#3DPrintTechnology

Explore tagged Tumblr posts

Text

3D Printing Plastic Market Industry Forecast, 2024–2030

3D Printing Plastic Market Overview

3D Printing Plastic Market size is forecast to reach $3,004.71 million by 2030, after growing at a CAGR of 17.1% during 2024–2030. Globally, the demand for 3D printing plastic is rising from various application sectors such as aerospace and defense, electrical and electronics, and healthcare, by reducing the efforts, time, and costs incurred in the project. The increasing demand for 3D printing plastic from various industries, such as aerospace, automotive, healthcare, and electronics, for applications such as prototyping, tooling, and functional parts. The cost-effectiveness, strength, durability, and versatility of 3D printing plastic compared to other materials. The development of new types and grades of 3D printing plastic, such as biodegradable, conductive, and flexible plastics. The increasing use of photopolymers and polyamide (nylon) materials in 3D printing owing to its alluring properties is estimated to drive the 3D printing plastics market growth. Furthermore, the development of innovative, stronger, lighter, and safer components and parts with lower lead times and costs is anticipated to create new opportunities for the growth of the global 3D printing plastic industry in the forecast period.

Request sample:

Covid-19 Impact

The rise in positive COVID-19 cases worldwide generated a huge demand for the 3D printing plastics market from the healthcare sector. The market for medical components such as face shields, masks, ventilator vales, and others has seen an upsurge since the outbreak of COVID-19. Owing to the COVID-19 palindrome the increasing demand of medical components from across the globe, has also increased the demand for 3D printing adoption in various regions.

Market Snapshot :-

3D Printing Plastic Market Report Coverage

The: “3D Printing Plastic Market Report — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the 3D Printing Plastic Market. By Form: Filament, Ink, and Powder.

By Type: Polycarbonates, Photopolymers, Acrylonitrile Butadiene Styrene (ABS), Polyamide/Nylon, Polylactic Acid, Polyethylene Terephthalate (PET), Glycolized polyester (PETG), High Performance Polymers, and Others.

By Application: Prototyping, Automotive, Healthcare, Consumer Goods, Aerospace & Defence, Electrical & Electronics, and Others.

By Geography: North America (U.S, Canada, and Mexico), Europe (U.K., Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), APAC (China, Japan India, South Korea, Australia & New Zealand, and Rest of Asia Pacific), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle east and Africa).

Inquiry Before Buying:

Key Takeaways

The rising demand for laser sintering technology by engineers and manufacturers in various commercial sectors will increase the demand for polyamide (nylon), which is further expected to drive the 3D printing plastic industry growth.

Owing to the ability of the plastic being shaped easily, they are used in the initial stages of the onset of 3D printers. Very recently, NASA has been using space-based 3D printers with plastic as the key material for space-based objects.

Also, the rise of the automobile industry is set to hold the market for 3D printing plastics at its height in the years to come. Quick advances in diverse materials and technology are allowing the industry to gain momentum.

For more details on this report — Request for Sample

3D Printing Plastic Market Segment Analysis — By Form

Filament form is widely used in the 3D Printing Plastic Market. They are only manufactured and consumed in two diameters, namely 1.75 mm and 3 mm. By using the process of heating, extruding and cooling plastic, filament form is produced to turn nurdles into finished product. Thus, it is possible to dye these filaments in various colours. Also, due to their flexible properties there is an increase in demand from several application industries such as food packaging, tableware, upholstery, and disposable clothing.

3D Printing Plastic Market Segment Analysis — By Type

Polyamide/Nylon segment held the largest share in the 3D Printing Plastic Market in 2023. Nylon (known as polyamide) is a synthetic linear polyamide thermoplastic and is a well-known 3D printing filament owing to its stability, toughness, low friction and corrosion resistance. Nylon is also a common substance used in the manufacture of clothing and accessories. Due to its improved strength and elasticity over PLA and ABS, Nylon is ideal for manufacturing uses, such as machine parts or equipment, or the replacement of automotive parts. As compared to ABS and PLA Nylon is tougher and more resistant to chemicals, but its poor strength and hardness prohibits it from being commonly used in the manufacturing industry. With the increasing demand for nylon the market for 3D printing plastic is also estimated to rise in the forecast period.

