#Biofilters

Explore tagged Tumblr posts

Text

Clearing the Air: Solving Sewage Pumping Station Odour Problems for a Fresher & Healthier City

As urban areas continue to expand, the demand for efficient wastewater management systems grows with them. Sewage pumping stations are vital infrastructure elements that transport sewage from lower to higher elevations, making it possible to send wastewater to treatment facilities where gravity flow is not feasible. However, one of the most common — and often overlooked — challenges of sewage pumping stations is odour control.

Odours from sewage pumping stations are more than just an inconvenience. They are a significant environmental concern, a public health risk, and a factor that can negatively impact the social well-being of communities. In this blog, we will explore the causes of sewage pumping station odours, the challenges of managing them, technologies available for odour control, and how Elixir Enviro Systems is helping industries and municipalities solve these challenges sustainably.

1. Why is Odour Control Important in Sewage Pumping Stations?

Odour emissions are not just a public nuisance; they pose serious health and environmental risks:

Respiratory Irritation: Prolonged exposure to H₂S and ammonia can cause irritation to the eyes, nose, and throat and may lead to more severe respiratory problems.

Corrosion of Infrastructure: Hydrogen sulfide can convert to sulfuric acid, corroding concrete structures and metal pipelines, leading to increased maintenance costs.

Environmental Degradation: Odour-causing gases contribute to atmospheric pollution and can have negative effects on nearby flora and fauna.

Community Complaints and Legal Issues: Persistent odour problems lead to public complaints, social unrest, and, in some cases, environmental regulatory penalties.

2. Why Sewage Pumping Stations Stinks?

Odour emission from sewage pumping stations happens because of the way they handle wastewater. Odour to become a problem, it must leave the wastewater and enter the air. This process, known as mass transfer, is driven by concentration differences—when there’s more of a compound in the water than in the air, nature pushes for balance, causing gases to be released. Ventilation and turbulence speed up this transfer, making the sewage pumping station prone to strong odors. While Henry’s Law predicts how much gas should be in the air, real-world factors like flow rates, temperature, and facility design create much more variability.

Let’s understand various factors contributing to odour emission from sewage pumping stations, drawing on various sources to ensure a thorough understanding.

2.1. Biological Sources of Odour

Odour in sewage pumping stations primarily arises from the anaerobic decomposition of organic matter, leading to the production of hydrogen sulphide (H₂S) and other volatile organic compounds (VOCs). H₂S, known for its rotten egg smell, is generated by sulfate-reducing bacteria in conditions where oxygen is depleted, such as in stagnant sewage. This process is particularly pronounced in wet wells, where sewage accumulates before pumping, and in rising mains, where hydraulic residence time exceeds 6 hours. The decomposition is accelerated by warmer temperatures and stronger sewage, often seen during dry weather, which reduces dilution and increases organic content.

2.2. Design & Operational Factors in Pumping Stations

Sewage pumping stations are designed to collect and pump wastewater to treatment facilities, often against gravity, using wet wells and force mains. The wet well, where sewage is stored before pumping, is a critical area for odour production due to the potential for stagnation. When sewage sits for extended periods, anaerobic conditions develop, fostering H₂S production. The pumping action itself, involving turbulence, exacerbates odour emission by agitating the sewage and releasing trapped gases into the atmosphere.

The length of the force main, the pipe from the pump to the discharge, also influences odour. Longer force mains increase the residence time of sewage, allowing more time for anaerobic decomposition and H₂S production. Design guidelines for sewage works emphasize keeping force main lengths short to reduce dynamic head losses and odour production. This is particularly important at initial and design flows, where prolonged exposure can lead to significant gas buildup.

Trends in sewer system design, such as centralizing treatment and moving to separate sewer systems, can exacerbate H₂S problems. Centralization increases pumping distances, leading to more stagnant conditions and higher H₂S production, while separate systems lack rainwater dilution, increasing the risk of odour issues. These trends highlight the need for adaptive odour control strategies in modern wastewater management.

2.3. Trade Effluent Impact

An interesting factor is trade effluent—wastewater from industries—which can add odorous compounds, making the smell stronger, especially in dry weather when sewage is more concentrated. Trade effluent, may itself be odorous or increase the strength of the sewage, leading to enhanced odour generation. This is particularly relevant in urban areas where industrial discharges are common.

2.4. Maintenance Influences

Maintenance is another critical factor. Poorly maintained stations, with blockages or grease buildup, can lead to increased odour emissions. Similarly, control float switch problems can cause pumps to remain on, potentially agitating sewage excessively and releasing more gases. Regular maintenance, including clearing debris and ensuring proper operation, is essential to mitigate these issues, as advised in community guidance for living near pumping stations.

2.5. Environmental Influences

Environmental factors, such as temperature, play a role in odour intensity. Warmer seasonal temperatures increase odour generation, as bacterial activity accelerates. Additionally, the design of ventilation systems can affect how odours are dispersed. For instance, rooftop vents and mechanical ventilation are used to manage pressure and flow, but improper design can lead to odours reaching ground levels, especially under wind currents or temperature inversions.

3. What Causes the smell-Uncovering the Smelly Secrets!

Wastewater isn’t just water—it’s a complex mix of organic compounds, many of which have strong, unpleasant odours. As oxygen is depleted and anaerobic conditions take over, these odours intensify, creating a bigger challenge for treatment facilities.

3.1. The Rotten Egg Culprit: Hydrogen Sulfide

Hydrogen sulfide (H₂S) is the main offender, notorious for its rotten egg smell. It forms when sulfate-reducing bacteria thrive in oxygen-starved conditions, often inside pipe biofilms and sludge layers. Factors like low oxygen, high organic content, and long retention times boost its production. Highly toxic at high levels, H₂S can be deadly, making its control a top priority.

3.2. The Stealthy Sulfur Compounds

Beyond H₂S, other sulfur-based compounds—mercaptans, dimethyl sulfide, and dimethyl disulfide—add to the stench. These compounds are even trickier because they don’t dissolve as easily in water. High-energy areas like junction chambers, mixing tanks, and dewatering processes release them in full force, making odour control a challenge.

3.3. The Ammonia Factor

While ammonia isn’t as pungent as sulfur compounds, it can still be a problem, especially in solids processing. Dewatering, lime stabilization, and composting can trigger ammonia emissions, sometimes mixed with fishy-smelling amines. Anaerobic digestion and high-temperature processes further intensify these odours.

3.4. The Hidden Odour Offenders

Odour isn’t just about sulfur and nitrogen. Wastewater also contains volatile organic compounds (VOCs), aldehydes, ketones, and carboxylic acids, which contribute to its distinct, unpleasant scent. While not always the main culprits, they can make odour control even more complex.

Understanding these odour sources is key to managing them effectively.

4. Design Strategies to Minimize Odour Emissions from Sewage Pumping Stations

Effective design is paramount to minimizing odour emissions, and several strategies can be implemented based on engineering guidelines and best practices. The following sections outline these considerations

4.1. Location and Layout Considerations

The station’s location and layout can also influence odour impact:

Site Selection: Positioning the station away from residential areas to minimize community exposure, though this may not always be feasible.

