Don't wanna be here? Send us removal request.

Text

BLIIoT Water Meter Pulse Counting Gateway S271

Background

No matter where you live, water and electric meters are an absolute must. Water meters record how much water you use and how much you pay for it. Water meters help monitor data, conserve water, and lower water bills.

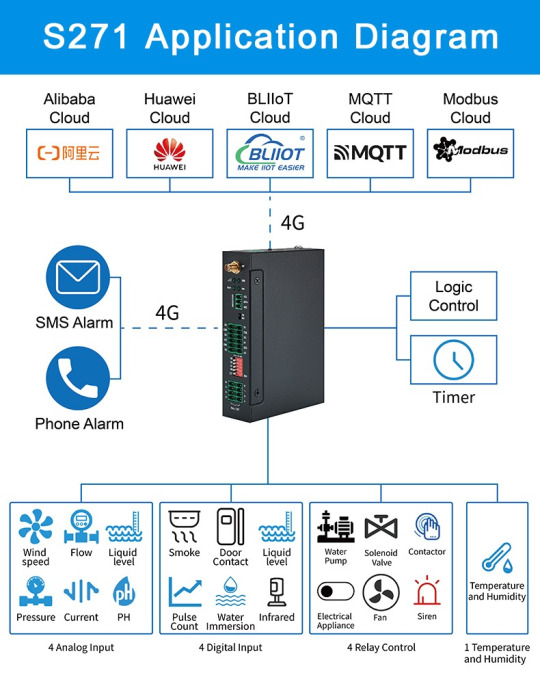

Pulse Counting Gateway

Pulse Counting Gateway S271 is designed to count the number of pulses from electricity meters, water meters or general meters as well as machinery and equipment with pulse outputs. Quickly and cost-effectively transform your traditional water meter into a smart water meter, monitoring data in real time.

Solution

Pulse Counting Gateway S271 can be used in different applications such as agricultural irrigation, smart building meter reading and industrial water use. The device can be connected to a pulse water meter, and then collect water use data and upload the data to the IoT cloud platform via 4G for further visualization. Users can check the status of the water meter and perform monitoring and control at any time. The pulse counter can provide remote monitoring and visual intelligent data management to achieve water conservation.

More information about Water Meter Pulse Counting Gateway S271: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

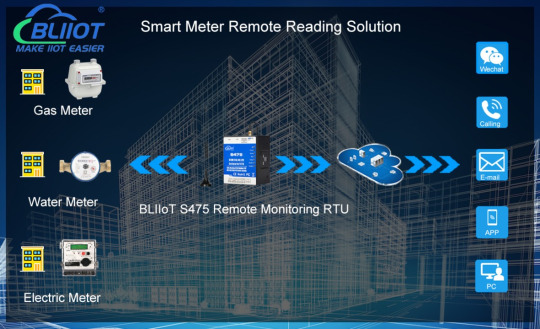

BLIIoT Smart Meter Remote Reading Solution

Background

The smart meter remote reading system is a new IoT technology designed to improve the integrated billing management of water meters and electricity meters. The automatic meter reading method of the intelligent meter reading system can replace the traditional manual meter reading. The smart water meter remote meter reading system can use wired technology or wireless technology to report and collect users' water and electricity data in real time, achieving remote monitoring, centralized data storage and unified management.

Smart Meter Remote Reading Solution

The smart meter remote meter reading system is divided into comprehensive application layer, data management layer and data collection layer. The principle of the data collection layer is to collect data from each meter through transmission media (such as RS485 interface, power supply, 4G,Ethernet, etc.). According to the meter reading task of the management center, the data of each meter is automatically collected through Remote Monitoring RTU S475.

The concentrator RTU S475 can transmit data to the data server via Ethernet or GPRS. The data server is a smart meter remote reading system that can perform data processing, classification, and screening, saving manual work.

Advantage

1.RTU S475 connects to the smart meter through RS485 or RS232 interface, and uploads data through Ethernet or 4G.

2. RTU S475 supports Modbus RTU, Modbus TCP and MQTT protocols, and supports active reporting mode and polling mode.

3. RTU S475 can be connected to Alibaba Cloud, Huawei Cloud, BaRe Cloud, SCADA and third-party cloud platforms.

4. Users can receive and monitor real-time water meter data through the cloud or SCADA large screen

In Conclusion

To sum up, Remote Monitoring RTU S475 plays a key role in remote reading of smart water, electricity and gas meters. Its application not only improves the efficiency of public utility management, but also provides feasibility and convenience for the scientific utilization of resources.

More information about BLIIoT Remote Monitoring RTU S475: https://www.bliiot.com/remote-terminal-units-p00178p1.html

0 notes

Text

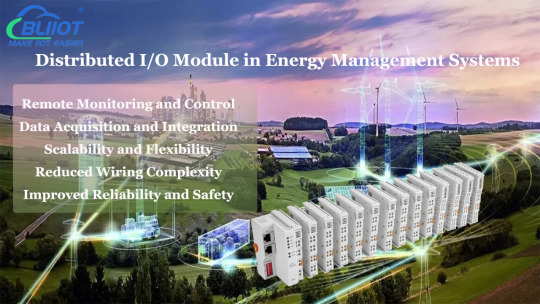

Why Does Distributed I/O Module Play an Important Role in Energy Management Systems?

Distributed I/O (Input/Output) modules play a crucial role in energy management systems.

