#1 jaw crusher machines

Text

KV Metal Works design manufacture advanced Single Toggle Jaw Crusher based on modern technology They are highly sophisticated machine, produce maximum output

#single toggle jaw crusher#double toggle jaw crusher#best jaw crusher#best jaw crusher machine#jawcrushermanufacturer#jaw crusher machine manufacturer#best jaw crusher machine in indore#1 jaw crusher machines#jaw crusher manufacturer#1doubletogglejawcrusheratbestprice#1singletogglejawcrusheratbestprice#1stonecrushermachinemanufacturer#singletogglejawcrusherinIndore#bestjawcrushermachineinIndore#1jawcrushermachinesinIndore#buybeststonecrusherplant#IndoreJawcrushermachinemanufacturer

0 notes

Text

Comprehensive Guide to Crusher Parts

Crushers play a crucial role in mining, quarrying, and recycling operations by reducing large rocks, ore, and other materials into smaller, more manageable sizes. To maintain optimal performance and reliability, it’s important to understand the various components that make up these machines and their unique functions. This guide provides an in-depth overview of everything you need to know about crusher parts.

1. Frame or Housing

The frame or housing is the structural backbone of the crusher parts for sale. It provides support for all the other components and ensures they are properly aligned. The frame must be sturdy and durable to withstand the heavy loads and vibrations generated during the crushing process.

2. Jaw or Rotor

The jaw or rotor is the crusher part Canada that actually performs the crushing action. In jaw crushers, two opposing jaws (fixed and movable) work together to compress and break the material. In rotary crushers, a rotor with attached hammers or teeth rotates rapidly, impacting the material and causing it to fracture.

3. Crushing Chamber

The crushing chamber is the enclosed space where the crushing action occurs. It is designed to contain the material to be crushed and allow it to be gradually reduced in size as it passes through the machine. The chamber may be lined with wear-resistant materials to extend its lifespan.

4. Feed Mechanism

The feed mechanism is responsible for delivering the material to the crushing chamber. It may consist of a conveyor belt, hopper, or vibrating feeder. The feed mechanism must be able to handle the volume and type of material being crushed while ensuring a consistent and controlled feed rate.

5. Discharge Mechanism

Once the material has been crushed to the desired size, it needs to be discharged from the crusher. The discharge mechanism may consist of a conveyor belt, chute, or other device that transports the crushed material away from the machine.

6. Drive System

The drive system provides the power to operate the crusher. It may include an electric motor, diesel engine, or hydraulic motor. The drive system must be powerful enough to generate the required torque and speed to effectively crush the material.

7. Lubrication System

Proper lubrication is crucial for ensuring the smooth and efficient operation of a crusher. The lubrication system ensures that all moving crusher parts for sale Canada are adequately lubricated to reduce friction, wear, and heat generation.

8. Safety Features

Crushers must be equipped with safety features to protect operators and equipment from potential hazards. These features may include guards to restrict access to dangerous areas, emergency stop buttons, and sensors to detect overloads or malfunctions.

In conclusion, crusher parts Canada play a vital role in ensuring the efficient and reliable operation of crushing equipment. Understanding the function and importance of each part is crucial for maintaining and optimizing the performance of your crusher. Regular maintenance and timely replacement of worn-out parts can extend the lifespan of your crusher and ensure it continues to deliver the desired results.

0 notes

Text

Comprehensive Guide to Essential Crusher and Equipment Parts

In the heavy machinery industry, maintaining the efficiency and longevity of equipment is paramount. The following is a detailed guide on various crucial parts for crushers and other heavy machinery, which are essential for optimal performance. This guide will also highlight the significance of using high-quality parts to ensure durability and productivity.

Crusher Parts

1. Cone Crusher Parts

Cone crushers are pivotal in mining, aggregate production, and mineral processing industries. Key components include:

- **Mantle and Concave:** Essential for the crushing process, ensuring material is broken down efficiently.

- **Eccentric Assembly:** Provides the gyratory motion needed for crushing.

- **Main Frame and Adjustment Ring:** Support and adjust the machine's output size.

2. Jaw Crusher Parts

Jaw crushers are crucial for primary crushing in mining and construction. Important parts include:

- **Jaw Plates:** Made from manganese steel, these parts crush material.

- **Toggle Plates:** Provide safety and are adjustable for controlling output size.

- **Pitman and Flywheel:** Ensure motion and balance of the crusher.

3. Impactor Blow Bars

Used in impact crushers, blow bars crush material upon impact. They are typically made from high-chromium or manganese steel for durability.

4. Vertical Roller Mills Roller or Tire

In vertical roller mills, rollers or tires are essential for grinding materials. High-quality, wear-resistant materials ensure longevity and efficiency.

5. Hammer Mills Hammers

Hammers in hammer mills are used for grinding and shredding materials. They must be durable to withstand high-impact operations.

6. Wear Blocks

Wear blocks are protective components used in various machinery to prevent wear and tear, extending the life of the equipment.

7. Cutting Edge

Cutting edges are critical for machinery used in excavation and material handling, providing precision and durability.

8. Storage Shelter

Storage shelters are used to protect equipment from environmental elements, ensuring they remain in good condition.

9. Stretch Hood Tube

Stretch hood tubes are used for packaging and securing products during transport and storage, providing protection and stability.

10. Crusher Parts

A broad category that includes various essential components for different types of crushers, ensuring their proper function and longevity.

11. Excavator Bucket Teeth

Bucket teeth are used on excavators for digging and material handling. They must be tough and wear-resistant to handle harsh conditions.

12. Skid Steer Loader Parts

These parts include attachments and components that enhance the versatility and functionality of skid steer loaders.

13. Equipment Attachment

Attachments are used to enhance the capability of machinery, allowing them to perform a variety of tasks efficiently.

Importance of High-Quality Parts

Using high-quality parts for crushers and heavy machinery is crucial for several reasons:

- **Durability:** Ensures parts withstand harsh operating conditions and reduce the frequency of replacements.

- **Efficiency:** High-quality parts improve machine performance, leading to higher productivity.

- **Cost-Effectiveness:** Although high-quality parts may have a higher upfront cost, their longevity and performance result in lower long-term costs.

- **Safety:** Reliable parts ensure the safe operation of machinery, protecting operators and reducing the risk of accidents.

Maintaining heavy machinery and crushers requires using durable and efficient parts. From cone and jaw crusher parts to attachments and wear blocks, each component plays a critical role in the machine's performance and longevity. Investing in high-quality parts ensures that your machinery operates efficiently, safely, and cost-effectively, ultimately enhancing productivity and profitability in various industries, particularly in Canada's resource-rich sectors.

For more information on sourcing premium parts for your crushers and heavy machinery, explore the extensive range offered by reputable suppliers to keep your equipment running at its best.

0 notes

Text

Melting & Pouring

1000 KW dual track with 2 Nos of 2000 Kg Crucible.

175 KW single track 2 Nos of 300 Kg Crucible

Bottom Pouring Ladles - 2000 Kgs & 1500 Kgs of 2 Nos each.

Lip Pouring Ladles – 1000 kgs 2 Nos, 2000 Kgs 4 Nos, 1500 Kgs 1 No, 300 Kgs 2 Nos each.

0 notes

Text

From Quarry to Construction Site – The Journey of Sand and Gravel

When we think about construction jobs, towering skyscrapers, sturdy bridges, and well-paved roads often come to mind. However, there's a crucial element in the construction industry that often goes unnoticed but plays an indispensable role in bringing these projects to life – sand and gravel. These humble materials are the unsung heroes of the construction world, and their journey from quarry to construction site is a fascinating process that deserves our attention.

The Quarry: Where It All Begins

The journey of sand and gravel starts at the heart of the operation – the quarry. Quarries are massive open-pit mines or excavation sites where these essential construction materials are extracted from the Earth. These sites can vary in size from small local operations to sprawling complexes that span acres of land.

At the quarry, heavy machinery like bulldozers, excavators, and crushers come to life. Bulldozers are responsible for stripping away the topsoil and vegetation to expose the valuable deposits below. Then, excavators dig deep into the Earth, scooping up vast amounts of sand and gravel. These materials are then transported to the crushers.

