Don't wanna be here? Send us removal request.

Text

The Basics of How Ore Processing and Recovery Plants Work

The term processing and recovery plant is broad to say the least so we are going to give some basic examples of the types of ore processing plants. It is important to understand that each full scale ore processing plant, backfill plant, placer mining plant, or even a small scale test plant is specifically engineered for the material it will be processing. The type of plant at any given mine or recovery operation also depends on permits, available road access, amount of precious materials to be mined, and of course cost. In this article we will be focusing on ore processing plants.

What kind of material are you processing?

Technically all ore processing falls under the field of extractive metallurgy, mineral engineering, and mineral processing also known as mineral dressing or ore dresing. It is the process of separating commercially valuable minerals from their ores. Commonly, haul trucks transport the ore from open pits or underground operations to processing operations. Ore may be stockpiled for later processing. The grade and type of ore determines the mineral processing method used. Additionally, the geochemical makeup of the ore, including its hardness, sulfur content, carbon content, and other minerals found within, impact the cost and methods used to extract gold, silver, and other precious metals and minerals.

What can you recover?

Ore processing recovery systems are used for everything from recovering precious metals, industrial minerals, and rare earth minerals. Plants for recovering precious metals often recover multiple metals or minerals in the same operation. This is because often where there is gold the ore will contain copper and silver. When talking about the recovery of precious metals we are identifying the noble metals like gold, silver, platinum, and palladium. Other primary metals that ore processing plants are used to recover includes copper and iron ore. There are rare metallic minerals such as nickel, cobalt, and scandium which are mined using similar processes. There is also the processing of rare earth minerals.

How much material will an ore processing plant process per day?

Ore & Mineral Processing Plants are designed for various purposes and capacity, for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, recycling, mining, and treatment facilities. They are mostly measured by TPD (tons per day). Based on the capacity of the plant and the grade of the ore it is processing, engineers and mining geologists can determine the economic viability of the mine. The investment made in a gold processing plants, silver processing plants, as well as plants for recovery of other precious metals and rare earth minerals is impacted by the cost and methods used to extract gold, silver, and other precious metals and minerals. It is also impacted by the market price and market projections of the material being mined. A 6500 TPD Gold & Silver Processing Plant will cost millions of dollars where small mineral pilot plants may cost hundred of thousands and a portable pilot plant may cost only thousands. Many full scale operations begin with a test plant before upgrading to a full production ore processing plant.

What equipment is included in an Ore Processing Plant?

Each plant is different but there are several common pieces of equipment you will almost always find through 5 stages of processing. The first is size reduction meant to break up the largest of material which includes crushers, industrial screens, and large hoppers and feeders. The second process is the gravity circuit which further breaks down the material for further processing and includes grinding mills, cyclones, and depending on the process gravity concentrators. The third is the leaching process that uses equipment with industrial grade agitators and mixers and contains a leaching solution and allows the valuable material to leach from the ore into solution. The fourth stage is the actual recovery of the material being processed which greatly depends on the material itself and the ore it is mixed with. For gold it could be a refining and smelting system, bullion furnace, or concentrating tables. The fifth stage is the tailings treatment. Tailings are the byproducts left over from mining and extracting resources, such as extracting bitumen from the oilsands or minerals such as copper or gold from ores. Tailings include: Finely ground rock particles – ranging from sand-sized to silt-sized. Chemicals used to extract the valuable mineral or oil. The treatment is meant to process the tailings remove the sediments and chemicals and then often reuse the water for going back into the processing plant. Mixed in with the entire process are various types of industrial pumps, belt conveyors, electrical equipment including large generators, and heavy equipment.

How can you purchase an Ore Processing Plant?

There are many ways to purchase a plant. Large scale mines will often engineers and new plant. In some case publicly traded companies require new processing equipment for the main components of the plants. A second common option is to buy a used plant that has already been in service. This can often greatly reduce the cost while still getting a plant that is engineered as well as proven to operate efficiently. It also minimizes the lead times of waiting for new equipment to be manufactured. The third option is to buy each piece of mining and milling equipment individually and mix new and used equipment. This can lead to even a further reduction in your cost but can be a challenge to find each piece of equipment that will fit your specifications.

This article is a brief overview of an ore processing and recovery plant. The first step is to speak with a reputable professional in the industries including mine engineers, mining geologists, and equipment experts. Once you have the right team in place it will be much easier to find the right equipment and purchase the plant which produces the highest profits.

