For over 25 years, Mudar-M Metalworking Machine Tools has been a leader in the industry, providing high-quality metalworking machines and solutions. With a rich history and a commitment to excellence, we have proudly served over 2,500 clients across various sectors, delivering precision and reliability.Our extensive experience and dedication to innovation ensure that we offer the best machinery and services to meet the ever-evolving needs of our customers. Whether you are looking for state-of-the-art CNC machines, lathes, milling machines, or other metalworking tools, Mudar-M Metalworking Machine Tools has the expertise and product range to support your business.Trust in our legacy of quality and customer satisfaction. Join the thousands of businesses that rely on Mudar-M Metalworking Machine Tools for their machining needs.Contact us today to learn more about our products and how we can help your business achieve its goals.#MetalWorking #MachineTools #CNC #Lathe #PrecisionMachinery #IndustrialEquipment #Manufacturing #Engineering #Machinery #IndustryLeaders #CustomerSatisfaction #MudarM #25Years #2500Clients

Don't wanna be here? Send us removal request.

Text

For Sale: Russian Hollow Spindle Lathe (Oil Country Lathe) – Model 1M832 (Year 2001)

Key Specifications:

- Swing Over Bed: 850 mm

- Total Length: 3000 mm

- Spindle Bore Diameter: 320 mm

- Year: 2001

Heavy-duty construction, built for durability.

Designed for machining large-diameter pipes and heavy components, this lathe is ideal for the oil & gas industries and industrial-scale work.

Machine available for inspection upon request, Contact Us today

Mudar-M Metalworking Machine Tools Trading.

WhatsApp: +359878840661, +359878840660

Email: [email protected], [email protected]

Website: www.mudar-m.com

#OilCountryLathe #RussianLathe #HollowSpindleLathe #HeavyMachinery #Manufacturing #Engineering #Machining #Metalworking #مخرطة #حديد @highlight

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

0 notes

Text

For Sale: Russian Hollow Spindle Lathe (Oil Country Lathe) – Model 1M832 (Year 2001)

Key Specifications:

- Swing Over Bed: 850 mm

- Total Length: 3000 mm

- Spindle Bore Diameter: 320 mm

- Year: 2001

Heavy-duty construction, built for durability.

Designed for machining large-diameter pipes and heavy components, this lathe is ideal for the oil & gas industries and industrial-scale work.

Machine available for inspection upon request, Contact Us today

Mudar-M Metalworking Machine Tools Trading.

WhatsApp: +359878840661, +359878840660

Email: [email protected], [email protected]

Website: www.mudar-m.com

#OilCountryLathe #RussianLathe #HollowSpindleLathe #HeavyMachinery #Manufacturing #Engineering #Machining #Metalworking #مخرطة #حديد @highlight

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

0 notes

Text

For Sale: Russian Hollow Spindle Lathe (Oil Country Lathe) – Model 1M832 (Year 2001)

Key Specifications:

- Swing Over Bed: 850 mm

- Total Length: 3000 mm

- Spindle Bore Diameter: 320 mm

- Year: 2001

Heavy-duty construction, built for durability.

Designed for machining large-diameter pipes and heavy components, this lathe is ideal for the oil & gas industries and industrial-scale work.

Machine available for inspection upon request, Contact Us today

Mudar-M Metalworking Machine Tools Trading.

WhatsApp: +359878840661, +359878840660

Email: [email protected], [email protected]

Website: www.mudar-m.com

#OilCountryLathe #RussianLathe #HollowSpindleLathe #HeavyMachinery #Manufacturing #Engineering #Machining #Metalworking #مخرطة #حديد @highlight

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

0 notes

Text

For Sale: Heavy Duty Vertical Turning Lathe Titan SC27

Key Specifications

Max. Turning Diameter (Swing): 2700-2900 mm

Table Diameter (Chuck): 2500 mm

Max Turning Height 1900 mm

Max. Workpiece Height: 1900-2000 mm

Max. Weight Capacity: 16500 kg

Machine Weight 38800 kg

Take on substantial vertical machining tasks with this robust Titan SC27 Vertical Turning Lathe! Built for handling large and heavy workpieces with impressive turning capacity. Ideal for various heavy-duty industrial applications.

available for inspection upon request.