1. Remote Monitoring and Control: Distributed I/O modules allow for remote monitoring and control of various devices and equipment in an energy management system. They provide the ability to collect data from sensors, meters, and other devices located throughout a facility or an industrial plant, enabling real-time monitoring and control of energy usage.

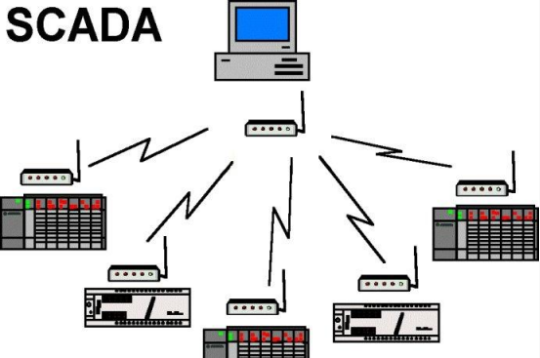

2. Data Acquisition and Integration: Distributed I/O modules act as data acquisition points, collecting data from different sensors and meters distributed across the energy management system. This data is then integrated into a central control system or a supervisory control and data acquisition (SCADA) system, allowing for comprehensive analysis, visualization, and decision-making.

3. Scalability and Flexibility: With distributed I/O modules, it becomes easier to scale up or expand an energy management system. Additional modules can be added as needed to accommodate new equipment, devices, or areas within a facility. This scalability and flexibility enable effective energy management across different zones or buildings, providing a holistic view of energy consumption.

4. Reduced Wiring Complexity: Distributed I/O modules eliminate the need for extensive wiring by allowing sensors and devices to be connected directly to the modules located closer to the field devices. This reduces the complexity of wiring infrastructure, minimizes installation costs, and simplifies maintenance and troubleshooting.

5. Improved Reliability and Safety: By distributing I/O modules throughout an energy management system, the risk of single-point failures is reduced. Even if one module fails, the rest of the system can continue to operate. Additionally, distributed I/O modules often have built-in safety features, such as short-circuit protection and electrical isolation, ensuring the safety of personnel and equipment.

Overall, distributed I/O modules enhance the efficiency, visibility, and control of energy management systems. They enable remote monitoring, data integration, scalability, and simplify installation and maintenance, contributing to effective energy management and optimization.

0 notes

Text

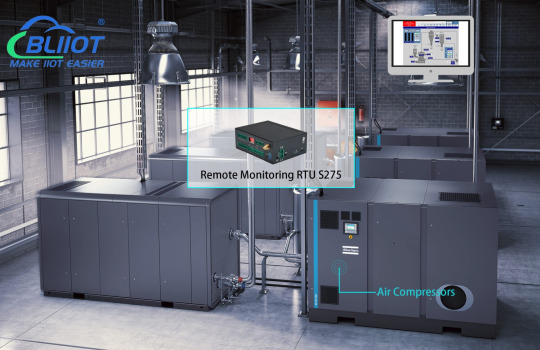

BLIIoT Air Compressor Remote Monitoring Solution

Background

As a large mechanical equipment, air compressors will generate a lot of after-sales maintenance and troubleshooting needs during long-term use. High power consumption and maintenance costs amplify the impact of failures, which can result in significant losses through delayed repairs and extended downtime.

By making air compressors IoT-enabled, maintenance personnel can remotely monitor compressor operation, detect abnormalities in a timely manner and proactively solve problems. This strategy minimizes downtime-related losses, enriches customer service, and enhances the overall value proposition.

Air compressor monitoring requirements

Real-Time Monitoring and Remote Control

Through real-time collection of key parameters such as temperature, pressure, and rotational speed of the air compressor. Allows remote control to adjust parameters and optimize production processes.

Troubleshooting and Predictive Maintenance

Analyze collected data and diagnose potential machine failures, issuing timely alerts to prevent production interruptions and equipment damage.

Data Analysis and Reporting

Advanced data analytics platforms are required to process, analyze and visualize machine operation data. It should support report and chart generation, allowing customers to monitor production efficiency, quality metrics, equipment utilization and drive continuous improvement.

Application of RTU S275 in Remote Monitoring of Air Compressors

Data collection and monitoring

Through RTU S275, we can easily configure oil temperature and lubricant level sensors to monitor key parameters of the air compressor in real time. The equipment provides data storage and historical recording functions to ensure the traceability of production data.

Air compressor controller connection

RTU S275 can establish a connection with the air compressor controller to realize real-time monitoring and remote control of the air compressor status. In this way, operators can adjust operating parameters in a timely manner to optimize production efficiency.

4G network transmission

The device supports 4G network communication and transmits the collected data to the remote management platform in a dedicated protocol format. This ensures efficient transmission and real-time performance of data.

Remote visualization and analysis

The remote management platform receives, parses and stores data transmitted through RTU S275, providing customers with a convenient way to view, count and analyze data anytime and anywhere through a computer or mobile phone. This provides more intuitive and real-time data support for production management.

Security

To ensure the security of data transmission and storage, RTU S275 provides multiple security measures, including data encryption and authentication. These measures help prevent unauthorized access and ensure data integrity.

In conclusion

RTU S275 provides an intelligent solution for remote monitoring of air compressors. Its powerful functions and flexible configuration make it suitable for various industrial environments. Through real-time monitoring and remote control, RTU S275 not only improves the safety and reliability of the air compressor system, but also reduces maintenance costs and production risks.

