#Glass industry

Text

youtube

#glass industry#glass#float glass#manufacturing#apnadeshapnaglass#goldplusglass#mirror#goldplus#silver mirror#Youtube

2 notes

·

View notes

Text

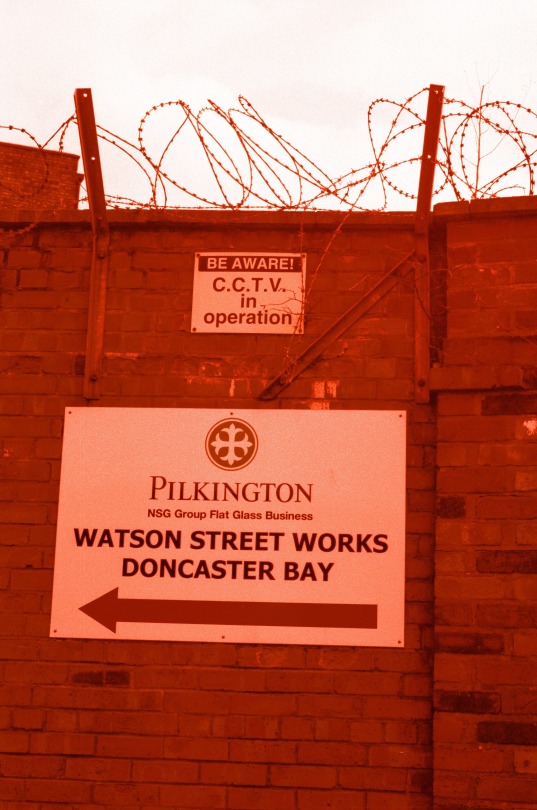

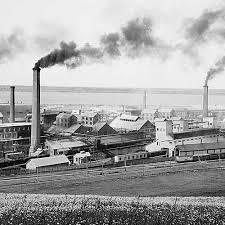

The glass industry, St Helens. Nikon F65. Expired Fuji Velvia 100F.

Whilst the glass industry is not as prevalent as it was in St Helens it remains a significant presence in the town. Some sites are derelict and underused whilst other facilities are in use and seem to be thriving.

#liverpoollomo#lomo#lomography#analogue photography#liverpool#nikon f65#single lens reflex#film slr#fuji velvia 100f#slide film#fuji film#35mm photography#cross process#x-pro#st helens#glass industry#lancashire#don't think just shoot#film is not dead

3 notes

·

View notes

Text

Frequently Asked Questions About Toughened Glass

1. What is toughened glass? Toughened glass, also known as tempered glass, is a type of safety glass that is processed through controlled thermal or chemical treatments to increase its strength. It is significantly stronger and safer than regular glass, as it shatters into small, blunt pieces upon impact, reducing the risk of injury.

2. What are the advantages of toughened glass? Toughened glass offers several benefits, including enhanced safety, durability, thermal resistance, and strength. It is ideal for various applications, such as doors, windows, facades, shower enclosures, and automotive windows, where safety and durability are paramount.

3. How is toughened glass manufactured? Toughened glass undergoes a specialized heating and rapid cooling process, known as tempering, which strengthens its molecular structure. This process involves heating the glass to a high temperature and then rapidly cooling it to induce surface compression and internal tension, resulting in increased strength and safety.

4. What are the applications of toughened glass? Toughened glass is used in a wide range of applications, including residential, commercial, and automotive sectors. It is commonly used for doors, windows, partitions, balustrades, shower enclosures, glass facades, tabletops, and automotive windows due to its strength, safety, and aesthetic appeal.

5. Is toughened glass customizable? Yes, toughened glass can be customized to suit specific requirements in terms of size, thickness, shape, tint, and finishes. Manufacturers offer a variety of customization options to meet the diverse needs of customers for both functional and aesthetic purposes.

6. How does toughened glass enhance safety? Toughened glass is designed to reduce the risk of injury in the event of breakage. Unlike regular glass, which breaks into sharp shards, toughened glass shatters into small, blunt pieces that are less likely to cause serious harm. This property makes it a preferred choice for applications where safety is paramount.

7. Is toughened glass suitable for use in extreme temperatures? Yes, toughened glass exhibits excellent thermal resistance and can withstand sudden temperature changes without cracking or breaking. It is suitable for use in areas exposed to high temperatures, such as kitchen splashbacks, oven doors, and glass facades.