Pipework Design: Minimizing bends and drops in pipework to reduce turbulence, which can release trapped gases. Avoiding long force mains is also advised, as they can increase retention time and odour production.

4.2. Minimizing Retention Time

One of the most effective ways to reduce odour is to minimize the time sewage spends in the pumping station, particularly in the wet well. This can be achieved through:

Proper Wet Well Sizing: Ensuring the wet well is appropriately sized to match inflow rates, preventing overflow and stagnation. For example, operating wet wells at lower levels can reduce detention times. The Ontario guidelines, recommend more frequent pumping for fill-and-draw stations and lowering level set-points for variable speed pump stations where odour is an issue.

Pump Capacity and Operation: Selecting pumps with sufficient capacity to handle inflows promptly and using variable frequency drives (VFDs) to match pumping rates with inflow, thus avoiding prolonged storage. This reduces the likelihood of anaerobic conditions developing, which is a major source of H₂S production.

4.3. Pump Selection and Operation

The type and operation of pumps can influence odour emissions:

Submersible Pumps: These are often preferred as they reduce turbulence and splashing compared to dry pit pumps, minimizing gas release. In other words, the pump selection should prioritize low turbulence.

Operational Practices: Ensuring pumps operate frequently to prevent stagnation, and designing for easy maintenance to allow routine cleaning, which reduces organic buildup and odour production.

4.4. Wet Well Design for Self-Cleaning and Maintenance

The wet well’s design can directly impact odour control:

Sloped Bottoms and Fillets: Incorporating sloped bottoms or fillets in rectangular channels and tanks to prevent sediment accumulation. This reduces ‘dead zones’ where solids can settle and foster anaerobic conditions.

Aeration Where Needed: Providing aeration to maintain solids in suspension where self-cleaning velocities cannot be achieved, though excessive aeration should be avoided to prevent increased turbulence and odour release.

Access for Cleaning: Ensuring easy access for routine hosing and debris removal, which helps maintain hygienic conditions and reduces odour production.

4.5. Liquid Phase Treatment – Chemical Dosing for Odour Prevention

Liquid side treatments focus on preventing odour formation in the wastewater itself, targeting the root cause by maintaining aerobic conditions or neutralizing odorous compounds. Chemical treatment can be integrated into the design to prevent odour-causing gas formation:

Oxidizing Agents: Adding substances like chlorine, hydrogen peroxide, or pure oxygen to oxidize sulphides and inhibit their production. The air injection can be successful for short to moderate force mains, though care must be taken to avoid air binding at high points.

Precipitants and pH Control: Using iron or zinc salts to precipitate sulphides or raising pH with sodium hydroxide to inhibit H₂S off-gassing. These measures are effective in localized areas but require careful consideration of impacts on solids handling, such as increased sludge production.

Electron Acceptors: Implementing sodium nitrate in sewers, which has advantages like slower consumption and non-hazardous properties.

Other Agents: Anthraquinone inhibits sulphate-reducing bacteria, effective for several days to six weeks, but limited by low solubility for force main applications. Caustic slug dosing with sodium hydroxide shifts sulphide equilibrium, inactivating the slime layer, effective for days to weeks but not for continuous addition.

4.6. Vapour Phase (Air side) Treatments for Odour Control

In the previous point we discussed the possibilities and options to avoid odour emissions to the gas phase. Generally, without a proper air treatment, it is hard to operate the pumping station, especially since the odour threshold of the compounds causing odour are very small making it detectable at very low concentrations. So, odour emission is unavoidable in most cases and therefore odour control equipment is absolute necessary. The Air side treatments focus on capturing and treating odorous air to prevent its release into the environment. The air side treatment includes Containments, Ventilation and Odour Control Units (OCUs).

4.6.1. Sealing and Containment

Preventing odours from escaping into the environment requires robust containment measures:

Airtight Covers: Designing covers for wet wells with minimal joints and using seals at all access points to contain gases. Corrosion-resistant materials, such as stainless steel or epoxy-coated aluminium, or FRP is preferred due to the corrosive nature of sulphides and sulfuric acid formed from H₂S.

Avoiding Condensate Points: Ensuring covers are designed to prevent condensate collection, which can exacerbate corrosion and odour release. This is particularly important for maintaining long-term structural integrity.

4.6.2. Ventilation Systems

Ventilation is critical for removing odorous air from the wet well. Design considerations include:

Forced Ventilation: Installing air extraction systems to remove odorous gases, maintaining a slight negative pressure to prevent fugitive odours and ensure that the air is treated before release.

Gravity (passive) Ventilation: Employs natural ventilation for low airflow applications, such as roof vents, to equalize pressure and control odour.

4.6.3. Odour Control Units (Technologies) for Sewage Pumping Stations

1. Biofilters & Biotrickling FIlters

Use microorganisms to biologically degrade odorous compounds in the air. They can remove 99.9% of H₂S, ammonia, and other odours. They perform best with stable airflow and are eco-friendly, requiring no chemicals and have low operating costs.

2. Activated Carbon Adsorption Units

Activated carbon units are compact and effective at adsorbing odour-causing gases, particularly VOCs and H₂S. These systems are suitable for locations where space is a constraint and where moderate odour loads are encountered. Regular carbon replacement is required based on load.

3. Chemical Wet Scrubbers

Wet scrubbers use chemical solutions based on the type of compounds to be removed from the air stream. Chemicals such as sodium hydroxide or chlorine-based compounds to neutralize hydrogen sulfide and acids to remove ammonia. Therefore, it is generally called Acid and Alkali Scrubbers and are suitable for high contaminant levels.

4. Thermal Oxidation

Burns odorous air at high temperatures, though less common for pumping stations due to energy costs.

5. Monitoring and Compliance

Effective odour control doesn’t end with treatment — continuous monitoring is key:

Portable H₂S Detectors: For on-the-spot odour monitoring.

Continuous Online Monitoring Systems: Enable real-time tracking of gas concentrations and air quality.

Olfactometry Surveys: Human sensory measurement of odour concentrations for community impact assessments.

Regulatory Compliance: Many environmental regulations specify acceptable odour levels and H₂S concentration limits that must be met.

6. Elixir Enviro Systems: Your Partner in Odour Control

At Elixir Enviro Systems, we understand the complexity of sewage odour control and offer customized solutions that combine efficiency, sustainability, and long-term reliability. Our services include:

✅ Biofilter & Bioscrubber Design & Installation – Tailored systems with optimized media selection for maximum efficiency.

✅ Scrubber Systems – Wet and dry scrubber solutions for handling high-concentration odour streams.

✅ Odour Control Units (OCUs) – Different modular solutions combining biofiltration, carbon adsorption, and chemical scrubbing are available based on the client requirement.

✅ Odour Impact Assessment and Modeling – Using advanced simulation tools to predict odour dispersion and community impact.

