Don't wanna be here? Send us removal request.

Text

Odour Control in Fish and Shrimp Feed Manufacturing: Strategies for a Cleaner Production Process

Introduction

The fish and shrimp feed manufacturing industry plays a vital role in aquaculture, providing essential nutrition for farmed species. However, one of the major challenges faced by feed producers is odour emissions during processing. Strong, unpleasant odours can arise from raw materials like fishmeal, fish oil, and other protein-rich ingredients, leading to environmental concerns and potential regulatory issues.

Effective odour control is crucial not only for maintaining a healthy work environment but also for ensuring compliance with environmental regulations and fostering good community relations. In this blog, we will explore the sources of odour in fish and shrimp feed production and discuss practical strategies to mitigate them

Common Sources of Odour in Fish and Shrimp Feed Manufacturing

1. Raw Materials

Fish Meal: Made from whole fish or fish byproducts; has a strong, pungent odour due to the presence of volatile nitrogen compounds like trimethylamine.

Shrimp Shell meal: Often contains chitin, protein residues, and fats that decompose quickly and emit foul smells.

Other Marine Ingredients: Algae, krill, squid, and crustacean byproducts all contribute to the distinctive odour due to high protein and oil content.

Animal Fats and Oils: These can oxidize and emit rancid smells.

2. Processing Stages

Grinding and Mixing: Releases dust and odorous particles from protein-rich materials.

Cooking/Extrusion: High temperatures volatilize amines, sulfur compounds, and fatty acids, leading to a cooked or burnt protein smell.

Drying: Moisture evaporation carries volatile organic compounds (VOCs) into the air, intensifying odour.

Cooling and Packaging: Residual heat and exposed feed particles can continue to release odours if not quickly cooled or sealed.

3. Storage and Waste Handling

Spoiled Raw Materials: Decomposition of ingredients in storage can produce ammonia, hydrogen sulfide, and VOCs.

Wastewater and Solid Waste: Effluents from wash water and organic solids (like sludge or leftover ingredients) decay and emit unpleasant odours.

4. Microbial Activity

Bacteria and fungi acting on proteins and fats in raw materials and waste streams produce odorous compounds such as:

Ammonia

Hydrogen sulfide

Volatile fatty acids

Putrescine and cadaverine (from protein decay)

Environmental and Community Impact of Odour in Fish and Shrimp Feed Manufacturing

Odour emissions from fish and shrimp feed manufacturing plants are a significant environmental concern affecting air quality and local communities. These odours, mainly caused by volatile organic compounds (VOCs) and nitrogenous compounds released during processing, contribute to air pollution and can lead to frequent community complaints. Persistent and strong odours from aquafeed production can also negatively impact local biodiversity by disturbing nearby ecosystems and sensitive wildlife.

Effective odour control in fish feed manufacturing not only reduces these environmental impacts but also helps improve relations with surrounding communities. By managing odour emissions proactively, feed manufacturers can prevent complaints, avoid costly fines, and reduce the risk of legal action. Strong odour management practices enhance a company’s reputation and demonstrate a commitment to sustainable and responsible aquaculture production.

Regulatory Framework and Compliance for Aquafeed Odour Control

The fish and shrimp feed manufacturing industry must comply with strict environmental regulations related to odour emissions and air pollution control. In India, agencies like the Central Pollution Control Board (CPCB) enforce standards for odour limits and air quality that feed producers must meet. Globally, regulations from bodies such as the United States Environmental Protection Agency (EPA) and the European Union (EU) provide guidelines for industrial odour control and emissions management in aquafeed production.

Compliance with these odour regulations is essential for legal operation and plays a vital role in corporate social responsibility (CSR) and sustainability reporting. Meeting regulatory requirements helps aquafeed manufacturers avoid penalties, ensures operational continuity, and supports environmental stewardship goals. Integrating advanced odour control technologies and following regulatory frameworks enable companies to reduce volatile organic compounds (VOCs) and improve air quality, fostering sustainable fish and shrimp feed production.

Proven Odour Control Strategies in Aquafeed Production

To address these challenges, manufacturers can adopt the following strategies:

1. Optimize Raw Material Handling

Proper Storage: Store fish meal and oil in sealed, temperature-controlled environments to minimize oxidation and VOC release.

Quality Control: Use fresh, high-quality raw materials to reduce the presence of odorous compounds.

Inventory Management: Implement first-in, first-out (FIFO) systems to prevent spoilage.

2. Install Odour Control Systems

Biofilters: These use microorganisms to break down odourous compounds. They are cost-effective and environmentally friendly for treating exhaust air from processing areas.

Scrubbers: Wet scrubbers can neutralize odours by passing exhaust gases through a liquid solution, capturing VOCs and amines.

Thermal Oxidizers: For high-odour loads, thermal oxidizers burn off volatile compounds, converting them into less harmful substances like carbon dioxide and water.

3. Enhance Processing Techniques

Low-Temperature Processing: Use lower temperatures during drying and extrusion to reduce the release of volatile compounds.

Enclosed Systems: Design processing equipment with enclosed systems to contain odours and direct them to treatment units.

Ventilation: Install high-efficiency ventilation systems to capture and treat odourous air before release.

4. Waste Management

Effluent Treatment: Treat wastewater and processing byproducts promptly to prevent odor generation. Anaerobic digesters can convert waste into biogas, reducing odour and generating energy.

Regular Cleaning: Clean equipment and storage areas regularly to prevent residue buildup, which can contribute to odours.

5. Monitor and Maintain

Odour Monitoring: Use sensors to detect and measure odour levels in real-time, allowing for quick adjustments to control systems. Electronic noses and gas sensors such as Odosnese of Oizom provide continuous monitoring, enabling rapid response to odour spikes.

Maintenance of Equipment: Regularly maintain odour control systems like biofilters and scrubbers to ensure optimal performance.

Case Study: How Elixir Enviro Systems Helped a Shrimp Feed Plant Achieve 4 OU/m3 at outlet

A leading shrimp feed manufacturer with a production capacity of 400 tons per day was facing persistent and intense odour emissions at its facility. The primary raw materials—fishmeal, fish oil, soybean meal, vitamins, and minerals—generated strong, fishy odours, particularly during cooking, drying, and cooling phases. Additional odour sources included the grinder unit and material conveying systems.

The company approached Elixir Enviro Systems Pvt. Ltd. for an end-to-end odour control solution. After a detailed site audit and airflow assessment, Elixir designed and installed a high-performance odour abatement system consisting of:

Dust scrubbers to remove particulates and pre-condition the exhaust air

Two high-rate Ultrafil biofilters in parallel to biologically treat odourous compounds like trimethylamine, diamines, and ammonia

A blower system rated at 75,000 CMH, equipped with a Variable Frequency Drive (VFD) for optimal flow control

The system was engineered to handle a process airflow of 75,000 CMH, blending hot air from the dryer and directing it efficiently into the biofilters. Performance testing revealed a remarkable odour removal efficiency with final odour concentration at the outlet measuring just 4 OU/m3 (Odour Units), when tested using field olfactometry—well below industry standards

💡 Outcomes:

✅ Extremly high odour reduction, ensuring environmental compliance

✅ Drastic improvement in workplace air quality

✅ Fewer complaints from neighbouring communities

✅ Enhanced brand reputation and community relations

✅ System designed for scalability and long-term operational efficiency

This successful implementation not only eliminated odour-related complaints but also helped the client align with environmental norms, boosting their sustainability credentials.

Elixir Enviro Systems – Experts in Aquafeed Odour Control

If you’re seeking reliable odour control solutions for fish and shrimp feed manufacturing, Elixir Enviro Systems is your trusted partner. We specialize in industrial odour treatment, wastewater management, and biofiltration systems for factories and processing plants.

With years of experience, Elixir offers complete turnkey solutions—from design and installation to testing and long-term maintenance. Whether your facility requires wet scrubbers, biofilters, regenerative thermal oxidizers (RTOs), or real-time odour monitoring systems, Elixir has you covered.

Why Choose Elixir Enviro?