#mining#mining industry#ore processing#ore processing plant#recovery plants#gold#gold mining#screens#hoppers and feeders#crushers#industrial concentrators#grinding mills#cyclones#industrial pumps#belt conveyors#electrical equipment#heavy equipment rental#generators#mining and milling equipment#mining and milling

0 notes

Text

Cone Crusher

Cone Crushers:

A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones. As rock enters the top of the cone crusher, it becomes wedged and squeezed between the mantle and the bowl liner or concave. Large pieces of ore are broken once, and then fall to a lower position (because they are now smaller) where they are broken again. This process continues until the pieces are small enough to fall through the narrow opening at the bottom of the crusher.

Mobile Cone Crushing Plants:

A portable crushing plant allows you to transport your cone crusher from one area of you operation to another in a quick and cost efficient manner. Crushing plants make use of a large range of equipment, such as a pre-screener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc. When we custom build your Crushing Plant it will be built to your specifications.

Features:

A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear resistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner.

1 note

·

View note

Text

Jaw Crushers

A jaw crusher is crude piece of equipment that is used to crush all kinds of hard rocks and block material. Mainly jaw crushers are used in the following industries: minerals, quarry, building materials, road, rail way, water conservancy and hydropower.

Most jaw crushers work as follows:

The motor drives the belt wheel, and makes movable jaw up and down by eccentric shaft. When the jaw rises, the angle between the fixed jaw and movable jaw gets larger and the materials can be crushed. When the movable jaw is down, the angle between the fixed jaw and movable jaw becomes smaller. The movable jaw plate leaves the fixed jaw plate under the function of drawbar and spring, at which point the crushed materials are discharged from the lower outlet of the crushing cavity.

Features: It features a simple structure, large crushing ratio, high output, even particles, convenient maintenance and subsequently low production costs.

So whether you are looking to buy or sell jaw crusher equipment. Our staff will help ensure that we find you the very best piece of equipment for the very best price.

1 note

·

View note

Text

Grinding Mills - Types, Working Principle & Applications

As is quite evident (Marty knows that you know!), the ultimate objective of processing a mineral is to extract the maximum value from a raw material. There are two end results that one is trying to achieve - either to get a crushed product that can be directly used for industrial application or to recover a metal from a complex ore.

Before we proceed, let’s take a quick look at the top manufacturers of Grinding Mills.

Marty wants you to go back in time and take a look at the major player Metso whose roots can be traced as far back as the 1930’s when the first Hardinge Cascade Mills were built. In the 1970’s and 1980’s, Hardringe (then Koppers) was competing with other market leaders namely Dominion Engineering and Allis Chalmers. In 2001, brands including Allis-Chalmers, Hewitt-Robins, Nordberg, Hardinge, and Dominion were all combined under Metso Minerals Svedala grinding range. Today, Metso is the biggest player in the grinding equipment space and competes with FLSmidth, CITIC, and ThyssenKrupp.

Minerals Processing Framework (diagram)

Stage 1 – Drilling

This is the stage where it all begins. A rock cutting process, drilling sets the stage for the next steps in the mineral processing operation. Be it surface or underground deposits, we are mining our way to the next stage!

Stage 2 – Crushing & Screening

So now the size reduction of our ore begins! In terms of tonnage, this is the biggest process in the processing cycle. Different types of crushers are used as per the various established parameters of size, shape, and strength. Jaw Crushers, Roll Crushers, Gyratory Crushers, Cone Crushers are some of the crushers that are used in this process.

But wait! This is not an article on Crushing & Screening (coming soon!) so why are we talking about crushing? Well, crushing and grinding in various combinations are used to maximize the value in size reduction so we wanted to give you a little peek into this stage. But with no further ado, let’s move on to the third stage and the one that brought you here – Grinding!

Stage 3 – Grinding

Following the first controlled size reduction stage of crushing, we want to further reduce our ore to obtain a mineral powder. There could be various reasons for reducing the size – we might want to free the individual minerals trapped in ores or simply expose the mineral to a leach solution. Grinding can be either Dry or Wet. Dry processing (Marty says that you would have guessed!) either does not require water for processing or no water is permitted in the processing of the ore. Wet grinding is generally preferred because of lower power consumption and higher mill capacity. Dry grinding must be used where wet grinding is feared to change the physical or chemical structure or/and if a higher percentage of fines is required.

How does grinding work? What are the forces in play? Imagine (Marty says “wait, see the diagram below!”) a cylindrical steel vessel with an ore and a grinding medium moving inside the mill, the rotating drum lifting this material and finally breaking the ore into a specified product.

Further, the grinding mills can be categorized into three major types – rod mills, ball mills, and SAG mills. So, which one is for you? Well, the answer essentially lies in the feed size and the required product size.