Crushing It: Transforming Raw Materials

Once the sand and gravel have been excavated from the quarry, the next step in their journey is the crushing process. Crushers are colossal machines equipped with powerful jaws or hammers that break down raw materials into smaller, more manageable sizes.

Crushing serves a critical purpose in the construction industry. It not only reduces the size of the materials but also ensures uniformity in their composition. The crushed sand and gravel are sorted into various grades based on size, quality, and intended use.

Washing Away Impurities

Before the sand and gravel can be used in construction, they undergo another essential process – washing. This step is crucial for removing impurities such as clay, silt, and organic matter. These impurities can weaken the final product and compromise the structural integrity of construction projects.

Washing equipment typically uses water to separate the impurities from the valuable sand and gravel. This results in cleaner and more reliable materials ready for use in construction jobs. Once the washing process is complete, the materials are sorted into different categories based on their specific applications.

Storage and Transportation

After washing, the sand and gravel are stored in large stockpiles at the quarry. These stockpiles can be massive, resembling small mountains of materials waiting to be transported to construction sites. The storage area plays a crucial role in ensuring a steady supply of materials to meet the demands of the construction industry.

Transportation is another critical aspect of the journey. Sand and gravel must be efficiently transported from the quarry to construction sites, which can sometimes be hundreds of miles away. Various methods are used, including trucks, barges, and railroads, depending on the location and infrastructure.

At the Construction Site: Where Sand and Gravel Shine

Once the sand and gravel have completed their journey from the quarry to the construction site, they truly shine in the world of construction. These materials are versatile and find applications in a wide range of projects.

1. Concrete Production: Sand and gravel are essential ingredients in concrete, one of the most fundamental construction materials. The mixture of cement, sand, gravel, and water forms the backbone of countless buildings, bridges, and roads.

2. Road Construction: Gravel is commonly used as a base material for road construction. Its excellent drainage properties and ability to provide a stable foundation make it ideal for supporting heavy traffic loads.

3. Landscaping: Sand and gravel are also used in landscaping projects. They can create pathways, driveways, and decorative features in gardens and outdoor spaces.

4. Foundation Work: Sand is often used as a bedding material for laying foundations. It provides a level and stable surface for building structures.

5. Erosion Control: Gravel can be used for erosion control measures, such as building retaining walls or stabilizing slopes.

6. Filtration: Sand is used in water treatment and filtration systems to remove impurities and ensure clean, safe drinking water.

7. Sports Fields: Sand is used in the construction of sports fields, particularly in golf course bunkers and beach volleyball courts.

8. Glass Production: Sand is a primary component in the production of glass, another essential construction material.

The Environmental Considerations

While the journey of sand and gravel is crucial for the construction industry, it's essential to consider the environmental impact of these operations. Quarrying can have significant ecological consequences, including habitat disruption, soil erosion, and water pollution. Responsible quarrying practices, land reclamation, and sustainable resource management are essential to minimize these negative effects.

In recent years, there has been a growing awareness of the need for sustainable sourcing of construction materials. Many quarries now adhere to strict environmental regulations and implement best practices to minimize their environmental footprint. Reclamation efforts aim to restore quarry sites to their natural state once mining operations have concluded, ensuring that the land can be repurposed for other uses or returned to its natural state.

Conclusion: The Unsung Heroes

In the grand symphony of construction, it's easy to overlook the unsung heroes of the industry – sand and gravel. Their journey from the quarry to the construction site is a remarkable process that underpins every building, road, and infrastructure project we depend on.

As we marvel at the towering skyscrapers and the intricate web of highways that connect our cities, let's not forget the humble materials that make it all possible. Sand and gravel, with their journey from quarry to construction site, truly deserve our appreciation for their vital role in shaping our built environment.

In conclusion, the construction industry relies on the tireless work of sand and gravel, from their extraction in quarries to their transformation into essential construction materials. These materials may not always be in the spotlight, but their journey is a testament to the intricate processes that drive the world of construction jobs forward. As we look to the future, it's essential to continue developing sustainable practices that ensure a steady supply of sand and gravel while safeguarding our environment for generations to come.

0 notes

Text

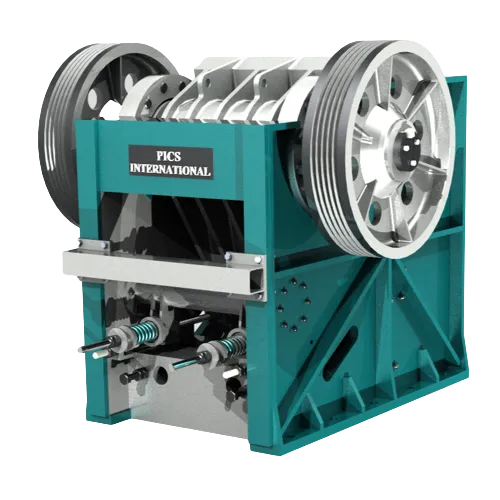

Pics International

We Engineer, We Manufacture,

We Deliver..... Worldwide

Picson Construction Equipments Pvt. Ltd.

PICS INTERNATIONAL is a leading global engineering and manufacturing unit engaged in supplying cutting-edge crushing and screening equipment for applications in mining, quarrying, and infrastructure projects, Construction and Demolition and waste recycling.

We have more than three decades of experience in supplying a robust range of crushing, screening and washing equipment, including varying sizes of stationary and mobile jaw, cone and impact crushers; heavy duty screens and mobile plants for recycling construction and demolition waste. These high-quality industrial equipments ensures a fine and precise performance promises an end result which is nothing less than the best.

Our Quality Products

1.CRUSHER

2.IMPACTORS

3.WASHING SYSYTEM

4.SCREENS

5.FEEDERS

6.MIXING

OUR PRODUCTS

1.Single Toggle Jaw Crusher

2 Double Toggle Jaw Crusher

3 Cone Crusher HC Series

4 Cone Crusher GC Series

Our Products

Crusher

Sand Making Machine

C & D Waste Recycling Plant

Washing System

Semi Mobile Series

Applications

Quarrying & Aggregate

Sand Processing

C & D Waste Recycling

Mining

Industrial Sand

Supports

Parts

Service

Operator Training

Dealer Portal

Manuals

Get In Touch

986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat, India.

9081777945

https://www.picsinternational.com/

#Stone Crusher#Cone Crusher#Jaw Crusher#C&D Waste#C&D Waste Recycling#C&D Waste Recycling Plant#C&D Waste Recycling Plant Manufacturer#C&D Waste Recycling Plant Manufacturer in India#Construction & Demolition Waste Recycling#Construction & Demolition Waste#Stone Crusher Manufacturers

0 notes

Text

Hydraulic Generator and Bucket Crusher from DCS Techno

Bucket Crusher from DCS Techno

DCS Techno is a customer Acquainted company. We supply Bucket Crusher fitting for all major brands on request. We are a truly voila developing organization with basically inventive mates with a charge to lead the change into a more computerized and reasonable one from now on. Inside mining and development, we have accumulated plan insight and devout visitors in many tasks in India as well as in import demands. all things considered, mines, thruways, if you work in a pursuit, We have a result for you. We cover areas from mining, development, brand, concrete, structure, Pharma, Emergency clinic, and recovering industriousness.

We have items and assaults that can take care of the enterprising nature referenced. DCS Techno Offers a Bucket Crusher with a flexible, a provident, and effective result for Crushing and webbing conditions at Construction Jobsites, Stone chases, and annihilation operations.

Bucket crushers are an innovative answer to Crushing conditions on moment’s Worksites. Using the bucket capper all types of inert obliteration material can be crushed and re–used on point. During the Crushing Process, the bucket capper is deposited vertically so that the racked material can be released.

Ideal for the right-on-track pulverizing of idle stuff and the first of its sort to be presented on demand, the MB Smasher Can is a piece of outfit that works by taking advantage of the hydraulic system of the excavators, descent haul, haul, and backhoe cargo to which it is fitted. It has multitudinous areas of operations from erecting demolitions in general to the requalification of former artificial and communal areas to the processing of excavation paraphernalia, from the earth movement sector to road factory, from chases to mines, from environmental recovery to operations on rocky soil.

1. A Smasher container is a financially savvy result for transforming demolition flotsam and jetsam and point squander into useable material, excepting pulling and removal costs.