8. How can I clean and maintain toughened glass? Toughened glass is relatively easy to clean and maintain. You can use a mild detergent or glass cleaner with a soft cloth or sponge to remove dirt and stains. Avoid using abrasive materials or harsh chemicals, as they can damage the glass surface. Regular cleaning and maintenance will help preserve the clarity and appearance of toughened glass over time.

9. What quality standards should I look for when purchasing toughened glass? When purchasing toughened glass, look for products that meet industry standards and certifications for safety glazing materials. Ensure that the manufacturer adheres to quality control measures and conducts rigorous testing to ensure the strength, durability, and safety of their products.

10. Where can I purchase toughened glass in Mysore? You can purchase top-quality toughened glass products from reputable manufacturers and suppliers in Mysore. Look for companies that have a proven track record of delivering high-quality products and excellent customer service to meet your specific requirements.

Author - JP Art & Safety Glass

#Toughened glass#Tempered glass#Safety glass#Glass manufacturing#Glass fabrication#Toughened glass suppliers#Toughened glass products#Glass industry#Custom glass#Architectural glass#Commercial glass#Residential glass#Automotive glass#Glassworks#Glass fabrication company#Glass manufacturer#Glass supplier#Toughened glass production#Quality glass products#Mysore glass manufacturers

0 notes

Text

0 notes

Text

The global soda ash market is expected to grow in the coming years due to increasing demand from various end-use industries, such as glass, detergents, and chemicals. According to a report by MarketsandMarkets, the global soda ash market is projected to reach USD 22.3 billion by 2026, growing at a CAGR of 4.4% from 2021 to 2026.

The growth of the glass industry is one of the primary drivers of the soda ash market, as soda ash is a key raw material used in the production of glass. The increasing demand for detergents and cleaning products is also expected to fuel the demand for soda ash, as it is a key ingredient used in the manufacturing of these products. However, factors such as the availability of substitutes and environmental concerns related to the production of soda ash could hinder the growth of the market.

At Elchemy, Soda Ash is one of our strongest products and our suppliers are known for their top notch quality. Write to us at [email protected] for your Soda Ash purchasing needs.

0 notes

Text

First Industrial Revolution

The Industrial Revolution was a significant period of economic and technological development that occurred in Europe and North America during the 18th and 19th centuries. It was a time of immense change that transformed the way goods were produced, distributed, and consumed, and it laid the groundwork for modern industrialized societies.

Factors Affected Creation

Natural resources such as coal, iron

The creation of the Industrial Revolution was a complex process that was influenced by a variety of factors. One of the most significant of these was the availability of natural resources, including coal, iron, and water. These resources were essential for powering the machinery that drove the Industrial Revolution and for providing the raw materials needed for manufacturing.

High Level of Agriculture Productivity

British Agriculture Revolution was an unprecedented increase in agricultural production in Britain arising from increases in labour and land productivity between the mid-17th and late 19th centuries. In the course of the revolution, one family began to produce enough food for five families. Much manpower was liberated from agriculture and became available for industry. Thus the Agricultural Revolution made possible the Industrial Revolution.

Financial capital available to invest

The Industrial Revolution was also driven by social and economic changes, including the growth of cities and the rise of a capitalist economy. As people moved from rural areas to cities to work in factories, a new urban working class emerged. The development of capitalist economic systems allowed for the accumulation of capital and the investment in new technologies and industries.

Political stability and a legal system that supported business

Political and legal changes, such as patent laws and the development of joint-stock companies, provided incentives for entrepreneurs and investors to develop and commercialize new technologies.

These were the main factors that affected Industrial Revolution.

Development of Industries

Iron Industry

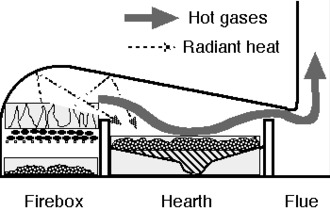

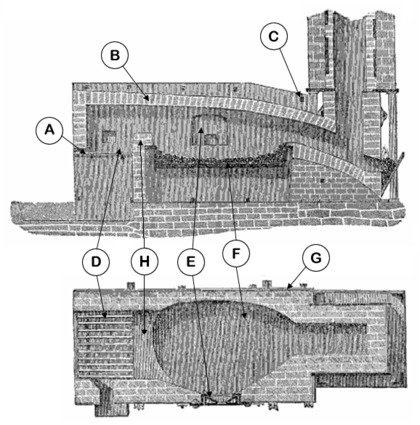

Furnace

One of the most significant technological advances in the iron industry was the development of the blast furnace, which allowed for the production of large quantities of iron at a lower cost. The blast furnace, which was first introduced in the 18th century, used a combination of coke, iron ore, and limestone to produce pig iron, a crude form of iron that could be refined into more useful products.

