#materialise software

Explore tagged Tumblr posts

Text

Why Materialise Software Is Quietly Powering the Future of 3D Printing

There’s a quiet revolution happening in how things are made—and it doesn’t involve a factory floor in the traditional sense. More and more, it's about pixels becoming parts, about software guiding lasers and powdered metals into shape. This is the world of 3D printing, and it’s changing everything from how surgeons plan operations to how rockets get off the ground.

But while most of the attention goes to the machines—the printers themselves—the real magic often starts in the software. And one name keeps coming up in professional circles: Materialise.

Materialise isn’t flashy. It doesn’t market like a lifestyle brand. But behind the scenes, it’s empowering some of the world’s most advanced 3D printing operations with software that’s as powerful as it is practical.

So, Why Does Software Matter in 3D Printing?

Think of the printer as the muscle. The software? That’s the brain.

It’s responsible for making sure every digital design becomes a real-world object without falling apart—literally or figuratively. In additive manufacturing (the fancy term for industrial 3D printing), software helps to:

Clean up and prep messy or incomplete 3D models

Slice designs into printable layers

Add supports where needed

Choose the best part orientation for strength or efficiency

Simulate prints to avoid failures

Keep everything traceable and organized

Without good software, even the best hardware can struggle. That’s where Materialise comes in.

Meet Materialise: Software That Works Hard So You Don’t Have To

Materialise Software isn’t a single program. It’s more like a modular toolkit built for different needs—whether that’s printing custom implants for patients or manufacturing lightweight parts for satellites.

Let’s break it down a bit:

1. Materialise Magics

This is where most people start. Magics is the go-to tool for fixing, prepping, and organizing 3D models before they ever hit the printer. It can:

Automatically repair broken STL files (and there are a lot of broken STL files out there)

Optimize how parts are placed in the build space

Add support structures intelligently

Nest multiple parts to save on space and material

Basically, it makes sure your model is actually printable—before wasting time or money.

2. Build Processor

This tool connects the dots between software and your 3D printer. It standardizes the process of translating your design into instructions the machine understands. And it works with a wide variety of printers, so you’re not locked into one hardware brand.

You can control job settings, monitor print progress, and ensure consistency even across different machines.

3. Streamics

For anyone running 3D printing at a production level (think hundreds or thousands of parts), Streamics helps manage it all. It:

Tracks jobs from start to finish

Connects with other systems (like your business’s ERP or quality control software)

Makes sure everything is logged and traceable—super important in regulated industries like aerospace or medical

Smart Features That Make a Big Difference

Materialise Software isn’t just about functionality—it’s about smart functionality. There’s a lot under the hood designed to improve performance, save material, and reduce human error.

Some of the more interesting tools include:

Lattice structure generation – Helps create lightweight, strong internal patterns

Topology optimization – Adjusts designs to use less material while staying strong

Automatic labeling – Adds unique identifiers to each part for easy tracking

Simulation tools – Predicts issues before you hit “print”

These features don’t just improve the outcome—they reduce failed builds, save resources, and give designers more freedom.

This Isn’t Just for Tech Geeks—It’s Changing Entire Industries

One of the coolest things about Materialise Software is how it’s showing up in totally different places. It’s not just engineers or designers using it—it’s transforming how professionals work across industries:

Healthcare

Doctors and hospitals use 3D printing to create patient-specific models for surgery or custom implants. Materialise helps manage that entire process—ensuring designs are clean, safe, and ready for use in critical scenarios.

Aerospace & Automotive

Need a part that’s ultra-light but still durable? Materialise lets engineers experiment with designs that would be impossible to make any other way. Plus, everything stays traceable—which is essential when lives (or millions of dollars) are on the line.

Consumer Goods

From eyewear to high-end sneakers, product designers are using Materialise tools to prototype quickly and manufacture small runs without outsourcing or waiting for molds. That means faster design cycles and more creative freedom.

More Than Just Efficient—It’s Sustainable, Too

It’s not talked about enough, but 3D printing can be surprisingly eco-friendly—when done right.

Materialise helps reduce waste by:

Optimizing part placement to use less raw material

Cutting down on failed prints through simulation and testing

Tracking and analyzing production data to improve efficiency

When manufacturers can get things right the first time, it saves energy, materials, and time. That’s a win for the planet—and the bottom line.

Open, Flexible, and Built for the Long Haul

One of the things that sets Materialise apart is how open it is. You’re not stuck in a closed system. It works with:

Popular CAD tools

Business systems like ERP or MES

IoT-enabled printers

Quality control software

This open architecture makes it easy for teams to scale, customize, and build workflows that actually make sense for their business.

Software That Quietly Powers a Bold Future

3D printing isn’t just about printing things—it’s about rethinking how things are made.

Materialise Software isn’t the flashiest part of the 3D printing process. But it might be the most important. Behind every flawless part or breakthrough design is software making it all possible—checking every file, guiding every layer, and managing every job.

For anyone working in digital manufacturing, Materialise offers the tools to move faster, waste less, and design more freely. It’s quietly enabling the future of making—and doing it with care, intelligence, and purpose.

To learn more or get started, check out: 👉 https://www.tridaxsolutions.com/product/materialise-3d-printing-software-tools/

0 notes

Text

GUYS AND GAYS I WANNA MAKE A BYLER EDIT TO I BET ON LOSING DOGS BUT I'VE NEVER MADE AN EDIT BEFORE IDK WHAT SOFTWARE TO USE I DON'T EVEN KNOW HOW TO GET CLIPS HELPPPPPP I MUST MATERIALISE MY ARTISTIC VISION

32 notes

·

View notes

Text

False God

Statement of Saskia Rambeau regarding an unusual meeting. Original statement given 3rd December 2006. Committed to tape 29th March 2024. Audio recording by [REDACTED], Head Archivist of the Magnus Institute, Manchester.

Statement begins.

Oh, uh. Should I just...start? Well, ok, well- I guess I've never quite been a lonely person. Alone maybe, but it's, I've never found it uncomfortable. I have a small flat, I'm busy with my job as a software engineer, I never exactly found it easy to make friends. That's just how life is. Was. I guess.

Anyway, you don't want a sob story about my life, sorry! I, uh, first noticed something strange a couple weeks ago. Just some rustling outside my flat, which I chalked up to a cat or something, probably chasing some rat in a bush. That was, until I remembered that I lived on the top floor. It would be sort of impossible for a cat to be rustling outside my window on the top floor. I didn't go to check what it was, I'm not an idiot. I know what happens to people who are curious. It was only on the fourth night of the noises, when I was so delirious from anxiety that I had gotten less than an hour's sleep within those four days, that I cracked. I wasn't sure what I would find, just that I wanted to make it stop.

You might sit there and think, it's just a rustling noise, it's probably the wind or some piece of litter getting jostled through a drain pipe, but you don't understand. When you spend all that time with just your thoughts for company, going from screen to screen to the dark walls of your bedroom, it does something to you. And usually that's fine. Comfortable, even. But when that predictability is disturbed, you start to do stupid things, like walk up to your window with a kitchen knife tucked under your sleeve.

I inched towards it, moved more by adrenaline than coherency. The night was clear, weird for a Manchester night, but I wasn't focused on that. There was just enough moonlight to illuminate my hand and the little jutting out piece of brick just outside my window. Now that I think about it, it seems almost...intentional. I gripped on to the handle, took a few short breaths and wrenched the window open with a small shriek. There was nothing. Of course there was nothing. Of course I had tormented myself over a silly little noise for days on end, for nothing.

And then I turned around.