Contact Us Today Mudar-M Metalworking Machine Tools Trading

WhatsApp: +359878840661, +359878840660

Email: [email protected], [email protected]

Website: www.mudar-m.com

#Morando #SC27 #VerticalTurningLathe #VTL #HeavyMachinery #Metalworking #CNC (If applicable) #Manufacturing #Engineering #Machining #IndustrialLathe #مخرطة# #حديد

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

0 notes

Text

For Sale: Heavy Duty Lathe KRAMATORSK 1A660

Key Specifications:

Turning Diameter Over Bed: 1250 mm

Turning Diameter Over Slide Rest: 900 mm

Turning Length: 10000 mm

Max. Weight Capacity: 35,000 kg

Range of Spindle Speeds: 1.6–200 RPM

Feed Range: 0.64–3.26 mm/U

Threading Metric: 1–96 mm/Stg.

Thread Cutting Inch: 20–3/8

Total Power Requirement: 90 kW

Machine Weight: Approx. 55,000 kg

A powerful and reliable lathe designed for industrial applications. Built to handle large-scale machining with precision and efficiency. Operational and available for trials upon request.

Contact Us Today Mudar-M Metalworking Machine Tools Trading WhatsApp:

+359878840661, +359878840660

Email:

Website: www.mudar-m.com

#kramatorskk #lathework #heavymachinery #metalworking #cnc #manufacturing #engineering #machining @followers #lathe

#metalworking#machinery#machinetools#manufacturing#lathe#engineering#forsale#metalwork#milling#industrial

0 notes

Text

Unveiling the Horizontal Gear Hobber 1250X6000: Revolutionizing Large-Scale Gear Manufacturing

In the ever-evolving world of manufacturing, the need for precision and efficiency is paramount. Enter the Horizontal Gear Hobber 1250X6000, a machine that stands tall in the realm of large-scale manufacturing environments. Designed for producing high-module gears and other components, this gear hobber is the epitome of engineering excellence, robust build, and massive capacity.

Technical Specifications:

- Gear Diameter x Length (DxL): 1250×6000 mm

- Max Workpiece Length: 6000 mm

These impressive specifications underscore its capacity to handle large workpieces with ease. The Horizontal Gear Hobber 1250X6000 is a game-changer for industries that demand size and power.

Why Choose the Horizontal Gear Hobber 1250X6000?

1. Massive Capacity: Capable of processing workpieces up to 6000 mm in length and 1250 mm in diameter, this gear hobber is built for large-scale operations. Its ability to handle such substantial workpieces makes it indispensable in industries that rely on large gears and components.

2. Versatile Applications: The versatility of the Horizontal Gear Hobber 1250X6000 is unmatched. It's perfect for gear manufacturing in various sectors, including:

- Wind Turbines: As the world shifts towards renewable energy, the demand for wind turbine components has skyrocketed. This gear hobber can produce the high-module gears required for these massive structures.

- Mining Equipment: The heavy-duty nature of mining equipment requires robust gears that can withstand extreme conditions. This machine ensures the production of such gears with precision.

- Marine Propulsion Systems: The maritime industry relies on powerful and reliable propulsion systems. The Horizontal Gear Hobber 1250X6000 is ideal for crafting the gears that keep these systems running smoothly.

3. Precision Engineering: Precision is the hallmark of the Horizontal Gear Hobber 1250X6000. Its advanced engineering ensures that every gear produced meets the highest standards of quality and accuracy.

Contact Us Today!

At Mudar-M Metalworking Machine Tools Trading, we are committed to providing the best solutions for your manufacturing needs. If you're interested in the Horizontal Gear Hobber 1250X6000 or have any questions, feel free to reach out to us.

Email:

Phone:

- +359878840661

- +359878840660

Website:

- http://www.mudar-m.com

Explore the Future of Gear Manufacturing

The Horizontal Gear Hobber 1250X6000 is not just a machine; it's a testament to the future of gear manufacturing. With its unparalleled capacity, versatile applications, and precision engineering, it stands as a beacon of innovation in the industry. Don’t miss out on the opportunity to elevate your manufacturing capabilities with this remarkable gear hobber.