2. The capper bucket eliminates the need to transport, hire or buy and maintain separate mobile crushing outfits.

3. Crushes a wide range of sizes and types of material, including slipup, concrete, and rock. Indeed, material with buttressing bars can be crushed so that the brand can be recovered for scrap. This point is not available with other mobile crushers.

4. Heavy-duty flywheel storage energy optimizes the machine’s hydraulic power and generates a sustained crushing action for the topmost productivity.

Right-on-track cement and rock pulverizing made simple BC can smashers are an imaginative solution to squashing conditions on second's worksites. Using a carriage-mounted bucket capper, all types of inert annihilation material can be crushed and reused on-point. This process requires lower mechanical outfit, lower transportation, and dumpsite cost, and only one motorist handles the annihilation attachment as well as the bucket capper.

Advantages Viability Utilizing a tractor-mounted squashing can or connections has various benefits over utilizing a versatile smaller than usual capper or jaw capper. As it needed one machine lower space demanded on point lower transport Lower energy consumption Labor – no need for the precious and hard-to-find labor force to supervise capper pivotal risks Machinery guarding Clearing Blocked or Stalled crushers Slips and trips Transport – in encountering excavators loading the capper ensure rovers and obstructions are barred from the bucket operating arc.

A properly designed mobile crushing operation should not need any person to be present on the capper access platform during normal crushing operations. With a bucket capper, there is no need for anyone other than the excavator motorist. There is no haul. still, utmost blockages can be dealt with easily, by flipping the bucket to empty, I fun- crushable material- wood or substance – finds its way into the feed pile.

Dynaset- Powered by Hydraulics

Dynaset, a Finnish Organization water-powered outfit changes over the water-driven force of versatile service into power, high-pressure water, packed air, attraction power, vibration, and power boost. Dynaset innovation expands the efficiency of portable service from little vehicles to weighty machines by adding new capabilities with the water-powered outfit. Water-driven makers produce top-notch power utilizing the power from the base machine's pressure-driven Framework. The Pressure driven maker is turned on by opening the water-powered oil painting transition to it.

A hydraulic creator is a quiet handling creator that doesn't need a fresh pump or motor. Introducing a Water driven maker into a portable machine builds the vehicle's efficiency and total assets. There could be no further requirement for hauling large separate makers to the work Spots, Water powered maker is consistently ready and prepared for use. By introducing the water-driven designer to the portable machine the activity pace of the machine increment and there is a lower need for various machines on the worksite.

Crucial Benefits Always ready for use Saves time, spaces, and coffers further continuity Easy installation on all hydraulic systems. Why Hydraulic Systems Are Considered Superior Numerous systems moments calculate on hydraulics to perform different tasks. Unlike mechanical systems which need solid factors to move other factors, hydraulics relies on fluids and the force generated by them.

Pros of hydraulic systems

Fluids flow easily and this point is applied to systems and heavy outfits. The force generated by hydraulics produces veritably smooth movement which is inestimable in operations where jerky movements cannot be permitted. An alternate point of such a system is cargo-bearing capacity. Unlike curvaceous systems that calculate on compressed gas, hydraulics is suitable to bear much heavier weights as it's incompressible.

It does it easily too, commodity curvaceous systems cannot achieve this as the air pressure alters with cylinder movement and cargo changes. also, the quantum of force needed to induce the same produced by a hydraulic system is much further.

This can restate into advanced charges as larger and more important factors carry heftier price markers. In terms of energy, hydraulics uses a lot lower when compared to others like curvaceous systems. Heat loss is also lower which means no important energy is used to induce the required force.

Since similar systems are generally used in large-scale operations in settings like manufactories and shops, it becomes important to cut corners without compromising quality and product volume. Hydraulics allows this while combining all the other benefits mentioned over.

Cons of hydraulics

While there are a few advantages to utilizing power through pressure there are likewise cons. This should not interfere but should rather give us an understanding of what to anticipate. Since hydraulics relies on fluids, there is a chance of leakage. Not only does this reduce the effectiveness and power of the system but it causes a mess. Since numerous systems and factors bear clean surroundings and surroundings, there is a chance that the oohing fluid may beget damage and fire hazards.

Bear in mind, still, that since this is a known fact, ways are always taken to insure that accidents do not do. The hydraulic systems themselves are designed in such a way that they pose little peril to you and to factors indeed during leakage. The liquid utilized in these frameworks should be perfect as pollutants can clog pipes. still, it is possible that adulterants can enter in which case efficacity can be reduced. The terrain or setting must, thus, following strict aseptic norms during all points of the manufacturing process.

Like all systems, hydraulics has its benefits and downsides. But at a time when big factors are beginning to be edged out in favour of lower and more effective systems, hydraulics trumps. Curvaceous and electrical-grounded machines and factors work well too but they bear an advanced source of power or larger pumps to induce the same quantum of force given out by a hydraulic system. For manufacturers and druggies taking similar high affairs, it is further cost-effective to calculate hydraulics. product time is reduced as effectiveness maintains a high normal.

Hydraulic Cylinder - Operations, Parts, and Designs

A hydraulic cylinder or hydraulic motor is one of the many mechanical devices used in engineering vehicles. It makes use of pressurized hydraulic fluid in order to produce linear force or motion. In many instances, it serves purposes in power transfer. When it comes to choosing such a product, one must be able to investigate the configuration, operating specifications, materials of construction, and other features.

When it comes to the operation of hydraulic cylinders, one must be able to understand what transpires in the process. With the presence of different components in these products, proper functioning is obtained. The primary parts are the cylinder barrel, piston, and piston rod. Take note of the following facts about this industrial product.

More on activities and the various pieces of the pressure-driven chamber the chamber barrel is the region where the cylinder makes this way and that developments. This is the same part that is closed with the aid of the cap end. The piston rod comes out from the cylinder as it pushes to the cylinder head. The piston, on the other hand, is one that contains seals and sliding rings. It is responsible for dividing the cylinder into the rod end and the cap end. When hydraulic pressure is applied to the cylinder, linear motion is achieved. With the aid of the piston rod, the product may be attached to another object.

On its generator side, the water-driven siphon is found. The pump is tasked with bringing the right amount of oil into the bottom part of the cylinder.

The oil makes the piston rod move in an upward motion. Through this process, the oil goes back to its original basin or tank. Other parts of the cylinder are the seals, cushions, and cylinder bottom connections.

Designs for hydraulic cylinders

A hydraulic cylinder is designed in two different styles. The first one is known as the tie rod cylinder or the one that makes use of strengthened and threaded steel poles to interface the end covers to that of the chamber barrel. This is highly popular in factories. Popular types of such designs are small bore cylinders with the typical 4 tie rods and the large bore cylinders that often contain at least 16 tie rods to make them function properly.

In contrast with the tie rod design is the next design of the hydraulic cylinder known as the welded body cylinder. The barrel and the end caps are welded together while the ports are connected through the welding process into the cylinder barrel. These designs are highly advantageous in some equipment including bulldozers, excavators, and road graders for construction as well as forklift trucks and lift gates for material handling.

Hydraulic Systems and Their Use in Modern Operations

Water power is the utilization of fluid to prompt power. The liquid may be water, oil painting oil, esters, and indeed blood- our heart is like an introductory hydraulic system, pumping blood to blood vessels which in turn enable the body to serve. In modern operations, hydraulics plays a big part as the systems to which they're applied are more feathery, easily manoeuvrable, and suitable for handling unlooked-for and rapid-fire-fire-changing favas.

nearly every major operation relies on hydraulic systems. The genuinely simple protection contrasted with electrical and mechanical frameworks has made them essential at the time's popularity world. In construction large ministries analogous to earthmovers and cranes use hydraulic systems to lift and move weighty accoutrements. These machines are assigned with shifting truly heavyweight and though mechanical and electrical systems also work, the time and trouble taken to move booms, for illustration, would be extensively longer.

Hydraulic systems produce steady force to pickers and motors so work is fulfilled hastily and with lower room for error. Down from heavy ministry, hydraulic systems are applied to tools analogous to aphorisms, impact wrenches, and post-pullers. The clamour produced is lowered as is exhaust. In aviation, aviation sedulity utilizes hydraulic systems on an extensive scale.