You know how different religions have different images of their gods? How some have 5 hands, others 10? Some view it as heresy to even try to imagine their god? Some have wildly different interpretations even within one singular religion. Describing what materialised in my bedroom that night, would sort of be like if you asked me to describe god. If you asked me 3 days ago, I would've said it was a bright, pulsating light, softening and sharpening my vision in tune of the beating of my heart in my throat. That night, I would've said it was insectoid, feelers twitching towards me in a curious manner. Yesterday, I wouldn't have been able to begin to describe the events of that night. But today? Today, it seems more like a- a deer. The one you see at 2 am on a country road, that stops you in your tracks, headlights shimmering off the darkness of their eyes. It's nothing you've seen before and you know it's nothing you'll see again. The only thing I can say with absolute certainty is that it was beautiful.

I'll be honest with you. I'm not sleeping. I quit my job. The couple of people I would occasionally talk to haven't seen me in weeks. I spend my days staring out that window, into the glorious light of the day and darkness of the night. Nothing can shroud the Holy One. Don't you see, Archivist? I didn't have anything before and now I have someone to serve. My god is benevolent, it has granted me a new chance at life. I know my identity, where I belong, clearer than I ever have and I think it's time you saw it too.

It will be beautiful.

Statement ends. Did not love that ending. The original copy came with a sealed container of what seemed to be...dust? It says "Do Not Open" and I've never been one for defying authority. Any attempted follow ups to this case have obviously led to dead ends. 2 weeks in and I'm already starting to see a pattern here. I'm...gonna...go get some water.

13 notes

·

View notes

Text

31.01.25

It was a rainy day today.

We started the day by going to Redfields in the morning, Shepherd & Flock for lunch, a drive around Aldershot and Farnham and then we went to see Roger the Ragdoll kitten.

He is even bigger!

-

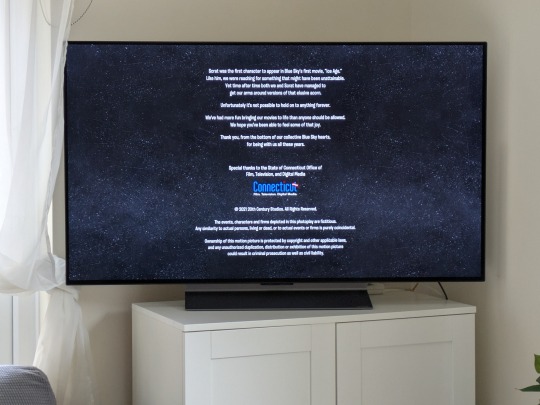

Whilst we visited the Floof prince, we watched a collection of Ice Age Scrat Tales shorts on Disney+. These shorts were released in April 2022.

IMDb link:

https://www.imdb.com/title/tt18302114/

Scrat Tales was the last project by some of the original crew at Blue Sky Studios.

It was done as a farewell to the studio, Scrat the Sabertoothed Squirrel and the studios franchise: Ice Age, Ice Age 2 The Meltdown, Ice Age 3 Dawn of the Dinosaurs, Ice Age 4 Continental Drift and Ice Age 5 Collision Course.

I reviewed each film in 2020. See the write ups on this blog!

Scrat discovers that he has a son and he learns to become a father figure.

It is directed by Donnie Long, with music by Batu Sener and John Powell.

Each short is about four minutes long, and was rendered with Pixar's Renderman software, as CGI Studio was phased out. This meant that Scrats character had to be completely re-furred, re-materialised and re-rigged. Chris Wedge does the voice of Scrat.

Blue Sky Studios was shut by its parent company Disney in April 2021 following the financial impacts of the Covid pandemic on the Walt Disney company.

It is exclusive to Disney+ and can be watched here:

https://www.disneyplus.com/en-gb/series/ice-age-scrat-tales/5ppXOZifX38d

Read more about it here:

https://en.wikipedia.org/wiki/Ice_Age:_Scrat_Tales

The end episode 'Nut the End' features the studios closure message, which can also be seen here:

youtube

For an earlier post on my blog see:

https://www.tumblr.com/bjsmall/685531526143868928/on-the-30th-april-2022-dad-and-i-watched-blue?source=share

It was simple, but looked really well animated and faithful to the original version.

4 notes

·

View notes

Text

Mastering Web Development: A Comprehensive Guide for Beginners

In the vast landscape of technology, web development stands as a crucial cornerstone. It encompasses the art and science of building websites, ranging from simple static pages to complex web applications. Whether you're aiming to pursue a career in software development or seeking to enhance your digital presence, understanding web development is essential.

In this comprehensive guide, we'll take you through the fundamental concepts and practical skills needed to master web development from scratch. Let's dive in!

1. Understanding HTML (Hypertext Markup Language)

HTML serves as the backbone of every web page, providing the structure and content. It uses tags to define different elements such as headings, paragraphs, images, and links. By mastering HTML, you'll be able to create well-structured and semantically meaningful web documents.

2. Exploring CSS (Cascading Style Sheets)

CSS is the language used to style HTML elements, enhancing their appearance and layout. With CSS, you can customize colors, fonts, spacing, and more, giving your website a polished and professional look. Understanding CSS selectors and properties is essential for effective styling.

3. Introduction to JavaScript

JavaScript is a versatile programming language that adds interactivity and dynamic behavior to web pages. From simple animations to complex web applications, JavaScript powers a wide range of functionalities. Learning JavaScript fundamentals such as variables, functions, and events is crucial for web development.

4. Building Responsive Websites

In today's mobile-centric world, it's essential to create websites that adapt seamlessly to various screen sizes and devices. Responsive web design achieves this by using fluid grids, flexible images, and media queries. Mastering responsive design principles ensures that your websites look great on desktops, tablets, and smartphones.

5. Introduction to Version Control with Git

Git is a powerful tool for tracking changes in your codebase and collaborating with other developers. By learning Git basics such as branching, merging, and committing, you can streamline your development workflow and effectively manage project versions.

6. Introduction to Front-End Frameworks

Front-end frameworks like Bootstrap, Foundation, and Materialise provide pre-designed components and stylesheets to expedite web development. By leveraging these frameworks, you can create responsive and visually appealing websites with less effort and code.

7. Introduction to Back-End Development

While front-end development focuses on the user interface, back-end development deals with server-side logic and database management. Learning back-end languages such as Node.js, Python, or PHP enables you to build dynamic web applications and handle user interactions efficiently.

8. Deploying Your Website

Once you've developed your website, it's time to make it accessible to the world. Deploying a website involves selecting a web hosting provider, uploading your files, and configuring domain settings. Understanding the deployment process ensures that your website goes live smoothly.

9. Conclusion and Next Steps

Congratulations on completing this comprehensive guide to mastering web development! By now, you've gained a solid understanding of HTML, CSS, JavaScript, version control, frameworks, and deployment. As you continue your journey in web development, remember to stay curious, practice regularly, and explore advanced topics to further refine your skills.

Resources for Further Learning:

Online tutorials and documentation

Interactive coding platforms

Community forums and discussion groups

Next Steps:

Explore advanced topics such as web performance optimization, server-side rendering, and progressive web apps.

Build real-world projects to apply your skills and showcase your portfolio.

Stay updated with the latest trends and technologies in web development through blogs, podcasts, and conferences.

With dedication and perseverance, you'll continue to evolve as a proficient web developer, creating innovative solutions and contributing to the ever-changing digital landscape . Happy coding!

4 notes

·

View notes

Text

3D Printing Plastic Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus

Executive Summary: 3D Printing Plastic Market

Data Bridge Market Research analyses the 3D printing plastic market will exhibit a CAGR of 27.70% for the forecast period of 2022-2029.

