#chemical processing

Text

A second key feature regarding chemical processes that occur in the atmosphere is the way in which free radicals³ take part in many reactions.

³ Free radicals are atoms or molecules that have one or more unpaired electrons. They are usually highly reactive species. In most cases, we will denote radicals using a dot (•) beside or above the radical species. While some compounds containing nitrogen (like NO2) or chlorine (like ClO) atoms have an unpaired electron, we make an exception and will not usually show the unpaired electron in such compounds, unless some other radical species is involved in the reaction.

"Environmental Chemistry: A Global Perspective", 4e - Gary W. VanLoon & Stephen J. Duffy

#book quotes#environmental chemistry#nonfiction#textbook#chemical processing#atmosphere#free radicals#chemical reactions#atom#molecule#electrons#reactivity#nitrogen#nitrogen dioxide#chlorine#hypochlorite

0 notes

Text

Exploring ASTM B619 Welded Pipe: Applications and Advantages

ASTM B619 is a standard specification for welded nickel-chromium-molybdenum-copper alloy (UNS N06022) and nickel-chromium-molybdenum-tungsten alloy (UNS N10665) pipe. These alloys are designed for use in corrosive environments, particularly those containing reducing and oxidizing chemicals. ASTM B619 welded pipes are critical in industries such as chemical processing, petrochemicals, pharmaceuticals, and power generation. This blog explores the properties, applications, and benefits of ASTM B619 welded pipes, emphasizing their importance in modern industrial applications.

What is ASTM B619 Welded Pipe?

ASTM B619 specifies seamless and welded pipes made from nickel-chromium-molybdenum-copper (Alloy C276, UNS N06022) and nickel-chromium-molybdenum-tungsten (Alloy B-2, UNS N10665) alloys. These materials are highly resistant to corrosion in a wide range of aggressive environments, including acids, chlorides, and seawater. Welded pipes under ASTM B619 are manufactured using fusion welding processes, ensuring uniformity, strength, and integrity throughout the pipe length.

Key Properties of ASTM B619 Welded Pipe

ASTM B619 welded pipes exhibit several critical properties that make them suitable for corrosive environments:

Corrosion Resistance: Nickel-based alloys like C276 and B-2 offer exceptional resistance to a wide range of corrosive chemicals, including acids (sulfuric, hydrochloric), chlorides, and seawater.

High Temperature Performance: These alloys maintain their mechanical strength and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications.

Mechanical Strength: ASTM B619 welded pipes provide excellent mechanical properties, including high tensile strength and toughness, ensuring reliability in demanding conditions.

Weldability: The alloys are easily weldable using conventional welding techniques, allowing for easy fabrication and repair of piping systems.

Low Maintenance: Due to their corrosion resistance, ASTM B619 welded pipes require minimal maintenance, reducing downtime and operational costs.

Longevity: These pipes have a long service life in aggressive environments, offering reliable performance over extended periods.

Applications of ASTM B619 Welded Pipe

ASTM B619 welded pipes find extensive use in industries requiring resistance to corrosive environments:

Chemical Processing: They are used in chemical plants for transporting acids, alkalis, and other corrosive chemicals.

Petrochemical Industry: ASTM B619 pipes are employed in oil refineries, gas processing plants, and offshore platforms where exposure to corrosive fluids is common.

Pharmaceutical Industry: These pipes are used in pharmaceutical manufacturing processes that involve corrosive solvents and chemicals.

Power Generation: ASTM B619 pipes are utilized in power plants for handling corrosive cooling water, steam, and chemicals in boiler systems.

Waste Treatment: They are used in wastewater treatment facilities for conveying corrosive liquids and gases.

Pulp and Paper Industry: ASTM B619 pipes find application in pulp and paper mills for handling corrosive chemicals used in bleaching and processing.

Benefits of Using ASTM B619 Welded Pipe

ASTM B619 welded pipes offer numerous advantages, making them a preferred choice in corrosive environments:

Corrosion Resistance: Superior resistance to a wide range of corrosive chemicals ensures longevity and reliability.

High Performance: These pipes maintain their mechanical properties at high temperatures, ensuring consistent performance in demanding conditions.

Safety: Reliable corrosion resistance reduces the risk of leaks and failures, enhancing operational safety.

Cost-Effectiveness: Despite their initial cost, ASTM B619 welded pipes offer long-term savings due to reduced maintenance and extended service life.

Versatility: Available in various sizes and configurations, they can be tailored to meet specific application requirements.

Environmental Sustainability: Nickel-based alloys are fully recyclable, promoting environmental sustainability and compliance with green initiatives.

