Don't wanna be here? Send us removal request.

Text

Top 5 Inventions Related to Electricity

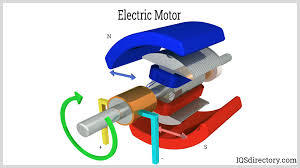

1. Electric Motor

Electric motors are an integral part of modern society, powering everything from household appliances to automobiles. These devices convert electrical energy into mechanical energy, allowing for the efficient operation of a wide range of machinery. But how were electric motors created, and what were the key developments that led to their widespread use today?

Creation

The first electric motors were simple electrostatic devices described in experiments by Scottish monk Andrew Gordon and American experimenter Benjamin Franklin in the 1740s. The theoretical principle behind them, Coulomb's law, was discovered but not published, by Henry Cavendish in 1771. This law was discovered independently by Charles-Augustin de Coulomb in 1785, who published it so that it is now known with his name. Due to the difficulty of generating the high voltages they required, electrostatic motors were never used for practical purposes. But the invention of the electrochemical battery by Alessandro Volta in 1799 made possible the production of persistent electric currents.

Michael Faraday

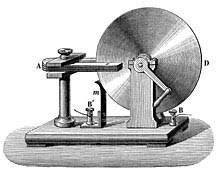

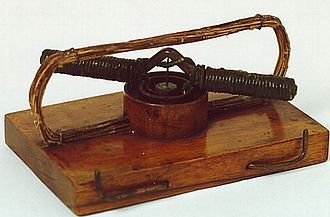

Michael Faraday dynamo

The first steps towards the creation of practical electric motors were taken in the early 19th century. In 1821, Michael Faraday discovered that an electric current could be used to produce a magnetic field. This discovery paved the way for the development of the first electric motors, which used electromagnetic principles to produce motion. Faraday demonstrated the principle of electromagnetic induction, showing that a moving magnetic field could produce an electric current in a wire. This discovery led to the development of the first practical electric generators, which could convert mechanical energy into electrical energy.

Faraday's electromagnetic experiment, 1821, the first demonstration of the conversion of electrical energy into motion

Ányos Jedlik

Jedlik's "electromagnetic self-rotor", 1827 (Museum of Applied Arts, Budapest). The historic motor still works perfectly today.

In 1828 Jedlik demonstrated the first device to contain the three main components of practical DC motors: the stator, rotor and commutator. The device employed no permanent magnets, as the magnetic fields of both the stationary and revolving components were produced solely by the currents flowing through their windings.

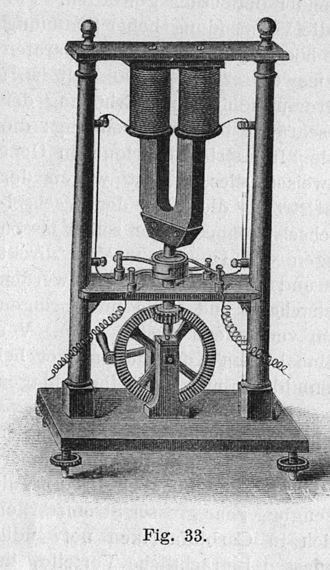

An early form of an alternating current electrical generator built by Pixii

The next major breakthrough in the creation of electric motors came in 1832, when French physicist Hippolyte Pixii developed the first electromagnetic device capable of continuous rotation. This device, known as the Pixii machine, used a rotating magnet to induce an electric current in a stationary coil, producing continuous motion. The first commutator DC electric motor capable of turning machinery was also invented in 1832 by British scientist William Sturgeon.

Other Important Events In Electric Motor

Moritz von Jacobi created the first real rotating electric motor in May 1834.

In 1855, Jedlik built a device using similar principles to those used in his electromagnetic self-rotors that was capable of useful work.

The drum rotor was introduced by Friedrich von Hefner-Alteneck of Siemens & Halske to replace Pacinotti's ring armature in 1872, thus improving the machine efficiency.

The laminated rotor was introduced by Siemens & Halske the following year, achieving reduced iron losses and increased induced voltages.

In 1880, Jonas Wenström provided the rotor with slots for housing the winding, further increasing the efficiency.

In 1873, American inventor Zenobe Gramme developed the first practical DC motor, which used a commutator to produce continuous rotation. This design was highly efficient and quickly became the standard for electric motors in a wide range of applications.

Growth

In 2022, electric motor sales were estimated to be 800 million units, increasing by 10% annually. Electric motors consume ~50% of the world's electricity.

Components

Stator

The stator is the stationary part of the electric motor. It consists of a steel frame, which houses a series of electromagnets. These electromagnets are called stator windings and are made of copper wire. When an electric current flows through the stator windings, they produce a magnetic field.

Rotor

The rotor is the rotating part of the electric motor. It is located inside the stator and is mounted on a shaft. The rotor is made of a series of electromagnets that are arranged in a specific pattern. When the electric current flows through the stator windings, it produces a magnetic field, which interacts with the magnetic field of the rotor, causing it to rotate.

Commutator

The commutator is a component that is located on the rotor shaft. It consists of a series of copper segments that are separated by insulating material. The commutator is responsible for changing the direction of the electric current as the rotor rotates. This is necessary to ensure that the rotor continues to rotate in the same direction.

Brushes

The brushes are components that are located on the stator. They are made of carbon and are in contact with the commutator. The brushes transfer the electric current from the power source to the commutator, which then transfers it to the rotor.

Bearings

The bearings are components that support the rotor shaft and allow it to rotate smoothly. They are usually made of metal and are located at both ends of the motor.

Enclosure

The enclosure is a component that covers the motor and protects it from the environment. It is usually made of metal or plastic and is designed to prevent dust, moisture, and other contaminants from entering the motor.

Advantages

Firstly, electric motors are incredibly efficient. Unlike internal combustion engines, which convert only around 20% of the energy stored in fuel into motion, electric motors are much more efficient. In fact, they can convert up to 90% of the electrical energy they receive into mechanical energy. This means that they are much more energy-efficient, resulting in lower energy costs and reduced carbon emissions.

