At Solico Tanks, quality and durability are always our top priorities when it comes to designing and manufacturing premium GRP water tanks.

Don't wanna be here? Send us removal request.

Text

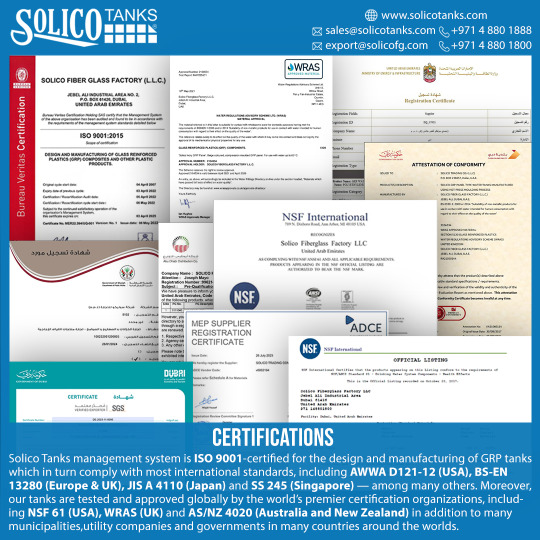

International Standards and Certifications a Water Tank Should Have

When it comes to water storage, compliance with international standards isn’t just a formality—it’s a vital assurance of safety, quality, and long-term performance. At Solico Tanks, our commitment to excellence is backed by some of the most respected certifications and approvals worldwide, ensuring that our GRP (Glass Reinforced Plastic) tanks meet and exceed global expectations.

Here’s a closer look at the key international standards and certifications every water tank should have—and what they mean for quality and trust.

✅ ISO 9001 – Quality Management System

Issued by: International Organization for Standardization (ISO) Applies to: Organizational processes, quality assurance, and customer satisfaction

What It Means: ISO 9001 certification confirms that Solico Tanks has a well-defined and consistently applied quality management system in place for the design and manufacturing of GRP tanks. It ensures continual improvement, risk management, and a customer-focused approach in every product we deliver.

🌍 AWWA D121-12 – American Standard for Bolted Glass-Fiber-Reinforced Plastic (GRP) Panel-Type Tanks

Issued by: American Water Works Association (AWWA) Applies to: Design, fabrication, installation, and testing of GRP tanks

What It Means: This standard is widely recognized in the United States and ensures that GRP tanks meet structural, hydraulic, and durability requirements for use in water utility systems. Tanks compliant with AWWA D121-12 are trusted in public waterworks and large infrastructure projects across the U.S.

🇬🇧 BS-EN 13280 – European & UK Standard for Cold Water Storage Tanks

Issued by: British Standards Institution (BSI) / European Committee for Standardization (CEN) Applies to: Non-pressurized water tanks for potable water storage

What It Means: BS-EN 13280 specifies performance requirements for cold water storage tanks, particularly in residential and commercial buildings. It ensures that tanks are safe, durable, and hygienic. Compliance with this standard demonstrates suitability for the UK and European markets.

🇯🇵 JIS A 4110 – Japanese Industrial Standard for FRP Water Tanks

Issued by: Japanese Standards Association (JSA) Applies to: Construction, performance, and testing of fiber-reinforced plastic water tanks

What It Means: This Japanese standard outlines material and design requirements for GRP water tanks, especially for domestic and municipal use. Compliance indicates that the tank is suitable for use in Japan, where stringent material testing and safety are paramount.

🇸🇬 SS 245 – Singapore Standard for Water Storage Tanks

Issued by: Enterprise Singapore / SPRING Singapore Applies to: Design, material, and testing of water tanks

What It Means: SS 245 is Singapore’s recognized standard for potable water tanks, particularly those used in buildings and public facilities. Compliance signifies high standards for hygiene, material safety, and design—vital for water conservation in tropical climates.

🧪 NSF/ANSI 61 – Drinking Water System Components

Issued by: NSF International (USA) Applies to: Materials and components that come into contact with drinking water

What It Means: NSF/ANSI 61 is one of the most important certifications for tanks used in potable water storage. It ensures that materials used in the tank do not leach harmful contaminants into the water. Tanks certified under this standard are accepted throughout North America and globally for their health and safety compliance.

💧 WRAS – Water Regulations Approval Scheme (UK)

Issued by: WRAS (United Kingdom) Applies to: Water fittings and materials used in potable water systems

What It Means: WRAS approval guarantees that the tank and its components do not contaminate water and meet the requirements of UK water supply regulations. It’s especially crucial for projects in the United Kingdom, assuring compatibility with local water authorities.

🇦🇺 AS/NZS 4020 – Products for Use in Contact with Drinking Water

Issued by: Standards Australia / Standards New Zealand Applies to: Testing of products that contact drinking water

What It Means: AS/NZS 4020 specifies testing procedures to ensure that products do not leach contaminants, affect water taste or odor, or promote microbial growth. Tanks certified under this standard are approved for potable water use in Australia and New Zealand.

🏛️ Approved by Global Authorities

Beyond formal certification, Solico Tanks’ GRP solutions are independently tested and approved by a wide range of municipalities, utility companies, and government agencies across the globe. This includes strict vetting processes to meet local building codes, environmental regulations, and water quality standards.

🔒 Why Certifications Matter

When choosing a water tank, certifications offer more than just a stamp—they ensure:

Public health protection through non-toxic, hygienic materials

Structural integrity in demanding conditions (extreme temperatures, seismic zones, etc.)

Regulatory compliance for local and international projects

Trust and transparency in both product performance and business ethics

💧 The Solico Assurance

When you choose Solico Tanks, you’re partnering with an internationally recognized water tank manufacturer known for delivering proven reliability, global compliance, and engineering excellence. Our presence across Asia, the Middle East, Europe, and Oceania stands as a testament to the trust placed in us by municipalities, infrastructure developers, and utility providers worldwide.

✅ Conclusion

At Solico Tanks, international standards are not just milestones—they are the foundation of our engineering philosophy. Every certification we hold—from ISO 9001 to NSF 61—reflects our unwavering commitment to delivering safe, sustainable, and high-performance water storage systems that serve communities and industries across the world.

Whether you're sourcing tanks for a municipal water system, a residential tower, or an industrial facility, always choose products that carry globally recognized certifications for water tanks. Because when it comes to water, quality can't be compromised.

#business#grp water tanks#water tank#tanks#water industry#architecture#history#home & lifestyle#science#water storage#SMC water tank#GRP water tank#Water tank manufacturer#Certifications for water tank#Global standards#Construction#Mechanical Engineering#Civil Engineering

0 notes

Text

Modern Solutions in Water Storage: The Comprehensive Guide to GRP Panel Tanks

Overview

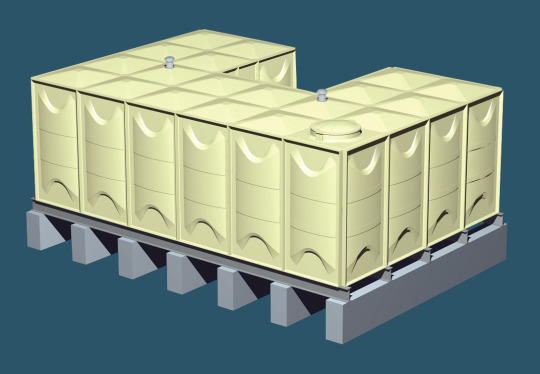

As the demand for reliable, hygienic, and adaptable water storage grows across industries, Glass Reinforced Plastic (GRP) panel tanks have emerged as a top-tier solution. Lightweight yet incredibly strong, GRP tanks blend innovation and practicality, making them suitable for everything from household water systems to large-scale industrial applications. This comprehensive guide explores the core materials, construction components, and performance advantages that make GRP tanks a preferred choice in modern water infrastructure.