#gearhob #Metalworking #manufacturing #machinetools #usedmachinery #gearhobbing #metalwork #lathe #machinery #industrial

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

0 notes

Text

For Sale: Cylindrical Rolling Machine 450mm

Specifications:

- Maximum Length of Roll Forged Part: 450mm

- Effective Width of Roll Forging: 360mm

- Adjustment Range of Roll Center Distance: ±15mm

- Roll Speed: 65 RPM

- Longitudinal Stroke of Mechanical Hand: 420mm

- Transverse Stroke of Mechanical Hand: 360mm

- Rotation Angle of Mechanical Hand: 0°-90°

- Maximum Diameter for Return Material: 60mm

- Motor Power: 18.5 kW

- Weight of Machine: 10 tons

Machine Description:

Powerful ring rolling machine designed for seamless ring manufacturing. This machine can roll rings up to 450mm in diameter, making it ideal for various metalwork industrial manufacturing

Company: Mudar-M Metal Working Machinery Trading

Email: [email protected] ,

WhatsApp : +359878840661,

+359878840660

Website

www.mudar-m.com

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

0 notes

Text

FOR SALE: W200HC Skoda Boring Machine

Key Specifications

Model: W200HC

X-Axis Travel: 11,000 mm

Y-Axis Travel: 4,000 mm

Z-Axis Travel: 2,000 mm

Spindle Diameter: 200 mm

Spindle Speed: 0.8-800 RPM

Max. Boring Depth: 2,000 mm

Milling Spindle Torque: 35,000 Nm

Machine Weight: 86,200 kg

the Skoda W200HC Horizontal Boring Machine is prefect for Heavy-duty machining

Large-scale industrial projects

MUDAR-M METALWORKING MACHINETOOLS TRADING

E-mail

WhatsApp

+359878840661, +359878840660

Website

www.mudar-m.com

#Machining #CNCMachining #Metalworking #HorizontalBoringMachines #MachineTools #IndustrialEquipment #HeavyMachinery #MetalFabrication #Engineering #Manufacturing #MachineShop #FabricationMachinery

#metalworking#lathe#machinery#machinetools#manufacturing#engineering#forsale#metalwork#milling#industrial

0 notes

Text

C13MB BULGRIAN BULGARIAN LATHE 800MM X 5000MM

Specifications:

- Distance Between Centers: 5000 mm

- Center Height: 400 mm

- Turning Diameter:

- Over the bed: 800 mm

- Over the cross slide: 540 mm

- In the gap: 1050 mm

- Spindle Bore: 103 mm

- Spindle Speed: 8-1000 rpm

- Main Motor Power: 15 kW

- Maximum Workpiece Weight: 3150 kg

Looking for a reliable and robust lathe? Our C13MB lathe is designed for heavy-duty industrial applications, ensuring top-notch performance.

This lathe offers exceptional precision and durability, making it perfect for your industrial machining needs. With a powerful motor and versatile turning capabilities, it's an ideal choice for enhancing your production line.

Contact Us:

WhatsApp: +359878840661, +359878840660

Email: [email protected], [email protected]

Website: http://www.mudar-m.com

#metalworking#machinery#lathe#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial#Manufacturing#CNC#Precision#HeavyDuty#Equipment#Sales

0 notes

Text

three TOS Boring Machines Available: TOS 63A and TOS WH 63 , TOS WHN 11

Precision-engineered for high-performance boring operations, this machine ensures accuracy and efficiency in every task. Perfect for demanding metalworking projects.

Mudar-M Metalworking Machine Tools Trading offering metalworking machinery from leading manufacturers in Europe, Taiwan, Japan, and China.

Contact Us or Visit our website today.

