#Remote Monitoring RTU Gateway

Explore tagged Tumblr posts

Text

BLIIoT Remote Monitoring RTU Gateway S275 Provides an Efficient Solution for Pipeline Monitoring

Foreword

Pipeline systems play an important role in various industries such as water supply, natural gas transportation, and chemical production. However, the safety and reliability of pipelines are crucial to ensuring the normal operation of the system.

The use of IoT technology can not only achieve the goal of visualizing and digitizing pipeline integrity management, but also minimize time and space risk factors to ensure safe and smooth operation of pipelines.

Pipeline Monitoring Requirements

In pipeline monitoring applications, the following parameters typically need to be monitored:

Liquid Level Monitoring: Make sure the liquid in the pipeline is at a safe level to avoid leaks or excessive water discharge.

Temperature Monitoring: Monitoring the temperature within pipes can help prevent overheating or undercooling.

Pressure Monitoring: Maintain normal pressure within the pipeline to ensure normal operation of the system.

Leak Detection: Detect leaks promptly to avoid environmental damage and personnel safety issues.

Valve Status Monitoring: Monitor the opening or closing status of the valve to achieve remote control.

etc.

Application of Remote Monitoring Gateway S275 in Pipeline Monitoring

Data Collection and Monitoring

Remote Monitoring Gateway S275, which supports RS485 and multiple IO channels, the sensor can be easily configured to monitor various parameters of the pipeline system in real time. By connecting analog and digital sensors, the device can collect data such as level, temperature, pressure, etc. and save it in an internal database for subsequent analysis and reporting. This helps identify potential problems early and take appropriate action.

Alarms and Notifications

Remote Monitoring Gateway S275 has a powerful alarm function, and users can set alarm thresholds based on monitoring data. Once these thresholds are exceeded or dropped, the device will trigger an SMS alarm to notify relevant personnel. This real-time alert can help take quick action to reduce potential risks.

Remote Control

Maintaining the safety and reliability of your pipeline system is not just about monitoring, but also about real-time control. The relay outputs of Remote Monitoring Gateway S275 can be used to control valves, pumps and other equipment to remotely close or open them when necessary. This remote control capability helps reduce risk and improve operational efficiency.

Data Upload and Integration

Remote Monitoring Gateway S275 supports multiple communication protocols such as SMS, Modbus, MQTT, etc., and transmits data to cloud platforms, SCADA, etc. This means pipeline monitoring data can be integrated into cloud solutions, enabling remote access, data visualization and analysis. In addition, the device is also compatible with multiple public cloud platforms such as Huawei Cloud and Alibaba Cloud, as well as users' private cloud platforms.

Summarize

Remote Monitoring Gateway S275 is a powerful IoT terminal device that can be widely used in the field of pipeline monitoring. Provides comprehensive data collection, monitoring, alarm and control functions, while supporting multiple communication protocols and cloud platform integration to ensure the safety and reliability of the pipeline system. Whether it is water supply, natural gas transmission or chemical production, Remote Monitoring Gateway S275 can provide efficient solutions for pipeline monitoring.

More information about BLIIoT Remote Monitoring RTU Gateway S275: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

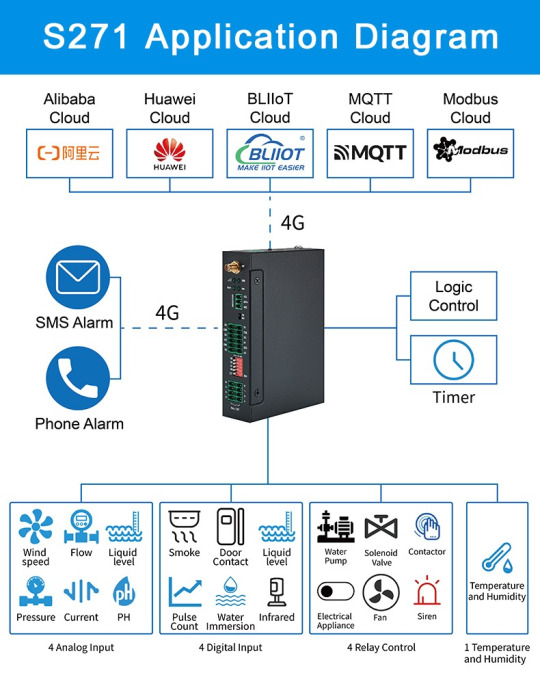

BLIIoT Water Meter Pulse Counting Gateway S271

Background

No matter where you live, water and electric meters are an absolute must. Water meters record how much water you use and how much you pay for it. Water meters help monitor data, conserve water, and lower water bills.

Pulse Counting Gateway

Pulse Counting Gateway S271 is designed to count the number of pulses from electricity meters, water meters or general meters as well as machinery and equipment with pulse outputs. Quickly and cost-effectively transform your traditional water meter into a smart water meter, monitoring data in real time.

