#Weldability

Explore tagged Tumblr posts

Text

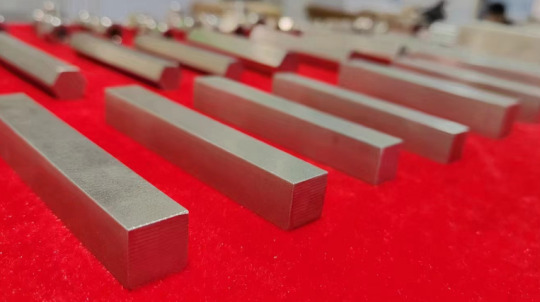

Discovering the Advantages and Uses of DHP Copper Bars

DHP copper bars, known for their superior formability and excellent corrosion resistance, play a pivotal role in various industrial applications. DHP stands for Deoxidized High Phosphorus, indicating the specific treatment and composition that enhances the properties of this copper alloy. This blog explores the unique features, applications, and benefits of DHP copper bars, highlighting their importance in modern manufacturing and construction.

What are DHP Copper Bars?

DHP copper, designated as C12200, is a type of copper alloy that contains a small amount of phosphorus (around 0.015% to 0.040%) which acts as a deoxidizing agent. This deoxidation process reduces the oxygen content in the copper, improving its ductility and making it more suitable for welding and forming. DHP copper bars are solid, rectangular bars known for their excellent workability and corrosion resistance.

Key Properties of DHP Copper Bars

DHP copper bars possess several key properties that make them highly desirable for various applications:

Excellent Formability: The presence of phosphorus enhances the ductility of DHP copper, allowing it to be easily formed into different shapes without cracking.

Corrosion Resistance: DHP copper bars exhibit outstanding resistance to corrosion, particularly in moist and marine environments, making them ideal for outdoor applications.

Weldability: The deoxidized nature of DHP copper ensures superior weldability, making it a preferred choice for applications requiring strong, reliable joints.

Thermal Conductivity: DHP copper bars have high thermal conductivity, making them efficient in heat transfer applications.

Durability: These bars are durable and have a long service life, even in harsh conditions.

Applications of DHP Copper Bars

DHP copper bars find extensive use across multiple industries due to their versatile properties:

Plumbing and HVAC Systems: They are commonly used in plumbing and HVAC systems for tubing, fittings, and components due to their corrosion resistance and ease of joining.

Heat Exchangers and Radiators: The high thermal conductivity of DHP copper makes it ideal for heat exchangers, radiators, and other heat transfer equipment.

Marine Applications: DHP copper bars are used in marine environments for applications such as shipbuilding and offshore structures due to their excellent resistance to seawater corrosion.

Construction and Architecture: In the construction industry, DHP copper bars are employed in roofing, flashing, and decorative elements due to their durability and aesthetic appeal.

Electrical Applications: Although not as conductive as ETP copper, DHP copper bars are still used in certain electrical applications where weldability and formability are critical.

Benefits of Using DHP Copper Bars

DHP copper bars offer numerous advantages, making them a preferred material in various applications:

Enhanced Workability: The excellent formability of DHP copper allows for complex shapes and intricate designs, facilitating a wide range of manufacturing processes.

Superior Corrosion Resistance: DHP copper's resistance to corrosion ensures long-lasting performance, reducing maintenance costs and extending the lifespan of the products.

Reliable Weldability: The deoxidized composition of DHP copper bars ensures strong, reliable welds, enhancing the structural integrity of the applications.

Efficient Heat Transfer: High thermal conductivity makes DHP copper bars efficient in heat transfer applications, improving the performance of heating and cooling systems.

Sustainability: DHP copper is fully recyclable, contributing to environmental sustainability and reducing the carbon footprint of manufacturing processes.

Conclusion

DHP copper bars are indispensable in many industrial and construction applications, offering superior formability, corrosion resistance, and weldability. Their unique properties make them ideal for plumbing, HVAC systems, heat exchangers, marine applications, and more. Understanding the benefits and applications of DHP copper bars highlights their critical role in modern manufacturing and construction, ensuring efficient, durable, and sustainable solutions.