More information about BLIIoT Remote Monitoring RTU Gateway S275 : https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

BLIIoT Smart Meter Remote Reading Solution

Background

The smart meter remote reading system is a new IoT technology designed to improve the integrated billing management of water meters and electricity meters. The automatic meter reading method of the intelligent meter reading system can replace the traditional manual meter reading. The smart water meter remote meter reading system can use wired technology or wireless technology to report and collect users' water and electricity data in real time, achieving remote monitoring, centralized data storage and unified management.

Smart Meter Remote Reading Solution

The smart meter remote meter reading system is divided into comprehensive application layer, data management layer and data collection layer. The principle of the data collection layer is to collect data from each meter through transmission media (such as RS485 interface, power supply, 4G,Ethernet, etc.). According to the meter reading task of the management center, the data of each meter is automatically collected through Remote Monitoring RTU S475.

The concentrator RTU S475 can transmit data to the data server via Ethernet or GPRS. The data server is a smart meter remote reading system that can perform data processing, classification, and screening, saving manual work.

Advantage

1.RTU S475 connects to the smart meter through RS485 or RS232 interface, and uploads data through Ethernet or 4G.

2. RTU S475 supports Modbus RTU, Modbus TCP and MQTT protocols, and supports active reporting mode and polling mode.

3. RTU S475 can be connected to Alibaba Cloud, Huawei Cloud, BaRe Cloud, SCADA and third-party cloud platforms.

4. Users can receive and monitor real-time water meter data through the cloud or SCADA large screen

In Conclusion

To sum up, Remote Monitoring RTU S475 plays a key role in remote reading of smart water, electricity and gas meters. Its application not only improves the efficiency of public utility management, but also provides feasibility and convenience for the scientific utilization of resources.

More information about BLIIoT Remote Monitoring RTU S475: https://www.bliiot.com/remote-terminal-units-p00178p1.html

0 notes

Text

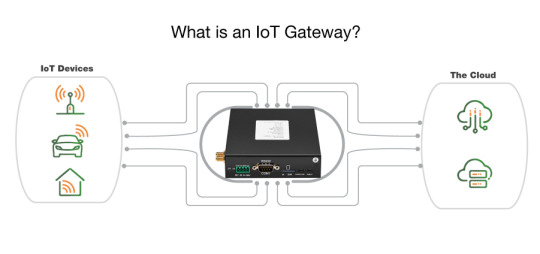

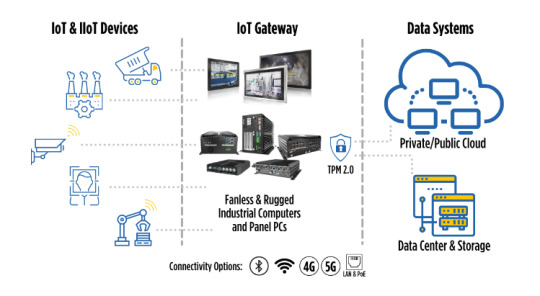

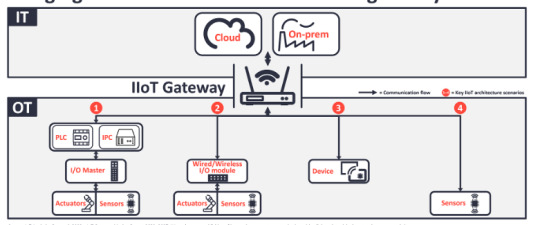

What is an IoT gateway? The Definition, Function and Application

Introduction

IoT gateway is essentially an intelligent central hub for IoT devices. An Internet of Things (IoT) gateway is a physical device or software program that acts as a connection point between the cloud and IoT devices such as controllers, sensors, and smart devices.

Organizations can use gateways to connect IoT devices for data processing and to monitor and manage IoT devices.

Why do you need to use industrial IoT gateways?

Almost all Industrial IoT solutions require gateways because small IoT devices such as sensors and actuators cannot connect directly to the IT infrastructure. Device limitations such as small physical size, harsh environmental conditions, remote locations, large battery power, fast response times, and low costs require suitable IoT device platforms, protocols, and networks to accommodate uses that are different from mainstream IT systems.

1. Protocol conversion – The main function of the gateway is to convert industrial system-specific protocols into business application languages: BACnet, Ethernet/IP, EtherCat, PROFINET and OPC UA

2. Edge Computing – Local applications running on the gateway interact directly with connected IoT devices, thereby improving response times, improving reliability, and reducing upstream bandwidth.

Features

1. Industrial IoT gateways wirelessly connect traditional and remote industrial equipment to next-generation smart infrastructure.

2. The Industrial IoT gateway is designed to be rugged and suitable for mission-critical systems and industrial environments that use sensor nodes or I/O devices to collect data.

3. IoT gateways can be configured with a variety of different protocols that enable them to communicate with these end-to-end sensor nodes or I/O devices.

4. Deploying an industrial IoT gateway can collect, filter, process and analyze data locally at the edge and then send it to the cloud. They relieve the burden on clouds and data centers from processing the vast amounts of data generated by sensors and industrial IoT devices, improving response times and reducing network transmission costs.

Finally, employing an IoT gateway to access previously hidden data from sensors, embedded controllers, and IO devices can be valuable for many enterprise processes and applications, such as:Remote monitoring, Maintenance,Production Optimization,Building Automation ect.

BLIIOT Industrial Edge IoT Gateway

Multi-serial ports and multi-network ports, downlink collection of multiple protocols, uplink compatible with multiple protocols, can collect data from 100 devices at the same time, and access multiple platforms at the same time. Applicable to Industrial Internet of Things, digital transformation, smart city, smart property, smart energy, smart transportation, etc.