Large aircraft use two or further systems to power factors like wheel chaparrals, windshield wipers, flaps, and weight doors among multitudinous others. Since the proper working of a hydraulic system depends on precise temperatures, heat, and zero fluid contamination, strict checks are made to ensure that all conditions are met and maintained. Consider the checks conducted former to take-off. Technicians and engineers examine and test all vital factors- not only hydraulic but electric and mechanical- so that aircraft do not stall, fly with no issues, and land fluently.

In manufacturing shops industriousness and factories produce massive volumes of products. You can well envision how significant power is requested to work the machines. Hydraulic systems deliver power to motors, gates, and pickers to enable the ministry to operate. The consistency they give means that processes that carry on with lower crimes and productivity is maintained. In automotive perhaps the most well-known use of hydraulics is in automotive sedulity.

multitudinous machine manufacturers have made hydraulic chaparrals standard as they have better deceleration power and modulation and handle heat well. Of course, they are more precious and must be maintained well as fluid contamination can hamper performance but the overall benefits overbalance the downsides. Another illustration is dump exchanges which use a movable bed to dispose of trash.

This development is made conceivable because of one or the support of water-driven chambers. In transport outfits like lifts and escalators make wide use of hydraulics. They do not need large motors to induce the required force and speed is still maintained if there is a leak or power shuts down. The lifts do come with their shortcomings in that leaks can develop but safety measures like installing PVC coverings around cylinders have made them much safer than ahead.

These are only numerous samples of what hydraulic systems are used for. There are numerous other operations that earn citations but listing all would fill a brochure. The under most line is that they are suitable to induce further force, enhance systems, and are feathery compared to other types of systems. The excrescencies they hold are currently being smoothed and deciding from how endless tasks compute on hydrodynamics, it is not probably going to be gradually eliminated at any point soon.

To know more information about Hydraulic Generator and Bucket Crusher Visit: dcstechno.com

Contact us:

Plot No 169, Road No.11,

Prashasan Nagar,

Jubilee Hills,

Hyderabad,

Telangana – 500096

+91-9849009875

0 notes

Text

Leading Manufacturer of gc vsi 75 vertical shaft impactor, gc vsi 300 vertical shaft impactor, gc vsi 200 vertical shaft impactor and gc vsi 100 vertical shaft impactor from Indore

#double toggle jaw crusher#jawcrushermanufacturer#single toggle jaw crusher#best jaw crusher machine#best jaw crusher#best jaw crusher machine in indore#1 jaw crusher manufacturer#jaw crusher machine manufacturer#jaw crusher manufacturer#1 jaw crusher machines

0 notes

Text

BDI Wear Parts: Your Trusted Source for High-Quality Crusher Components

Amid the demanding and competitive world of heavy-duty crushing equipment, BDI Wear Parts shines as a symbol of quality and dependability. As a top supplier of crusher parts, we serve the mining, quarrying, construction, and recycling industries, providing a wide range of components designed to improve the efficiency and longevity of crushing machinery.

Our Key Solutions: Complete Range of Crusher Components

1. Jaw Crusher Parts: Durability Combined with Precision

At the heart of our product portfolio are jaw crusher parts, essential for primary crushing applications. Our jaw plates, available in various profiles and materials including high-manganese steel, are engineered to withstand extreme compressive forces and abrasive wear. Precision-machined to ensure a seamless fit, these parts minimize downtime and optimize crushing efficiency. Our commitment to durability ensures that you can rely on BDI Wear Parts to keep your jaw crushers running smoothly for longer.

2. Cone Crusher Parts: Power in Simplicity

Moving further down the crushing line, our cone crusher parts represent the epitome of engineering excellence. From bowl liners and mantles to concaves and adjusting rings, every component is crafted from premium materials such as high-chrome iron and manganese steel. These parts are designed to balance wear resistance with cost-effectiveness, ensuring maximum production with minimal downtime. With BDI Wear Parts, you can count on precise fitment, enhanced performance, and a lower total cost of ownership.

3. Impact Crusher Parts: Versatility Meets Durability

For applications requiring high throughput and versatility, our impact crusher parts are the ultimate solution. Our blow bars, hammers, and impact plates are constructed from the toughest alloys available, withstanding the intense impacts and abrasive wear characteristic of impact crushing. By utilizing advanced heat treatment and surface finishing techniques, we enhance the durability of these crusher parts for sale, extending their service life and reducing the need for frequent replacements.

4. Cutting Edge Components: Leading the Way in Innovation

BDI Wear Parts is constantly pushing the boundaries of innovation with our cutting-edge components. Our cutting edges, designed for screen decks, conveyor belts, and other applications, incorporate advanced materials like tungsten carbide to improve wear resistance and performance. Whether you’re looking to increase the throughput of your screening system or prolong the life of your conveyor components, our cutting-edge products offer the perfect solution.

In-House Manufacturing & Streamlined Logistics: Your Edge in the Market

What sets BDI Wear Parts apart is our advanced in-house manufacturing and efficient logistics network. Equipped with state-of-the-art machinery and skilled technicians, our facilities ensure that every component meets the highest standards of quality and precision. Coupled with our optimized logistics system, we deliver parts swiftly to customers around the globe, reducing downtime and boosting operational efficiency.

Conclusion

In summary, BDI Wear Parts is the go-to source for premium crusher components that enhance the performance and longevity of your crushing equipment. From jaw crusher parts to cone crusher parts for sale Canada, impact parts, and cutting-edge components, our extensive product range caters to the diverse needs of the mining, quarrying, construction, and recycling industries. With our in-house manufacturing and streamlined logistics, we are dedicated to delivering the best solutions for your crushing needs. Choose BDI Wear Parts today and discover the impact that quality and reliability can have on your operations.

0 notes

Text

Essential Parts and Attachments for Heavy Machinery and Crushers

In the heavy machinery and mining industries, ensuring the efficiency and longevity of equipment is crucial. This guide provides an in-depth look at various essential parts and attachments, highlighting their functions and the importance of using high-quality components. This guide will also touch on the significance of these parts in the Canadian industry context.

Key Machinery Parts and Attachments

1. Slurry Pump

Slurry pumps are essential for transporting abrasive and corrosive slurry in mining, dredging, and mineral processing. High-quality slurry pumps are designed to withstand heavy wear and ensure efficient material handling.

2. Auto Shredder Parts

Auto shredders are used to reduce the size of scrap metal for recycling. Key parts include:

- **Hammer:** Used for breaking down materials.

- **Grates:** Help size the output material.

- **Anvils and Liners:** Protect the shredder from wear and tear.

3. Bucket Elevators

Bucket elevators are used for vertically lifting bulk materials. High-quality bucket elevators are essential for efficient material handling in industries such as agriculture and mining.

4. Ceramic Insert Blow Bars

Ceramic insert blow bars are used in impact crushers to improve wear resistance and extend the lifespan of the bars, providing a cost-effective solution for crushing abrasive materials.

5. Toolholder for Cold Milling

Toolholders are essential for holding cutting tools in cold milling machines. They must be durable and precisely engineered to ensure accurate and efficient milling operations.

6. Crusher Wear Parts

Wear parts for crushers include mantles, concaves, jaw plates, and blow bars. These parts must be made from high-quality materials to withstand the harsh conditions of crushing operations and ensure longevity.

7. Skid Steer Attachment

Attachments for skid steers, such as buckets, augers, and trenchers, enhance the machine's versatility. High-quality attachments ensure efficient performance in various applications, from construction to landscaping.

8. Wheel Loader Attachment

Attachments for wheel loaders, such as forks, grapples, and sweepers, increase the machine's functionality. Durable attachments are essential for handling heavy loads and performing various tasks efficiently.

9. Mini Skid Steer Attachment

Mini skid steers can be equipped with various attachments, including mini buckets, augers, and trenchers, to perform a wide range of tasks. High-quality mini attachments ensure efficient and versatile operations.

10. Mini Excavator Attachment

Mini excavators can be equipped with attachments like hydraulic hammers, thumbs, and compactors. Durable attachments enhance the machine's versatility and efficiency in construction and landscaping projects.