The reverberatory furnace could produce cast iron using mined coal. The burning coal remained separate from the iron and so did not contaminate the iron with impurities like sulfur and silica. This opened the way to increased iron production.

Rolling and Puddling

Conversion of cast iron had long been done in a finery forge. An improved refining process known as potting and stamping was developed, but this was superseded by Henry Cort's puddling process. Cort developed two significant iron manufacturing processes: rolling in 1783 and puddling in 1784. Puddling produced a structural grade iron at a relatively low cost. Puddling was a means of decarburizing molten pig iron by slow oxidation in a reverberatory furnace by manually stirring it with a long rod. The decarburized iron, having a higher melting point than cast iron, was raked into globs by the puddler. When the glob was large enough, the puddler would remove it. Puddling was backbreaking and extremely hot work. Few puddlers lived to be 40. Because puddling was done in a reverberatory furnace, coal or coke could be used as fuel. The puddling process continued to be used until the late 19th century when iron was being displaced by steel. Because puddling required human skill in sensing the iron globs, it was never successfully mechanised. Rolling was an important part of the puddling process because the grooved rollers expelled most of the molten slag and consolidated the mass of hot wrought iron. Rolling was 15 times faster at this than a trip hammer. A different use of rolling, which was done at lower temperatures than that for expelling slag, was in the production of iron sheets, and later structural shapes such as beams, angles, and rails.

Horizontal (lower) and vertical (upper) cross-sections of a single puddling furnace. A. Fireplace grate; B. Firebricks; C. Cross binders; D. Fireplace; E. Work door; F. Hearth; G. Cast iron retaining plates; H. Bridge wall

The puddling process was improved in 1818 by Baldwyn Rogers, who replaced some of the sand lining on the reverberatory furnace bottom with iron oxide. In 1838 John Hall patented the use of roasted tap cinder (iron silicate) for the furnace bottom, greatly reducing the loss of iron through increased slag caused by a sand lined bottom. The tap cinder also tied up some phosphorus, but this was not understood at the time. Hall's process also used iron scale or rust which reacted with carbon in the molten iron. Hall's process, called wet puddling, reduced losses of iron with the slag from almost 50% to around 8%. Puddling became widely used after 1800. Up to that time, British iron manufacturers had used considerable amounts of iron imported from Sweden and Russia to supplement domestic supplies. Because of the increased British production, imports began to decline in 1785, and by the 1790s Britain eliminated imports and became a net exporter of bar iron.

Usage

The Iron Bridge, Shropshire, England, the world's first bridge constructed of iron, opened in 1781.

The growth of the iron industry was also driven by increased demand for iron products, particularly in the construction of new buildings, bridges, and railroads. Iron was used to create structural supports, reinforcing rods, and other components that were critical for the development of modern infrastructure.

Availability

The availability of natural resources was also a significant factor in the growth of the iron industry. Britain, which was the center of the Industrial Revolution, had large deposits of iron ore, coal, and limestone, which provided the raw materials necessary for iron production. The development of transportation infrastructure, such as canals and railroads, made it easier to transport these resources to the iron mills.

Growth

In the UK in 1720, there were 20,500 tons of cast iron produced with charcoal and 400 tons with coke. In 1750 charcoal iron production was 24,500 and coke iron was 2,500 tons. In 1788 the production of charcoal cast iron was 14,000 tons while coke iron production was 54,000 tons. In 1806 charcoal cast iron production was 7,800 tons and coke cast iron was 250,000 tons.

In 1750 the UK imported 31,200 tons of bar iron and either refined from cast iron or directly produced 18,800 tons of bar iron using charcoal and 100 tons using coke. In 1796 the UK was making 125,000 tons of bar iron with coke and 6,400 tons with charcoal; imports were 38,000 tons and exports were 24,600 tons. In 1806 the UK did not import bar iron but exported 31,500 tons.