Conclusion

Odour control in sewage pumping stations is not just a regulatory requirement — it’s a commitment to public health, environmental stewardship, and community welfare. By leveraging advanced technologies and proactive monitoring, municipalities and industries can effectively mitigate odour issues and create more liveable urban environments.

At Elixir Enviro Systems, we are proud to be part of that mission, offering reliable, innovative, and sustainable odour control solutions that protect both people and the planet.

#OduorControl#OdorControl#PumpingStation#LiftingStation#SewageManagement#WastewaterTreatment#CleanAir#UrbanPlanning#InfrastructureDesign#EnvironmentalEngineering#SustainableCities#AirQuality#PublicHealth#EngineeringSolutions#EcoFriendly#FreshAir#WaterTreatment#VentilationSystems#ChemicalDosing#Biofilters#AirTreatment#LiquidTreatment#WetWellDesign#PumpStations#SewagePumping#Bioscrubber#ChemicalScrubber#BioTricklingFilter#OCU

0 notes

Text

4 more hours I can do this I'm so brave and strong and pretty

20 notes

·

View notes

Text

BioClear Solutions

BioFilter

Filters in Aquariums

Aquarium filters play a vital role in maintaining the health and cleanliness of aquatic ecosystems. They remove harmful toxins, debris, and waste from the water, ensuring a balanced environment for fish and plants to thrive. For aquarium owners, filters reduce the need for frequent water changes, simplify tank maintenance, and protect aquatic life, making them indispensable tools for both beginners and seasoned hobbyists.

Introducing the BioFilter

Our BioFilter is an innovative biological filter designed to revolutionize aquarium care. Unlike conventional filters, it uses advanced biofiltration technology to efficiently break down harmful ammonia and nitrites, promoting a healthier aquatic environment. Its unique design enhances water clarity, reduces maintenance requirements, and is eco-friendly. Compared to commercial filters, the BioFilter stands out for its cost-effectiveness, durability, and superior filtration performance, making it a valuable investment for aquarium enthusiasts.

The BioFilter offers a game-changing solution for aquarium owners seeking effective and sustainable filtration. Its innovative design and exceptional advantages over conventional filters ensure healthier aquatic ecosystems while simplifying maintenance tasks. With the BioFilter, maintaining a thriving aquarium has never been easier.

0 notes

Note

id also like a happy meal with extra happy

Of course!!

1 note

·

View note

Text

O822.4577.1975 | Jual Media Sarang Tawon IPAL Surabaya

Hub : O822-4577-1975 (AUROZA TEKNIK), Kami jual media sarang tawon untuk IPAL di Surabaya - Sidoarjo. Menerima pemesanan jual sarang tawon septic tank, harga sarang tawon septic tank, biofilter sarang tawon surabaya, sarang tawon septic tank surabaya, sarang tawon honeycomb surabaya, sarang tawon ipal sidoarjo, harga sarang tawon ipal, jual media sarang tawon sidoarjo, sarang tawon untuk ipal

Untuk info dan pemesanan, silakan hubungi :

0822-4577-1975 (Telp/WA)

#jual media sarang tawon ipal surabaya#jual sarang tawon septic tank#harga sarang tawon septic tank#biofilter sarang tawon surabaya#sarang tawon septic tank surabaya#sarang tawon honeycomb surabaya#sarang tawon ipal sidoarjo#harga sarang tawon ipal#jual media sarang tawon sidoarjo#sarang tawon untuk ipal

1 note

·

View note

Text

SELALU READY, CALL +62 852-1533-9500, Jual Septic Tank Anti Penuh Melayani Jember

ORDER KLIK http://wa.me/6285215339500, Bio Sepiteng Melayani Pengiriman ke Jember, Bio Bakteri Septic Tank Melayani Jember, Harga Sepiteng Bio Melayani Jember, Ukuran Septic Tank Biotech Melayani Jember, Biosung Melayani Jember

TANQUE FORTE Merupakan Merek Bio Septic Tank Terbaik, Tahan lama dan Bergaransi Panjang, cocok untuk rumahan, IPAL Komunal, IPAL Medis, Rumah Sakit atau HOTEL

SIAP MELAYANI PENGIRIMAN KE SELURUH INDONESIA

PABRIK SEPTIC TANK BIO TANQUE FORTE

Jl. Cangkudu No. 7-9

Sukamukti Ranca Manyar

Kab. Bandung Jawa Barat- Indonesia

Bapak Hendra

CALL 0852-1533-9500

UkuranBiotankAndirJember, #HargaBioSepitengJember, #HargaBiofil1M3diJember, #UkuranBiofilSepticTankJember, #HargaBiotankSepticTankJember

Posting By:

Sarah Nabila Azzahra

SMK Plus Pelita Nusantara

#Harga Biofil 2 M3 di Jember#Harga Septic Tank Bio Murah Jember#Harga Septik Tank Biofilter Jember#Tangki Biofil di Jember#Biotank 800 Liter Jember

0 notes

Text

SELALU READY, CALL +62 852-1533-9500, Jual Septic Tank Anti Penuh Melayani Gresik

ORDER KLIK http://wa.me/6285215339500, Bio Sepiteng Melayani Pengiriman ke Gresik, Bio Bakteri Septic Tank Melayani Gresik, Harga Sepiteng Bio Melayani Gresik, Ukuran Septic Tank Biotech Melayani Gresik, Biosung Melayani Gresik

TANQUE FORTE Merupakan Merek Bio Septic Tank Terbaik, Tahan lama dan Bergaransi Panjang, cocok untuk rumahan, IPAL Komunal, IPAL Medis, Rumah Sakit atau HOTEL

SIAP MELAYANI PENGIRIMAN KE SELURUH INDONESIA

PABRIK SEPTIC TANK BIO TANQUE FORTE

Jl. Cangkudu No. 7-9

Sukamukti Ranca Manyar

Kab. Bandung Jawa Barat- Indonesia

Bapak Hendra

CALL 0852-1533-9500

UkuranBiotankAndirGresik, #HargaBioSepitengGresik, #HargaBiofil1M3diGresik, #UkuranBiofilSepticTankGresik, #HargaBiotankSepticTankGresik

Posting By:

Sarah Nabila Azzahra

SMK Plus Pelita Nusantara

#Harga Biofil 2 M3 di Gresik#Harga Septic Tank Bio Murah Gresik#Harga Septik Tank Biofilter Gresik#Tangki Biofil di Gresik#Biotank 800 Liter Gresik

0 notes

Note

hey. hey. ever think about how ax knows how to combine DNA on the fly and only does it once to create his humansona. and then as far as I'm aware this is never brought up again.