11. Ball Mill or SAG Mill Liners

Mill liners protect the mill shell from wear and transfer energy to the grinding charge. High-quality liners made from durable materials are crucial for efficient grinding operations in mining and mineral processing.

The Importance of High-Quality Parts

Using high-quality parts and attachments for crushers and heavy machinery is essential for several reasons:

- **Durability:** Ensures parts can withstand harsh operating conditions, reducing the frequency of replacements.

- **Efficiency:** High-quality parts improve machine performance, leading to higher productivity.

- **Cost-Effectiveness:** Though high-quality parts may have a higher initial cost, their longevity and performance result in lower long-term costs.

- **Safety:** Reliable parts ensure the safe operation of machinery, protecting operators and reducing the risk of accidents.

In the heavy machinery and mining industries, maintaining equipment with high-quality parts is crucial for efficiency, safety, and cost-effectiveness. From slurry pumps and auto shredder parts to ceramic insert blow bars and mini excavator attachments, each component plays a vital role in the machine's performance and longevity. In Canada, where industries like mining and construction are significant, investing in durable and efficient parts ensures the continued productivity and profitability of your operations.

For sourcing premium parts and attachments for your machinery, consider trusted suppliers who offer an extensive range of high-quality components designed to meet the rigorous demands of these industries.

0 notes

Text

Going back to Revolution, the House of Black stood tall over The Elite, and took the AEW World Trios Championships in an exciting, but heart-breaking night for fans of Kenny Omega and the Young Bucks, but a night that propelled The Fallen into near-untouchable status. Holding belts in six different wrestling promotions is a feat few other factions can hold, but it’s a current fact of The Fallen. The bad blood has spilled into MPW, as The Elite are collecting old friends for their inevitable collision course with The Fallen - but first, Omega finds himself locking horns with the once unbeatable Sardonyx. The Best Bout Machine versus the Savior, the former undefeated mysterious shadow of the cult versus a man with a whole lot of singles victories. Only one can win…

Going low, they slide around the canvas, trying to get a hold of the other, but remaining elusive, just out of grasp. Omega rolls around into a waistlock, and counters Sardonyx at every turn, trying to wrap his arms around her, keep her pinned in one spot. Grabbing her by the head, they’re brought back to their feet and to the ropes, They slowly pull apart, before Omega puts his finger trigger to Sardonyx’s head and pulls it, running the ropes, and knocking her down with a shoulder tackle! Only for Sardonyx to kip right back up! Omega looks annoyed, maybe even amused, before he runs the ropes. Sardonyx dropping down in front of him, only to blow past him with a cartwheel on the rebound, knocking Omega down with a leg trip, before Sardonyx drops onto her palms, switching from hand to hand before dropping a breaking dancing leg drop right across Omega’s throat! Kenny momentarily rolls to the floor, and as Sardonyx celebrates her minor victory, she gets up, and walks right into a knife edge chop! Sardonyx grimaces as Omega grabs his throat, shaking his head as he rolls out his jaw. Grabbing Sardonyx by the wrist, Omega shoves her back onto the ropes, and blasts her with another chop. Omega with an irish whip, wanting to hit that swinging double axe handle, but Sardonyx ducks under and nails him with a shoot kick, nearly knocking Kenny to his knees with that one!

Sardonyx hits another shoot kick, only to take a chop to the chest before Omega runs the ropes, and takes a roundhouse kick to the temple! Omega drops to the mat and rolls to the floor, Sardonyx watches him before looking at the ropes. Almost immediately Scarlett is banging on the apron, encouraging Sardonyx to run the ropes and fly, wanting to hit that Barrel Roll Tope - but nobody’s home! Sardonyx tries to stick the landing, but ends up crashing chest first into the barricade! Omega grabs her from behind, and slams an elbow into Sardonyx’s lower back, before lifting her up, and dumping her on the apron! Sardonyx lands on her lower back, and melts to the floor! Omega quickly gets her back inside the ring, but takes a moment to point to Scarlett, telling him to shoo, before Omega jumps into the ring. With a skip in his step, Omega bounces off the ropes, dropping Sardonyx with the Kotaro Crusher! Omega rolls her over to make the cover!

1… 2… Kickout!

Omega stands up and shakes it off, almost taking a light stroll around the ring, before he stomps on Sardonyx’s back. Trying to prevent Sardonyx from hitting the Nine of Swords, but she’s got plenty other tricks in her arsenal that Kenny needs to be careful to avoid, if she can turn things around. Kenny stays in control with firm stomps to the back, to the head, while Sardonyx struggles to sit up. Kenny swats his leg at the lower back, but it doesn’t deter her. Omega shakes his head before running the ropes, nailing her with a basement dropkick, and dropping into another pinning attempt.

1… 2 - Kickout!

Omega seems annoyed as Sardonyx throws the shoulder up a bit easier than the first time, and draws her to her feet, only to eat an uppercut. Sardonyx rears back her fist and nails him with a forearm smash, before slapping her leg against his chest, nailing him with another brutal shoot kick. Omega’s getting weaker as Sardonyx hits a snapmare, blasting him with a shoot kick across the spine! Omega’s back arches as Sardonyx throws another kick, aimed at the shoulder, and Omega springs to his feet, nailing her with a forearm. Sardonyx throws one back, and they trade heavy blows back and forth. Sardonyx has to shake one off, and responds with a forearm that spins Kenny around. He shakes his head and nails a gut kick, before shoving Sardonyx into the ropes with a front kick. Omega takes too long to charge, and Sardonyx lifts herself up and over the ropes, nailing Omega with a big kick to send him stumbling back. Off the top rope, Sardonyx wants a springboard Uppercut, but Omega counters with a V-Trigger against the spine! The point of Omega’s knee was driven into that lower back, and Sardonyx is compliant as Omega gets her across the shoulders….

“You can’t escape!”

Sardonyx is driven into the mat, and Omega springs up into the Moonsault, only to land on Sardonyx’s knees! She throws the knees up just in the nick of time, but it’s not enough to stop Omega from getting back to his feet. Omega with a hurricanrana, tossing Sardonyx, but she’s able to roll through and blast Omega with a bicycle kick! Omega once again finds his way out to the Fillmore Auditorium floor, as Sardonyx wants to keep the momentum going. Matt and Nick Jackson look on in concern for their friend, while Malakai Black and Scarlett Bordeaux loom in the background. Always ready to strike, the House of Black, but they won’t have to lift a finger as long as Sardonyx hits here. With Omega on the floor, Sardonyx goes to the top rope, but her risky intentions are thwarted as Omega knocks her down, dragging her to the apron. Omega wants to hit the One Winged Angel to the floor, but Sardonyx reverses, landing on the ropes inside the ring and wrapped her arm around his throat, trying to choke Omega out with a Dragon Sleeper! Completely illegal here, as the referee tries to warn her, but it doesn’t matter! Omega drags her over his shoulder! He has Sardonyx in the Tombstone position… but she slips, and Omega wraps his arms over her legs… and hits a Bastard Driver on the apron! Sardonyx’s dropped on her neck!

She’s gotta be feeling crunchy after that, and Omega desperately needs to capitalize. He has to roll to the floor just to get back to his feet, shoving Sardonyx under the ropes. He jumps to the top rope, measures her, before nailing a missile dropkick to the back of the head! But Omega isn’t done! He pulls her up AGAIN, lifting Sardonyx up, legs crossed, and delivers the Ai Shoudou! Sardonyx could be out, Omega covers!

1… 2… Kickout!

The House look antsy on the outside, but Sardonyx manages to stay alive in this matchup. It may not be for long, however, as Sardonyx has unknowingly put herself in the danger zone against the ropes. Omega pulls the trigger, runs the ropes, wanting to crush her with that V-Trigger - but Sardonyx moves out of the way, and Omega bounces off the ropes, into a snap Dragon suplex, only to land on his feet! Sardonyx doesn’t even get the chance to stand up before Omega plows through the back of her head with an impactful V Trigger! Sardonyx is on wobbly legs as Omega lifts her up by the tights, getting her in the electric chair. Scarlett Bordeaux jumps up on the apron, trying to distract the referee, as Sardonyx throws her legs back over his shoulder. Omega tries to fight her off, but Sardonyx doesn’t budge, and eventually Matt Jackson pulls Scarlett down, the two going at it verbally at ringside, while Omega drops Sardonyx down, and delivers the Croyt’s Wrath! Omega bridges into the cover!