The growth of the iron industry had a significant impact on the economy and society. Iron production created new jobs and industries, driving economic growth and increasing the standard of living. The availability of cheap iron products also made it easier for people to build their own homes, purchase tools, and engage in other activities that were previously prohibitively expensive.

Coal Industry

The development of the coal industry was a gradual process that began in the 16th century, when coal was first mined in Britain for use as fuel. At the time, coal was primarily used for domestic heating and cooking, but as the population grew and new industries emerged, demand for coal increased.

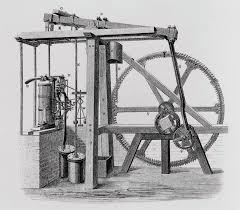

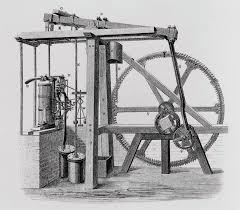

Steam Engine By James Watt

By the 18th century, coal was being used to power steam engines, which were being developed for a variety of purposes, including mining, transportation, and textile manufacturing. The steam engine, invented by James Watt in 1765, was a game-changing technology that allowed for the mechanization of many industries and greatly increased productivity.

The growth of the coal industry was also driven by the expansion of the transportation network, particularly the development of canals and railroads. Canals allowed coal to be transported more easily and cheaply than ever before, while railroads enabled coal to be transported faster and over longer distances. As demand for coal increased, so too did the size and scale of the industry. Large-scale coal mines were developed, often employing hundreds or thousands of workers, and new technologies were developed to extract coal more efficiently and safely.

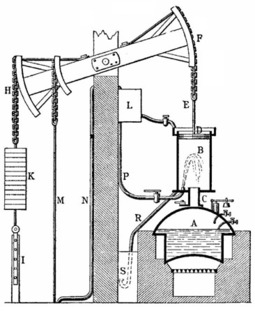

Inventions

Coal was extracted by mining on underground. There were many hardships in this process, while water being one of the main one. Water was removed by hauling buckets of water up the shaft or to a sough (a tunnel driven into a hill to drain a mine). In either case, the water had to be discharged into a stream or ditch at a level where it could flow away by gravity. The introduction of the steam pump by Thomas Savery in 1698 and the Newcomen steam engine in 1712 greatly facilitated the removal of water and enabled shafts to be made deeper, enabling more coal to be extracted.

Coal mining was very dangerous owing to the presence of firedamp in many coal seams. Some degree of safety was provided by the safety lamp which was invented in 1816 by Sir Humphry Davy and independently by George Stephenson. However, the lamps proved a false dawn because they became unsafe very quickly and provided a weak light. Firedamp explosions continued, often setting off coal dust explosions, so casualties grew during the entire 19th century. Conditions of work were very poor, with a high casualty rate from rock falls.

Steam Power Industry

The history of steam power can be traced back to the 17th century, when inventors began experimenting with ways to use steam to power machinery. However, it was not until the late 18th century that the steam engine was developed to the point where it could be used effectively in industry. The first successful steam engine was built by James Watt in 1765, and it was used primarily for pumping water out of coal mines.

Development

Steam Engine By James Watt

The real breakthrough came in the late 1700s and early 1800s, when steam power was harnessed to power textile mills and other manufacturing processes. The steam engine was used to power spinning machines, looms, and other equipment, greatly increasing the efficiency of textile production. Steam power also allowed for the mechanization of other industries, such as iron and steel production and transportation.

Newcomen's steam-powered atmospheric engine was the first practical piston steam engine. Subsequent steam engines were to power the Industrial Revolution.

The first successful piston steam engine was introduced by Thomas Newcomen before 1712. Newcomen engines were installed for draining hitherto unworkable deep mines, with the engine on the surface; these were large machines, requiring a significant amount of capital to build, and produced upwards of 3.5 kW (5 hp). They were also used to power municipal water supply pumps. They were extremely inefficient by modern standards, but when located where coal was cheap at pit heads, they opened up a great expansion in coal mining by allowing mines to go deeper. Despite their disadvantages, Newcomen engines were reliable and easy to maintain and continued to be used in the coalfields until the early decades of the 19th century. By 1729, when Newcomen died, his engines had spread (first) to Hungary in 1722, Germany, Austria, and Sweden. A total of 110 are known to have been built by 1733 when the joint patent expired, of which 14 were abroad.

Growth

In Britain, by 1800 an estimated 10,000 horsepower was being supplied by steam. By 1815 steam power had grown to 210,000 hp.