#iot devices#smartcities#iot solutions#datacollection#awscloud#thingsboard#modbus#mqtt#edgecomputing

0 notes

Text

BLIIOT Industrial Edge IoT Gateway Helps the Development of Photovoltaic Industry

Background

Photovoltaic power generation is based on the principle of photovoltaic effect, using solar cells to directly convert sunlight energy into electrical energy. Whether it is used independently or connected to the grid for power generation, the photovoltaic power generation system mainly consists of three parts: solar panels (components), controllers and inverters. They are mainly composed of electronic components and do not involve mechanical parts. Therefore, photovoltaic power generation equipment Extremely refined, reliable, stable, long life, easy to install and maintain.

Program Overview

All photovoltaic equipment is assembled on the roof. The solar cells use the principle of photovoltaic effect produced by surface semiconductors to generate direct current. The direct current is converted into alternating current through a three-phase inverter and connected to the grid.

The photovoltaic system is mainly composed of inverters, controllers, energy meters, environmental sensors, etc. There are a large number of point signals in the system that need to be collected, such as: current, voltage, alarm, control, temperature and humidity, lighting, etc. It is characterized by a large number of signals and complex signal types, including 16bit, 32bit, and bitwise reading and writing. The cloud uses the MQTT protocol.

The project uses BL110 Edge gateway for data collection and transmission. The gateway will collect signal data from inverters, environmental sensors, and energy meters through the RS485 serial port Modbus protocol for edge computing processing, and transmit it to the photovoltaic operation and maintenance platform using MQTT.

Features

1.Stable and Reliable

BLIIOT BL110 industrial IoT gateway, industrial-grade design, has stable and reliable characteristics. The equipment has a trouble-free operation time of more than 30W hours, ensuring that data is online in real time. On the basis of the traditional photovoltaic power station, the RS485 serial port Modbus RTU communication protocol is added, which has strong versatility and strong anti-interference ability.

2.High Cost-effective

BLIIOT BL110 industrial IoT gateway has excellent performance. One gateway supports the collection of up to 50 inverters and 4,000 inverter variable attributes, greatly saving costs for users.

3.Multi-platform Concurrency

BLIIOT Technology BL110 industrial IoT gateway can upload the collected inverter data to Alibaba Cloud, Huawei Cloud, AWS, ThingsBoard and other platforms. Users can connect to public or private clouds according to their needs.

4.Security Encryption

BLIIOT BL110 industrial IoT gateway supports TSL, SSL, X.509 authentication encryption, OPEN VPN, etc. to ensure safe data transmission.

View more about BL110

0 notes

Text

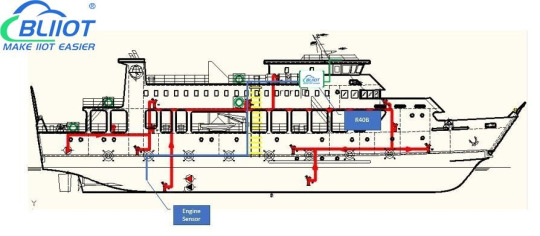

BLIIoT Industrial Edge Router R40B for Marine Automation

Introduction

In the current era of booming industrial Internet of Things, the shipping industry has an increasing demand for automation and intelligence. With its excellent performance and rich functions, the R40B industrial 4G edge computing router has shown broad application prospects in Marine Automation.

Marine Automation

Marine Automation ranges from main propulsion monitoring and alarm systems to highly integrated automation systems, including process control, ballast control, tank measurement monitoring, pump/valve control, bilge control, cargo load control and stability calculation, information management, fault The diagnostic and power management system adopts a modular design, which allows the system to be flexibly configured to meet the different requirements of users. It allows users to quickly and conveniently monitor the operation of related equipment through a graphical human-machine interface, optimize operation management, and thereby improve the automation level of the entire ship.

Application scenarios

Remote ship monitoring system

Real-time monitoring of ship engine status to improve real-time understanding of engine performance.

Remote tracking of ship position enhances precise monitoring of ship position.

Remote maintenance and fault diagnosis of shipboard equipment can reduce ship maintenance time and improve operational efficiency.

Marine Power Management System

Generator unit status is monitored in real time to ensure the stability of power supply.

Collect and analyze energy efficiency data to achieve optimal management of energy consumption.

Real-time reporting and forecasting of energy consumption provides more accurate energy planning for ships.

Marine Environmental Monitoring and Safety System

Monitoring of ship's internal environmental parameters ensures the safety and comfort of the crew's working environment.

Real-time monitoring of dangerous events such as fires and leaks to improve rapid response to dangerous situations.

Crew safety alarm system to ensure the safety of crew members.

Ship logistics and cargo tracking system

Real-time location tracking of goods improves real-time management and control of goods.

Monitor the status of ship cargo holds to ensure that cargo is transported in good conditions.

The temperature and humidity of ship cargo are remotely controlled to provide a precise transportation environment for special cargo.

In Conclusion

The wide application of R40B industrial 4G edge computing router in ship automation not only improves the operational efficiency and safety of ships, but also brings new opportunities for the shipping industry to embrace the digital era. In the future, with the continuous innovation of technology, R40B will play a more important role in the field of Marine automation and promote the progress of the entire shipping industry.

More information about BLIIoT Industrial Edge Router R40B: https://www.bliiot.com/edge-iot-router-p00307p1.html

#iot devices#iot solutions#datacollection#industrial automation#awscloud#thingsboard#smartcities#Marine Automation

0 notes

Text

Application of Distributed I/O in Lithium Battery Industry

Distributed I/O (Input/Output) is a technology that involves the use of multiple input/output devices and controllers to collect and distribute information throughout a system. In the lithium battery industry, distributed I/O systems are used to monitor and control various aspects of the battery manufacturing process.