1… 2… Kickout!

Sardonyx has had a few spots thus far, but most of this match has been coming up Kenny. A near certainty in most of Omega’s contests. There’s a reason he is the Best Bout Machine, and Sardonyx is finding that out the hard way.

Nothing has yet to come out of that head to head on the outside, but as tensions rise between the Bucks and the House, Sardonyx is seconds away from having her lights shut off for the night, as Omega delivers an explosive V Trigger! Catching her right under the chin, Sardonyx melts to the ropes, and Omega spins her back around, going for a double underhook. Somehow, Sardonyx is able to counter, but swings and misses, allowing Omega to run the ropes, taking her to the mat with a tornado DDT! Sardonyx is dropped on her head once again! Even if Omega doesn’t win this contest, Sardonyx may not make it to Darkness Falls!

With Sardonyx struggling to stand, Omega drops to his knees in the ring, the fans in Denver already clapping along for the Rise of the Terminator. Omega turns and runs the ropes, picking up a considerable amount of steam before he perfectly leaps over the ropes, nailing a Tope Con Hilo! Omega quickly throws her back inside the ring, trying to take advantage with another high risk move. Sardonyx, unsure of where she even is, manages to get her feet back under her and jump to the top rope, nailing Omega with a Superkick! She drops back to her feet, leaning against the ropes for support, as Omega holds himself from falling off the top rope, dazed from that powerful kick. Omega starts to slide, but Sardonyx gets under him, hooks him under the arms, and prying Omega off the ropes! Sardonyx uses the ropes as leverage to lift him up, planting him with a sitout Crucifix powerbomb!

1… 2… Kickout!

Omega throws the shoulder up at two!

Soon thereafter they’re both on their feet, Omega having to roll to the outside to find a vertical base, but he’s on spaghetti legs. Sardonyx is on spaghetti legs. Neither can barely stand, neither probably knows where they are right now,but Sardonyx still rushes across the ring and springboards, hitting the double rotation, before CRUSHING Omega with a Moonsault to the floor! Sardonyx taking high risk to new levels to earn her team some bragging points, and she looks to capitalize here, throwing Omega back in the ring. He stumbles to his feet, and Sardonyx tries another chance with that springboard Uppercut - only for Omega to pull her off the ropes! He switches her into an electric chair, but Sardonyx pierces his skull with sharp elbows, blocking the One Winged Angel with everything she has. Omega sets her back on her feet and Sardonyx unloads with a vicious flurry of palm strikes before finally dropping Omega with a roundhouse kick. Omega hits the mat hard, and Sardonyx kicks him onto his stomach and positions herself over her head. Pointing out her arms at either side, Sardonyx tilts her head back before hitting a backflip, scooping Omega up by the waist, and planting him with a German suplex! Sardonyx arches her hips into a bridge…

1…. 2…. Kickout!

Omega throws his body at two, forcing himself out of the pin attempt, and out of Sardonyx’s grasp. But she doesn’t let him go far before grabbing him, only for Omega to swing out, trying to hit a clothesline, but Sardonyx ducks under it and CRACKS him under the jaw with a bicycle knee strike! Omega is out on his feet as Sardonyx lifts him up, trying to get the Nine of Swords, but her back won’t let her hit it! Omega shoves her back, tries to hit the V Trigger, but Sardonyx has just enough time to throw her arms up to block. But Omega throws up a second knee, catching her right under the chin! Sardonyx melts into Omega’s arms, and he spins her around, trying to hit a Dragon suplex, but Sardonyx has just enough in her to block. Omega releases, only to throw himself at the back of her head, whipping his leg into the base of her skull! That wheel kick nearly takes Sardonyx out, and she leans against the turnbuckles. Using for support as Omega lines her up from across the ring. Exhaustion creeps in, but Omega is the king of digging down deep to find that second wind, and pulls the trigger on Sardonyx, crushing her against the turnbuckles with another V Trigger to the back of the head.

Sardonyx is dead weight as Kenny brings her up to the top rope, pushing her out onto the turnbuckle. Omega looks around him before climbing up, trying to watch out for the House, but Malakai creeps in beside him. Trying to sneak in a mist, but Nick is right there, the referee is right there, and Omega has to look out of the corner of his eye as he grabs both of Sardonyx’s arms for a Dragon suplex - but off the split second distraction, Sardonyx is able to slide out right under him! Kenny can barely react before Sardonyx pries him off the ropes, holding him up in a powerbomb position… before dropping him with a Powerbomb Backbreaker! What a rough landing for Kenny, but Sardonyx hurt her own back in the process, and can’t capitalize!

With a dead look on the face of Sardonyx, Kenny intense as ever, they charge at each other, nailing duel clotheslines! Colliding against one another, they then throw duel bicycle knee strikes, nailing him on point! They’re both stumbled, but Omega changes it up, kicking Sardonyx’s leg as she tries to swing, before CLOBBERING her with a V Trigger! Sardonyx is OUT as Omega grabs her for the Dragon suplex, only for Sardonyx to slip out, nailing a snap Dragon suplex of her own! Omega still rolls through, firing himself up, but Sardonyx ducks and uses his momentum to plant him with a Saito suplex! Sardonyx snaps her hips with an intensity that could duel Omega’s own, but nobody does it quite like the Cleaner. The Cleaner is reeling, and Sardonyx could be tasting victory sooner rather than later as she bounces off the ropes, turning Kenny inside out with a Busaiku knee strike!

Both wrestlers are down for the moment. The Auditorium and the Young Bucks rooting Kenny back into the fight, while Malakai hangs low, leaning against the apron and talking to Sardonyx. Malakai is Sardonyx’s mentor, the person who brought her to this side of the globe, the person who recruited her into The Fallen ,and she hangs onto every word. Sardonyx is the first to her feet, and she grabs Omega, hauling him to the middle of the ring. Picking Omega up, Sardonyx switches from a vertical suplex, and delivers a Suplex Piledriver in the middle of the ring! Omega’s folded up!

1… 2… KICKOUT!

Every time Kenny Omega steps into the ring, he always amazes, but nothing can be taken away from Sardonyx tonight. She has fought tooth and nail, with or without The Fallen, but the whole venue is shaking for Omega. Sardonyx is the one standing tall, however, and continues to do so as she grabs both of Kenny’s wrists, forcing him to sit up and look her in the eye before she swings her legs, blasting him over and over again on the chest, before she pivots, catching him with a Buzzsaw, and lifting him right up, planting Omega with a Northern Lights Bomb! Sardonyx covers!

1… 2… Kickout!

Still not enough! Sardonyx is starting to wonder what it’s gonna take to end this, as Hell on Earth starts to replay in her mind. The worst loss, the worst night, of Sardonyx’s career, and it took her a long time to return from that dark place. Despite a few fluke losses, Sardonyx has gotten back into her groove, and she doesn’t want to end it at the hands of Kenny Omega. If that means she has to eradicate him from this plane of existence, then so be it.

Back on their feet, Sardonyx throws the first shot, nailing him with an elbow smash, but Omega comes back with one of his own. Another forearm, and another. Trading powerful blows back and forth, neither one wanting to give an inch. Several seconds pass before either one starts to give, Sardonyx throwing a weaker punch, and Omega wakes her up with a headbutt. Sardonyx with a low kick to the calf before she swings high, missing a roundhouse, and Omega makes her pay with a STIFF knee strike! Right under Sardonyx’s jaw! She tries to stay on her feet, but collapses to her knees, but Kenny isn’t much better off. Denver is on their feet for Kenny, the Bucks slamming their hands on the apron, getting the room rocking, only for Sardonyx to start slapping the shit out of Omega. Swatting at him with vicious palm strikes, beating his head in from side to side, as sweat flies in either direction. Sardonyx turns around to run the ropes, but Omega is hot on her heels! He jumps, nailing her with a SICK V Trigger! Sardonyx melts to the ropes, clinging to the middle rope just to stay afloat, as Omega slaps himself into a new bout of emergy, as he runs the ropes again - but Sardonyx PLOWS through him with a running bicycle knee strike! Omega’s head whips to the side before he crumbles to the mat, and Sardonyx, dazed, but not out yet, makes her way to the top rope. She quickly plants her feet and leaps, wanting a Phoenix Splash, but nobody’s home! She crashes and burns!

