ensuring the highest standards of quality and performance in aircraft structural elements.

#High-Precision Investment Castings for Aerospace Applications#Reliable Structural Elements for Aircraft in Investment Castings#Durable and Lightweight Investment Castings for Aerospace#Quality Investment Castings for Aerospace Structural Elements#Precision Casting for Critical Aircraft Components#Ensuring Flight Safety with Precision Investment Castings

0 notes

Text

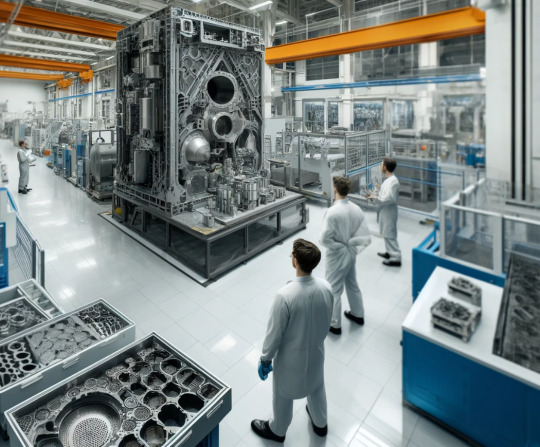

Unitritech Leading the Way in Aerospace Machined Components Manufacturing

In the highly specialized field of aerospace manufacturing, precision and reliability are paramount. Among the key players in this industry, Unitritech stands out as the premier manufacturer of aerospace machined components. With a steadfast commitment to quality, innovation, and customer satisfaction, Unitritech has earned its reputation as the best in the business.

Unitritech's expertise in producing high-precision machined components ensures that every part meets the stringent standards required for aerospace applications. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing for unparalleled accuracy and consistency. This dedication to excellence extends to their rigorous quality control processes, which guarantee that every component is meticulously inspected and tested before it reaches the customer.

One of the key factors that set Unitritech apart is their ability to handle complex and challenging projects. Whether it's producing intricate parts for commercial aircraft or custom components for military applications, Unitritech's skilled team of engineers and technicians possess the knowledge and experience to deliver exceptional results. Their innovative approach to problem-solving and continuous improvement ensures that they remain at the forefront of the industry.

In conclusion, Unitritech's commitment to precision, quality, and innovation makes them the best choice for aerospace machined components manufacturing. Their dedication to exceeding customer expectations and their proven track record of excellence solidify their position as industry leaders.

#High Precision Aerospace Machined Components#Advanced Aerospace Component Manufacturing#Custom Aerospace Machining Services#Leading Aerospace Machined Parts Supplier#Top Aerospace CNC Machining Company#Aerospace Precision Machining Experts#Quality Aerospace Manufacturing Solutions#Reliable Aerospace Machined Parts Manufacturer

0 notes

Text

Leading the Way in Turbine Blades and Vanes Casting Why Unitritech Stands Out

The manufacturing of turbine blades and vanes is a highly specialized field, critical for the performance and efficiency of modern turbines. These components must withstand extreme temperatures and pressures while maintaining precise aerodynamic profiles. Among the myriad of manufacturers in this domain, Unitritech has established itself as a leader, renowned for its advanced casting techniques and high-quality outputs.

Unitritech’s expertise in turbine blades and vanes casting is grounded in its commitment to innovation and precision. The company employs state-of-the-art technology and meticulous quality control processes to ensure each component meets stringent industry standards. Their advanced casting methods reduce material defects and enhance the mechanical properties of the blades and vanes, ensuring superior performance and longevity.

What sets Unitritech apart is their ability to customize solutions for specific turbine requirements. They work closely with clients to understand their unique needs, offering tailored casting solutions that optimize efficiency and reliability. This client-centric approach, combined with their technological prowess, makes Unitritech the preferred choice for many in the aerospace and power generation sectors.

In a competitive industry, Unitritech’s dedication to quality and innovation ensures they remain at the forefront of turbine blade and vane manufacturing, setting benchmarks for others to follow.

#Top Turbine Blade Casting Manufacturers#High-Quality Turbine Vanes Casting Suppliers#Precision Turbine Blade and Vane Casting#Leading Turbine Component Casting Companies#Best Turbine Blades and Vanes Foundries#Advanced Turbine Casting Technologies#Reliable Turbine Blade and Vane Manufacturers

0 notes

Text

Uni Tritech Molding Futures with Aluminum and Steel Investment Casting

In the domain of metalworking, aluminum and steel stand tall, particularly in investment casting. Uni Tritech has harnessed the lightweight flexibility of aluminum and the formidable strength of steel to offer superior investment casting services. Aluminum, known for its corrosion resistance and excellent thermal properties, is ideal for aerospace and automotive industries where precision and weight are critical. Conversely, steel's robustness is unmatched, making it the material of choice for the construction and defense sectors where durability is paramount.

