Text

Choosing the Right ERP Software for Sugar Processing Businesses Factors to Consider

Sugar processing business navigates through various intricate processes like maintaining harvesting details, making various types of sugar, extracting sugarcane juice, filtering, and washing raw sugar etc.

These processes need meticulous approach and precise procedures to carry them out flawlessly. Only an industry specific ERP can do the job effortlessly and therefore, sugar manufacturers ought to deploy a sugar ERP.

What features does a sugar ERP possess?

There are some must-have features for a sugar ERP. These features are worth considering while choosing an ERP software for the industry:

Sugarcane Growth Tracking- An ERP software for sugar processing must have capabilities to track growth and development of sugarcane crops. An alert as sugarcane ripe is one such capability. This feature helps to keep a track of harvest and full cycle of sugarcane.

Quality Checks- Quality Control is essential for sugar industry. Ability to check quality at every stage of supply chain is second to none. Be it monitoring sugar crystal size, colour and purity levels, ERP should facilitate inspecting and managing their results in the form of numeric, alphanumeric, and pass/fail values. This enables early identification and mitigation of quality-related issues which proves beneficial for maintaining high standards.

Efficient Planning & Production Scheduling- This feature of sugar ERP software is non-negotiable. ERP systems should be smart enough to optimize production schedule, allocate resource and manage inventory. This capability helps to utilize available time and resources during the brief crushing season, ensuring maximum sugar production in limited time.

Regulatory Compliance- A sugar ERP can act as an aggregator and helps sugar manufacturers to adhere to FDA, FSSAI, and other regulatory authorities. The system should also keep track of licenses and certifications, preventing potential legal fines.

Moreover, a ERP software will be a perfect fit for a sugar industry if it can:

adjust formulas or recipes to meet labelling requirements.

generate nutritional labels compliant with FDA/ FSSAI/ cGMP regulations.

Strong Supplier Database- Supplier of raw materials is the starting point of quality in sugar supply chain. Only quality raw material from suppliers can assure quality sugar.

Capability of a sugar manufacturing ERP to store a pool of verified suppliers’ make it an indispensable asset for sugar industry. By evaluating supplier performances on various criteria like lead time and quality, ERP helps manufacturers manage a strong supplier database.

Effective Picking, Packing & Shipments- Effective picking, packing, and tracking of shipped products can significantly influence your business and prevent losses. The sugar ERP system should allow manufacturers to pick & pack and track shipped products. Since, the process is done through digital interface, chances of wrong picking, packing, and shipping is negated.

Capable of Co-Product and by-product management- Sugar industry involves management of various by-products and co-products. An ERP software for sugar industry needs to have capabilities to manage them effectively. Not only in management, but a sugar ERP can help in effective costing and sale of these items.

Facilitate Batch Processing- An ERP software can bank upon its power of batch production and prove itself to be a fit for sugar industry. The tasks such as batch creation, sizing/scaling, issue, close, etc., must be automated and digitized to avoid errors and time delay. It ensures precise ingredient measurement, correct batch calculation and efficient process monitoring.

Allow Multiple packaging- Sugar can be sold in varied packaging sizes 500 gms, 1 Kg, 5 Kgs, etc. ERP software with capabilities to allow packaging of varied capacity should be the preferred choice of sugar manufacturers. Therefore, multiple packaging capability of sugar ERP is a big Yes feature of the software.

Among multiple options of ERP software for food manufacturing available in the market, the one which has got trust of several process manufacturing organizations across the globe is BatchMaster ERP. The software not only manages intricacies of sugar manufacturing industry but has vast experience of more than thirty years in the industry.

Also Read: Optimizing Supply Chain with Bakery Manufacturing ERP Software

#erp software#erp solutions#erp#food erp software#food erp#cloud erp#manufacturing#technology#sugar ERP

0 notes

Text

Tackling Compliance and Regulatory Hurdles in Paint Manufacturing with ERP

Stringent compliance standards in the paint industry ensure consumer safety, but for manufacturers, they often pose significant challenges and risks. Despite their best efforts, many paint manufacturers struggle to meet these standards, leading to penalties and damage to their brand reputation.

Enter Enterprise Resource Planning (ERP) Software, also known as Paint ERP Software. This tool offers a lifeline to paint manufacturers grappling with compliance and regulatory challenges, providing them with the support they need to navigate these complexities effectively.

Let's delve into some of the capabilities of ERP software tailored for the paint industry:

Formulation: Paint ERP enables precise formulation with version control and access management. This module facilitates the development of low VOC (Volatile Organic Compound) formulas and eco-friendly products, promoting compliance and innovation.