Holding her chest, Sardonyx sits up, and gets drilled in the back of the head by a V Trigger! Omega lifts her up with an underhook, and quickly spikes Sardonyx with a Piledriver! Omega with the cover!

1… 2… KICKOUT!

How the hell did Sardonyx kick out of that?! The Bucks are incensed, The House getting worried, as Sardonyx looks dead to rights. Omega’s psyching himself up, and delivers one more brutal V Trigger, before pulling her into the corner. Omega moves up to the top rope, picking Sardonyx up with him, trying to set up for an avalanche One Winged Angel, when Scarlett gets involved She jumps on the apron, yelling at Kenny, trying to distract him, but Sardonyx looks to be out cold at this point. The interference won’t do her any good, especially as Nick Jackson jumps onto the apron, and blasts Scarlett with a Superkick! She melts to the floor, but on the other side of the ring, Matt Jackson just got thrown into the barricade, courtesy of Buddy Matthews! Nick jumps to the floor as Malakai makes his way around in his blind spot, and blasts Nick Jackson with a running kick! Suddenly, Sardonyx starts to elbow her way out of the OWA, before jumping up, crushing the back of Omega’s head with a double foot stomp! The Bucks are getting beaten up on the outside as Sardonyx slithers her way back to the top rope, slowly picking Omega up, and delivering the Nine of Swords from the top rope! She turns him over, shoulders down, as all chaos has broken loose!

1… 2… 3!

“Here is your winner, Sardonyx!”

Sardonyx wins, but there’s too much going on, the production crew doesn’t play her music amongst the carnage. Scarlett calls for it, but she doesn’t get what she asked for…

0 notes

Text

Various Designs of Concrete Crusher Machines

Concrete is the most responsible for developments in architectural design and construction out of all the construction materials known to man. Without concrete, there would be no urban expansion, highway construction, dam construction, military sites, or a plethora of other critical parts of modern society. Despite its value due to its high durability, any concrete structure has a limited life duration. As a result, the very characteristic that makes concrete valuable is also what makes it difficult to recycle or dispose of. We have become reliant on the concrete crusher as the demand for concrete has increased.

The purpose of a concrete crusher is to break down huge blocks of concrete waste into smaller bits that may be disposed of or recycled more efficiently. The following is a general explanation of the many types of concrete crushers in use today.

Concrete crushing is accomplished in steps. The first vykin stage is where big concrete blocks are broken down into smaller, more manageable bits. At this point of the demolition, a jaw crusher is often used. These machines can accept concrete blocks of any size, with a reduction ratio ranging from 3/1 to 5/1. Because the process of breaking concrete appears to be quite similar to chewing, jaw crushers have a pretty simple design. Two strengthened metal plates form a tapering funnel. One of the plates is fixed in place, while the other moves back and forth. The concrete is crushed into smaller and smaller boulders as it passes along the chute, until the pieces are finally small enough to fall out.

Depending on the intended use of the concrete, the concrete will either be reused in this form or crushed further. Secondary concrete crushers, the most popular of which are cone crushers and impact crushers, are frequently used. Each one is named after the mechanical process that was employed to break down the concrete.

Cone crushers have a concave tapering region with a revolving spindle that gyrates as it turns. Concrete is dropped into the machine at the top and crushed into smaller and smaller pieces as it goes down into smaller gaps. Pieces eventually grow small enough to pass through the chute and into a hopper. Cone crushers, like jaw crushers, have a reduction ratio of 3/1 to 51/. Cone crushers can be enormous, but there are also smaller, portable models that can be moved between locations.

Impact crushers operate by using hitting force rather than pressure. Impact crushers are classified into two types: horizontal shaft impactors and vertical shaft impactors. The concrete is held in a metal container by a horizontal impact crusher. Hammers attached to a spinning rotor pound the concrete until it breaks down into manageable pieces that can be pushed out of slots in the machine's side. They feature a reduction ratio of 25/1 and are better suited to softer materials.

The velocity of a vertical shaft concrete crusher is used rather than surface force. A high-speed rotor smashes concrete blocks against a hard interior surface. The rotor speed and distance thrown influence the size of the ultimate product. The smaller the fragments, the harder the concrete hits the confining wall or anvil. Because of the quadratic shape of the end product, recycled concrete produced using this technology has a wide range of applications. A typical vertical shaft concrete crusher has an 8/1 reduction ratio.

We can reasonably expect that the concrete crusher will continue to be a helpful instrument for some time to come due to the constantly expanding use of concrete in the building industry. Although alternate development methods and materials are being utilised, concrete has yet to find a sustainable successor for large-scale constructions. As a result, the concrete crusher will most likely be around for a long time.

Are you interested in learning more about concrete crusher [http://concretecrusher.net] machines? Please go to [concretecrusher.net]. Further information on these powerful machines, their different varieties, and concrete recycling may be found here. Doug Henderson is a big fan of the economic and environmental savings these devices bring.

1 note

·

View note

Text

Various Designs of Concrete Crusher Machines

Concrete is the most responsible for developments in architectural design and construction out of all the construction materials known to man. Without concrete, there would be no urban expansion, highway construction, dam construction, military sites, or a plethora of other critical parts of modern society. Despite its value due to its high durability, any concrete structure has a limited life duration. As a result, the very characteristic that makes concrete valuable is also what makes it difficult to recycle or dispose of. We have become reliant on the concrete crusher as the demand for concrete has increased.

The purpose of a concrete crusher is to break down huge blocks of concrete waste into smaller bits that may be disposed of or recycled more efficiently. The following is a general explanation of the many types of concrete crushers in use today.

Concrete crushing is accomplished in steps. The first stage is where big concrete blocks are broken down into smaller, more manageable bits. At this point of the demolition, a jaw crusher is often used. These machines can accept concrete blocks of any size, with a reduction ratio ranging from 3/1 to 5/1. Because the process of breaking concrete appears to be quite similar to chewing, jaw crushers have a pretty simple design. Two strengthened metal plates form a tapering funnel. One of the plates is fixed in place, while the other moves back and forth. The concrete is crushed into smaller and smaller boulders as it passes along the chute, until the pieces are finally small enough to fall out.

Depending on the intended use of the concrete, the concrete will either be reused in this form or crushed further. Secondary concrete crushers, the most popular of which are cone crushers and impact crushers, are frequently used. Each one is named after the mechanical process that was employed to break down the concrete.

Cone crushers have a concave tapering region with a revolving spindle that gyrates as it turns. Concrete is dropped into the machine at the top and crushed into smaller and smaller pieces as it goes down into smaller gaps. Pieces eventually grow small enough to pass through the chute and into a hopper. Cone crushers, like jaw crushers, have a reduction ratio of 3/1 to 51/. Cone crushers can be enormous, but there are also smaller, portable models that can be moved between locations.

Impact crushers operate by using hitting force rather than pressure. Impact crushers are classified into two types: horizontal shaft impactors and vertical shaft impactors. The concrete is held in a metal container by a horizontal impact crusher. Hammers attached to a spinning rotor pound the concrete until it breaks down into manageable pieces that can be pushed out of slots in the machine's side. They feature a reduction ratio of 25/1 and are better suited to softer materials.

The velocity of a vertical shaft concrete crusher is used rather than surface force. A high-speed rotor smashes concrete blocks against a hard interior surface. The rotor speed and distance thrown influence the size of the ultimate product. The smaller the fragments, the harder the concrete hits the confining wall or anvil. Because of the quadratic shape of the end product, recycled concrete produced using this technology has a wide range of applications. A typical vertical shaft concrete crusher has an 8/1 reduction ratio.

We can reasonably expect that the concrete crusher will continue to be a helpful instrument for some time to come due to the constantly expanding use of concrete in the building industry. Although alternate development methods and materials are being utilised, concrete has yet to find a sustainable successor for large-scale constructions. As a result, the concrete crusher will most likely be around for a long time.