1. The Building Blocks: GRP Panels Explained

At the heart of every GRP (Glass Reinforced Plastic) tank lies its most essential component: the GRP panel. These panels are not simply molded sheets; they are the result of advanced composite engineering that combines durability, flexibility, and lightweight efficiency into one high-performance structure.

What Are GRP Panels Made Of?

GRP panels are manufactured using a specialized process called Sheet Molding Compound (SMC) technology. This technique involves blending glass fibers with a matrix of polyester resin and specialized fillers, then compressing the mixture under high temperature and pressure to form rigid, durable panels. The glass fibers provide tensile strength, while the resin matrix contributes to the material’s overall chemical resistance and structural integrity. The fillers enhance specific properties such as thermal resistance, dimensional stability, and surface finish.

This composite material offers the best of both worlds: the toughness and resilience of metals with the lightweight nature and flexibility of plastics.

Why GRP Panels Stand Out: Key Advantages

Superior Strength-to-Weight Ratio One of the most notable features of GRP panels is their exceptional strength in relation to their weight. Unlike concrete or steel, GRP is significantly lighter, which reduces transportation and installation costs. Despite its reduced weight, it retains a high load-bearing capacity, making it ideal for large-volume water storage tanks without compromising on structural integrity.

Corrosion and Chemical Resistance GRP panels are inherently resistant to corrosion, especially when exposed to moisture, salt air, or industrial chemicals. This makes them a superior alternative to metal tanks, which are prone to rust and degradation over time. GRP panels perform consistently even in coastal regions, high-humidity zones, or chemically aggressive environments, where traditional materials often fail.

Smooth, Hygienic Surfaces The non-porous and smooth finish of GRP panels plays a vital role in maintaining water quality. The sleek interior surface discourages the accumulation and growth of algae, bacteria, mold, and other microorganisms, which are common issues in porous materials. This ensures that water stored in GRP tanks remains clean, safe, and potable, with minimal risk of contamination.

Highly Customizable and Modular GRP panels are available in a variety of sizes and shapes, allowing for modular tank construction that can be tailored to fit specific capacity requirements or space limitations. Whether the tank needs to be rectangular, square, or built to fit within a confined area, GRP panels provide unmatched flexibility in design. This modularity also makes future expansion or relocation of tanks much easier than with monolithic storage options.

Application in Challenging Environments

Thanks to their unique properties, GRP panel tanks are particularly well-suited for use in extreme climatic conditions, including areas with intense heat, cold, or rapid temperature fluctuations. The thermal stability of the material prevents warping or cracking under such stresses, ensuring long-term reliability. Furthermore, their ability to maintain water purity makes them ideal for sanitation-critical uses, such as:

Drinking water storage

Food and beverage production facilities

Hospitals and medical centers

Agricultural irrigation systems

In summary, GRP panels are not just a structural component—they're a technological advancement in material science that elevates the performance, lifespan, and versatility of GRP water tanks across all sectors. Their combination of mechanical strength, environmental resistance, and sanitary safety makes them a smart, future-ready choice for modern water storage needs.

2. Fastening Systems: The Backbone of Structural Integrity

While the GRP panels form the body of the tank, it is the fastening systems that provide the crucial support necessary for structural stability. These systems are responsible for securely holding the panels together, ensuring that the tank retains its shape and withstands the pressures exerted by the stored water.

The Role of Fasteners in GRP Tank Construction

The fastening system used in GRP panel tanks typically consists of high-grade stainless steel bolts, nuts, and washers. The materials used in these fasteners are critical to the long-term performance and integrity of the tank, as they must hold the panels together under varying environmental conditions and mechanical stresses. The most commonly used grades of stainless steel for this purpose are 304 and 316, both of which offer outstanding resistance to corrosion and provide durability even in challenging environments.

Why Fasteners Are Crucial for Structural Integrity:

Corrosion Resistance One of the primary reasons for choosing stainless steel fasteners is their corrosion resistance. Water storage tanks are often exposed to humid, salty, or chemically active environments, particularly in coastal areas, industrial zones, or regions with high rainfall. Stainless steel fasteners, particularly grade 316, which contains additional molybdenum for enhanced corrosion resistance, ensure that the fastening system will remain intact without rusting or degrading over time. This corrosion resistance extends the lifespan of the tank, even when exposed to harsh environmental conditions, preventing costly repairs or replacements due to rust damage.

Leak Prevention and Pressure Management The tightness and precision of the fastening system are essential for maintaining a leak-proof seal between the panels. Any gaps or loose fasteners can lead to water leakage or pressure loss, which compromises the structural integrity and functionality of the tank. High-quality stainless steel fasteners provide the necessary tension to pull the panels together, ensuring that they remain tightly sealed under the weight of the stored water. Additionally, fasteners play a key role in managing the hydrostatic pressure inside the tank, preventing the panels from bulging, warping, or shifting out of place, which could otherwise result in catastrophic failure.

Structural Stability Under Fluctuating Pressures The installation standards and the tightness of the fasteners are essential for maintaining the structural strength of the tank, especially when the internal water pressure fluctuates due to varying tank levels. The fasteners help to distribute the weight evenly across the tank, ensuring that no part of the tank experiences excessive stress or strain. This is particularly important for large tanks that can store significant volumes of water, where even slight shifts in the tank's shape could lead to leaks, cracks, or collapse. Rigorous installation of these fasteners ensures that the tank can withstand dynamic loads and environmental factors (such as earthquakes, winds, or heavy rains) without losing its structural integrity.

Long-Term Durability Fasteners are often underestimated in their importance to the longevity of GRP tanks. However, they are a critical component that directly affects the durability and reliability of the entire structure. Over time, the fasteners continue to hold the tank together, resisting the constant tension and environmental forces exerted on the structure. As a result, even under high pressures and constant exposure to water and weathering, these fasteners ensure that the tank remains securely intact and maintains its function for many years.

Although GRP panels are often the focal point when discussing tank construction, it is the fastening systems that provide the ultimate structural support and ensure the tank’s long-term durability. Stainless steel bolts, nuts, and washers not only hold the panels together but also prevent leaks, manage pressure, and help the tank endure over time. In environments that experience high humidity, extreme temperatures, or chemical exposure, the role of fasteners becomes indispensable for ensuring the water-tight, corrosion-resistant, and structurally sound performance of the GRP tank.

Without the right fastening system, even the most advanced composite panels would be ineffective in providing a reliable and long-lasting water storage solution.

3. Leak Prevention: Sealants and Gaskets

Ensuring that a GRP panel tank remains watertight over the long term is critical for both its structural integrity and the safety of the water stored within. A leak-free seal is essential not only for maintaining the tank's ability to store water efficiently but also for preventing contamination or water loss that could lead to environmental or operational issues.

To achieve this, specialized sealants and gaskets are applied between the panel joints. These components are integral to creating a strong, secure barrier that prevents water from escaping, even under the internal pressures exerted by the tank’s contents.

The Role of Sealants in Leak Prevention

A sealant is a substance used to fill the gaps and cracks between two surfaces to create a waterproof seal. When it comes to GRP water tanks, sealants are applied between the edges of the panels to ensure that no water leaks through the joints during storage.

The most commonly used sealant material is non-toxic rubber foam. This material is highly valued for its elasticity and adhesion properties. The elasticity of rubber foam ensures that it can accommodate any slight movements or expansions of the tank due to temperature changes or water pressure. This makes it particularly effective in maintaining a secure seal over time, preventing water seepage that could otherwise compromise the tank’s performance.

Rubber foam also has excellent long-term durability, which means it can withstand the rigors of constant exposure to water and environmental elements without breaking down or losing its sealing capabilities.