Secondly, electric motors are extremely reliable. They have fewer moving parts than internal combustion engines, which means that there are fewer parts that can wear out or break down. This translates to lower maintenance costs and fewer breakdowns, making electric motors a more cost-effective option in the long run.

Thirdly, electric motors are much quieter than internal combustion engines. This is because they produce less noise and vibration during operation. This makes them ideal for use in a wide range of applications, from electric cars to household appliances, where noise pollution is a concern.

Fourthly, electric motors are much more environmentally friendly than internal combustion engines. As they produce no emissions during operation, they have no negative impact on the environment. This makes them ideal for use in a range of industries, from transport to manufacturing, where environmental concerns are a key consideration.

Finally, electric motors are versatile and can be used in a wide range of applications. They are used in everything from electric cars to industrial machinery and household appliances, and their adaptability means that they are likely to be used in many more applications in the future.

2. Electric Light Bulb

The invention of the electric light bulb is one of the most important developments in modern history. The ability to produce light without relying on flames or other hazardous materials revolutionized the way we live and work. The creation of the electric light bulb was a long and arduous process, with many scientists and inventors contributing to its development over the years.

Creation

Alessandro Volta

The story of the electric light bulb begins in the early 1800s, with the invention of the electric battery by Alessandro Volta. This invention made it possible to store and use electricity in new and innovative ways, and many scientists and inventors began to experiment with its applications.

Sir Humphry Davy

One of the early pioneers of electric light was Sir Humphry Davy, who in the early 1800s demonstrated the incandescent light, where a wire heated by an electric current produced light. However, this design was not practical for everyday use as the wire would quickly burn out.

It wasn't until the late 1800s that Thomas Edison was able to develop a commercially viable electric light bulb. Edison began experimenting with electric lighting in the 1870s, and by 1879 he had developed a carbon filament that was capable of withstanding the heat and producing light for an extended period of time. Edison's breakthrough came through his development of a vacuum pump that could remove air from the bulb, which greatly reduced the amount of heat and prevented the filament from burning out. He also experimented with different materials for the filament, finally settling on carbonized bamboo.

Edison's first public demonstration of his electric light bulb took place in December of 1879, and it quickly became clear that this invention was going to change the world. Edison founded the Edison Electric Light Company and began installing electric lighting systems in homes, businesses, and public spaces around the country.

Growth

The electric light bulb was a major breakthrough in human history, paving the way for many other technological developments. With the ability to produce light on demand, people could work and play long into the night, and entire industries were created around the production and distribution of electricity. Today, the electric light bulb is still an essential part of modern life, although it has evolved significantly since its early days. Modern LED bulbs are much more efficient and long-lasting than Edison's original design, and they are used in everything from streetlights to smartphones.

3. Electric Battery

The electric battery is a device that converts chemical energy into electrical energy, and it has become an essential component of modern life. From powering our smartphones and laptops to enabling electric cars to run, the electric battery has revolutionized the way we use and consume energy.

Creation

Benjamin Franklin

Benjamin Franklin first used the term "battery" in 1749 when he was doing experiments with electricity using a set of linked Leyden jar capacitors. Franklin grouped a number of the jars into what he described as a "battery", using the military term for weapons functioning together. By multiplying the number of holding vessels, a stronger charge could be stored, and more power would be available on discharge.

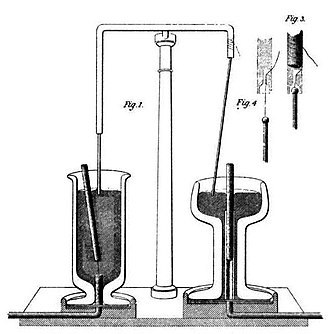

Alessandro Volta

Italian physicist Alessandro Volta demonstrating his pile to French emperor Napoleon Bonaparte

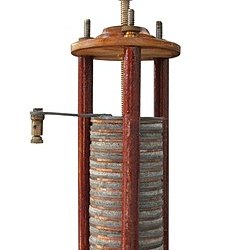

A voltaic pile, the first battery

The history of the electric battery dates back to the late 1700s, when Italian physicist Alessandro Volta discovered the principle of the electric cell. Volta's invention consisted of two different metals, typically copper and zinc, which were separated by a moistened piece of cardboard or paper. This simple device, known as the "Voltaic pile," generated a steady stream of electricity.

Volta's invention was soon improved upon by other inventors, including William Cruickshank and John Daniell, who developed more practical batteries. In 1836, John F. Daniell invented the Daniell cell, which used a copper sulfate solution and a zinc electrode to produce electricity. This battery was used extensively in telegraphy, which was the first major application of electricity in communication.

Georges Leclanché

In the late 1800s, another important development in the field of batteries occurred. French engineer Georges Leclanché developed the Leclanché cell, which used a zinc electrode and a manganese dioxide electrode in a solution of ammonium chloride. The Leclanché cell was smaller, more reliable, and less expensive than previous batteries, and it became the standard battery for telegraphy and early electric lighting. In the early 1900s, American inventor Thomas Edison developed the nickel-iron battery, which was used in electric cars and trucks. Edison's battery was durable, rechargeable, and long-lasting, but it was also heavy and expensive, and it ultimately lost out to the lead-acid battery, which was cheaper and easier to manufacture.

Modern Battery

The modern electric battery, which is used in everything from cell phones to electric cars, is a much more sophisticated device than its early predecessors. Modern batteries are made up of many individual cells, each of which contains an anode, a cathode, and an electrolyte. The anode is typically made of lithium or another metal, while the cathode is made of a metal oxide. The electrolyte is a liquid or gel that allows ions to flow between the anode and the cathode.

Growth

Between 2010 and 2018, annual battery demand grew by 30%, reaching a total of 180 GWh in 2018. Conservatively, the growth rate is expected to be maintained at an estimated 25%, culminating in demand reaching 2600 GWh in 2030. In addition, cost reductions are expected to further increase the demand to as much as 3562 GWh.

The development of modern batteries has been driven by a combination of research and development, technological advancements, and market demand. In recent years, there has been a surge of interest in developing new types of batteries that are more efficient, more powerful, and more environmentally friendly.