#DHP Copper Bars#Deoxidized High Phosphorus Copper#Corrosion Resistance#Formability#Weldability#Thermal Conductivity

0 notes

Text

The Range of Size of Weldable Rebar Coupler

As a leading manufacturer in the construction industry, we specialize in producing high-quality weldable rebar couplers, our weldable rebar couplers come in a range of sizes, starting from 16mm up to T 40mm, making them suitable for a variety of construction applications.

One of the key advantages of our weldable rebar couplers is their ease of use in welding applications. Unlike standard rebar couplers, our weldable couplers can be directly welded onto a base plate, simplifying the construction process and saving valuable time on the job site.

Our weldable rebar couplers are available in a range of sizes to meet the specific needs of your project, including:

- 16mm Weldable Rebar Coupler

- 20mm Weldable Rebar Coupler

- 25mm Weldable Rebar Coupler

- 32mm Weldable Rebar Coupler

- 40mm Weldable Rebar Coupler

When it comes to ensuring the structural integrity and durability of your construction projects, our weldable rebar couplers provide a reliable and efficient solution. Trust in our expertise and commitment to quality to deliver weldable rebar couplers that meet the highest industry standards.

1 note

·

View note

Video

youtube

Hex Nut for 15/17mm Formwork Tie Rod System - Weldable -30mm&50mm Height...

0 notes

Text

Weld-ASSIST: Weldability Assessment for In-Space Conditions using a Digital Twin

ESI24 Haghighi Quadchart Azadeh HaghighiUniversity of Illinois, Chicago In-space manufacturing and assembly are vital to NASA’s long-term exploration goals, especially for the Moon and Mars missions. Deploying welding technology in space enables the assembly and repair of structures, reducing logistical burdens and supply needs from Earth. The unique challenges and extreme conditions of space–high thermal variations, […] from NASA https://ift.tt/ICdQPpD

#NASA#space#Weld-ASSIST: Weldability Assessment for In-Space Conditions using a Digital Twin#Michael Gabrill

0 notes

Text

Penstock Pipes For Hydropowers Manufacturer Supplier India

Manufacturer, Supplier, Exporter of MS Mild Steel Penstock Pipes, Penstock Pipes For Hydropowers from Ahmednagar, Maharashtra, India.

Flange Adapter, Flange Adapters, Flange Type Adapter, Flange Type Adapters, MS Flange Adaptor, MS Flange Adaptors, MS Dismantling Joint, MS Dismantling Joints, Weldable Type Flange Adapter, Weldable Type Flange Adapters, Flange Type Flange Adapter, Flange Type Flange Adapters, Dismantling Joint, Dismantling Joints, Slip Type Expansion Joint, Slip Type Expansion Joints, Slip Type Flanged Expansion Joint, Slip Type Weldable Expansion Joints, Pipe Compensator, MS Slip Type Expansion Joint, MS Slip Type Expansion Joints, Expansion Joint, Expansion Joints, Slip Type Expansion Joint, Slip Type Expansion Joints, Mechanical Slip Type Expansion Joint, Mechanical Slip Type Expansion Joints, Mechanical Joint, Mechanical Joints, Mechanical Expansion Joint, Mechanical Expansion Joints, Steel Fabricated Expansion Joint, Steel Fabricated Expansion Joints, Fabricated Steel Mechanical Expansion Joint, Fabricated Steel Mechanical Expansion Joints, MS PSC Pipe Mould, Penstock Pipes For Hydropower, Penstock Pipes For Hydropowers, MS Penstock Pipe, MS Penstock Pipes, Manufacturer Supplier Exporter, Ahmednagar Maharashtra India.

#Flange Adapter#Flange Adapters#Flange Type Adapter#Flange Type Adapters#MS Flange Adaptor#MS Flange Adaptors#MS Dismantling Joint#MS Dismantling Joints#Weldable Type Flange Adapter#Weldable Type Flange Adapters#Flange Type Flange Adapter#Flange Type Flange Adapters#Dismantling Joint#Dismantling Joints#Slip Type Expansion Joint#Slip Type Expansion Joints#Slip Type Flanged Expansion Joint#Slip Type Weldable Expansion Joints#Pipe Compensator#MS Slip Type Expansion Joint#MS Slip Type Expansion Joints#Expansion Joint#Expansion Joints#Mechanical Slip Type Expansion Joint#Mechanical Slip Type Expansion Joints#Mechanical Joint#Mechanical Joints#Mechanical Expansion Joint#Mechanical Expansion Joints#Steel Fabricated Expansion Joint

0 notes

Text

Explore the numerous benefits of Shree TMT Xtra 550 ribbed bars for your construction needs. This detailed infographic highlights key features such as strong bonding, earthquake resistance, customized product options, cost-effectiveness, higher strength, strain aging, bendability, fire resistance, weldability, corrosion resistance, and formability. Ensure your construction projects are safe, durable, and efficient with Shree TMT Xtra 550 ribbed bars.