Alternative Sealant Materials

While rubber foam is the most common, there are other sealants that might be used depending on the specific requirements of the tank. Each alternative has unique characteristics that offer additional benefits for specialized applications:

Silicone Sealant: Silicone is a highly flexible, heat-resistant material that performs exceptionally well in environments subjected to high temperatures or rapid thermal fluctuations. Silicone sealants maintain their integrity at temperatures ranging from extreme cold to high heat, making them ideal for applications in hot climates or situations where the tank might be exposed to heat sources. Additionally, silicone has excellent adhesion to both GRP panels and metal surfaces, ensuring a strong, durable seal.

Polyurethane Sealant: Polyurethane is known for its resilience and durability in fluctuating environmental conditions. It is highly effective at maintaining a solid seal under varying temperatures and humidity levels, making it a great option for tanks that may experience changes in environmental conditions over time. Polyurethane also offers strong water resistance, which helps preserve the tank’s structure even when exposed to rain, snow, or humidity over extended periods.

Hybrid Sealants: In certain cases, a combination of sealants may be used, such as rubber-based sealants with polyurethane additives. These hybrid materials can offer a balance of flexibility, durability, and water resistance, ensuring a robust, long-lasting seal under diverse conditions.

Gaskets: The Silent Protectors

In addition to sealants, gaskets play a crucial role in preventing leaks at the junctions where the panels meet. A gasket is a sealing material placed between two surfaces (in this case, the edges of the GRP panels) to ensure an airtight or watertight seal.

The most commonly used materials for gaskets include:

Rubber Gaskets: Rubber gaskets are widely used for their flexibility and compression resistance. When compressed between the panel edges, they create a tight, waterproof seal that prevents any leakage at the panel connections. Rubber gaskets are especially useful in systems that experience vibration or pressure fluctuations, as they can compress and expand to maintain the seal.

Silicone Gaskets: Like silicone sealants, silicone gaskets offer excellent temperature resistance and maintain their sealing properties even in extreme conditions. They are commonly used for tanks located in areas with high temperatures or chemical exposure. Their flexibility ensures they provide a secure seal even when the tank is subjected to shifting or slight movements over time.

How Sealants and Gaskets Work Together

Together, sealants and gaskets form a comprehensive leak-proof system that ensures the long-term integrity of the GRP tank. While the sealants provide an initial adhesive bond and prevent minor leaks at the panel joints, the gaskets serve as the primary barrier against water seepage, especially in areas of high pressure or frequent movement.

This two-tiered system of protection is what guarantees a watertight performance for the tank, even in the most challenging conditions. By ensuring that the tank remains securely sealed, both sealants and gaskets contribute to enhanced safety and hygiene. For water storage tanks, especially those used for potable water storage, maintaining a leak-free seal is paramount to prevent contamination and ensure water quality remains at its highest standard.

Importance of Regular Maintenance

Even though these materials are designed to last for many years, regular inspection of the sealant and gasket systems is necessary to maintain their effectiveness. Over time, exposure to the elements, temperature fluctuations, and constant water pressure may cause slight wear and tear. Ensuring that the seals remain intact and replacing any worn components promptly will help extend the life of the tank and maintain its performance.

In summary, sealants and gaskets are critical to ensuring that a GRP water tank performs efficiently over its entire lifespan. These components work together to provide a robust, leak-proof seal, preventing water loss, contamination, and maintaining the safety of the stored water. Whether using rubber foam, silicone, or polyurethane as sealants, or employing rubber or silicone gaskets for airtight junctions, these materials enhance the overall safety and sanitation of the tank, making them essential for reliable water storage.

4. Reinforcement Systems: Internal and External Support

For GRP (Glass Reinforced Plastic) tanks, especially those designed to store large volumes of water, the ability to withstand the significant hydrostatic pressure created by the weight of the water is essential. As the volume of water increases, so does the pressure exerted on the walls of the tank. To ensure that the tank remains structurally sound and capable of maintaining its shape under these stresses, reinforcement systems are employed. These systems consist of both internal and external support elements, each playing a crucial role in maintaining the tank’s integrity over time.

External Frameworks: Providing Stability and Shape

The external framework of a GRP tank is designed to resist the outward bulging forces exerted by the weight of the water inside the tank. These external reinforcements work to maintain the tank's shape and prevent deformation under hydrostatic pressure.

Key elements of the external framework include:

Box Sections: Box sections are structural supports that are typically used to frame the tank. These sections are usually made from high-strength, corrosion-resistant steel (such as hot-dipped galvanized steel or stainless steel) and provide robust external support for the tank walls. Box sections are strategically placed around the tank to create a rigid framework that enhances the tank’s structural rigidity and resistance to deformation. These sections are essential for large-scale tanks, where the sheer weight of the water can create significant stresses on the outer walls.

Angle Braces: Angle braces are additional supports that are used to prevent the tank from bulging or warping under the pressure of the stored water. These braces work in tandem with box sections to create a triangular support system that distributes the force more evenly across the tank. By connecting various points along the tank’s exterior, angle braces help reinforce the tank’s frame, ensuring that it can withstand the stresses generated by the internal pressure without collapsing or losing its shape.

Together, these external support elements create a strong, stable framework that helps the tank retain its form and resist deformation even under dynamic load conditions such as fluctuating water levels, external environmental factors, or seismic activity.

Internal Tie Rods and Bracing: Managing Stress Distribution

While the external framework is vital for preventing outward bulging, the internal reinforcement elements of the tank are equally crucial in managing internal pressure and distributing stress evenly across the structure.

Key internal support elements include:

Tie Rods: Tie rods are steel rods that are placed internally in the tank to help distribute the internal pressure more evenly across the tank walls. These rods are typically made from corrosion-resistant steel and are designed to be tensioned to provide additional strength. The tension in the tie rods helps counteract the pressure exerted by the water inside the tank and ensures that the walls do not buckle or collapse under the weight. Tie rods are particularly important for large tanks with high water volumes, as they help ensure that the tank remains stable and evenly stressed.

Bracing Systems: Bracing systems are another crucial component in the internal support structure of a GRP tank. These systems, often made of steel, are used to reinforce the tank’s walls and distribute stress more effectively. Braces can be configured in various shapes—such as X-shaped braces or diagonal supports—to enhance the tank’s overall structural integrity. The strategic placement of these braces helps prevent the walls from bulging inwards and ensures that the tank maintains its shape under various loading conditions.

By using these internal components, GRP tanks can manage the internal stresses resulting from the weight of the stored water and maintain their shape and stability over the long term. This internal reinforcement system is especially critical for tanks that are exposed to extreme environmental conditions or high volumes of water.

Corrosion-Resistant Materials for Long-Term Durability

To ensure the longevity and effectiveness of these reinforcement elements, corrosion-resistant materials are chosen for both internal and external components. The most common materials used for GRP tank reinforcement include:

Galvanized Steel: Hot-dipped galvanized steel is often used for external support systems such as box sections and braces. The galvanization process involves coating the steel with a layer of zinc, which provides excellent protection against corrosion. This is particularly important for tanks that are exposed to moisture, saltwater, or harsh industrial environments. The zinc coating protects the steel from rust, ensuring the reinforcement remains effective for many years.

Stainless Steel: Stainless steel is another popular choice for reinforcement, particularly for internal components like tie rods and bracing systems. Stainless steel offers superior resistance to both corrosion and high-temperature environments, making it ideal for long-term use in challenging conditions. Stainless steel’s resilience ensures that the reinforcement elements maintain their strength and structural properties even when exposed to fluctuating temperatures or aggressive chemicals.

By using these high-quality, corrosion-resistant materials, the reinforcement systems ensure that the GRP tank remains structurally sound and effective throughout its service life, regardless of environmental factors.

Why Reinforcement Systems Matter

Reinforcement systems are not just about preventing structural failure—they are about ensuring the tank remains safe, functional, and reliable under all conditions. Without these internal and external support systems, a GRP tank would be vulnerable to bulging, deformation, or collapse, especially as the water volume increases or if the tank is exposed to dynamic environmental loads such as earthquakes, extreme winds, or temperature fluctuations.

