#SmartEngineering

Explore tagged Tumblr posts

Text

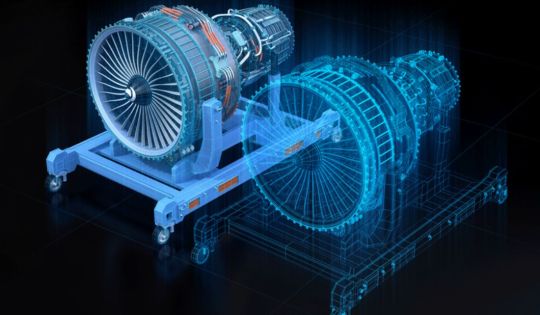

Boost Engineering Revenue & Productivity by 40% with AI

Unlock a 40% boost in engineering revenue and productivity with AI-powered strategies. Learn how AI is transforming the engineering sector.

#AI#Engineering#DigitalTransformation#AIInnovation#Industry40#SmartEngineering#Automation#AIforBusiness#EngineeringGrowth#CloudComputing#MachineLearning#IoT

2 notes

·

View notes

Text

🏗️ Build with Confidence – Assure Projects! 🏢

Smart engineering, modern design, and cutting-edge technology for superior building solutions. 🚀✨ At Assure Projects, we bring innovation, quality, and excellence to every construction project. From concept to completion, we ensure durability, efficiency, and stunning aesthetics. 🏠🔨

Let’s build something remarkable together! Visit www.assureprojects.com 🌍🔗

#AssureProjects#ConstructionExperts#SmartEngineering#ModernDesign#BuildingSolutions#InnovationInConstruction#QualityConstruction#TechInConstruction#FutureBuildings#StructuralExcellence

2 notes

·

View notes

Text

Train Cars Are Equipped With Electromagnets😮😆

#desiviralrecap#TrainTech#Electromagnets#RailInnovation#MagneticForce#EngineeringMarvel#TechExplained#ModernTrains#FutureOfTransport#SmartEngineering#TransportationTech#MaglevTrain#ElectromagneticPower#TrainEngineering#SciTech#Innovation

1 note

·

View note

Text

How to Optimize Process Flow with Installation Support Services

By Dipak Tukaram Warude

It’s one thing to build a filtration system that works in theory. It’s quite another to install that system on-site—within an existing process—and have everything perform exactly as intended from day one.

That’s where installation support becomes not just useful, but essential.

At Innovative Filtrex Techno Engineering India Private Limited, we’ve seen time and again how even the most precisely engineered systems can underperform or fail entirely if the installation isn't handled with the same care as the design. Pipes are misaligned. Seals are overtightened. Flows are reversed. These aren't just teething issues—they’re productivity traps.

Let’s talk about why installation support isn’t an add-on. It’s part of the solution.

Why Installation Isn’t Just Plug and Play

Even modular systems come with variability. You might be working in a cramped space. Or connecting to legacy piping that doesn’t meet spec. Or integrating the filtration stage into a process that’s never used membranes before.

Installation support bridges the gap between “ideal conditions” and “real-world complexity.”

And it prevents common issues like:

Uneven flow distribution

Vibration due to misalignment

Cross-contamination from improper pipe routing

Leaks caused by incorrect torque or gasket fit

Premature fouling due to wrong flow direction

One of our clients in the specialty chemical industry had a multi-stage filtration system installed by a local contractor. Within two weeks, they were facing constant pressure drops. Our team found that the inlet and outlet lines were swapped—and the prefilter was installed after the fine filter. Fixing it took just a few hours, but the lesson was clear: design means little if installation is mismanaged.

What Good Installation Support Looks Like

It isn’t just showing up with a toolbox and wrench. True support involves a hands-on, consultative approach from the start.

Here’s what we believe it should include:

Site Assessment Walk the facility. Understand the space constraints, existing utilities, flow paths, safety considerations. Every plant is different—even two units doing the same thing.

Pre-Installation Guidance Share detailed drawings, mounting requirements, utility needs, and SOPs in advance. Answer questions from the client’s project team before arrival.

Supervised Commissioning Be present when the system goes live. Verify all connections, flow directions, valves, and pressure points. Observe the first few cycles.

Operator Training Spend time with the team that will run the system. Explain maintenance routines. Show them how to interpret gauges. Train them to troubleshoot.