(also do you think K.A.A. was Aware they were creating a straight up intersex character, or)

the frolis maneuver is actually brought up one other time, when elfangor makes his human morph and becomes a nothlit to stay with loren on earth. i do think it's weird that i'd only have two nickels, though, because you'd think this kind of insane tech would be explained more or used in other contexts, but i guess there were just. not enough applications for it to matter??? i guess??? even though ax's human morph is commented on in pretty much every book he uses it in.

i feel like, using the frolis maneuver, you could pose as a random controller pretty easily for like, spy-work, at least outside the pool, but who knows. i also wonder how the gleet biofilter exactly works in the books, because from what i'm seeing from a gloss-through (i meant for it to be brief, but it just left me with more questions and now ive been at this for an hour), in the tv show it can sniff out the lack of yeerk in your brain, and in the books the biofilter can't actually detect anything inside the body of anything else??? even though cassie goes through the biofilter with tidwell in her brain, and says it detected "only yeerk and human", exactly ONE book before that the animorphs, confusingly, successfully negate it by sneaking in through the nostrils of a cow...! which seems weird, to me. if the biofilter can detect a yeerk through the scalp and skull of a human, why can't it detect a fly in a cow nose??

anyway, i think you could make potentially infinite random guys to morph into and pose as to sneak past the biofilter. depending on whether it allows non-infested humans through or not. which seems to be a big fat question mark. if so, more "fun" missions to drag tidwell and aftran into!

and as for applegate Knowing she was creating an intersex character, i think that's something you'd have to ask her. super cool that it turned out that way though!

#ask#animorphs#andalite#txt#the answer may just be that the ghostwriter for book 28 phoned it in. not a very good book anyway woops#and the frolis maneuver just never got super explained or used anytime else because that would require EVEN MORE rules#and there are already so many to keep track of. two hour limits and allergies and distractions and exhaustion and#not to mention all the bullshit that had to be made up for scenarios you'd never ever find yourself in. like looking through fly eyes#or morphing a flea when you've been hit with a shrink ray#or seeing erek's metal chassis through a hologram with spider eyes Y'know. theres a lot going on here#andalite tech#tagging because i might want to do a proper deep dive into the inconsistencies of andalite tech and its yeerk offshoots

28 notes

·

View notes

Note

anitv Jake did WHAT

OP refers to these tags #4d chess psychological warfare#like that time in anitv jake acquires tom and successfully talks a bunch of controllers into shooting the real tom

The episode "Face/Off Pt. 3" is a classic combination of AniTV having some plot ideas with fascinating potential... and then executing those ideas so badly the show is nigh-unwatchable.

Various Animorphs are running around the yeerk pool in the season finale. (Rachel is in Tobias's brain as a yeerk to defeat the Gleet Biofilter, speaking of cool ideas that got wasted.) Jake drags Tom into a back room, and when the controllers break down the door, there are two identical copies of Tom standing there. It's kinda cool that the audience also doesn't know which one's Tom and which is Jake, because both of them immediately start shouting about how the other one is an imposter and the controllers should shoot that guy.

For the rest of the episode — which switches to focus on how Marco collapses the entire yeerk pool cavern by pulling down a single ceiling tile and throwing it against a pillar — there are two copies of Tom running around. There's some dramatic tension when we see one of the Toms get crushed to death by falling rubble and don't know if Jake just died, as well as in a later scene where one of the Toms walks in on Cassie mid-morph. That Tom demorphs into Jake, with the honestly funny line "Phew! My parents were about thirty seconds away from having a set of identical twins." Original flavor Tom is dead in the basement, but that's fine, because the Animorphs are off to a dance party. Also, Tom's back two episodes later with no explanation because Melissa Chapman needs a boyfriend. Sigh. So much potential, so badly wasted.

#animorphs#anitv#jake berenson#tom berenson#yes i know there are *glaring* plot holes and character inconsistencies in this concept#including tom not recognizing jake as jake is standing six inches away and talking directly to him#including jake casually trying to get tom killed after proving willing to let cassie maybe-die to save tom in an earlier episode#but i still think it's a really cool idea that i wish we'd seen k.a. applegate explore in animorphs canon#with good writing and coherent plotting and all

207 notes

·

View notes

Text

Day Twelve - Kinktober 2024

Day 12: Breeding / Collars / Sex Pollen Male Sole Survivor/Paladin Danse Rating: Explicit | Word Count: 1451 Warnings: Sex pollen, dubcon, oral sex, rough oral sex, come eating

Ghost of a Boy Kinktober Prompt List | Kinktober '24 Masterlist Divider by @saradika-graphics

The trap had gone off unexpectedly. One moment Nate and Danse had been walking down a corridor, heading back towards the exit of the long-forgotten bunker they had stumbled on, their packs filled with salvage, ammo, and a brand new bobblehead to add to Nate’s collection. The next moment the entire area was filled with a strange purple mist that left Nate spluttering and running for the main doors.

“It’s breached my power armor’s biofilters!” He heard Danse call out, before feeling the large armored hand of the paladin pushing him forward. “Keep moving soldier! We need to get out of this enclosed environment!”

Coughing and wheezing, Nate fell to his knees as soon as they got outside, the twinkling stars of the Commonwealth sky never looking more welcoming. Turning back to the bunker doors Nate watched as Danse finally appeared in a swirl of purple. Pulling off his helmet, Danse’s eyes were streaming with tears, as the larger man dropped to one knee while a hacking cough wracked his body.

“What the hell was that?” Nate choked out between coughs. “We passed through there on the way in. There was nothing to trigger. We cleared it.”

“Clearly a secondary security system we missed.” Danse frowned, standing back up and offering Nate a hand. “Perhaps designed to trigger as people were leaving.”

“Assholes.” Nate brushed specks of purple dust off his shoulders and collected a small amount on his fingertips. Carefully he held it up to his Pip-Boy’s sensor.

“Indeed.”

“Well, I’ve no idea what that shit was, but hopefully my Pip-Boy will be able to figure it out.” Looking around the area, Nate pointed off into the distance to the familiar red glow of an old Red Rocket station. “In the meantime, we should get somewhere safe, or you know, safer.”

“Affirmative.” Danse nodded, blinking his eyes with a shake of his head. “Lead on.”

The Red Rocket couldn’t have been more than fifteen minutes away from the bunker, but the journey felt like forever. At first, they had walked in silence, as night was especially dangerous in the Commonwealth. But soon the cramps had hit and both men had let out involuntary groans, Nate dropping to his knees once more until the pain subsided. From there it had only gotten worse.

By the time the two men stumbled through the doors of the dilapidated gas station, they were both pouring with sweat. Danse looked pale with a constant expression of intense pain and determination on his handsome face. Nate’s head was swimming and he was struggling to focus. His attention was constantly shifting between trying to be aware of his environment and the dull throbbing ache between his legs.

The heat and arousal had started not long after the cramps, beginning with an intense thrum that seemed to spread through his entire body sending goosebumps dancing across his skin. With each wave of pain, the tingling got worse, until Nate’s cock was hard and heavy. It ached and throbbed with each movement, pulling soft moans from him as he walked.

Danse knew; he had to. There was no hiding Nate’s erection in his condition. His dust-covered jeans obviously tented as he leaned against the cool wall of the building. And glancing over Nate could see Danse’s eyes flicking between the door and Nate’s crotch.