By incorporating both external frameworks and internal bracing systems, GRP tanks are able to handle the substantial pressure exerted by stored water while maintaining their shape, strength, and safety over time. This makes them an excellent choice for large-scale water storage solutions, ensuring that they remain structurally stable and durable even under challenging conditions.

In conclusion, the reinforcement systems of GRP water tanks are essential for ensuring the tank’s long-term structural integrity. By using a combination of external frameworks, internal tie rods, and bracing systems, these tanks can handle the significant pressures exerted by the stored water while maintaining their shape and strength. The use of corrosion-resistant materials ensures these support systems remain effective and reliable, providing a secure and safe water storage solution.

5. Foundation Matters: Base Support Systems

The foundation of a GRP (Glass Reinforced Plastic) water tank is critical to ensuring its stability and longevity. Regardless of how durable the tank material may be, its performance and structural integrity ultimately depend on the support it receives from the foundation. A well-designed base ensures the tank remains level, secure, and functionally sound throughout its service life, even under the weight of the stored water and external environmental factors.

The foundation type is determined by several factors, including the size of the tank, its location, and the design of the tank. Choosing the appropriate foundation is essential to prevent issues like shifting, settling, or uneven loading, which could compromise the tank's integrity and performance.

Foundation Types: Ensuring Stability and Load Distribution

The type of foundation selected for a GRP water tank depends largely on the specific design and installation requirements. There are two main types of foundations commonly used:

1. Concrete Pads: Even Load Distribution for Internally Flanged Tanks

Concrete pads are one of the most common foundation types used for internally flanged GRP tanks. The primary function of a concrete pad is to provide a level, stable surface that distributes the weight of the tank evenly across the ground. This helps prevent the tank from shifting or settling over time.

Even Load Distribution: Concrete pads help in distributing the weight of the tank evenly across the surface area, which is crucial for avoiding point loads that could lead to cracking or uneven settling of the tank. By spreading the load evenly, the concrete pad ensures that the structural integrity of the tank is maintained over the long term.

Strong, Durable Base: Concrete pads offer excellent compressive strength, which makes them capable of supporting large, heavy water tanks without risk of shifting or settling. The concrete is also resistant to the effects of moisture, ensuring that the foundation remains intact even when exposed to wet conditions.

Suitability for Internally Flanged Tanks: Internally flanged tanks, which have flanges on the inside of the tank structure, are typically installed on a level concrete surface to ensure that the tank is securely supported. The concrete pad allows for proper alignment and support for the tank walls, helping to prevent deformation under the weight of the water.

2. Pier Walls: Elevated Support for Externally Flanged Tanks

For externally flanged GRP tanks, pier wall foundations are often the preferred choice. These foundations involve constructing a wall or series of pillars around the base of the tank to elevate it slightly off the ground. Pier walls provide numerous advantages, especially for larger tanks or those located in areas with specific design or environmental requirements.

Elevated Design: The pier wall system raises the tank slightly above the ground level, preventing water pooling around the base. This is particularly important in regions where waterlogging, high water tables, or heavy rainfall may create conditions that could compromise the tank’s structural stability. By elevating the tank, pier walls help keep the base dry, preventing potential issues like rusting or corrosion of the lower parts of the tank.

Prevention of Stagnant Water: The design of pier walls also prevents stagnant water from collecting around the base of the tank, which could lead to moisture-related problems. By ensuring that water can drain away, pier walls help maintain the dryness of the foundation and avoid moisture accumulation, which could potentially weaken the structure over time.

Support for Large Tanks: For larger tanks, pier walls provide a reliable and stable foundation, supporting the weight of the tank and evenly distributing the load across the foundation pillars. This makes pier walls particularly useful in heavy-duty applications, such as large industrial water storage systems.

Key Considerations for Foundation Design

Regardless of the foundation type, certain factors must be taken into account during the design phase to ensure the foundation’s suitability and effectiveness in supporting the tank over its service life.

Soil Stability: The stability of the soil beneath the tank is a crucial consideration in foundation design. If the ground is unstable or prone to shifting, the tank may not remain level or secure over time. Soil tests are often conducted to assess the soil’s load-bearing capacity and determine whether additional reinforcement is needed. For example, unstable soils might require compaction or geotextile fabrics to provide a stable base.

Terrain Irregularities: The terrain of the installation site can have a significant impact on the choice of foundation. If the ground is uneven or sloped, a more elaborate foundation may be required to level the tank and provide a stable base. This may include excavation, fill material, or even the use of pier walls to elevate the tank and provide stability on uneven surfaces.

Load-Bearing Capacity: The foundation must be designed to handle the weight of both the tank and the water it stores. The load-bearing capacity of the soil and foundation materials must be carefully calculated to prevent settling or shifting that could damage the tank. For larger tanks, reinforced foundations using high-strength materials such as concrete, steel, or composite materials may be necessary to ensure the tank remains level and secure.

Environmental Factors: Environmental conditions, such as extreme weather or earthquake activity, must also be considered in foundation design. For example, in areas prone to seismic activity, seismic reinforcements may be required to ensure the tank remains intact during an earthquake. Similarly, for regions with high rainfall or flood risks, the foundation must be designed to handle water drainage effectively and prevent damage.

Ensuring Long-Term Performance

A well-designed and properly constructed foundation is critical for the long-term performance of a GRP tank. It ensures that the tank remains level, stable, and safe under the constant pressure exerted by the stored water. By properly considering factors such as soil stability, load distribution, and environmental conditions, the right foundation can prevent costly damage, reduce the risk of tank failure, and extend the tank's service life.

In conclusion, the foundation is the cornerstone of a GRP water tank’s structural integrity. Whether using concrete pads for internally flanged tanks or pier walls for externally flanged tanks, a solid foundation is essential for ensuring even load distribution, preventing water pooling, and maintaining long-term stability. By taking soil conditions, terrain irregularities, and environmental factors into account, the appropriate foundation system ensures the tank remains secure, functional, and reliable throughout its life.

6. Functional Add-Ons: Accessories That Enhance Usability

Modern GRP (Glass Reinforced Plastic) tanks are designed not only for durability and strength but also with a focus on enhanced usability, safety, and system integration. To improve the overall functionality of these tanks, a range of accessories can be incorporated. These additions ensure that the tank remains easy to use, efficient to maintain, and safe for both operators and the environment. Below are the essential accessories commonly found on modern GRP tanks and their functions.

Essential Accessories:

1. Inlet/Outlet Ports: Seamless System Integration

The inlet and outlet ports are vital for connecting the tank to various water systems, such as plumbing networks, irrigation systems, or water distribution networks. These ports facilitate the flow of water into and out of the tank and are essential for the tank’s primary function of water storage and distribution.

Functionality and Versatility: The inlet port allows for the controlled entry of water into the tank, while the outlet port enables the release of water when needed. Whether for drinking water, irrigation, or industrial use, these ports help ensure that the tank integrates seamlessly into the larger water supply or distribution system.

Customization: Inlet and outlet ports are available in a variety of sizes and configurations, depending on the specific water flow and capacity requirements. For example, larger ports may be used for industrial-scale applications, while smaller ports are suitable for residential or agricultural uses. The flexibility of these connections ensures that the tank can be adapted to meet diverse needs.

Material Selection: The ports are typically made from corrosion-resistant materials such as PVC, stainless steel, or polypropylene to ensure durability and resistance to chemicals or environmental factors that could cause degradation.

2. Overflow Screens: Preventing Debris Contamination

Overflow screens are a critical accessory designed to prevent debris and other foreign materials from entering the tank when the water level exceeds the maximum limit. Overflow screens are placed on the overflow outlets, ensuring that water can exit the tank without carrying along dirt, leaves, twigs, or other contaminants that could compromise water quality.