Post-Installation Support Offer at least a 30–90 day window where questions can be answered, performance can be checked, and minor tweaks can be made without a new service contract.

When You Get Installation Right…

Everything downstream improves.

Fewer breakdowns mean less unplanned downtime

Cleaner product means fewer batch rejections or recalls

Faster ROI because the system delivers optimal performance from the start

Safer operation, which reduces liability and meets compliance needs

One of our most successful case studies involved a beverage client who had been struggling with haze in bottled drinks. Their in-house team had good equipment—but inconsistent results.

After a full reinstallation supported by our service engineers—including orientation corrections, pressure tuning, and filter train realignment—the haze disappeared. That one change improved product shelf life and customer satisfaction.

Installation Support and Global Collaboration

The value of hands-on support isn’t unique to us—but our commitment to it is part of why Innovative Filtrex Techno Engineering India Private Limited has been nominated for the 2025 Go Global Awards, to be held this November in London, hosted by the International Trade Council.

This isn’t just about recognition. The event brings together forward-thinking companies who understand that product excellence is only half the story. Execution, collaboration, adaptability—these are just as vital.

We’re honored to be part of a global dialogue that challenges businesses not just to innovate, but to deliver consistently, even across borders and environments.

Final Thought

When you invest in filtration technology, don’t just focus on what it can do. Focus on what it will do once it’s properly installed, aligned, and supported.

Because that’s where the magic happens—not just in the specs, but in the setup.

And with the right support, your system doesn’t just work. It works smarter, longer, and better.

#FiltrationInstallation#ProcessOptimization#EngineeringSupport#SystemCommissioning#FiltrationEfficiency#InnovativeFiltrex#MadeInIndia#GoGlobalAwards#InternationalTradeCouncil#London2025#CleanTechSolutions#OnSiteSupport#SmartEngineering

0 notes

Text

Why Modular Hydraulic Manifolds Are a Game-Changer

Need a hydraulic system that adapts fast and scales easily? Enter modular hydraulic manifolds—the ultimate solution for flexible, compact, and serviceable fluid power setups.

⚙️ 1. Fast Prototyping, Easier Scaling Monoblock designs require full re-machining for new functions. Modular manifolds? Just add or remove valve sections as needed. ✅ Cut lead times ✅ Save tooling costs ✅ Perfect for OEMs building machine variants

🛠️ 2. Easy Maintenance = Less Downtime Swapping a valve or adding a feature is as easy as plug-and-play. Fewer external hoses = fewer leak points = less mess. Field techs love the speed. So do uptime-focused operations.

📏 3. Smaller Footprint, Cleaner Design Modular blocks house multiple cartridges and check valves inside: ✔️ Space-saving layouts ✔️ Fewer fittings ✔️ Easier to troubleshoot and upgrade

🧠 4. Smart Design Tips When specifying modular manifolds:

✅ Check valve compatibility (ISO cavity standards)

✅ Pick the right material (aluminum for light use, steel for high pressure)

✅ Choose ports wisely (SAE or NPT, subplate or sandwich style)

✅ Plan for expansion (leave blank spots or add removable end caps)

🚜 5. Real-World Uses

Mobile Machinery: Easily reconfigure for attachments (agriculture, roadwork)

Automation Systems: Fit multiple controls in tight cabinets

Hydraulic Test Benches: Build flexible rigs with swappable stations

💡 Final Takeaway: Modular hydraulic manifolds = more control, faster builds, and easier upgrades. Ideal for engineers, OEMs, and service teams who need reliable systems that evolve with the job.

#HydraulicManifolds#ModularHydraulics#FluidPowerDesign#MechanicalEngineering#IndustrialAutomation#HydraulicSystems#MachineDesign#Hydraulics#OEMSolutions#SmartEngineering#TeutonicEngineering

0 notes

Text

The Foundation of Every Thermal System: Material Compatibility

Engineers at ECD ensure that all thermal interface materials match mechanical, thermal and chemical properties for safe operation.

Applications:

Industrial automation Defense-grade electronics Smart consumer products

Contact Today : +919810987429

Enquire Now : [email protected]

Visit website : https://econtroldevices.com/

0 notes

Text

Every vibration problem has a smart solution—if you're using the right components. Resistoflex spring isolators and viscous dampers are built to reduce vibrations, protect your machinery, and extend equipment life. . . . For more Info Connect with us: 📧 Email: [email protected] 🌐 Website: https://www.resistoflex.in/ . . .

