#machinetools

Explore tagged Tumblr posts

Text

Unlocking the Power and Precision of Machine Tool Fabrication Equipment

Explore Accurpress India’s advanced solutions in press brakes, turret punch presses, shears, and automation systems. Designed for unmatched accuracy, strength, and productivity—trusted by global manufacturers like GM, Ford, and Boeing.

🔧 Servo-electric & hydraulic press brakes 🔩 CNC-controlled shearing systems 🛠️ High-precision turret punch press 🤖 Robotic automation for bending & punching

🔗 https://accurpress.in/ 📧 [email protected] | [email protected]

#Accurpress#MachineTools#PressBrakes#PunchPress#ShearPower#AutomationSolutions#MetalFabrication#CNCmachines#IndustrialMachinery#MadeInIndia#ManufacturingExcellence#PrecisionEngineering

0 notes

Text

Machine Tools in Manufacturing: Growth Drivers and Challenges

The global machine tools market size is expected to reach USD 137.43 billion by 2030, registering to grow at a CAGR of 7.0% from 2025 to 2030 according to a new report by Grand View Research, Inc. The increased need for higher efficiency and precision in complex machining tools, as well as lower operating costs in industries, such as aerospace, automotive, and defense, have led to an increased usage of machine tools.

The machining time is more expensive than the setup fees, material expenses, and fees for custom finishing a job or workpiece. Owing to all these advantages, manufacturers are gradually shifting toward the automation of machines to reduce time by rolling out connectivity networks and deploying the latest software. Such technological developments are anticipated to boost the sales of machine tools in the forecast period.

Machine Tools Market Report Highlights

Machine tools are used across various industries and industry verticals, including automobile, aerospace, and others, to manufacture various components with precision and speed while ensuring adequate flexibility.

Metal cutting machines are widely utilized in many end-use sectors such as automotive, mechanical engineering, metal working, and aerospace, to produce completed products with the necessary geometry by cutting various types of ferrous and non-ferrous metals.

The use of CNCs as milling machines, lathes, abrasive jet cutters, laser cutters, press brakes, punch presses, and other industrial instruments has been expanding quickly with the development of computers.

The electrical and electronics industry is one of the world’s largest industries. It includes a broad range of goods, from bulky consumer electronics to tiny electrical parts.

For More Details or Sample Copy please visit link @: Machine Tools Market Report

The machine tools products are increasingly getting complex in line with the shifting customer preferences toward higher-quality products. Hence, manufacturers are also gearing up to develop complex products and are accordingly automating their CNC machining processes to enhance product quality while reducing operating costs. For instance, in July 2020, SKODA AUTO Germany GmbH launched automated supplying and ordering of parts for CNC processing lines at its plant in Vrchlabi, Czech Republic as part of the efforts to increase the productivity of the plant.

Machine tool manufacturers are trying aggressively to develop energy-efficient tools to cater to the manufacturers’ needs to reduce operating costs while eliminating errors in manufacturing, leveraging IoT technology and predictive analytics capabilities. For instance, automotive companies are increasingly opting for CNC machining in line with the growing demand for spare parts with higher precision.

Industry 4.0 is particularly encouraging digital transformation across the entire automotive industry, spanning automotive OEMs, dealers, and suppliers, among other industry stakeholders, which bodes well for the growing demand for CNC machine tools. The motorsport industry is particularly using CNC machine tools to reduce manufacturing time and to ensure that components are manufactured flawlessly. As such, various racing car manufacturers are striking partnerships with CNC machine tool providers to manufacture precision components.

List of Key Players of Machine Tools Market

Amada Machine Tools Co., Ltd.

CHIRON GROUP SE

DMG MORI. CO., LTD.

DN Solutions

Georg Fischer Ltd.

HYUNDAI WIA CORP

JTEKT Corporation

Komatsu Ltd

We have segmented the global machine tools market on the basis of type, technology, end use, and region

#MachineTools#MachineToolsMarket#ManufacturingIndustry#MarketResearch#Automation#Industry40#CNCmachines#PrecisionMachining#Metalworking#IndustrialAutomation#SmartManufacturing#IoT#AIinManufacturing#AdvancedManufacturing

0 notes

Text

THK Ball Screw | Seimitsu Factory Automation

#MachineTools#PrecisionEngineering#BallScrews#linearguideways#SEIMITSU#linearmotion#thkdistributor#THK

0 notes

Text

Machine Tools and Automation in Kolkata

Indus-Tech Expo 2025 is coming to Kolkata! Don’t miss West Bengal’s biggest B2B exhibition for industrial tools and technology, showcasing the latest innovations in machine tools and automation. Connect with industry leaders and explore fresh opportunities in this exciting debut event!