Chemistry

Electric batteries convert chemical energy into electrical energy by means of a redox reaction. In a redox reaction, one substance is oxidized, losing electrons, while another substance is reduced, gaining electrons. This transfer of electrons creates an electric current, which can be used to power electronic devices. The basic components of an electric battery are an anode, a cathode, and an electrolyte. The anode is the negative electrode, while the cathode is the positive electrode. The electrolyte is a solution or a solid material that allows ions to move between the anode and cathode. When a battery is charged, electrons are removed from the anode and transferred to the cathode through the external circuit. This creates a buildup of positively charged ions at the cathode and negatively charged ions at the anode. When the battery is discharged, the opposite happens, and the ions flow from the cathode to the anode, creating an electric current.

There are many different types of electric batteries, each with its own unique chemistry. The most common type of battery is the lead-acid battery, which is used in cars and other applications. Lead-acid batteries consist of lead dioxide as the positive electrode, lead as the negative electrode, and a sulfuric acid electrolyte. When the battery is charged, lead dioxide is reduced to lead, and lead is oxidized to lead dioxide when the battery is discharged.

Another common type of battery is the lithium-ion battery, which is used in smartphones, laptops, and electric cars. Lithium-ion batteries use lithium cobalt oxide as the positive electrode, graphite as the negative electrode, and a lithium salt electrolyte. When the battery is charged, lithium ions move from the positive electrode to the negative electrode, where they are stored in the graphite. When the battery is discharged, the lithium ions move back to the positive electrode, creating an electric current. Other types of batteries include nickel-cadmium batteries, nickel-metal hydride batteries, and sodium-ion batteries. Each of these batteries has its own unique chemistry, which determines its performance, cost, and environmental impact.

4. Electric Trolley

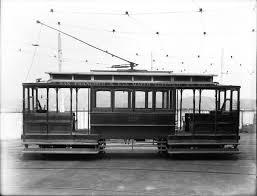

The electric trolley is a revolutionary invention that changed the way people travel in cities. It is a form of public transportation that operates on rails and is powered by electricity. The invention of the electric trolley can be attributed to the efforts of one man, Frank J. Sprague.

Creation

The first working trolley pole was developed and demonstrated by Charles Van Depoele, in autumn 1885 but the use of overhead wire in a system of current collection is reputed to be the 1880 invention of Frank J. Sprague.

Frank J. Sprague

Frank J. Sprague was born in 1857 in Milford, Connecticut. He was a brilliant inventor and electrical engineer, who made many contributions to the field of electricity. In the late 19th century, he began working on the development of an electric streetcar system, which would be powered by an overhead wire.

Sprague's first electric streetcar system was installed in Richmond, Virginia, in 1888. The system consisted of a single trolley car that was powered by a generator located at the end of the line. The car was equipped with an electric motor, which was connected to the overhead wire by a trolley pole. The trolley pole was a long pole that extended from the roof of the car and made contact with the overhead wire.

Sprague's system was a great success, and it soon caught the attention of other cities. Over the next few years, Sprague installed electric streetcar systems in several other cities, including Brooklyn, New York; Chicago, Illinois; and Boston, Massachusetts. By 1890, there were over 100 electric streetcar systems operating in the United States.

Advantages

The electric trolley had several advantages over the horse-drawn streetcars that were in use at the time. The electric trolley was faster and more reliable than the horse-drawn streetcar. It was also cleaner, as it did not produce the waste and odor associated with horse-drawn transportation. In addition, the electric trolley was quieter than the horse-drawn streetcar, which made it more pleasant for passengers.

Growth

The electric trolley quickly became a popular form of transportation in many cities. It was used by people from all walks of life, including businessmen, workers, and tourists. The electric trolley helped to make cities more accessible, and it played an important role in the development of urban transportation.

5. Electric Power Grid

The development of the electric power grid was a pivotal moment in the history of electricity. Before the grid was created, electricity was only available to a select few, mainly the wealthy, who could afford their own generators and power plants. However, the power grid changed all that, allowing for electricity to be distributed over long distances and reaching millions of people.

Creation

Nikola Tesla

The idea for the electric power grid was first proposed in the late 19th century by a few pioneering engineers and scientists who saw the potential for electricity to revolutionize society. These early pioneers recognized that if they could develop a system to transmit electricity over long distances, they could bring electricity to homes, businesses, and industries around the world.

One of the key figures in the development of the electric power grid was Nikola Tesla. Tesla was a Serbian-American inventor, electrical engineer, and physicist who is best known for his work on alternating current (AC) electricity. In the late 1880s, Tesla began working on the design of a system to transmit AC electricity over long distances, and in 1891, he patented the design for the first AC power transmission system. Despite the groundbreaking work of Tesla and other pioneers, the development of the electric power grid was slow at first. The early power grids were small and localized, and they were often owned and operated by private companies or municipalities. It wasn't until the early 20th century that the idea of a national power grid began to take shape.

One of the key drivers of the national power grid was the need to bring electricity to rural areas. In the early 20th century, rural areas were still largely without electricity, and many farmers and rural residents were forced to rely on kerosene lamps and other sources of light and heat. The federal government recognized the need to bring electricity to these areas, and in 1935, President Franklin D. Roosevelt signed the Rural Electrification Act, which provided funding for the construction of electric power lines and other infrastructure in rural areas.

Growth

The construction of the national power grid accelerated in the post-World War II era, as the demand for electricity increased dramatically. The power grid grew in size and complexity, and new technologies were developed to improve the efficiency and reliability of the system. Today, the electric power grid is a vast network of power plants, transmission lines, and distribution networks that stretches across the United States and around the world.

Advantages

The electric power grid has had a profound impact on society, enabling countless technological advancements and improving the quality of life for millions of people. From powering our homes and businesses to fueling the growth of new industries, the electric power grid is a critical part of modern life, and its development stands as a testament to the power of human ingenuity and innovation.

#Top#5#Electricity#Electrical#Inventions#Electronic#Light bulb#Battery#Dynamo#Motor#Nikola Tesla#Benjamin Franklin#Thomas Edison#Best#Creations

1 note

·

View note

Text

First Industrial Revolution

The Industrial Revolution was a significant period of economic and technological development that occurred in Europe and North America during the 18th and 19th centuries. It was a time of immense change that transformed the way goods were produced, distributed, and consumed, and it laid the groundwork for modern industrialized societies.