The research and analysis carried out in this 3D Printing Plastic Market report helps clients to predict investment in an emerging market, expansion of market share or success of a new product with the help of global market research analysis. This market report is also enriched with historic data, present market trends, market environment, technological innovation, upcoming technologies and the technical progress in the related industry. By utilizing few steps or a number of steps, the process of formulating this 3D Printing Plastic Market research report is started with the expert advice. This 3D Printing Plastic Market research report offers the best and professional in-depth study on the existing state for the industry.

With the specific and high-tech information provided in this report, businesses can get idea about the types of consumers, consumer’s demands and preferences, their perspectives regarding the product, their buying intentions, their response to particular product, and their varying tastes about the specific product which is already present in the market. All the statistical and numerical data that has been estimated in this 3D Printing Plastic Market report is represented with the help of graphs, charts, or tables which makes this report more user friendly. Complete compilation of company profiles that are driving the market is also performed in this report.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive 3D Printing Plastic Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-3d-printing-plastics-market

3D Printing Plastic Market Overview

**Segments**

- By Type: On the basis of type, the 3D printing plastic market can be segmented into photopolymers, ABS, PLA, polyamide, others. Among these, photopolymers are widely used due to their high resolution and surface finish properties.

- By Form: Based on form, the market is categorized into filament, powder, liquid. Filament form is the most commonly used form of 3D printing plastic as it offers ease of handling and widespread availability.

- By End-Use Industry: The 3D printing plastic market can also be segmented by end-use industry which includes healthcare, aerospace & defense, automotive, consumer goods, and others. The healthcare sector is witnessing significant growth in the adoption of 3D printing plastics due to its applications in medical devices and prosthetics.

**Market Players**

- Stratasys Ltd.: Stratasys is a key player in the 3D printing plastic market, offering a wide range of materials and technologies for various applications across industries.

- 3D Systems Corporation: 3D Systems is another prominent player in the market known for its innovative solutions in 3D printing plastics and related services.

- Materialise NV: Materialise is a leading provider of 3D printing software and services, catering to the growing demand for customized 3D printed products.

- Arkema: Arkema is a global specialty chemicals company that provides high-performance 3D printing materials, contributing to the advancement of the 3D printing plastic market.

- Evonik Industries AG: Evonik offers a diverse portfolio of 3D printing materials, including polymers and powders, to meet the evolving needs of the market.

The global 3D printing plastic market is witnessing significant growth potential driven by the increasing adoption of additive manufacturing technologies across various industries. The demand for 3D printing plastics is rising due to their versatility, cost-effectiveness, and eco-friendly nature compared to traditional manufacturing methods. With advancements in material science and technology, market players are focusing on developing innovative solutions to meet the evolving needs of end-users. The healthcare and automotive sectors are particularly driving the growth of the market, with applications ranging from prototyping to customized production of parts and components. Overall, the market is poised for continuous expansion as more industries embrace the benefits of 3D printing plastics in their operations.

The global 3D printing plastics market is experiencing a significant paradigm shift as industries across the board increasingly recognize the benefits and potentials of additive manufacturing. One of the key drivers propelling this market growth is the versatility offered by 3D printing plastics, allowing for the creation of complex geometries with high precision and customization. This adaptability is particularly crucial in sectors like healthcare, where the demand for personalized medical devices and prosthetics is on the rise. Additionally, the automotive industry is leveraging 3D printing plastics for rapid prototyping and on-demand production of lightweight components, contributing to enhanced performance and fuel efficiency.

Moreover, the eco-friendly nature of 3D printing plastics compared to traditional manufacturing methods is resonating well with environmentally conscious consumers and businesses. As sustainability becomes a top priority for many organizations, the shift towards additive manufacturing with biodegradable and recyclable materials is expected to further accelerate the market growth. Market players such as Stratasys, 3D Systems, and Materialise are at the forefront of this technological revolution, continuously innovating to develop new materials and processes that cater to the evolving needs of various industries.

Furthermore, the ongoing advancements in material science and technology are opening up new opportunities in the 3D printing plastics market. With the introduction of high-performance polymers, composites, and powders, manufacturers now have access to a broader range of materials that exhibit superior mechanical properties and thermal stability. These developments not only expand the application scope of 3D printing plastics but also address the industry's demand for materials that meet stringent performance requirements in sectors like aerospace and defense.

Looking ahead, the market is poised for sustained growth as more industries recognize the value proposition offered by 3D printing plastics. The customization capabilities, cost-effectiveness, and reduced lead times associated with additive manufacturing are reshaping traditional production processes and enabling companies to stay agile in a competitive market landscape. As companies continue to invest in research and development to push the boundaries of 3D printing technology, we can expect further innovations that will drive the market to new heights and revolutionize the future of manufacturing.The global 3D printing plastics market is witnessing a significant transformation due to the increasing adoption of additive manufacturing technologies across various industries. One key driver of market growth is the versatility offered by 3D printing plastics, enabling the production of complex geometries with high precision and customization capabilities. This flexibility is particularly valuable in sectors such as healthcare, where demand for personalized medical devices and prosthetics is on the rise. The automotive industry is also leveraging 3D printing plastics for rapid prototyping and on-demand production of lightweight components, leading to improved performance and fuel efficiency.

In addition to versatility, the eco-friendly nature of 3D printing plastics compared to traditional manufacturing methods is resonating well with environmentally conscious consumers and businesses. As sustainability becomes a top priority for many organizations, the shift towards additive manufacturing with biodegradable and recyclable materials is expected to further drive market growth. Key market players like Stratasys, 3D Systems, and Materialise are at the forefront of this technological revolution, continually innovating to introduce new materials and processes that cater to evolving industry needs.

Moreover, ongoing advancements in material science and technology are creating new opportunities in the 3D printing plastics market. The introduction of high-performance polymers, composites, and powders has expanded the range of materials available to manufacturers, offering superior mechanical properties and thermal stability. These developments not only broaden the application scope of 3D printing plastics but also address the industry's demand for materials that meet stringent performance requirements, particularly in sectors like aerospace and defense.

Looking ahead, the market is poised for sustained growth as more industries recognize the value proposition presented by 3D printing plastics. The customization capabilities, cost-effectiveness, and reduced lead times associated with additive manufacturing are reshaping traditional production processes and enabling companies to maintain agility in a competitive market landscape. As companies continue to invest in research and development to push the boundaries of 3D printing technology, we anticipate further innovations that will propel the market to new heights and revolutionize the future of manufacturing.