Solution

Pulse Counting Gateway S271 can be used in different applications such as agricultural irrigation, smart building meter reading and industrial water use. The device can be connected to a pulse water meter, and then collect water use data and upload the data to the IoT cloud platform via 4G for further visualization. Users can check the status of the water meter and perform monitoring and control at any time. The pulse counter can provide remote monitoring and visual intelligent data management to achieve water conservation.

More information about Water Meter Pulse Counting Gateway S271: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

Masterbatch manufacturers in India

https://bsmasterbatch.com/masterbatch-manufacturers-in-india.php

Welcome to CMSGP, the most trusted and reputed distribution transformer monitoring manufacturer

At CMSGP, we are proud to be recognized as one of the most reliable names in Distribution Transformer Monitoring solutions. With over 20 years of proven expertise, we have become a key player in the industrial automation space. Known for our innovation and quality-driven approach, we are the preferred partner for top industries across India, delivering advanced monitoring technologies and exceptional service.

Distribution Transformer Monitoring System

Distribution Transformer Monitoring plays a critical role in enhancing grid efficiency and ensuring the long-term performance of transformers. These systems offer real-time insights into crucial metrics such as load conditions, temperature, oil levels, and overall power quality. By integrating IoT sensors with advanced data analytics, these monitoring solutions allow utilities to detect potential faults early, extend asset life, and reduce unexpected downtime. The result is a smarter, more efficient power distribution network with lower maintenance costs and increased reliability.

Our Product Portfolio

CMSGP provides an extensive array of industrial communication and monitoring solutions tailored for the energy and automation sectors. Our offerings include meter interface modems, data concentrator units, industrial 4G routers, RTUs, edge gateways, and integrated gateways. Every product is rigorously tested to meet stringent performance and safety standards. We also offer custom engineering to ensure our devices align precisely with your operational and infrastructure needs.

Delivering Quality Products

Quality is at the heart of everything we do. As a trusted provider of Distribution Transformer Monitoring systems, CMSGP is committed to excellence at every phase from design to deployment. Our manufacturing processes follow strict quality control protocols to ensure that each product delivers long-term durability and optimal performance. This dedication to superior product quality helps us eliminate inefficiencies and consistently exceed client expectations.

Constant Innovation

Innovation fuels our progress. Our commitment to continuous improvement enables us to develop Distribution Transformer Monitoring systems that set new benchmarks for reliability and performance. By minimizing downtime and enhancing the resilience of grid infrastructure, our solutions empower businesses to stay ahead in a competitive energy market. We constantly invest in R&D to provide smarter, more adaptive systems that elevate operational excellence.

State-of-the-Art Production and Scalable Operations

We utilize the latest manufacturing technologies to deliver scalable and precise Distribution Transformer Monitoring systems. Our production capabilities are built to handle both small-scale custom projects and large infrastructure deployments with ease. By blending automation with accuracy, we ensure product reliability and high throughput. Our scalable operations support esteemed clients like Honeywell, JSW, L&T, BHEL, ABB, KPTCL, and Crompton Greaves.

Bespoke Monitoring and Automation Solutions

Leveraging years of domain experience, CMSGP designs customized Distribution Transformer Monitoring and automation systems tailored to client-specific goals. Our solutions integrate IoT sensors, real-time analytics, and remote-control functions to provide end-to-end grid visibility and control. Whether it’s fault detection, power quality analysis, or remote asset management, we deliver adaptable systems that enhance operational performance while maintaining compliance with industry standards.

Strong Supply Network

Our reliable supply chain infrastructure ensures seamless product delivery and implementation. We maintain strong relationships with our suppliers and partners to source premium components that meet the requirements of advanced Distribution Transformer Monitoring applications. With streamlined logistics and efficient inventory control, we’re able to deliver solutions quickly, reduce lead times, and keep projects on track year-round.

Our Commitment

CMSGP’s leadership in Distribution Transformer Monitoring is driven by our customer-centric philosophy. We believe in building lasting relationships through transparency, innovation, and excellence. Our goal is to create collaborative, sustainable solutions that drive value for all stakeholders and support the long-term growth of the power sector.

Applications

Remote telemetry systems

Security and surveillance integration

CNC machinery monitoring

Smart lighting management

Support for legacy serial interface printers

Address: No. 300-B, 5th Main, 4th Phase, Peenya Industrial Area, Bangalore, Karnataka 560058.