Factors Affected Creation

Natural resources such as coal, iron

The creation of the Industrial Revolution was a complex process that was influenced by a variety of factors. One of the most significant of these was the availability of natural resources, including coal, iron, and water. These resources were essential for powering the machinery that drove the Industrial Revolution and for providing the raw materials needed for manufacturing.

High Level of Agriculture Productivity

British Agriculture Revolution was an unprecedented increase in agricultural production in Britain arising from increases in labour and land productivity between the mid-17th and late 19th centuries. In the course of the revolution, one family began to produce enough food for five families. Much manpower was liberated from agriculture and became available for industry. Thus the Agricultural Revolution made possible the Industrial Revolution.

Financial capital available to invest

The Industrial Revolution was also driven by social and economic changes, including the growth of cities and the rise of a capitalist economy. As people moved from rural areas to cities to work in factories, a new urban working class emerged. The development of capitalist economic systems allowed for the accumulation of capital and the investment in new technologies and industries.

Political stability and a legal system that supported business

Political and legal changes, such as patent laws and the development of joint-stock companies, provided incentives for entrepreneurs and investors to develop and commercialize new technologies.

These were the main factors that affected Industrial Revolution.

Development of Industries

Iron Industry

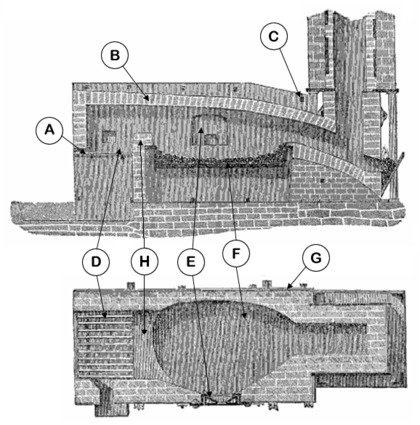

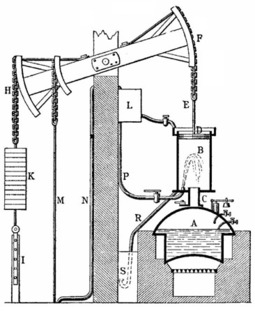

Furnace

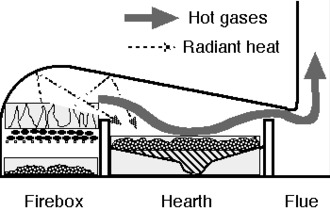

One of the most significant technological advances in the iron industry was the development of the blast furnace, which allowed for the production of large quantities of iron at a lower cost. The blast furnace, which was first introduced in the 18th century, used a combination of coke, iron ore, and limestone to produce pig iron, a crude form of iron that could be refined into more useful products.

The reverberatory furnace could produce cast iron using mined coal. The burning coal remained separate from the iron and so did not contaminate the iron with impurities like sulfur and silica. This opened the way to increased iron production.

Rolling and Puddling

Conversion of cast iron had long been done in a finery forge. An improved refining process known as potting and stamping was developed, but this was superseded by Henry Cort's puddling process. Cort developed two significant iron manufacturing processes: rolling in 1783 and puddling in 1784. Puddling produced a structural grade iron at a relatively low cost. Puddling was a means of decarburizing molten pig iron by slow oxidation in a reverberatory furnace by manually stirring it with a long rod. The decarburized iron, having a higher melting point than cast iron, was raked into globs by the puddler. When the glob was large enough, the puddler would remove it. Puddling was backbreaking and extremely hot work. Few puddlers lived to be 40. Because puddling was done in a reverberatory furnace, coal or coke could be used as fuel. The puddling process continued to be used until the late 19th century when iron was being displaced by steel. Because puddling required human skill in sensing the iron globs, it was never successfully mechanised. Rolling was an important part of the puddling process because the grooved rollers expelled most of the molten slag and consolidated the mass of hot wrought iron. Rolling was 15 times faster at this than a trip hammer. A different use of rolling, which was done at lower temperatures than that for expelling slag, was in the production of iron sheets, and later structural shapes such as beams, angles, and rails.

Horizontal (lower) and vertical (upper) cross-sections of a single puddling furnace. A. Fireplace grate; B. Firebricks; C. Cross binders; D. Fireplace; E. Work door; F. Hearth; G. Cast iron retaining plates; H. Bridge wall

The puddling process was improved in 1818 by Baldwyn Rogers, who replaced some of the sand lining on the reverberatory furnace bottom with iron oxide. In 1838 John Hall patented the use of roasted tap cinder (iron silicate) for the furnace bottom, greatly reducing the loss of iron through increased slag caused by a sand lined bottom. The tap cinder also tied up some phosphorus, but this was not understood at the time. Hall's process also used iron scale or rust which reacted with carbon in the molten iron. Hall's process, called wet puddling, reduced losses of iron with the slag from almost 50% to around 8%. Puddling became widely used after 1800. Up to that time, British iron manufacturers had used considerable amounts of iron imported from Sweden and Russia to supplement domestic supplies. Because of the increased British production, imports began to decline in 1785, and by the 1790s Britain eliminated imports and became a net exporter of bar iron.

Usage

The Iron Bridge, Shropshire, England, the world's first bridge constructed of iron, opened in 1781.

The growth of the iron industry was also driven by increased demand for iron products, particularly in the construction of new buildings, bridges, and railroads. Iron was used to create structural supports, reinforcing rods, and other components that were critical for the development of modern infrastructure.

Availability

The availability of natural resources was also a significant factor in the growth of the iron industry. Britain, which was the center of the Industrial Revolution, had large deposits of iron ore, coal, and limestone, which provided the raw materials necessary for iron production. The development of transportation infrastructure, such as canals and railroads, made it easier to transport these resources to the iron mills.

Growth

In the UK in 1720, there were 20,500 tons of cast iron produced with charcoal and 400 tons with coke. In 1750 charcoal iron production was 24,500 and coke iron was 2,500 tons. In 1788 the production of charcoal cast iron was 14,000 tons while coke iron production was 54,000 tons. In 1806 charcoal cast iron production was 7,800 tons and coke cast iron was 250,000 tons.