Conclusion

ASTM B619 welded pipes made from alloys such as C276 and B-2 play a crucial role in industries where corrosion resistance and reliability are paramount. Their exceptional properties make them ideal for handling corrosive chemicals in chemical processing, petrochemicals, pharmaceuticals, and power generation. Understanding the benefits and applications of ASTM B619 welded pipes underscores their critical importance in ensuring efficient, safe, and sustainable operations in modern industrial environments.

#ASTM B619 Welded Pipe#Nickel-Chromium-Molybdenum Alloys#Corrosion Resistance#Chemical Processing#Petrochemical Industry#Power Generation#Mechanical Strength#High Temperature Performance

0 notes

Text

Durable and Corrosion-Resistant Stainless Steel 304 Pipe Fittings for Reliable and Efficient Fluid Handling in Diverse Industrial Applications

Our Stainless Steel 304 Pipe Fittings provide reliable and corrosion-resistant connections for various piping systems. Suitable for applications such as food processing, chemical processing, and water treatment, these fittings ensure a precise fit and long-lasting service. Available in multiple sizes and configurations, they meet the demands of projects requiring efficient fluid handling solutions.

#Stainless Steel 304#Pipe Fittings#Corrosion Resistance#Piping Systems#Food Processing#Chemical Processing#Water Treatment#Precise Fit#Long-Lasting Service#Fluid Handling Solutions

0 notes

Text

chemical process equipment’s manufacturers | Mathesis

Our chemical Process equipments manufacturers ,are custom-built, entirely indoor, and provided in a safe and secure manner. These are manufactured at our facilities, sent to client sites in India, installed, and then safely commissioned.

For more information visit: https://www.mathesis.co.in/index.php

Plot No. B-35, BHEL-AIE, Ramachandrapuram, Hyderabad – 502032

+91 98857 04874

0 notes

Text

Driving Efficiency and Precision: Exploring the Metering Pumps Market

In the intricate landscape of industrial processes, where accuracy and efficiency are paramount, metering pumps play a pivotal role. These precision instruments are designed to deliver fluids with absolute consistency, making them indispensable across various sectors such as chemical processing, water treatment, and pharmaceuticals.

The metering pumps market is witnessing steady growth, fueled by the increasing demand for accurate and reliable fluid delivery systems. As industries strive for higher productivity and tighter quality control, the need for precise metering solutions becomes more pronounced.

One of the key drivers of metering pumps market is the expanding scope of applications. Metering pumps are not limited to a specific industry; rather, their versatility allows them to be deployed in diverse settings. Whether it's adding precise amounts of chemicals in industrial processes or delivering medications in healthcare settings, these pumps offer unmatched reliability and control.

Moreover, advancements in technology are further propelling the growth of the metering pumps market. Manufacturers are constantly innovating to enhance the precision, efficiency, and durability of these pumps. From sophisticated electronic controls to improved materials and designs, the latest generation of metering pumps sets new standards for performance and reliability.

Another factor driving market growth is the increasing emphasis on sustainability and resource optimization. Metering pumps enable precise dosing, minimizing wastage of chemicals, water, and energy. This not only reduces operational costs but also aligns with environmental regulations and sustainability goals.

Furthermore, the integration of automation and digitalization is transforming the metering pumps market. Smart metering solutions equipped with sensors and connectivity features enable remote monitoring, predictive maintenance, and real-time optimization. This enhances operational efficiency while minimizing downtime and maintenance costs.

In conclusion, the metering pumps market is poised for significant growth as industries continue to prioritize efficiency, precision, and sustainability in their operations. With ongoing technological advancements and expanding applications, metering pumps are set to play an increasingly indispensable role across various sectors, driving productivity and innovation.

Contact us for more information.

#Metering Pumps#Industrial Equipment#Chemical Processing#Precision Engineering#Fluid Dynamics#environmental sustainability#innovation#sustainability#technology#augmented reality#immersive experiences#additive manufacturing#ai#aiincelltherapy#compliance

0 notes

Text

Chicago, March 06, 2024 (GLOBE NEWSWIRE) -- The global Pressure Vessels Market size is expected to grow from USD 50.3 billion in 2023 to USD 62.7 billion by 2028, at a CAGR of 4.5% according to a new report by MarketsandMarkets™. A pressure vessel is a container designed to hold gases or liquids at a pressure significantly different from the ambient pressure. The pressure within the vessel may be higher or lower than the atmospheric pressure outside the vessel. Pressure vessels are used in a variety of industrial and commercial applications, including chemical processing, oil and gas production, power generation, and manufacturing.