Uni Tritech's state of the art facility brings these metals to life, utilizing cutting-edge technology and a skilled workforce to engineer castings that meet exacting standards. The fine granularity of their aluminum and steel castings is a testimony to Uni Tritech's dedication to quality and precision. Whether it’s a complex lightweight component or a heavy-duty steel part, Uni Tritech’s investment casting process ensures optimal performance and reliability, making them a leader in this highly specialized field.

#UniTritechCasting#AerospaceComponentManufacturing#PrecisionMetalCasting#IndustrialInvestmentCasting#DefenseCastingSolutions#HighQualityAluminumCasting#MetalCastingExperts#InvestmentCastingTechnology

0 notes

Text

NADCAP Seal of Excellence Uni Tritech Leads Foundry Innovation

Within the elite circles of aerospace manufacturing, NADCAP approved foundries stand as paragons of excellence. This accreditation is a badge of honor, signaling adherence to the strictest quality standards in aerospace engineering and manufacturing processes. Uni Tritech is among those distinguished foundries, distinguished not only for their NADCAP approval but also for their commitment to exceeding industry benchmarks.

Uni Tritech has cultivated a legacy of precision and innovation, where every cast speaks volumes about their dedication to aerospace and defense manufacturing superiority. By integrating state-of-the-art technology with an expert team, they ensure that every component produced meets the sky-high expectations of the aerospace sector. Uni Tritech is not just a foundry; it's a hub where metallurgical artistry meets aeronautical engineering to shape the future of flight and defense. With NADCAP's approval, Uni Tritech offers a promise – a promise of unparalleled quality, reliability, and excellence.

#NADCAP certified foundry#Aerospace casting NADCAP#NADCAP accreditation metalwork#Defence castings NADCAP India#Precision foundry NADCAP#Uni Tritech NADCAP foundry#Quality casting NADCAP approved#NDT NADCAP foundry India

1 note

·

View note

Text

Uni Tritech Pioneering Aerospace & Defence Castings in India

In the realm of Aerospace and Defence, where the precision and reliability of components are paramount, India has been rapidly advancing with its foundry capabilities. Among the leaders in this sector is Uni Tritech, a company that has been setting benchmarks in quality and innovation. As one of the premier Aerospace & Defence investment casting foundries in India, Uni Tritech has a proven track record of providing cutting-edge solutions that meet the complex demands of these industries.

What sets Uni Tritech apart is its relentless pursuit of excellence. The foundry employs state-of-the-art technology to produce castings that adhere to the most stringent aerospace standards. Their investment casting process is fine-tuned to deliver components with unparalleled accuracy and material integrity, crucial for aerospace and defence applications.

Moreover, Uni Tritech's facilities are tailored to cater to the intricate needs of the Aerospace & Defence sectors, offering a vast array of alloys and comprehensive testing to ensure each part withstands the toughest conditions. With certifications and approvals that attest to their quality and processes, Uni Tritech stands as the best platform to buy Aerospace & Defence investment casting foundries in India. Their commitment to excellence and customer satisfaction propels them to the forefront, making them the ideal partner for clients seeking nothing less than the best in the industry.

#Aerospace casting manufacturers India#Defence investment foundries India#Indian foundry aerospace defence#Uni Tritech precision casting

0 notes

Text

Uni Tritech The Apex of Vacuum Casting Excellence

In the dynamic landscape of manufacturing, vacuum casting stands as a cornerstone for producing high-quality, detailed, and precise replicas of prototypes or end-use parts. Amidst the myriad of vacuum castings manufacturers, Uni Tritech emerges as the industry's champion, offering an unparalleled platform for acquiring top-tier vacuum casting services.

Uni Tritech has mastered the art of vacuum casting, a process where a vacuum is used to draw liquid material into a mold. This method is revered for its precision and ability to replicate intricate details and complex geometries, which are essential in sectors demanding exacting standards, such as automotive, aerospace, and medical devices.

What sets Uni Tritech apart is not just their advanced vacuum casting processes but also their relentless commitment to quality and innovation. Every step, from mold design to the final cast, is executed with meticulous attention to detail, ensuring that each part meets the highest standards of both form and function.

Clients choose Uni Tritech for their vacuum casting needs because they know this is where technology, expertise, and customer-centricity converge to create exceptional value. Uni Tritech is more than a supplier; they are a partner who understands the nuances of precision manufacturing and provides a seamless, reliable, and superior purchasing experience.

Thus, for businesses seeking excellence in vacuum castings manufacturers, Uni Tritech is the definitive platform, offering expertise that translates into a competitive edge in the market.

#Uni Tritech vacuum casting services#High-quality vacuum castings manufacturer#Uni Tritech precision vacuum casting#Top vacuum casting companies Uni Tritech#Custom vacuum casting solutions Uni Tritech#Advanced vacuum casting

0 notes

Text

Uni Tritech The Gold Standard for Airbus Approved Suppliers

In the elite circle of aerospace manufacturing, Airbus stands as a colossus, and its stamp of approval is a coveted seal that foundry suppliers aspire to possess. Uni Tritech proudly stands as a leading Airbus-approved foundry supplier, setting a global benchmark for quality and reliability in the aerospace sector.