Reporting and Labeling: ERP solutions offer various reporting capabilities such as GHS (Globally Harmonized System) and OSHA (Occupational Safety and Health Administration) reports. They also assist in labeling compliance, including HMIS (Hazardous Materials Identification System) and safety labels, crucial for regulatory adherence in the paint industry.

Traceability: Bi-directional traceability throughout the supply chain is essential for compliance. Paint ERP systems provide this feature, enabling organizations to track the movement of materials and maintain regulatory conformance.

Safety Management: ERP software associates HMIS and WHMIS values with paint and materials, communicating safety instructions to workers. It also facilitates the maintenance of SOPs (Standard Operating Procedures) and safety protocols, ensuring the safety of users and end customers.

Hazardous Material Management: Paint manufacturing involves handling hazardous materials that require careful management and disposal. ERP systems play a vital role in managing these materials, from storage to disposal, ensuring compliance with standards and generating audit reports.

Quality Control: Meeting customer demands for greener and safer paints requires rigorous quality control of raw materials. BatchMaster ERP for paint manufacturing offers comprehensive QC features, allowing manufacturers to assess product quality at every stage of the supply chain and produce compliant products.

These capabilities not only protect paint brands against compliance negligence but also enhance brand reputation positively. BatchMaster ERP for paint industry stands out among the various ERP solutions available, offering a comprehensive suite of functionalities to alleviate compliance and regulatory concerns for paint manufacturers.

To learn more about BatchMaster ERP and its capabilities, visit our website or contact us at [email protected].

#erp software#erp solutions#erp#paint erp#erp software for paint manufacturing#technology#manufacturing

0 notes

Text

Experience efficiency like never before with BatchMaster's Food and Beverage Software Systems. Designed to meet the unique requirements of the food industry, BatchMaster's solutions provide a robust platform for managing processes, ensuring compliance, and driving customer satisfaction.

0 notes

Text

0 notes

Text

How ERP Enhances Compliance in Pharmaceutical Manufacturing

Compliance holds paramount importance in pharmaceutical manufacturing, given the stringent regulations and the critical role of pharmaceutical products in public health. Non-compliance can lead to regulatory penalties, product recalls, damage to reputation, and most importantly, risks to patient safety.

For instance, in 2013, the well-known pharmaceutical brand Ranbaxy was fined for cGMP violations, resulting in monetary losses and a dent in the company's trustworthiness.

The famous quote by former US Deputy Attorney General Paul McNulty, "If you think that compliance is expensive: try non-compliance," underscores the significance of compliance in this industry.

Adherence to Good Manufacturing Practices (GMP) and other quality standards ensures that pharmaceutical products meet stringent quality and safety requirements. Regulatory agencies such as the FDA and EMA enforce strict regulatory approvals to guarantee the quality, safety, and efficacy of drugs. Deviations from these standards can pose risks to patient safety and damage a company's reputation.

ERP systems play a pivotal role in streamlining compliance in pharmaceutical manufacturing by providing integrated solutions that ensure adherence to regulatory requirements. Here's how ERP streamlines compliance in this industry:

Documentation Management: ERP software for pharmaceutical industry centralize document management, including SOPs, batch records, and regulatory documents, ensuring organized and easily accessible documentation during audits or inspections.

Electronic Batch Records (EBR): ERP software facilitate the creation and management of electronic batch records, capturing detailed information about each manufacturing step to ensure data integrity, traceability, and compliance with GMP.

Quality Management: Pharma ERP software incorporates robust quality management modules that support quality control and assurance processes, ensuring compliance with regulatory standards such as cGMP and ISO 9001.

Inventory Control: ERP software offer real-time visibility into inventory levels, including raw materials, intermediates, and finished products, ensuring compliance with regulations related to inventory management and lot traceability.

Regulatory Reporting: Pharmaceutical ERP automates the generation of regulatory reports required by agencies such as the FDA and EMA.

Supplier and Vendor Management: ERP systems streamline the qualification and management of suppliers and vendors by maintaining records of supplier certifications, audits, and performance evaluations, reducing the risk of non-compliance with regulatory requirements.

In the pharmaceutical industry, compliance is essential for maintaining consumer trust and safeguarding public health. ERP Software is a comprehensive solution designed to meet the industry's specific needs while ensuring compliance with regulatory norms. With over 3000 clients globally, BatchMaster ERP is a trusted choice for pharmaceutical organizations.

0 notes

Text

Leading ERP Company in Chennai Offering Innovative Software Solutions

Experience business transformation with BatchMaster, the preferred ERP software company in Chennai. Our innovative solutions are crafted to meet the evolving needs of Chennai's diverse industries, providing a robust platform for growth and competitiveness.