Semi-Autogenous Mills/ SAG Mills (primary grinding mill) – these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in finer particles. Feed size range is 400 mm / 16 in and product size of 75 microns. The product of the large SAG grinding is either a finished size ready for processing, or an immediate size for further grinding. Examples include use in gold, copper and platinum mines with applications also in the lead, zinc, silver, alumina and nickel industries.

Rod Mills – these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles. Rod mills can accept feed up to approximately 50 mm. (2 in.) and produces the product size of 600 microns. Rod mills are more suitable for breaking up large pieces of ore due to the heavy weight of the rods. Examples include large pieces of rock, coal, copper or other media. The product will be a fine aggregate for use in building materials and chemical industries. Also, desirable when grinding coarse-grained ores.

Ball Mills – these use balls for grinding media breaking the coarse feed materials by impact and attrition into extremely fine powder. Ball mills use a feed of about 15 mm (½ in.) or finer and product size is very fine with no actual grind limit indicated. Examples include use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. Widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals.

More questions? Read on...

How long do Grinding Mills last?

As a matter of fact, well-maintained mills will give you dependable and hassle-free operation year after year. Capacity or product size remain unaffected by any wear on the grinding surfaces. Very little upkeep is required and inactivity has a negligible effect if any. (Marty says we have serviced 40-50 years old mills and received client’s feedback of “Excellent Condition!” each time).

Which parts commonly wear out? The internal shell liners and headwear liners. These are parts that are installed to protect the main structure of the grinding mill and are replaced as they wear out. Liners are available in various materials and several designs. Most commonly used liners are made of hardened steel, rubber, and ceramic.

Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new liners. Ball Mills commonly use rubber liners while steel liners are mostly used for larger SAG/AG/Ball mills. Marty says liners are prone to metal or rubber contamination and should be replaced to ensure higher efficiency.

At Savona Equipment, as part of the reconditioning process, we also replace liners providing you with a fully operational mill. All our refurbished grinding mills are inspected and supplied ready for service.

Still not sure which grinding mill is the best fit for you? Contact us and we will be happy to assist you!

0 notes

Text

Mineral Jig Concentrators for Ore Processing & Separation, How Jigs use Gravity Separation

What is a mineral jig?

Mineral jigs are a type of mining equipment, also referred to as gravity concentrators or jig concentrators, that are used in operations to separate different ore materials based on their densities. Usually they will process material that is a similar size after the ore has passed through a crusher or over a screening plant. Although there are many variants that will take place in a mineral jig, certain principles remain constant. Material is first fed into the jig bed, usually made with a screen, then propulsing columns thrust water upward which suspend particles in the water because they have been exposed to gravitational energy. Frequencies normally range in between 125-350 strokes/minute. In between the pulses material that is heavier will be trapped in the bed filled with steel shot (small round steel media) and settle in the bottom of the jig and the concentration is removed separately for further processing with an example being over a gold concentrating table or if the grade is high enough in a smelting furnace. If a jig concentrator is being used for minerals that are lower in density, coal being one, the gravitational energy has a reverse effect because material around coal is heavier and the coal will float towards the top.

What companies manufacture mineral jigs?

There have been many different companies who have manufactured their own version of a mineral jig. Madden Steel Inc. (MSI Mining) produces the 4Plex Gold Roughing Jig and Duplex Jig.

The 4Plex gold jig uses a roughing 50 inch 4plex jig and twin 36 inch cleaning jigs underneath with gold recovery rates of up to 98 percent. Their 50 inch Duplex jig is able to recover gold down to 400 mesh (37 micron) while processing 56 tons per hour. Savona Equipment regularly has used MSI mineral jigs for sale and will provide necessary modifications and reconditioning before the jig goes out into the field.

Mineral Technologies produces the Kelsey Centrifugal Jig. This circular jig has been engineered when a miner needs extremely fine concentrate grades and mineral recovery. The process combines conventional gravity separation and centrifugal force allowing for size recovery down to 10 microns.

Sepro builds selective mineral jigs ranging in capacity from 5-400 tons per hour. They supply in Simplex Models (single unit) or the Duplex Models (2 jigs in series). Their units are made to process material that has a minimum difference in specific gravity units of 1.0.

Some other past producers of jigs for ore processing included Pro-Pulse and Gardner Denver.

What type of mining operations are mineral jigs used for?

Mineral jigs in mining are known as one of the most complex areas in mineral processing because of the continuously changing hydrodynamics. Jigs are used to separate materials in alluvial deposits to anthracites. If a jig is used in hard rock mining the material will need to be crushed before the recovery of diamonds, gemstones, gold, and coal is able to take place. They are also common in platinum, tin, tungsten, and sapphire operations and other lower density mineral mines. Iron, manganese and other base metal mines are also able to use mineral jigs in their processes.