“Any indiction… ahhh… any…” Danse tried to speak, his face twisting in a mixture of pain and ecstasy. “What the hell was that stuff?”

Nate’s arm had never felt so heavy as he lifted his Pip-Boy. The progress bar of the analysis had moved, but not by much. Shaking his head, Nate let out a long sigh.

“No idea yet. Come on, we need to get into the office. We can secure the door better and get you out of that armor.”

Danse just nodded, following Nate into the small back office of the Red Rocket, before closing the heavy door behind him. Danse paused, resting his head against the door, before slowly opening his power armor and climbing out.

It occurred to Nate that he’d never seen Danse outside his power armor in all the months they’d known each other. And as that strange thought struck him, his eyes were immediately drawn to the very obvious erection straining against Danse’s orange flight suit. Palming his own hardness Nate felt as though his whole body was on fire, and the only way to extinguish it was Danse’s cock.

“Danse…” Nate’s mouth felt dry as he approached the panting man. “I need… fuck…I need…”

“I think it’s safe to assume that… damn it… that the substance was an aphrodisiac,” Danse growled, his eyes fixed on Nate’s groin. “We may have to… act… on these urges to purge them.”

“Fuck me then.” Nate staggered over to Danse, burying his face in the paladin’s neck as he bucked against his leg. Danse’s hands roamed over his body, pulling open and off his shirt while Nate fumbled with his fly to free his aching dick.

“Negative.” Danse groaned, cupping Nate’s ass. “As much as I might want to, we don’t have any suitable lubricant.”

“Just fuck me raw,” Nate whined, dropping to his knees to mouth at Danse’s erection through the flight suit, pulling off the remains of his clothes and armor. “I can take it.”

“No.” Danse began to pull off his clothes, throwing his hood to the floor, before tugging open the suit. “I won’t be able to stop and… and I don’t want to hurt you.”

“Fuck my mouth then.” Nate pleaded, pulling and yanking at Danse’s uniform until it was around the larger man’s knees. Almost immediately Danse’s cock sprang free, the angry red tip dripping precum as it twitch in front of Nate’s face.

“That’s my plan.” Danse nodded, taking his cock by the base and guiding it past Nate’s lips. “Open wide soldier.”

Nate didn’t need to be told twice, opening his mouth as wide as he could to take Danse’s girth. As the paladin’s fingers wove into his hair, Nate began to stroke his own cock in time with Danse’s thrusts.

The length of the other man easily hit the back of Nate's throat and Nate gagged and drooled as Danse bucked into his waiting mouth. With Danse's hand firmly holding his head in place all Nate could do was take it. Take every thrust, every jerk, every jolt as Danse used him. And he loved it. He needed it. This is what he was for, right?

All sense of self melted away, until all Nate was, all he became, was the hot needy hole for Danse to use. Danse's pace was merciless, leaving Nate breathless. Nate's eyes watered as he choked around the thick cock in his mouth, each hungry roll of Danse's hips hitting his gag relax.

But Nate could take it. The fog was easier to see through while he was on his knees, cock in hand, pumping in time with Danse. Each snap of the paladin's hips chasing away any doubt, sending sparks of pleasure directly to Nate's core.

With a hoarse moan, Danse came, flooding Nate's mouth with thick, salty release which he greedily swallowed. Nate could feel it spilling from the corners of his stretched lips, as his own climax hit. Still sucking and milking Danse, Nate emptied himself onto the floor, his hips bucking into his fist making ropes of cum spatter over Danse's feet.

The small dimly lit office stank of sweat and sex as the shrill beeps of the Pip-Boy jolted Nate from his sleep. His jaw ached and he instinctually rubbed it as he glanced down at his cum splattered body. He lost count of how many times he and Danse made each other climax. Time after time pulling and forcing each other to the edge until finally collapsing on the floor. The fever, the pain, and the urges finally subsiding and allowing them to sleep.

Crawling over to his discarded equipment Nate blinked at the bright light of the Pip-Boy. It seemed it had finally finished analyzing the strange purple dust that had triggered the night’s lustful activities.

[Unknown aphrodisiac. Traces of bufotenin. Proceed with caution.]

“No shit.” Nate rolled his eyes, throwing the Pip-Boy back down onto his clothes pile.

His whole, sticky body ached as he crawled back over to Danse’s sleeping form. He’d tell him later when he woke up. They’d need to be checked over by Knight-Captain Cade later, so perhaps he’d known more and be able to tell them about any long-term consequences. But that was something for later. Right now Nate was content to curl up in Danse’s arms and drift off back to sleep.

23 notes

·

View notes

Text

Unnatural Selection

oh no this was really bad

quite likely the worst episode of tng so far

(except for Code of Honor for its racism)

so this episode is held together by poor judgment, spit and technobabble.

The basic plot is as follows: They find out about some new disease that fast-forwards your aging and kills you. They quarantine the station that it's on, but they have children there, that they say have been in isolation and are definitely not infected, so the Enterprise beams one aboard, and of course they are infected, doctor Pulaski also gets infected and has to quarantine on the station, but then Data looks at some graphics and finds the cause of the disease and then they technobabble so hard that they figure out how to undo it all.

And in case it wasn't clear enough from that summary. The Enterprise finds a station full of people dying from a disease and the medical staff makes seemingly no effort at all to figure out what's going on. All they do is beam the children aboard, who are in absolutely no danger, beyond starving to death in a few weeks when all the adults are dead. It makes absolutely no sense to be concerned with the children, before trying to heal these adults.

And the medical problem was extremely solvable. Data did it within two scenes of being on the station. Did no one think "maybe we should request all data that the station has and give it to literally Data to look at?" Did no one think "Maybe the fast-aging children and the illness that makes you age fast could be connected?" (Ironically they were connected in a much more convoluted way)

But from there on it only gets worse. In my opinion, this is the most significant episode yet for technobabble. Of course we had some jargon here or there, but here have three dedicated scenes of people talking about poorly defined concepts like biofilters and transporter traces and genetic make-up (literally the worst kind!) and these are absolutely vital to the plot progression. I will always take a quick and simple "bad space weather, no transporter/sensors/warp" over any of this bullshit.

And the worst part is that after multiple experts in medicine and engineering (La Forge, O'Brien, Data, Pulaski) did not come up with the ultimate solution. It is instead Picard who thinks of "let's give the transporter Pulaski's DNA, so it can rebuild her to normal levels". Obviously none of the experts thought of it, because it was a contrived explanation, there to finally end this shit show.

But the glaring structural issues aside, what good is there here?

O'Brien has a name now, and he got quite a bit to do so that's nice.

Data and Pulaski get to interact a bit more.

Data initially believing that Pulaski is going rogue is great.

Maybe I'm reading too much into it, but there's a scene on the shuttle with the infected child where Pulaski tells Data that he doesn't have to worry, because he's a machine, and Data retorts (quite correctly, see The Naked Now) that he very much could be infected, but that he was concerned with Pulaski's safety, to which Pulaski replies that medical research is risky and it's all part of being human. And like, that kinda implies that she thinks of Data as more human, right? Like he is also taking a risk here.