One application of distributed I/O in the lithium battery industry is in the monitoring and control of battery production lines. Multiple sensors and controllers are placed at various points along the production line to collect data on parameters such as temperature, pressure, and chemical composition. This data is then transmitted to a central control system where it is analyzed and used to optimize the production process.

Another application of distributed I/O in the lithium battery industry is in the monitoring and control of battery management systems (BMS). BMSs are responsible for monitoring and controlling the state-of-charge, voltage, temperature, and other parameters of individual battery cells. Distributed I/O systems can be used to collect this data from multiple BMSs and transmit it to a central control system for analysis and optimization.

Overall, distributed I/O systems have become an important tool in the lithium battery industry for improving production efficiency, reducing costs, and ensuring product quality and reliability.

0 notes

Text

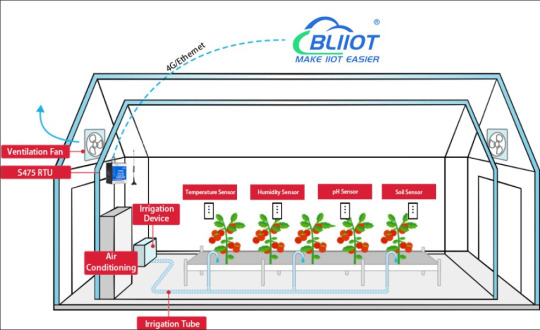

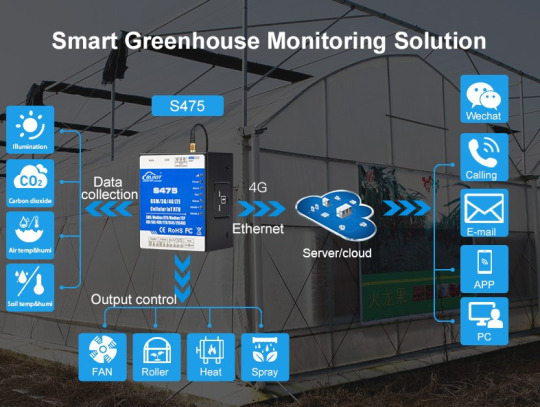

BLIIoT

Remote Monitoring RTU

S475 used in Smart Greenhouse Monitoring

Introduction

With the continuous development of modern agriculture, greenhouse management is becoming intelligent and technological. Under this trend, the remote monitoring RTU gateway S475 supports multi-IO channels to collect sensor and device data, providing innovative solutions for greenhouse monitoring.

Greenhouse monitoring needs

The production environment of the greenhouse is affected by many factors, including temperature, humidity, light intensity, soil moisture, wind speed, wind direction, air pressure, etc. To accurately monitor these critical parameters, the S475 enables comprehensive monitoring of the greenhouse environment through analog and digital data acquisition capabilities.

Application scenarios

In actual greenhouse monitoring, S475 plays an irreplaceable role. Through real-time data collection and monitoring, the equipment can ensure that various parameters in the greenhouse are within the ideal range. At the same time, the device supports the setting of high and low limit parameters. Once an abnormal environment is detected, the S475 will notify relevant personnel through SMS, WeChat or phone alarms to ensure timely measures are taken. The remote control function also provides flexibility for greenhouses. For example, the status of doors and windows can be remotely controlled to optimize the greenhouse environment.

Benefits and Advantages

The application of S475 in greenhouse monitoring has brought significant benefits and advantages to agricultural production. First of all, the equipment improves production efficiency. Through data monitoring and alarm systems, farmers can respond to environmental changes in a more timely manner and ensure the steady growth of plants. Secondly, the remote monitoring and control function of S475 reduces labor costs. Farmers can remotely monitor the greenhouse status from any location and make timely adjustments without having to go to the site in person.

In Conclusion

The application of S475 has injected new vitality into greenhouse monitoring and promoted the development of agricultural management in a more intelligent and efficient direction. With the continuous advancement of Internet of Things technology, the application prospects of S475 in the agricultural field will be broader, providing strong support for the sustainable development of agricultural production. This innovative solution is not only an advancement in greenhouse monitoring, but also an epitome of modern agricultural intelligence.

More information about Remote Monitoring RTU S475: https://www.bliiot.com/remote-terminal-units-p00178p1.html

0 notes

Text

Predictive Maintenance at EdgeCOM

Predictive maintenance is the process of analyzing the operating conditions of equipment or machine to predict when maintenance should be performed on that asset based on current and historical data.

Many companies install IoT sensors such as humidity, temperature, motion, vibration, gases, and other factors that affect machine operation and wear and tear in their equipment to monitor machine conditions.

The amount of data that needs to be collected and analyzed in this process is huge, and it is costly to transfer all of this data to the server or cloud, so EdgeCOM can be used to process a portion of the data in real time, reducing the cost of data storage and also improving security. This is critical for industries where a slight delay in response time can lead to disaster.

Benefits of Predictive Maintenance

Reduced Downtime

One of the biggest concerns for manufacturers is reducing unplanned downtime. Even a small period of unplanned downtime can lead to very significant losses. Once an IoT device detects frequent spikes in any variable, managers can take preventative measures to avoid downtime or reduce it, lowering maintenance costs while reducing production time lost to maintenance.