#pressure vessels#pressure vessel#pressure vessels market#nuclear power plant#energy#energia#power#power generation#nuclear power#nuclear energy#power plant#power plants#chemical industry#chemical processing#oil and gas industry#oil and gas#oil and gas production#offshore oil and gas#manufacturing#refinery#oil refinery#chemical plant#processing vessels

0 notes

Text

Spray Dryer manufacturers in India

Ronetech: Leading Spray Dryer Manufacturers in India. Expert solutions for efficient drying processes. Explore now!

https://ronetech.co.in/spray-dryer/

#Spray Dryer#Spray Dryer India#Industrial Dryers#Spray Drying Technology#Indian Manufacturing#Drying Equipment#Chemical Processing#Pharmaceutical Dryers#Food Processing Dryers

0 notes

Text

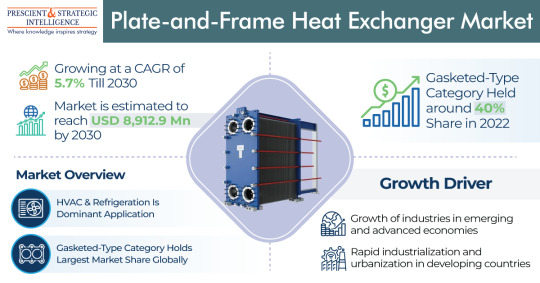

Europe Dominated the Plate-and-Frame Heat Exchanger Market

The size of the plate-and-frame heat exchanger market will power at a compound annual growth rate of 5.7% during 2022-2030, to touch a value of USD 8912.9 million by 2030.

The welded type was the fastest-growing category due to the extensive use of these alternatives in industries, such as HVAC & refrigeration, pharmaceuticals, power generation, pulp & paper, petrochemicals, and oil & gas. Some…

View On WordPress

#advancements#chemical processing#compact design#efficient heat transfer solutions#food and beverage industry#heat exchange performance#HVAC systems#Key players#market trends#plate-and-frame heat exchanger market#power generation industry

0 notes

Text

The focus of this chapter is on the fundamental concepts needed to understand the chemical processes that occur in the atmosphere – processes that will be examined in more detail over the next several chapters.

"Environmental Chemistry: A Global Perspective", 4e - Gary W. VanLoon & Stephen J. Duffy

#book quotes#environmental chemistry#nonfiction#textbook#fundamentals#chemical processing#atmosphere#chemical reactions#examination#detail

0 notes

Text

ASTM A516 GR. 60 HIC Plates: Ensuring Reliability in Pressure Vessel Applications

ASTM A516 GR. 60 HIC (Hydrogen Induced Cracking) plates are pivotal components in industries requiring robust materials for pressure vessels and boilers. These carbon steel plates are specifically engineered to withstand hydrogen-induced cracking, ensuring safety and durability in high-pressure environments. This blog explores the key features, applications, and advantages of ASTM A516 GR. 60 HIC plates, highlighting their critical role in maintaining structural integrity and reliability in industrial settings.

Introduction to ASTM A516 GR. 60 HIC Plates

ASTM A516 GR. 60 HIC plates are normalized carbon steel plates known for their excellent weldability and toughness. They are designed to resist hydrogen-induced cracking, a common issue in environments with high hydrogen content. These plates undergo a stringent heat treatment process to enhance their mechanical properties, making them suitable for use in pressure vessels and boilers operating at moderate temperatures.

Key Features of ASTM A516 GR. 60 HIC Plates

Hydrogen Induced Cracking Resistance: These plates are specifically formulated to resist hydrogen-induced cracking, ensuring long-term reliability and safety.

Good Tensile Strength: ASTM A516 GR. 60 HIC plates offer good tensile strength, providing structural integrity and durability under high-pressure conditions.

Normalized Heat Treatment: The plates undergo normalization to improve their mechanical properties and ensure uniformity across the thickness.

Excellent Weldability: They exhibit excellent weldability, facilitating ease of fabrication and assembly in pressure vessel manufacturing.

Applications of ASTM A516 GR. 60 HIC Plates

ASTM A516 GR. 60 HIC plates are widely used across various industries, including:

Oil and Gas: Used in storage tanks and pressure vessels for oil refining, gas processing, and offshore platforms.

Power Generation: Essential for boilers and heat exchangers in thermal power plants for generating electricity.

Chemical Processing: Ideal for chemical reactors and vessels handling corrosive substances and high-pressure gases.

Petrochemical Industry: Critical for storing and transporting petrochemical products under high-pressure conditions.

Advantages of ASTM A516 GR. 60 HIC Plates

Hydrogen Induced Cracking Resistance: Ensures safety and reliability in environments prone to hydrogen-induced cracking.

High Tensile Strength: Offers robust mechanical properties suitable for demanding industrial applications.

Reliability: Known for consistent performance under varying temperature and pressure conditions.

Cost-Effectiveness: Provides a cost-effective solution with long-term durability and low maintenance requirements.

Conclusion

ASTM A516 GR. 60 HIC plates play a crucial role in ensuring safety and reliability in pressure vessel applications across diverse industries. Their resistance to hydrogen-induced cracking, combined with good weldability and mechanical strength, makes them an ideal choice for critical applications where structural integrity is paramount. Understanding the unique features and applications of ASTM A516 GR. 60 HIC plates empowers industries to select materials that meet stringent safety standards and ensure operational efficiency.