Call: +91-98450-49177 or Email: [email protected]

#Top Masterbatches Manufacturers#India's largest masterbatch manufacturer#White masterbatch manufacturers#Masterbatch Exporters

0 notes

Text

RS485/RJ45 Modbus RTU to Ethernet/IP protocol Converter for Remote Monitoring Application

BL124 Modbus to Ethernet/IP gateway is a device that enables communication between Modbus devices and Ethernet/IP networks. The Modbus to Ethernet/IP gateway serves as a bridge between devices that use the Modbus protocol and devices that use the Ethernet/IP protocol. This allows for seamless communication and data exchange between different parts of an industrial system that may use different protocols.

0 notes

Text

Improving Industrial Communication: Modbus Gateways' Function

In the field of industrial automation, it is critical that different systems and equipment communicate with each other seamlessly. Developed in 1979, the Modbus protocol is still a mainstay of industrial communication. But as technology advances, it can become more difficult to integrate Modbus devices with contemporary systems. Modbus gateways can help bridge the gap between outdated and modern communication protocols in this situation.

What is a Modbus Gateway?

A Modbus gateway is a hardware component that facilitates protocol-based communication between Modbus devices and networks. It facilitates seamless communication between devices on various networks by translating Modbus RTU/ASCII messages to Modbus TCP/IP and vice versa. When combining older Modbus equipment with modern systems that employ Ethernet or other communication protocols, this translation capability is crucial.

Important attributes and advantages

Protocol Conversion: A Modbus gateway's main job is to convert protocols so that different devices work together. This eliminates the need for significant hardware modifications and enables current Modbus devices to communicate over contemporary networks.

Network Integration: Gateways make it possible to integrate Modbus devices into bigger, more intricate industrial networks by enabling communication between Modbus RTU/ASCII and Modbus TCP/IP. For centralized monitoring and control, this integration is essential.

Enhanced Data Access: By enabling remote access to Modbus devices, Modbus gateways increase data accessibility. This functionality is especially useful for centrally monitoring and managing devices spread across multiple locations.

Scalability: Modbus gateways provide a scalable option to integrate more devices and increase network capabilities without completely rebuilding the infrastructure as industrial systems evolve.

Cost-Effectiveness: Modbus gateways offer a reasonably priced way to update outdated systems. Businesses can utilize gateways to increase the functionality and lifespan of their Modbus devices rather than replacing them.

Applications in Industry

Industrial Automation: Modbus gateways facilitate smooth communication between human-machine interfaces (HMIs), programmable logic controllers (PLCs), and other devices in industrial plants. Efficient process control and automation are ensured by this integration.

Building Management Systems (BMS): Modbus gateways connect HVAC, lighting, security, and other systems, and are essential to BMS functionality. Building management and energy efficiency are enhanced by the centralized control and monitoring made possible by this link.

Energy Management: Modbus gateways make it easier for different sensors and meters to provide data to energy management systems. For the purpose of tracking energy use, maximizing efficiency, and putting energy-saving measures into practice, this data is essential.

Water and Wastewater Management: To connect various sensors, pumps, and control systems, water treatment facilities employ Modbus gateways. The real-time monitoring and management of water quality and treatment procedures is facilitated by this integration.

Selecting the Appropriate Modbus Gateway

There are a few things to take into account while choosing a Modbus gateway:

Make sure the gateway is compatible with the particular Modbus versions and communication protocols that are in use on your network.

Performance: Take into account the gateway's data throughput and processing power to ensure that it meets the needs of your system.

Reliability: Seek out industrial-grade gateways with steady performance under challenging conditions.

Ease of Use: Select a gateway with strong technical support and easily configurable tools.

In summary In today's industrial environments, Modbus gateways are essential because they serve as a bridge connecting vintage Modbus devices to newer communication networks. Through the provision of smooth protocol translation and network integration, these gateways guarantee that enterprises may embrace new technologies and still make full use of their current infrastructure. Modbus gateways increase connectivity, boost productivity, and stimulate innovation in a variety of applications, including energy systems, building management, and industrial automation. The significance of dependable and adaptable communication solutions, such as Modbus gateways, will only increase with industry evolution, solidifying their place in the future of industrial networking.

0 notes

Text

𝐌𝐚𝐱𝐢𝐦𝐢𝐳𝐞 𝐆𝐫𝐢𝐝 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲: 𝐆𝐞𝐭 𝐓𝐡𝐞 𝐁𝐞𝐬𝐭 𝐑𝐞𝐭𝐫𝐨𝐟𝐢𝐭𝐭𝐢𝐧𝐠 𝐒𝐜𝐚𝐝𝐚/𝐑𝐓𝐔/𝐆𝐚𝐭𝐞𝐰𝐚𝐲 & 𝐄𝐧𝐞𝐫𝐠𝐲 𝐌𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭 & 𝐋𝐨𝐚𝐝 𝐒𝐡𝐞𝐝𝐝𝐢𝐧𝐠 𝐒𝐞𝐫𝐯𝐢𝐜𝐞𝐬 𝐅𝐨𝐫 𝐘𝐨𝐮𝐫 𝐒𝐲𝐬𝐭𝐞𝐦

In today's rapidly evolving energy landscape, optimizing grid efficiency is paramount. Industries, municipalities, and businesses are seeking innovative solutions to streamline operations, reduce costs, and ensure reliable energy supply. Retrofitting SCADA/RTU/Gateway systems and implementing comprehensive Energy Management & Load Shedding Services have emerged as key strategies to achieve these goals. In this blog, we delve into the benefits and importance of these solutions for maximizing grid efficiency.