#Ribbed bars#Construction materials#TMT bars benefits#Earthquake-resistant materials#Cost-effective construction#High-strength TMT bars#Fire-resistant materials#Weldable TMT bars#Corrosion resistance#Construction industry#Customized construction materials#Durable building materials#Construction safety

0 notes

Text

Ammonia weldable valves| Ammonia weldable valves supplier, Manufacturer in Pune, Mumbai, India

Asha Enterprises, is best Ammonia weldable valves supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia weldable valves#Ammonia weldable valves supplier#Ammonia weldable valves manufacturer#Ammonia weldable valves in Pune#Ammonia weldable valves in Mumbai#Ammonia weldable valves in Thane#Ammonia weldable valves in Navi Mumbai#Ammonia weldable valves in Kolhapur#Ammonia weldable valves in Ratnagiri#Ammonia weldable valves in Raigad#Ammonia weldable valves in Nashik#Ammonia weldable valves in Solapur#Ammonia weldable valves in Latur#Ammonia weldable valves in Aurangabad#Ammonia weldable valves in Sindhudurg#Ammonia weldable valves in Sangli#Ammonia weldable valves in Ahmednagar#Ammonia weldable valves in Satara#Ammonia weldable valves in Maharashtra#Ammonia weldable valves supplier in Pune#Ammonia weldable valves supplier in Mumbai#Ammonia weldable valves supplier in Thane#Ammonia weldable valves supplier in Navi Mumbai#Ammonia weldable valves supplier in Kolhapur#Ammonia weldable valves supplier in Ratnagiri#Ammonia weldable valves supplier in Raigad#Ammonia weldable valves supplier in Nashik

0 notes

Text

Buy MS Seamless Pipe from Leading Manufacturers in Delhi

When it comes to purchasing MS seamless pipes in Delhi, finding a reliable and trusted supplier is essential for ensuring quality and performance. Mild Steel (MS) seamless pipes are widely used in various industries, such as construction, oil and gas, plumbing, and manufacturing, due to their strength, durability, and resistance to corrosion.

In this article, we’ll explore why MS seamless pipes are important, their applications, and how you can find the best suppliers in Delhi.

What Are MS Seamless Pipes?

MS seamless pipes are made from mild steel, a low-carbon steel known for its flexibility and weldability. These pipes are manufactured without any seams or joints, providing a smoother finish and superior strength compared to welded pipes. The seamless construction ensures that the pipe can withstand high pressure and temperature without weakening, making it ideal for demanding applications.

Applications of MS Seamless Pipes

MS seamless pipes have a variety of uses across multiple industries, such as:

Construction: Used for building frames, scaffolding, and structural support due to their high tensile strength.

Oil & Gas Industry: Perfect for transporting fluids and gases under high pressure, ensuring safety and efficiency.

Water Supply: MS seamless pipes are used in water distribution systems as they prevent leakage and can handle large volumes of water.

Automotive: Employed in making parts for vehicles due to their strength and lightweight properties.

The versatility of MS seamless pipes makes them essential in industries where strength and reliability are paramount.

Why Buy MS Seamless Pipes from Leading Manufacturers?

Purchasing MS seamless pipes from leading manufacturers offers several advantages:

Guaranteed Quality: Leading manufacturers ensure that the pipes meet international standards, providing high durability and strength.

Wide Range of Sizes: Established suppliers offer a variety of sizes and specifications to cater to different industrial needs.

Competitive Pricing: Leading suppliers often provide the most competitive prices due to their ability to source materials and manufacture in bulk.

After-Sales Support: Trusted manufacturers provide excellent customer service, helping you with installation, maintenance, and any other post-purchase concerns.

Where to Buy MS Seamless Pipes in Delhi?

