#3d-cad-design-services

Explore tagged Tumblr posts

Text

Professional CAD Design Services | Custom CAD Design Manufacturer

Computer-Aided Design (CAD) has revolutionized the engineering and manufacturing industry via providing effective gear for certain, specific, and cost-powerful layout. Opting for expert CAD Design Services now not simplest optimizes your design procedure but also opens up an international of opportunities.

Advanced Technology enables Sophisticated Services to utilize leading-edge technology which transforms business concepts into real-life applications thus allowing business innovation through digital design processes. Traditional paper drawings no longer apply to your current needs.

The early detection of ability flaws through actual-global simulation in CAD design services accelerates challenge transport time while reducing both cost and duration of physical test runs.

Businesses with expert these services achieve competitive advantages since the competitive market requires unique features today. The numerous capabilities of converting 2D drawings to 3D models with flexible layout modifications producing high-quality output will maximize your task success.

You need to invest in premium CAD Design Services in order to gain a better system with fewer errors due to human factors. Your thoughts develop into real-life achievements through first-class accuracy and productive performance. Business growth will be successful as you innovate with complete confidence. CAD Design empowers companies in their current operations.

Revolutionizing Prototyping: A Deeper Dive into Custom CAD Design Manufacturer

The evolving global production sector enables Custom CAD Design Manufacturer to establish itself as a transformative solution whose time has come for all progressive industries. The innovative technology eliminates the traditional design to production distinctions which enables flexible efficient manufacturing methods.

• Streamlined Designing Process: With a minimal margin of mistakes, Custom CAD layout guarantees precision, resulting in perfect and compact designs delineated right away and appropriately. This streamlining significantly cuts down manufacturing time and cost.

• Flexibility: Whether it’s aerospace, automotive, or architectural industries, precise customization requirements may be met efficiently. Direct design interest in each respective component leads to premium solutions for every unique customer requirement.

The advanced options of custom CAD layout allow businesses to innovate because it gives contemporary 3-d visualization skills for enhanced creativity and innovation. The system lets organizations try out sophisticated designs while bolstering their continuous enhancement efforts.

Every contemporary business needs custom CAD design manufacturing as an essential competitive tool that must be used to thrive. The revolutionary technological device stands as robust and provides users with improved performance levels coupled with cost reductions along with enhanced capacity to innovate. Reliable. Revolutionary. Future requires us to advance past our current systems based on the implementation of creative thinking integrated with manufacturing processes.

Redefining Innovation with CAD Design Services in Canada: Unleashing Endless Possibilities

Modern design functions powered by Computer-Aided Design (CAD) drive the development of an endless variety of industries. In Canada's dynamic and changing market CAD design services drive both remarkable growth and business advancement.

• Precision with High Efficiency– CAD layout solutions provides unparalleled precision, ensuring the reduction of manual errors, which, in flip, saves time and fee. With those offerings, businesses are sculpting extraordinary analytical intensity and application accuracy, riding increase and business performance.

• Immersive Customization– CAD enables the creation and manipulation of 3D gadgets, allowing designers to pivot, zoom, and spin designs with a few clicks. This provision for personalization empowers industries to higher visualize their stop merchandise, scrutinize them minutely, and convey treasured merchandise to market speedy.

The sustainability principle exists within CAD equipment because of their integrated sustainability capabilities. The CAD offerings from Canada push the country toward environmental sustainability through their production of sustainable residential design and environmental product development.

The leading edge of innovation demands that CAD Design Services in Canada integrate CAD design services as part of their operations. The revolutionary trend allows Canadian industries to do more than simple adaptation of change because they now set the path for innovative solutions of tomorrow. Companies that invest in CAD solutions achieve more than modernization trends because they dedicate to both drive technology progress and sustainable development.

Transforming Concepts into Reality with Custom CAD Design Services

Computer-Aided Design (CAD) offerings have revolutionized the way agencies method product design and development. A sophisticated fusion of creativity and technology, Custom CAD Design Services has emerged as a sport-changer, seamlessly transforming initial ideas into a tangible, geared up-to-manufacture design.