Are there different machines connected to a mineral jig?

Electric motors would be the common machine directly connected to the jig providing the power, and some units may also include an electric starter. Using a scenario where mineral jigs are in a tungsten recovery process there are many different equipment items before and after the jigging takes place. Material will be transported to a roll crusher after initial screening and crushing. The ore will be fed into a vibrating screen to sort, with oversize being fed into a ball mill for additional processing and the specific sized material sent into the mineral jig. The concentrate produced in the first jig will be processed by an additional cleaner jig which produces the first batch of high-grade concentrate. Material that needs additional processing from both jigs will be sent to a classifier and then to concentrating table circuit producing a second batch of high grade concentrate. Common with most mine operations, mineral jigs are one part of the extensive ore extraction process.

How do mineral jigs range in size and capacity?

A mineral jigs size and capacity range will depend on the operation. If one is being used for a small placer mine, capacity may be 5 tons per hour. Using 2 tons/hour per square foot of jig bed is a good rule of thumb.

In large scale mines a single duplex mineral jig will process up to 450 TPH and this will be scaled up by adding more units to reach capacity required. Capacities are always estimated based on closed grinding circuit with re-circulating load.

Capacity will range depending on the mineral being liberated. The size range which gravity concentration is able to be applied is up to 1 metre (3.2 ft.), but the ideal largest size to process is around 500mm (19.7 in.). On the small spectrum material that is around micrometres is the cutoff for reasonable processing results.

If you have any questions, please feel free to contact us.

#mining#mining industry#mining equipment#mineral jigs#gold recovery#electric motors#concentrators#gold

0 notes

Text

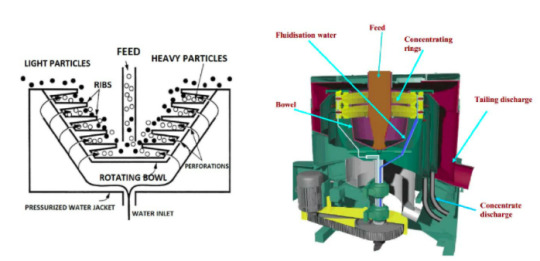

How Centrifugal Concentrators Changed What It Means To Recover Fine Gold

Gold centrifugal concentrators have been developed over the past century and allow for mining operations to trap a higher percentage of the fine gold and other precious metals in black sands that used to disappear into tailing ponds. Along with the higher yields, operations are now able to run for extended periods of time because of the advancement in automation equipment allowing for run times of 8 hours up to 24 hour cycles. There has also been larger concentrator bowls developed increasing production capacity to thousands of tons per day. These advances have made significant impacts in many areas that are being mined in Northern Canada and Alaska that have short seasons because of permafrost and short snowless periods. In areas with high gold recovery rates the black sands produced are able to be directly processed over a gold separation table.

The Centrifugal Concentrators History

There have been three standouts for centrifugal gold concentrators since the 1900’s. What is known today as the Falcon Concentrator has been developed over time from the smooth walled Falcon “B-Bowl and MacNicol bowl that originated in Australia. While the technology was available under patent since the 1930’s, for the most part no commercialization took place until the patent expired in 1982.

In the 1960’s Byron Knelson settled down in British Columbia, and while running his excavating company he watched as alluvial gold miners in the Yukon Territory used sluice boxes to recover course gold while most of the fine gold would end up in tailings ponds. This set him on a course to invent the Knelson Concentrator that would go on to change how placer mining operations are designed worldwide.

The Hy-G Consentrator was another centrifugal concentrator that was developed soon after the original patent from Australia had expired. The late Don Brember tested and refined the centrifugal concentrator technology and wanted to develop a machine that would run continually for up to 24 hours with high recovery rates before cleanout was needed in turn increasing the miner’s gold yield.

Technology Inside

Centrifugal gold concentrators operate using G-forces which allow for separation of the heavier particulate including fine gold and other metals. When material is introduced to the bowl from 50 up to 600 G’s the gravitational field allows for recovery of fines that are 3 microns small. The main feature of the concentrator is the bowl itself that has been designed over the years for increased recovery rates. Specially designed ribs inside the cone trap heavy particles which are then discharged through the concentrate discharge, while all the lighter material is discharged through the tailings discharge. Inside the bowl there are fluidization holes for water feed at the start of the process. In the middle of the cone a stationary feed tube introduces the slurry material at the bottom of the cone which is then forced upward and outward. In a Knelson Concentrator the entire process “concentration cycle” will be completed in about one minute after each rib in the cone is filled with heavier concentrate. Large bowls with surface areas up to 3.37 m2 process the highest quantities of materials. Now with the latest innovations in gold concentrators the process of feeding, discharging the concentrates and tailings, and re-starting the feed again can all be automated.