Debris Prevention: By filtering out debris, overflow screens prevent clogging of the tank’s outlets, ensuring optimal water flow. This also reduces the risk of contamination, keeping the water inside the tank cleaner and safer for its intended use.

Ensuring Compliance: Overflow screens are especially important in applications where water quality is critical, such as drinking water storage or sanitation-sensitive operations. Keeping debris out of the tank helps ensure compliance with health and safety regulations.

Maintenance and Functionality: These screens are designed for easy cleaning, allowing the maintenance team to quickly remove any accumulated debris. Proper cleaning ensures that the tank's overflow system remains functional and that the water remains uncontaminated.

3. Manhole Covers: Safe Inspection and Access

Manhole covers provide safe and secure access to the interior of the tank for inspection, maintenance, and cleaning. These covers are essential for ensuring that the tank can be properly maintained without compromising safety.

Secure and Safe Access: Manhole covers are typically made from heavy-duty materials like steel, fiberglass, or composite materials to withstand external pressure and prevent unauthorized access. They are designed to seal tightly, preventing contaminants from entering the tank and maintaining water quality.

Convenient Inspections and Repairs: The manhole cover allows maintenance personnel to access the inside of the tank to inspect water levels, check for potential damage, or clean the tank when necessary. This accessibility is important for ensuring that the tank operates efficiently and safely over its lifespan.

Variety of Sizes: Manhole covers come in various sizes, depending on the size of the tank and the nature of the intended use. Larger tanks may require larger access points, while smaller tanks may only need a more compact cover. The design of the manhole cover is crucial to ensure that it fits securely and prevents leaks.

4. Ladders and Handrails: Ensuring Safe Maintenance Access

Ladders and handrails are important for providing safe access to the top of the tank for inspection, cleaning, or routine maintenance. These accessories are crucial for ensuring that personnel can safely enter and exit the tank, especially when working at height.

Safe Climbing: Ladders are typically made from stainless steel, aluminum, or fiberglass, offering a non-corrosive and durable solution for accessing the tank. They are designed to provide a secure foothold for workers, ensuring safe ascent and descent, even in challenging conditions.

Supportive Handrails: Handrails are installed alongside ladders or at the top of the tank to provide extra support for personnel during maintenance activities. These rails ensure that workers can hold on securely, minimizing the risk of accidents when accessing the tank’s upper sections.

Compliance with Safety Standards: In addition to improving safety, ladders and handrails help tanks meet regulatory requirements for workplace safety. Many local regulations require such features to ensure worker safety when performing tasks like cleaning, inspection, or repairs on large tanks.

Why Functional Add-Ons Matter

While the primary function of a GRP tank is to provide secure and durable water storage, functional add-ons significantly enhance its usability, safety, and overall performance. These accessories contribute to:

Improved Water Management: Inlet/outlet ports and overflow screens play a pivotal role in controlling the flow and quality of water entering and exiting the tank, ensuring that the system remains efficient and functional.

Ease of Maintenance: Features like manhole covers, ladders, and handrails simplify routine inspections and cleaning, which are essential for the long-term performance and cleanliness of the tank. Easy access to the tank’s interior and exterior ensures that it can be properly maintained, preventing issues such as mold, algae growth, or water contamination.

Safety and Compliance: Ladders, handrails, and secure manhole covers ensure that maintenance activities are conducted safely, protecting workers from accidents while meeting regulatory compliance. This is especially important in commercial, industrial, or public sector applications, where safety standards must be met.

In conclusion, functional accessories enhance the versatility, safety, and ease of use of GRP water tanks, ensuring that they remain efficient and safe throughout their lifespan. Whether it’s the inlet/outlet ports for seamless integration into water systems, overflow screens for contamination prevention, manhole covers for easy access, or ladders and handrails for safe maintenance, these accessories contribute significantly to the tank’s overall performance, usability, and compliance with safety and hygiene standards.

7. Thermal Protection: Insulation for Water Quality

For water storage systems, maintaining a stable and consistent temperature is essential, especially when dealing with potable water or water used in environments where temperature fluctuations could impact its quality. A GRP (Glass Reinforced Plastic) tank offers the flexibility to incorporate thermal insulation, which is particularly valuable in warm climates or areas with extreme weather conditions. One of the most common insulation materials used in GRP tanks is Expanded Polystyrene (EPS), but other materials can also be used depending on the specific needs of the application.

Benefits of Thermal Insulation:

1. Prevention of Temperature Spikes: Reducing the Risk of Bacterial Growth

One of the primary functions of thermal insulation in GRP water tanks is to maintain a consistent temperature inside the tank. Without insulation, water temperatures can fluctuate significantly, particularly in regions with high external temperatures. These fluctuations can create conditions conducive to bacterial growth, which is especially concerning for potable water storage.

Temperature Stability: Thermal insulation helps to buffer the water from external temperature variations, preventing rapid increases or decreases in temperature. This is crucial because warmer temperatures can accelerate the growth of harmful microorganisms such as bacteria, algae, or fungi, which can negatively impact water quality and safety.

Preserving Potable Water: For drinking water, maintaining a cool and stable temperature is essential to ensuring the water remains free from contaminants. Insulation creates a barrier that helps keep the water within ideal temperature ranges, particularly in areas where the external temperature may cause water to warm up quickly, promoting the growth of unwanted organisms.

2. Maintaining Water Quality, Especially in Warm Climates

In regions with warm climates, the temperature of stored water can rise significantly, affecting the taste, odor, and overall quality of the water. Thermal insulation helps regulate the water temperature, ensuring it remains cool and fresh throughout the year, despite external heat.

Enhanced Water Freshness: The EPS insulation surrounding the GRP tank helps prevent the water from becoming too warm, which can result in unpleasant taste and odor issues due to microbial activity. By ensuring the temperature stays within a stable range, the water remains fresh, clean, and more pleasant to use.

Ideal for Hot Climates: In tropical or desert environments, water storage tanks are often exposed to harsh sunlight and high ambient temperatures. Insulation effectively shields the water from these temperature extremes, making it ideal for water storage in hot climates or areas with high solar exposure.

3. Increased Energy Efficiency in Climate-Controlled Environments

In industrial or commercial settings, where water might be used in climate-controlled environments such as greenhouses, cooling systems, or industrial processes, maintaining a consistent temperature is crucial for energy efficiency and system performance. Insulated GRP tanks contribute to energy savings by reducing the need for external cooling systems to regulate water temperature.

Lower Energy Consumption: When water temperature is maintained consistently through insulation, the need for energy-intensive cooling or heating systems is reduced. This leads to lower energy consumption and operational costs, particularly in applications where temperature control is a significant factor, such as in the food and beverage industry, pharmaceutical manufacturing, or agriculture.

Eco-Friendly Option: By reducing energy consumption, thermal insulation in GRP tanks also contributes to a more sustainable approach to water management. This eco-friendly option helps businesses and homeowners reduce their carbon footprint, aligning with modern goals of energy efficiency and environmental sustainability.

The Role of Expanded Polystyrene (EPS) Insulation:

Expanded Polystyrene (EPS) is a commonly used insulation material due to its lightweight, cost-effective, and highly efficient thermal resistance properties. EPS insulation works by trapping air within its cellular structure, creating an insulating barrier that reduces the transfer of heat between the water inside the tank and the external environment.

Benefits of EPS:

Lightweight and Easy to Handle: EPS is easy to install and doesn’t add significant weight to the tank, which is especially beneficial for larger water storage systems.

High Insulation Value: EPS offers excellent thermal resistance, which helps maintain water temperatures effectively over time.

Cost-Effective: Compared to other insulation materials, EPS is relatively inexpensive, making it an accessible option for both small-scale and large-scale water storage applications.

Durability and Longevity: EPS is a durable material that is resistant to moisture and environmental conditions, ensuring it remains effective over the long term without degrading or losing its insulating properties.