• Enhancing Prototype Accuracy: Custom CAD offerings allow an in depth examination of the product earlier than moving to the production degree. By reducing inaccuracies and layout flaws, companies store time, money, and effort.

• Efficient Design Modifications: With CAD software program, making layout changes will become a smooth procedure. This flexibility ensures a consistent evolution, aiming to gain the suitable prototype.

• Ease of Collaboration: CAD files can be shared amongst team members, customers, and other stakeholders. Consequently, thoughts, remarks, and improvements may be communicated correctly, fostering a collaborative running environment.

With every task, our crew here at Design Services strives to apply these advantages, orchestrating a layout procedure that meets your unique needs and finances. Our experts are professional at expertise your vision, and remodeling it into a CAD design that embodies precision and innovation. Together, permits catalyze your product's journey from idea to production through our custom CAD layout offerings.

Unleashing the Power of 3D CAD Design Services

Transforming ideas into tangible merchandise is the spine of any design and manufacturing enterprise. One generation that has revolutionized this procedure is Computer-Aided Design (CAD). Today, let's delve into the three notable functions of 3D CAD Design Services.

1. Precision and Efficiency: 3D CAD software offers an unprecedented level of precision that traditional hand-drawing methods actually cannot healthy. With this software in hand, designers can visualize a product's specifics in 3 dimensions, lowering mistakes due to guide interpretation.

2. Rapid Prototyping: This era has substantially accelerated the product development process. Designers can take a look at principles and prototypes digitally before investing time and assets into growing physical fashions.

3. Effective Collaboration: 3-D CAD services sell green collaboration throughout globally dispersed design teams. CAD documents are effortlessly sharable and viewable on nearly any device, making collective enter and revisions greater on hand than ever.

For any commercial enterprise within the manufacturing and designing space, embracing 3-d CAD layout services propels you to new heights of efficiency, accuracy, and cost-effectiveness. With its unique features, it's time to step into the future of design with 3-D CAD. Unlock the potential of your designs—and your enterprise—nowadays.

Conclusion

Because it offers accurate, targeted, and economical layout solutions, computer-aided design, or CAD, has completely transformed the engineering and manufacturing sectors. Through digital design processes, expert CAD design services streamline design processes and create new avenues for creativity. Sophisticated services that turn company ideas into practical applications are made possible by advanced technology, which also speeds up production and lowers mistakes. Manufacturers of CAD designs provide a simplified design method that guarantees accuracy and lowers human error.

Krishani deals with 3D CAD design services and various molds and will be happy to inform you of the best options that suit your needs in your area. We interact with everyone concerned and analyze return on investment so that you can gain optimum value for your investment. Moreover, we offer services to enhance the feeling of customization including other features aimed at boosting your industry.

Source link:- https://sanfranciscodaily360.com/professional-cad-design-services-custom-cad-design-manufacturer

0 notes

Text

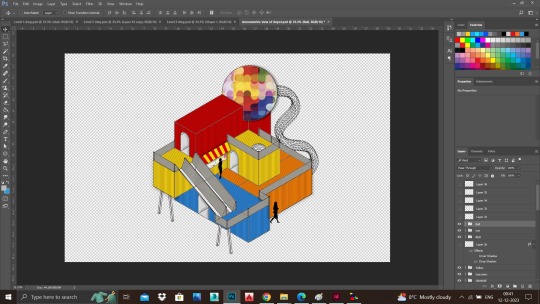

MCR Interior Design (Solo Project Task) - 2010

#MCR#mcr tour#empower#promote#service#marketing#branding#presentation#3d cad modeling#3d render#design#digital art#portfolio#artist#automotive design#concept#umarali#khokhar#bristol#umi3-nous design#technology#futuristic#ideas#innovation#artwork#UK#tech skills#self taught designer