Optimized Operations

Based on size and application the concentrator will be used in, different material feed and discharge options are used. In flow sheets provided by Knelson Concentrators they give the examples of a “Conventional Grinding Circuit” or the “Extreme Gravity Circuit”.

In the conventional circuit a Semi-Continuous Concentrator is fed by material after it is processed through a screen and the concentrate material is discharged into either a Acacia Reactor or Gold Concentrating Table.

Using an Extreme Gravity Circuit one Semi-Continuous concentrator and one Variable Discharge Concentrator would be used. First both would be fed through a cyclone with the concentrate discharged from the Semi-Continuous unit going into the gold room for further processing. Material processed through the Variable Discharge unit would be then sent into a thickener or the concentrate gathered for further treatment.

Following are examples of the wide range in size from the top Centrifugal Concentrator manufacturers in the world.

KC-MD3 Knelson Concentrator processes up to 100 lbs/hr and is ideal for small batch testing in the field or inside laboratories.

Hy-G p40 Placer Gold Concentrator provides optimal capacity of 60 tons per hour (TPH) is excellent for placer site operations that require semi-automated operation from 8 to 24 hour periods

Falcon SB5200 Concentrator will process 200-400 TPH and is used in large scale mining operations.

Where Are they Now?

In 2008 Falcon Concentrators purchased Sepro Mineral Processing International and shortly after rebranded under the name Sepro Mineral Systems. The Falcon Concentrators are still sold under their original name.

Knelson Concentrators are also sold under the original name and after the passing of Byron Knelson, the founder, FLSmidth purchased the company in 2011 and continues on his legacy.

Hy-G Concentrators are now manufactured and distributed exclusively through Savona Equipment Ltd. These units are ever popular with placer miners due to the design that collects high grade concentrates.

VIEW OUR FULL GOLD CONCENTRATORS INVENTORY

If you are interested, have any questions, or you would like to get more information on any of the following information provided for Gold Concentrating & Refining Equipment, please contact us.

#mining#mining industry#mining equipment#gold concentrators#gold mining#knelson concentrator#falcon concentrator#centrifugal concentrator

0 notes

Text

Thickeners — Types, Working Principle & Applications

What is a Thickener?

In very simple words, a thickener is a machine that separates liquid from solids. It is defined as a method of continuous dewatering of a dilute pulp, wherein a regular discharge of a thick pulp takes place which is of uniform density, concurrently with an overflow of clarified solution. The solids particle size range in thickeners is generally from 0.5 mm to a few microns. Thickeners are often rated on lbs. of solids per square foot of surface area.

Briefly, its functioning can be explained with Scraper blades or “rakes” that are used in a thickener, which rotate slowly over the bottom of the tank, and slope down towards the centre and move the material settled on the bottom to a central opening or discharge. Thickeners are generally used in metallurgical field with the purpose of thickening prior to agitation, filtration, in the countercurrent washing of cyanide slime, and more thickening ahead of floatation, for dewatering tailing to recover the water for reuse in the mill and for thickening concentrates.

Fundamentally, thickeners and clarifiers (which look visually like thickeners) are both used to settle solids which results in the separation of liquids and solids. The difference however is that thickeners are used to concentrate solids, while clarifiers are used to purify liquids.

Historically, thickeners were introduced to the mining industry in 1905. They are widely used in various industries including mining, coal, chemical, industrial, environmental (wastewater management), municipal and paper industry.

Working of a Thickener

Let us understand in detail about how thickeners work. To start with, it works on the principle of Gravity sedimentation and the most common construction of a thickener would be of iron or steel.

The continuous thickener consists of a cylindrical tank. Pulp is fed into the centre of the tank via a feed-well placed up to 1 m below the surface of the suspension. The clarified liquid overflows a trough, while the solids which settle at the bottom of the tank are withdrawn as a thickened pulp from an outlet at the centre. One or more rotating radial arms are there within the tank, from each of which are suspended a series of blades, shaped so as to rake the settled solids towards the central outlet.

With modern thickeners, there is a functionality of these arms rising automatically if the torque exceeds a certain value, thus preventing any damage which can result due to overloading. The blades also help in concentration of the settled particles by simple setting which enable a thicker underflow. In this way, solids move downwards, and then inwards towards the thickened underflow outlet and the liquid moves upwards and radially outwards.

Types of thickeners

The thickeners can be classified into two types depending on location of rake driving mechanism. They are known as either Centrally driven or Peripherally driven.