✅ Pioneer in Industrial Odour Control in India

✅ Largest player in India, treating about 1 Million cubic meters of air per hour

✅ Experts in aquafeed manufacturing odour control

✅ Custom solutions tailored to your industrial odour challenges

✅ In-house R&D and advanced simulation tools

✅ Onsite odour audits and pilot testing for optimized solutions

✅ Solutions designed to meet all local and global environmental regulations

Our expertise and innovative technology ensure your facility operates with minimal odour impact while maintaining productivity and compliance

Conclusion

As the aquafeed industry continues to grow, so does the responsibility to operate sustainably and sensitively—especially when it comes to odour emissions. Effective odour control in fish and shrimp feed manufacturing is not just about meeting regulations; it’s about protecting the health and well-being of plant workers, maintaining good relationships with surrounding communities, and upholding your company’s environmental integrity.

By implementing smart engineering controls, modern treatment technologies, and best operational practices, facilities can significantly reduce their odour footprint while improving overall efficiency and compliance.

At Elixir Enviro Systems, we specialise in designing and delivering tailored odour control solutions that work—from raw material intake to final air discharge. Whether you’re upgrading an existing system or planning a new facility, we’re here to help you create a cleaner, safer production environment.

📞 Ready to tackle odour challenges at your aquafeed plant?

💬 Contact Elixir Enviro Systems today for expert consultation, onsite assessment, or a custom solution that meets your regulatory and operational goals.

FAQ

Q1: Why is odour control important in fish and shrimp feed manufacturing?

Odour control helps reduce environmental pollution, ensures compliance with regulations, protects worker health, and maintains good relations with nearby communities.

Q2: What are the main sources of odour in aquafeed production?

Odour mainly originates from raw materials like fishmeal and shrimp meal, processing stages (grinding, cooking, drying), storage of raw materials and waste, and microbial activity breaking down organic compounds.

Q3: Which technologies are effective for odour control in feed plants?

Common technologies include biofilters, wet scrubbers, thermal oxidizers, enclosed systems, and advanced ventilation combined with real-time odour monitoring.

Q4: How can wastewater treatment help with odour control?

Treating wastewater and organic solids promptly prevents decomposition that generates odours. Methods like anaerobic digestion reduce odours and produce useful biogas.

Q5: How often should odour control equipment be maintained?

Regular maintenance is essential and should be conducted based on manufacturer guidelines and site-specific needs to ensure continuous effective performance.

0 notes

Text

How to Manage Odour in Pet Food Manufacturing: Proven Technologies & Regulatory Insights

Introduction

The pet food manufacturing industry has grown significantly in recent years, driven by increasing pet ownership and demand for high-quality, specialized pet nutrition. However, one of the persistent challenges in this sector is managing odours generated during production. The processing of animal proteins, fats, and other organic materials creates volatile organic compounds (VOCs), sulfur compounds, and amines, which produce strong, often unpleasant odours. These odours can affect worker safety, community relations, and regulatory compliance. Effective odour control is thus critical for operational success, environmental responsibility, and maintaining a positive public image.

This article explores the sources of odours in pet food manufacturing, their impact, and the technologies and strategies available for effective odour management. It also examines Regulations, industry best practices, and emerging innovations, providing a comprehensive guide for manufacturers seeking to mitigate odour-related challenges.

What Causes Odours in Pet Food Manufacturing?

Pet food manufacturing involves several processes that contribute to odour emissions, including raw material handling, cooking, extrusion, drying, and packaging. Understanding these sources is the first step in designing effective control measures.

1. Raw Material Handling

Pet food production often begins with the receipt and storage of raw materials such as meat, fish, poultry by-products, grains, and fats. These materials, particularly animal-based ingredients, can emit odours during unloading, storage, and preprocessing. Decomposition of organic matter, especially if storage conditions are suboptimal, exacerbates the issue.

2. Batching and Grinding

The raw materials or all the ingredients defined based on the formulation of the company, including protein sources such as fishmeal, chicken-meal etc. are grinded along with the other materials. During this time there will be VOC and dust generation, which will be handled in a bag filter. The dust gets trapped in the bag filter but the exhaust air after the bag filter will be having VOCs and that causes odour emission from the process.

3. Cooking

A key process in which animal by-products are cooked at high temperatures (often exceeding 120°C), leading to the release of VOCs, including aldehydes, ketones, and sulfur-containing compounds like hydrogen sulfide (H₂S). These compounds have low odour thresholds, meaning even small concentrations are detectable and potentially offensive.

4. Extrusion and Drying

Extrusion involves mixing, cooking, and shaping pet food under high pressure and temperature. The process releases steam and volatile compounds, contributing to odour emissions. Drying, used to reduce moisture content in kibble or treats, further volatilizes organic compounds, releasing them into the exhaust air.

5. Packaging and Storage

While less intense, odours can also arise during packaging if residual volatile compounds are released from freshly processed products. Improperly sealed storage areas may allow odours to escape into the surrounding environment.

Why Odour Control Matters in the Pet Food Industry

Odour emissions from pet food manufacturing have wide-ranging implications:

Community Relations: Facilities located near residential areas often face complaints from neighbors about unpleasant smells. Persistent odours can strain relationships with local communities and harm a company’s reputation.

Regulatory Compliance: Many countries have strict regulations governing odour emissions to protect public health and the environment. Non-compliance can result in fines, operational restrictions, or legal action.

Worker Health and Safety: Prolonged exposure to odorous compounds, especially those like H₂S, can pose health risks to employees, including respiratory irritation and headaches.

Environmental Impact: Some odorous compounds contribute to air pollution or greenhouse gas emissions, necessitating control to align with sustainability goals.

Given these impacts, effective odour control is not just a technical necessity but a strategic priority for pet food manufacturers.

Regulations Governing Odour Emissions

Odour regulations vary by region but generally aim to limit nuisance and protect air quality. In the United States, the Environmental Protection Agency (EPA) and state-level agencies enforce standards under the Clean Air Act, which may include limits on VOCs and hazardous air pollutants (HAPs). Facilities must also comply with local zoning laws and nuisance ordinances.

In the European Union, the Industrial Emissions Directive (2010/75/EU) sets guidelines for managing emissions, including odours, from industrial processes. Member states often have additional requirements, such as Germany’s Technical Instructions on Air Quality Control (TA Luft), which specify odour thresholds.

In Australia, the Environmental Protection Authority (EPA) in each state regulates odour emissions, often requiring facilities to conduct odour impact assessments and implement control measures. Similar frameworks exist in Canada, where provincial governments oversee compliance.

Pet food manufacturers must stay informed about applicable regulations and engage with regulatory bodies to ensure compliance. This often involves monitoring emissions, modeling odour dispersion, and reporting to authorities.

Top Odour Control Technologies for Pet Food Manufacturing

A range of technologies is available to control odours in pet food manufacturing, each suited to specific processes and compounds. These can be broadly categorized into physical, chemical, and biological methods, often used in combination for optimal results.

1. Physical Methods

Ventilation and Containment: Proper ventilation systems capture odorous air at the source, preventing it from escaping into the environment. Capturing Fugitive emissions, especially from the extruder area, Enclosed processing areas and negative pressure systems help contain emissions.

Adsorption: Activated carbon filters adsorb VOCs and odorous compounds from exhaust streams. These systems are effective for low-concentration odours but require regular replacement of carbon media.

Thermal Oxidation: Thermal oxidizers and catalytic oxidizers combust VOCs at high temperatures, converting them into carbon dioxide and water. Regenerative thermal oxidizers (RTOs) are energy-efficient options widely used in pet food facilities.

Condensation: Cooling exhaust gases condenses volatile compounds into liquid form, reducing odour emissions. This method is often used in saturated air treatment. Also used in pet food manufacturing plants having rendering plants for the raw material pre-treatment.

2. Chemical Methods

Scrubbers: Wet scrubbers use water or chemical solutions (e.g., sodium hydroxide or Acids or chlorine dioxide or combination of other chemicals) to neutralize and remove odorous compounds like H₂S and amines. Packed-bed scrubbers are particularly effective for high-intensity odours.

Ozonation: Ozone generators oxidize odorous compounds, breaking them down into less offensive molecules. This method is suitable for treating exhaust air but requires careful control to avoid ozone-related health risks and to destruct the unused ozone after the treatment, as ozone has it own distinctive smell and also due to its high Global Warming Potential (GWP).