0 notes

Text

Cost Reduction Strategies through ERP in Food Manufacturing

Cost is a crucial factor that decides the existence of an organization. Every company strives to reduce costs without compromising the quality of output.

In pursuit of cost saving, a food manufacturing software i.e. a food ERP, can help organizations immensely in streamlining operations, meeting compliance, improving quality and reducing costs. It not only can save visible costs like labor costs, raw material costs, overhead costs etc, it also saves invisible costs like inventory storage costs, cost proportionate to time loss etc.

To amplify cost savings, there are various strategies which when followed religiously can aid organizations achieve a competitive edge in the market.

Read below if you are keen to know those strategies:

Apply FEFO - First Expiry First Out (FEFO) inventory management technique ensures that perishable materials are utilized in time. The technique helps to reduce wastage and hence saves costs.

Utilize alerts- Organizations can define active ingredients and set a threshold level, known as reorder point. Food ERP software can provide alerts if active ingredient touches the threshold level. Utilizing the power of alerts will avoid sudden halts in production due to unavailability of basic ingredients and avert losses.

Dynamic Pricing- Dynamic pricing algorithm of ERP helps to adjust product prices based on factors like demand, market trends, maximizing profitability and remain competitive in the market. Although dynamic pricing does not impact costs directly, but it helps to optimize revenue generation which can offset other costs within the business.

Production Planning: Utilize planning ability of ERP to ensure that your production plan is as per demand. MRP and MPS strategy helps to procure raw material according to demands, and plan production so that neither sales opportunity is lost, nor inventory is over stocked. This accurate planning and strategy save huge cost, optimize resource allocation, and help in revenue generation.

JIT Production- Lean manufacturing principle like Just-in -Time (JIT) production can help food manufacturers to reduce inventory holding costs, minimize waste and streamline operations. By applying such technique through ERP modules, organization can maintain continuous flow of production and avoid bottlenecks which will eventually reduce costs.

Material sourcing- ERP analytics provide insights for optimal sourcing strategies. Analytics give a fair point for raw material sourcing, ingredient sourcing, packaging material. It also helps to include options for local sourcing, bulk purchasing, or strategic partnerships, to secure the best prices and minimize procurement costs.

SKU rationalization- ERP analytics can help to identify and rationalize underperforming product variants which will enhance inventory management, reduce chaos in distribution and can lead to cost savings in manufacturing and warehousing.

Supplier Consolidation- ERP driven supplier analysis can help food manufacturing organizations to negotiate better price, reduce administrative overhead, achieve economies of scale, and streamline procurement processes.

Food manufacturing ERP system is an inevitable part of food manufacturing unit. But only the efficient and proven ERP can do justice to your investment. BatchMaster ERP is one of the solutions which has served more than 3000 clients across the globe in past 30 years. With industry specific expertise, and features, the solution can give in-depth insights of your production process and helps you to save costs where-ever possible.

To know more about BatchMaster ERP on how it can help to save costs, discuss it with our experts. Connect with us on [email protected]

0 notes

Text

Dairy ERP Trends: What's Next in Technology for the Dairy Sector?

Milk holds a unique significance in India, being consumed for centuries as a vital source of essential vitamins and minerals. However, the journey from extraction to your table involves intricate operations such as clarification, pasteurization, homogenization, cooling, and packaging, all requiring precision and calibration due to milk's perishable nature.

Manual execution of these operations proves challenging, error-prone, and time-consuming for milk manufacturers, with even slight contamination posing risks to consumer health. Adopting an Dairy ERP software emerges as a highly effective solution, automating and streamlining business processes to minimize manual efforts.

This blog discusses emerging ERP trends poised to revolutionize the dairy industry:

Cloud-Based Solutions: Cloud-based ERP solutions offer scalability, flexibility, and cost-effectiveness, providing real-time data access, enhanced visibility and control over the supply chain, and reduced infrastructure requirements.

Mobile Accessibility: This trend enables dairy manufacturers to access critical business data and perform tasks remotely via smartphones and tablets, increasing efficiency in managing operations and making data-driven decisions on the go.

Integration with IoT Devices: Seamless integration with IoT devices like RFID tags and sensors simplifies real-time monitoring and data collection across the supply chain, providing valuable insights into production conditions, equipment performance, and product quality.

Machine Learning and AI: AI and ML technologies automate repetitive tasks in the dairy industry, saving human effort and time.

Digital Twin: This technology digitally replicates the entire dairy production process, allowing manufacturers to analyze key parameters, detect inefficiencies, and fine-tune operations for higher yields.

For a robust and competent ERP software company in Pune, BatchMaster ERP stands out as the top choice. With over 30 years of experience and expertise, BatchMaster ERP is poised to transform your dairy business. Reach out to us today to learn more.