Further, under centrally driven type there are two types depending on method of supporting the drive mechanism and the raking arms.

a) Column type: A kind of thickener where a central steel or concrete column takes vertically the reaction to the weight of the mechanism and horizontally the torque load.

b) Bridge type: Here, a structure spans across the tank and is subjected vertically to the weight of the mechanism plus any solids that accumulate within the arms truss and horizontally to the twin forces imposed by the density of the raked underflow.

Generally, and for larger diameters the former type is used and for tanks up to 25–30 meter diameter the later type is preferred.

What are high-capacity thickeners and how they work?

In the 1980’s, machines known as “high capacity” or “high rate” thickeners were introduced by various manufacturers. These machines are characterized by a reduction in unit area requirement for conventional installations.

Here, the feed enters through a hollow drive shaft where flocculent (used to help thickening) is added and is rapidly dispersed by staged mechanical mixing. Further, this staged mixing action helps to improve and enhance thickening. This feed is then added into a blanket of slurry where the feed solids are further flocculated by contacting previously flocculated material. Since there is a direct contact between rising fluid and settling solids, which is common to most thickeners, it is averted with slurry blanket injection. There are radially mounted inclined plates which are partially submerged in the slurry blanket; the settling solids in the slurry blanket slide downwards along the inclined plates, producing faster and more effective thickening than vertical descent. Level sensor are used to automate the height of the slurry blanket.

Factors determining efficiency of Thickener

Several types of thickeners have been developed and classified according to the arrangement of feed and discharge in the various compartments.

For effective thickener control, key considerations are bed mass inventory, underflow density and flow, bed level, overflow clarity and flocculent dosing. All these parameters and measurements of these are not easy and one must factor in accuracy and reliability to select and install the proper equipment. Some of thickening equipment from well-known and respected brand names such as Eimco, FLSmidth, Dorr-Oliver, Phoenix, Lamella and Westech are popularly used.

Choosing a right thickener for your process and industry shall determine efficiency in its output and we strive to help you find one here!

0 notes

Text

Centrifugal Pumps for Mining, Their Purpose, Top Brands & Fluid Handling Capabilities

What is a centrifugal pump?

Centrifugal pumps are used in applications that need to transport fluid. This is done by the conversion of rotational kinetic energy to the hydrodynamic energy. The rotational energy moves fluid from point A to B either at a relatively even grade or by pumping the fluid or slurry vertically. Common types of these pumps would be vertical tank pumps, froth pumps, trash pumps, slurry pumps, and multistage centrifugal pumps.

What are the main brands of centrifugal pumps?

In 2016 according to research done by Persistence, centrifugal pumps had a market share of over 90 percent. Positive displacement pumps are in a distant second accounting for less than 9 percent of the market. Major players in the centrifugal pump manufacturing market are KSB AG, Flowserve Corporation, Sulzer AG, Ebara Corporation, Grundfos, The Weir Group Plc, WILO SE, Xylem Inc., Ruhrpumpen Group, and Kirloskar Brothers Ltd. These leading companies were part of the $34.39 billion USD estimated pump deployment market in 2016.

What do the main brands specialize in?

KSB specializes in long-life pumps made under their GIW Industries brand. If needed at copper mines in Chile or tar sands in Canada they will manufacture pumps that stand up to whatever corrosive materials a mine has to be able to process.

If you recognize the names such as Flygt, Godwin, Bell & Gossett, or Goulds pumps these are all now manufactured under Xylem’s brand. Flygt Submersible pumps are renowned and handle jobs from small drainage to large dewatering applications. Godwin offers automatic self-priming pumps that are run by diesel and electric power. Used in many different industries worldwide including mining and construction Godwin pumps excel in dewatering and liquid transfers.

The Weir Group sells pumps in over 15 different categories including mine dewatering pumps, vertical slurry pumps, and high-pressure pumps. In the Centrifugal pump category brands include Warman, Floway, Lewis, and Gabbioneta that have a capacity for pumping solids >270mm.

What types of fluid do centrifugal pumps move?

There are many different liquids that centrifugal pumps process and they have the highest flow rates when pumping water and relatively thin liquids. If thicker oil needs to be moved a different pump should be selected. If your mining application includes separating bitumen and minerals from clay and sand then centrifugal pumps are the right choice of product. Centrifugal pumps are also used for applications in the chemical, paint, petrochemical, pharmaceutical, cellulose, and hydrocarbon sectors.

What machines are centrifugal pumps connected to at a mine?

Aside from power sources, centrifugal pumps will normally be connected to hose or pipe for fluid transfers. Here is an example of how much pumps are relied upon in a mine process circuit:

A ball mill will crush ore into a slurry which is then fed into a centrifugal pump

The pump feeds ore into a classifier and conditioning tank.