Advantages

One of the key advantages of steam power was that it could be used anywhere, regardless of the availability of water power. This made it possible to locate factories in urban areas, close to sources of labor and raw materials. As a result, the use of steam power helped to drive the growth of cities and the development of urban industrial centers.

Challenges

The development of steam power was not without its challenges, however. One of the biggest obstacles was the need for a reliable source of coal to power the steam engines. This led to the development of coal mines and the expansion of the coal industry, which in turn had significant environmental and social impacts. Despite these challenges, the development of steam power had a profound impact on the world economy and the course of human history. It laid the groundwork for modern industrialized societies and transformed the way goods were produced and distributed.

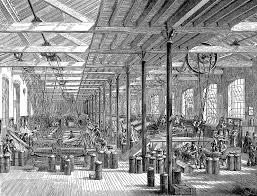

Glass Making Industry

The glass making industry had been around for centuries before the Industrial Revolution, but the traditional methods of producing glass were slow and inefficient. Glassmakers relied on manual labor and hand-blown glass techniques that limited the scale and speed of production. This all changed with the invention of new machines and technologies that revolutionized the glass making process.

Inventions

One of the most significant developments was the invention of the glass pressing machine in 1825 by John P. Bakewell. This machine allowed for the mass production of sheet glass, which was used for windows, mirrors, and other products. The machine worked by pressing molten glass between two rollers, which created uniform sheets of glass that could be cut to size. Another important development was the invention of the soda-lime glass making process in the 19th century. This process replaced the traditional lead glass making process, which was expensive and time-consuming. The soda-lime process used cheaper and more readily available materials, including soda ash and lime, and allowed for the mass production of glass at a lower cost.

The Industrial Revolution also saw the development of new glass making techniques, including the cylinder blown glass process and the Fourcault process. The cylinder blown glass process allowed for the production of seamless glass tubing, which was used in scientific instruments and lighting. The Fourcault process was a continuous glass making process that allowed for the mass production of flat glass sheets.

The development of new glass making techniques during the Industrial Revolution had a significant impact on the glass industry and the wider economy. The mass production of glass led to the creation of new markets and industries, including the production of bottles, mirrors, and glassware. The use of glass in construction and transportation also increased, as new techniques allowed for the production of larger and more durable glass products.

Transportation Industry

At the beginning of the Industrial Revolution, inland transport was by navigable rivers and roads, with coastal vessels employed to move heavy goods by sea. Wagonways were used for conveying coal to rivers for further shipment, but canals had not yet been widely constructed. Animals supplied all of the motive power on land, with sails providing the motive power on the sea. The first horse railways were introduced toward the end of the 18th century, with steam locomotives being introduced in the early decades of the 19th century. Improving sailing technologies boosted average sailing speed by 50% between 1750 and 1830. The Industrial Revolution improved Britain's transport infrastructure with a turnpike road network, a canal and waterway network, and a railway network. Raw materials and finished products could be moved more quickly and cheaply than before. Improved transportation also allowed new ideas to spread quickly.

Railway Industry

Painting depicting the opening of the Liverpool and Manchester Railway in 1830, the first inter-city railway in the world and which spawned Railway Mania due to its success

In the early 19th century, Britain had a transportation problem. There were no roads suitable for heavy wagons, and rivers were not efficient for long-distance transport. At the same time, the growth of industrialization was creating an ever-increasing demand for coal and other raw materials, as well as a need for faster and more efficient ways of transporting goods.

Growth

The solution was to build a network of railways that would connect the major industrial centers of the country. The first railway was built in 1804, and by 1850, there were over 6,000 miles of railway track in Britain, linking the major cities and ports.

Inventions

The development of the railway industry was made possible by several technological innovations. The steam engine, invented by James Watt in the late 18th century, provided the power needed to move heavy loads. The development of iron and steel production allowed for the construction of stronger and more durable tracks and locomotives, while new manufacturing techniques, such as mass production, made it possible to build large numbers of locomotives and carriages at a relatively low cost.

Advantages

The railways had a profound impact on the economy and society of Britain. They made it possible to transport goods and raw materials quickly and cheaply, reducing the cost of production and increasing the profitability of industry. They also made it possible for people to travel more easily and cheaply, enabling the growth of tourism and the development of new markets. The railways also helped to drive further technological innovation. The development of the railway industry led to advances in the production of steel, locomotives, and other machinery, as well as the development of new technologies, such as telegraphs and signaling systems, which made the railways safer and more efficient.