3. Biological Methods

Biofilters: Biofilters use microorganisms to degrade odorous compounds in a bed of organic material. They are cost-effective and environmentally friendly, ideal for treating large volumes of low-concentration odours.

Bioscrubbers: Similar to wet scrubbers, bioscrubbers use a liquid medium containing microorganisms to break down odorous compounds. They are compact and effective for continuous operation.

Biotrickling Filters: These combine elements of biofilters and bioscrubbers, using a synthetic medium irrigated with water to support microbial activity. They are highly efficient for treating sulfur compounds.

Best Practices for Pet Food Manufacturing Odour Management

Beyond installing control technologies, pet food manufacturers can adopt operational and strategic practices to minimize odours:

1. Process Optimization

Temperature Control: Lowering cooking temperatures where possible reduces the release of volatile compounds.

Material Handling: Prompt processing of raw materials and proper storage to avoid decomposition and odour generation.

Cleaning Protocols: Regular cleaning of equipment and processing areas minimizes residual organic matter that can produce odours.

2. Facility Design

Enclosed Systems: Designing facilities with enclosed processing units and sealed transfer systems reduces fugitive emissions.

Stack Height and Placement: Exhaust stacks should be tall enough to disperse odours above ground level and positioned away from residential areas to minimize impact.

Buffer Zones: Maintaining a distance between facilities and sensitive receptors (e.g., schools, homes) reduces odour complaints.

3. Monitoring and Modeling

Odour Sampling: Regular sampling and analysis of emissions using olfactometry or gas chromatography identify problem areas and verify control effectiveness.

Dispersion Modeling: Software tools like AERMOD or CALPUFF predict how odours will spread, helping manufacturers assess their impact on nearby communities.

Real-Time Sensors: Electronic noses and gas sensors such as Odosnese of Oizom provide continuous monitoring, enabling rapid response to odour spikes.

4. Community Engagement

Transparency: Communicating with local communities about odour control efforts builds trust and reduces complaints.

Odour Logs: Encouraging residents to report odour incidents helps manufacturers correlate emissions with weather conditions or operational issues.

Public Tours: Inviting community members to visit facilities demonstrates commitment to environmental stewardship.

5. Training and Maintenance

Employee Training: Educating workers on odour control systems and best practices ensure consistent operation and early detection of issues.

Preventive Maintenance: Regular inspection and servicing of scrubbers, oxidizers, and biofilters prevent malfunctions that could lead to odour releases.

Elixir Enviro Systems – Experts in Pet Food Odour Control

If you’re looking for reliable pet food odour control, Elixir Enviro Systems is your trusted partner. We specialize in industrial odour treatment, wastewater management, and biofiltration systems for factories and processing plants.

With years of experience, Elixir offers complete solutions—from design and installation to testing and maintenance. Whether your facility needs scrubbers, biofilters, RTOs, or real-time odour monitoring, we’ve got you covered.

Why Choose Elixir Enviro?

✅ Pioneer in Industrial Odour Control in India

✅ Largest player in India having treating about 1 Million cubic meter of air each hour

✅ Experts in pet food manufacturing odour control

✅ Custom solutions for industrial odour problems

✅ In-house R&D and simulation tools

✅ Onsite odour audits and pilot testing

✅ Solutions that meet all local and global regulations

Visit www.elixirenviro.in to learn more or contact us for a custom consultation on odour control for your facility.

Conclusion

Odour control in the pet food manufacturing industry is a multifaceted challenge requiring a combination of advanced technologies, operational best practices, and community engagement. By understanding the sources of odours—raw materials, batching-Grinding, extrusion, and wastewater—manufacturers can deploy targeted solutions like scrubbers, biofilters, and oxidizers. Regulatory compliance, worker safety, and environmental sustainability further underscore the importance of effective odour management.

As industry continues to grow, so too will the need for innovative, cost-effective, and eco-friendly odour control strategies. Manufacturers that invest in these solutions will not only mitigate risks but also strengthen their reputation as responsible corporate citizens. By prioritizing odour control, the pet food industry can ensure a harmonious coexistence with communities and a sustainable future for pet nutrition.

📌 FAQ Section

Q1. What causes odour in pet food manufacturing?

A: Odours are primarily caused by raw material handling, grinding & batching of ingredients, extrusion, drying, and improper wastewater management. These processes release VOCs, sulfur compounds, and amines.

Q2. How can odour emissions be controlled in pet food factories?

A: Odour control can be achieved using technologies like biofilters, wet scrubbers, regenerative thermal oxidizers (RTOs), and proper ventilation systems. Process optimization and regular maintenance also play a crucial role.

Q3. Are odour control systems mandatory for pet food manufacturers?

A: In many regions, yes. Regulatory bodies like the US EPA, EU’s Industrial Emissions Directive, and local environmental agencies require odour emissions to be controlled and monitored. Other locations around the globe mostly have nuisance law, meaning if the neighborhood complains, the factory might need to shut down until the issue is rectified. Considering this, the cost of installation of the Odour Control Unit surpasses the disadvantages of legal penalties, factory-closures and poor neighborhood relationships.

Q5. What role does Elixir Enviro Systems play in odour control?

A: Elixir Enviro Systems offers turnkey odour control solutions tailored to pet food manufacturing, including biofilters, scrubbers, oxidizers, and real-time monitoring. They also provide audits and pilot testing to ensure effectiveness.

#blog#environment#odourcontrol#elixirenvirosystems#sustainability#airpollution#ecofriendly#biofilter#pet food#pet food manufacturing

0 notes

Text

Composite Without Compromise: Odour Control in GRP, SMC, and FRP Vessel Manufacturing

Proven Strategies to Keep Emissions and Nuisance Odours in Check

1. Introduction

Composite vessels made from FRP, GRP, and SMC are the backbone of many industries—offering unmatched strength, corrosion resistance, and design flexibility. But behind these advanced materials lies a quieter challenge: the odours generated during manufacturing. These emissions, primarily from resin curing and finishing operations, can affect worker health, community relations, and regulatory compliance. In this blog, we explore the sources of odour in composite vessel production and share proven strategies to control them—so manufacturers can deliver high-performance products without compromising air quality or reputation.

2. Understanding the Materials

FRP (Fiber-Reinforced Plastic) refers to a broad category of composites made from a polymer matrix reinforced with fibres such as glass, carbon, or aramid. GRP (Glass-Reinforced Plastic) is a subset of FRP, where the reinforcing fibre is glass. SMC (Sheet Moulding Compound) is a type of pre-impregnated fibre composite, usually consisting of chopped glass fibres and thermoset resins, used in compression moulding. These materials are popular for vessel manufacturing due to their excellent mechanical properties, lightweight nature, and corrosion resistance. However, many of the resins used—particularly polyester and vinyl ester—emit volatile organic compounds (VOCs) like styrene during processing. These emissions are the primary source of odour and present both environmental and health concerns if not properly managed. Let’s first dive into little more details on each material.

A. GRP: Definition and Composition

GRP (Glass Reinforced Plastic) is a composite material composed of glass fibres, such as E-glass or S-glass, embedded in a plastic resin matrix, typically polyester, vinyl ester, or epoxy. The term emphasizes the use of glass fibres as the primary reinforcement, making GRP a specific subset of fibre-reinforced composites. It is widely chosen for its balance of strength, corrosion resistance, and affordability.GRP offers good mechanical strength, excellent corrosion resistance, and moderate stiffness, though it is heavier than carbon-based composites. It is cost-effective and ideal for large structures like storage tanks, pressure vessels, pipes, and marine vessels such as boat hulls. GRP is commonly used in industries like water treatment, air pollution control, chemical storage, oil & gas, and marine applications due to its durability and resistance to harsh environments.