Two more pumps will send slurry from the conditioning tank into either the sampling area or the flotation system.

Once the flotation system is finished two more pumps will send material into either a tailings thickener or concentrate thickener.

From the thickener, another pump will send material to the tailings pond, a second to the mine dewatering system for further processing, and a third into the plate filtration/dewatering process before being pumped into a secondary filtration process before the final product is sent to the smelter.

Material that went into the concentrate thickener will be pumped into the secondary filtration process and also sent to the smelting room.

Without having the pumps in between all the different equipment you would have to set up the process equipment to all run downhill and reprocessing material would pose a much harder challenge.

What range of fluid (capacity) do centrifugal pumps process?

The range of flow rate for centrifugal pump depends on a number of variables and will pump at 5-200,000 gallons per minute (19-757,080 lpm). A density of a liquid, particulate size in slurries, and total head needed are all common factors. If you only need 10 ft. total head (3m) then the flow rate will be much higher than if 7,500 ft. total head (2,286m) is needed.

What powers a centrifugal pump

Depending on all the application factors centrifugal pumps need anywhere from 0.125 to 5,000 hp. This requirement will usually be generated through an electric motor or diesel engine depending on the application. In remote locations such as a placer mine site where electricity is unavailable a diesel engine to power, your pumps will be adequate. In large mine processing plants that run 24 hours a day 365 days a year, electric power would be needed to allow for less maintenance and uninterrupted production.

VIEW FULL CENTRIFUGAL PUMPS INVENTORY

If you are interested, have any questions, or you would like to get more information on any of the following information provided for Centrifugal Pumps, please contact.

0 notes

Text

The Basics of Placer Mining Equipment for Mining Gold and Other Precious Metals

The Basics of Placer Mining Equipment

If you have ever watched hit tv shows like Gold Rush on Discovery or History’s Yukon Gold you have seen placer mining equipment at work. The equipment used in both the tv shows and in many other mining operations is a mixture of simple and complex mining technology. We have broken down the main types of equipment used for mining alluvial deposits. While there are a variety of equipment used in placer mining operations such as water pumps, generators, pipe, and excavators there are several types of equipment that are specific for recover freegold and other precious metals. Placer Mining Equipment includesgold wash plants, derockers, sluice boxes, and trommels.

The kind of mining that can be done with placer mining Equipment can be through open-pit mining (which is also called open-cast mining), or through various surface excavating equipment such as………... or tunnelling equipment including……….. Gems and heavy metals (such as gold) are considerably much more dense than sand, and they tend to accumulate at the base of placer deposits.

Placer mining equipment offers you products that are durable, and work efficiently in this kind of environment and gives you best equipment to recover gold, gems, and any other precious metals from any other of your placer mining operations. Below is more detailed information and descriptions of placer mining equipment.

Equipment:

Gold Wash Plants: Gold wash plants are offered in a variety of different options, for whatever your mining needs, including full production gold trommels, gold placer plants, and mining wash plants, which are all for gold mining. They also include testing plants which are often portable trommel wash plants which include top brands, such as MSI Wash Plants. You are also able to have the choice between Diesels or Gas Powered Gold Trommel Wash Plants, to fit whatever your needs are.

View Gold Wash Plants in Use

(Vibratory Gold Wash Plants; courtesy of

MSI Wash Plants

Derockers: Derockers are ideal for alluvial mining of gold and other precious metals in areas that have large boulders. Derockers, such as the RMS-Ross Derocker, delivers a -2" product to downstream recovery, and it discharges clean washed +2" rock and boulder separately. To optimize your placer mining operations your derockers should be a unit that is automatic, self cleaning, and efficient.

(RMS-Ross Derocker loaded for transport; courtesy of

RMS-Ross Derocker

Sluice Boxes: Placer mining operations, sluice boxes, are for recovering of gold, other precious metals, and stones. Sluice boxes are specifically used in gold mining paydirt and sluicing creek beds to recover gold. Gold dredge sluice boxes can also be supplied in various sizes upon request and depend on how much material you need to process.

View Sluice Boxes in Use

(RMS-Ross R9-9 Sluice Box; courtesy of RMS-Ross Derocker)

Trommels: Trommels are used for recovering gold and other precious metals from placer mining operations. Sizes vary but common sizes are 18 inch, 30 inch, 48 inch, 60 inch, & 7 foot Trommels. Many miners buy new but it is becoming more and more common for buyers to purchase used mining equipment including, trommel with refurbished parts that will be fully repaired or replaced as required/if necessary. Companies like Savona Equipment sell both the new and used Trommels and Gold Recovery Equipment worldwide including Portable Gold Trommels, Mini Wash Plants, and Gold Trommel Wash Plant from top trommel manufacturers such as Telsmith, McCloskey, Northern Placer, Aureco, Extrac-Tec. As well as selling top brands you can order a custom made gold recovery wash plant, that are designed, manufactured, and distributed by Savona Equipment.