These are development of some industries in Industrial Revolution.

Social Effects

Growth of Cities

One of the most significant social effects of the Industrial Revolution was the growth of cities. As people moved from rural areas to urban centers to work in factories, cities grew rapidly, with the population of some cities increasing tenfold or more. This rapid urbanization brought about significant changes in the way people lived and interacted with each other, leading to the development of new social structures and institutions.

Family Structure

The growth of cities also brought about significant changes in the family structure. As more and more people moved to urban centers to work in factories, family structures changed, with nuclear families becoming more common. The extended family, which had been the norm in rural areas, became less prevalent as people moved away from their ancestral homes to seek work in the cities.

Women society

The Industrial Revolution also had a significant impact on the role of women in society. As factory work became more prevalent, women began to enter the workforce in larger numbers. This led to significant changes in the way women were perceived and treated, as they began to gain more independence and autonomy.

Dangerous works

A young "drawer" pulling a coal tub along a mine gallery. In Britain, laws passed in 1842 and 1844 improved mine working conditions.

However, these changes were not all positive, as the working conditions in factories were often dangerous and unhealthy, leading to widespread illness and injury. Workers, including women and children, were often forced to work long hours in hazardous conditions, with little to no access to healthcare or education.

New middle class

Another significant social effect of the Industrial Revolution was the emergence of a new middle class. As new industries and technologies emerged, new job opportunities were created, leading to the growth of a middle class. This new class of people had a significant impact on society, as they were able to afford better education, healthcare, and living conditions.

Environment

Manchester, England ("Cottonopolis"), pictured in 1840, showing the mass of factory chimneys

The Industrial Revolution had a significant impact on the environment, with the development of new technologies leading to increased pollution and deforestation. This had a significant impact on the health and wellbeing of people living in urban areas, as air and water pollution led to widespread illness and disease.

Industrialization beyond Great Britain

The Habsburg realms which became Austria-Hungary in 1867 included 23 million inhabitants in 1800, growing to 36 million by 1870. Nationally the per capita rate of industrial growth averaged about 3% between 1818 and 1870. However, there were strong regional differences. The railway system was built in the 1850–1873 period. Before they arrived transportation was very slow and expensive. In the Alpine and Bohemian (modern-day Czech Republic) regions, proto-industrialization began by 1750 and became the center of the first phases of the Industrial Revolution after 1800. The textile industry was the main factor, utilizing mechanization, steam engines, and the factory system. In the Czech lands, the "first mechanical loom followed in Varnsdorf in 1801", with the first steam engines appearing in Bohemia and Moravia just a few years later. The textile production flourished particularly in Prague and Brno (German: Brünn), which was considered the 'Moravian Manchester'. The Czech lands, especially Bohemia, became the center of industrialization due to its natural and human resources. The iron industry had developed in the Alpine regions after 1750, with smaller centers in Bohemia and Moravia. Hungary—the eastern half of the Dual Monarchy, was heavily rural with little industry before 1870.

In 1791, Prague organized the first World's Fair/List of world's fairs, Bohemia (modern-day Czech Republic). The first industrial exhibition was on the occasion of the coronation of Leopold II as a king of Bohemia, which took place in Clementinum, and therefore celebrated the considerable sophistication of manufacturing methods in the Czech lands during that time period.

Technological change accelerated industrialization and urbanization. The GNP per capita grew roughly 1.76% per year from 1870 to 1913. That level of growth compared very favorably to that of other European nations such as Britain (1%), France (1.06%), and Germany (1.51%). However, in a comparison with Germany and Britain: the Austro-Hungarian economy as a whole still lagged considerably, as sustained modernization had begun much later.

Belgium

Belgium was the second country in which the Industrial Revolution took place and the first in continental Europe: Wallonia (French-speaking southern Belgium) took the lead. Starting in the middle of the 1820s, and especially after Belgium became an independent nation in 1830, numerous works comprising coke blast furnaces as well as puddling and rolling mills were built in the coal mining areas around Liège and Charleroi. The leader was a transplanted Englishman John Cockerill. His factories at Seraing integrated all stages of production, from engineering to the supply of raw materials, as early as 1825.