Email: [email protected] or [email protected]

WhatsApp: +359878840661 or +359878840660

Website: www.mudar-m.com

#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial#TOS#UsedMachines

1 note

·

View note

Text

Mazak Integrex 300IIIS - simultaneous 5 Axis Dual-spindle CNC Milling/Turning Center Lathe

Key Specifications:

Chuck Size: 254mm

Swing: 851mm

Turning Diameter: 762mm

Working Length: 1583mm

Bar Capacity: 88mm

Travel (X/Y/Z/W): 630mm / 230mm / 1,585mm / 1,050mm

Rapid Traverse Speed (X/Y/Z): 1,496 / 1,024 / 1,496 pm

Main Motor Power: 22 KW

main and Sub Spindle: speed 4,000 RPM up to 12,000 RPM

Live:

ATC Capacity: 40 stations

Features:

accuracy 0.001, Simultaneous 5 Axis Machining with W Axis.

Live Tooling with Y Axis , Tool Presetter with Sub Spindle.

Automatic Bar Feed Unit and tools catcher.

Renishaw Probing with full overload detection.

This Mazak Integrex 300IIIS is a high-performance with simultaneous 5-axis CNC machining, equipped with everything you need for advanced machining, aerospace precision work.

accuracy 0.001 with W AXIS capabilities dual spindle and simultaneous all AXIS work.

Contact Us:

Mudar-M Metalworking Machine Tools

Email: [email protected]

Email:[email protected]

WhatsApp: +359878840661

WhatsApp: +359878840660

Website: www.mudar-m.com

#metalwork #machinetools #metalworking #machinetools #Machinery #usedmachines #industrial @followers

#CNC #Machinery #Metalworking #Mazak #manufacturing

#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Text

For sale: CNC machines from Victor, Mazak, and Kamaro. Explore a new generation

-VICTOR lathe with tools in excellent condition.

-Mazak's SQT and INTEGREX lathes featuring 3, 4, and 5 axis for metalworking production.

-KAMARO lathe is perfect for everyday use. Enhance productivity with top metalworking equipment

.

Contact Us

e-mail: [email protected]

e-mail: [email protected]

WhatsApp: +359878840660

WhatsApp: +359878840661

Website:

WWW.MUDAR-M.COM

#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial#cnc

0 notes

Text

Mudar-M: 26 Years of Innovation and Excellence in Metalworking

Since its inception in 1998, Mudar-M Metalworking Machine Tools has been at the forefront of the global metalworking industry. With a rich history spanning over two decades, Mudar-M has continuously evolved, adapted, and expanded its reach, leaving an indelible mark on the world of manufacturing. Let's delve into the remarkable journey of Mudar-M, from its humble beginnings to its current position as a global leader.

Founding Years and International Expansion

- 1998: Mudar-M was established, laying the foundation for its future success.

- 1999: The company embarked on its international journey, initially operating in Iraq and Turkey.

- 2001: Officially incorporated, Mudar-M solidified its commitment to excellence.

- 2003: The Middle East became a strategic focus, with operations extending to Egypt and Saudi Arabia.

- 2005: Mudar-M expanded its horizons to the United States and Latin America.

- 2007: The introduction of advanced CNC lathe machines and refurbishment services met the growing demand for precision engineering.

- 2009: Mudar-M's global footprint expanded to 80 countries, showcasing its commitment to quality and reliability.

Digitalization and Adaptation

- 2011: The digitalization journey began, enhancing operational efficiency and customer service.

- 2013: Sales points in the GCC region strengthened Mudar-M's presence in the Middle East.

- 2015: The company embraced Industry 4.0 standards, transforming old industrial setups.

- 2017: Diversification into heavy transport solutions demonstrated Mudar-M's versatility.

Navigating Challenges and Achievements

- 2020: Amid the global pandemic, Mudar-M adapted swiftly, bolstering its online presence and virtual support.

- 2022: The company's excellence was recognized, making it the top exporter in Bulgaria and ranking among Eastern Europe's top 5.

- 2023: Collaborating with the Chinese market, Mudar-M established its headquarters in China, catering to Asian customers.

Celebrating 26 Years of Excellence

- 2024: Mudar-M proudly celebrates 26 years of innovation, precision, and reliability.

- Today, Mudar-M stands tall, serving over 100 countries with multiple sales points.

- Its legacy is built on unwavering support from partners, clients, and metalworking enthusiasts worldwide.

From the development of bronze and iron tools to the construction of towering skyscrapers, metalworking has left an indelible mark on our history. It has not only provided us with practical solutions but has also become an art form, with metalworkers showcasing their creativity and craftsmanship¹. Mudar-M's journey exemplifies this fusion of art and engineering, and its commitment to excellence continues to shape the metalworking landscape.