In summary, the integration of thermal insulation in GRP water tanks is a valuable feature that enhances water safety, quality, and overall tank performance, providing significant long-term benefits for both residential and industrial water storage solutions.

Conclusion: The Smart Choice for Sustainable Water Storage

GRP panel tanks represent a cutting-edge, future-proof water storage solution. From their advanced composite structure to their customizable features and reliable performance, these tanks offer unmatched advantages in a wide array of applications.

Whether you're managing a residential water system, an industrial process, or a municipal utility project, GRP tanks deliver the durability, hygiene, and efficiency you need—backed by smart engineering and superior materials, Contact Solico Tanks get deliver your water storage tanks at your door step!

#GRPWaterTanks#FiberglassReinforcedPlasticTanks#WaterStorageSolutions#ModularWaterTanks#CustomizableWaterStorage#HotPressedGRPPanels#PotableWaterStorage#CorrosionResistantTanks#DurableWaterTanks#EcoFriendlyWaterStorage#SustainableWaterTanks#FirefightingWaterStorage#OilAndGasWaterTanks#ReverseOsmosisWaterStorage#HydroponicWaterTanks#AquaponicWaterStorage#VerticalFarmingWaterSolutions#GRPPanelTypeWaterTanks#SectionalWaterTanks#InsulatedWaterTanks#LargeCapacityWaterStorage#LeakProofWaterTanks#GRPTankManufacturing#IndustrialWaterStorage#CommercialWaterTanks#ResidentialWaterStorage#WaterStorageTankDesign#WaterStorageTankSupplier#WaterStorageTankDistributor#WaterStorageTankExporter

0 notes

Text

Unveiling the Advantages of Hot Press GRP Panel Tanks for Potable Water Storage

Introduction

Choosing the right material for potable water storage involves evaluating various factors, such as hygiene, durability, environmental impact, and customization. Among the options available, hot press GRP (Glass Reinforced Plastic) panel tanks excel due to their superior attributes. Here’s a closer look at why hot press GRP tanks surpass other materials in providing safe and effective water storage solutions.

Optimal Hygiene and Chemical Purity

Conventional GRP Tanks: Standard GRP tanks, composed of fiberglass and resin, can retain volatile chemicals that might leach into the water if the resin is not fully cured. This poses risks to water quality and safety.

Concrete Tanks: Concrete’s porous nature can lead to the leaching of minerals such as lime, which can alter the water’s taste and quality. Regular maintenance is necessary to avoid contamination from cracks and leaks.

Steel Tanks: Steel tanks often need protective coatings to prevent rust and corrosion, which can deteriorate over time and potentially introduce harmful chemicals into the water. They also have a higher rust risk if the coating is damaged.

In contrast, hot press GRP tanks are manufactured at high temperatures, which evaporates any residual chemicals from the material, resulting in a stable and inert composite. This ensures that no harmful substances leach into the water, thereby maintaining its purity.

Exceptional Durability and Longevity

Conventional GRP Tanks: Although reasonably strong, standard GRP tanks can suffer from inconsistent strength and surface finish, leading to potential damage and deterioration over time, especially in harsh conditions.

Concrete Tanks: While concrete tanks are durable, they are prone to cracking and erosion and require regular inspections and maintenance to maintain their integrity.

Steel Tanks: Steel tanks are vulnerable to corrosion, particularly in humid or saline environments, and require ongoing maintenance and protective coatings to prevent rust.

Hot press GRP tanks, made from Sheet Molding Compound (SMC) and subjected to high pressure, feature a dense and uniform structure that offers superior resistance to physical damage, environmental stress, and chemical corrosion. This ensures a longer-lasting and more reliable storage solution.

Environmental Benefits and Efficiency

Conventional GRP Tanks: While an improvement over some alternatives, standard GRP tanks still involve resins that may have environmental impacts during production.

Concrete Tanks: Concrete production is highly energy-intensive and contributes significantly to CO2 emissions. Additionally, concrete tanks are heavy and resource-demanding in terms of transport and installation.

Steel Tanks: Steel production is resource-heavy and involves mining and processing that contribute to environmental degradation. Steel tanks also have a larger carbon footprint due to their weight and the need for protective coatings.

Hot press GRP tanks are manufactured with minimal environmental impact. The high-temperature process eliminates excess chemicals, and their lightweight nature reduces transportation emissions. Their durability also means fewer replacements and less overall waste.

Flexibility and Customization

Conventional GRP Tanks: While versatile, standard GRP tanks may lack the precise customization and finish that hot press tanks offer.

Concrete Tanks: Customizing concrete tanks can be challenging, often requiring significant on-site adjustments, and they are cumbersome to transport and install.

Steel Tanks: While customizable, steel tanks often need additional coatings and treatments, and their heavy weight can complicate installation.

Hot press GRP tanks offer outstanding flexibility in terms of size, shape, and features. The precision of the hot pressing process allows for exact specifications and customization, making them suitable for a wide range of applications.

In summary, hot press GRP panel water tanks provide unparalleled benefits over other materials for potable water storage. Their superior hygiene, durability, environmental efficiency, and customization options make them the optimal choice for safe and effective water storage.

#tanks#business#water tank#water industry#grp water tanks#architecture#water treatment#watertreatment#construction#water storage tanks#civil engineering#mechanical engineering#mep design

1 note

·

View note

Text

Solico Tanks: Internationally Certified Excellence

Solico Tanks boasts an impressive array of international certifications, showcasing our unwavering dedication to excellence in quality, safety, and reliability across our products and operations.

Management System: • ISO 9001: Design and manufacturing of GRP tanks

Product Compliance: • USA: AWWA D121-12 • Europe & UK: BS-EN 13280 • Japan: JIS A 4110 • Singapore: SS 245

Global Testing & Approval: • USA: NSF 61 • UK: WRAS • Australia and New Zealand: AS/NZ 4020

Additional Approvals: • Numerous municipalities • Utility companies • Government bodies worldwide

Why Our Certifications Matter:

Demonstrate commitment to quality, safety, and reliability

Showcase global recognition and trust

Reflect our dedication to transparency and accountability

Ensure consistent delivery of superior products

At Solico Tanks, we don't just meet standards - we exceed them. Our extensive list of international certifications is our promise to you: uncompromising quality, every time.

#business#water tank#grp water tanks#construction#water industry#watertreatment#water storage tanks#architecture#water treatment#tanks#GRP sectional water tank#long lasting water tank#Most durable water tank

1 note

·

View note

Text

Maximizing Flexibility: The Advantages of Relocatable GRP Panel Water Tanks

Introduction

In today’s ever-changing business world, having flexible and efficient infrastructure is crucial for success. Companies across various industries rely on effective water storage solutions to support their operations. Whether in construction, mining, event management, or manufacturing, the ability to adapt to dynamic environments can significantly impact productivity and cost efficiency. Traditional water storage solutions often pose challenges in terms of mobility and maintenance, but advancements in technology have brought forth innovative alternatives.

One such innovation is the GRP (Glass Reinforced Plastic) Panel Type Water Tank, which is transforming how businesses manage their water storage needs. These tanks offer unparalleled benefits, combining durability and low maintenance with the remarkable advantage of relocatability. Unlike traditional monolithic tanks, GRP panel tanks can be easily dismantled, transported, and reassembled, making them an ideal choice for businesses with temporary or project-based sites. This flexibility not only enhances operational efficiency but also contributes to long-term cost savings, positioning GRP panel tanks as a key asset in modern industrial infrastructure.

The Need for Relocatability

In industries such as construction, mining, and event management, the need for relocatability in infrastructure is paramount due to the often temporary and shifting nature of their operations. Construction sites frequently change as projects move from one location to another, and mining operations may shift based on resource availability and exploration results.