In 1750 the UK imported 31,200 tons of bar iron and either refined from cast iron or directly produced 18,800 tons of bar iron using charcoal and 100 tons using coke. In 1796 the UK was making 125,000 tons of bar iron with coke and 6,400 tons with charcoal; imports were 38,000 tons and exports were 24,600 tons. In 1806 the UK did not import bar iron but exported 31,500 tons.

The growth of the iron industry had a significant impact on the economy and society. Iron production created new jobs and industries, driving economic growth and increasing the standard of living. The availability of cheap iron products also made it easier for people to build their own homes, purchase tools, and engage in other activities that were previously prohibitively expensive.

Coal Industry

The development of the coal industry was a gradual process that began in the 16th century, when coal was first mined in Britain for use as fuel. At the time, coal was primarily used for domestic heating and cooking, but as the population grew and new industries emerged, demand for coal increased.

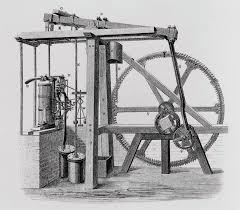

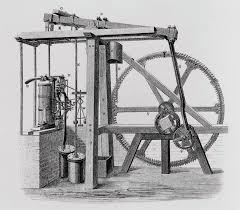

Steam Engine By James Watt

By the 18th century, coal was being used to power steam engines, which were being developed for a variety of purposes, including mining, transportation, and textile manufacturing. The steam engine, invented by James Watt in 1765, was a game-changing technology that allowed for the mechanization of many industries and greatly increased productivity.

The growth of the coal industry was also driven by the expansion of the transportation network, particularly the development of canals and railroads. Canals allowed coal to be transported more easily and cheaply than ever before, while railroads enabled coal to be transported faster and over longer distances. As demand for coal increased, so too did the size and scale of the industry. Large-scale coal mines were developed, often employing hundreds or thousands of workers, and new technologies were developed to extract coal more efficiently and safely.

Inventions

Coal was extracted by mining on underground. There were many hardships in this process, while water being one of the main one. Water was removed by hauling buckets of water up the shaft or to a sough (a tunnel driven into a hill to drain a mine). In either case, the water had to be discharged into a stream or ditch at a level where it could flow away by gravity. The introduction of the steam pump by Thomas Savery in 1698 and the Newcomen steam engine in 1712 greatly facilitated the removal of water and enabled shafts to be made deeper, enabling more coal to be extracted.

Coal mining was very dangerous owing to the presence of firedamp in many coal seams. Some degree of safety was provided by the safety lamp which was invented in 1816 by Sir Humphry Davy and independently by George Stephenson. However, the lamps proved a false dawn because they became unsafe very quickly and provided a weak light. Firedamp explosions continued, often setting off coal dust explosions, so casualties grew during the entire 19th century. Conditions of work were very poor, with a high casualty rate from rock falls.

Steam Power Industry

The history of steam power can be traced back to the 17th century, when inventors began experimenting with ways to use steam to power machinery. However, it was not until the late 18th century that the steam engine was developed to the point where it could be used effectively in industry. The first successful steam engine was built by James Watt in 1765, and it was used primarily for pumping water out of coal mines.

Development

Steam Engine By James Watt

The real breakthrough came in the late 1700s and early 1800s, when steam power was harnessed to power textile mills and other manufacturing processes. The steam engine was used to power spinning machines, looms, and other equipment, greatly increasing the efficiency of textile production. Steam power also allowed for the mechanization of other industries, such as iron and steel production and transportation.

Newcomen's steam-powered atmospheric engine was the first practical piston steam engine. Subsequent steam engines were to power the Industrial Revolution.

The first successful piston steam engine was introduced by Thomas Newcomen before 1712. Newcomen engines were installed for draining hitherto unworkable deep mines, with the engine on the surface; these were large machines, requiring a significant amount of capital to build, and produced upwards of 3.5 kW (5 hp). They were also used to power municipal water supply pumps. They were extremely inefficient by modern standards, but when located where coal was cheap at pit heads, they opened up a great expansion in coal mining by allowing mines to go deeper. Despite their disadvantages, Newcomen engines were reliable and easy to maintain and continued to be used in the coalfields until the early decades of the 19th century. By 1729, when Newcomen died, his engines had spread (first) to Hungary in 1722, Germany, Austria, and Sweden. A total of 110 are known to have been built by 1733 when the joint patent expired, of which 14 were abroad.

Growth

In Britain, by 1800 an estimated 10,000 horsepower was being supplied by steam. By 1815 steam power had grown to 210,000 hp.

Advantages

One of the key advantages of steam power was that it could be used anywhere, regardless of the availability of water power. This made it possible to locate factories in urban areas, close to sources of labor and raw materials. As a result, the use of steam power helped to drive the growth of cities and the development of urban industrial centers.

Challenges

The development of steam power was not without its challenges, however. One of the biggest obstacles was the need for a reliable source of coal to power the steam engines. This led to the development of coal mines and the expansion of the coal industry, which in turn had significant environmental and social impacts. Despite these challenges, the development of steam power had a profound impact on the world economy and the course of human history. It laid the groundwork for modern industrialized societies and transformed the way goods were produced and distributed.

Glass Making Industry

The glass making industry had been around for centuries before the Industrial Revolution, but the traditional methods of producing glass were slow and inefficient. Glassmakers relied on manual labor and hand-blown glass techniques that limited the scale and speed of production. This all changed with the invention of new machines and technologies that revolutionized the glass making process.

Inventions

One of the most significant developments was the invention of the glass pressing machine in 1825 by John P. Bakewell. This machine allowed for the mass production of sheet glass, which was used for windows, mirrors, and other products. The machine worked by pressing molten glass between two rollers, which created uniform sheets of glass that could be cut to size. Another important development was the invention of the soda-lime glass making process in the 19th century. This process replaced the traditional lead glass making process, which was expensive and time-consuming. The soda-lime process used cheaper and more readily available materials, including soda ash and lime, and allowed for the mass production of glass at a lower cost.