Innovative Solutions: Discover the most advanced technologies in machine tools and automation.

Big Networking: Meet top industry professionals and create valuable business connections.

Proven Success: Be part of the first-ever edition in Kolkata of this landmark event.

Major Impact: Engage with over 450+ exhibitors and 55,000+ visitors for valuable insights, business opportunities, and industry-leading innovations.

Book Your Spot: Secure your place at West Bengal’s premier industrial expo and showcase your brand!

Be part of history at the first-ever Indus-Tech Expo in Kolkata!

Date: April 25-28, 2025 Venue: Biswa Bangla Convention Centre, New Town, Kolkata, West Bengal – 700156 Email: [email protected]

0 notes

Text

There are multiple specifications for DEF FillingMachine which is beneficial for your machines. Patvin Engineering with years of experience provides the best DEF FillingMachine. Visit our webpage to know.

0 notes

Text

Learn How to Sharpen Knives with Expert Techniques

Check out the Bearded Sharpener and his channel for expert tips on knife sharpening tools and blade maintenance!

At The Bearded Sharpener, we focus on quality, offering the best sharpening tools backed by top-notch customer service.

Whether you're learning how to sharpen knives or refining your knife sharpening techniques, we’ve got you covered with tools we trust ourselves.

Our channel is perfect for knife sharpening beginners looking to elevate their skills.

Follow us to see the complete sharpening process and keep your blades in top shape!

Connect with us & Follow our journey on social media for the latest updates and more!

#cuttingtools#ductwork#engineer#engineers#fab101#fabrication#fabricator#fabshop#homemachineshop#hvachacks#hvacr#instamachining#instamachinist#machineshop#machinetools#machining#machinist#machinistsofinstagram#manualmachining#manualmachinist#mechanicalengineer#mechanicalengineering#metalwork#metalworker#metalworking#sheetmetalfab#sheetmetalworker#steelfab

0 notes

Text

Industries Using Different Types of Sheet Metal Machines and Their Applications

Explore the essential role of sheet metal machines across industries like automotive, aerospace, construction, and manufacturing. This video highlights different types of sheet bending machines—including Press Brakes for precise bends, Hydraulic Bending Machines for heavy-duty tasks, Mechanical Bending Machines for high-volume production, Roll Bending Machines for cylindrical shapes, and CNC Bending Machines for complex, precise bends—each transforming metal into vital components used in countless applications.

For more details, visit us at - https://www.sheetbendingmachine.net.in/

#SheetMetal#MetalBending#PressBrake#HydraulicBending#MechanicalBending#RollBending#CNCMachines#Manufacturing#IndustrialMachinery#AerospaceIndustry#ConstructionIndustry#MetalFabrication#MachineTools

0 notes

Text

Comprehensive Analysis of the Machine Tools Market

The Machine Tools Market is witnessing significant growth as industries continue to advance toward automation and precision manufacturing. These tools, essential for cutting, shaping, and finishing materials, are the backbone of sectors such as automotive, aerospace, and electronics.

Download a FREE Sample: https://www.nextmsc.com/machine-tools-market/request-sample

Key Trends:

Automation Integration: With the rise of Industry 4.0, there is a growing emphasis on integrating automation into machine tools. CNC (Computer Numerical Control) machines are becoming increasingly popular, allowing for higher precision and reduced human intervention.

Adoption of 3D Printing: Additive manufacturing, or 3D printing, is revolutionizing the machine tools market. This technology allows for the creation of complex parts with minimal material waste, offering a competitive edge in rapid prototyping and custom manufacturing.

Sustainability Focus: As environmental concerns become more pressing, the demand for energy-efficient and eco-friendly machine tools is rising. Manufacturers are investing in sustainable technologies that reduce energy consumption and minimize waste.