3D Printing Plastic Market Segment Analysis — By Application

Prototyping segment held the largest share in the 3D Printing Plastic Market in 2023 and is projected to grow at a CAGR of 17.1% during the forecast period 2024–2030. Creating a concept can be a costly and slow process. Fortunately, certain methods are available to help you enhance the product creation process, helping to make high-quality prototypes at a cheaper cost. From office to the factory floor, 3D printers produce plastic concept models, precision and practical prototypes, master patterns and actual end-use components for refining every project, streamlining the workflows and getting creative products to the market quicker. Besides, 3D printing plastic is the best solution for designing the prototypes. By beginning to create the 3D printing project, one will have access to a wide variety of efficient 3D printing supplies, saving time and resources. Thus, rising usage of 3D printing plastic for prototyping applications is set to drive the market growth over the forecast period.

Schedue a call :

3D Printing Plastic Market Segment Analysis — By Geography

North America held the largest share with 51% in 3D Printing Plastic Market in 2023 Due to the increasing demand for 3D printing plastics in medical devices and equipment, and the increasing adoption of 3D printing technology in U.S., Canada, Mexico and various other countries in the region is set to drive the market growth in the upcoming future. According to the U.S. Department of Health and Human Services, the Fiscal Year (FY) 2023 budget represents the responsibilities of the U.S. government to advance a patient-centered healthcare system. The budget proposes a discretionary budget authority of $96.1 billion and mandatory support for Health and Human Services of $1.86 trillion.Thus, the rising investments by the government in the healthcare sector are estimated to boost the 3D Printing Plastic Market growth in the forecast period.

3D Printing Plastic Market Drivers

Rising Demand for 3D Printing Plastic from the Healthcare Industry

Rising usage of 3D printing plastic in the healthcare sector is driving the market growth. Key factors driving demand in the medical industry for 3D printing plastics include cost-effectiveness, ease of customization, as well as the rising occurrence of vascular and osteoarthritis diseases. Polyamide or nylon is often used for injection molding in medical device owing to its inflexible nature, strength, chemical compatibility, and temperature resilience. Increasing use of photopolymers for high-resolution, ultra-fine parts in medical devices will also drive the market growth. Moreover, the market demand in medical applications is expected to be fueled by advanced 3D technology, favorable government funding, and rapid product growth. According to the India Brand Equity Foundation, the government of India aims to increase the healthcare spending to 3% of the GDP by 2022, which means the healthcare sector will rise three-fold to Rs. 8.6 trillion (US$ 133.44 billion). Hence, the growing demand for 3D printing plastic from the healthcare sector will raise the growth for 3D Printing Plastic Market in the forecast period.

Increasing Demand for Biodegradable Materials for 3D printing

The growing need for the “green” alternative to traditional polymers has propelled the demand for polylactic acid in the 3D printing plastic industry. Since, polylactic acid is very inexpensive, easy to print, and produces components that can be used for a wide variety of applications, it is the ideal first material to be used in 3D printing. It is also one of the most environmental friendly products made from crops such as corn and cane that are used today. This material is thermoplastic aliphatic polyester and is the predominant natural raw material that consists of recycled raw materials used in 3D printing plastics. For most extrusion-based 3D printing, polylactic acid is also the default filament of choice, since it can be printed at low temperatures and does not require a heated bed. Thus, with the rising demand for biodegradable materials the growth for 3D printing plastics market is estimated to rise in the forecast period.

3D Printing Plastic Market Challenges

Environmental Issues Regarding 3D Printing Plastic Materials will Hamper the Market Growth

Over the last few years, one environmental issue has gradually stolen the spotlight that is plastic pollution. The reliance on plastics-especially single-use plastics-is now one of the world’s leading environmental concerns. 3D printing uses the flexible, durable design of plastics in a wide variety of applications, from aerospace to healthcare. Polyethylene terephthalate (PET) is one of the most common filaments used in plastics such as bottles of disposable beverages and food packaging. Other filaments include polycarbonate and ABS: both are relatively inexpensive, flexible and easy to manufacture. Unfortunately, these materials are not commonly recyclable and so any waste generated in the printing process would find its way to the landfill or to the natural environment. Thus, rising environmental concerns due to the use of various 3D printing plastics is estimated to hinder the 3D printing plastics market growth.