Wallonia exemplified the radical evolution of industrial expansion. Thanks to coal (the French word "houille" was coined in Wallonia), the region geared up to become the 2nd industrial power in the world after Britain. But it is also pointed out by many researchers, with its Sillon industriel, 'Especially in the Haine, Sambre and Meuse valleys, between the Borinage and Liège...there was a huge industrial development based on coal-mining and iron-making...'. Philippe Raxhon wrote about the period after 1830: "It was not propaganda but a reality the Walloon regions were becoming the second industrial power all over the world after Britain." "The sole industrial centre outside the collieries and blast furnaces of Walloon was the old cloth-making town of Ghent." Professor Michel De Coster stated: "The historians and the economists say that Belgium was the second industrial power of the world, in proportion to its population and its territory [...] But this rank is the one of Wallonia where the coal-mines, the blast furnaces, the iron and zinc factories, the wool industry, the glass industry, the weapons industry... were concentrated." Many of the 19th-century coal mines in Wallonia are now protected as World Heritage sites.

Wallonia was also the birthplace of a strong socialist party and strong trade unions in a particular sociological landscape. At the left, the Sillon industriel, which runs from Mons in the west, to Verviers in the east (except part of North Flanders, in another period of the industrial revolution, after 1920). Even if Belgium is the second industrial country after Britain, the effect of the industrial revolution there was very different.

France

One of the earliest countries to experience industrialization was France. In the late 18th century, French inventors developed new technologies, such as the spinning jenny and power loom, which increased the efficiency of textile production. The French government also supported industrialization by providing incentives for entrepreneurs and investing in infrastructure projects, such as canals and railways.

Germany

Germany was another country that experienced rapid industrialization during the 19th century. The country had a large supply of coal and iron, which were essential for powering machinery and producing steel. German inventors developed new technologies, such as the steam engine and gas lighting, and the government supported industrialization by investing in infrastructure and creating a national railway system.

United States

The United States also experienced significant industrialization during the 19th century. The country had a large supply of natural resources, including coal, iron, and timber, which were used to fuel the growth of manufacturing. American inventors developed new technologies, such as the telegraph, sewing machine, and typewriter, which revolutionized communication and manufacturing.

Japan

In Japan, the Meiji Restoration in 1868 marked the beginning of a period of rapid industrialization. The government recognized the importance of industrialization for economic growth and national security and invested in infrastructure, education, and technology. Japanese inventors developed new technologies, such as the steam engine and electric power, and the country rapidly modernized its manufacturing industries.

Industrial Revolution's impact was immense, transforming societies and economies around the world and laying the foundation for the modern world.

#Industrial Revolution#Industrial#Industry#Revolution#Importance#Development#Growth#Iron Industry#Coal industry#Steam Power Industry#Glass industry#Business#British#Britain

1 note

·

View note

Text

Strengthening Sustainability in the Glass Industry.

Growing global concerns over climate change are putting an increasing focus on sustainability. This report is part of an occasional series on sustainability in industry which examines the opportunities and challenges facing various industrial sectors and the role that the International Finance Corporation can play to support their efforts and contribute to a greener planet.

Glass is present in a myriad of products used in both daily life and manufacturing, from beverage containers to windows to fiber optic cables. Its many properties and affordable cost make it an essential material for development, whether in the construction of houses and high rises where people live and work or for use in industries such as agribusiness and automaking.

Glass is also attractive because of its sustainability—a growing consideration for countries, companies, and consumers as the world seeks to address climate change. Because glass products are 100-percent recyclable, the industry lends itself well to the circular economy. At the same time, glass can be used to help other industries become more energy efficient and sustainable.

The industry’s own high energy use remains a challenge, although in the last few decades companies have introduced innovations in glass production processes to reduce waste and boost efficiency. With support from the International Finance Corporation (IFC) and the private sector, the industry can continue to improve its energy efficiency while meeting increased demand for sustainable glass products.

Strengthening Sustainability in the Glass Industry.