If you’re looking for the best MS seamless pipe supplier in Delhi, Udhhyog is a top choice. Udhhyog is known for its wide selection of MS seamless pipes at the lowest prices in India. They cater to both large industrial needs and small business requirements, ensuring that every customer finds the right solution.

Why Choose Udhhyog?

High-Quality Products: Udhhyog ensures that their pipes meet stringent quality standards, making them durable and efficient for various uses.

Competitive Pricing: By leveraging their strong supply chain, Udhhyog offers MS seamless pipes at highly competitive rates, helping businesses cut costs without compromising on quality.

Wide Availability: As one of the leading suppliers in Delhi, Udhhyog ensures that you can easily get the sizes and specifications you need for your project.

Reliable Service: Udhhyog prides itself on excellent customer service, offering prompt delivery and responsive after-sales support.

How to Order from Udhhyog?

Ordering MS seamless pipes from Udhhyog is straightforward. You can visit their website to explore their product range, check specifications, and place an order. You can also contact their sales team for any specific inquiries or bulk orders. Udhhyog offers flexible payment options and ensures timely delivery across India, making procurement easier for businesses

#MSSeamlessPipes#MSPipes#SeamlessPipes#PipeFittings#IndustrialPipes#SteelPipes#DelhiSuppliers#DelhiManufacturers#DelhiBusiness#ConstructionMaterials#OilAndGas#WaterSupplyPipes#AutomotiveParts#BuyMSSeamlessPipes#SteelAtLowestPrices#Udhhyog#MSSeamlessPipeSupplier#MSSteelPipesIndia#PipeSuppliersIndia#SteelManufacturersDelhi

5 notes

·

View notes

Text

Advantages of Weldable Rebar Coupler

Weldable rebar couplers offer a convenient solution for connecting reinforcing bars to structural steel plates or sections. Designed specifically for perpendicular connections, these couplers provide numerous advantages that make them a go-to choice for professionals in the industry.

Designed for perpendicular connections: Weldable rebar couplers are specifically designed to connect reinforcing bars perpendicular to structural steel sections or plates, ensuring a strong and secure connection.

Internally taper threaded and weldable: With one end internally taper threaded and the other end prepared for welding, our couplers offer a versatile solution that can adapt to various project requirements.

Machined from weldable grades of steel: We use high-performance low carbon alloy steel (20Cr) to manufacture couplers, guaranteeing exceptional welding quality and durability.

When using our couplers, it is essential to consider the type and size of weld required, as well as the properties of the plate and tube. It is important to select the appropriate electrode and ensure that the welders are qualified for the specific weld required.

Choose weldable rebar couplers for a reliable and efficient solution that meets your project's needs. Connect with us today to learn more about how our couplers can enhance your structural steel connections!

1 note

·

View note

Text

What Is Mild Steel And Cast Iron?

The Mild Steel and Cast Iron both are very useful for the manufacturing of heavy items and construction. The mild steel prices are very low and better quality and the cast Iron quality is better rather than mild steel. Mild steel has 99% of Iron and carbon content is very low and carbon content means mild steel is relatively soft and malleable compared to higher carbon steels. It may also contain small amounts of manganese, silicon, sulfur, and phosphorus. The Mild steel is easily weldable and Cast Iron difficult to weld because it's very stronger,harder from the mild steel soft. The most important thing is that Mild Steel is used for the construction, automation machinery and the Cast Iron is used for the casting, engine books. Mild Steel and Cast Iron is necessary for the constructions without it you can't do it.

For more information you can visit here:

2 notes

·

View notes

Text

Welding in Space: Challenges and Innovations for Extraterrestrial Construction

Introduction:

As humanity expands its presence beyond Earth and ventures into space exploration and colonization, the need for construction and infrastructure development in space becomes increasingly apparent. Welding, a fundamental joining process in terrestrial manufacturing, also plays a crucial role in space construction projects, enabling the assembly of spacecraft, habitats, and infrastructure components in the harsh and challenging environment of space. In this article, we'll explore the unique challenges and innovative solutions associated with welding in space and its implications for future space exploration and habitation.

Microgravity Environment:

One of the primary challenges of welding undercut in space is the absence of gravity, which affects the behavior of molten metal and welding processes. In microgravity, weld pools form differently, and droplet detachment, gas bubble behavior, and heat dissipation are altered. Innovative welding techniques, such as electromagnetic welding and friction stir welding, have been developed to overcome the challenges posed by microgravity and enable reliable joining of metal components in space.