Thank you for being part of Mudar-M's remarkable journey!

#machineshop#heavyequipment#metallica art#machinetools#metalworking#lathe#machinery#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Text

Mudar-M Metalworking Machine Tools: Precision, Innovation, and Excellence

Introduction

Mudar-M Metalworking Machine Tools, headquartered in Sofia, Bulgaria, stands at the forefront of the metalworking industry. With a rich history spanning over three decades, Mudar-M has consistently delivered cutting-edge solutions to meet the evolving needs of manufacturers, machinists, and engineers worldwide. Let's delve into the details of this remarkable company.

Origins and Founding Vision

Founded in 1990 by visionary Rakan Mhissen, Mudar-M emerged as a response to the growing demand for reliable and efficient metalworking machinery. Rakan passion for precision engineering and his unwavering commitment to customer satisfaction laid the foundation for the company's success. From its modest beginnings as a small workshop specializing in lathe repairs, Mudar-M expanded its operations, embracing technological advancements and diversifying its product range.

CNC Lathes

Mudar-M's CNC lathes are renowned for their accuracy, versatility, and robust construction. Whether it's turning intricate components for aerospace applications or creating precision parts for automotive manufacturing, these machines consistently deliver exceptional results. Features include:

- High Precision: Mudar-M CNC lathes achieve micron-level tolerances, ensuring flawless surface finishes.

- User-Friendly Controls: Intuitive interfaces allow operators to program complex machining sequences effortlessly.

- Customization Options: Customers can choose from various spindle configurations, tool changers, and automation solutions.

Vertical Lathes

Vertical lathes play a crucial role in heavy-duty machining. Mudar-M's vertical lathes excel in handling large workpieces, such as turbine components, gearboxes, and hydraulic cylinders. Key attributes include:

- Stability: The robust column design minimizes vibrations during heavy cuts.

- Swing Diameter: Mudar-M offers a range of swing diameters to accommodate diverse applications.

- Live Tooling: Some models feature live tooling for milling, drilling, and tapping operations.

Milling Machines

Mudar-M's milling machines combine precision with versatility. From 3-axis to 5-axis configurations, these machines empower manufacturers to create complex geometries efficiently. Notable features include:

- Rigidity: Sturdy construction ensures stability during high-speed machining.

- Advanced Controls: Mudar-M integrates state-of-the-art control systems for optimal performance.

- Tool Changers: Automatic tool changers enhance productivity.

Cylindrical Grinding Machines

For achieving precise cylindrical shapes and superior surface finishes, Mudar-M's cylindrical grinding machines are indispensable. These machines excel in applications like bearing manufacturing, toolmaking, and precision engineering. Highlights include:

- Grinding Accuracy: Mudar-M's machines maintain tight tolerances, critical for cylindrical components.

- Wheel Dressing Systems: Automatic wheel dressing ensures consistent results.

- Coolant Filtration: Efficient coolant management prolongs wheel life.

Horizontal Boring Machines

Mudar-M's horizontal boring machines tackle large-scale projects with ease. Whether it's boring engine blocks or creating intricate molds, these machines offer:

- Spindle Power: High-torque spindles handle heavy cutting loads.

- Linear Guideways: Smooth movement across axes ensures precision.

- Digital Readouts: Accurate positioning for intricate machining tasks.

Commitment to Quality

Mudar-M's success hinges on its unwavering commitment to quality. Rigorous testing, continuous research, and collaboration with industry experts ensure that every machine leaving their facility meets the highest standards. The ISO 9001 certification underscores their dedication to excellence.

Global Reach

Mudar-M ships its machines to more than 50 countries across Europe, Asia, the Middle East, and beyond. From small workshops to large manufacturing plants, their footprint extends across continents. By empowering businesses with reliable tools, Mudar-M contributes to the advancement of global manufacturing capabilities.

Conclusion

Mudar-M Metalworking Machine Tools embodies precision, innovation, and excellence. As technology evolves, the company remains steadfast in its mission: to equip the world with cutting-edge machinery, enabling manufacturers to shape the future. Whether it's a CNC lathe, a vertical mill, or a cylindrical grinder, Mudar-M's legacy continues to shape the metalworking industry, one precision cut at a time.