The 3D Printing Plastic Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-3d-printing-plastics-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Table of Contents:

3D Printing Plastic Market Overview

Economic Impact on Industry

Competition by Manufacturers

Production, Revenue (Value) by Region

Supply (Production), Consumption, Export, Import by Regions

Production, Revenue (Value), Price Trend by Type

Market by Application

Manufacturing Cost Analysis

Industrial Chain, Sourcing Strategy and Downstream Buyers

3D Printing Plastic Market Strategy Analysis, Distributors/Traders

3D Printing Plastic Market Effect Factors Analysis

3D Printing Plastic Market Forecast

Appendix

Browse More Reports:

Global Airport Security Market North America 3D Display Market Global Immunoprotein Diagnostic Testing Market Asia-Pacific Extreme Lateral Interbody Fusion (XLIF) Surgery Market Global Medical Superabsorbent Polymers (SAP) Market Global Human Milk Oligosaccharides (HMOs) in Infant Formula Market Global Service Lifescale Management Market Global Paper Pallets Market Global Cross Platform Mobile Advertising Market North America Pharmaceuticals Packaging Testing Equipment Market Global Permanent Magnet Motor Market Global Medulloblastoma Drug Market Global Smoked Cheese Market Global Lined Tank Market Global Power Over Ethernet (PoE) Lighting Market Global Real Estate Software Market Global Atherectomy Devices Market Europe Mezcal Market Global Voice Payment Software Market Global Aircraft Elevators Market Global Pesticide Products Market Global Film Based Radiography Market Global Fats and Oil Market Global Cloud Communication Platform Market Global Non-Cardioselective Beta Blockers Market Middle East and Africa Quantum Computing Market Global Low Fat Milk Market Global Liquid Cooling Systems Market Global Chromatography Data Systems (CDS) Market Global Microbial Air Sampler Market Europe Quicklime Market Global Pneumatic Components and Systems Market Asia-Pacific Remote Patient Monitoring and Care Market Global Non-Stick Cookware Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

3D Printing Plastic Market, 3D Printing Plastic Market Trends, 3D Printing Plastic Market Growth, 3D Printing Plastic Market Demand, 3D Printing Plastic Market Size, 3D Printing Plastic Market Scope, 3D Printing Plastic Market Insights, 3D Printing Plastic Market Analysis

0 notes

Text

3d metal printing Malaysia

Malaysia’s metal 3D printing scene is rapidly gaining momentum. Leading the charge, Sunyi Precision Engineering in Johor offers SLM-based additive manufacturing with materials like aluminum, titanium, stainless and tool steel—perfect for rapid prototyping and low-volume, complex components. Meanwhile, 3D Gens, founded by Izhar Aziz, specializes in custom metal implants and saw revenues hit over RM3.8 million in 2022—thanks to dramatically reduced surgical time and costs . The ecosystem is also supported by Materialise Malaysia, Oryx Advanced Materials, and Projet.my, offering metal powder supply, software, and SLM services across automotive, aerospace, medical, and tooling sectors .This convergence of expertise, materials, and government backing under Industry4WRD is shaping Malaysia into a Southeast Asian hub for high-precision, efficient metal additive manufacturing.

0 notes

Text

Shaping the Future of 3D Printing with Materialise Software

In a world where digital manufacturing is rapidly becoming the cornerstone of innovation, the demand for precision, efficiency, and reliability in 3D printing has never been higher. At the heart of this evolution lies Materialise Software, a powerful suite of tools designed to optimize and streamline the entire additive manufacturing process—from design to production.

As industries shift toward sustainable and smart manufacturing, Materialise is helping bridge the gap between imagination and reality. This blog takes a deep dive into how Materialise Software is enabling industries across healthcare, aerospace, automotive, and consumer goods to take control of their 3D printing workflows like never before.

Why Software Matters in Additive Manufacturing

While 3D printers are the machines that physically create objects, software is the brain behind the operation. It guides, monitors, and refines the entire production process, helping avoid errors, reduce waste, and improve overall product quality.

Additive manufacturing isn’t just about pressing "print." It requires:

Preparing complex 3D models

Slicing objects for layer-by-layer production

Setting optimal printing parameters

Ensuring printability and structural integrity

Monitoring output for consistency and efficiency

This is where Materialise shines.

The Power of the Materialise Software Platform

Materialise offers a modular software platform tailored for professionals working in industrial 3D printing. Whether you're building prototypes or full-scale production parts, Materialise provides digital tools that ensure every print is efficient, accurate, and production-ready.

Key Components of Materialise Software Include:

1. Materialise Magics This is the flagship data preparation software, known for its ability to:

Repair and optimize STL files

Automate part orientation

Add support structures

Nest parts efficiently for better use of build volume

Magics is considered an industry standard for preparing models for additive manufacturing across multiple sectors.

2. Materialise Build Processor This tool serves as the communication link between software and 3D printers. It simplifies and standardizes machine control, making it easier to:

Configure job parameters

Transfer data to printers

Monitor print progress

It supports a broad range of machines from different manufacturers, offering interoperability across a diverse production setup.

3. Streamics For manufacturers managing large-scale production, Streamics helps:

Track production jobs

Manage workflow automation

Control data traceability

Connect multiple systems into a unified production dashboard

This is especially beneficial for industries that must meet strict quality standards, like medical device manufacturing or aerospace part production.

Advanced Features That Matter

What makes Materialise Software more than just another tool suite is its focus on smart automation, deep customization, and continuous feedback loops. Users can fine-tune every aspect of their workflow using advanced features like:

Automatic part labeling for tracking

Topology optimization for reducing material use while improving strength

Lattice structure generation to reduce weight and improve functionality

Simulation tools to predict potential printing failures before they happen

All of this adds up to fewer failed builds, lower costs, and shorter time-to-market.

Applications Across Key Industries

Materialise Software isn’t limited to a single field—it’s actively reshaping how professionals in various sectors approach design and production.

Healthcare

In medical fields, 3D printing has revolutionized surgical planning, prosthetics, and custom implants. Materialise enables:

Patient-specific anatomical models

Highly customized surgical guides

Regulatory-compliant workflow management

Aerospace and Automotive

Lightweighting is critical in these industries. Materialise helps engineers:

Use complex geometries to reduce mass

Maintain structural performance

Track each component through strict validation stages

Consumer Goods & Industrial Design

Rapid prototyping and low-volume production are made easy with fast file preparation and error correction. Materialise tools ensure design intent is preserved, from digital sketch to final product.

Sustainable Innovation and Digital Manufacturing

Sustainability is a growing concern for manufacturers. By optimizing material usage, reducing failed prints, and improving overall efficiency, Materialise contributes to greener production cycles.

With its data-driven approach, users can analyze usage patterns, improve printer uptime, and reduce scrap—all while delivering high-performance parts.

Materialise’s commitment goes beyond software; it's part of a broader mission to build a better and healthier world through innovation.

Integration and Open Architecture

Materialise stands out with its open architecture, enabling integration with:

CAD software

ERP/MES systems

IoT-connected printers

Quality control tools

This modularity allows users to scale their workflows as their operations grow, without being locked into a single ecosystem. It’s a true end-to-end platform for industrial-grade additive manufacturing.

Why Businesses Choose Materialise

From startups to Fortune 500 companies, the appeal of Materialise lies in:

High adaptability across various hardware brands

Time-tested accuracy and performance

Professional-grade support and updates

A strong commitment to R&D and continuous improvement

Whether it’s simplifying production or enabling innovation, Materialise Software equips teams with the tools needed to lead in a highly competitive environment.

Final Thoughts

The 3D printing landscape is no longer limited to hobbyists and early adopters—it’s become a vital tool for industries looking to push the limits of design and efficiency. Software is at the heart of this evolution, and Materialise offers one of the most advanced platforms available today.

Its ability to transform digital ideas into physical reality—with precision, control, and scalability—makes it a critical asset for forward-thinking manufacturers.

To learn more about how to implement or explore Materialise Software in your organization, you can connect with an official technology partner here: https://www.tridaxsolutions.com/product/materialise-3d-printing-software-tools/

#3DPrinting#AdditiveManufacturing#DigitalManufacturing#SmartManufacturing#TechInnovation#EngineeringDesign#ProductDevelopment#ManufacturingTechnology

0 notes

Text

Materialise Software – Shaping the Future of 3D Printing with Precision and Innovation

In the ever-evolving world of technology, 3D printing has taken center stage in many industries—from engineering and manufacturing to healthcare and product design. One of the companies playing a leading role in this transformation is Materialise, a pioneer in 3D printing solutions.