B. SMC: Definition and Composition

SMC (Sheet Moulding Compound) is a composite material made of chopped glass fibres (typically 25-50 mm long) mixed with a thermosetting resin, usually polyester, along with fillers like calcium carbonate and additives. Supplied as mouldable sheets, SMC is designed for compression moulding, enabling the production of complex shapes with consistent thickness and high-quality surface finishes.SMC provides good mechanical strength, dimensional stability, and an excellent surface finish, but its shorter, chopped fibres result in lower strength compared to continuous-fibre composites like GRP for high-load applications. It is well-suited for smaller, intricate components such as covers, enclosures, automotive panels, or small tanks, where high-volume production and aesthetic quality are priorities. SMC is less common for large vessels due to its structural limitations, being that said, many companies have come up with designs with steel supports making the SMC panel tanks suitable for somewhat larger applications as well.

C. FRP: Definition and Composition

FRP (Fiber Reinforced Plastic) is a broad category of composites that includes any type of fibreglass, carbon, aramid, or basalt—embedded in a plastic resin matrix. GRP is a type of FRP when glass fibres are used, but FRP also encompasses high-performance fibres like carbon or aramid. This versatility allows FRP to be tailored for a wide range of applications, from general-purpose to specialized uses.FRP’s properties vary by fibre type: glass-based FRP (like GRP) offers corrosion resistance and moderate strength, carbon-based FRP provides a high strength-to-weight ratio and stiffness, and aramid-based FRP excels in impact resistance. Glass-based FRP is used for tanks and pipes, like GRP, while carbon or aramid-based FRP is employed in aerospace, automotive, high-pressure vessels, and advanced marine structures like aircraft components or high-performance yachts. FRP’s cost ranges from affordable (glass) to expensive (carbon/aramid), depending on the fibre and manufacturing process.

3. Why Odour Control Matters

Odour control in FRP/GRP manufacturing is far more than a matter of comfort—it’s a critical aspect of health, safety, and compliance. The Odours are largely caused by VOCs, such as styrene, a common component in polyester and vinyl ester resins. Prolonged exposure to styrene and similar compounds can lead to respiratory issues, neurological symptoms, and other health problems for workers. Additionally, regulatory agencies worldwide impose strict limits on VOC emissions to safeguard air quality and public health. Non-compliance can result in significant fines and legal challenges. Beyond regulations, persistent Odours can strain relationships with neighbouring residents and businesses, potentially damaging a company’s reputation. Effective Odour management, therefore, is essential for worker well-being, regulatory adherence, and maintaining community goodwill.

4. Odour Issues Specific to Each Material

The manufacturing of GRP (Glass Reinforced Plastic), SMC (Sheet Moulding Compound), and FRP (Fiber Reinforced Plastic) vessels involves processes and materials that can release odorous compounds. The primary sources of odours stem from the resins, solvents, and additives used, as well as specific manufacturing techniques. Below is a detailed breakdown of the odour sources for each material, organized by material type.

A. GRP Vessel Manufacturing: Odour Sources

GRP vessels are made using glass fibres and thermosetting resins (e.g., polyester, vinyl ester, or epoxy) through processes like hand lay-up, filament winding, or resin transfer moulding (RTM). Odour sources include:

(i) Resins (Styrene Emissions):

Polyester and vinyl ester resins, commonly used in GRP, contain styrene, a volatile organic compound (VOC) with a strong, sweet, and pungent odour. Styrene is released during resin mixing, application, and curing, especially in open-mould processes like hand lay-up or spray-up.

Epoxy resins, while less odourous than polyester, may still emit mild chemical smells during curing.

(ii) Solvents and Thinners:

Solvents like acetone or toluene are used to clean tools or thin resins, releasing sharp, chemical odours. These VOCs evaporate quickly, contributing to workplace odours.

(iii) Curing Agents and Catalysts:

Catalysts like methyl ethyl ketone peroxide (MEKP), used to initiate resin curing, have a strong, acrid odour. Improper handling or mixing can amplify these emissions.

(iv) Open-Mold Processes:

Processes like hand lay-up or spray-up expose wet resin to air, increasing the release of styrene and other VOCs. These methods are more odour-intensive compared to closed-mould processes like RTM.

(v) Dust and Fumes:

Cutting or grinding glass fibres during preparation or finishing generates dust with a faint, musty smell. Post-curing trimming or sanding of GRP parts can release resin fumes and fine particulate matter, adding to the odour profile.

B. SMC Vessel Manufacturing: Odour Sources

SMC is a pre-mixed composite of chopped glass fibres, polyester resin, fillers, and additives, moulded into sheets and compression-moulded under heat and pressure. Odour sources are generally less intense than GRP due to the closed-mould process but still significant:

(i) Resins (Styrene and Other VOCs):

SMC uses polyester resins containing styrene, which emits a pungent odour during the compounding stage when resin is mixed with fibres and fillers. However, since SMC is pre-mixed and stored as sheets, styrene emissions are more controlled compared to GRP open-mould processes.

(ii) Additives and Fillers:

Additives like low-profile agents (to reduce shrinkage) or thickeners (e.g., magnesium oxide) may release mild chemical odours during mixing or moulding. Fillers like calcium carbonate are odourless but can contribute to dust-related smells.

(iii) Compression Moulding:

During moulding, heat (typically 120-150°C) is applied, causing residual styrene or other VOCs in the SMC to volatilize, releasing a warm, chemical odour. Closed moulds reduce emissions compared to GRP’s open processes, but some odour escapes during Mould opening.

Use of mould release agents with distinct chemical odours.

(iv) Solvents for Equipment Cleaning:

Acetone or other solvents used to clean moulds or tools emit sharp, chemical smells. These are less frequent than in GRP manufacturing but still contribute to odours.

(v) Post-Moulding Finishing:

Trimming, drilling, or sanding SMC parts can release mild resin fumes and dust with a faint, chemical, or musty odour, especially if the material is not fully cured.

C. FRP Vessel Manufacturing: Odour Sources

FRP encompasses a broad range of composites, as an umbrella category, FRP includes both GRP and SMC, but also other forms like carbon-reinforced or aramid-reinforced plastics, or other fibres, using resins like polyester, vinyl ester, or epoxy. Odour sources depend on the fibre and process but overlap with GRP for glass-based FRP:

(i) Resins (Styrene and Epoxy Emissions):

For glass-based FRP (equivalent to GRP), styrene from polyester or vinyl ester resins is the primary odour source, with a strong, sweet smell during mixing, application, and curing.

Epoxy resins, common in carbon or aramid FRP, emit milder, chemical odours during curing, often described as less pungent than styrene but still noticeable.

(ii) Solvents and Cleaning Agents:

Acetone, toluene, or other solvents used for cleaning tools or preparing surfaces release sharp, chemical odours. These are common across all FRP types, especially in hand lay-up or filament winding.

(iii) Curing Agents:

Catalysts like MEKP for polyester resins or amines for epoxy resins have strong, acrid odours. Amine-based hardeners in epoxy systems, used for carbon/aramid FRP, can produce ammonia-like smells during curing.

(iv) Manufacturing Processes:

Open-mould processes (e.g., hand lay-up for glass FRP) release more styrene and VOCs than closed-mould methods (e.g., RTM or autoclave curing for carbon FRP). Autoclave curing, used for high-performance FRP, contains odours better but may still release epoxy fumes when moulds are opened.

High-temperature curing (e.g., in autoclaves for carbon FRP) can volatilize resin components, producing warm, chemical odours.

(v) Fiber-Specific Odours:

Glass fibres in FRP generate dust with a musty smell during cutting or sanding, like that of GRP.

Carbon or aramid fibres produce less dust but may release faint, burnt, or chemical odours during machining or if overheated during curing. These are minimal compared to resin-related odours.

5. Odour Control Strategies

The manufacturing of GRP (Glass Reinforced Plastic), SMC (Sheet Moulding Compound), and FRP (Fiber Reinforced Plastic) vessels involves resins, solvents, and additives that release odourous volatile organic compounds (VOCs), notably styrene from polyester resins. These odours, described as pungent or chemical, can affect worker health, community relations, and regulatory compliance. Effective odour control strategies are essential to mitigate these emissions, improve workplace safety, and adhere to environmental standards. The odour control strategies are categorised into two – process/product specific odour control strategies with respect each product and End of pipe solutions applicable for all the three products. First, we will cover few tailored strategies for each material, focusing on ventilation, material selection, process optimization, and followed by end-of-pipe solutions or advanced filtration methods.