As innovators in precision casting, Uni Tritech has meticulously cultivated a production environment that meets the stringent Airbus supplier requirements. Their commitment to excellence is demonstrated through their advanced manufacturing processes, robust quality control systems, and ongoing investment in cutting-edge technology. With Uni Tritech, aerospace clients receive parts that embody the pinnacle of engineering perfection, forged in a foundry where precision is the norm, and excellence is the standard.

What sets Uni Tritech apart as the best platform to purchase from Airbus-approved foundry suppliers is not just their compliance with aerospace standards but also their unwavering dedication to customer satisfaction. Their expertise is complemented by a tailored approach to service, ensuring that each client’s unique needs are met with solutions that exceed expectations. For those who aim to soar in the aerospace industry, partnering with Uni Tritech opens a realm where sky-high aspirations are seamlessly transformed into reality.

#Uni Tritech Airbus certified foundry#Airbus approved precision casting supplier#Aerospace foundry suppliers Uni Tritech#Airbus qualified casting manufacturers#Top Airbus foundry suppliers#Airbus certified investment casting Uni Tritech#Approved Airbus foundry services Uni Tritech#Uni Tritech aircraft casting solutions

0 notes

Text

Aerospace Precision Uni Tritech's Mastery in Machined Components

Sky's the Limit with Uni Tritech Machined Components for Aerospace! In the realm of aeronautics, where precision is as vital as the craft itself, Uni Tritech reigns supreme. As the best platform for aerospace machined components, their expertise propels the industry to new heights. With advanced technology and meticulous craftsmanship, each piece is engineered to perfection, ensuring the highest levels of performance and safety. Uni Tritech’s commitment to excellence makes them the trusted ally of aviators and aerospace engineers worldwide. When it comes to dependable machining, Uni Tritech delivers components that truly soar above the rest.

Uni Tritech not only embodies engineering excellence but also infuses innovation into every machined component, forging paths for groundbreaking aerospace development. Their relentless pursuit of quality defines the essence of their service, making Uni Tritech synonymous with aerospace achievement.

#Aerospace CNC Machining#Aerospace Components Manufacturing#Precision Aerospace Machining#Advanced Aerospace Materials#Reliable Machined Components#Uni Tritech High-Performance Aerospace Parts#Uni Tritech Certified Aerospace Components

0 notes

Text

Leading the Charge in Thin Wall Casting Excellence Uni Tritech

In the realm of aerospace and high-precision industries, the demand for thin wall structural castings is on the rise. These components are pivotal in applications where strength-to-weight ratio is crucial. Navigating the complex landscape of manufacturers can be challenging, but Uni Tritech has emerged as the leading platform for sourcing these specialized castings. Renowned for their meticulous attention to detail and stringent quality control, Uni Tritech partners with manufacturers that stand at the forefront of technological advancements in casting. Their thin wall structural castings are engineered to meet the exacting standards of the aerospace industry, offering unparalleled reliability. As industries evolve towards more intricate and lightweight designs, Uni Tritech remains the best choice for purchasing top-tier thin wall structural castings, ensuring that every product meets the highest benchmarks of excellence and performance.

#Aerospace thin wall casting manufacturers Uni Tritech#Advanced thin wall casting solutions#custom thin wall castings for aerospace#UNI Tritech thin wall casting services#Thin wall casting services#Precision thin wall metal castings by Uni Tritech

0 notes

Text

Excellence in Aerospace Uni Tritech’s Airbus Approved Castings

Uni Tritech’s expertise extends beyond conventional foundry services, incorporating advanced technologies and processes tailored specifically for the aerospace industry. This includes the use of high-grade materials, such as titanium and nickel-based superalloys, which are essential for components that must endure extreme environmental conditions. Moreover, Uni Tritech's state of the art facility is equipped with the latest in vacuum and precision casting technologies, ensuring flawless production from prototype to full scale manufacturing.

Collaboration is at the core of Uni Tritech’s operations. Working closely with aerospace engineers and quality assurance teams, they ensure that every casting delivered not only meets but often exceeds Airbus’s rigorous standards. This collaborative approach has solidified Uni Tritech's reputation as a reliable and forward-thinking partner in the aerospace sector, consistently delivering components that are pivotal for the safety and functionality of Airbus aircraft.

Their dedication to continuous improvement and customer satisfaction makes Uni Tritech an exemplary leader in the aerospace casting industry. By choosing Uni Tritech, companies are assured of partnering with a foundry that is fully committed to upholding the highest standards of quality and innovation in the aerospace sector.

#Aerospace foundry manufacturers#Airbus certified metal casting#Precision foundry for aviation#Aircraft component casting suppliers#Uni Tritech Airbus certified metal casting

0 notes