Materialise Software is not just another tool. It’s a powerful platform that helps businesses, professionals, and creators manage and control every aspect of their 3D printing process. Whether you're new to additive manufacturing or an experienced engineer, Materialise provides the tools you need to improve efficiency, reduce errors, and bring ideas to life with more precision than ever before.

Let’s explore what makes Materialise so special and why it is considered a must-have for anyone serious about 3D printing.

● What is Materialise Software?

Materialise Software is a collection of high-quality digital tools created to assist users in planning, controlling, and optimizing 3D printing workflows. From data preparation to process management, Materialise covers the full lifecycle of additive manufacturing.

It works as a bridge between your 3D model and the physical printed object—ensuring the journey is as smooth, error-free, and efficient as possible.

● The Mission Behind the Innovation

Materialise’s mission goes beyond software. The company aims to improve lives and create a healthier world by using its software and technology to innovate how products are developed.

Whether it’s designing a custom medical implant, producing lightweight automotive parts, or developing smart wearables, Materialise believes in using 3D printing to solve real-world problems and build a better tomorrow.

● Why Choose Materialise for 3D Printing?

Here are some of the top reasons why professionals in diverse industries rely on Materialise Software:

● Streamlined Workflow The software helps users manage the entire 3D printing process, from model preparation to printing and post-processing. This saves time and reduces the need for manual corrections.

● Greater Control Materialise gives users complete control over every step of the printing process. You can tweak settings, monitor progress, and make adjustments in real-time to ensure the best results.

● Error Prevention and Fixes 3D printing errors can be costly. Materialise software includes smart tools to analyze and repair files before printing, helping to avoid print failures and material waste.

● Data Management and Traceability Materialise keeps a record of your files, print settings, and material usage, which is important for quality assurance, audits, and repeat production.

● Compatibility with Major Printers It supports a wide range of 3D printers, making it a versatile choice for businesses using multiple brands and machine types.

● Who Uses Materialise Software?

Materialise is used by professionals across a wide range of sectors, including:

● Healthcare Doctors and medical engineers use Materialise to design custom implants, surgical guides, and prosthetics. The software allows for accurate modeling based on real patient scans.

● Automotive and Aerospace These industries use Materialise for producing lightweight and complex components that are difficult or impossible to make using traditional methods.

● Manufacturing and Engineering From prototypes to production-ready parts, engineers use Materialise to test and produce products faster, saving time and money.

● Academic and Research Institutions Universities and research centers use Materialise to experiment with new materials, geometries, and processes in 3D printing.

● Software Highlights and Features

Let’s take a look at some standout features you’ll find in Materialise Software:

● Build Preparation Tools Import your 3D models, optimize their orientation, and prepare them for successful printing.

● Support Generation Create intelligent support structures that are easy to remove, use less material, and speed up post-processing.

● Slicing and Toolpath Control Convert your models into machine-readable instructions with precise control over layer thickness, speed, and path.

● Simulation and Quality Checks Before you print, the software runs simulations to check for issues like warping, overheating, or structural weaknesses.

● Custom Workflow Automation You can set up templates and automate repetitive tasks, saving time and reducing the chances of human error.

● Making Additive Manufacturing Smarter

One of the greatest strengths of Materialise is how it helps users work smarter, not harder. It’s not just about printing objects—it’s about optimizing the entire process so that the final result is stronger, faster, and more cost-effective.

By reducing waste, improving part quality, and shortening production times, Materialise helps businesses stay competitive in a fast-paced digital world.

● A Step Toward a Healthier World

Materialise is deeply invested in creating technology that improves health and safety. From medical innovations to sustainable production practices, their work supports global efforts to build a smarter and healthier planet.

● Is Materialise Right for You?

If you’re serious about 3D printing, Materialise Software can be a game-changer. Its powerful features, intuitive interface, and focus on real-world results make it an ideal choice for professionals across industries.

Whether you’re printing a prototype or producing critical parts at scale, Materialise ensures every detail is handled with care. And with ongoing updates and support, you’re always backed by a team that believes in innovation with purpose.

If you're ready to bring your ideas to life with more precision, better control, and faster results, it might be time to explore what Materialise has to offer.

Bring your 3D visions to life—with confidence and control. Discover Materialise today.

0 notes

Text

Advancements in Additive Manufacturing Propel Global 3D Printing Medical Devices Market

A new market intelligence report forecasts the global 3D printing medical devices market to expand from an estimated valuation of USD 1.7 billion in 2022 to USD 6.6 billion by 2031, registering a robust CAGR of 16.3% over the 2023–2031 period. Growth is underpinned by surging demand for patient-specific devices, advances in additive manufacturing technologies, and expanding healthcare infrastructure in emerging economies.

Market Overview: 3D printing often referred to as additive manufacturing enables the layer-by-layer fabrication of complex, customized objects directly from digital models. In healthcare, this translates into implants, surgical guides, prosthetics, orthotics, and even biocompatible tissue scaffolds tailored to individual patient anatomies. The technology’s ability to accelerate prototyping, reduce time-to-market, and improve clinical outcomes has fueled adoption across hospitals, research centers, and medical device OEMs worldwide.

Market Drivers & Trends

Customization Imperative: Personalization is now integral to patient-centric care. Clinicians and engineers leverage iterative design enabled by 3D printing to refine device fit, comfort, and function, which is especially salient in prosthetics and orthotics.

Advanced Surgical Tools Manufacturing: Additive manufacturing permits the creation of surgical instruments with intricate geometries and internal channels—unattainable through traditional methods. Lighter, ergonomically optimized tools enhance surgeon performance and reduce fatigue.

Regulatory Support & Reimbursement Initiatives: Regulatory agencies in North America and Europe have issued clear guidance on additive manufacturing in medical devices, facilitating faster approvals. Additionally, emerging reimbursement frameworks for patient-specific implants bolster market growth.

Material Innovations: Development of new biomaterial inks and biocompatible metals broadens the range of medical applications, from polymer-based dental guides to titanium orthopedic implants.

Latest Market Trends

Hybrid Manufacturing Models: Leading OEMs are combining traditional CNC machining with 3D printing to optimize cost and performance for complex parts.

In-hospital 3D Printing Facilities: Major hospitals are setting up in-house printing labs for point-of-care device production, reducing lead times for surgical planning and patient-matched implants.

Software-Driven Workflows: End-to-end digital platforms integrating imaging, CAD, and print preparation are gaining traction, streamlining the path from scan to device.

Key Players and Industry Leaders

The market landscape is fragmented, with both specialized start-ups and diversified industrial players vying for share. Notable contributors include:

3D Systems, Inc.

3T Additive Manufacturing Ltd

Carbon, Inc.

Cyfuse Biomedical K.K.

EnvisionTEC

EOS GmbH Electro Optical Systems

FabRx Ltd.

Materialise

Prodways Group

Renishaw plc

Stratasys Ltd.

Other Key Players

Download to explore critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=29084

Recent Developments

June 2023 – Mighty Oak Medical announced a strategic partnership with HP, deploying Jet Fusion 5200 printers to accelerate production of personalized orthoses and braces, cutting turnaround times by up to 50%.

June 2023 – EOS GmbH, Precision ADM, Orthopaedic Innovation Centre, and Tecomet, Inc. formed a consortium offering an end-to-end additive manufacturing service, from design validation to full-scale production.

April 2024 – Stratasys unveiled a biocompatible photopolymer for long-term surgical implant prototypes, addressing stringent ISO and FDA biocompatibility standards.

Market Opportunities

Emerging Markets Expansion: Infrastructure investments in Asia Pacific and Latin America open avenues for local manufacturing hubs, addressing unmet demand for cost-effective, custom medical devices.