Similarly, large-scale events like festivals and exhibitions require adaptable setups that can be relocated as the event progresses. In these scenarios, having water storage solutions that can easily be moved is not just a convenience but a necessity. Traditional water storage systems, often fixed and cumbersome, are not designed for such dynamic environments. They can be costly to dismantle and transport, leading to operational delays and increased expenses.

This is where GRP Panel Water Tanks offer a transformative advantage. Designed with modularity in mind, these tanks can be quickly dismantled, transported, and reassembled at new locations with minimal effort. The lightweight and compact design of GRP panels allows for efficient handling and transportation, reducing the logistical challenges typically associated with moving large infrastructure components. Businesses can set up their water storage solutions at temporary sites without incurring high costs or extensive downtime. This flexibility not only supports operational efficiency but also helps manage resources more effectively, making GRP Panel Water Tanks a versatile and economical choice for industries that require adaptable and reliable water storage solutions.

The Advantages of GRP Panel Water Tanks

GRP Panel Water Tanks are designed to meet the unique demands of industries where temporary water storage solutions are essential. Their modular design enables them to be easily assembled and disassembled, which is a significant advantage for operations that are frequently relocating. The process of dismantling a GRP tank involves straightforward steps such as draining the tank, unfastening the panels, and packing the components for transport. This efficient process contrasts sharply with traditional water tanks, which are often fixed and difficult to relocate. The ability to quickly set up and move water storage facilities ensures that businesses can respond swiftly to changes in project demands or operational requirements.

Moreover, GRP Panel Water Tanks offer robust performance under diverse conditions. Constructed from Glass Reinforced Plastic, these tanks are durable and resistant to corrosion, ensuring long-term reliability even in harsh environments. The design includes features like gaskets and sealants that maintain structural integrity and functionality through multiple relocations. By investing in GRP Panel Water Tanks, businesses not only gain a flexible water storage solution but also a durable one that supports their needs across various locations and operational phases. This combination of flexibility, durability, and ease of relocation makes GRP tanks an invaluable asset for industries that operate in temporary or changing environments.

Use Cases Demonstrating the Need for Relocatability

The advantages of relocatability are best illustrated through practical use cases where GRP Panel Water Tanks have been employed effectively. For example, in the construction industry, GRP tanks have been used on multiple project sites to provide water storage for construction activities. As projects move from one location to another, these tanks are dismantled and relocated, ensuring that each new site has access to essential water resources.

Similarly, in the mining sector, GRP tanks support water management needs at various exploration and extraction sites, adjusting to the shifting demands of resource extraction. The event management sector also benefits from GRP tanks, which are used to supply water for large events and then relocated for different events or stored until needed again. These real-world applications underscore how GRP Panel Water Tanks provide a flexible, efficient, and cost-effective solution for temporary water storage needs.

Dismantling Process for GRP Panel Water Tanks

One of the standout features of GRP (Glass Reinforced Plastic) Panel Water Tanks is their modular design, which facilitates a straightforward and efficient dismantling process. The process begins with draining the tank of all water to ensure that it is empty and dry, which is essential for both safety and the integrity of the components during dismantling. Once the tank is drained, the panels are methodically unbolted, starting from the top and working downward.

This systematic approach ensures that the tank structure remains stable throughout the process and minimizes the risk of damage to the panels. Unlike traditional monolithic tanks that are fixed and challenging to move, GRP tanks are designed for ease of disassembly. The modular nature of the panels allows them to be handled individually, which significantly reduces the need for heavy machinery and complex equipment. Instead, only basic tools such as wrenches and screwdrivers are required, making the dismantling process more accessible and cost-effective.

In addition to their modular design, GRP Panel Water Tanks utilize gaskets and sealants at the joints between panels. These components are crucial for maintaining a watertight seal during operation, but they also simplify the dismantling process. When unbolting the panels, the gaskets and sealants can be easily separated without causing damage, which helps preserve the components for future reassembly. After removal, the panels and other parts can be packed efficiently for transportation, with minimal risk of damage due to the careful handling and straightforward disassembly methods. This efficient dismantling process not only extends the lifespan of the GRP tanks but also supports their reusability across different sites and projects, offering significant advantages for businesses that require flexible and reliable water storage solutions.

Packing and Preparation for Transport: Ensuring Safe and Efficient Relocation of GRP Panel Water Tanks

Once the dismantling of the GRP (Glass Reinforced Plastic) Panel Water Tank is complete, the next critical step is the meticulous packing and preparation of the panels and components for transport. This stage is essential to ensure that all parts arrive at the new location in excellent condition, ready for reassembly. The process begins with a thorough cleaning of each panel and component to remove any debris, dirt, or residual water that might have accumulated during the dismantling phase. This step is crucial for preventing potential damage or corrosion during transit and ensures that the panels are in the best possible condition for their next use.

After cleaning, each panel is carefully wrapped in protective materials such as bubble wrap or padded blankets. This cushioning layer protects the panels from scratches, dents, and other physical damage that could occur during transportation. The wrapped panels are then meticulously stacked onto pallets, arranged in a manner that ensures stability and minimizes movement during transit. Straps or bands are used to secure the panels to the pallets, providing additional stability and preventing any shifting that could cause damage.

In addition to the panels, all accessories, such as fasteners, gaskets, and sealants, are collected, boxed, and labeled. Each box is clearly marked with its contents and any necessary handling instructions to facilitate easy identification and reassembly at the new location. Detailed packing lists are created, which include a comprehensive inventory of all components and accessories, along with instructions for reassembly. This documentation is vital for ensuring that nothing is overlooked and that the reassembly process can proceed smoothly and efficiently. By organizing the components and accessories in this way, businesses can avoid delays and ensure that everything needed for reassembly is available and in good condition.

Effective Strategies for Transporting Dismantled GRP Water Tanks

Transporting dismantled GRP (Glass Reinforced Plastic) tanks is a highly efficient process thanks to their modular design and lightweight structure. The tanks are broken down into individual panels, which can be transported using a range of methods depending on the distance and location of the new site. For short-distance moves or urban settings, standard trucks and flatbed trailers are typically used. These vehicles are ideal for handling the panels and can navigate roads and highways without significant logistical challenges.

For longer distances or remote locations, alternative methods such as flatbed trailers for overland transport or air freight for more distant or inaccessible areas may be employed. The lightweight nature of GRP panels reduces fuel costs and minimizes environmental impact, making these transportation options both economical and eco-friendly.

Moreover, the modular design of GRP tanks facilitates efficient loading and unloading, as the panels are organized into stacks on pallets and secured with straps or bands. This design reduces the need for specialized heavy lifting equipment and lowers the risk of damage during transport. Detailed planning is essential for successful transportation, especially for international relocations or complex logistics, involving route selection, regulatory compliance, and transportation coordination. By leveraging the GRP tanks' modular features and exploring various transportation methods, businesses can ensure that the relocation process is both cost-effective and reliable, achieving timely and safe delivery to the new location.

Re-Assembly at the New Location: Ensuring Longevity and Functionality for GRP Water Tanks

Reassembling a GRP (Glass Reinforced Plastic) water tank at the new location is a meticulous process that ensures the tank's durability and functionality. The first step in this procedure involves carefully aligning the individual panels according to the original design specifications. Each panel is positioned and secured in place using the original fasteners, which are typically bolts and nuts, ensuring that all connections are firm and properly aligned. This careful alignment is crucial for achieving a stable structure that can withstand the pressure of water and environmental conditions. Gaskets and sealants are then applied at the joints between the panels to create a watertight seal. These components are essential for preventing leaks and ensuring the tank’s structural integrity. The reassembly process is not just about putting the pieces back together; it involves checking each joint for proper fit and sealing to maintain the tank’s performance over time.