View Trommels in Use

(Savona Equipment ST70 Trommel; courtesy of Savona Equipment)

If you are interested, have any questions, or you would like to get more information on any of the following information provided for Placer Mining Equipment, please contact.

0 notes

Text

Industrial Conveyor Systems for Transporting Bulk Materials

youtube

Types of Industrial Conveyor Systems for Transporting Bulk Materials

If you visit almost any mine or rock quarry in the world you will likely find a conveyor system integrated into the operation. Some are simple and used to transport material 50 meters from the crushers to a loading area, others are complex systems that carry various material with a wide range of densities through the entire process. Conveyors are engineered and designed to withstand different types of materials, environments, and even running time (some run several times per day, others 24 hours). In almost all industrial operations conveyors are made of industrial grade belting, steel trusses and angle iron, magnetic pulleys, idlers, and are powered by large electric motors and manufactured for the client's specific needs.

Conveyor Belting

The belt on the conveyor determines how wide the material can be or the maximum width of fine material able to be transported. The length of the conveyor not only determines how far the material will be transported but the types of pulleys, idlers, and steel that will be required. Distance also has a direct effect on the size of motor that will be required to keep the belt moving as it fills with the material.

Conveyors for Lighter Material

If a conveyor is carrying lighter materials buyers will often purchase a channel conveyor which has a simpler design, uses less steel but if used for the right purpose can still last for years. Conveyors built with channel have less support than other designs so they are also generally used for transporting over short distances and on flat surfaces.

Conveyors for Heavy material and longer distances.

When a channel conveyor doesn’t cut it the next most common type is a truss conveyor. They are designed and manufactured to carry large and dense materials over a longer distance and for are also common for transporting material up to a higher level. The crossing steel channel frame provides extra support and stability that keep the conveyor from not only bending but also twisting and damaging idlers, belting, or pulleys that would result in hours of downtime and could cost thousands or even millions of dollars.

Incline and Portable Conveyors System

The correct term for a portable conveyor is a Radial Stacking Conveyors and they can be used in a wide variety of applications from gravel pits to sawmills. Some can be hooked to a truck or machine and pulled from one location to another, others have wheels aligned to swivel in a circular pattern. Some portable stacking conveyor designs even allow you to fold the conveyor to allow easier and safer transportation of the unit. But they all share the same principle, to allow the material to be deposited into multiple locations using the same conveyor. Portable conveyors are almost always used to transport material on an incline to their destination. Often these conveyors use specially designed belting that has a cleated, rough top, diamond top, or extruded pattern to avoid material rollback or slippage.

Conveying Material Over Long Distances

Trucks and trains are expensive and often inconsistent. Overland Conveyor Systems are often the most efficient and cost-effective method of transporting large amounts of material over long distances. They can stretch miles and depend on the material are open or encased to keep material contained. The design of an overland conveyor is completely dependant on what is being transported. In different industrial sectors, you will see simple designs for light material and large heavy-duty truss designs to handle large, bulky, and dense materials.

Conveyors for Liquid and Granular Material

In many processing plants, the liquid is either added or is naturally mixed with the raw material making a standard belt conveyor useless for transporting even over short distances. Screw conveyors were designed as the solution to these applications. Auger conveyors or transfer augers move liquid or granular materials in various bulk handling industries from water treatment, to mines, and agriculture. However, auger conveyors also move semi-solid materials that are dry but difficult to manage on an open conveyor belt. Different uses will range from wood chip plants to food processors. Operating with auger conveying systems allow for better control of the material.

The Future of Conveyors

Like any technology conveyors, systems continue their advancement. Electronic monitoring of material and the conveyor itself is becoming more common and can save companies huge amounts of capital by decreasing downtime and serious damage to the conveyor. Overland conveyor systems will safely transport material for miles to shipping ports and complex ore processing plants run 24 hours per day using a combination of modern and tried and tested conveying methods. Watching a conveyor run from the distance may seem simple but the closer you get the more you realize it is an intricate machine essential to the operations it works in.

FULL CONVEYOR INVENTORY

Still not sure which conveyors to buy? Contact us with your requirement

#conveyors#Savona#industrial equipment#heavy equipment rental#construction equipment#equipment#inventory#sale#rent#new#used#rebuild#unused#ore processing#plants

0 notes