3 notes

·

View notes

Text

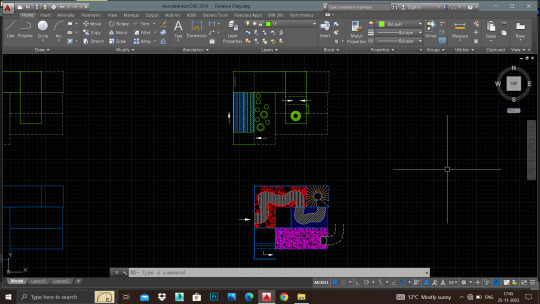

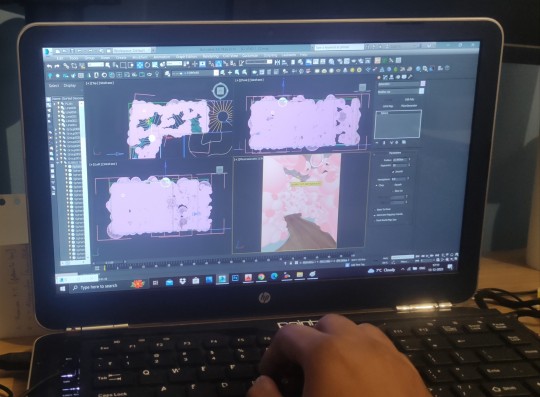

Sharing out some of my design process..... Work in Progress!

After the physical model-making part, it is time to complete the other process of design. I have used softwares like:-

AutoCAD - 2D drawing and drafting 3Dsmax with Vray- 3D Visualisation Photoshop- To give life to the design 🥰 Editing

Moving forward with the final stage of designing!

#work in progress#work#design#interior design#visualisation#drawing#architectural drafting services#cad design#cad drawing#autocad#3dsmax#3d modeling#photoshop#edit#editing#architecture#blog post#go with the flow#trust the process

5 notes

·

View notes

Text

Exploring the Benefits of CAD Jewelry Services for Custom Designs

Discover how CAD jewelry services enhance custom designs with precision, creativity, and faster turnaround times.

#Cad Jewelry Services#jewelry cad designer near me#cad designers for hire#jewelry cad and modeling#hire 3d cad designers#jewelry cad rendering services

0 notes

Text

Experience precision with our 3-D machining offerings. We offer bespoke solutions the use of advanced era for industries, ensuring complicated designs and complex geometries come to life with amazing fine. Choose us for innovation and reliability in 3D machining.

0 notes

Text

Bring Your Ideas to Life with Brisbane's Leading 3D Printing Services

As a leader in 3D printing service Brisbane, industrial design Brisbane, and plastic engineering services Brisbane, Red Labs provides a comprehensive suite of services tailored to meet the needs of engineers, designers, and manufacturers. Whether you're working on a complex prototype, a structural framework, or a custom component, our advanced capabilities can bring your ideas to life with unmatched precision and speed.

Comprehensive 3D Printing Service Brisbane

Our 3D printing service in Brisbane is designed to deliver rapid, accurate, and cost-effective solutions. From functional prototypes to high-quality end-use parts, we utilize state-of-the-art additive manufacturing technologies, including Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Our expert team ensures every detail is perfected, from material selection to final finishing.

Benefits of our 3D printing services include:

Rapid prototyping for faster product development

High precision and dimensional accuracy

Cost-effective production with minimal waste

Complex geometries made possible without traditional tooling

Innovative Industrial Design Brisbane

Our industrial design Brisbane team combines creativity with technical expertise to transform your concepts into market-ready products. We focus on ergonomics, aesthetics, and functionality, ensuring that your product not only stands out but also performs exceptionally in real-world conditions.

Services include:

Concept development and sketching

CAD modeling and 3D visualization

Design for manufacturing (DFM) and assembly (DFA)

User experience and usability testing

Precision Sheet Metal Design Brisbane

For projects requiring robust metal components, our sheet metal design Brisbane services are second to none. We handle everything from initial design through to fabrication, using advanced CAD software and precision machining. Our sheet metal solutions are perfect for custom enclosures, brackets, and structural supports.