Extended Equipment Life

By monitoring equipment in operation, it is possible to improve the health and extend the average lifespan of connected devices by repairing problems before they become irreparable.

Optimize Maintenance Schedules

Knowing in advance which parts are likely to fail allows you to plan ahead for repairs and also to rationalize spare parts ordering based on demand at the right time. Avoid overstocking spare parts or not having them when they are needed.

View More About EdgeCOM

0 notes

Text

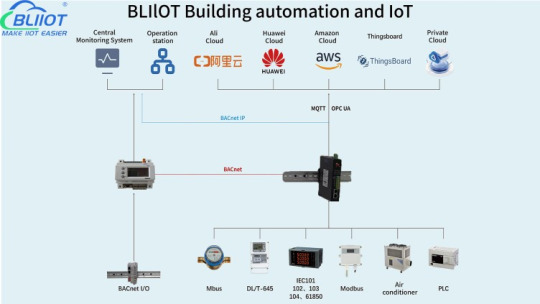

BLIIOT BACnet Gateway Promotes the Development of Building Automation

Background

BACnet is one of the communication protocols in the field of building automation. It provides a standardized way to achieve communication between devices. BACnet supports a variety of communication media and network topologies, and can easily integrate various devices, such as sensors, actuators, controllers, etc.

In the field of building automation, BACnet gateway can help realize automated control and intelligent management of building equipment, improving the operating efficiency and energy efficiency of the building.

Features

BL110 Edge Gateway can convert various PLC protocols, Modbus RTU, Modbus TCP, DL/T645, IEC101, IEC104, BACnet IP, BACnet MS/TP and other protocols into Modbus TCP, OPC UA, MQTT, BACnet IP and other protocols to achieve different Integration between systems.

For example, in large commercial buildings, there may be various brands and models of equipment, such as PLC, air conditioning systems, lighting systems, power management systems, etc. Intelligent building energy management system,need to monitor and control energy consumption of individual devices

These devices may use different communication protocols, such as Modbus, BACnet, etc. By using BACnet gateway, these devices can be integrated into a unified building automation system, monitored, controlled and optimized through a unified interface, achieving centralized management and unified control of data, improving energy efficiency and reducing energy consumption.

In Conclusion

In traditional buildings, these systems are often independent and lack collaboration and interconnection. With the development of intelligent buildings, these systems require more intelligent and efficient integration. The bliiot intelligent BACnet IoT Gateway is one of the key technologies that can achieve this integration.

More information about BACnet Gateway

#iotgateway#iot devices#iot solutions#datacollection#smartcities#building automation#awscloud#thingsboard

0 notes

Text

What is IoT RTU and Sensors?

What is RTU?

RTU is a remote monitoring and control device whose task is to communicate with various sensors and actuators to monitor and control remote equipment in real time. An RTU typically includes a processor, communication modules, storage devices, and various interfaces that enable it to be connected to different types of sensors and actuators.

What is Sensor?

A sensor is a device that converts physical or chemical quantities in the environment into electrical signals. Depending on their type, sensors can measure parameters such as temperature, humidity, pressure, flow, and more. Sensors play a key role in IoT collection, providing necessary information to RTU by collecting real-time data.

How do RTUs and sensors collaborate?

1. Data collection and transmission

The collaboration between RTU and sensors begins with data collection and transmission. By connecting to the sensor, the RTU obtains various data measured by the sensor in real time. These data can be environmental parameters such as temperature, humidity, and pressure, or key information on equipment status and production processes. The RTU transmits these data to the central control system or cloud platform through the built-in communication module to achieve remote monitoring and control.

2. Data processing and analysis

RTU is not only responsible for data transmission, but also has certain data processing and analysis capabilities. It can process data collected by sensors in real time, extract useful information, and make judgments and controls based on preset rules. This collaboration enables industrial systems to respond more intelligently to environmental changes and production needs.

In Conclusion

The close relationship between RTU and sensor plays a vital role in monitoring. Through effective data collection, transmission and processing, they jointly build an intelligent monitoring system, improve efficiency, reduce costs, and lay the foundation for the future development of the smart Internet of Things. As technology continues to develop, we can expect that the role of RTUs and sensors in monitoring will continue to expand and deepen.

More application scenarios

Agricultural monitoring, environmental monitoring, meteorological monitoring, greenhouse environment monitoring, temperature and humidity monitoring, energy monitoring, water quality monitoring, sewage treatment plant monitoring, oil field equipment monitoring, liquid storage tank level monitoring, water level monitoring and flood warning, energy consumption monitoring, street lights Monitoring, air quality monitoring, irrigation system control, water pump control and more

More information: https://www.bliiot.com/

0 notes

Text

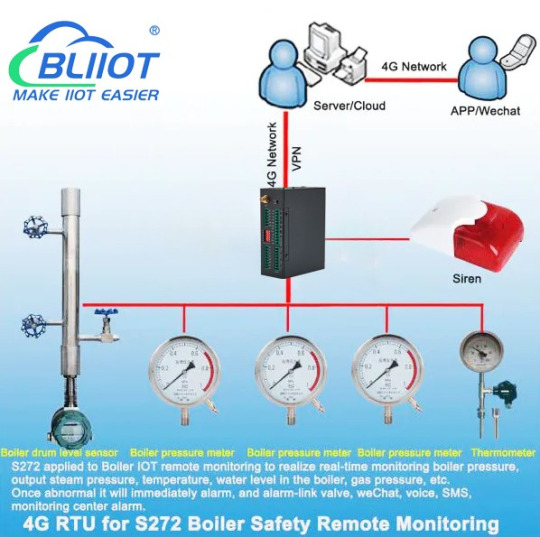

BLIIoT SMS/4G Remote Monitoring Gateway S275 Used in Boiler Monitoring

Foreword

Boilers are important equipment in industry and residential life. They provide hot water, steam and heat energy, but they also need to be closely monitored to ensure their safety and efficiency. BLIIoT SMS/4G Remote Monitoring Gateway S275 provides an intelligent solution for boiler monitoring to monitor the operating status of the boiler system such as air pressure, temperature, liquid level, and water leakage.