Buy Now :

3D Printing Plastic Market Outlook

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the 3D Printing Plastic Market. Major players in the 3D Printing Plastic Market are:

3D Systems Corporation

Arkema SA

Stratasys, Ltd.

Evonik Industries AG

HP Inc.

SABIC

DowDuPont Inc.

EOS GmbH Electro Optical Systems

Solvay

Royal DSM N.V., among others.

Acquisitions/Technology Launches

In March 2023, BASF SE acquired Sculpteo, a French online 3D printing service provider, to expand its 3D printing solutions portfolio and customer base.

In February 2023, Arkema acquired Lambson, a UK-based company that specializes in photo initiators for 3D printing, to strengthen its position in the 3D printing market and offer innovative solutions for UV-curable resins.

In January 2023, Stratasys Ltd. acquired Origin, a US-based company that develops 3D printers and materials for mass production, to enhance its capabilities in the fast-growing segment of end-use parts.

In December 2022, Evonik Industries AG acquired 3D Printing Materials, a US-based company that produces high-performance thermoplastics for 3D printing, to broaden its product portfolio and customer base in the additive manufacturing market.

For more Chemicals and Materials Market reports, please click here

#3DPrinting#3DPrintingPlastics#AdditiveManufacturing#3DMaterials#3DPrintedPlastics#PlasticInnovation#Sustainable3DPrinting#AdvancedMaterials#PolymerScience#Industrial3DPrinting#3DManufacturing#PlasticEngineering#3DPrintingSolutions#3DPrintTechnology#ManufacturingInnovation

0 notes

Photo

For all your 3D printing and consultancy needs please visit our SAMC website or DM me. Link in the bio. . . . . . #craftinicreativelounge #3dprint #3dprinting #3d #largescale3dprinter #big3dprinter #3dmodeling #3dprinter #industrial3dprinting #3dprinttechnology (at Pune, Maharashtra) https://www.instagram.com/p/CCN1320nu_H/?igshid=1v0lr9ip9atbx

#craftinicreativelounge#3dprint#3dprinting#3d#largescale3dprinter#big3dprinter#3dmodeling#3dprinter#industrial3dprinting#3dprinttechnology

0 notes

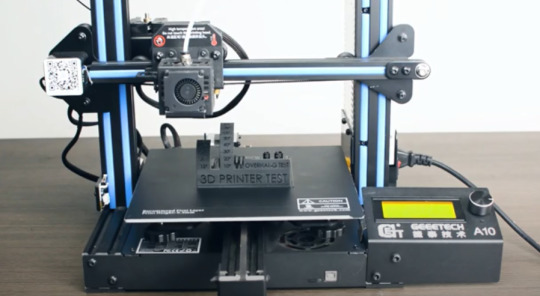

Photo

Tips on how to improve your print quality

3D printing can present all sorts of problems.Whether you are a newbie or expert, chances are you are constantly tweaking a bit here and a bit there just to get the desired results.There are, however, a number of things you can do to get around some common issues in 3D printing and improve your print quality. Good news is that you do not have to be an expert to get started.

Assembly & Set Up

Set up your 3D printer as per the instructions. No matter how experienced you are,your vendor supposedly knows the products better than you do. It is recommended that you use parts, software,and materials from the same brand wherever you can to get the best experience. Remember, every 3D printer has its own characteristics. Be open to some trial and error down the road.

Software Update

Keep your system up to date. Manufacturers and slicer companies are constantly experimenting with their software and firmware to fix bugs and improve performance. If your machine features an automatic update, enable it.

Maintenance

Perform regular maintenance and calibration on your 3D printer:form and maintain a routine of checks;keep your filaments from moisture and dust; calibrate the bed.

Supports

Bear in mind the 45-degree rule and 5mm rule. Any overhangs of above 45 degrees(or 60 degrees depending on your printer) may require supports. Just like overhangs, not all bridges require supports.Consider supports only when the bridge is more than 5mm long. “Rafts” , “brims” are great support tools to increase adhesion.Add support structures to your design for any steep overhanging features or models that have a small base.

While supports are great for some cases,you may want to avoid them,for the following reasons:first, it consumes extra filament; second, the print takes longer time; and finally, removing the support structure off the print can be a pain. If you are still not sure whether you need supports, run a test print to find out. You can also use your creativity to make the support structures part of your design, in case you think them necessary. Ways to circumvent supports: reorient your model; reduce the overhang angles;split your model into smaller parts.