The Industrial Revolution also saw the development of new glass making techniques, including the cylinder blown glass process and the Fourcault process. The cylinder blown glass process allowed for the production of seamless glass tubing, which was used in scientific instruments and lighting. The Fourcault process was a continuous glass making process that allowed for the mass production of flat glass sheets.

The development of new glass making techniques during the Industrial Revolution had a significant impact on the glass industry and the wider economy. The mass production of glass led to the creation of new markets and industries, including the production of bottles, mirrors, and glassware. The use of glass in construction and transportation also increased, as new techniques allowed for the production of larger and more durable glass products.

Transportation Industry

At the beginning of the Industrial Revolution, inland transport was by navigable rivers and roads, with coastal vessels employed to move heavy goods by sea. Wagonways were used for conveying coal to rivers for further shipment, but canals had not yet been widely constructed. Animals supplied all of the motive power on land, with sails providing the motive power on the sea. The first horse railways were introduced toward the end of the 18th century, with steam locomotives being introduced in the early decades of the 19th century. Improving sailing technologies boosted average sailing speed by 50% between 1750 and 1830. The Industrial Revolution improved Britain's transport infrastructure with a turnpike road network, a canal and waterway network, and a railway network. Raw materials and finished products could be moved more quickly and cheaply than before. Improved transportation also allowed new ideas to spread quickly.

Railway Industry

Painting depicting the opening of the Liverpool and Manchester Railway in 1830, the first inter-city railway in the world and which spawned Railway Mania due to its success

In the early 19th century, Britain had a transportation problem. There were no roads suitable for heavy wagons, and rivers were not efficient for long-distance transport. At the same time, the growth of industrialization was creating an ever-increasing demand for coal and other raw materials, as well as a need for faster and more efficient ways of transporting goods.

Growth

The solution was to build a network of railways that would connect the major industrial centers of the country. The first railway was built in 1804, and by 1850, there were over 6,000 miles of railway track in Britain, linking the major cities and ports.

Inventions

The development of the railway industry was made possible by several technological innovations. The steam engine, invented by James Watt in the late 18th century, provided the power needed to move heavy loads. The development of iron and steel production allowed for the construction of stronger and more durable tracks and locomotives, while new manufacturing techniques, such as mass production, made it possible to build large numbers of locomotives and carriages at a relatively low cost.

Advantages

The railways had a profound impact on the economy and society of Britain. They made it possible to transport goods and raw materials quickly and cheaply, reducing the cost of production and increasing the profitability of industry. They also made it possible for people to travel more easily and cheaply, enabling the growth of tourism and the development of new markets. The railways also helped to drive further technological innovation. The development of the railway industry led to advances in the production of steel, locomotives, and other machinery, as well as the development of new technologies, such as telegraphs and signaling systems, which made the railways safer and more efficient.

These are development of some industries in Industrial Revolution.

Social Effects

Growth of Cities

One of the most significant social effects of the Industrial Revolution was the growth of cities. As people moved from rural areas to urban centers to work in factories, cities grew rapidly, with the population of some cities increasing tenfold or more. This rapid urbanization brought about significant changes in the way people lived and interacted with each other, leading to the development of new social structures and institutions.

Family Structure

The growth of cities also brought about significant changes in the family structure. As more and more people moved to urban centers to work in factories, family structures changed, with nuclear families becoming more common. The extended family, which had been the norm in rural areas, became less prevalent as people moved away from their ancestral homes to seek work in the cities.

Women society

The Industrial Revolution also had a significant impact on the role of women in society. As factory work became more prevalent, women began to enter the workforce in larger numbers. This led to significant changes in the way women were perceived and treated, as they began to gain more independence and autonomy.

Dangerous works

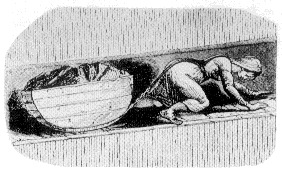

A young "drawer" pulling a coal tub along a mine gallery. In Britain, laws passed in 1842 and 1844 improved mine working conditions.

However, these changes were not all positive, as the working conditions in factories were often dangerous and unhealthy, leading to widespread illness and injury. Workers, including women and children, were often forced to work long hours in hazardous conditions, with little to no access to healthcare or education.

New middle class

Another significant social effect of the Industrial Revolution was the emergence of a new middle class. As new industries and technologies emerged, new job opportunities were created, leading to the growth of a middle class. This new class of people had a significant impact on society, as they were able to afford better education, healthcare, and living conditions.

Environment

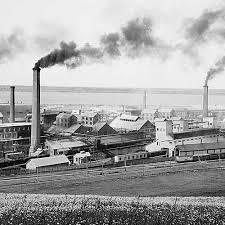

Manchester, England ("Cottonopolis"), pictured in 1840, showing the mass of factory chimneys

The Industrial Revolution had a significant impact on the environment, with the development of new technologies leading to increased pollution and deforestation. This had a significant impact on the health and wellbeing of people living in urban areas, as air and water pollution led to widespread illness and disease.

Industrialization beyond Great Britain

The Habsburg realms which became Austria-Hungary in 1867 included 23 million inhabitants in 1800, growing to 36 million by 1870. Nationally the per capita rate of industrial growth averaged about 3% between 1818 and 1870. However, there were strong regional differences. The railway system was built in the 1850–1873 period. Before they arrived transportation was very slow and expensive. In the Alpine and Bohemian (modern-day Czech Republic) regions, proto-industrialization began by 1750 and became the center of the first phases of the Industrial Revolution after 1800. The textile industry was the main factor, utilizing mechanization, steam engines, and the factory system. In the Czech lands, the "first mechanical loom followed in Varnsdorf in 1801", with the first steam engines appearing in Bohemia and Moravia just a few years later. The textile production flourished particularly in Prague and Brno (German: Brünn), which was considered the 'Moravian Manchester'. The Czech lands, especially Bohemia, became the center of industrialization due to its natural and human resources. The iron industry had developed in the Alpine regions after 1750, with smaller centers in Bohemia and Moravia. Hungary—the eastern half of the Dual Monarchy, was heavily rural with little industry before 1870.