The Picard arc reads really horribly here. He basically calls Pulaski's old captain for some plot-relevant info, which he doesn't have. Instead the old captain tells Picard that Pulaski is like Picard's number one fan, and that's the point where he shifts from disliking her to trying to save her. And it comes across as really self-agrandizing, like I thought she sucked before, but now that I know she has good taste in captains I guess she isn't so bad.

Also Jean-Luc "Shut Up Wesley" "Stop Babbling Data" Picard has absolutely no business being snippy to Pulaski about interrupting him. Picard probably interrupts other people more frequently this episode than Pulaski ever interrupts him.

Two notes on the genetic engineering: It is very funny to watch this episode post-DS9 (and more recently post-SNW) and see just how freely it features genetic engineering in the Federation. Although the episode is pretty clearly in the critical camp, if only vaguely.

I do think that the idea of "genetically engineered children that are immune to every disease but will still carry and mutate it"a would be a great basis for like a dystopian horror sci fi series. Where the remnants of the human race are monster, to be clear.

Also I did rather like the scene at the end, where they destroy the quarantined starship. It feels super wrong to see, in a way that was reasonably well done.

#the next generation rewatch#star trek#star trek tng#tng#star trek the next generation#this post was exiled by the queue continuum

3 notes

·

View notes

Text

Waste to Protein, Without the Smell: Engineering Cleaner Insect Meal Plants

Introduction

Insect meal processing is emerging as a sustainable and efficient solution to meet the growing demand for high-protein products, primarily used as feed for animals like fish, pet food and poultry, and sometimes for human consumption. The larvae stage is often targeted due to its high biomass and nutritional value.

In insect meal production, several types of larvae are commonly used due to their high nutritional value and efficiency in converting organic waste into biomass. The most widely used species is the black soldier fly larvae (Hermetia illucens), known for its ability to thrive on a variety of waste materials, including food scraps and manure. These larvae are rich in protein and fat, making them ideal for animal feed, and their frass is also valued as a fertilizer. Yellow mealworms (Tenebrio molitor) are another popular choice, especially in both animal and human food products. They are typically reared on grain-based substrates and have a high protein content with a lower fat profile compared to black soldier fly larvae. Lesser mealworms (Alphitobius diaperinus), or buffalo worms, are smaller but similarly used in poultry and aquaculture feed. Housefly larvae (Musca domestica) have been used for waste decomposition and feed, though they are less common today due to biosecurity concerns. Lastly, silkworm pupae (Bombyx mori), a by-product of the silk industry, are often utilized in insect meal, particularly for fish feed, owing to their high protein content.

Each species varies in terms of rearing requirements and nutritional composition. This different rearing conditions give rise to different levels of odour potential, ranging from the decaying waste to the final frass to the storage and transportation. Irrespective of the species used for the insect meal production, the processing of insect larvae to the meal always have similar line of odour generation. The decomposition of organic waste, microbial activity, and thermal processing contribute to the emission of volatile organic compounds (VOCs), ammonia, and sulfur-based gases, leading to unpleasant smells. These odours can impact worker comfort, community relations, and environmental compliance. To address these concerns, implementing effective odour control solutions is crucial. Being said that the black soldier fly larvae generally associated with stronger odours due to the nature of their feed substrates and metabolic activity.

This article explores the sources of odour in insect meal processing, the challenges they present, and the most effective strategies for odour mitigation.

Why Odour Control Matters in Insect Meal Manufacturing

Odour is a natural byproduct of organic processing, and insect meal production is no exception. The breakdown of insect biomass, drying processes, and fermentation stages can release volatile organic compounds (VOCs) and other odorants. While these smells might not bother the insects, they can be off-putting to nearby residents or workers. Effective odour management not only ensures compliance with environmental regulations but also fosters good relationships with local communities and supports the industry’s reputation as a sustainable solution.

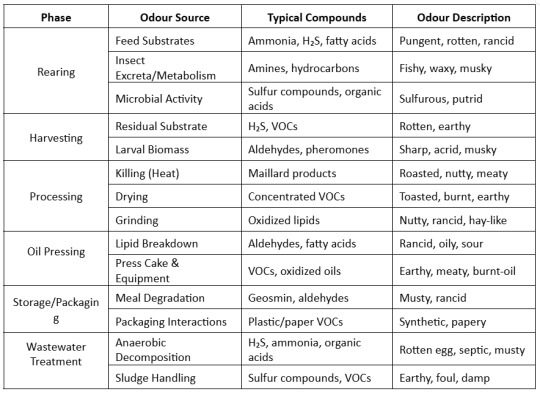

Sources of Odour in Insect Meal Production Plants

Insect meal processing is a highly sustainable source of protein, but it presents significant odour challenges. Understanding the sources of these odours is essential for developing effective control strategies. The primary sources of odour in insect meal production stem from raw material decomposition, insect rearing conditions, processing stages, byproduct treatment, and wastewater management.

1. Rearing Phase (Larvae Growth)

This initial stage involves growing insect larvae—such as black soldier flies, mealworms, or houseflies—on organic substrates. The odours emitted during this phase originate from the feed, the larvae themselves, and microbial activity. Feed substrates play a significant role: organic waste like food scraps or manure decomposes, releasing volatile organic compounds (VOCs) such as ammonia, hydrogen sulfide (with its characteristic rotten egg smell), and short-chain fatty acids like butyric acid, which smells like rancid butter. Grain-based feeds, such as wheat bran or oats, can undergo fermentation or fungal growth, producing odours like alcohols (ethanol) and esters that have fruity or solvent-like characteristics.

Larval metabolism contributes further to the odour profile. Frass—the combination of insect excreta and undigested substrate—produces nitrogenous compounds such as ammonia and amines, which smell sharp, fishy, or decayed. In addition, larvae release hydrocarbons through their cuticles, emitting faint waxy or oily odours. The microbial decomposition of feed, whether through aerobic or anaerobic pathways, generates sulfur compounds like mercaptans and additional organic acids, which amplify the odour intensity and complexity during this stage.

2. Harvesting Phase

During harvesting, mature larvae are separated from their substrate, often through mechanical means. This disruption enhances the release of odorous compounds. Residual wet substrate left behind after separation can undergo anaerobic decomposition, producing intensified sulfurous and putrid smells. Handling live larvae may cause stress responses, leading them to release defensive compounds like aldehydes (which have sharp, green odours) or pheromones that are often musky or acrid, depending on the species.

Cleaning processes during harvesting, such as rinsing the larvae with water or solvents, may dilute some of the odours but can also stir up stagnant, earthy smells from organic residue. The combination of biological and mechanical factors in this phase makes it one of the more dynamic contributors to the odour profile in insect meal production.

3. Processing Phase (Conversion to Insect Meal)

This phase includes the killing, drying, and grinding of larvae into meal. Different killing methods impact odour differently: freezing typically emits minimal odour at first, though thawing may release faint protein breakdown smells. In contrast, heat-based methods like blanching or boiling cause Maillard reactions (browning reactions between proteins and sugars), producing more pronounced roasted, nutty, or even meat-like aromas.