The first layer

Your first layer is the foremost important layer of your print. Make sure it sticks well to the bed. Again, supports can be great tools to help with adhesion. Use a heated bed or apply glue to prevent warping from happening.

Details

Examine the details of your model. Are there any tiny projections or parts that are too small to print on a desktop 3D printer? In your printer, there is a very important but often overlooked variable, that is the line width, which is determined by the diameter of the printer nozzle. And most printers come with a nozzle of 0.4 mm or 0.5 mm in the diameter.

This post is originally published on geeetech official blog

#3dprinter#desktop3dprinter#3dprinting#3d technology#3Ddesign#3d model#slicer#Geeetech#3Dprinttechnology

0 notes

Video

(vía https://www.youtube.com/watch?v=bjhlQK0W0Dc)

Adidas and Carbon Futurecraft 4D: Sneakers in 3D print technology.

Adidas has chosen a new process for creating the sole of these shoes, called Continuous Liquid Interface Production, basically what it does in it is to remove the piece from a liquid polymer...

#fashion #Adidas #Nike #shoes #Carbon3D #Makers #AdidasCarbonFuturecr4Daft #AdidasFuturecraft4D #technology #3DPrintTechnology #Innovation #Technology #Futurecraft4D

0 notes

Photo

ABCs of 3D Printing

Contents

What is 3D printing?

3D printing technologies

The history of 3D printing

3D printing applications

What is a 3D printer?

What are the differences between a basic rapid prototyping machine and a 3D printer?

What can you make with a 3D printer?

What materials are used to print 3D objects?

What 3D modeling software is suitable for a beginner in 3D design?

How long does it take for a newbie to get the hang of 3D modeling?

Where can I get 3D models?

What Is 3D Printing?

3D printing, also known as desktop fabrication or additive manufacturing,is a prototyping process whereby a real object is created from a 3D design. The digital 3D-model saved in STL format is sent to a 3D printer. The 3D printer then prints the design layer by layer and form a real object. Read more..

3D Printing Technologies

There are a number of technologies used in 3D printing, with the most widely used ones being SLS (selective laser sintering), FDM (fused deposition modeling) & SLA (stereolithograhpy) . Selective laser sintering (SLS) and fused deposition modeling (FDM) use melting or softening materials to produce the layers.

This video illustrates how laser-sintering process melts fine powders, bit by bit, into 3D shapes. https://www.youtube.com/watch?v=wD9-QEo-qDk

This video shows how FDM works. https://www.youtube.com/watch?v=SPtkOmP_HoA

The video below explains the process of Stereolithography (SLA). https://www.youtube.com/watch?v=iceiNb_1E0I

History of 3D Printing

October 5, 2011 — Roland DG Corporation introduced the new iModela iM-01.

Sep, 2011 — Vienna University of Technology, a smaller, lighter and cheaper printing device developed.

This smallest 3D printer weighs 1.5 kilograms, costing around 1200 Euros.

Aug, 2011 — World’s first 3D printed aircraft by Engineers at the University of Southampton.

Read more.

3D Printing Applications

One of the most important applications of 3D printing is in the medical industry. With 3D printing, surgeons can produce mockups of parts of the patients’ body which needs to be operated upon.

3D printing makes it possible to produce an object from scratch in just a few hours.

Nowadays almost everything from aerospace components to toys are being built with the help of 3D printers. 3D printing is also used for jewelry and art, architecture, fashion design, architecture and interior design.

Here are some extraordinary examples of 3D-printing:

The World’s First 3D-Printed Car

https://www.youtube.com/watch?v=-rprfWfgnFc

World’s first chocolate printer

https://www.youtube.com/watch?v=BIFi8but3Vw

World’s first 3D printed bikini

https://www.youtube.com/watch?v=d2iT8S0m3m4

What is a 3D printer?

Unlike common printers,on a 3D printer the object is printed in three dimensions, built up layer upon layer. The whole process is sometimes refered to as apid prototyping, or 3D printing.

The resolution of the current printers is among the 328 x 328 x 606 DPI (xyz) at 656 x 656 x 800 DPI (xyz) in ultra-HD resolution. The accuracy is 0.025 mm — 0.05 mm per inch. The model size is up to 737 mm x 1257 mm x 1504 mm.