We provide Retrofitting Scada/ Rtu/Gateway solutions, an industry-leading collection of substation controllers and switches that may be used for a range of automation, control, monitoring, and control activities.

We provide comprehensive electrical and automation solutions for the oil and gas industry, as well as other manufacturing sectors like cement and metal, infrastructure, and utilities like power and water. Our expertise spans more than 40 years in a variety of industries, and our capabilities have been demonstrated throughout the whole value chain, including proposals, design, engineering, project planning, integration, software development, integrated testing / FAT, commissioning / SAT, and after-sales service.

Retrofitting SCADA/RTU/Gateway Systems

Enhancing Data Collection and Analysis:

Retrofitting your SCADA/RTU/Gateway infrastructure equips your system with advanced data collection and analysis capabilities. Real-time monitoring, data visualization, and remote control empower operators to make informed decisions promptly. This enables swift response to fluctuations and emergencies, thereby minimizing downtime and optimizing system performance.

Seamless Integration:

Upgrading your existing SCADA/RTU/Gateway systems ensures compatibility with modern technologies and communication protocols. This streamlined integration enhances data exchange between various components, leading to improved data accuracy, reduced communication errors, and increased system reliability.

Predictive Maintenance:

Retrofitting allows for predictive maintenance implementation. By monitoring equipment health and performance metrics in real-time, you can schedule maintenance activities proactively, reducing unplanned outages and prolonging the lifespan of critical components.

Energy Management & Load Shedding Services

Efficient Resource Allocation:

Energy Management solutions enable you to monitor energy consumption patterns across your operations. This insight allows for strategic resource allocation and demand response, minimizing peak demand charges and optimizing energy usage during off-peak hours.

Cost Savings:

Implementing Load Shedding Services helps you curtail energy demand during peak periods, mitigating the risk of overloading and grid instability. This not only avoids costly penalties but also reduces overall energy expenses by optimizing load distribution.

Resilience and Reliability:

Energy Management & Load Shedding Services bolster the resilience and reliability of your system. During grid disturbances or emergencies, load shedding ensures essential equipment remains operational, preventing cascading failures and accelerating recovery times.

SCADA and Energy Management Solution

Experience a cost-effective SCADA and Energy Management Solution package that empowers you to effortlessly monitor and control your operations.

Embrace our intelligent and cutting-edge system that offers a holistic solution for energy monitoring and management within industrial plants, complemented by robust control and automation functionalities.

Integrated SCADA with energy management system along with meters, RTU, Data concentrator, software and Data converters supply

Present real-time parameters alongside energy data in a seamless display.

Showcase trends, alarms, as well as minimum, maximum, and average values.

Opportunities for seamless integration with air conditioning, water, and gas meters.

Conclusion:

In a world increasingly reliant on efficient energy systems, the significance of Retrofitting SCADA/RTU/Gateway systems and implementing Energy Management & Load Shedding Services cannot be overstated. These solutions empower you to navigate the challenges of a dynamic energy landscape, ensuring optimal performance, cost savings, and environmental sustainability.

By embracing these technologies, you're not only maximizing grid efficiency but also positioning your organization at the forefront of a more reliable, responsive, and resilient energy future. Reach out to us today to explore how Retrofitting SCADA/RTU/Gateway systems and Energy Management & Load Shedding Services can revolutionize your energy infrastructure and drive your operations towards a brighter, more efficient tomorrow.

Reliserv Solution offers comprehensive and reliable solutions for Retrofitting Scada/Rtu/Gateway Energy management, and load shedding. Our portfolio includes top-tier Retrofitting SCADA/RTU/Gateway solutions. This suite comprises advanced substation controllers and switches designed to cater to a wide range of functions and applications such as substation control, communication, monitoring, protection, and automation. To know more about Retrofitting Scada/Rtu/Gateway Energy management, and load shedding Click Here

#scada#rtu#gateway#energymanagement#retrofitting#solutions#substation#electricalengineering#energysavings#industrialautomation#smartenergy

0 notes

Link

Applied Systems Engineering (ASE) is one of the pioneers in the industry that is dedicated to the development of Remote Terminal Unit (RTU)/Intelligent Electronic Device (IED) protocol test equipment for the Supervisory Control And Data Acquisition (SCADA) industry.