Drying, whether via oven or air, concentrates VOCs by evaporating moisture. This can result in toasted, earthy, or slightly burnt odours—especially if overheating occurs, which can create acrid or charred smells. Grinding the dried larvae into meal releases fine particulates, emitting nutty, hay-like scents. However, if the lipids in the larvae oxidize during this process, particularly in fat-rich species like black soldier flies, they can produce aldehydes such as hexanal, which carry rancid or oily smells.

4. Oil Pressing Phase (Lipid Extraction)

In facilities that separate insect oil from the protein meal—especially with species like black soldier flies—mechanical oil pressing introduces additional odour sources. When pressing is done with heat, or when heat is generated from friction, thermal breakdown of lipids can occur. This leads to the formation of aldehydes, ketones, and volatile fatty acids, producing smells ranging from grassy and paint-like to rancid or sour. If pressing temperatures are too high, acrid or burnt-oil odours may develop.

Oxidation of fats during or after pressing is another key contributor to odour. Rancid, stale-oil-like smells can emerge from unsaturated fats breaking down, particularly if the oil is not processed or stored in an oxygen-limited environment. The residual press cake may still contain fat and moisture, contributing warm, earthy, or slightly sour odours if it is not cooled and dried promptly. Emissions may also arise from hot surfaces and oil collectors, especially in enclosed spaces without adequate ventilation, resulting in a lingering oily or meaty atmosphere.

5. Storage and Packaging Phase

Once insect meal is produced, it is stored and packaged, and these post-processing conditions can influence odour stability. Properly stored dry meal usually has a mild, nutty, or toasted grain-like smell. However, if moisture infiltrates the product during storage, it can support mould growth, leading to musty or fungal odours associated with compounds like geosmin.

Packaging materials can also interact with the meal. For example, VOCs from the insect meal can adsorb onto plastic or paper packaging, subtly altering the perceived odour with synthetic or papery notes. While this phase may seem passive, it can significantly affect product perception, especially in high-value feed or food applications.

6. Wastewater Treatment Phase

Water is used at various stages of insect meal processing—for cleaning larvae, blanching, or cleaning equipment—and all of this generates wastewater rich in organic matter. The treatment of this wastewater introduces another significant odour source.

If anaerobic conditions develop in wastewater holding tanks, collection pits, or equalization tanks, foul-smelling gases such as hydrogen sulfide (H₂S), ammonia, and volatile fatty acids are released. H₂S, in particular, contributes a rotten egg odour that is often the most intense and noticeable. In addition, foaming and surfactant-rich wastewater can carry odorous compounds into the air as aerosols, especially during agitation or aeration in treatment tanks.

Further odours can arise from sludge handling—the thickened solids separated from the wastewater—which may emit earthy, septic, or musty odours, particularly if not properly stabilized or rapidly removed. Without adequate aeration or treatment, wastewater components can be a persistent and site-wide source of offensive odours, particularly in warm climates or enclosed processing facilities. If not treated properly, this wastewater can become a significant source of odour pollution.

Key Odorous Compounds to Monitor

Impact of Uncontrolled Odour

1. Environmental Concerns

Odorous emissions contribute to air pollution and can negatively impact local ecosystems. VOCs and ammonia released into the atmosphere can react with other pollutants, forming secondary air contaminants.

2. Health Hazards

Workers in insect meal plants may experience respiratory discomfort, nausea, and headaches due to prolonged exposure to odours. Strong odours can also lead to reduced air quality in surrounding areas.

3. Regulatory Compliance

Environmental regulations impose strict limits on odour emissions. Failure to comply with these standards can result in fines, operational restrictions, or shutdowns.

4. Community Complaints & Business Reputation

Foul odours can lead to complaints from nearby residents and businesses, potentially damaging the company’s reputation and straining relations with the local community.

Odour Control Strategies for Insect Meal Processing Plants

To mitigate odour challenges, insect meal processing facilities can adopt various control measures. Biofilters and scrubbers can be used to capture and neutralize odorous compounds before they are released into the atmosphere. Proper ventilation systems can help reduce indoor odour buildup. Wastewater treatment processes should be implemented to prevent the accumulation of organic waste that leads to odour formation. Additionally, optimizing rearing conditions by maintaining controlled humidity, aeration, and feed quality can help minimize metabolic odours from insect populations.

Implementing a robust odour control strategy is essential to maintaining air quality, regulatory compliance, and operational efficiency in insect meal processing plants. Below are some of the most effective odour mitigation techniques:

1. Biofiltration Systems

Biofilters are an eco-friendly solution that uses microorganisms to break down odorous compounds like volatile organic compounds (VOCs), ammonia, and hydrogen sulfide (H₂S). The process involves passing contaminated air through a biofilter medium (such as compost, peat, or wood chips), where microorganisms degrade odorous compounds into harmless byproducts like carbon dioxide and water.

2. Chemical Scrubbers

Scrubbers use liquid chemicals to neutralize odour-causing gases. The two main types include:

Acid Scrubbers: Effective for ammonia removal.

Alkaline Scrubbers: Target hydrogen sulfide and organic acids. This method is highly efficient for treating large air volumes and removing multiple odorous compounds simultaneously.

3. Activated Carbon Filtration

Activated carbon filters are ideal for adsorbing VOCs and organic odour compounds. These filters trap odorous molecules within the porous carbon structure, effectively neutralizing them before they are released into the atmosphere. This method is particularly effective in handling residual odours after primary treatment.

4. Enclosed Processing & Ventilation Systems

Enclosed Facilities: Sealing processing areas prevents odours from escaping into the environment.

Proper Ventilation: Strategic placement of ventilation ducts and air handling systems ensures the efficient capture and treatment of odorous air before release.

5. Thermal Oxidation

Thermal oxidation or combustion-based systems break down odorous gases at high temperatures, converting them into non-odorous byproducts like carbon dioxide and water. Though effective, this method requires high energy consumption and is best suited for large-scale operations.

6. Onsite Odour Monitoring & Control Systems

Real-time odour monitoring technologies such as Oizom (www.oizom.com) help track odour levels and detect problem areas. Implementing automated odour control systems allows plants to adjust treatment processes dynamically based on odour intensity.

Elixir Enviro Systems: Your Partner in Odour Control

Elixir Enviro Systems is the pioneer in industrial Odour Control system provider in India. Have installed odour control unit in various industries such as :

Biofiltration systems for VOC and odour reduction

Chemical scrubbers for ammonia and hydrogen sulfide removal

Advanced air purification technologies

Onsite odour measurement and regulatory compliance consulting

we provide the best suited odour control system tailored for each individual cases.

You may Consult Elixir Enviro Systems for for all your odour control and wastewater treatment related enquiries.