A. GRP Vessel Manufacturing

(i) Ventilation and Air Extraction Systems:

GRP vessel manufacturing frequently employs open-mould techniques such as hand lay-up or spray-up, where styrene-rich polyester resins are exposed to air, resulting in significant VOC emissions. To address this, robust ventilation systems, including local exhaust ventilation (LEV) systems, are critical. These systems are installed at key emission points, such as resin application and curing stations, to capture odorous air. Regular maintenance of these systems prevents resin residue buildup, which could otherwise exacerbate odours, and ensures consistent performance in high-emission environments.

The implementation of ventilation systems not only reduces odours but also enhances workplace safety by minimizing worker exposure to harmful VOCs. For closed-mould processes like resin transfer moulding (RTM), sealing moulds tightly and integrating ventilation at demoulding stages further controls odour escape. These systems can be tailored to facility size, with smaller setups using standalone filtration units and larger plants opting for integrated HVAC solutions.

(ii) Use of Low-Styrene or Alternative Resins:

A proactive approach to odour control in GRP manufacturing involves selecting low-styrene or styrene-free resins to reduce VOC emissions at the source. Traditional polyester resins contain high styrene levels, contributing to strong odours and health risks. Low-styrene polyester resins or vinyl ester resins emit fewer VOCs during curing, significantly decreasing odour intensity. While these resins may increase material costs, they offer long-term benefits, including reduced odour complaints, improved worker safety, and alignment with environmental regulations.

The adoption of alternative resins requires careful consideration of application suitability, as vinyl ester or epoxy resins may have different mechanical properties or curing requirements compared to polyester. Manufacturers must evaluate these factors against the specific needs of GRP vessels, such as corrosion resistance for chemical storage. Pilot testing low-styrene resins can help assess performance without disrupting production. This strategy also supports sustainability goals by reducing the environmental impact of VOCs, making it appealing for facilities aiming to enhance their corporate social responsibility profile.

B. SMC Vessel Manufacturing

(i) Enclosed Mixing and Moulding Processes

SMC manufacturing involves pre-mixing chopped glass fibres with polyester resins and additives to create mouldable sheets, followed by compression moulding in closed systems, which inherently produces fewer odours than GRP’s open-mould processes. To control odours during mixing, enclosed systems with integrated ventilation or extraction units are essential. Automated mixing equipment minimizes styrene release by containing the process, while local exhaust ventilation captures any emissions during material handling. During compression moulding, closed moulds reduce odour escape, but residual styrene may be released when moulds are opened. Installing LEV systems near moulding machines ensures these emissions are captured and treated, maintaining a low-odour environment.

Enclosed processes offer significant advantages, including reduced worker exposure to VOCs and compliance with workplace safety regulations. For facilities producing high volumes of SMC components, such as small tanks or automotive parts, these systems enhance efficiency by streamlining odour control within the production line.

Additionally, Regular cleaning of mixing and moulding equipment prevents resin buildup, which could contribute to persistent odours.

(ii) Post-Curing and Off-Gassing Management

After moulding, SMC vessels may retain residual styrene, leading to odours during storage or use. Post-curing techniques, such as exposing moulded parts to controlled heat in a dedicated chamber, accelerate the off-gassing process, allowing VOCs to be released in a contained environment. This can be achieved using ovens or curing rooms equipped with ventilation systems that direct off-gassed air through and odour control unit (OCU). Alternatively, parts can be stored in well-ventilated off-gassing areas before finishing or packaging, reducing odour levels in the final product.

C. FRP Vessel Manufacturing

(i) Ventilation and Air Extraction Systems:

FRP vessel manufacturing, which includes GRP and other fibres like carbon or aramid, often involves open-mould processes that release significant styrene and other VOCs. Therefore, proper ventilation and air extraction is the key strategy.

(ii) Process Optimization and Enclosure:

Optimizing the manufacturing process for FRP vessels can significantly reduce odour emissions by minimizing solvent use, use of epoxy resins with milder odour and optimising curing times. Selecting faster-curing resins or adjusting formulations to lower styrene content decreases VOC release during production. Enclosing open-mould processes in booths or isolated areas equipped with exhaust systems allows for better control of odorous air, directing it through filtration units before release.

For closed-mould processes like filament winding or pultrusion, ensuring moulds are tightly sealed and equipped with integrated ventilation systems prevents odour escape during curing or demoulding, enhancing overall air quality management. Process enclosures offer dual benefits of odour control and improved production efficiency by reducing material waste and worker exposure to VOCs.

D. End-of-Pipe solutions or Advanced Filtration Systems

Effective odour control combines process optimization, engineering controls, and air treatment technologies. By combining enclosed systems with air treatment, manufacturers can achieve a cleaner workplace and minimize community complaints, particularly in urban settings where facilities are near residential areas.

Advanced air filtration systems are highly effective for removing these compounds from the exhausted air. These filters adsorb styrene and other organic molecules, achieving up to 99.5% reduction in odourous VOCs. Key advanced filtration strategies include:

Scrubbers:

Wet Scrubbers: Use water or chemical solutions to absorb and neutralize VOCs.

Dry Scrubbers: Use dry media (e.g., activated alumina or impregnated pellets) to capture specific compounds.

Activated Carbon Filters: Adsorb VOCs and odorous gases effectively; ideal for point-source or room-scale filtration. Regular monitoring of filter performance and replacement of saturated carbon are necessary to maintain effectiveness.

Biofiltration Systems: Especially for larger facilities, biofilters offer a sustainable method for treating air streams by using microbial action to degrade odorous compounds. They are effective for low-concentration, high-volume emissions.

Regenerative thermal oxidizers (RTOs) or catalytic oxidizers: Are also applicable for large facilities having separate streams for high concentration streams. The system can destroy VOCs through high-temperature oxidation, converting them into carbon dioxide and water. These are generally deployed as standalone units near high-emission areas like spray booths or lay-up stations of large facilities.

Employing these systems can mitigate community complaints by preventing odourous emissions from escaping the facility, which is critical for plants located near residential areas. Another factor which is overlooked in many places are the employee training; Ensuring proper storage, mixing, and application techniques minimizes unnecessary emissions. Implementing these changes requires upfront investment in equipment and process redesign, but the resulting reduction in odour complaints, improved public relations and regulatory penalties offsets these costs and justify the investment. Regular process audits and air quality monitoring ensure that optimizations remain effective, allowing manufacturers to adapt to changing production demands or regulatory requirements while maintaining a low-odour environment.

6. Regulatory and Community Considerations

Odour is not just an operational issue—it’s a community and compliance matter. Many jurisdictions have strict odour and VOC regulations. For example, styrene is a listed hazardous air pollutant (HAP) under U.S. EPA regulations. Manufacturers must monitor emissions and often report to local environmental authorities. In regions like the EU, occupational exposure limits (OELs) and industrial emissions directives (IED) govern VOC discharge. Facilities must demonstrate that Best Available Techniques (BAT) are being used for odour control.

Equally important is proactive communication with the community. Transparent environmental practices and prompt response to concerns build trust and social license to operate.

7. What EES Can Do for FRP/GRP Manufacturers

Elixir Enviro Systems Pvt Ltd (EES) offers specialized odour control solutions tailored to the unique challenges of FRP/GRP manufacturing facilities. Our services and technologies help reduce VOC emissions, improve workplace safety, and ensure regulatory compliance.

🔧 Customised Solutions We Offer:

1. Design of Ventilation systems, Enclosure and Containment Solutions

Design of proper ventilation systems and its installation.

Design and installation of enclosed curing booths with integrated emission control.

Modular systems for retrofitting existing facilities.

2. Process Optimisation Consulting

Transition support for low-VOC or styrene-free resins.

Guidance on closed-mould systems and curing environment improvements.

Process audits to identify and reduce emission hotspots.

3. On-site Services

Odour Assessment & Mapping: Identify sources and odour dispersion patterns.

VOC Monitoring & Analysis: Using state-of-the-art instruments.

Preventive Maintenance & Operator Training: To ensure ongoing system performance and compliance.

4. Odour Control Equipment

Activated Carbon Filters: For capturing VOCs like styrene.