ASE aiding global transformation by providing innovative products like communication protocols translators, Gateway software, front-end processors, substation alarm annunciators, terminal servers, protocol converter, modems, and source code libraries.

These products are very effective in substation automation, distribution automation, advanced grid metering, wide-area monitoring, Power Plant Optimization, and energy IoT management.

1 note

·

View note

Text

BL103UA Energy monitoring BACnet to MQTT 2RJ45 Industrial IoT gateway

BACnet gateway BL103 is a cost-effective industrial IoT Gateway, for building automation and HVAC control systems, which is used to convert BACnet MS/TP to BACnet/IP, Modbus to BACnet/IP, BACnet to MQTT, BACnet to OPC UA protocol.

BACnet gateway BL103 adopts embedded ARM MCU, based on Linux OS, equipped with 1WAN/LAN, 1LAN, 1 RS485, 4G module optional.

BACnet gateway BL103 has powerful protocol conversion function, which can realize simultaneous acquisition of multiple protocols, including: BACnet MS/TP, BACnet/IP, Modbus RTU, Modbus TCP, DLT645. Upstream supports BACnet/IP, Modbus TCP, MQTT, OPC UA It has built-in cloud drivers such as Huawei Cloud, Alibaba Cloud, KPIIOT, Amazon Cloud, Thingsboard Cloud, and Sparkplug B, which can be directly connected to various mainstream cloud platforms.

BACnet gateway BL103 supports OPENVPN network security protection protocol, is compatible with TLS SSL X.509 root certificate and other data encryption technologies to ensure data security.

Moreover, BACnet Gateway BL103 adopts the unique data integrity technology of breakpoint data supplementary transmission.

BACnet gateway BL103 integrates the user-friendly configuration interface, as well as functions such as remote configuration and remote firmware upgrade;

The BACnet gateway BL103 adopts a fastened structure, redundant power supply design, and can be installed on a standard DIN35 rail.

0 notes

Text

MODBUS REMOTE IO MODULE

MODBUS REMOTE IO MODULE is Modbus RTU Remote IO Module to help PLC/SCADA/BMS and any IoTs gateway extend the number of I/O capabilities. STHM-MBIO has a simple but powerful design with 4 AI/DI, 4 DI, 4 Relay, 1 Pulse PWM output, 1 RS485 Master ModbusRTU and 2 RS485 Slave ModbusRTU allow them to connect to more devices such as sensors, meters, … directly and easily.

The module with advanced technology provide high stability and reliability, multiple functions and easy installation with DIN rail design. The module can be used in many applications such as machine monitoring, manufacture monitoring, environmental monitoring, smart farms, etc.

Modbus Protocol

Easily integrate to PLC/SCADA/BMS system via standard Modbus Protocol

Multiple I/O

Multiple I/O like Digital, Analog, Relay, Pulse in one Single Device

Easy Config

Easy configuration by Modbus master software on PC

DIN rail

DIN rail design for easy mounting

Daviteq Technologies Inc

1 note

·

View note

Text

BLIIoT Water Meter Pulse Counting Gateway S271

Background

No matter where you live, water and electric meters are an absolute must. Water meters record how much water you use and how much you pay for it. Water meters help monitor data, conserve water, and lower water bills.

Pulse Counting Gateway

Pulse Counting Gateway S271 is designed to count the number of pulses from electricity meters, water meters or general meters as well as machinery and equipment with pulse outputs. Quickly and cost-effectively transform your traditional water meter into a smart water meter, monitoring data in real time.

Solution

Pulse Counting Gateway S271 can be used in different applications such as agricultural irrigation, smart building meter reading and industrial water use. The device can be connected to a pulse water meter, and then collect water use data and upload the data to the IoT cloud platform via 4G for further visualization. Users can check the status of the water meter and perform monitoring and control at any time. The pulse counter can provide remote monitoring and visual intelligent data management to achieve water conservation.

More information about Water Meter Pulse Counting Gateway S271: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

BLIIoT Remote Monitoring RTU Gateway S275 is used in Oil Tank Monitoring

Introduction

Oil tank monitoring is an important task, involving many aspects such as liquid level monitoring, temperature monitoring, leak detection, remote control, etc. These challenges require reliable monitoring equipment to ensure storage tanks are safe, compliant and efficient. Level, temperature and leakage monitoring are critical in tank management

Application of RTU Gateway S275 in Oil Tank Monitoring

The RTU Gateway S275 has a wide range of application potential in oil tank monitoring and control. It can connect to various monitoring devices, including liquid level sensors, temperature sensors and liquid level switches, and collect liquid level data, temperature data, liquid level switch status and alarm information in real time. This data can be transmitted via a variety of communication protocols, ensuring the feasibility of remote monitoring. At the same time, RTU S275 supports remote control, such as controlling equipment such as valves and pumps, to ensure the stable and safe operation of the oil tank.