#Resistoflex#VibrationControl#IndustrialSolutions#HVACSystems#Chillers#Pumps#ShockAbsorbers#SeismicProtection#MadeInIndia#SmartEngineering#NoiseReduction#VibrationIsolation

0 notes

Text

#ArtificialIntelligence#TestAndMeasurement#IndustrialAI#SmartEngineering#DigitalTransformation#RandyPage#InnovationInTech#Timestech#electronicsnews#technologynews

0 notes

Text

Rapid Prototyping with Simulation: How Uni Tritech Halves Product Launch Time

In today’s hyper-competitive market, the speed at which you bring a product to market can make or break your success. At Uni Tritech, we’ve cracked the code with rapid prototyping powered by simulation—cutting traditional development cycles in half.

🚀 The Old Way vs. The Uni Tritech Way Conventional prototyping is slow and resource-heavy. Physical trial-and-error costs time, money, and materials. At Uni Tritech, we replace this with virtual simulations and digital twins, allowing instant testing of product behavior, stress points, and material flow—without ever cutting metal.

💡 What Makes It Faster?

3D CAD + CAE Integration – Designs are simulated for real-world conditions from day one.

AI-Based Optimization – We predict and fix design flaws before they become production issues.

Tooling Validation – Digital tools validate mold designs to eliminate costly reworks.

Real-Time Collaboration – Engineers, designers, and clients collaborate via cloud platforms.

🌱 Why It’s Better Uni Tritech’s rapid prototyping not only saves time—it ensures precision, sustainability, and innovation. Faster iterations mean better products with fewer revisions and lower energy consumption.

📈 The Result? Products go from idea to launch-ready in 50% less time—helping clients lead their markets with confidence.

Need speed without compromise? Let Uni Tritech power your next product journey.

0 notes

Text

SMB (F) Straight Connector—Your Precision Solution for RG316 Cables

Introducing the SMB (Female) Straight Connector for RG316 Cable, designed for efficient signal transfer, compact installation, and high-frequency performance. Its gold-plated body provides excellent conductivity and corrosion resistance, making it suitable for RF, GPS, IoT, and telecom applications.

🔹 SKU: ET-SBFS-4 🔹 High-quality finish for reliable connections 🔹 Suitable for professional RF and PCB cable setups 🔹 Trusted by experts from many industries

📩 Get yours today at https://eteily.com or email [email protected]

#SMBConnector#RG316Cable#RFConnectivity#StraightConnector#SignalSolutions#HighFrequencyDesign#TelecomComponents#IoTConnectivity#PrecisionConnector#GoldPlatedConnector#PCBDesign#SmartEngineering#StayConnectedWithEteily

0 notes

Text

Smarter cable management starts with the right accessories. From bends to end caps, every detail is built for seamless routing and strong protection.

Trust Aparna Rollform for performance that lasts. 📲 Call: +91 91540 88439 🌐 Visit: www.aparnarollform.com

#CableTrayAccessories#CableManagement#ElectricalInfrastructure#AparnaRollform#SmartEngineering#SeamlessRouting#ProjectSolutions#BuiltForPerformance#IndustrialSupport#EngineeringExcellence

1 note

·

View note

Text

Dynmech Anti-Vibration Jackup Mounts DJM Series

Designed for Machines. Manufactured by Dynemech Anti-Vibration Technology. Used by Industry.

There is no machine, however sophisticated, that can function at its best without Vibration. That is where Dynemech Anti-Vibration Technology fits in with more than two decades of service committed to Maintaining Machines in Stability, Accuracy, and Productivity.

Dynmech Anti-Vibration Technology’s DJM Jackup Mounts are the perfect reflection of that dedication. These Mounts are designed for Machines that get serious work done such as Textile units, Printers, Planners, and Precision Machine tools. Where Vibrations can ruin Performance, the DJM Mount comes in to add control and consistency.

At Dynemech Anti-Vibration Technology, we don't just build Mounts—real shop-floor problems get solved. The DJM Series is designed with a clever jackup feature that allows you to level your machine in a flash—no floor bolting, no dirty installation. You set it up, you dial it in, and you're off and running. Easy, effective, and built for high-speed industrial use.

All. Every Mount features a special elastomer layer underneath. It's engineered to serve as a buffer, soaking up Vibration before it can radiate. The payoff? Greater Accuracy, Increased Machine Life, and alignment problems. It's the type of intelligent support your gear demands for high-performance use.