Biofilters: Use microorganisms to biologically degrade odorous compounds.

Chemical Scrubbers: For targeted removal of specific VOCs.

Thermal Oxidizers: High-efficiency systems that destroy VOCs via combustion.

5. Regulatory Compliance Support

Emission modelling and simulation for statutory reporting.

Documentation support for local and international environmental standards.

💡 Why Partner with Elixir Enviro?

Deep domain knowledge in industrial odour and air quality management

Proven experience in custom-engineered solutions for composite industries

Commitment to sustainability, worker health, and community welfare

Responsive after-sales support and service contracts

8. Conclusion

Controlling odour in GRP, SMC, and FRP vessel manufacturing is not just a regulatory necessity—it’s a mark of modern, responsible manufacturing. By combining smarter material choices, better processes, and effective air treatment systems, companies can uphold product quality while protecting the environment and their communities. The result is a cleaner, more sustainable path forward for the composites industry. Partnering with Elixir Enviro Systems ensures access to industry-leading solutions for effective Odour management.

#odourcontrol#environment#sustainability#elixirenvirosystems#airpollution#ecofriendly#biofilt#3#frp tanks#grp

0 notes

Text

Waste to Protein, Without the Smell: Engineering Cleaner Insect Meal Plants

Introduction

Insect meal processing is emerging as a sustainable and efficient solution to meet the growing demand for high-protein products, primarily used as feed for animals like fish, pet food and poultry, and sometimes for human consumption. The larvae stage is often targeted due to its high biomass and nutritional value.

In insect meal production, several types of larvae are commonly used due to their high nutritional value and efficiency in converting organic waste into biomass. The most widely used species is the black soldier fly larvae (Hermetia illucens), known for its ability to thrive on a variety of waste materials, including food scraps and manure. These larvae are rich in protein and fat, making them ideal for animal feed, and their frass is also valued as a fertilizer. Yellow mealworms (Tenebrio molitor) are another popular choice, especially in both animal and human food products. They are typically reared on grain-based substrates and have a high protein content with a lower fat profile compared to black soldier fly larvae. Lesser mealworms (Alphitobius diaperinus), or buffalo worms, are smaller but similarly used in poultry and aquaculture feed. Housefly larvae (Musca domestica) have been used for waste decomposition and feed, though they are less common today due to biosecurity concerns. Lastly, silkworm pupae (Bombyx mori), a by-product of the silk industry, are often utilized in insect meal, particularly for fish feed, owing to their high protein content.

Each species varies in terms of rearing requirements and nutritional composition. This different rearing conditions give rise to different levels of odour potential, ranging from the decaying waste to the final frass to the storage and transportation. Irrespective of the species used for the insect meal production, the processing of insect larvae to the meal always have similar line of odour generation. The decomposition of organic waste, microbial activity, and thermal processing contribute to the emission of volatile organic compounds (VOCs), ammonia, and sulfur-based gases, leading to unpleasant smells. These odours can impact worker comfort, community relations, and environmental compliance. To address these concerns, implementing effective odour control solutions is crucial. Being said that the black soldier fly larvae generally associated with stronger odours due to the nature of their feed substrates and metabolic activity.

This article explores the sources of odour in insect meal processing, the challenges they present, and the most effective strategies for odour mitigation.

Why Odour Control Matters in Insect Meal Manufacturing

Odour is a natural byproduct of organic processing, and insect meal production is no exception. The breakdown of insect biomass, drying processes, and fermentation stages can release volatile organic compounds (VOCs) and other odorants. While these smells might not bother the insects, they can be off-putting to nearby residents or workers. Effective odour management not only ensures compliance with environmental regulations but also fosters good relationships with local communities and supports the industry’s reputation as a sustainable solution.

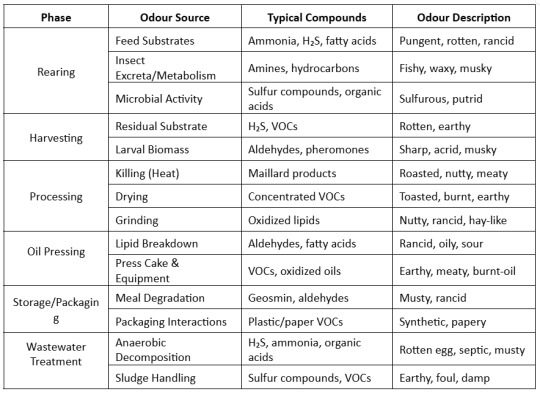

Sources of Odour in Insect Meal Production Plants

Insect meal processing is a highly sustainable source of protein, but it presents significant odour challenges. Understanding the sources of these odours is essential for developing effective control strategies. The primary sources of odour in insect meal production stem from raw material decomposition, insect rearing conditions, processing stages, byproduct treatment, and wastewater management.

1. Rearing Phase (Larvae Growth)

This initial stage involves growing insect larvae—such as black soldier flies, mealworms, or houseflies—on organic substrates. The odours emitted during this phase originate from the feed, the larvae themselves, and microbial activity. Feed substrates play a significant role: organic waste like food scraps or manure decomposes, releasing volatile organic compounds (VOCs) such as ammonia, hydrogen sulfide (with its characteristic rotten egg smell), and short-chain fatty acids like butyric acid, which smells like rancid butter. Grain-based feeds, such as wheat bran or oats, can undergo fermentation or fungal growth, producing odours like alcohols (ethanol) and esters that have fruity or solvent-like characteristics.

Larval metabolism contributes further to the odour profile. Frass—the combination of insect excreta and undigested substrate—produces nitrogenous compounds such as ammonia and amines, which smell sharp, fishy, or decayed. In addition, larvae release hydrocarbons through their cuticles, emitting faint waxy or oily odours. The microbial decomposition of feed, whether through aerobic or anaerobic pathways, generates sulfur compounds like mercaptans and additional organic acids, which amplify the odour intensity and complexity during this stage.

2. Harvesting Phase

During harvesting, mature larvae are separated from their substrate, often through mechanical means. This disruption enhances the release of odorous compounds. Residual wet substrate left behind after separation can undergo anaerobic decomposition, producing intensified sulfurous and putrid smells. Handling live larvae may cause stress responses, leading them to release defensive compounds like aldehydes (which have sharp, green odours) or pheromones that are often musky or acrid, depending on the species.

Cleaning processes during harvesting, such as rinsing the larvae with water or solvents, may dilute some of the odours but can also stir up stagnant, earthy smells from organic residue. The combination of biological and mechanical factors in this phase makes it one of the more dynamic contributors to the odour profile in insect meal production.

3. Processing Phase (Conversion to Insect Meal)

This phase includes the killing, drying, and grinding of larvae into meal. Different killing methods impact odour differently: freezing typically emits minimal odour at first, though thawing may release faint protein breakdown smells. In contrast, heat-based methods like blanching or boiling cause Maillard reactions (browning reactions between proteins and sugars), producing more pronounced roasted, nutty, or even meat-like aromas.

Drying, whether via oven or air, concentrates VOCs by evaporating moisture. This can result in toasted, earthy, or slightly burnt odours—especially if overheating occurs, which can create acrid or charred smells. Grinding the dried larvae into meal releases fine particulates, emitting nutty, hay-like scents. However, if the lipids in the larvae oxidize during this process, particularly in fat-rich species like black soldier flies, they can produce aldehydes such as hexanal, which carry rancid or oily smells.

4. Oil Pressing Phase (Lipid Extraction)

In facilities that separate insect oil from the protein meal—especially with species like black soldier flies—mechanical oil pressing introduces additional odour sources. When pressing is done with heat, or when heat is generated from friction, thermal breakdown of lipids can occur. This leads to the formation of aldehydes, ketones, and volatile fatty acids, producing smells ranging from grassy and paint-like to rancid or sour. If pressing temperatures are too high, acrid or burnt-oil odours may develop.

Oxidation of fats during or after pressing is another key contributor to odour. Rancid, stale-oil-like smells can emerge from unsaturated fats breaking down, particularly if the oil is not processed or stored in an oxygen-limited environment. The residual press cake may still contain fat and moisture, contributing warm, earthy, or slightly sour odours if it is not cooled and dried promptly. Emissions may also arise from hot surfaces and oil collectors, especially in enclosed spaces without adequate ventilation, resulting in a lingering oily or meaty atmosphere.