In addition, RTU S275 can store and connect data to cloud platforms. Whether it is connected to public cloud platforms (such as Huawei Cloud, Alibaba Cloud) or users' own private cloud platforms, it can realize real-time transmission and backup of data. Data analysis and visualization are also realized, helping users better understand oil tank monitoring data by displaying data charts, trend analysis and exception reports.

Advantages of RTU Gateway S275

1. Data Collection and Analysis

RTU Gateway S275 can monitor the liquid level and temperature of oil tanks in real time, record the data, conduct historical data analysis, and provide visual reports so that operators can better understand the status of the oil tanks.

2. Alarm and Notification System

RTU Gateway S275 can set thresholds for liquid level, temperature and leakage parameters. Once the parameters exceed the limits, the operating personnel will be notified through multiple notification channels (SMS, phone, email) so that they can take timely measures.

3. Remote Access and Control

Through SMS, mobile phones, computers and other devices, operators can remotely access monitoring data at any time, and can even remotely control and adjust the tank liquid level and temperature, or deal with leaks.

4. Data Recording and Reporting

The system can record historical data and generate reports and trend analysis to help operators develop more effective management strategies.

The application of RTU Gateway S275 lies in its ability to solve challenges in the field of monitoring and control. By using RTU S275, tank managers can achieve remote monitoring, instant alarm, reduce manual intervention, improve safety and compliance, reduce operating costs, and ensure effective utilization of resources.

Summarize

BLIIoT Remote Monitoring RTU Gateway S275 provides an efficient and reliable solution for oil tank monitoring and control. By making full use of its multi-functional features, tank managers can achieve remote monitoring and intelligent control, improve safety and compliance, reduce costs, and ensure the efficiency and reliability of tank operations.

More information about BLIIoT Remote Monitoring RTU Gateway S275: https://www.bliiot.com/m2m-rtu-p00174p1.html

#Oil Tank Monitoring#IoT#IoT Solution#Remote Monitoring#Remote Control#mqtt#modbus#sms#4G#alarm controller#rtu#gateway#sms alarm#huawei cloud#bliiot

0 notes

Text

Distribution Transformer Monitoring

https://www.cmsgp.com/distribution-transformer-monitoring.php

Welcome to CMSGP, the most trusted and reputed distribution transformer monitoring manufacturer

At CMSGP, we are proud to be recognized as one of the most reliable names in Distribution Transformer Monitoring solutions. With over 20 years of proven expertise, we have become a key player in the industrial automation space. Known for our innovation and quality-driven approach, we are the preferred partner for top industries across India, delivering advanced monitoring technologies and exceptional service.

Distribution Transformer Monitoring System

Distribution Transformer Monitoring plays a critical role in enhancing grid efficiency and ensuring the long-term performance of transformers. These systems offer real-time insights into crucial metrics such as load conditions, temperature, oil levels, and overall power quality. By integrating IoT sensors with advanced data analytics, these monitoring solutions allow utilities to detect potential faults early, extend asset life, and reduce unexpected downtime. The result is a smarter, more efficient power distribution network with lower maintenance costs and increased reliability.

Our Product Portfolio

CMSGP provides an extensive array of industrial communication and monitoring solutions tailored for the energy and automation sectors. Our offerings include meter interface modems, data concentrator units, industrial 4G routers, RTUs, edge gateways, and integrated gateways. Every product is rigorously tested to meet stringent performance and safety standards. We also offer custom engineering to ensure our devices align precisely with your operational and infrastructure needs.

Delivering Quality Products

Quality is at the heart of everything we do. As a trusted provider of Distribution Transformer Monitoring systems, CMSGP is committed to excellence at every phase from design to deployment. Our manufacturing processes follow strict quality control protocols to ensure that each product delivers long-term durability and optimal performance. This dedication to superior product quality helps us eliminate inefficiencies and consistently exceed client expectations.

Constant Innovation

Innovation fuels our progress. Our commitment to continuous improvement enables us to develop Distribution Transformer Monitoring systems that set new benchmarks for reliability and performance. By minimizing downtime and enhancing the resilience of grid infrastructure, our solutions empower businesses to stay ahead in a competitive energy market. We constantly invest in R&D to provide smarter, more adaptive systems that elevate operational excellence.

State-of-the-Art Production and Scalable Operations

We utilize the latest manufacturing technologies to deliver scalable and precise Distribution Transformer Monitoring systems. Our production capabilities are built to handle both small-scale custom projects and large infrastructure deployments with ease. By blending automation with accuracy, we ensure product reliability and high throughput. Our scalable operations support esteemed clients like Honeywell, JSW, L&T, BHEL, ABB, KPTCL, and Crompton Greaves.