Advantages of choosing our sheet metal design services:

High strength-to-weight ratios

Versatile material options, including aluminum, stainless steel, and mild steel

Tight tolerances for critical applications

Efficient and repeatable production processes

Expert CAD Drafting Services Brisbane

Accurate technical drawings are the foundation of any successful engineering project. Our CAD drafting services Brisbane ensure that every line, curve, and dimension is meticulously planned and executed. We provide detailed 2D and 3D CAD drawings that are fully compatible with industry standards, ensuring seamless integration into your manufacturing processes.

Key benefits:

Precision designs for complex components

High-quality digital files for CNC machining and 3D printing

Reduced design errors and production delays

Comprehensive support for mechanical and structural designs

Reliable Structural Drafting Brisbane

Structural integrity is crucial for any construction or engineering project. Our structural drafting Brisbane services are tailored to deliver accurate and detailed blueprints for everything from small components to large-scale structures. We work closely with engineers and architects to ensure every detail is structurally sound and compliant with Australian standards.

Services include:

Steel detailing and connection designs

Reinforced concrete detailing

Structural steel layouts and assembly drawings

3D modeling and clash detection

Plastic Fabrication Experts Brisbane

Our plastic fabrication Brisbane services provide bespoke solutions for industries ranging from medical devices to automotive components. We specialize in custom plastic parts, ensuring high durability, chemical resistance, and lightweight designs. Our capabilities include vacuum forming, CNC machining, and precision cutting.

Why choose our plastic fabrication experts Brisbane?

Custom designs to fit exact specifications

Wide range of plastic materials, including acrylic, polycarbonate, and HDPE

Quick turnaround times with competitive pricing

Exceptional quality and durability for demanding applications

Plastic Engineering Services Brisbane

For businesses looking for specialized plastic engineering services Brisbane, we offer comprehensive support from initial design through to final production. Our engineers have extensive experience in plastics, ensuring optimal material selection, strength analysis, and cost-efficient manufacturing processes.

Key advantages:

Innovative solutions for complex challenges

Advanced material knowledge for superior product performance

In-house testing and quality assurance

Cost-effective, scalable production

Why Choose Red Labs for Your Engineering and Manufacturing Needs?

Plastic Fabrication Experts Brisbane- At Red Labs, we pride ourselves on our commitment to quality, precision, and customer satisfaction. With a full range of services, including 3D printing service Brisbane, industrial design Brisbane, sheet metal design Brisbane, CAD drafting services Brisbane, structural drafting Brisbane, plastic fabrication Brisbane, and plastic engineering services Brisbane, we are your one-stop solution for all your design and manufacturing needs.

Contact Us Today

Ready to bring your ideas to life? Contact Red Labs for a consultation and see how we can support your next project with world-class engineering and manufacturing services.

#3d printing service Brisbane#Industrial Design Brisbane#Sheet Metal Design Brisbane#CAD Drafting Services Brisbane#Structural Drafting Brisbane#Plastic Fabrication Brisbane#plastic engineering services brisbane#plastic fabrication experts brisbane

1 note

·

View note

Text

The Future of Jewelry Design: Exploring CAD Designing Services

Discover the future of jewelry design with professional Jewelry CAD Designing Services. Learn how CAD software boosts precision, customisation, and sales.

#Jewelry CAD Designing Services#jewelry cad services#jewelry cad rendering services#jewelry cad software#jewelry cad design#3d jewelry cad software#best jewelry cad software

0 notes

Text

Top Questions to Ask a CAD Drafter Before Hiring a CAD Outsourcing Firm

When top architecture firms, construction companies, or product designers look for CAD drafting services, they don’t just skim through portfolios and say, “Great, let’s go!” They ask questions, real, practical, sometimes tough ones, before they commit.

If you’re a CAD drafter or run a drafting firm, understanding what these clients want to know can help you close deals more smoothly. And if you’re someone looking to outsource your CAD drafting, these are the smart questions you should be asking.

Let’s break them down.

1. “What’s your experience in our industry?”

Top clients don’t want a generalist; they want someone who understands their world. An architect wants someone who knows how to draft detailed building plans. A mechanical engineer expects familiarity with tolerances, materials, and manufacturing processes.