0 notes

Text

Improving Traceability and Quality Control in Ethanol Manufacturing with ERP

Ethanol manufacturing plays a crucial role in producing biofuel, contributing to a sustainable and environmentally friendly energy source. Ensuring the traceability and quality control of ethanol production processes is essential for meeting regulatory standards, maintaining brand reputation, and ensuring customer satisfaction. Enterprise Resource Planning (ERP) software provides valuable tools for enhancing traceability and quality control in ethanol manufacturing.

Traceability: ERP systems offer robust traceability features that enable ethanol manufacturers to track every step of the production process, from raw material procurement to product distribution. BatchMaster ERP's lot traceability module, for instance, allows for comprehensive tracking of products from their source to customer delivery. This includes monitoring production batches, identifying raw material sources, and facilitating swift product recalls if necessary. By enabling serial or lot-wise tracking, ERP software enhances accountability and transparency throughout the supply chain.

Quality Control: Quality control is paramount in ethanol manufacturing to ensure the production of safe and high-quality products. ERP systems like BatchMaster ERP provide tools for implementing and managing quality control processes effectively. Quality managers can create and apply quality tests, inspection plans, and checklists to assess ethanol quality at various stages of production. From testing raw materials for compliance to conducting stability checks and accurate stock counts in warehouses, ERP software streamlines quality control procedures. Automated quality checks, including sampling, double sampling, pre-process, in-process, and post-process QC, help expedite assessments and improve the reliability of the final fuel product.

By leveraging ERP software for ethanol manufacturing, companies can optimize their operations, enhance traceability, and maintain stringent quality control standards. This not only ensures compliance with regulatory requirements but also strengthens brand reputation and fosters customer trust in the quality and reliability of ethanol products.

0 notes

Text

How can Pharma Manufacturers Effectively Manage Rapid Production Processes while Adhering to Quality Requirements?

COVID-19 has proved to be the biggest challenge in modern times – particularly from the perspective of pharmaceutical manufacturing industry.

Not only has it compressed the pharma go-to-market-timeline, prompting the manufacturers to develop new COVID-19-related medicines and vaccines in record time, but also forced them to ensure that the production of non-COVID-19 segment remains unaffected.

While doing so, the manufacturers need to ensure that rigorous regulatory compliance protocols are being maintained.

And to ensure the same, the pharma manufacturers find it increasingly important to rethink their approach to ensuring production quality, and become more proactive with predicting the potential quality issues before they actually take place.

Sound quality management in pharmaceutical industry while ramping up the production is particularly important for the pharma manufactures, as incidents related to quality violations have already had an impact on millions of doses of just the COVID-19 vaccines.

So, the question is, how can the pharma manufacturers effectively manage rapid production processes while adhering to quality requirements?

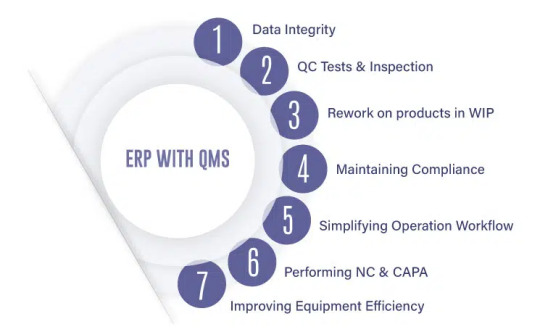

By having an ERP-QMS combo

For any pharma manufacturing enterprise, majority of challenges, including the ones related to managing the production processes as well as quality, stem either from over-reliance on manual processes and data exchange, or a lack of integration and interoperability between the disparate enterprise resource planning (ERP) software, and quality management system (QMS).

The latter of the two mentioned above adversely affects the efficiency and effectiveness of the quality management processes, besides giving rise to data integrity-related issues.

For pharmaceutical businesses, there is a significant amount of data available that can be harnessed to improve quality during the manufacturing process and manage product quality complaints, as well as other aspects of quality including pharma quality assurance, and quality control.

This collaboration between its enterprise and quality systems offers a way to better partner between quality, and manufacturing. It essentially:

– Allows protecting data integrity

The integration between the quality systems and the enterprise system increases efficiency and reliability in quality control.

The combination of the two systems working in tandem makes initial results available during the production process, and reports and compliance documentation as soon as a batch is finished.

The electronic storage of data reduces the likelihood of errors.

Moreover, if the recorded production data goes outside the expected range, quality management receives an automatic alert.

And if the systems are cloud-based, all the stakeholders get access to the most up-to-date data.

– Allows defining QC tests, inspection plans, and checklists

By having good ERP software in place, pharmaceutical manufacturers can define the inspection plans based on the inspection checklists.