5. Storage and Packaging Phase

Once insect meal is produced, it is stored and packaged, and these post-processing conditions can influence odour stability. Properly stored dry meal usually has a mild, nutty, or toasted grain-like smell. However, if moisture infiltrates the product during storage, it can support mould growth, leading to musty or fungal odours associated with compounds like geosmin.

Packaging materials can also interact with the meal. For example, VOCs from the insect meal can adsorb onto plastic or paper packaging, subtly altering the perceived odour with synthetic or papery notes. While this phase may seem passive, it can significantly affect product perception, especially in high-value feed or food applications.

6. Wastewater Treatment Phase

Water is used at various stages of insect meal processing—for cleaning larvae, blanching, or cleaning equipment—and all of this generates wastewater rich in organic matter. The treatment of this wastewater introduces another significant odour source.

If anaerobic conditions develop in wastewater holding tanks, collection pits, or equalization tanks, foul-smelling gases such as hydrogen sulfide (H₂S), ammonia, and volatile fatty acids are released. H₂S, in particular, contributes a rotten egg odour that is often the most intense and noticeable. In addition, foaming and surfactant-rich wastewater can carry odorous compounds into the air as aerosols, especially during agitation or aeration in treatment tanks.

Further odours can arise from sludge handling—the thickened solids separated from the wastewater—which may emit earthy, septic, or musty odours, particularly if not properly stabilized or rapidly removed. Without adequate aeration or treatment, wastewater components can be a persistent and site-wide source of offensive odours, particularly in warm climates or enclosed processing facilities. If not treated properly, this wastewater can become a significant source of odour pollution.

Key Odorous Compounds to Monitor

Impact of Uncontrolled Odour

1. Environmental Concerns

Odorous emissions contribute to air pollution and can negatively impact local ecosystems. VOCs and ammonia released into the atmosphere can react with other pollutants, forming secondary air contaminants.

2. Health Hazards

Workers in insect meal plants may experience respiratory discomfort, nausea, and headaches due to prolonged exposure to odours. Strong odours can also lead to reduced air quality in surrounding areas.

3. Regulatory Compliance

Environmental regulations impose strict limits on odour emissions. Failure to comply with these standards can result in fines, operational restrictions, or shutdowns.

4. Community Complaints & Business Reputation

Foul odours can lead to complaints from nearby residents and businesses, potentially damaging the company’s reputation and straining relations with the local community.

Odour Control Strategies for Insect Meal Processing Plants

To mitigate odour challenges, insect meal processing facilities can adopt various control measures. Biofilters and scrubbers can be used to capture and neutralize odorous compounds before they are released into the atmosphere. Proper ventilation systems can help reduce indoor odour buildup. Wastewater treatment processes should be implemented to prevent the accumulation of organic waste that leads to odour formation. Additionally, optimizing rearing conditions by maintaining controlled humidity, aeration, and feed quality can help minimize metabolic odours from insect populations.

Implementing a robust odour control strategy is essential to maintaining air quality, regulatory compliance, and operational efficiency in insect meal processing plants. Below are some of the most effective odour mitigation techniques:

1. Biofiltration Systems

Biofilters are an eco-friendly solution that uses microorganisms to break down odorous compounds like volatile organic compounds (VOCs), ammonia, and hydrogen sulfide (H₂S). The process involves passing contaminated air through a biofilter medium (such as compost, peat, or wood chips), where microorganisms degrade odorous compounds into harmless byproducts like carbon dioxide and water.

2. Chemical Scrubbers

Scrubbers use liquid chemicals to neutralize odour-causing gases. The two main types include:

Acid Scrubbers: Effective for ammonia removal.

Alkaline Scrubbers: Target hydrogen sulfide and organic acids. This method is highly efficient for treating large air volumes and removing multiple odorous compounds simultaneously.

3. Activated Carbon Filtration

Activated carbon filters are ideal for adsorbing VOCs and organic odour compounds. These filters trap odorous molecules within the porous carbon structure, effectively neutralizing them before they are released into the atmosphere. This method is particularly effective in handling residual odours after primary treatment.

4. Enclosed Processing & Ventilation Systems

Enclosed Facilities: Sealing processing areas prevents odours from escaping into the environment.

Proper Ventilation: Strategic placement of ventilation ducts and air handling systems ensures the efficient capture and treatment of odorous air before release.

5. Thermal Oxidation

Thermal oxidation or combustion-based systems break down odorous gases at high temperatures, converting them into non-odorous byproducts like carbon dioxide and water. Though effective, this method requires high energy consumption and is best suited for large-scale operations.

6. Onsite Odour Monitoring & Control Systems

Real-time odour monitoring technologies such as Oizom (www.oizom.com) help track odour levels and detect problem areas. Implementing automated odour control systems allows plants to adjust treatment processes dynamically based on odour intensity.

Elixir Enviro Systems: Your Partner in Odour Control

Elixir Enviro Systems is the pioneer in industrial Odour Control system provider in India. Have installed odour control unit in various industries such as :

Biofiltration systems for VOC and odour reduction

Chemical scrubbers for ammonia and hydrogen sulfide removal

Advanced air purification technologies

Onsite odour measurement and regulatory compliance consulting

we provide the best suited odour control system tailored for each individual cases.

You may Consult Elixir Enviro Systems for for all your odour control and wastewater treatment related enquiries.

Conclusion

Odour control is a critical aspect of operating a successful insect meal production plant. By understanding the sources of odour and implementing a combination of ventilation, filtration, and waste management strategies, plant operators can minimize odour emissions and create a more pleasant working environment. Additionally, investing in odour control technologies not only improves the quality of life for workers and nearby communities but also enhances the overall sustainability and reputation of the insect meal industry.

As the insect meal industry continues to grow, innovative odour control solutions will play a key role in ensuring its long-term success. By prioritizing odour management, insect meal producers can contribute to a cleaner, greener future for animal feed production.

0 notes

Text

Clearing the Air: Solving Sewage Pumping Station Odour Problems for a Fresher & Healthier City

As urban areas continue to expand, the demand for efficient wastewater management systems grows with them. Sewage pumping stations are vital infrastructure elements that transport sewage from lower to higher elevations, making it possible to send wastewater to treatment facilities where gravity flow is not feasible. However, one of the most common — and often overlooked — challenges of sewage pumping stations is odour control.

Odours from sewage pumping stations are more than just an inconvenience. They are a significant environmental concern, a public health risk, and a factor that can negatively impact the social well-being of communities. In this blog, we will explore the causes of sewage pumping station odours, the challenges of managing them, technologies available for odour control, and how Elixir Enviro Systems is helping industries and municipalities solve these challenges sustainably.

1. Why is Odour Control Important in Sewage Pumping Stations?

Odour emissions are not just a public nuisance; they pose serious health and environmental risks:

Respiratory Irritation: Prolonged exposure to H₂S and ammonia can cause irritation to the eyes, nose, and throat and may lead to more severe respiratory problems.

Corrosion of Infrastructure: Hydrogen sulfide can convert to sulfuric acid, corroding concrete structures and metal pipelines, leading to increased maintenance costs.

Environmental Degradation: Odour-causing gases contribute to atmospheric pollution and can have negative effects on nearby flora and fauna.

Community Complaints and Legal Issues: Persistent odour problems lead to public complaints, social unrest, and, in some cases, environmental regulatory penalties.

2. Why Sewage Pumping Stations Stinks?

Odour emission from sewage pumping stations happens because of the way they handle wastewater. Odour to become a problem, it must leave the wastewater and enter the air. This process, known as mass transfer, is driven by concentration differences—when there’s more of a compound in the water than in the air, nature pushes for balance, causing gases to be released. Ventilation and turbulence speed up this transfer, making the sewage pumping station prone to strong odors. While Henry’s Law predicts how much gas should be in the air, real-world factors like flow rates, temperature, and facility design create much more variability.

Let’s understand various factors contributing to odour emission from sewage pumping stations, drawing on various sources to ensure a thorough understanding.