Bespoke Monitoring and Automation Solutions

Leveraging years of domain experience, CMSGP designs customized Distribution Transformer Monitoring and automation systems tailored to client-specific goals. Our solutions integrate IoT sensors, real-time analytics, and remote-control functions to provide end-to-end grid visibility and control. Whether it’s fault detection, power quality analysis, or remote asset management, we deliver adaptable systems that enhance operational performance while maintaining compliance with industry standards.

Strong Supply Network

Our reliable supply chain infrastructure ensures seamless product delivery and implementation. We maintain strong relationships with our suppliers and partners to source premium components that meet the requirements of advanced Distribution Transformer Monitoring applications. With streamlined logistics and efficient inventory control, we’re able to deliver solutions quickly, reduce lead times, and keep projects on track year-round.

Our Commitment

CMSGP’s leadership in Distribution Transformer Monitoring is driven by our customer-centric philosophy. We believe in building lasting relationships through transparency, innovation, and excellence. Our goal is to create collaborative, sustainable solutions that drive value for all stakeholders and support the long-term growth of the power sector.

Applications

Remote telemetry systems

Security and surveillance integration

CNC machinery monitoring

Smart lighting management

Support for legacy serial interface printers

Address: No. 300-B, 5th Main, 4th Phase, Peenya Industrial Area, Bangalore, Karnataka 560058.

Call: +91-98450-49177 or Email: [email protected]

#Industrial IoT Gateway Devices#IoT Platform Providers in India#Meter Data Acquisition System#Integration of IoT with Cloud computing

0 notes

Text

Modbus RTU to MQTT Modbus TCP RTU AWS IoT 4G RS485 DTU SMS Alarm Gateway for Electric Power Control

IoT gateway BL100 is a Modbus to MQTT gateway that converts Modbus RTU to MQTT protocol. BL100 is a Modbus to MQTT gateway based on cellular network. It supports Modbus RTU, MQTT Protocols. The Modbus Gateway supports Modbus Slave and Modbus RTU Master with up to 48 Modbus Slave devices for data acquisition. BL100 Modbus gateway support remote monitoring, configuration, inquiry and control with SMS. Built-in timer function to perform scheduled automatic data reporting, SMS, Arm/Disarm and device restarting. The Modbus to MQTT gateway supports Alibaba Cloud, HUAWEI Cloud, BLIIoT Cloud, custom platform, and transparent data transmission, data retransmission. Users can connect it to third-party server, cloud platform and SCADA easily.

0 notes

Text

Unlocking Seamless Data Communication with Modbus Gateway

In the realm of industrial automation, efficiency and reliability are paramount. Imagine a manufacturing plant where various devices and systems need to communicate seamlessly to ensure smooth operations. This is where Modbus gateway steps in as a crucial component, serving as the bridge between different protocols and facilitating efficient data exchange.

What exactly is a Modbus gateway, and why is it so integral to modern industrial processes?

At its core, Modbus is a communication protocol widely used in industrial automation for connecting electronic devices. It allows for the transmission of data between devices over serial lines or Ethernet networks. However, the challenge arises when different devices speak different languages, so to speak, in terms of communication protocols. This is where the Modbus gateway shines.

A Modbus gateway acts as a translator, facilitating communication between devices that use different protocols. Whether it's Modbus RTU, Modbus ASCII, or Modbus TCP/IP, the gateway ensures seamless interoperability, enabling devices from various manufacturers to communicate effectively.

One of the key benefits of using a Modbus gateway is its versatility. It supports a wide range of industrial protocols beyond Modbus, including Profibus, Profinet, EtherNet/IP, and more. This flexibility makes it an ideal solution for integrating legacy systems with modern infrastructure or connecting disparate devices within a network.

Moreover, the Modbus gateway enhances the scalability of industrial automation systems. As businesses grow and evolve, they often need to integrate new devices or expand their existing infrastructure. With a Modbus gateway in place, this process becomes streamlined, as it allows for the seamless integration of new devices without the need for extensive reconfiguration.

Another crucial aspect of Modbus gateways is their role in enhancing data security. In today's interconnected world, cyber threats pose a significant risk to industrial systems. By acting as a secure intermediary between devices, the gateway helps protect sensitive data and prevents unauthorized access to critical systems.

Furthermore, Modbus gateways contribute to improved operational efficiency by providing real-time monitoring and control capabilities. Operators can remotely access and manage connected devices, troubleshoot issues, and optimize performance without the need for physical intervention. This remote accessibility not only saves time and resources but also minimizes downtime and maximizes productivity.

In addition to its technical capabilities, the Modbus gateway offers cost-effective solutions for industrial automation. By enabling the integration of diverse devices and protocols, businesses can avoid the need for costly hardware upgrades or system overhauls. This cost-effectiveness makes Modbus gateways an attractive option for businesses looking to optimize their automation infrastructure without breaking the bank.