In 1791, Prague organized the first World's Fair/List of world's fairs, Bohemia (modern-day Czech Republic). The first industrial exhibition was on the occasion of the coronation of Leopold II as a king of Bohemia, which took place in Clementinum, and therefore celebrated the considerable sophistication of manufacturing methods in the Czech lands during that time period.

Technological change accelerated industrialization and urbanization. The GNP per capita grew roughly 1.76% per year from 1870 to 1913. That level of growth compared very favorably to that of other European nations such as Britain (1%), France (1.06%), and Germany (1.51%). However, in a comparison with Germany and Britain: the Austro-Hungarian economy as a whole still lagged considerably, as sustained modernization had begun much later.

Belgium

Belgium was the second country in which the Industrial Revolution took place and the first in continental Europe: Wallonia (French-speaking southern Belgium) took the lead. Starting in the middle of the 1820s, and especially after Belgium became an independent nation in 1830, numerous works comprising coke blast furnaces as well as puddling and rolling mills were built in the coal mining areas around Liège and Charleroi. The leader was a transplanted Englishman John Cockerill. His factories at Seraing integrated all stages of production, from engineering to the supply of raw materials, as early as 1825.

Wallonia exemplified the radical evolution of industrial expansion. Thanks to coal (the French word "houille" was coined in Wallonia), the region geared up to become the 2nd industrial power in the world after Britain. But it is also pointed out by many researchers, with its Sillon industriel, 'Especially in the Haine, Sambre and Meuse valleys, between the Borinage and Liège...there was a huge industrial development based on coal-mining and iron-making...'. Philippe Raxhon wrote about the period after 1830: "It was not propaganda but a reality the Walloon regions were becoming the second industrial power all over the world after Britain." "The sole industrial centre outside the collieries and blast furnaces of Walloon was the old cloth-making town of Ghent." Professor Michel De Coster stated: "The historians and the economists say that Belgium was the second industrial power of the world, in proportion to its population and its territory [...] But this rank is the one of Wallonia where the coal-mines, the blast furnaces, the iron and zinc factories, the wool industry, the glass industry, the weapons industry... were concentrated." Many of the 19th-century coal mines in Wallonia are now protected as World Heritage sites.

Wallonia was also the birthplace of a strong socialist party and strong trade unions in a particular sociological landscape. At the left, the Sillon industriel, which runs from Mons in the west, to Verviers in the east (except part of North Flanders, in another period of the industrial revolution, after 1920). Even if Belgium is the second industrial country after Britain, the effect of the industrial revolution there was very different.

France

One of the earliest countries to experience industrialization was France. In the late 18th century, French inventors developed new technologies, such as the spinning jenny and power loom, which increased the efficiency of textile production. The French government also supported industrialization by providing incentives for entrepreneurs and investing in infrastructure projects, such as canals and railways.

Germany

Germany was another country that experienced rapid industrialization during the 19th century. The country had a large supply of coal and iron, which were essential for powering machinery and producing steel. German inventors developed new technologies, such as the steam engine and gas lighting, and the government supported industrialization by investing in infrastructure and creating a national railway system.

United States

The United States also experienced significant industrialization during the 19th century. The country had a large supply of natural resources, including coal, iron, and timber, which were used to fuel the growth of manufacturing. American inventors developed new technologies, such as the telegraph, sewing machine, and typewriter, which revolutionized communication and manufacturing.

Japan

In Japan, the Meiji Restoration in 1868 marked the beginning of a period of rapid industrialization. The government recognized the importance of industrialization for economic growth and national security and invested in infrastructure, education, and technology. Japanese inventors developed new technologies, such as the steam engine and electric power, and the country rapidly modernized its manufacturing industries.

Industrial Revolution's impact was immense, transforming societies and economies around the world and laying the foundation for the modern world.

#Industrial Revolution#Industrial#Industry#Revolution#Importance#Development#Growth#Iron Industry#Coal industry#Steam Power Industry#Glass industry#Business#British#Britain

1 note

·

View note

Text

Battle of Leyte Gulf

The Battle of Leyte Gulf was a crucial naval engagement that occurred during World War II in October 1944. It was the largest naval battle of the war, involving the combined forces of the United States and Australia against Japan. The battle took place in the waters surrounding the Philippine island of Leyte, and it played a critical role in the Allied victory in the Pacific theater.

Reasons for the Battle

One of the primary reasons for the battle was the strategic importance of the Philippines to both the Allied and Japanese forces. The Philippines had been under Japanese occupation since 1942, and the Allies were eager to retake the islands in order to establish a base from which to launch further attacks on Japan. The Japanese, meanwhile, recognized the strategic value of the Philippines and were determined to defend their position.

Another reason for the battle was the Japanese naval strategy of launching kamikaze attacks against Allied forces. Kamikaze attacks involved Japanese pilots deliberately crashing their planes into Allied ships, causing significant damage and loss of life. The Japanese hoped that these attacks would deter the Allies from continuing their offensive, and they planned to use kamikaze attacks extensively during the battle.

A third reason for the battle was the Japanese plan to divide the Allied forces by launching a decoy attack in the north while their main force attacked from the south. This strategy was intended to confuse the Allies and allow the Japanese to gain a tactical advantage.

The battle of Leyte Gulf was also fought due to the importance of the sea lanes surrounding the Philippines. The waters around the islands were key shipping routes for both the Allies and the Japanese, and control of these lanes was vital for the success of both sides.

Some say, The battle was fought because of the personal ambitions of the commanders involved. Admiral Kurita, the Japanese commander, was determined to win a major naval battle and achieve a decisive victory for Japan. Admiral Halsey, the American commander, was similarly ambitious and was eager to prove his worth as a naval commander.

Decision to Invade Philippines by Allies

A meeting between MacArthur, Nimitz, and President Roosevelt helped confirm the Philippines as a strategic target but did not reach a decision, and the debate continued for two months. Eventually Nimitz changed his mind and agreed to MacArthur's plan, and it was eventually decided that MacArthur's forces would invade the island of Leyte in the central Philippines. Amphibious forces and close naval support would be provided by Seventh Fleet, commanded by Vice Admiral Thomas C. Kinkaid.