If you’re offering CAD drafting services, this is your cue to showcase your niche experience. Talk about past projects, industry standards you’re familiar with, and the challenges you’ve solved.

Outsourcing tip: When looking for an outsourced CAD drafting partner, choose a company that has experience in your field. A jack-of-all-trades might seem flexible, but deep industry know-how makes a big difference in speed, accuracy, and cost-efficiency.

2. “Can you share samples of similar work?”

This is one of the most common and important asks. It’s not just about how nice your drawings look; clients want to see how well your drafts align with real-world requirements. Clean layers, proper annotations, and clear dimensioning—those are the things that impress professionals.

If you’re on the client side, don’t settle for generic samples. Ask for drawings related to your industry or project type. Look for attention to detail and consistency.

3. “How do you ensure accuracy and quality control?”

Mistakes in CAD drawings can lead to costly errors down the line. Top clients know that. That’s why they want to know how you catch errors before a drawing reaches them.

Are you using a checklist? Is there a peer-review system? Do you run clash detection or 3D validation? These processes matter.

Outsource smartly: One reason many top firms outsource CAD drafting is that they get access to quality control systems that are hard to implement in-house. A good CAD drafting company will have multiple layers of checks before delivering files.

4. “How fast can you deliver, and how do you handle revisions?”

Deadlines are non-negotiable in design and construction. A great CAD drafter or drafting company doesn’t just promise fast work, they deliver it consistently without compromising quality.

Clients want to know:

What's the typical turnaround time?

Do you charge for revisions?

How do you handle scope changes?

Clear answers here build trust. And if you’re the one outsourcing, ask how they prioritize urgent work. Do they offer dedicated resources for faster turnaround?

5. “What software do you use?”

Top clients often work with specific CAD platforms—AutoCAD, Revit, SolidWorks, Inventor, etc., and want seamless integration. They’ll ask if you use the same software, what versions you support, and how you deliver the final files.

They don’t want compatibility issues that waste time and money. Make sure the software you use aligns with your client’s workflows.

Bonus tip for clients: Outsourcing to a professional CAD drafting firm usually means they’re equipped with all the major platforms and can adapt to your preferences.

6. “How do you protect our data and IP?”

This is a big one. When clients share floor plans, product blueprints, or confidential models, they want assurance that their intellectual property is safe.

Clients ask:

Do you sign NDAs?

Where is the data stored?

Who has access to the files?

Professional CAD drafting companies often have secure servers, confidentiality agreements, and access controls in place, one more reason outsourcing can be safer than hiring freelancers without infrastructure.

7. “Can you scale with us?”

If a client has an ongoing need for drafting—say, 30+ hours a week or multiple projects a month—they’ll ask if you can scale up (or down) when needed.

This is where outsourced CAD drafting shines. Instead of hiring new staff every time the workload spikes, clients can rely on a drafting team that expands with their needs.

If you’re offering services, be ready with a plan: Do you have other drafters to support larger projects? Do you offer flexible engagement models?

So… Why Do Many Top Clients Prefer Outsourcing?

All these questions lead to one thing: confidence. Top clients want to feel confident that you’ll deliver quality work, on time, without creating extra headaches.

That’s why more and more of them are choosing to outsource CAD drafting to experienced companies rather than hire in-house or rely on solo freelancers.

Here’s why:

Lower costs without sacrificing quality.

Scalability during busy project cycles.

Specialized expertise in a wide range of industries.

Streamlined processes for collaboration, revisions, and quality control.

Faster delivery times with dedicated teams.

Final Thoughts

If you're a CAD drafter or represent a CAD drafting company, be ready for these questions. They’re not meant to trip you up, they’re signs that a client is serious, thoughtful, and wants a partner, not just a service provider.

And if you’re a client looking to outsource, these questions will help you separate the pros from the pretenders. Looking for a reliable, skilled, and scalable outsourced CAD drafting partner? Let’s talk. At ProtoTech Solutions, we’ve helped clients across architecture, engineering, and manufacturing bring their ideas to life, accurately, affordably, and on time.