This way, they can have a mechanism to determine what to inspect, how and when to inspect, and a basis for inspection.

The manufacturers can know post-inspection whether the item is within tolerance or can be rejected if it fails to meet the defined standards.

This way, quality is ensured as only those items are used for production that meet the set standards.

An ERP also allows creation and storage of QC tests in its quality libraries, where the parameters for each QC test for a specified item or item group can be defined.

It also enables manufacturers to manage the records of all the tests, and accept or reject the product based on inspection result, thus ensure quality at all stages of production process.

– Allows rework on products in WIP

An ERP further allows pharmaceutical manufacturers to capture QC tests, and make changes in the ongoing production process if there’s any discrepancy.

Based on the result of the QC test, the users can rework on the product in WIP by adjusting certain batch job formula values and equipment settings.

This ensures that the quality remains uncompromised even when the production work is in progress.

– Allows maintaining compliance

The integration of an ERP system and a QMS system makes quality management in pharmaceutical industry a cakewalk for the manufacturers by providing full, out-of-the-box compliance as standard.

The manufacturers can meet regulations such as FDA 21 CFR Part 11, and also the requirements of current Good Manufacturing Practice (cGMP).

The features of the two systems enable manufacturers to meet compliance requirements more easily and efficiently.

– Simplifies operation workflows

Since pharma manufacturing involves batch manufacturing, the stakes are higher, for a single error can ruin an entire batch, resulting in significant loss of money, time, raw materials, and sometimes, even in fines, lawsuits, and damaged reputation.

Effective batch control that an ERP provides is essential for the same, which allows manufacturers to easily control the process and optimize production.

– Manages NC and CAPA activities

The ERP-QMS combine also allows the pharmaceutical manufacturers to manage non-conformance (NC) and corrective action preventative action (CAPA) activities.

With it in place, the events of NC are immediately identified so that the corrective action can be taken promptly to minimize the damage or loss.

The manufacturers can respond swiftly to any current/potential product quality risks, thus ensuring quality.

– Improves the life of equipment

To ensure effective quality management in pharma industry, alongside managing the rapid production processes, pharma manufacturers, most importantly, need to ensure that the production processes run uninterrupted.

This can be done by maintaining and improving the life and uptime of their machinery, because when equipment breaks down or underperforms, companies lose valuable resources such as money and wasted production time.

By having a pharma ERP software in place, the manufacturers can have an effective predictive maintenance program in action.

It allows them to know when equipment need maintenance work so that the production batches can be scheduled accordingly.

By having a robust ERP system, the manufacturers can eventually avoid downtime, and errors in production, thereby managing production while meeting the quality needs.

Conclusion

In today’s challenging business environment that involves cut-throat competition, the pharma manufacturers need to make efforts to manage production ramp-up, comply with the stringent quality as well as compliance regulations, and offer safe and quality products to their customers.

The right blend of technology can help them achieve these objectives.

Over the last 30+ years, we at BatchMaster have worked with some of the leading pharmaceutical manufacturing companies around the world to help them manage their business operations on the whole, flag potential issues, and improve productivity in quality and operations.

To know how our pharma ERP, as well as QMS software solutions, can help your pharmaceutical manufacturing business scale up the production processes while efficiently meeting the quality requirements, and manage pharma quality assurance, quality control, and other aspects of quality management, contact us today. Our team of experts would be happy to help you with a demo or a no-obligation consultation.

0 notes

Text

Best Ways of Tracking Inventory if you are a Small or Midsize Speciality Food Manufacturer

The scope of food manufacturing industry is tremendously vast, as it comprises of a number of sub-verticals and stakeholders.

Rightly so, it is one of the largest industries in the world, and the biggest in the process manufacturing sector.

Therefore, it comes as no surprise that the stakeholders — especially the manufacturers — face numerous challenges in successfully operating in an industry this diverse.

While the challenges such as thin margins, labor complexities, long & complex supply chains, and stringent regulatory & food safety requirements etc. are tough nuts to crack, perhaps the biggest of them all for the food manufacturers is the challenge of effectively managing and controlling the inventory, which comes with limited shelf life.

If you are into a food manufacturing business, you know that keeping track of your inventory is a serious business.

Fortunately, there are different practices that can be implemented in order to get the most out of your inventory tracking.

Every food business these days looks to employ such sound inventory tracking practices within their organizations.

What are those best ways of tracking inventory — especially if you are a small or a midsized food manufacturer?

This blog discusses the two different approaches of the use of manual methods and automated ones for inventory tracking and goes further deep in reviewing the contemporary, and more practical methods of inventory tracking utilizing technology.

But why’s inventory tracking important in the first place?