Boiler Monitoring Needs

In boiler monitoring applications, we usually need to monitor the following parameters:

Air Pressure Monitoring: Maintaining proper air pressure is critical to proper boiler operation.

Temperature monitoring: Monitoring the temperature of your boiler can help prevent overheating or cooling.

Liquid level monitoring: Ensure the water level is within a safe range to avoid low water levels or overflows.

Water leakage detection: timely detect water leakage to avoid equipment damage and reduce energy waste.

Flue gas emission monitoring: Monitor flue gas emissions to ensure the environmental protection of the boiler.

Alarm notification: promptly notify operation and maintenance personnel or management personnel to deal with emergencies or abnormal situations.

Application of Remote Monitoring Gateway S275 in Boiler Monitoring

Data Collection and Monitoring

Using Remote Monitoring Gateway S275, we can easily configure the sensor to monitor various parameters of the boiler system in real time. By connecting analog and digital sensors, the device can collect data on air pressure, temperature, liquid level, water leakage, smoke emissions, etc. and save it in an internal database for subsequent analysis and reporting. This helps identify potential problems early and take appropriate action.

Alarms and Notifications

Remote Monitoring Gateway S275 has a powerful alarm function, and users can set alarm thresholds based on monitoring data. Once these thresholds are exceeded or dropped, the device triggers an alarm notification to notify relevant personnel. This real-time alert can help take quick action to reduce potential risks.

Remote Control

Keeping your boiler system safe and reliable isn't just about monitoring, it's also about real-time control. The relay output of Remote Monitoring Gateway S275 can be used to control pumps, valves, fans and other equipment, shutting down or starting them remotely when needed. This remote control capability helps reduce risk and improve operational efficiency.

Data Transfer and Cloud Integration

Remote Monitoring Gateway S275 supports multiple communication protocols such as SMS, Modbus, MQTT, etc. to transmit data to the cloud platform. This means you can integrate boiler monitoring data into cloud solutions, enabling remote access, data visualization and analysis. In addition, the device is also compatible with multiple public cloud platforms such as Huawei Cloud and Alibaba Cloud, as well as users' private cloud platforms.

Safety

Data security is critical for boiler monitoring. Remote Monitoring Gateway S275 provides security measures for data transmission and storage, including data encryption and authentication. This helps ensure your boiler monitoring data is protected from unauthorized access and manipulation.

In Conclusion

Remote Monitoring Gateway S275 is a powerful terminal device that can be widely used in the field of boiler monitoring. It provides comprehensive data collection, monitoring, alarm and control functions, and supports multiple communication protocols and cloud platform integration to ensure the safety and reliability of the boiler system. Whether it is an industrial boiler, heating boiler or other type of boiler, Remote Monitoring Gateway S275 can provide an efficient solution for boiler monitoring.

More information about BLIIoT SMS/4G Remote Monitoring Gateway S275 : https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

BLIIoT Remote Monitoring RTU Gateway S275 Provides an Efficient Solution for Pipeline Monitoring

Foreword

Pipeline systems play an important role in various industries such as water supply, natural gas transportation, and chemical production. However, the safety and reliability of pipelines are crucial to ensuring the normal operation of the system.

The use of IoT technology can not only achieve the goal of visualizing and digitizing pipeline integrity management, but also minimize time and space risk factors to ensure safe and smooth operation of pipelines.

Pipeline Monitoring Requirements

In pipeline monitoring applications, the following parameters typically need to be monitored:

Liquid Level Monitoring: Make sure the liquid in the pipeline is at a safe level to avoid leaks or excessive water discharge.

Temperature Monitoring: Monitoring the temperature within pipes can help prevent overheating or undercooling.

Pressure Monitoring: Maintain normal pressure within the pipeline to ensure normal operation of the system.

Leak Detection: Detect leaks promptly to avoid environmental damage and personnel safety issues.

Valve Status Monitoring: Monitor the opening or closing status of the valve to achieve remote control.

etc.

Application of Remote Monitoring Gateway S275 in Pipeline Monitoring

Data Collection and Monitoring

Remote Monitoring Gateway S275, which supports RS485 and multiple IO channels, the sensor can be easily configured to monitor various parameters of the pipeline system in real time. By connecting analog and digital sensors, the device can collect data such as level, temperature, pressure, etc. and save it in an internal database for subsequent analysis and reporting. This helps identify potential problems early and take appropriate action.

Alarms and Notifications

Remote Monitoring Gateway S275 has a powerful alarm function, and users can set alarm thresholds based on monitoring data. Once these thresholds are exceeded or dropped, the device will trigger an SMS alarm to notify relevant personnel. This real-time alert can help take quick action to reduce potential risks.

Remote Control

Maintaining the safety and reliability of your pipeline system is not just about monitoring, but also about real-time control. The relay outputs of Remote Monitoring Gateway S275 can be used to control valves, pumps and other equipment to remotely close or open them when necessary. This remote control capability helps reduce risk and improve operational efficiency.