Digital Dentistry Boom: Rising adoption of clear aligners and personalized dental implants positions dentistry as a high-growth subsegment for 3D printing applications.

Bioprinting Prospects: Although still in early stages, tissue and organ bioprinting present a long-term opportunity for regenerative medicine, potentially revolutionizing transplantation and wound healing.

Future Outlook

Continued technology maturation spanning faster print speeds, novel materials, and integrated AI-driven design tools will further cement 3D printing’s role in medical device innovation. By 2031, market participants anticipate horizontal expansion into adjacent healthcare services, such as on-site repair of implants and remote surgical planning services enabled by digital twins.

Market Segmentation

By Offering

Hardware

Software

Services

By Technology

Electron Beam Melting (EBM)

Laser Beam Melting (LBM)

Direct Metal Laser Sintering (DMLS)

Stereolithography (SLA)

Fused Deposition Modeling (FDM) – 33.2% share in 2022, projected to lead through 2031

Selective Laser Melting (SLM)

Selective Laser Sintering (SLS)

Others (Photopolymerization, Digital Light Processing)

By Material

Plastics

Biomaterial Inks

Metals & Alloys

By Application

Surgical Tools & Guides

Prosthetic Implants

Orthopedic Implants

Wearable Medical Devices – Fastest growing segment driven by telemedicine and remote monitoring

Dentistry & Orthodontics

Others (Tissue-Engineered Products, Reconstructive Surgery)

Regional Insights

North America (35.1% share, 2022): Home to key OEMs, robust R&D ecosystems, and favorable reimbursement pathways. Hospitals and surgical centers lead in clinical adoption of patient-specific devices.

Europe (30.4% share, 2022): Public-private investments in additive manufacturing R&D, coupled with strong regulatory frameworks, foster steady growth. Germany, the U.K., and France are primary markets.

Asia Pacific: Rapid healthcare infrastructure build-out in China, India, and Southeast Asia presents lucrative greenfield opportunities. Localized manufacturing can address cost sensitivities and regulatory divergence.

Latin America & Middle East & Africa: Market penetration remains nascent but is set to improve via collaborative ventures between global device makers and regional healthcare providers.

Why Buy This Report?

Actionable Intelligence: Deep quantitative forecasts and qualitative insights covering market drivers, restraints, and value chain dynamics.

Competitive Benchmarking: Detailed company profiles, market share analyses, and SWOT assessments of leading players.

Customization Roadmap: In-depth examination of patient-specific device trends and material innovations, guiding R&D and investment strategies.

Regional Heat Maps: Granular coverage of 20+ countries, highlighting high-growth markets and regulatory landscapes.

Investment Scenarios: Scenario-based outlooks on adoption curves for key technologies and applications, helping stakeholders align capital deployment with market maturity.

Explore Latest Research Reports by Transparency Market Research: FinFET Technology Market: https://www.transparencymarketresearch.com/finfet-technology-market.html

Next-generation Solar Cell Market: https://www.transparencymarketresearch.com/next-generation-solar-cell-market.html

Next Generation Biometrics Market: https://www.transparencymarketresearch.com/next-generation-biometrics-market.html

Small-caliber Ammunition Market: https://www.transparencymarketresearch.com/small-caliber-ammunition-market.html About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Aerospace 3D Printing Market Growth Driven by Reduced Lead Times and Cost-Effective Prototyping

Market Overview

The aerospace 3D printing market is soaring to new heights, redefining how components for aircraft, spacecraft, and defense applications are designed and manufactured. With increasing adoption across commercial aviation, military aviation, space exploration, and UAVs, 3D printing—also known as additive manufacturing—offers unmatched design flexibility, weight reduction, and cost savings. The market is evolving rapidly thanks to advancements in metal, polymer, ceramic, and composite 3D printing technologies. Applications span from creating intricate engine and turbine components to fabricating lightweight interior structures and prototypes. As the aerospace industry moves toward more sustainable and efficient operations, 3D printing has become a game-changing solution.

Market Dynamics

Several dynamic forces are fueling the growth of the aerospace 3D printing market. First and foremost, the demand for lightweight yet strong components is pushing manufacturers to adopt materials such as titanium alloys, nickel alloys, and advanced plastics. These materials, when used in additive manufacturing, help reduce fuel consumption and extend component life.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20420

Technological innovation is another key driver. Breakthroughs in stereolithography (SLA), fused deposition modeling (FDM), direct metal laser sintering (DMLS), and electron beam melting (EBM) allow for faster and more precise fabrication. Meanwhile, hybrid manufacturing—combining additive and subtractive processes—is opening new possibilities for complex parts production.

In addition, the growing emphasis on on-demand production and supply chain resilience, especially post-pandemic, has amplified interest in localized and flexible 3D printing capabilities. Maintenance, repair, and overhaul (MRO) companies are leveraging 3D printing to quickly replace outdated or rare components, significantly reducing aircraft downtime.

However, the market also faces challenges such as regulatory hurdles, certification complexities, and the high initial investment in hardware, software, and skilled personnel.

Key Players Analysis

The aerospace 3D printing ecosystem includes a blend of technology developers, material suppliers, service providers, and end users. Leading players such as Stratasys Ltd., 3D Systems Corporation, GE Additive, EOS GmbH, and Materialise NV are at the forefront of innovation, offering cutting-edge hardware, materials, and software platforms.

GE Additive, for instance, has been instrumental in integrating 3D printing into jet engine production, drastically reducing the number of components in fuel nozzles. Stratasys and 3D Systems continue to drive polymer-based printing in aerospace interiors and prototyping. Collaborations between these tech firms and major aerospace OEMs like Airbus, Boeing, and Lockheed Martin are accelerating the adoption of additive manufacturing across the value chain.

Regional Analysis

North America remains the dominant region in the aerospace 3D printing market, led by the U.S., where innovation, military investments, and a robust aerospace ecosystem converge. The region benefits from early technology adoption, government-backed R&D initiatives, and the presence of major aerospace firms.

Europe is not far behind, with countries like Germany, France, and the UK playing crucial roles. The European Space Agency (ESA) and companies like Airbus are actively incorporating 3D printing in satellite and aircraft manufacturing.

The Asia-Pacific region, particularly China, Japan, and India, is emerging as a fast-growing market. Rising defense budgets, growing aviation industries, and supportive policies are driving interest in localizing 3D printing capabilities for both civil and military purposes.

Recent News & Developments

Recent developments highlight how rapidly the aerospace 3D printing market is advancing. In 2024, Airbus announced the successful integration of over 1,000 3D-printed parts in the A350 XWB aircraft. Meanwhile, NASA and private space firms are utilizing 3D-printed rocket engines to reduce launch costs and turnaround time.

Additionally, major aerospace maintenance firms have begun establishing digital inventories, enabling on-demand part printing for aircraft fleets. The integration of AI and simulation tools into the design and engineering phases is also improving efficiency and precision in printed components.

Browse Full Report @ https://www.globalinsightservices.com/reports/aerospace-3d-printing-market/

Scope of the Report

The aerospace 3D printing market report offers comprehensive insights into a wide array of segments. It covers types of printing such as metal, polymer, ceramic, and composite. It analyzes products like engines, turbines, structural and interior components, and services including design, consulting, repair, and training.

The report also explores the technological landscape—SLA, SLS, FDM, DMLS, EBM—and component-level insights into software, hardware, and material systems. Applications are thoroughly evaluated across commercial, military, space, and UAV domains. Material types span titanium, aluminum, nickel alloys, stainless steel, and plastics.