Are you interested in learning more about concrete crusher [http://concretecrusher.net] machines? Please go to [concretecrusher.net]. Further information on these powerful dirt screeners machines, their different varieties, and concrete recycling may be found here. Doug Henderson is a big fan of the economic and environmental savings these devices bring.

1 note

·

View note

Text

Various Designs of Concrete Crusher Machines

Concrete is the most responsible for developments in architectural design and construction out of all the construction materials known to man. Without concrete, there would be no urban expansion, highway construction, dam construction, military sites, or a plethora of other critical parts of modern society. Despite its value due to its high durability, any concrete structure has a limited life duration. As a result, the very characteristic that makes concrete valuable is also what makes it difficult to recycle or dispose of. We have become reliant on the concrete crusher as the demand for concrete has increased.

The purpose of a concrete crusher is to break down huge blocks of concrete waste into smaller bits that may be disposed of or recycled more efficiently. The following is a general explanation of the many types of concrete crushers in use today.

Concrete crushing is accomplished in steps. The first stage is where big concrete blocks are broken down into smaller, more manageable bits. At this point of the demolition, a jaw crusher is often used. These machines can accept concrete blocks of any size, with a reduction ratio ranging from 3/1 to 5/1. Because the process of breaking concrete appears to be quite similar to chewing, jaw crushers have a pretty simple design. Two strengthened metal plates form a tapering funnel. One of the plates is fixed in place, while the other moves back and forth. The concrete is crushed into smaller and smaller boulders as it passes along the chute, until the pieces are finally small enough to fall out.

Depending on the intended use of the concrete, the concrete will either be reused in this form or crushed further. Secondary concrete crushers, the most popular of which are cone crushers and impact crushers, are frequently used. Each one is named after the mechanical process that was employed to break screener topsoil down the concrete.

Cone crushers have a concave tapering region with a revolving spindle that gyrates as it turns. Concrete is dropped into the machine at the top and crushed into smaller and smaller pieces as it goes down into smaller gaps. Pieces eventually grow small enough to pass through the chute and into a hopper. Cone crushers, like jaw crushers, have a reduction ratio of 3/1 to 51/. Cone crushers can be enormous, but there are also smaller, portable models that can be moved between locations.

Impact crushers operate by using hitting force rather than pressure. Impact crushers are classified into two types: horizontal shaft impactors and vertical shaft impactors. The concrete is held in a metal container by a horizontal impact crusher. Hammers attached to a spinning rotor pound the concrete until it breaks down into manageable pieces that can be pushed out of slots in the machine's side. They feature a reduction ratio of 25/1 and are better suited to softer materials.

The velocity of a vertical shaft concrete crusher is used rather than surface force. A high-speed rotor smashes concrete blocks against a hard interior surface. The rotor speed and distance thrown influence the size of the ultimate product. The smaller the fragments, the harder the concrete hits the confining wall or anvil. Because of the quadratic shape of the end product, recycled concrete produced using this technology has a wide range of applications. A typical vertical shaft concrete crusher has an 8/1 reduction ratio.

We can reasonably expect that the concrete crusher will continue to be a helpful instrument for some time to come due to the constantly expanding use of concrete in the building industry. Although alternate development methods and materials are being utilised, concrete has yet to find a sustainable successor for large-scale constructions. As a result, the concrete crusher will most likely be around for a long time.

Are you interested in learning more about concrete crusher [http://concretecrusher.net] machines? Please go to [concretecrusher.net]. Further information on these powerful machines, their different varieties, and concrete recycling may be found here. Doug Henderson is a big fan of the economic and environmental savings these devices bring.

1 note

·

View note

Text

Various Designs of Concrete Crusher Machines

Concrete is the most responsible for developments in architectural design and construction out of all the construction materials known to man. Without concrete, there would be no urban expansion, highway construction, dam construction, military sites, or a plethora of other critical parts of modern society. Despite its value due to its high durability, any concrete structure has a limited life duration. As a result, the very characteristic that makes concrete valuable is also what makes it difficult to recycle or dispose of. We have become reliant on the concrete crusher as the demand for concrete has increased.

The purpose of a concrete crusher is to break down huge blocks of concrete waste into smaller bits that may be disposed of or recycled more efficiently. The following is a general explanation of the many types of concrete crushers in use today.

Concrete crushing is accomplished in steps. The first stage is where big concrete blocks are broken down into smaller, more manageable bits. At this point of the demolition, a jaw crusher is often used. These machines can accept concrete blocks of any size, with a reduction ratio ranging from 3/1 to 5/1. Because the process of breaking concrete appears to be quite similar to chewing, jaw crushers have a pretty simple design. Two strengthened metal plates form a tapering funnel. One of the plates is fixed in place, while the other moves back and forth. The concrete is crushed into smaller and smaller boulders as it passes along the chute, until the pieces are finally small enough to fall out.

Depending on the intended use of the concrete, the concrete will either be reused in this form or crushed further. Secondary concrete crushers, the most popular of which are cone crushers and impact crushers, are frequently used. Each one is named after the mechanical process that was employed to break down the concrete.

Cone crushers have a concave tapering region with a revolving spindle that gyrates as it turns. Concrete is dropped into the machine at the top and crushed into smaller and smaller pieces as it goes down into smaller gaps. Pieces eventually grow small enough to pass through the chute and into a hopper. Cone crushers, like jaw crushers, have a reduction ratio of 3/1 to 51/. Cone crushers can be enormous, but there are also smaller, portable models that can be moved between locations.

Impact crushers operate by using hitting force rather than pressure. Impact crushers are classified into two types: horizontal shaft impactors and vertical shaft impactors. The concrete is held in a metal container by a horizontal impact crusher. Hammers attached to a spinning rotor pound the concrete until it breaks down into manageable pieces that can be pushed out of slots in the machine's side. They feature a reduction ratio of 25/1 and are better suited to softer materials.

The velocity of a vertical shaft concrete crusher is used rather than surface force. A high-speed rotor smashes concrete blocks against a hard interior surface. The rotor speed and distance thrown influence the size of the ultimate product. The smaller the fragments, the harder the concrete hits the confining wall or anvil. Because of the quadratic shape of the end product, recycled concrete produced using this technology has a wide range of applications. A typical vertical shaft concrete crusher has an 8/1 reduction ratio.

We can reasonably expect that the concrete crusher will continue to be a helpful instrument for some time to come due to the constantly expanding use of concrete in the building industry. Although alternate development methods and materials are being utilised, concrete has yet to find a sustainable successor for large-scale constructions. As a result, the concrete crusher will most likely be around for a long time.

Are you interested in learning more about concrete crusher [http://concretecrusher.net] machines? Please go to [concretecrusher.net]. Further information on these powerful machines, their different varieties, and concrete recycling dirt screener may be found here. Doug Henderson is a big fan of the economic and environmental savings these devices bring.

1 note

·

View note

Text

Various Designs of Concrete Crusher Machines

Concrete is the most responsible for developments in architectural design and construction out of all the construction materials known to man. Without concrete, there would be no urban expansion, highway construction, dam construction, military sites, or a plethora of other critical parts of modern society. Despite its value due to its high durability, any concrete structure has a limited life duration. As a result, the very characteristic that makes concrete valuable is also what makes it difficult to recycle or dispose of. We have become reliant on the concrete crusher as the demand for concrete has increased.

The purpose of a concrete crusher is to break down huge blocks of concrete waste into smaller bits that may be disposed of or recycled more concrete crushers for sale efficiently. The following is a general explanation of the many types of concrete crushers in use today.

Concrete crushing is accomplished in steps. The first stage is where big concrete blocks are broken down into smaller, more manageable bits. At this point of the demolition, a jaw crusher is often used. These machines can accept concrete blocks of any size, with a reduction ratio ranging from 3/1 to 5/1. Because the process of breaking concrete appears to be quite similar to chewing, jaw crushers have a pretty simple design. Two strengthened metal plates form a tapering funnel. One of the plates is fixed in place, while the other moves back and forth. The concrete is crushed into smaller and smaller boulders as it passes along the chute, until the pieces are finally small enough to fall out.

Depending on the intended use of the concrete, the concrete will either be reused in this form or crushed further. Secondary concrete crushers, the most popular of which are cone crushers and impact crushers, are frequently used. Each one is named after the mechanical process that was employed to break down the concrete.