#metalmachining#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Text

Mudar-M Metalworking Machine Tools: Precision, Innovation, and Excellence

Introduction

Mudar-M Metalworking Machine Tools, headquartered in Sofia, Bulgaria, stands at the forefront of the metalworking industry. With a rich history spanning over three decades, Mudar-M has consistently delivered cutting-edge solutions to meet the evolving needs of manufacturers, machinists, and engineers worldwide. Let's delve into the details of this remarkable company.

Origins and Founding Vision

Founded in 1990 by visionary Rakan Mhissen, Mudar-M emerged as a response to the growing demand for reliable and efficient metalworking machinery. Rakan passion for precision engineering and his unwavering commitment to customer satisfaction laid the foundation for the company's success. From its modest beginnings as a small workshop specializing in lathe repairs, Mudar-M expanded its operations, embracing technological advancements and diversifying its product range.

CNC Lathes

Mudar-M's CNC lathes are renowned for their accuracy, versatility, and robust construction. Whether it's turning intricate components for aerospace applications or creating precision parts for automotive manufacturing, these machines consistently deliver exceptional results. Features include:

- High Precision: Mudar-M CNC lathes achieve micron-level tolerances, ensuring flawless surface finishes.

- User-Friendly Controls: Intuitive interfaces allow operators to program complex machining sequences effortlessly.

- Customization Options: Customers can choose from various spindle configurations, tool changers, and automation solutions.

Vertical Lathes

Vertical lathes play a crucial role in heavy-duty machining. Mudar-M's vertical lathes excel in handling large workpieces, such as turbine components, gearboxes, and hydraulic cylinders. Key attributes include:

- Stability: The robust column design minimizes vibrations during heavy cuts.

- Swing Diameter: Mudar-M offers a range of swing diameters to accommodate diverse applications.

- Live Tooling: Some models feature live tooling for milling, drilling, and tapping operations.

Milling Machines

Mudar-M's milling machines combine precision with versatility. From 3-axis to 5-axis configurations, these machines empower manufacturers to create complex geometries efficiently. Notable features include:

- Rigidity: Sturdy construction ensures stability during high-speed machining.

- Advanced Controls: Mudar-M integrates state-of-the-art control systems for optimal performance.

- Tool Changers: Automatic tool changers enhance productivity.

Cylindrical Grinding Machines

For achieving precise cylindrical shapes and superior surface finishes, Mudar-M's cylindrical grinding machines are indispensable. These machines excel in applications like bearing manufacturing, toolmaking, and precision engineering. Highlights include:

- Grinding Accuracy: Mudar-M's machines maintain tight tolerances, critical for cylindrical components.

- Wheel Dressing Systems: Automatic wheel dressing ensures consistent results.

- Coolant Filtration: Efficient coolant management prolongs wheel life.

Horizontal Boring Machines

Mudar-M's horizontal boring machines tackle large-scale projects with ease. Whether it's boring engine blocks or creating intricate molds, these machines offer:

- Spindle Power: High-torque spindles handle heavy cutting loads.

- Linear Guideways: Smooth movement across axes ensures precision.

- Digital Readouts: Accurate positioning for intricate machining tasks.

Commitment to Quality

Mudar-M's success hinges on its unwavering commitment to quality. Rigorous testing, continuous research, and collaboration with industry experts ensure that every machine leaving their facility meets the highest standards. The ISO 9001 certification underscores their dedication to excellence.

Global Reach

Mudar-M ships its machines to more than 50 countries across Europe, Asia, the Middle East, and beyond. From small workshops to large manufacturing plants, their footprint extends across continents. By empowering businesses with reliable tools, Mudar-M contributes to the advancement of global manufacturing capabilities.

interested in more details? Contact us now: Email: [email protected] | [email protected] WhatsApp: +359878840661 | +359878840660

Conclusion

Mudar-M Metalworking Machine Tools embodies precision, innovation, and excellence. As technology evolves, the company remains steadfast in its mission: to equip the world with cutting-edge machinery, enabling manufacturers to shape the future. Whether it's a CNC lathe, a vertical mill, or a cylindrical grinder, Mudar-M's legacy continues to shape the metalworking industry, one precision cut at a time.