Inventory tracking, which refers to the process of tracking how much of an individual product a business is procuring and storing for resale, and keeping a count of how much of it is being sold and how much remains in stock, is an integral part of any manufacturing business.

It is an important aspect of the manufacturing business because it lets the manufacturers know what they have in stock, how much of it do they have, where is it stored, whether or not it is selling, and also when to re-order a particular item before it runs out.

Talking particularly about the food manufacturing businesses, inventory tracking gains greater significance due to the limited shelf life of the products, which is one of the biggest drawbacks of this industry.

The food manufacturers need to know how fast a product or its ingredients need to be consumed before they expire.

Also in case of any non-conformity, the food manufacturers need to have a proper mechanism to track the inventory from source to sale.

Manual method:

The manual method is the traditional, or the old-school approach of tracking inventory. A tiresome method, it involves tracking the inventory with the use of spreadsheets.

The setting-up of this method involves the creation of rows and columns in a computer spreadsheet or inventory log book.

The rows are then labelled with the product names and descriptions, while the columns are labelled with the date, total inventory count, expiry dates, and the inventory on hand.

Once this is done, the next step includes applying price tags to all the products along with other details that accurately match with the product name entered in the records.

After the sale is made, the price tags can be removed and used to record the sale. Every transaction is being accounted for, and the items are updated by subtracting the quantity sold from the last total after every sale made.

The manual method of tracking the inventory is feasible for small and midsized manufacturers, as it has its own benefits.

This method allows for the condition of goods to be assessed when counting the stock physically. However, the manual method has its downside as well, as it is extremely labor intensive, time-consuming and requires continuous monitoring to be up-to-date with on-hand inventory.

Then there’s always the risk of human errors and inaccurate inventory counts. This has gradually paved the way for the use of technology and automated methods for inventory tracking.

Automated tracking:

Automated tracking of inventory has many benefits, as it eliminates the risk of manual errors, improves accuracy, and increases overall operational efficiency.

For effective inventory tracking, there are different automated methods which when implemented in close collaboration with a food manufacturing software, can deliver great results for the food manufacturers.

An ERP for food manufacturing industry that uses barcode technology and radio frequency provides advanced inventory management and optimized workflows.

Universal Product Code (UPC):

The UPC or barcode method serves as the most common, and perhaps the most important, inventory tracking method.

It has been designed specifically keeping today’s retail environment in mind. It allows the retailers to track inventory through point-of-sale (POS) equipment, which is usually a wireless handheld scanner.

Barcodes assign a special number to each and every item that is there to be tracked.

When the inward or outward inventory’s barcodes are scanned, they get decoded and entered into a database, which then allows tracking and maintaining of inventory quantities, pricing, and any other saved data related to the inventory.

This method ensures that every time an item is sold or shipped, it gets logged. As the quantity of items in stock goes down, the quantity of items needing replacement goes up.

Radio Frequency Identification (RFID):

Food manufacturers also use the RFID technology for inventory tracking.

RFID readers identify products on their arrival and track these products in real-time as they transition through the warehouse.

The RFID technology allows contactless reading and writing of data and importing multiple tags in batches.

Thanks to this technology, the inventory can now be received in bulk. Also, it can be easily tracked using the RFID tags, thus saving on crucial man hours as well as money.

Unlike the barcode technology, the RFID technology can scan more than one unit at a time, and does not require human intervention to work.

Tag System:

Many small and midsized specialty food manufacturers also use a tag system to track their inventory.

They tag their merchandise daily, weekly, monthly or at any other required interval. The retailer removes the tag at the point-of-sale, and the collected tags are verified against the physical inventory to determine sales quantities.

This method only tracks the inventory movement based on sales, and is mostly used by retailers who usually don’t use the barcode or POS systems.

Conclusion:

Manual or automated — no matter which method you use, inventory tracking should be a fundamental task of your food manufacturing business.

However, the need of the hour is automating the process of inventory tracking. And fortunately, you can make a seamless transition from the manual processes to an automated inventory tracking system.

A good ERP for food industry supports the different automated methods of inventory tracking like the barcode scanning, RFID, and tag system. Its robust inventory management module enables tracking and locating inventory within the business, giving the manufacturers an insight into the quantity of stock they have in hand, its location, and whether or not there is a need to replenish it.

Having this knowledge eventually helps business save crucial time while improving the efficiency.

If you are looking for one such food manufacturing ERP software in Delhi to automate the inventory tracking process for your food manufacturing business, reach out to us at [email protected] for a free consultation.

We at BatchMaster have over 30 years’ experience of serving different process manufacturing industries – including the food manufacturing businesses – with solutions designed specifically keeping their needs in mind.