In conclusion, Modbus gateways play a crucial role in modern industrial automation by facilitating seamless data communication between devices and systems. Their versatility, scalability, security features, and cost-effectiveness make them indispensable tools for businesses looking to enhance efficiency and productivity in their operations. As industries continue to evolve, the demand for robust and reliable communication solutions like Modbus gateways is only set to grow.

0 notes

Text

Digital Oilfield Technology Proving Effective in Reducing Cost of Oil Production

The need of oil companies to reduction the production cost and increasing participation of software firms is driving the growth of the digital oilfield technology market across the globe. Already generating $26,570.4 million revenue in 2017, the market is expected to advance at a CAGR of 4.6% during 2018–2023 (forecast period), ultimately growing to $34,871.6 million by 2023. Digital oilfield technology refers to the software and hardware used to optimize the production of oil in order to reduce production costs and generate the maximum revenue.

On segmenting by process, the digital oilfield technology market can be categorized into reservoir optimization, drilling optimization, production optimization, and others. Among these, the production optimization category held the largest revenue share (over 35.0%) in 2017, as it helps companies identify underperforming wells or assets and come up with a solution. In Europe, the number of mature oilfields, where the production has peaked and started declining, is increasing. This is resulting in a growing demand for digital technology for production optimization, which is why this category is predicted to grow with a CAGR of 4.8%.

Further, the device segment of the digital oilfield technology market has gateway and remote terminal unit (RTU) as its two subdivisions. Of the two, the RTU subdivision led the market in 2017 with over 50.0% revenue share, due to the growing adoption of such systems to monitor various parameters of an oilfield and collating and storing the data at a central location. The growing number of oilfields being digitized is one of the major reasons for the present and expected future market dominance of RTUs.

However, the gateway subdivision of the digital oilfield technology market is predicted to advance faster, at 4.7% CAGR during the forecast period, as gateways are instrumental in transmitting the data collected by RTUs to the IT network of the oil company. Therefore, with the increasing need to make data sharing and analysis easier and faster, gateways will be adopted more in the future compared to RTUs. Now, the market can also be segmented on the basis of services, wherein IT expenditure, and instrumentation and automation would be the two resulting categories.

Of these, the instrumentation and automation dominated the digital oilfield technology market in 2017 with more than 50.0% revenue share and is also predicted to advance faster during the forecast period at a CAGR of 4.7%. Its dominance is majorly buoyed by a growing demand for digital oilfield technology automation and by reduction in human capital. Further, the growing need for safeguarding, real-time monitoring, and analyzing the data is also playing a significant role in this regard.

Across the globe, oil companies are increasingly digitizing their oilfields to achieve optimum production and operation cost reduction. The digital technology in oilfield helps make drilling and transportation efficient and the production process transparent, thereby leading to decreased operational costs. Another reason for the growth of the digital oilfield technology market is the increasing volume of data and the need to analyze it. This why, software companies, including Microsoft, IBM, SAS, Progress, and EMC Corporation, are increasingly foraying into the field of big data analytics for oilfields.

Hence, we see that the market will continue to progress during the forecast period owing to the increasing cost reduction steps taken by oil firms.

#Digital Oilfield Technology Market#Digital Oilfield Technology Market share#Digital Oilfield Technology Market size#Digital Oilfield Technology Market growth#Digital Oilfield Technology Market overview#Digital Oilfield Technology Market outlook#Global Digital Oilfield Technology Market#Market share#Market Growth#Industry Size#Future of Digital Oilfield Technology Market#Digital Oilfield Technology Market future

0 notes

Text

Features of USR-N668

USR-N668 is an 8-serial-port serial to ethernet converter which produced by USRIOT.

This article is to introduce the features of USR-N668:

Two 10/100Mbps Ethernet port, support Auto MDI/MDIX.

8 serial ports all support RS232/RS485/RS422.

Support Static IP or DHCP.

TCP Server, TCP Client, UDP Clie nt, UDP Server, HTTPD Client .

8 serial ports all support two sockets ,and all can send data to two different servers when work as Client.

It works as TCP client, supports to 16(max) TCP Client.

Keep alive & Registration package

Modbus TCP to Modbus RTU.

U ser defined overtime Reload (no data reload)and overtime connection.

The modifiable , one and only MAC.

DNS domain name resolution ,user defined DNS server address.

R emote monitoring and remote firmware upgrading.

Network time synchronization +RTC real ti me clock.

U ser defined Task Scheduler.

Support s web server configuration.

Support s V COM.

Reload by h ardware and software.

R un across gateways, switches and routers.

Work in LAN or external network.

Related Products

8 serial ports Ethernet Converter Server | 8 Ports RS232/RS485/RS422 Serial to Ethernet Converters

USR-N668

0 notes