War Structur

The battle was fought between the Japanese Imperial Navy and the Allied naval forces, which included the United States Navy's Third and Seventh Fleets, as well as the Royal Australian Navy. The Japanese fleet, under the command of Admiral Takeo Kurita, was tasked with destroying the Allied landing force at Leyte and disrupting their operations in the Philippines. The Allied forces, under the command of Admiral William Halsey and Admiral Thomas Kinkaid, were determined to protect their troops on the ground and secure the island.

Allies Strength

~300 ships in total

8 fleet carriers

9 light carriers

18 escort carriers

12 battleships

24 cruisers

116 destroyers and destroyer escorts

Many PT boats, submarines, and fleet auxiliaries

About 1,500 planes

Imperial Japan's Strength

67+ ships in total

1 fleet carrier

3 light carriers

2 hybrid-carriers/battleships

7 battleships

13 heavy cruisers

6 light cruisers

35+ destroyers

300+ planes (including land-based aircraft)

Beginning

The battle began on October 23, 1944, with a series of naval engagements between the opposing forces. The Japanese launched a surprise attack on the Allied fleet with their powerful battleships and cruisers, but the Americans were able to quickly regroup and launch a counterattack. Over the next few days, the two sides engaged in intense fighting that involved multiple naval battles and air strikes.

Significant Events

Musashi

Musashi under aerial bombardment

One of the key moments in the battle came on October 25, when the Japanese attempted to penetrate the Leyte Gulf with their battleships. However, the Allied forces were prepared for this maneuver and were able to sink several of the Japanese ships, including the battleship Musashi, one of the largest and most powerful warships ever built. The loss of the Musashi dealt a significant blow to the Japanese fleet and boosted the morale of the Allied forces.

Sinking of Fusō

The traditional account of the sinking of Fusō was that she exploded into two halves that remained floating for some time. However, Fusō survivor Hideo Ogawa, interrogated in 1945, in an article on the battleship's last voyage, stated: "Shortly after 0400 the ship capsized slowly to starboard and Ogawa and others were washed away," without specifically mentioning the bisection. Fusō was hit on the starboard side by two or possibly three torpedoes. One of these started an oil fire, and as the fuel used by IJN ships was poorly refined and easily ignited, burning patches of fuel could have led to the description from Allied observers of Fusō "blowing up". However, battleships were known sometimes to be cut into two or even three sections which could remain afloat independently, and Samuel Morison states that the bow half of Fusō was sunk by gunfire from Louisville, and the stern half sank off Kanihaan Island.

First kamikaze attacks of the Pacific War

The first kamikaze attacks of the Pacific War occurred on October 25, 1944, during the Battle of Leyte Gulf. The attacks were carried out by Japanese pilots who deliberately crashed their planes into Allied ships, causing significant damage and loss of life. The kamikaze attacks represented a new tactic in the war, and they would go on to have a significant impact on the course of the conflict.

The idea of kamikaze attacks originated in Japan in the months leading up to the Battle of Leyte Gulf. The Japanese military was facing a dire situation, with their forces in the Pacific stretched thin and the Allies gaining momentum. The Japanese were looking for new tactics to use in the fight against the Allies, and they began to consider the use of suicide attacks.

The first kamikaze attacks were carried out by a group of Japanese pilots who had been specially trained for the task. The pilots flew their planes directly into Allied ships, causing massive explosions and fires. The first attack was on a escort carrier named Santee. The attack killed 16 crewmen. Even though emergency repairs saved Santee from sinking. The second attack was on escort carrier named Suwannee which killed 71 crewmen. Suwannee was hit by another kamikaze around noon on 26 October that caused even more damage and killed 36 more crewmen. This second kamikaze strike caused a large fire that was not extinguished until nine hours later. A total of 107 sailors were killed and over 150 were wounded on Suwannee in the kamikaze attacks on 25–26 October. 5 Avenger torpedo bombers and 9 Hellcat fighters on Suwannee were destroyed.

The attacks were highly effective, and the Allies were caught off guard by the new tactic. The kamikaze attacks caused significant damage to the Allied fleet, sinking or damaging several ships. The kamikaze attacks were highly controversial, even within Japan. Many Japanese military leaders opposed the tactic, believing that it was wasteful and dishonorable. However, others saw it as a necessary measure to turn the tide of the war. Despite the controversy, the kamikaze attacks would go on to become a staple of Japanese military strategy in the Pacific War. The attacks were highly effective, and they caused significant damage to Allied forces. The kamikaze pilots were revered in Japan as heroes, and their sacrifice was seen as a necessary measure to defend the homeland. The kamikaze attacks also had a significant psychological impact on the Allied forces. The pilots were willing to give up their lives for their cause, and this willingness to die for their country was something that the Allies found difficult to understand. The attacks created a sense of fear and dread among Allied troops, as they knew that they could be targeted by kamikaze pilots at any time.

End

Despite this setback, the Japanese continued to fight fiercely, and the battle raged on for several more days. In the end, the Allied forces emerged victorious, having successfully repelled the Japanese attack and secured their position on the island of Leyte. The battle was a decisive moment in the war in the Pacific, as it effectively ended Japan's naval supremacy and paved the way for the eventual Allied victory.

The Battle of Leyte Gulf was a complex and highly strategic engagement that involved multiple naval tactics and maneuvers. It demonstrated the importance of air power in naval warfare, as both sides heavily relied on their aircraft carriers and fighter planes to gain an advantage. The battle also showcased the bravery and skill of the sailors and pilots involved, many of whom made significant sacrifices to ensure victory for their respective sides. Today, the Battle of Leyte Gulf is remembered as one of the most significant naval battles in history. It played a crucial role in the Allied victory in the Pacific and helped to shape the course of World War II. Its legacy continues to be felt to this day, as the lessons learned from the battle continue to inform modern naval strategy and tactics.

#Battle of leyte gulf#Leyte Gulf#Naval#Navy#Battle#Largest#Japanese#Imperial#America#Allies#Axis#Australia#Musashi#World War#2#Greatest

1 note

·

View note