Vacuum Conditions:

Space is characterized by a vacuum environment with near-zero atmospheric pressure, which presents challenges for welding processes involving shielding gases and arc stability. Traditional gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW) techniques require modifications to operate effectively in vacuum conditions. Advanced welding technologies, such as laser welding and electron beam welding, offer advantages in vacuum welding applications due to their ability to operate without the need for shielding gases.

Material Selection and Compatibility:

The selection of materials for space welding applications is critical due to the extreme temperature variations, radiation exposure, and vacuum conditions encountered in space. Weldable materials must exhibit high strength, corrosion resistance, and thermal stability while being compatible with the space environment. Advanced alloys, composites, and ceramic materials with tailored properties are being developed for space welding applications, offering enhanced performance and durability in extraterrestrial environments.

Automation and Robotics:

Automation and robotics play a crucial role in space welding operations, enabling precise control, repeatability, and efficiency in extraterrestrial construction projects. Robotic welding systems equipped with advanced sensors and adaptive control algorithms can perform welding tasks autonomously, reducing the reliance on human intervention and minimizing the risk of errors in space missions. Additionally, modular robotic platforms and manipulators are being developed for in-situ welding and assembly of space habitats and infrastructure components on planetary surfaces.

In-Situ Resource Utilization (ISRU):

In-situ resource utilization (ISRU) is a key strategy for sustainable space exploration and colonization, allowing for the extraction and utilization of resources available on celestial bodies such as the Moon and Mars. Welding technologies are being integrated into ISRU systems to enable the fabrication of structures and infrastructure using locally sourced materials, such as lunar regolith or Martian soil. Additive manufacturing techniques, such as 3D printing with in-situ materials, offer opportunities for on-demand fabrication of habitats and infrastructure components in extraterrestrial environments.

Conclusion:

Welding in space presents unique challenges and opportunities for construction and infrastructure development in the extraterrestrial frontier. By leveraging innovative welding techniques, materials, and automation technologies, humanity can overcome the challenges of welding in microgravity and vacuum conditions and enable the assembly of spacecraft, habitats, and infrastructure necessary for sustainable space exploration and habitation. Continued research and development efforts in space welding will be essential to advancing humanity's capabilities in space and unlocking the full potential of extraterrestrial construction.

2 notes

·

View notes

Text

Flanges, Large Diameter Flanges, Flange Adaptors, India

Manufacturer, Supplier, Exporter of Flanges, Large Diameter Flanges, Flange Adaptors, Flange Type Adapters from Ahmednagar, Maharashtra, India.

Flange Adapter, Flange Adapters, Flange Type Adapter, Flange Type Adapters, MS Flange Adaptor, MS Flange Adaptors, MS Dismantling Joint, MS Dismantling Joints, Weldable Type Flange Adapter, Weldable Type Flange Adapters, Flange Type Flange Adapter, Flange Type Flange Adapters, Dismantling Joint, Dismantling Joints, Slip Type Expansion Joint, Slip Type Expansion Joints, Slip Type Flanged Expansion Joint, Slip Type Weldable Expansion Joints, Pipe Compensator, MS Slip Type Expansion Joint, MS Slip Type Expansion Joints, Expansion Joint, Expansion Joints, Slip Type Expansion Joint, Slip Type Expansion Joints, Mechanical Slip Type Expansion Joint, Mechanical Slip Type Expansion Joints, Mechanical Joint, Mechanical Joints, Mechanical Expansion Joint, Mechanical Expansion Joints, Steel Fabricated Expansion Joint, Steel Fabricated Expansion Joints, Fabricated Steel Mechanical Expansion Joint, Fabricated Steel Mechanical Expansion Joints, MS PSC Pipe Mould, Penstock Pipes For Hydropower, Penstock Pipes For Hydropowers, MS Penstock Pipe, MS Penstock Pipes, Manufacturer Supplier Exporter, Ahmednagar Maharashtra India.