#CAD Drafting Services#Outsource CAD Drafting#Architectural Drafting#Engineering Design Support#CAD Outsourcing Tips#outsource cad drafting services#cad outsourcing services#cad drafting outsourcing services#cad drafting services#cad outsourcing companies#cad drafting outsourcing#drafting services in india#outsource drafting services#3d cad drafting services#outsource autocad drafting

0 notes

Text

What Is Reverse Engineering and When Should You Use It?

In today’s competitive and innovation-driven manufacturing landscape, companies are continually searching for methods to optimize designs, streamline production, and gain deeper insight into existing products. One of the most powerful yet often misunderstood tools that supports these objectives is reverse engineering.

Reverse engineering enables organizations to deconstruct a product or system to understand its components, functions, and design principles. This process is not only used to replicate products but also to analyze their structure, improve upon them, or integrate them into new applications.

This article offers a comprehensive explanation of reverse engineering—what it is, how it works, the technologies involved, its applications across industries, and the scenarios where it proves most valuable.

Defining Reverse Engineering

At its core, reverse engineering is the process of disassembling or analyzing an object to understand how it was designed and manufactured. It involves extracting design information from existing products, often in the absence of technical documentation or original design files.

Unlike traditional engineering, which moves from concept to product, reverse engineering starts with the finished item and works backwards to deduce the original specifications. The insights gained are often used to:

Create 3D models and CAD files

Improve product design

Develop compatible components

Diagnose failures or weaknesses

Reproduce obsolete or legacy parts

Reverse engineering does not necessarily imply copying or duplication. Rather, it is a legitimate and valuable practice in modern product development, maintenance, and innovation.

How Reverse Engineering Works

The reverse engineering process varies depending on the object, industry, and intended outcome, but it generally follows a consistent sequence:

1. Data Acquisition

The first step involves capturing detailed information about the object’s geometry, dimensions, and features. This is typically done using advanced 3D scanning technologies such as:

Laser Scanners: Emit laser beams to detect surface contours.

Structured Light Scanners: Project light patterns and measure distortions to determine surface geometry.

Computed Tomography (CT) Scanners: Capture both internal and external features using X-ray technology.

Coordinate Measuring Machines (CMMs): Use touch probes to precisely measure specific points.

These tools collect millions of data points, forming a comprehensive digital representation of the object known as a point cloud.

2. Data Processing and Mesh Generation

The raw point cloud data is cleaned, aligned, and processed to remove noise and inconsistencies. The next step is to convert the point cloud into a polygonal mesh—a 3D surface composed of interconnected triangles.

This mesh is then optimized to ensure it accurately reflects the physical object’s shape while maintaining a manageable file size for further use.

3. 3D Modeling and CAD Conversion

Once a high-quality mesh is obtained, it is used to reconstruct the object in a computer-aided design (CAD) environment. Engineers develop a fully parametric or feature-based CAD model that replicates the part’s geometry.

At this stage, material specifications, tolerances, and functional features may also be analyzed and documented. The final CAD model can be edited, shared, or integrated into larger assemblies.

4. Analysis and Application

The finished model is then used for various purposes, including design improvements, simulation, tooling development, or manufacturing reproduction. Engineers may also perform stress tests, fit checks, and other simulations using the digital model.

Key Technologies in Reverse Engineering

Advances in digital manufacturing and metrology have significantly expanded the capabilities of reverse engineering. The following technologies are essential:

3D Scanning

High-resolution 3D scanning tools rapidly capture the surface geometry of physical objects, forming the foundation for all subsequent steps. These scanners vary in accuracy, speed, and suitability depending on the object's size, complexity, and material.

CAD Software

CAD platforms such as SolidWorks, Autodesk Inventor, Siemens NX, and others play a crucial role in interpreting scanned data and creating usable design files. These models are often parametric, allowing engineers to modify features and dimensions easily.

Simulation Tools

Finite Element Analysis (FEA) and other simulation tools are used in conjunction with CAD models to evaluate a product’s performance under various conditions. These insights support design optimization and failure analysis.