#ASTM A516 GR. 60 HIC plates#hydrogen induced cracking resistance#pressure vessel steel#boiler plates#industrial applications#oil and gas#power generation#chemical processing

0 notes

Text

Stable Bleaching Powder Manufacturers

As an Stable Bleaching Powder Manufacturers, we pride ourselves on our exceptional customer service and our ability to provide flexible and reliable solutions that meet our customers' needs.

#Bleaching Powder#Stable Bleaching Powder#Calcium Hypochlorite#Ca(ClO)2#Chemical Industry#chemical industry#Chemical Compound#Chemical Processing#Calcium Compound#Chemical Production#Chemical Manufacturing#Inorganic Compound#Chemical Synthesis#Chemical Engineering#Chemical Research#Chemical Reagent#Chemical Formula#Chemical Supply#Chemical Wholesale#Chemical Import#Chemical Export#Water Treatment#Wastewater Treatment#Disinfectant#Bleaching Agent#Pool Chemicals#Chlorinating Agent#Sterilization Chemicals

0 notes

Text

gaz: is tav okay?

ghost: he’s calmed down

gaz: really? usually takes longer

ghost: put on his favorite youtube series

soap: [watching metal mailboxes being stripped and cleaned with muriatic acid]

#ghost coming up with the idea: sometimes my genius is frightening#calm down your sergeant by letting him explain the chemical processes on how muriatic acid works with rust#soapghost#john soap mactavish#ghoap#ghostsoap#ghost x soap#soap x ghost#soap cod#simon ghost riley#soap call of duty#ghost cod#gaz kyle garrick#ghostsoapgaz#soap x gaz#gaz x soap#ghost x gaz#gaz x ghost#call of duty incorrect quotes#cod incorrect quotes#incorrect call of duty quotes#incorrect cod quotes#ear incorrect quotes

932 notes

·

View notes

Text

wip!!

#mcr gerard#gerard way#artists on tumblr#mcr fanart#art#mcr tumblr#my chemical romance#work in process#digital art#digital painting

656 notes

·

View notes

Note

more winged tim? 👉👈

#fic rec#flight feathers by chemical processes#FAV#tim drake#prompt response#He’s a baby your honor#<3#wip on wing detail

797 notes

·

View notes

Text

"It's more than something. It's everything."

s8e11 "Life Time"

painted screenshot. cannot give a time estimate, i lost track long ago. still gouache brush, my beloved, with blur tools to fade edges and so on

i have to go to the zoo now and will be making the version with the clock later [i cannot express how long ive been battling with hawkeye's face, gamers]. background went very fast like i said it would lol

version 2 [as in, w/ clock] will probably be done later today, and i will edit this and add it when that happens [and prolly make a separate post too, for celebration purposes, and will link them]. i will also compile progress pics for that post. they are terrifying early on lmao

"A lot of very touching songs came outta that war" previous painting

"It was pink, and perfect, and I tossed it in the scrap bucket" previous painting

everyone say thank you to bj to being a perfect painting subject today he was very polite and he looks about how i wanted unlike SOME PEOPLE

that was me to my sibling last night, and i stayed up til 1:10ish and still didnt finish the final pass over hawkeye's eye. everything else took like 5ish minutes

also everyone say thank you to margaret and nurse kellye for also being perfect and lovely and pleasant to work with

photo used blatantly stolen from this post thank you again @remyfire i owe you my life

update edit;

clock back

#mash#mash 4077#m*a*s*h#mash fanart#mash art#mashblr#hawkeye pierce#bj hunnicutt#margaret houlihan#nurse kellye#just so you know the working title for the last piece was 'detroit: become sleepy'#and the piece before that was just called 'teehee' because i couldnt think of anything clever when i saved the file#and the working title for THIS piece was 'heterosexual staring'#i also might post my layer names throughout the process just to show off how goofy it got#like i got one now just called 'crunch'. i dont even know what its for#not to mention 'hair shit debacle augh' and 'paint [real]' with its brother 'paint [imposter]'#anyway the parts im most proud of are hawkeye's clothes and his neck creases#and then bj's forehead and eyes and nose and hair#that lamp is also a banger that shit took like 40 minutes it was a great little treat#also shoutout to their ears wherein#once again. i put off the ears til the last minute and then nailed them immediately#i just hate doing them. i do well at it but i hate em#.update#.my art#not a screenshot#i used a screenshot to paint over it piece by backbreaking wristspraining piece but this IS a painting#anyway go check out my fic its somethin. i am a man of many talents. and they're all being used to give me the brain chemicals from MASH#.reasons my wrist is suing me

184 notes

·

View notes