Data Upload and Integration

Remote Monitoring Gateway S275 supports multiple communication protocols such as SMS, Modbus, MQTT, etc., and transmits data to cloud platforms, SCADA, etc. This means pipeline monitoring data can be integrated into cloud solutions, enabling remote access, data visualization and analysis. In addition, the device is also compatible with multiple public cloud platforms such as Huawei Cloud and Alibaba Cloud, as well as users' private cloud platforms.

Summarize

Remote Monitoring Gateway S275 is a powerful IoT terminal device that can be widely used in the field of pipeline monitoring. Provides comprehensive data collection, monitoring, alarm and control functions, while supporting multiple communication protocols and cloud platform integration to ensure the safety and reliability of the pipeline system. Whether it is water supply, natural gas transmission or chemical production, Remote Monitoring Gateway S275 can provide efficient solutions for pipeline monitoring.

More information about BLIIoT Remote Monitoring RTU Gateway S275: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

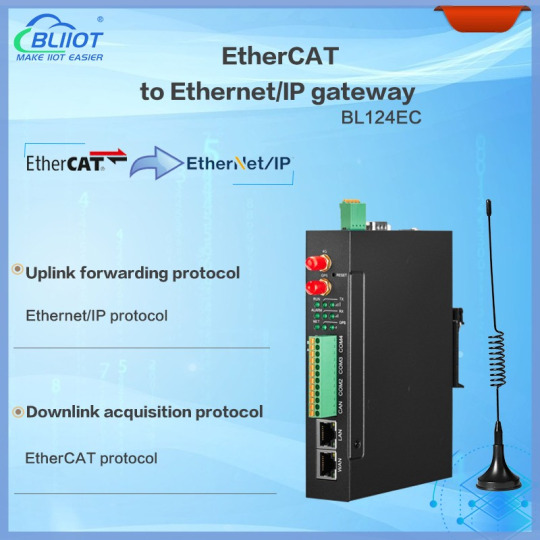

EtherCAT to EtherNet/IP IoT Gateway BL124EC

Introduction

BL124EC EtherCAT to EtherNet/IP Gateway establishes a connection between devices using the EtherCAT bus protocol and devices using the Ethernet/IP protocol. It receives data from EtherCAT devices and converts it into Ethernet/IP format for transmission. Likewise, it can receive data from Ethernet/IP devices and convert it into EtherCAT format. Therefore, BL124EC realizes interoperability and conversion between the two protocols.

The purpose of this protocol conversion gateway is to allow devices using different network protocols to work together seamlessly. It provides greater flexibility and interoperability for industrial control systems, improving the overall efficiency and performance of the production

Features

BL124EC EtherCAT to EtherNet/IP Gateway with high performance, stability and reliability, and supports fast data transmission and processing. It also has rich configuration options and flexible functions that can be customized and expanded according to actual needs. By using the BL124EC EtherCAT to Ethernet/IP gateway, industrial network communication becomes more convenient, efficient and reliable.

How to achieve EtherCAT to EtherNet/IP ?

In order to implement the conversion function, the BL124EC must be able to handle the protocol differences between EtherCAT and Ethernet/IP. Therefore, it uses advanced hardware and software mechanisms to effectively interpret and translate the differences between these two protocols

BL124EC reads data from the EtherCAT device through serial communication and packages it into data packets of the Ethernet/IP protocol. BL124EC sends the packaged Ethernet/IP data packets to the target Ethernet/IP device through the Ethernet interface.

At the same time, BL124EC can also receive data from the target Ethernet/IP device, decompress it into the correct EtherCAT message format, and then send it to the relevant device through the EtherCAT bus.

View more about IoT Gateway

#iot solutions#iot devices#datacollection#industrial automation#smartcities#EtherCAT to EtherNet/IP Gateway

0 notes

Text

Why Industrial Edge Computing is Important for Building Maximally Efficient Factories

Industrial Edge computing ensures that data can be captured, managed, analyzed, and immediate decisions can be made in real time at a standalone device, and that data that is no longer needed can be discarded at the end of the process, or portions of the data can be transferred to the cloud for storage and analysis.

The key to smart factories is data integration and real-time communication, and edge computing simplifies the process of data collection, processing, and analysis, and enables rapid and controlled decision-making, making it the key to highly automated and maximally efficient smart factories.

What are the main benefits of edge computing in industrial applications?

Improve Process Efficiency

Low latency, high bandwidth edge computing speeds up the process of downloading and analyzing data, allowing each data point to process its own information. Data is available and actionable in real-time, EdgeCOM enables real-time decision making and immediate action, and the ability to optimize data and analyze complex data sources with the "always-on" EdgeCOM integration can take the quality of industrial processes to the next level.

Data Security

The proximity of edge computing and data sources reduces data risks during transmission and ensures strong network security. The data is partially processed in EdgeCOM, not all transferred to the cloud platform through the network. Cyber attacks will not have a chance to destroy the whole network, which ensures the system's stable operation to a certain extent.

Reduce Costs

Not all data needs to be sent to the cloud. Leaving some of the data at the edge and discarding it when it is finished being processed, and transmitting only a portion of it to the cloud, can reduce the costs associated with cloud servers and data transfer functions. Edge computing can also minimize network latency and make critical control applications more connected.

Flexible Management

Supports a variety of development tools and programs for customized functions and remote maintenance, allowing for more flexible management and processing of data.

#iot devices#iot solutions#industrial automation#datasecurity#Building Maximally Efficient Factories

0 notes