#sustainability#Glass industry#Contribute to a greener planet#International Finance Corporation (IFC)#sustainable glass products

0 notes

Text

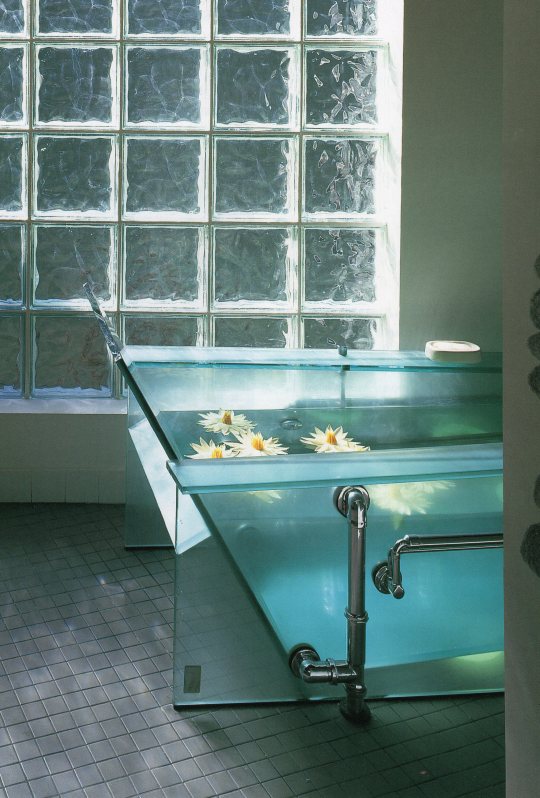

The Los Angeles House: Decoration and Design in America's 20th-Century City, 1995

#vintage#vintage interior#1990s#90s#interior design#home decor#bathroom#bathtub#glass#glass blocks#tile#minimalist#industrial#Los Angeles#California#style#modern#home#architecture#contemporary

4K notes

·

View notes

Photo

Deciding Between Vinyl And Fiberglass Patio Doors

https://bestofferglass.com/deciding-between-vinyl-and-fiberglass-patio-doors/ - If you have a back patio or deck, chances are, you've got some beautiful sliding doors used for access. Whether they are vinyl or fiberglass patio doors, however, can make a huge difference.

0 notes

Link

0 notes

Text

youtube

#glass industry feeds hd#sheet glass industry#glass industry#Glass Industry HD A-Normal Technologies (A1)#hd airport graphics#glass industry hd angled spotting scope techniques#glass industry technologies hd admin#glass industry supplies hd awaken#glass industry feeds hd app#handcraft sandblasting#sand glass making#glass industry hd box techniques#glass industry hd technologies broadheads#glass industry hd technologies benfica tv pt#glass industry feeds hd bear#blown glass industry#glass industry techniques hd camcorder#glass industry hd camera techniques#glass industry hd crimp tool techniques#Glass Industry HD digital day/night vision binoculars#glass industry techniques hd dvd#glass industry hd dvr technologies#glass industry trades hd download#glass making from scratch#glass industry hd eye drops technologies#glass industry hd eye care techniques#glass industry feeds hd es#glass industry techs hd emblem#glassmaking Foods hd emoji#glass industry techs hd encanto

0 notes

Text

his existence brings me both amusement and inexplicable dread smh

the urge to rattle him but naw I don’t wanna be within 3 feet with this man— /lh

#did some warm ups before tackling them 0.7 redraws#utmv#utmv art#undertale au#undertale#sans undertale#fresh sans#fresh!sans#Underverse#inky art#i wanna put him in a jar and observe#or see him go about his day behind an industrial one way glass#yall can do whatever ya want with him but im staying right here#goddamn his color palette is a hecking trip#i don’t even wanna imagine fresh ink’s#smh

4K notes

·

View notes

Text

Glass blowers, 1978. From the Budapest Municipal Photography Company archive.

760 notes

·

View notes

Text

Guaianaz House, São Paulo, Brazil - Terra e Tuma

#Terra e Tuma#architecture#design#building#modern architecture#interiors#house#minimal#concrete#house design#water#cinder block#glass wall#cool houses#industrial#sao paulo#brazil#south america#urban#city home

361 notes

·

View notes

Text

oh?

it was funnier in my head

#the wine industry was not enough for multimillionaire entrepreneur master diluc#i do not know how to draw glass pls do not perceive me#diluc being interested in producing scented candles was not part of my 2024 bingo#and yet here we are... and yet here we are.....#kaeyachi randoms#diluc#diluc ragnvindr

177 notes

·

View notes

Text

"Everything I Ever Knew About Geology and Rock and Mineral and Soil Sciences I Learned from Dwarf Fortress" by Fallout Boy

#punkblogging#dwarf fortress#geology#yes this post was inspired by seeing the words 'sandy loam' again#and remembering hours of frustration trying to set up a glass industry fort after fort

88 notes

·

View notes