Aside from being costly,3D printers for home use are slow in delivering real objects(hours or even days,depending on the complexity and resolution of the model).On top of that, prices for professional 3D software and 3D model design are high.

Alternatively there are simplified 3D printers which are much more affordable,so are the materials they consume. These 3D printers for home use are not as accurate as their commercial counterparts .

What are some differences between a rapid prototyping machine and a 3D printer?

3D printers are the simplified version of rapid prototyping machines. It is of lower cost and less capable.

Rapid prototyping is a conventional method that has been used by automotive and aircraft industries for years.

In general, 3D printers are compact and smaller than RP machines. They are ideal for use in offices,consuming less energy and taking less space,and are designed for low- volume production of real objects made of nylon or other plastics. That means 3D printers make smaller parts. A rapid prototyping machines have build chambers at least 10 inches on a side,while a 3D printer has less than 8 inches on a side. Despite its smaller size, a 3D printer is capable of all the functions of a rapid prototyping machine such as verifying and validating design, creating prototype, remote sharing of information ,and etc.

Consequently, 3D printers are easy to handle and cheap to maintain. You can buy one of those DIY kits in the market and build it up yourself. It is cheaper than a professional rapid prototyping machine.For a mere shy of $1000 you can have one on the market. While a professional rapid prototyping machine is sold for at least $50,000.

A 3D printers is less accurate than a rapid prototyping machine,due to its simplicity, and they can only work with a limited number of materials.

What can you make with a 3D printer?

In the arena of 3D printing, people say “If You Can Draw It, You Can Make It”. The video below shows many items can be made with a 3D printer. However complicated objects can only be produced by professional 3D printers,which are not yet affortable for common households. https://www.youtube.com/watch?v=HdzooQQDWGg

What materials are used to print 3D objects?

Many kinds materials can be used for 3D printing, such as ABS plastic, PLA, polyamide (nylon), glass filled polyamide, stereolithography materials (epoxy resins), silver, titanium, steel, wax, photopolymers and polycarbonate.

What 3D modeling software is suitable for a beginner in 3D design?

If you’re just getting started, you can try 3D modeling software that can be downloaded for free.

Google SketchUp — Google SketchUp is fun and free, and is known for being easy to use. To build models in SketchUp, you draw edges and faces using a few simple tools that you can master in a short time.With Push/Pull tool you can extrude any flat surface into a 3D form. Furthermore, it works together with Google Earth, that you can import a scaled aerial photograph directly from Google Earth, or use SketchUp to build models which can be seen in Google Earth.

3Dtin — The simplest 3D software. You can draw directly from your browser.

Blender — Blender is the free open source 3D content creation suite, available for all major operating systems under the GNU General Public License. Blender was developed as an in-house application by the Dutch animation studio NeoGeo and Not a Number Technologies (NaN). It is a powerful program contains features that are characteristic of high-end 3D software.

OpenSCAD — OpenSCAD is a software for creating solid 3D CAD objects. It is free and available for Linux/UNIX, MS Windows and Mac OS X. It does not focus on the artistic aspects of 3D modelling but instead on the CAD aspects.

http://tinkercad.com/ Tinkercad] — Tinkercad is a new and faster way of creating designs for your 3D printer. With only three basic tools you can create a wide range of useful things. Once your project is ready simply download the STL file and start your 3D print.

Commercial software such as CAD software AutoCAD and Pro Engineer, software packages Rhino, Maya, and SolidWorks are all pretty good for designing 3D models.

I have no 3D design experience, how long does it take to learn 3D modeling?

You can start out by learning how to use modeling tools such as Rhino, Blender or SketchUp. It will take you some weeks to be familiar with 3D modeling tools such as SketchUp, Rhino and Blender. To become a professional user it will take you at least half a year of study and practice.

Where can I get 3D models online?

Here are some websites with 3D model database:

3D Marvels

3D Via

GrabCAD

Google 3D Warehouse

Ponoko Product Plans

Shapeways 3D Parts Database

Thingiverse

Turbosquid: Free objects

This article is originally published on the Geeetech wiki page.

3D Printing

3d Modeling

3d Design

3d Printer

Additive Manufacturing

#3dprinting#3dprinter#desktop3dprinter#additivemanufacturing#prototyping#3dprinttechnology#diy#3d modling#3ddesign

0 notes