2.1. Biological Sources of Odour

Odour in sewage pumping stations primarily arises from the anaerobic decomposition of organic matter, leading to the production of hydrogen sulphide (H₂S) and other volatile organic compounds (VOCs). H₂S, known for its rotten egg smell, is generated by sulfate-reducing bacteria in conditions where oxygen is depleted, such as in stagnant sewage. This process is particularly pronounced in wet wells, where sewage accumulates before pumping, and in rising mains, where hydraulic residence time exceeds 6 hours. The decomposition is accelerated by warmer temperatures and stronger sewage, often seen during dry weather, which reduces dilution and increases organic content.

2.2. Design & Operational Factors in Pumping Stations

Sewage pumping stations are designed to collect and pump wastewater to treatment facilities, often against gravity, using wet wells and force mains. The wet well, where sewage is stored before pumping, is a critical area for odour production due to the potential for stagnation. When sewage sits for extended periods, anaerobic conditions develop, fostering H₂S production. The pumping action itself, involving turbulence, exacerbates odour emission by agitating the sewage and releasing trapped gases into the atmosphere.

The length of the force main, the pipe from the pump to the discharge, also influences odour. Longer force mains increase the residence time of sewage, allowing more time for anaerobic decomposition and H₂S production. Design guidelines for sewage works emphasize keeping force main lengths short to reduce dynamic head losses and odour production. This is particularly important at initial and design flows, where prolonged exposure can lead to significant gas buildup.

Trends in sewer system design, such as centralizing treatment and moving to separate sewer systems, can exacerbate H₂S problems. Centralization increases pumping distances, leading to more stagnant conditions and higher H₂S production, while separate systems lack rainwater dilution, increasing the risk of odour issues. These trends highlight the need for adaptive odour control strategies in modern wastewater management.

2.3. Trade Effluent Impact

An interesting factor is trade effluent—wastewater from industries—which can add odorous compounds, making the smell stronger, especially in dry weather when sewage is more concentrated. Trade effluent, may itself be odorous or increase the strength of the sewage, leading to enhanced odour generation. This is particularly relevant in urban areas where industrial discharges are common.

2.4. Maintenance Influences

Maintenance is another critical factor. Poorly maintained stations, with blockages or grease buildup, can lead to increased odour emissions. Similarly, control float switch problems can cause pumps to remain on, potentially agitating sewage excessively and releasing more gases. Regular maintenance, including clearing debris and ensuring proper operation, is essential to mitigate these issues, as advised in community guidance for living near pumping stations.

2.5. Environmental Influences

Environmental factors, such as temperature, play a role in odour intensity. Warmer seasonal temperatures increase odour generation, as bacterial activity accelerates. Additionally, the design of ventilation systems can affect how odours are dispersed. For instance, rooftop vents and mechanical ventilation are used to manage pressure and flow, but improper design can lead to odours reaching ground levels, especially under wind currents or temperature inversions.

3. What Causes the smell-Uncovering the Smelly Secrets!

Wastewater isn’t just water—it’s a complex mix of organic compounds, many of which have strong, unpleasant odours. As oxygen is depleted and anaerobic conditions take over, these odours intensify, creating a bigger challenge for treatment facilities.

3.1. The Rotten Egg Culprit: Hydrogen Sulfide

Hydrogen sulfide (H₂S) is the main offender, notorious for its rotten egg smell. It forms when sulfate-reducing bacteria thrive in oxygen-starved conditions, often inside pipe biofilms and sludge layers. Factors like low oxygen, high organic content, and long retention times boost its production. Highly toxic at high levels, H₂S can be deadly, making its control a top priority.

3.2. The Stealthy Sulfur Compounds

Beyond H₂S, other sulfur-based compounds—mercaptans, dimethyl sulfide, and dimethyl disulfide—add to the stench. These compounds are even trickier because they don’t dissolve as easily in water. High-energy areas like junction chambers, mixing tanks, and dewatering processes release them in full force, making odour control a challenge.

3.3. The Ammonia Factor

While ammonia isn’t as pungent as sulfur compounds, it can still be a problem, especially in solids processing. Dewatering, lime stabilization, and composting can trigger ammonia emissions, sometimes mixed with fishy-smelling amines. Anaerobic digestion and high-temperature processes further intensify these odours.

3.4. The Hidden Odour Offenders

Odour isn’t just about sulfur and nitrogen. Wastewater also contains volatile organic compounds (VOCs), aldehydes, ketones, and carboxylic acids, which contribute to its distinct, unpleasant scent. While not always the main culprits, they can make odour control even more complex.

Understanding these odour sources is key to managing them effectively.

4. Design Strategies to Minimize Odour Emissions from Sewage Pumping Stations

Effective design is paramount to minimizing odour emissions, and several strategies can be implemented based on engineering guidelines and best practices. The following sections outline these considerations

4.1. Location and Layout Considerations

The station’s location and layout can also influence odour impact:

Site Selection: Positioning the station away from residential areas to minimize community exposure, though this may not always be feasible.

Pipework Design: Minimizing bends and drops in pipework to reduce turbulence, which can release trapped gases. Avoiding long force mains is also advised, as they can increase retention time and odour production.

4.2. Minimizing Retention Time

One of the most effective ways to reduce odour is to minimize the time sewage spends in the pumping station, particularly in the wet well. This can be achieved through:

Proper Wet Well Sizing: Ensuring the wet well is appropriately sized to match inflow rates, preventing overflow and stagnation. For example, operating wet wells at lower levels can reduce detention times. The Ontario guidelines, recommend more frequent pumping for fill-and-draw stations and lowering level set-points for variable speed pump stations where odour is an issue.

Pump Capacity and Operation: Selecting pumps with sufficient capacity to handle inflows promptly and using variable frequency drives (VFDs) to match pumping rates with inflow, thus avoiding prolonged storage. This reduces the likelihood of anaerobic conditions developing, which is a major source of H₂S production.

4.3. Pump Selection and Operation

The type and operation of pumps can influence odour emissions:

Submersible Pumps: These are often preferred as they reduce turbulence and splashing compared to dry pit pumps, minimizing gas release. In other words, the pump selection should prioritize low turbulence.

Operational Practices: Ensuring pumps operate frequently to prevent stagnation, and designing for easy maintenance to allow routine cleaning, which reduces organic buildup and odour production.

4.4. Wet Well Design for Self-Cleaning and Maintenance

The wet well’s design can directly impact odour control:

Sloped Bottoms and Fillets: Incorporating sloped bottoms or fillets in rectangular channels and tanks to prevent sediment accumulation. This reduces ‘dead zones’ where solids can settle and foster anaerobic conditions.

Aeration Where Needed: Providing aeration to maintain solids in suspension where self-cleaning velocities cannot be achieved, though excessive aeration should be avoided to prevent increased turbulence and odour release.

Access for Cleaning: Ensuring easy access for routine hosing and debris removal, which helps maintain hygienic conditions and reduces odour production.

4.5. Liquid Phase Treatment – Chemical Dosing for Odour Prevention

Liquid side treatments focus on preventing odour formation in the wastewater itself, targeting the root cause by maintaining aerobic conditions or neutralizing odorous compounds. Chemical treatment can be integrated into the design to prevent odour-causing gas formation:

Oxidizing Agents: Adding substances like chlorine, hydrogen peroxide, or pure oxygen to oxidize sulphides and inhibit their production. The air injection can be successful for short to moderate force mains, though care must be taken to avoid air binding at high points.

Precipitants and pH Control: Using iron or zinc salts to precipitate sulphides or raising pH with sodium hydroxide to inhibit H₂S off-gassing. These measures are effective in localized areas but require careful consideration of impacts on solids handling, such as increased sludge production.

Electron Acceptors: Implementing sodium nitrate in sewers, which has advantages like slower consumption and non-hazardous properties.

Other Agents: Anthraquinone inhibits sulphate-reducing bacteria, effective for several days to six weeks, but limited by low solubility for force main applications. Caustic slug dosing with sodium hydroxide shifts sulphide equilibrium, inactivating the slime layer, effective for days to weeks but not for continuous addition.

4.6. Vapour Phase (Air side) Treatments for Odour Control