Asia-Pacific Dominance: The Asia-Pacific region, particularly China, Japan, and India, is leading the market due to rapid industrialization and the expansion of manufacturing facilities. The region's focus on innovation and cost-effective production is driving demand for advanced machine tools.

Growth Drivers:

Rising Demand in Automotive and Aerospace Sectors: The need for precision parts in the automotive and aerospace industries is a significant driver for the machine tools market. These sectors require advanced tools for high-quality production and consistency.

Technological Advancements: Continuous innovation in machine tool technology, including the development of smart and connected tools, is propelling market growth. The integration of IoT (Internet of Things) allows for real-time monitoring and maintenance, enhancing operational efficiency.

Increasing Investments in Manufacturing: Governments and private sectors are investing heavily in manufacturing infrastructure, particularly in emerging economies. This is creating a robust demand for machine tools to support large-scale production.

As the machine tools market evolves, the emphasis on automation, precision, and sustainability will continue to shape its trajectory, offering opportunities for growth and innovation across various industries.

#MachineTools#Manufacturing#Industry40#Automation#3DPrinting#Sustainability#Market Research#Market Trends

0 notes

Text

Discover the Hydraulic Pipe Bending Machine, engineered for precise, high-volume pipe bending with seamless operation and exceptional results.

To know more, Visit https://www.yashmachine.com/product/sheet-metal-machine/hydraulic-pipe-bending-machine

0 notes

Text

Electric Handheld Power Tools

Power Saws #1 Circular Saw #2 Track Saw #3 Reciprocating Saw #4 Jigsaw

Drills & Drivers #5 Drill #6 Hammer Drill #7 Impact Driver #8 Electric Screwdriver #9 Impact Wrench

Grinders & Sanders #10 Angle Grinder #11 Belt Sander#12 Orbital Sander / Random Orbital Sander

Other Power Tools #13 Rotary Tool #14 Router

Electric Stationary Power Tools

Power Saws #15 Band Saw #16 Miter Saw #17 Table Saw #18 Wet Tile Saw

Machine Tools #19 Bench Grinder #20 Drill Press #21 Lathe #22 Milling Machine #23 CNC Router

Air Tools

#24 Air Compressor #25 Nail Gun

Outdoor Power Equipment

#26 Chainsaw #27 Pole Saw #28 Log Splitter #29 Hedge Trimmer #30 String Trimmer #31 Lawn Mower #32 Leaf Blower #33 Snow Blower

#ElectricHandheldPowerTools#PowerSaws#CircularSaw#TrackSaw#ReciprocatingSaw#Jigsaw#DrillsAndDrivers#Drill#HammerDrill#ImpactDriver#ElectricScrewdriver#ImpactWrench#GrindersAndSanders#AngleGrinder#BeltSander#OrbitalSander#RandomOrbitalSander#RotaryTool#Router#ElectricStationaryPowerTools#BandSaw#MiterSaw#TableSaw#WetTileSaw#MachineTools#BenchGrinder#DrillPress#Lathe#MillingMachine#CNCRouter

0 notes

Text

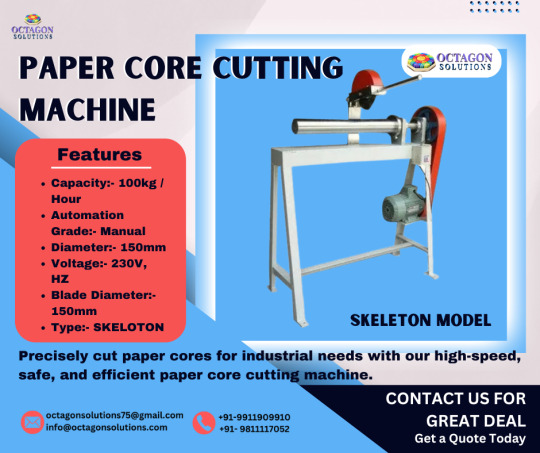

Paper Core Cutting Machine and Core Cutter blade

Paper Core Cutting Machine

Efficiently cut paper cores with our precision machine. Designed for high-speed production, our cutter delivers accurate and clean cuts. Ideal for paper mills, packaging industries, and more.