3D Printing and Prototyping

Rapid prototyping allows teams to test modifications derived from reverse engineering efforts. By printing physical models, engineers can assess fit, function, and ergonomics quickly and affordably.

When Should You Use Reverse Engineering?

Reverse engineering is applicable in a wide range of situations across multiple industries. It is especially useful when dealing with legacy components, product innovation, or systems integration. Below are the most common scenarios that justify the use of reverse engineering.

1. Recreating Obsolete or Legacy Parts

One of the primary uses of reverse engineering is to reproduce discontinued components for machines, vehicles, or systems that are no longer supported by the original manufacturer. With no access to original drawings or tooling, reverse engineering provides a reliable way to maintain critical assets and extend their lifecycle.

This is particularly valuable in aerospace, defense, rail, and heavy industries, where replacing entire systems is impractical or cost-prohibitive.

2. Product Improvement and Optimization

Reverse engineering enables manufacturers to analyze existing products and identify opportunities for improvement. Engineers can assess design weaknesses, material inefficiencies, or manufacturing complexities and apply innovative solutions to enhance performance, durability, or cost-effectiveness.

The process often leads to

Lighter and stronger designs

Reduced manufacturing steps

Better ergonomics or aesthetics

Improved energy efficiency

3. Competitive Analysis

Organisations often use reverse engineering to examine competitor products and gain insights into their features, performance, and manufacturing techniques. This helps in benchmarking, identifying intellectual property challenges, and driving innovation.

While care must be taken to respect legal and ethical boundaries, competitive reverse engineering is a legitimate practice used for market intelligence and strategic planning.

4. Integrating New Components with Existing Systems

In cases where new parts or systems need to work seamlessly with older components, reverse engineering ensures dimensional compatibility and functionality. By modeling the existing hardware accurately, engineers can design new components that align perfectly without trial and error.

This use is common in:

Automotive retrofits

Industrial equipment upgrades

Electronic system integration

5. Quality Control and Inspection

Reverse engineering is sometimes used as a validation tool in quality assurance. By scanning and modeling a manufactured part, teams can compare it to the original design and detect any deviations or defects.

This process enhances dimensional verification, especially for complex geometries that are difficult to measure with traditional tools.

6. Digital Archiving

Preserving the design data of critical components through reverse engineering creates a digital archive for future reference. This is important in museums, aerospace restoration, and asset management, ensuring that data is never lost even if physical components degrade or disappear.

Industries Benefiting from Reverse Engineering

The versatility of reverse engineering means it is widely applicable across a variety of sectors:

Aerospace

Airplane components, many of which have long service lifecycles, often require replacement or refurbishment after the original manufacturing data is lost. Reverse engineering ensures structural integrity and regulatory compliance.

Automotive

Classic cars, custom vehicles, and prototype parts benefit greatly from reverse engineering. It enables part reproduction, modification, and even digital recreation of entire vehicle systems.

Medical Devices

Medical implants, prosthetics, and surgical instruments are reverse-engineered to improve functionality, ensure anatomical fit, or replicate discontinued designs.

Consumer Electronics

Electronics companies often disassemble products to understand PCB layouts, circuitry, and design logic. This enables repair, customization, or the development of compatible accessories.

Industrial Manufacturing

Reverse engineering supports tooling design, process improvement, and machine maintenance. It is also used to digitize old parts or machinery for integration into modern workflows.

The Role of Reverse Engineering in Innovation

Beyond its practical applications, reverse engineering fosters innovation by bridging the gap between legacy knowledge and modern capabilities. It encourages experimentation, cross-functional learning, and iterative improvement.

By understanding the details of how a product works, engineers can:

Identify underutilized features

Explore alternative materials

Develop more efficient manufacturing methods

Combine legacy and modern technologies

This approach is particularly important for companies striving to remain competitive in rapidly evolving markets. It allows them to leapfrog development stages, reduce R&D costs, and bring products to market faster.

Ethical and Legal Considerations

While reverse engineering is a powerful tool, it must be practiced within ethical and legal boundaries. It is important to respect patents, copyrights, trade secrets, and intellectual property (IP) rights.