#Flange Adapter#Flange Adapters#Flange Type Adapter#Flange Type Adapters#MS Flange Adaptor#MS Flange Adaptors#MS Dismantling Joint#MS Dismantling Joints#Weldable Type Flange Adapter#Weldable Type Flange Adapters#Flange Type Flange Adapter#Flange Type Flange Adapters#Dismantling Joint#Dismantling Joints#Slip Type Expansion Joint#Slip Type Expansion Joints#Slip Type Flanged Expansion Joint#Slip Type Weldable Expansion Joints#Pipe Compensator#MS Slip Type Expansion Joint#MS Slip Type Expansion Joints#Expansion Joint#Expansion Joints#Mechanical Slip Type Expansion Joint#Mechanical Slip Type Expansion Joints#Mechanical Joint#Mechanical Joints#Mechanical Expansion Joint#Mechanical Expansion Joints#Steel Fabricated Expansion Joint

0 notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Asha Enterprises | Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves Pune, India

Asha Enterprises is best Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves, Ammonia level control with indicator, Ice plant equipment, Ice cans, Refrigeration compressor spare parts, Ammonia compressor spare parts, Ammonia IBT Coil, Ammonia condensers, Ammonia receiver storage tanks supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia valves#Ammonia refrigeration compressors#Ammonia solenoid valves#Ammonia weldable valves#Ammonia level control with indicator#Ice plant equipment#Ice cans#Refrigeration compressor spare parts#Ammonia compressor spare parts#Ammonia IBT Coil#Ammonia condensers#Ammonia receiver storage tanks#Pune#Mumbai#Thane#Navi Mumbai#Kolhapur#Ratnagiri#Raigad#Nashik#Solapur#Latur#Aurangabad#Sindhudurg#Sangli#Ahmednagar#Satara and Maharashtra.

0 notes

Text

Best TMT Bars Manufacturer In India | TMT Bar | Nakoda TMT Group We at NAKODA ensure constant supervision, so that we churn out superior quality products! Nakoda TMT is Best TMT Bar Supplier In India having Different TMT bars Like Fe 500,Fe-500D,Fe-550 D,Fe-600.TMT steel bars are durable for construction

https://www.nakodagroup.com/ https://www.nakodagroup.com/tmt.html

#nakodaTMT#nakodagroup#savemore#buildbetter#pillarsofsuccess#TMTBars#steelbars#fireresistant#reinforcementbars#flexibility#CorrosionResistant#weldable#bondable#bendable#strongenough#engineering#Perfect#insta360onex#explorepage#strongTMTBars#sturdyfoundation#corrosionresistant#infrastructure#trust#durableconstruction#qualitysteel

0 notes

Text

ThaiOil-approved flanges in UAE

Being a quality driven firm, Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is offering a quality-upheld group of Incoloy 825 Flanges to the clients. Chromium content in Incoloy 825 Slip on Flanges (UNS N08825) gives assurance from oxidizing conditions, as nitric destructive courses of action, nitrates and oxidizing salts. These Incoloy 825 Scene Blind Flanges sidesteps pressure-disintegration-breaking and has extraordinary weldability by each normal communication.

Incoloy 825 Weld Neck Flanges accepts a basic part in heat exchangers for engineered dealing with, pollution control gear, oil well and gas gathering pipes - even as clad steel pipes - where security from stress breaking or general utilization to an extent of diminishing or oxidizing acids is normal. Meanwhile, these Incoloy 825 Lap Joint Flanges are similarly being introduced in different sizes and shapes to our clients. Between the Molybdenum, Nickel and Titanium, Incoloy UNS N08825 Hung Flanges gives phenomenal insurance from sulfuric and phosphoric acids.

These Incoloy 825 Weld Flanges is by and large used in Air - cooled heat exchangers in oil refineries, Engineered and Food Taking care of. Incoloy 825 Outwardly impeded Flanges is fundamental for totally clean all traces of lubes directly following molding as embrittlement of the composite would occur at high temperatures thusly. These Incoloy 825 Ring Joint Sort Flanges is titanium offset to go against pitting and cover - granular attack after produce, particularly welding, which warmed for the fundamental refinement temperature range (650 Degree C - 760 Degree C).

#Incoloy 825 Flanges Manufacturers in Dubai#Incoloy 825 Flanges Suppliers in Dubai#Incoloy 825 Flanges Stockists in Dubai#Incoloy 825 Flanges Exporters in Dubai#TCO Tengizchevroil Approved Flanges in Oman

2 notes

·

View notes