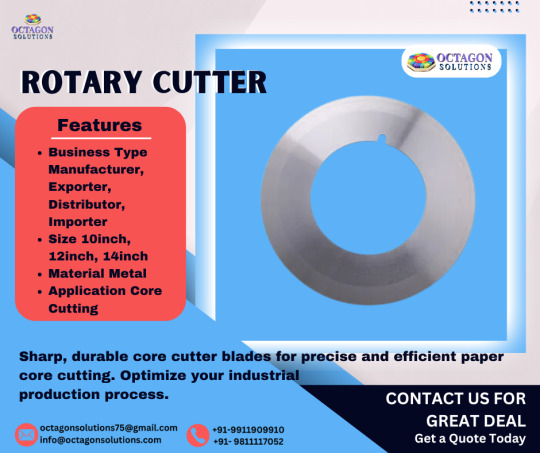

Core Cutter Blade

Sharp and durable core cutter blades for precise cutting. Engineered for optimal performance, our blades ensure clean cuts and extended lifespan. Compatible with various paper core cutting machines.Sources and related content

#PaperCoreCutting#CoreCutterBlade#IndustrialTools#CuttingMachine#PrecisionCutting#Manufacturing#Engineering#ProductivityBoost#TechInnovation#CuttingEdge#Machinery#QualityTools#IndustryLeaders#Efficiency#CleanCuts#ToolTech#EngineeringSolutions#CuttingSolutions#FactoryEquipment#InnovationInIndustry#HeavyDuty#TechSavvy#ProfessionalGrade#IndustrialMachinery#AdvancedTechnology#MachineTools

0 notes

Text

Introducing our cutting-edge Hydraulic Pipe Bending Machine! Engineered for flawless operation, precise results, and high-volume production. To know more, Visit

https://www.yashmachine.com/product/sheet-metal-machine/hydraulic-pipe-bending-machine

0 notes

Text

#Makishinko#Jack#linearmotion#PrecisionEngineering#machinetools#automation#ultrahighrigidity#seimitsu#makishinkoproducts#ballscrew#GlobalPartner#channelpartner#distributer#dealer#supplier#manufacturer

0 notes

Text

Understanding Heat Staking Machines

The Ultimate Guide to Heat Staking Machines: Basics, Applications, and Benefits

In the world of manufacturing, precision and reliability are paramount. One technology that embodies these qualities is the heat staking machine. This guide delves into the fundamentals of heat staking machines, explores their applications across various industries, and highlights the benefits they offer. By the end, you’ll understand why a heat staking machine from Vimalssonic could be a game-changer for your production processes.

Basics of Heat Staking Machines

What is a Heat Staking Machine?

How Does a Heat Staking Machine Work?

The heat staking process can be broken down into several key steps:

Heating: The machine heats a staking tip to a specific temperature, which is determined by the type of plastic and the desired bond strength.

Pressing: The heated tip is then pressed against the plastic part, causing it to soften and flow.

Forming: The softened plastic deforms and fills the cavity or groove of the mating part, creating a mechanical bond.

Cooling: The assembly is allowed to cool, solidifying the bond.

Heat staking machines come in various configurations, including manual, semi-automatic, and fully automatic systems. Each type is designed to meet different production needs, from low-volume, high-mix production to high-volume, low-mix environments.

Applications of Heat Staking Machines

Heat staking machines are incredibly versatile and find applications across a wide range of industries. Here are some common uses:

Automotive Industry

In the automotive sector, heat-staking machines are used to assemble components like dashboards, door panels, and electronic modules. The precision and reliability of heat staking ensure that these critical components are securely joined, enhancing the overall quality and safety of vehicles.

Consumer Electronics

Heat staking is widely used in the assembly of consumer electronics, including smartphones, tablets, and laptops. The process helps in joining delicate plastic parts without the risk of damaging sensitive electronic components.

Medical Devices

The medical device industry relies on heat staking for assembling products such as disposable medical instruments, diagnostic devices, and housing for electronic medical equipment. The strong, reliable bonds created by heat staking are essential for ensuring the safety and functionality of medical devices.

Aerospace

In aerospace applications, where durability and precision are critical, heat staking machines are used to join components in aircraft interiors, control panels, and other equipment. The process provides robust bonds that can withstand extreme conditions.