#erp software#erp solutions#erp system#erp#erp implementation#manufacturing#technology#food erp software#food erp#cloud erp

0 notes

Text

How to Choose the Best Suitable ERP Solution for your Business

In a way, the process of choosing the best suitable Enterprise Resource Planning (ERP) solution for your business is no less than bride hunting for an eligible bachelor. In both the cases, one wants a long-term association, which is not only trustworthy but also understands and fills the gap of each other’s requirements. Since there is a lot of capital investment involved, no one wants costly and bitter divorces or precisely, implementation failures. However, the vendor you approach will never turn down your proposal, unlike the real-life bride or groom.

Any organization considers adopting an ERP solution to manage financial, inventory, production, and supply chain challenges in a more efficient way. But, in the process of selecting the best suitable solution for your business, you encounter a number of issues before reaching a fruitful, result oriented solution. This blog tries to guide you through the key steps for selecting the right ERP software.

Moving ahead without review and analysis is a mistake– Strength weakness opportunity threat (SWOT) analysis, the basic and most essential step in ERP selection, should be conducted and documented based on your current business operations. In order to avoid ‘blow up in face’ situations, the analysis should also include the desired customization and your expectations from the solution. Everything has to be time bound with regular analysis or deviation check in order for your business to be within the time frame.

Planning & Preparation is the key– Before you take the plunge, everything from soup to nuts should be well thought of and properly planned for a rewarding ERP solution. Prepare a list of expectations from your ERP but remember ‘The motto of the wise is to be prepared for surprise!’- Always keep room for the unexpected, this way you will always have a workaround and the blow will be less intense. Plan your move, have the right people with sufficient knowledge of your operations and business processes fetched in the team. Set deadlines for the every stage of your ERP selection, from searching/googling to shortlisting to taking a demo and finally giving your thumbs up. This prevents the selection process from going in an endless loop.

The secret to happily ever after is choosing the right partner– Select the vendor smartly by judging them on various parameters such as solution capability, industry knowledge, implementation experience, time and cost, support and services terms, etc. Always ask for a product demo and their customer references to evaluate available options and zeroing on any particular vendor. Such comparison also helps you to figure out all possible customizations you can ask from the vendor, you finally selected. Additional tip: The success for ERP vendor & client association largely depends on the decided business terms and conditions at the elementary stage. Mutual acceptance of them on paper is very important so that neither party can diverge from the pact at any stage of implementation.

Budget is the deciding factor– Undoubtedly, ERP systems are costly, difficult to integrate, and challenging in terms of measuring ROI, but if you are able to manage the funds the result will worth the cost of the solution. The best way is to break down payments into equal instalments at each succeeding stage of the implementation. So check, if your vendor is ready for this. Also, ensure to figure out “hidden costs” associated with the solution, including consultation charges, hardware investment, implementation cost, maintenance, upgrades, service charges, etc. Like this, you save your company from suffering a serious monetary setback.

Keep room for technological modifications– Since ERP is a technological initiative; it should well align with your current IT infrastructure and should be scalable enough to meet your future goals. Considering the latest trends like Artificial Intelligence, Big Data Analysis, Internet of Things (IoT), cloud and such, ensure that your product is flexible enough to accommodate it later in the scene.

Education, Training and Support lay the foundation for crisis management– It’s important you select an ERP that’s easy to use and possesses a simple friendly GUI. That doesn’t mean that way you can ignore the importance of training. Training, knowledge base and support are a major factor in giving a thumbs up to an ERP. Check for the dedicated training schedules and documented knowledge transfer for future reference. Dyed-in-the-wool post-implementation support is the sign of a good vendor and if one doesn’t offer that; you must ask for it determinately. You can easily sidestep technical difficulties and production halts later, only with a strong customer support.

Conforming to existing operations, infrastructure, and business processes are obligatory for any ERP solution to become best suited for your company. ERP, being a transformational business change and bringing key competitive advantages to your company, should be adopted after rigorous brainstorming and expert analysis. Apart from the above-discussed suggestions, the decision should never be taken in the absence of adequate information.

0 notes

Text

Chemistry Of An ERP With Chemical Industry

There’s always been a lot of buzz around ERP and the value it brings to chemical manufacturing industries.

Several processes, activities, and systems are used to carry out operations in chemical industries. Abundant workflows and procedures – some manual, some automated – that may or may not be properly acknowledged. And a variety of departmental applications and databases that are likely disjointed and not well-integrated.

Cumbersome, error-prone, labor-intensive manual processes can draw off both time and money. A manual approach may have served its purpose in the past but in today’s dynamic and highly spirited soul, it can seriously encumber productivity, profitability, and growth. Businesses must operate as lean as possible in order to keep the bottom line in check, and failing to automate critical, yet routine business activities makes it nearly impossible to do that. So, the chief grounds an ERP solution is so essential to a company’s coup is efficiency.