Once the panels are aligned and secured, the flexibility of the GRP panel system allows for adjustments in size and configuration to meet the specific needs of the new site. This adaptability is one of the key advantages of GRP water tanks, enabling modifications to the tank’s dimensions or shape as required. After the panels are assembled and the sealants are applied, the tank undergoes a thorough inspection to ensure that all connections are secure and that there are no potential points of failure. This inspection includes checking for leaks and verifying that the sealant has been properly applied. Proper reassembly not only extends the tank’s service life but also ensures that it functions efficiently and reliably. By following these detailed procedures, the GRP tank can continue to serve its intended purpose effectively at the new location, providing a durable and flexible solution for water storage needs.

Advantages of Relocatability for GRP Panel Water Tanks

The relocatability of GRP (Glass Reinforced Plastic) panel water tanks provides a range of significant advantages that make them an excellent choice for diverse water storage needs. One of the primary benefits is cost-effectiveness. The modular design of GRP tanks allows them to be disassembled, transported, and reassembled at a new location, which can dramatically reduce the need for purchasing multiple tanks for different sites or projects. Instead of investing in new tanks for every new location, businesses can relocate a single GRP tank as needed, which lowers overall investment costs and offers a flexible solution for varying water storage requirements.

Another key advantage is adaptability. GRP panel water tanks can be easily expanded or reduced in size to meet the changing demands of the site. This flexibility is particularly useful for projects where water storage needs may fluctuate over time. By adding or removing panels, the tank's capacity can be adjusted to accommodate more or less water, providing a customizable solution that can evolve with the project's requirements. This adaptability not only helps manage costs but also ensures that the tank can meet future needs without requiring a complete replacement.

In addition to cost and adaptability, reduced environmental impact is a major benefit of the relocatability of GRP tanks. By reusing and relocating the same tank, there is less waste generated compared to the disposal of old tanks and the production of new ones. This approach also minimizes the carbon footprint associated with manufacturing, transporting, and disposing of tanks. The environmental benefits are further enhanced by the GRP tanks’ long service life and durability, which contribute to a more sustainable solution for water storage.

Minimal downtime is another advantage offered by the relocatability of GRP tanks. The efficient dismantling and reassembly processes are designed to be quick and straightforward, which minimizes operational disruptions during the relocation. Skilled teams can complete the disassembly, transport, and reassembly tasks in a timely manner, ensuring that water storage needs are met with minimal interruption to services.

Finally, the long-term investment potential of GRP panel water tanks is a significant advantage. The durable construction of GRP panels ensures a long service life, which translates into a reliable and cost-effective solution for water storage over many years. The combination of durability, low maintenance requirements, and the ability to relocate the tank to different sites makes GRP tanks a smart investment for businesses seeking a flexible and long-lasting water storage solution.

Detailed Use Cases for GRP Panel Water Tanks

GRP (Glass Reinforced Plastic) panel water tanks offer versatile solutions for a variety of applications across different sectors. Each use case highlights the tank's adaptability, efficiency, and reliability in meeting specific water storage needs. Here’s a detailed look at the diverse applications where GRP tanks prove to be invaluable:

Industrial Applications

In industrial settings, GRP panel water tanks are an essential component for managing water resources through different stages of production and operational processes. Their modular and relocatable nature makes them ideal for dynamic production phases, where water storage requirements can fluctuate based on production schedules, maintenance needs, or facility expansions. For instance, a manufacturing plant might need to scale up its water storage capacity during peak production periods and downsize during off-peak times. GRP tanks can be easily reconfigured to adjust to these changing demands, offering a cost-effective and flexible solution for industrial water management. Additionally, their durability and resistance to corrosion make them suitable for storing a variety of liquids used in industrial processes, from water to chemical solutions.

Military Bases

On military bases, GRP panel water tanks provide critical support for logistics and operational flexibility. Military operations often require quick deployment and reconfiguration of resources to meet evolving strategic needs. GRP tanks are well-suited for these scenarios due to their ease of assembly and disassembly, which allows for efficient relocation between different base locations or forward operating positions. Whether for storing potable water for personnel or for managing water resources for various base operations, these tanks offer a reliable and flexible solution. Their modular design supports rapid setup and takedown, ensuring that water storage solutions can adapt to the ever-changing demands of military logistics.

Oil and Gas Industry

In the oil and gas industry, GRP panel water tanks serve a crucial role in supporting shifting drilling operations. The nature of oil and gas exploration often involves moving equipment and resources between different drilling sites. GRP tanks offer the advantage of being portable and modular, which means they can be transported to new locations as drilling sites move from one area to another. This flexibility is essential for managing water resources at remote or temporary drilling sites, where reliable and adaptable storage solutions are required. Additionally, the tanks' resistance to harsh environmental conditions and their easy reconfiguration make them suitable for the demanding and dynamic environments typical of oil and gas operations.

Airports

At airports, GRP panel water tanks are invaluable for scaling water storage solutions in line with growing infrastructure needs. Airports often experience fluctuating water demands due to varying passenger volumes, seasonal changes, and ongoing expansion projects. GRP tanks offer a scalable solution that can be expanded or reduced based on current and future water storage requirements. For example, as an airport undergoes expansion to accommodate more passengers or new facilities, additional GRP tanks can be added to meet increased water demands. Their modular nature also supports efficient management of water resources across different airport functions, such as for maintenance, emergency response, or facility operations.

Conclusion

GRP (Glass Reinforced Plastic) panel water tanks stand out as the premier choice for businesses seeking flexible, efficient, and sustainable water storage solutions. Their unique design offers unparalleled flexibility, allowing for easy expansion, reduction, or relocation based on evolving needs. This adaptability is particularly valuable for industries and organizations with fluctuating water requirements, from manufacturing plants and military bases to oil and gas operations and airports. The modular nature of GRP tanks means they can be dismantled, packed, and transported with relative ease, facilitating smooth transitions between locations or adapting to new demands without the need for significant investment in new infrastructure. Contact Solico Tanks for all your water storage solution needs.!

#business#grp water tanks#water tank#tanks#water industry#watertreatment#construction#water storage tanks#architecture#water treatment

1 note

·

View note

Text

youtube

Learn more about GRP sectional water tanks, and find your perfect water storage solution!

Also you can visit our website; https://www.solicotanks.com

#grp water tanks#business#water tank#water industry#water storage tanks#watertreatment#construction#tanks#architecture#Youtube

1 note

·

View note

Text

The panel-based design of GRP panel tanks offers several advantages in terms of palletizing and transportation efficiency. Due to their modular nature, these tanks can be easily disassembled into flat panels, which significantly simplifies the palletizing process. This means that the tank components can be stacked neatly onto pallets for transportation, maximizing space utilization and minimizing the need for additional packaging materials.

Additionally, the ability to flat pack the tank components allows for significant space savings during transportation. When compared to shipping fully assembled tanks, flat packing can reduce the volume required for shipment by up to 90%. This not only lowers shipping costs but also speeds up the transportation process as more tanks can be transported in a single shipment.

Furthermore, flat packing reduces the amount of storage space required for both the tank components and the finished tanks. This is particularly beneficial for storage facilities with limited space, as it allows for more efficient use of available storage areas.

Moreover, the ease of assembly of flat-packed tanks also reduces the need for labor during installation. With simplified assembly processes, installation times are decreased, resulting in quicker implementation of the tanks on-site.

Overall, the panel-based design of GRP panel tanks offers significant financial benefits through reduced shipping costs, minimized storage requirements, and streamlined labor processes, making them a highly efficient choice for fluid storage solutions.

Contact Solico Tanks for all your fluid storage solution needs.!

#tanks#water tank#grp water tanks#business#water industry#water storage tanks#construction#watertreatment#GRP panel tank#GRP modular tanks#GRP sectional water tanks

1 note

·

View note

Text

Engineering Excellence in GRP Panel Tanks

One of the ingenious engineering features incorporated into GRP panel tanks lies in the design of the bottom panels. These panels are meticulously crafted with a convex shape, a strategic engineering choice aimed at optimizing the tank's performance under varying water pressures.