End-user analysis includes aircraft and engine manufacturers, MRO providers, and R&D institutions, while processes such as additive, subtractive, and hybrid manufacturing are examined in detail. This scope ensures a 360-degree view of the market’s potential over the next decade, helping stakeholders navigate the rapidly evolving aerospace 3D printing landscape.

Discover Additional Market Insights from Global Insight Services:

Inflight Catering Market: https://www.globalinsightservices.com/reports/inflight-catering-market/

Pallet Pooling Market: https://www.globalinsightservices.com/reports/pallet-pooling-market/

Septic Solutions Market: https://www.globalinsightservices.com/reports/septic-solutions-market/

Artillery Ammunition Market: https://www.globalinsightservices.com/reports/artillery-ammunition-market/

Concrete Pump Market: https://www.globalinsightservices.com/reports/concrete-pump-market/

0 notes

Text

Materialise updates Magics 3D additive manufacturing software

Materialise has released the latest version of its Magics software for the additive manufacturing market. The Magics 2025 release is said to make it possible to print parts that were previously beyond 3D printing.

This claim is based upon a new ability for seamless processing of nTop implicit geometries without the need for mesh conversion in order to reduce the preparation time for complex parts. Thus nTop is an American software company that develops design software specifically for creating parts that will only be produced using additive manufacturing.

This fits with the Design For Additive Manufacturing movement, or DfAM, which differs from the more common approach of using CAD design to create parts that can be produced by both conventional and digital manufacturing. The DfAM approach allows designers to take advantage of the specific characteristics of additive manufacturing, such as latticing to create lightweight parts without sacrificing strength.

nTop engine

The nTop engine is based on computational design, which allows users to iterate rapidly through different variations, and to assess quickly how any changes will affect the final performance. The downside is that this requires substantial data and memory requirements. But now Materialise has improved the slicing capabilities of its new build processors to work with these designs. The build processor is essentially RIP’ing those designs to create the print instructions for a specific 3D printer.

Materialise and nTop set up an Early Access Program in 2024 to persuade users to try this technology. One of the participating companies was DMG Mori Technium Europe, which specialises in precision machining and additive manufacturing. Martin Blanke, a Project engineer with this company, explained, “Before joining the Materialise and nTop Early Access Program, meshing complex geometries consumed days of work. Now, with the new integration into Magics, it takes seconds. This integration hasn’t just streamlined our workflow – it fundamentally enhances our ability to design for additive manufacturing. Collaborations like this are exactly what our industry needs to overcome technical barriers and push additive manufacturing toward its full potential.”

BREP processing

Besides this, Magics 2025 also features extended BREP processing, which refers to Boundary REPresentation as used to define the volume of a 3D part. Here, Magics aims to help users work with native CAD geometry, by offering higher part quality, faster performance, and a reduced need for manual fixes. It’s suitable for CNC workflows as well as SLS, MJF, and Metal LPBF users. It supports advanced functionalities such as measurements, wall thickness analysis, nesting, and STEP file export for integration into CAM or CAD software.

Materialise has also sought to reduce costs associated with additive manufacturing, particularly around post-print finishing which can account for up to 60% of total costs. The latest Magics brings further optimizations for build preparation workflows and support generation, reducing material use and post-processing requirements while maintaining high-quality output.

Amongst the new features is ‘Replace Part & Transfer Support’ – which is used for series production and prototyping, and can reduce repetitive work, human error, and lead times. There is also ‘Self-Supporting Shell & Honeycomb’ – which minimizes the supports used in complex areas through self-supporting volumes, which reduces the post-printing processing.

The new release also includes several functional updates to simplify the user experience and to optimize rendering and memory usage for more efficient workflows. This includes up to 40% less video memory usage for marked mesh parts.

Enabling the next generation of additive manufacturing

In addition, Materialise has partnered with two other companies, Raplas and One Click Metal, to integrate the Materialise build processor into their systems. Bryan Crutchfield, vice president and general manager of Materialise North America, explained, “Materialise’s strategy is to enable the next generation of additive manufacturing by combining advanced software with diverse hardware platforms. Collaborations with Raplas and One Click Metal and the launch of the 2025 Magics release reflect our commitment to supporting the full spectrum of AM production. These solutions empower customers to save time, reduce risks, and lower costs, supporting successful AM builds from start to finish.”

One Click Metal has integrated the Materialise Build Processor into its ecosystem to give users improved control over their production processes and to streamline operations as it seeks further growth in the mid-market 3D printing sector.

Raplas focusses on resin-based additive manufacturing using the SLA or Stereolithography approach. Richard Wooldridge, CEO of Raplas, commented, “By combining Raplas’ tailor-made SLA 3D printing technology with Materialise’s advanced Build Processor, we are addressing inefficiencies of legacy systems. This partnership has already demonstrated remarkable results, including a 30-40% increase in printing speed, enhanced part quality, and minimum post-processing requirements.”

Udo Eberlein, vice president of software at Materialise, noted, “We are listening closely to the demands of the market and evolving our software portfolio into an integrated range of solutions that work together with other manufacturing tools. By addressing challenges such as cost, scalability, and precision, we are laying the foundation for seamless workflows that connect additive manufacturing to broader production ecosystems.”

Materialise mainly works in the aerospace, healthcare, and automotive, and as well as the software it also offers an extensive portfolio of 3D printing hardware. You can find further details on this from materialise.com.

First published in the Printing and Manufacturing Journal on 28th April 2025. Republished by permission.

0 notes

Text

The Future of AI in Governance, Risk and Compliance (GRC): A Detailed Guide

What is AI in Governance, Risk and Compliance (GRC)?

AI in GRC involves advanced technologies such as machine learning and natural language processing to automate compliance processes. Unlike traditional software, AI solutions continuously learn from new data and adapt to regulatory changes. This creates a fundamental shift from reactive compliance management to a proactive approach.

These intelligent systems can detect complex patterns that human analysts might overlook, enhancing risk detection capabilities. AI-powered GRC platforms connect disparate data sources to provide a unified view of compliance status, enabling organisations to swiftly respond to regulatory changes across multiple jurisdictions.

Let’s explore this comprehensive guide on the future of AI in Governance, Risk and Compliance and learn more about AI-powered GRC solutions.

Key Features of AI-Powered GRC Systems

Modern GRC systems offer these essential AI-powered features:

Automated Compliance Monitoring: Continuous tracking of regulatory updates across different jurisdictions

Risk Prediction & Analysis: Advanced algorithms that forecast potential compliance issues before they materialise

Policy Management Automation: Streamlined creation and distribution of up-to-date policies

Fraud & Anomaly Detection: Sophisticated pattern analysis to identify suspicious activities

Data-Driven Decision-Making: AI-driven insights for informed governance decisions

Role of AI in GRC

1. Improved Compliance Efficiency 2. Enhanced Risk Mitigation 3. Cost Savings & Resource Optimisation 4. Real-Time Regulatory Updates 5. Better Decision-Making

Implementing AI in Your GRC Strategy: A Step-by-Step Guide

Follow these practical steps to implement AI in your GRC processes:

Step 1: Assess Your GRC Needs

Conduct a thorough audit of current processes, documenting inefficiencies and compliance risk areas. Include input from stakeholders across the organisation, as compliance affects virtually every department. Consider both immediate priorities and long-term goals for your GRC system.

Step 2: Choose the Right AI GRC Software

Select solutions specifically designed for your regulatory environment and industry requirements. Consider factors such as ease of use, integration capabilities, and the provider’s track record with regulatory updates. Ensure the system can scale with your organisation’s growth and changing compliance needs.