Above All, In The Present Scenario…

Chemical manufacturers are facing the numerous challenges at customer and regulatory front. Major being- expecting absolutely safe product at lower cost, and providing assurance for safety of their customers and of workers with accurate accountability of potential hazardous materials.

Thus, to remain competitive and retain the customer base, manufacturers are seeking for the appropriate software solutions to run their business and to confront multifold challenges. An ERP solution can hurl remarkable benefits to businesses of all types and sizes – increased productivity, reduced operating expenses, improved information flow, and enhanced performance management.

Operational Benefits Of An ERP

ERP is the best option for any type of chemical industry irrespective of their strength or volume. It enables chemical manufacturers to efficiently manage and record formulation, execute quality control, strengthen customer management, streamline production and simplify financial reporting. The embedded and tightly integrated modules of an ERP help manage data flow right from managing formulas to manufacturing and shipping the orders in line with regulatory requirements.

Chemical manufacturers need the control and confidence that will allow them to maintain a minimum stock and keep costs in line, without missing any profitable opportunities. And, an ERP provides a comprehensive Inventory Management feature for chemical processors. It allows them to define inventory by item type, location, or physical properties of any raw material. All inventory items from raw material, packaging to finished product are accurately tracked and monitored. This eases to build the detailed formulas and maintains an accurate inventory status and costing of all finished products. Moreover, the production functions and the plant management feature of an ERP allows a complete shaping of the shop floor, and work centers.

Compliance Benefits

Some of the unique manufacturing needs of the chemical industry include, inconsistent quality of raw materials; once processed the products cannot be reduced back to their original state; product is normally manufactured in bulk, then packed according to requirements; conformance to control of hazardous materials and storage of the necessary backup certificates of approval; and in a number of industries every order represents a new product, depending on the formula used and the substitutions made. And, ERP galvanizes the chemical industries by satisfying these needs and thus, empowers them to boom in today’s competitive environment by providing the some special features like:

User & staff safety: One of the most important aspects of workplace safety is the prevention of accidents with chemicals. HMIS & WHMIS values can be associated with formulas and items for the safety of workers. While the automatic generation of SDS for formulas, items, batches, Sales Orders and more, ensure safety of the end-user along with conforming adherence to GHS requirements. Along with this, Safe disposal, accountability & costing of hazardous materials as well as support for NC/CAPA, keep you clean in audits too.

Quality Control: ERP’s Quality Management allows the quality department to define its own quality test cases required at different phases of production, beginning from quality check required during the inward of raw materials. Further Quality Characteristics, parameters and expected results, under each quality process check can be configured without any programming assistance. It even maintains an extensive history to improve product quality and identify recurring problems.

Innovating Greener Products: An ERP aids in extensive R&D to develop a new product through automatic reformulation based on greener substitutes, targeted cost, active ingredient strength and physical property values. At the formula level also, it enables click-on material substitution based on greener product identification.

Lot Traceability: Lot traceability enables manufacturers to strengthen quality control through the tracking and replacement of any defective materials. ERP provides the facility to assign the unique identification number to raw material lots and the serialization of the products made from those lots. This capability ensures keen tracking of materials right from entry as raw material to its exit as finished good.

MPS/MRP: Chemical manufacturers need to control the types and quantities of materials they purchase, plan which products are to be produced and in what quantities and ensure that they are able to meet current and future customer demand, all at the lowest possible cost. And, an ERP aids in the proficient planning of manufacturing, purchasing and delivering activities.

One Such Solution – BatchMaster ERP

BatchMaster ERP for Chemicals is a nimble IT solution. It is designed with in-depth industry knowledge and proper understanding of unique challenges. The power of reliable and speedy laboratory calculations to on-site chemists, ability to manage hundreds, maybe thousands of formulas and their derivatives, multiple packaging options, assuring quality, superior private labeling capability as well as meeting the regulatory compliance- BatchMaster ERP company in Pune provides all.

0 notes

Text

As the preferred ERP software in Pune, BatchMaster brings innovation and efficiency to businesses across the city. Our solutions are crafted to address the dynamic needs of Pune's diverse industries, providing a robust platform for growth and success. Experience the difference with BatchMaster.

0 notes

Text

As a premier ERP company in Delhi, BatchMaster stands out for its commitment to innovation and client success. Our ERP solutions are tailored to meet the unique requirements of businesses in Delhi, providing a robust platform for growth and efficiency. Experience the BatchMaster advantage today.

0 notes

Text

0 notes