Conclusion

Odour control is a critical aspect of operating a successful insect meal production plant. By understanding the sources of odour and implementing a combination of ventilation, filtration, and waste management strategies, plant operators can minimize odour emissions and create a more pleasant working environment. Additionally, investing in odour control technologies not only improves the quality of life for workers and nearby communities but also enhances the overall sustainability and reputation of the insect meal industry.

As the insect meal industry continues to grow, innovative odour control solutions will play a key role in ensuring its long-term success. By prioritizing odour management, insect meal producers can contribute to a cleaner, greener future for animal feed production.

0 notes

Text

The Business Model Canvas

Tank filters are essential for maintaining a healthy and balanced environment in aquariums. In a contained water system, waste products from fish, uneaten food, and decaying plant matter accumulate quickly, releasing harmful toxins such as ammonia, nitrites, and nitrates. Filters play a critical role by removing these pollutants, promoting water clarity, and supporting a balanced nitrogen cycle. This keeps the water safe and healthy for fish and other aquatic organisms. Additionally, tank filters enhance oxygen circulation, which is vital for fish respiration. Without effective filtration, aquariums would require frequent water changes to maintain water quality, making filters indispensable for aquarium hobbyists looking to ensure a thriving aquatic ecosystem.

Here's Froilan Fiel, an aquarium enthusiast. He keeps many aquatic pets in his aquarium. The common issue he frequently encounters is keeping his aquariums clean and providing a safe habitat for his aquatic pets. That's why choosing a reliable and efficient tank filter is a big deal for him. That's why I introduced to him our innovative BioFilter. I asked a series of questions to him after trying out the Bio Filter.

Questions Asked

a.) How important is it for you to have a reliable filtration system in place for your aquarium? b.) What specific challenges do you encounter when using your aquarium filter? c.) What benefits do you expect to experience if you use biological pebbles in your current filtration system?

Interviewee's Response

a.) "It's extremely important because a reliable filtration system ensures clean water and keeps my fish healthy by maintaining the right balance in the tank."

b.) "The main challenge I face is frequent clogging, which slows down water flow and forces me to clean the filter more often than I'd like."

c.) "I would feel more confident knowing that biological pebbles support the natural balance in my aquarium, providing a healthier environment for my fish."

Insights

High Value on Reliable Filtration for Fish Health The interviewee places high importance on having a reliable filtration system to maintain a healthy environment for their fish. This underscores the value that aquarium owners place on the stability and efficiency of their filters. Insight: Positioning your natural filter as a reliable solution that ensures optimal water balance will resonate well with aquarium owners who prioritize their fish's health.

Maintenance Challenges with Current Filters Frequent clogging emerged as a primary issue, leading to slow water flow and increased cleaning frequency. Many aquarium enthusiasts encounter this challenge, which adds to maintenance costs and time. Insight: Emphasize the low-maintenance aspect of your natural filter, especially if it effectively minimizes clogging or requires less frequent cleaning. Reducing maintenance could be a strong selling point for your target market.

Interest in Natural, Biological Filtration for a Balanced Environment The interviewee expressed confidence in biological filtration, such as biological pebbles, to support natural balance. This suggests a preference among aquarium owners for eco-friendly and biological methods over purely mechanical solutions. Insight: Highlight the ecological and natural benefits of your filter. Marketing it as an eco-conscious choice that complements the aquarium’s natural ecosystem will likely attract users interested in sustainable, healthy filtration solutions.

Desire for Confidence in Aquarium Management The interviewee indicated that using biological pebbles would make them feel more confident about the health of their aquarium. This desire for peace of mind reflects the need for products that not only perform well but reassure users that they’re providing the best for their aquatic life. Insight: Position your filter as a product that offers peace of mind by actively contributing to a stable, thriving environment, reducing the need for constant monitoring and maintenance.

0 notes

Text

what everyone absolutely needs to know is that it’s by no means a glamorous or ‘dignified’ job lmfao when our probes get stuck we smack them with hammers and/or yank on the casing with all our strength or use our weight as leverage and it’s not uncommon to get mineral build-up or biofilter sludge or grease or other such assorted substances all over oneself in the process. doing maintenance on pumps and skimmers and ozone injectors (and other adjacent equipment) is a very physical and sweaty and loud job. not uncommon to have to stop what i’m doing to stretch / drop a layer of uniform before going back in to take another shot at unsticking that lever or unscrewing that probe casing. ive built more muscle doing this job for the past handful of months than i did in four years of stocking 50lb bags of dog food and 80lb boxes of saltwater 7hrs a day. what i’m saying is that loids job is not all scanning papers and taking notes and sitting at a desk looking pretty he’s also climbing around in the bowels of whatever plumbing or piping there is and prying shit open with his bare hands and hauling heavy equipment around and hitting stubborn switches or casings with a mallet hard enough to flake rubber off the thing and regularly have to replace it. just so everyone knows. working as part of a very small technician team in a facility with any amount of large, delicate, specialized equipment that sees heavy use, be it life support systems like air or water filtration or specific instruments for void research, you end up wearing several hats just to keep everything moving smoothly and safely, so while on paper you might be there to do ‘assorted maintenance tasks’, in reality you’re part mechanic, HVAC tech, electrician, janitor, inventory manager, secretary, IT guy, the list goes on and on ON TOP OF whatever science you’re also doing. i ran out of time to type i ahve tasks to be doing i’m just going to post this as is hang on

13 notes

·

View notes

Text

Getting the ol' Kandrona-starvation for installing a Gleet BioFilter across the drive-thru window of this Starbucks. I know it's a breach of covert operations, but damn were there a fuckton of flies making their way past the air curtain

5 notes

·

View notes

Text

PABRIKNYA LANGSUNG, CALL +62 852-1533-9500, Kontaktor Septic Tank Biotech Melayani Jember

ORDER KLIK http://wa.me/6285215339500, Harga Biotank 2023 Melayani Pengiriman ke Jember, Harga Biotank 1 M3 Melayani Jember, Harga Bio Septic Tank 1000 Liter Melayani Jember, Jual Septic Tank Biofil Melayani Jember, Harga Bioseptic Melayani Jember

TANQUE FORTE Merupakan Merek Bio Septic Tank Terbaik, Tahan lama dan Bergaransi Panjang, cocok untuk rumahan, IPAL Komunal, IPAL Medis, Rumah Sakit atau HOTEL

SIAP MELAYANI PENGIRIMAN KE SELURUH INDONESIA

PABRIK SEPTIC TANK BIO TANQUE FORTE

Jl. Cangkudu No. 7-9

Sukamukti Ranca Manyar

Kab. Bandung Jawa Barat- Indonesia

Bapak Hendra

CALL 0852-1533-9500

HargaBiotech2M3Jember, #Biotank500LiterJember, #BiofilSepticTankHargaJember, #JualBiotankJember, #BioPenguraiTinjaJember

Posting By:

Sarah Nabila Azzahra

SMK Plus Pelita Nusantara

#Harga Biofil 2 M3 di Jember#Harga Septic Tank Bio Murah Jember#Harga Septik Tank Biofilter Jember#Tangki Biofil Jember#Biotank 800 Liter Jember

0 notes