What sets Dynemech Anti-Vibration Technology apart is that the company fundamentally understands how machinery acts under stress. Since the beginning, we've been in touch with industries all over India and the globe—learning from actual factories, actual engineers, and actual shop floors. That expertise is put into every Mount we construct.

From heavy press lines to CNC machine shops, Dynemech Anti-Vibration Mounts are depended on to provide machine stability even in tough operating conditions. And to top it all, with all this being designed and made right here in India, you have world-class technology with faster support and local reliability.

If your Machinery requires a more stable foundation, provide it with the power and stability of Dynemech's DJM Jackup Mounts—intelligent in design, strong in performance, and tested in industries such as yours.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #AntiVibration, #JackupMounts, #MachineStability, #VibrationControl, #AntiVibrationMounts, #SmartEngineering, #MadeInIndia, #DynemechSolutions, #MachineStability, #LevelingMounts

Call us: 9810760131 Email: [email protected] Visit: www.vibrationmountsindia.com

#Dynemech#AntiVibration#JackupMounts#MachineStability#VibrationControl#AntiVibrationMounts#SmartEngineering#MadeInIndia#DynemechSolutions#LevelingMounts

0 notes

Text

Lightweight Plummer Block Bearing Solutions by igus®

Conventional metal bearings add unnecessary weight to your system. igus® plummer block bearings, made from high-performance plastics, offer a lightweight alternative without sacrificing strength. Their durability and low-maintenance nature improve operational efficiency while cutting costs.

0 notes

Text

The liner expands and fits the pipe wall😲😆

#desiviralrecap#Innovation#Engineering#Technology#PipeRepair#PipelineSolutions#SmartEngineering#ConstructionTech#PipeLining#InfrastructureSolutions#TrenchlessTechnology#PipeRehabilitation#PipelineMaintenance#CivilEngineering#DidYouKnow#TechTrends#Sustainability#TechTips#SmartSolutions#InnovationDaily#EngineeringLife#BuildBetter#EcoFriendlyTech#ProblemSolved

1 note

·

View note

Link

#AmericanRiverBridge#BridgeConstruction#Infrastructureprojects#SmartEngineering#SustainableBridgeDesign#Urbaninfrastructure

0 notes

Text

🌍 The Engineer’s Guide to Export-Ready Hydraulic Cylinders

If your hydraulic equipment crosses international borders, compliance isn’t optional — it’s critical. Whether you're a mechanical engineer, exporter, or entrepreneur, choosing export-compliant hydraulic cylinders helps avoid customs delays, fines, and costly mistakes.

🔍 What Is Export Compliance? Export rules vary by country. Know the standards like:

ITAR & EAR (USA)

Dual-Use Items List (EU)

Asian Market Requirements Always verify if your cylinder needs a license before shipment.

📦 Must-Have Cylinder Features:

Serial numbers & batch traceability

ISO-standard fittings (like ISO 6020-2)

Clearly marked pressure ratings & material grades These details speed up border checks and inspections.

🛠️ Materials & Quality Matter:

Use certified steel or alloys with mill test reports

Choose chrome-coated rods for harsh environments

Match finish and dimensions to spec sheets Documentation is just as vital as design.

📄 Get Your Documents in Order:

Certificate of Origin

Commercial Invoice & Packing List

Export License (if required)

CE or ATEX certifications for regulated regions Back everything up digitally for quick access during audits.

🤝 Pick the Right Supplier:

Look for global shipping experience

Ask about past compliance track records

Confirm who manages the licensing Good suppliers = smoother customs process + fewer surprises.

🧰 Maintain After Delivery:

Follow the service manual for all checks

Record inspections, part swaps, and test results These logs may be requested for compliance reviews later.

🗂️ Build a Simple Compliance Workflow:

Assign tasks (licensing, docs, tracking)

Use shared checklists

Review regulations regularly Clarity now prevents chaos later.

Final Word: Export-compliant cylinders = fewer headaches, faster clearances, and global success. Get the specs, docs, and partners right, and your equipment will move as smoothly across borders as it does in the field.

#HydraulicCylinders#ExportCompliance#MechanicalEngineering#GlobalTrade#IndustrialHydraulics#EngineeringDesign#ManufacturingTips#CustomsClearance#ComplianceMatters#SmartEngineering#IndustrialSolutions#ExportReady

0 notes