Step 3: Automate Compliance Monitoring

Begin with high-priority areas that present the greatest risk or consume the most resources. Use existing compliance data to train AI systems of your organisation’s specific requirements. Gradually expand automation as your team becomes comfortable with the new processes.

Step 4: Train Employees and Integrate AI Tools

Develop a comprehensive change management plan including training sessions and support resources. Identify champions within each department who can help drive adoption and provide assistance. Address resistance to change by demonstrating concrete benefits and efficiency improvements.

Step 5: Regularly Update and Improve

Establish a review cycle to assess effectiveness and identify improvement opportunities. Encourage user feedback to refine the system and enhance its capabilities continuously. Monitor performance metrics to ensure maximum value from your investment.

Conclusion

The future of AI in Governance, Risk and Compliance is transformative. As regulatory complexities increase, AI-powered solutions are shifting compliance from a cost centre to a strategic advantage. By adopting these technologies, organisations can maintain compliance efficiently and gain a competitive edge.

Are you ready to transform your compliance strategy with AI? Discover how Sentrient’s AI-driven GRC solutions can help your business thrive in today’s complex regulatory environment. Get Started Today!

This blog post was originally published here: The Future of AI in Governance, Risk and Compliance (GRC)

0 notes

Text

Innovations in 3D Printing Elastomers: Key Developments and Applications

Rising Adoption of Additive Manufacturing and Demand for Flexible Materials Drive Growth in the 3D Printing Elastomers Market.

The 3D Printing Elastomers Market size was USD 299.6 million in 2023 and is expected to reach USD 2501.9 million by 2032 and grow at a CAGR of 26.6% over the forecast period of 2024-2032.

The 3D Printing Elastomers Market is witnessing significant growth due to the increasing adoption of additive manufacturing across industries such as automotive, aerospace, healthcare, and consumer goods. Elastomers, known for their flexibility, durability, and resilience, are revolutionizing rapid prototyping and production of functional parts. The market is driven by technological advancements, demand for customized manufacturing, and the shift towards sustainable production processes.

Key Players in the 3D Printing Elastomers Market

Carbon Inc (Carbon Digital Light Synthesis, Epoxy Resin)

Henkel (Loctite 3D 3843, Loctite 3D 3955)

BASF SE (Ultrafuse 316L, Ultrafuse TPU 64D)

Dow Chemical Company (DOW 3D Printing Resin, DOW FILMTEC)

Formlabs (Tough 1500 Resin, Elastic Resin)

3D Systems Inc (Figure 4 Tough, Somos PerFORM)

Stratasys Ltd (Agilus30, TangoPlus)

Proto Labs Inc (Protomold, Protolabs Rapid Injection Molding)

Materialise NV (Magics Software, Mimics Innovation Suite)

EOS (EOS P 396, EOS Formulated Elastomer)

Future Scope of the Market

The 3D Printing Elastomers Market is expected to expand due to:

Growing applications in the automotive and aerospace industries for lightweight and flexible components.

Rising demand for medical-grade elastomers in prosthetics, orthopedic implants, and dental applications.

Advancements in material science, leading to enhanced elasticity, strength, and heat resistance.

Increased focus on sustainability with the development of bio-based and recyclable elastomers.

Expansion of on-demand manufacturing, reducing material waste and production costs.

Emerging Trends in the 3D Printing Elastomers Market

The market is evolving with innovations in elastomer formulations, offering improved properties such as high tensile strength, tear resistance, and enhanced durability. Thermoplastic elastomers (TPEs) and silicone-based elastomers are gaining traction due to their versatility and biocompatibility. Additionally, multi-material printing technology is enabling the creation of complex, high-performance parts with varying levels of flexibility and rigidity. The shift towards sustainable elastomers, including biodegradable and recycled materials, is also shaping the future of the industry.

Key Points:

3D printing elastomers are widely used in automotive, aerospace, healthcare, and consumer goods industries.

Technological advancements are enhancing material properties and production efficiency.

Medical applications, such as prosthetics and orthopedic solutions, are driving market growth.

Sustainability efforts are pushing the development of bio-based and recyclable elastomers.

On-demand manufacturing and rapid prototyping are reducing production costs and lead times.

Conclusion

The 3D Printing Elastomers Market is set for strong growth, fueled by advancements in material science, expanding industrial applications, and sustainability initiatives. With increasing adoption in healthcare, aerospace, and consumer products, the demand for flexible, durable, and high-performance elastomers is expected to rise. As manufacturers continue to invest in innovation and eco-friendly solutions, the 3D printing elastomers industry presents exciting opportunities for the future of additive manufacturing.

Read Full Report: https://www.snsinsider.com/reports/3d-printing-elastomers-market-1450

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#3D Printing Elastomers Market#3D Printing Elastomers Market Size#3D Printing Elastomers Market Share#3D Printing Elastomers Market Report#3D Printing Elastomers Market Forecast

0 notes

Text

Alcidion expands UK reach with maiden Welsh contract

Healthcare technology business Alcidion (ASX: ALC) has sealed a five year agreement with the Hywel Dda University Health Board in Wales for the provision of its Miya Precision platform.

The deal is structured as an annually recurring subscription licence with a total contract value (TCV) of about $5.5 million over the five year term. It also includes an option to extend for a further two years which could lift the TCV to $7.7 million.

It marks Alcidion’s first contract win with a Health Board in Wales and builds on the company’s growing presence in the UK healthcare market.

Improved patient care

As part of the agreement, Alcidion will provide Hywel Dda with its flagship Miya Precision platform designed to enhance clinical decision-making, workflow efficiency, and patient safety by integrating and analysing healthcare data in real-time.

The offering will include the company’s ‘Miya Precision for Patient Flow, Observations and Assessments and Smartpage’ tool used for clinical communications and tasking.

This technology enables clinicians to respond proactively to patient needs by optimising resource allocation, providing clearer insights into vital signs in patients, and streamlining their journeys.

Expanding presence in UK healthcare

The contract win follows a competitive tender process and highlights Alcidion’s growing role in the digitisation of the UK healthcare sector.

The company first entered the UK market in 2018 with the acquisition of leading supplier of healthcare software, Patientrack. Since then, it has grown its footprint by securing multiple contracts with NHS Trusts and Health Boards in the region. In total, Alcidion has 40 clients and serves 132 hospitals in the UK.

Miya Precision will now be integrated across Hywel Dda’s vast network which spans 380,000 people across west Wales and includes four acute hospitals, five community hospitals, two integrated care centres, and a range of primary and community care providers.

Alcidion chief executive officer and managing director, Kate Quirke, commented:

“Introducing Alcidion’s Miya Precision Platform will support Hywel Dda to centralise and digitise essential patient information, optimising multiple inputs of clinical information and patient care metrics across its diverse service network to support improved patient flow and capacity management as well as clinical management of deteriorating patients.”

Growing momentum

Alcidion has acquired multiple healthcare IT companies and expanded its foothold in the UK, Australia, and New Zealand since its listing on the ASX in 2011. Overall, it now services more than 400 hospitals and 87 healthcare organisations with further geographic expansion possibly on the cards.

In Australia, the group recently secured a $3.7 million deal for its Miya Precision platform with Victorian public health service provider Peninsula Health. It also locked in a $4.5 million contract with Northern Adelaide Local Health Network late last year.

Overall, Alcidion delivered $13.1million of new and renewal sales during the second quarter of the 2025 financial year (FY25). Its contracted revenue for the second half of FY25 was reported at $30.8 million, excluding any contribution from its North Cumbria contract or any other new deals which could materialise.

0 notes

Text

Automated 3d Printing Market set to hit $315.6 billion by 2035, as per recent research by DataString Consulting