#metalmachining#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Text

Introducing Two Exceptional WMW Modul ZFWZ Machines! 🚀

MUDAR-M LTD مضر للمخارط proudly presents the WMW Modul ZFWZ 2000 and 3150 Vertical Gear Hobbing Machines, designed for high-precision metalworking and efficiency.

1. WMW Modul ZFWZ 2000 Vertical Gear Hobbing Machine 2. WMW Modul ZFWZ 3150 Vertical Gear Hobbing Machine

🔧 Features:

Full change gears

Head for internal teeth cutting

Multiple shafts for diverse tasks

These robust machines ensure superior performance, making them a perfect fit for your industrial needs.

📩 Interested in more details? Contact us now: Email: [email protected] | [email protected] WhatsApp: +359878840661 | +359878840660

#GearHobber#Metalworking#MachineTools#Industrial#Manufacturing#lathe#machinery#metalworking#engineering#machinetools#manufacturing#metalwork#forsale#milling

0 notes

Text

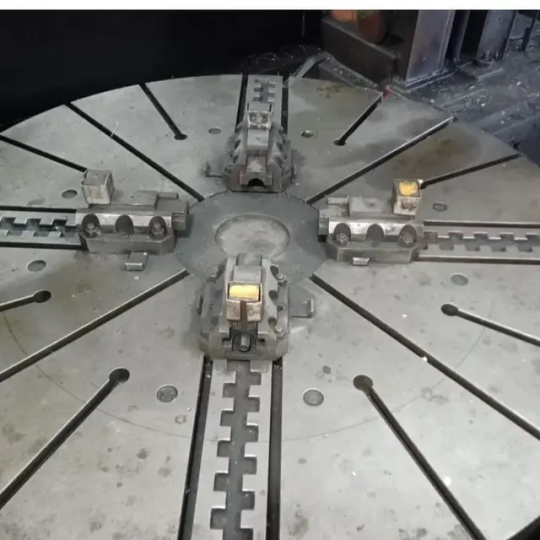

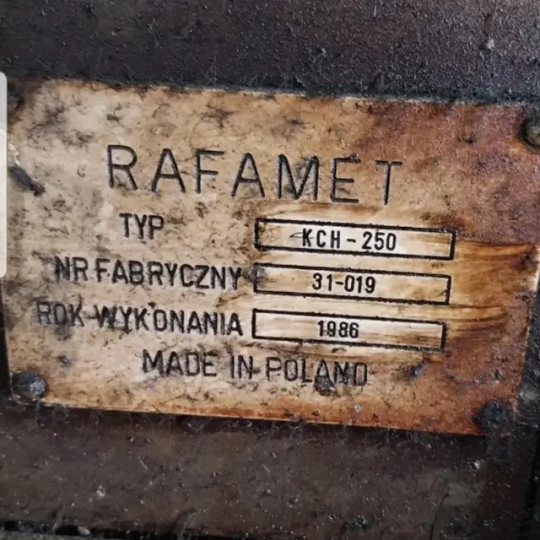

KCH 250 Vertical Turning Lathe

Specifications:

Table Diameter: 2,600 mm

Max Turning Diameter: 2,800 mm

Max Weight of Workpiece: 25 × 10 kN

Cross-Rail Max Height of Turning: 2,500 mm

Ram Stroke (Z-Axis): 1,500/2,100 mm

Railhead Width: 300 × 300 mm

Machine Weight (Approx): 100 × 10 kN

Robust construction for heavy-duty machining

Suitable for turning, milling, and drilling operations

Precision and rigidity for complex workpieces.

Contact us at Mudar-M Metalworking Machine Tools

E-mail: [email protected]

WhatsApp

+359878840662

+359878840661

www.mudar-m.com

#Metalworking#Machinery#IndustrialTools#RafametKCH250#ForSale#CNC#Lathe#Grinding#Milling#HeavyDuty#MetalMachining#Workshop#UsedMachines#QualityMachinery#MachineTools

0 notes