Household Appliances

Manufacturers of household appliances like vacuum cleaners, coffee makers, and washing machines use heat staking machines to assemble various plastic components. The process ensures a neat finish and long-lasting bonds, contributing to the overall durability of the products.

Benefits of Heat Staking Machines Vimalssonic

Using a heat staking machine offers several advantages that make it a preferred choice in many manufacturing settings:

1. Strong and Reliable Bonds

Heat staking creates robust mechanical bonds that are resistant to vibrations, impacts, and environmental factors. This makes it ideal for applications where durability and reliability are crucial.

2. Versatility

Heat staking machines can handle a wide range of materials and part geometries, making them suitable for various industries. Whether you need to join small, intricate parts or larger components, a heat staking machine can accommodate your needs.

3. Cost-Effective

Compared to other joining techniques like ultrasonic welding or adhesives, heat staking is often more cost-effective. It requires less energy and fewer consumables, reducing overall production costs.

4. Clean and Aesthetic Joints

The heat staking process produces clean, neat joints without the need for additional finishing steps. This is particularly important in applications where the appearance of the final product is a critical factor.

5. Flexibility in Design

Heat staking allows for more flexibility in the design of components. Engineers can design parts with specific features, such as bosses or studs, that can be easily heat staked, providing more design freedom.

6. Minimal Thermal Stress

The localized heating in heat staking minimizes the risk of thermal stress on surrounding areas, preserving the integrity of sensitive components. This is especially important in the assembly of electronic devices and medical instruments.

7. Environmentally Friendly

Heat staking is an environmentally friendly process as it does not involve the use of adhesives or solvents that can release harmful chemicals. This aligns with the growing demand for sustainable manufacturing practices.

Why Choose Vimalssonic Heat Staking Machines?

youtube

When it comes to selecting a heat staking machine, reliability and performance are key. Vimalssonic, a leading manufacturer and exporter of heat staking machines, offers a range of high-quality solutions tailored to meet your specific needs. Here’s why you should consider Vimalssonic:

1. Superior Quality and Precision

Vimalssonic heat staking machines are built with precision and durability in mind, ensuring consistent and reliable performance across various applications.

2. Customizable Solutions

Whether you require a manual, semi-automatic, or fully automatic machine, Vimalssonic provides customizable solutions to match your production requirements.

3. Global Reach

As an exporter, Vimalssonic serves clients worldwide, delivering cutting-edge heat staking technology to manufacturers across different industries.

4. Comprehensive Support

Vimalssonic offers extensive support and training to ensure that your team can operate the machines efficiently and effectively, maximizing your investment.

Heat staking machines are a vital tool in modern manufacturing, offering a reliable, versatile, and cost-effective method for joining plastic and plastic-to-metal components. Their applications span across various industries, including automotive, consumer electronics, medical devices, aerospace, and household appliances. By understanding the basics, applications, and benefits of heat staking machines, manufacturers can make informed decisions to enhance their production processes and product quality.

Investing in a heat staking machine from Vimalssonic can lead to stronger, more reliable bonds, greater design flexibility, and improved overall efficiency. Whether you are looking to optimize your current manufacturing process or develop new products, a heat staking machine from Vimalssonic could be the solution you need.

Ready to take your manufacturing to the next level? Contact Vimalssonic today to learn more about our high-quality heat staking machines and find the perfect solution for your production needs. Visit our website or reach out to our sales team for more information.

#Vimalssonic#PrecisionMachines#AssemblyProcess#PrecisionInstruments#SkilledTeam#QualityProducts#Manufacturing#MachineTools#Accuracy#Technology#Youtube

0 notes

Text

youtube

#engineering#lasercutting#lasermachine#industrial#machinetools#hydraulic press#hydraulic lifts#industrialexhibition#engiexpo#Youtube

0 notes

Text

Visit Altem Technologies at INTEC CODISSIA 2024

📣 Attention Everyone! 🚀 Altem Technologies Pvt Ltd cordially invites you to join us at INTEC CODISSIA 2024 - the 20th edition of the International Machine Tools & Industrial Trade Fair. Visit us at Stall G157 from June 6th to 10th, 2024, at CODISSIA Trade Fair Complex, Coimbatore. 🛫 Don't miss this opportunity to witness the latest advancements in machine tools, industrial equipment, and manufacturing technology.

0 notes