Organizations using reverse engineering must ensure their efforts do not infringe on protected designs. In many jurisdictions, reverse engineering for interoperability or repair purposes is legal, but copying patented elements without permission is not.

Working with professional providers of reverse engineering services in Australia ensures that all procedures are carried out in compliance with local laws and international IP standards.

Choosing the Right Reverse Engineering Partner

The effectiveness of reverse engineering relies heavily on the skill, experience, and tools used. Partnering with specialists who understand materials science, digital modeling, and manufacturing processes ensures accurate, high-quality results.

Providers offering reverse engineering services in Australia are equipped with advanced scanning systems, robust CAD platforms, and cross-industry expertise. They help clients navigate complex engineering challenges, from legacy part digitization to modern product development, while maintaining confidentiality and regulatory compliance.

Conclusion

Reverse engineering is a powerful, multi-purpose process that enables organizations to derive valuable design and manufacturing data from existing physical products. Whether used for reproduction, enhancement, integration, or analysis, it offers significant advantages across the product lifecycle.

By turning physical objects into digital intelligence, reverse engineering allows industries to move forward while learning from the past. It supports innovation, sustainability, and precision in a world where adaptability and speed are crucial to success.

As industries increasingly adopt digital technologies and advanced manufacturing techniques, reverse engineering will play an even more integral role—especially when executed by trusted professionals who offer comprehensive reverse engineering services in Australia and beyond.

#reverse engineering#product development#3D scanning#CAD modeling#engineering services#component analysis#design replication

1 note

·

View note

Text

Advanced CAD Design Services Automation Solutions

Explore advanced CAD Design Services that beautify precision, productiveness, and sustainability. Trust our expert team to deliver awesome pleasant, from simple 2D drafting to notably complex three-D modeling. Experience the most fulfilling combination of innovation, generation, and design with our tailor-made answers. Read More:- https://jordansheel.in/cad-design-services/

#CAD-Design-Services#Custom-CAD-Design-Manufacturer#custom-cad-design-services#custom-CAD-Design-Company#3d-cad-design-services

0 notes

Text

Expert CAD Design Services in Sydney

Get professional CAD design services in Sydney for architectural, engineering, and product design projects. Our skilled team delivers precise, high-quality drawings tailored to your needs. Ideal for builders, developers, and designers seeking efficient and accurate CAD solutions. Contact us today for top-tier CAD design in Sydney.

1 note

·

View note

Text

1 note

·

View note

Text

How 3D Jewelry Animation Services Can Transform Your Marketing Strategy?

Boost your jewelry marketing with 3D jewelry animation services! Engage customers with lifelike visuals, 3D modeling, and CAD designs. Drive more leads today!

#3d Jewelry Animation Services#3d jewelry designers#3d jewelry modeling#3d jewelry designing services#3d jewelry photography#3d jewelry cad software

0 notes

Text

Organizational electrical design management is costly, time-consuming, and manpower-intensive. Companies need accuracy, quick results, and industry compliance. But doing it in-house takes longer and costs more.

That is where Electrical Design Service outsourcing becomes a strategic success. Employing external experts enables companies to work quicker, enhance quality, and cut costs. The following are reasons why outsourcing electrical design. Why is this the best option for your company?

0 notes

Text

Top Product Design Services 3D CAD Modeling and Prototyping Solutions From concept to prototype, Shalin Designs offers excellent product design services, 3D CAD modeling, and design for manufacturing to bring your ideas to life.

#Product design services#3D CAD modeling services#Prototype development services#Industrial product design#Custom product design solutions#Mechanical product design#Engineering design services#Product prototyping service#Manufacturing design solutions#CAD product design

0 notes

Text

Top CAD Drafting Trends to Watch in 2025

If you work in design, engineering, or architecture, you already know: CAD drafting is evolving fast. Every year brings new software features, smarter tools, and fresh ways of thinking about how we create, share, and even experience designs. As we move through 2025, it’s clear that CAD isn’t just about drawing anymore — it's about innovation, automation, and real-time collaboration.

So what’s next? Let’s take a look at the top CAD drafting trends that are shaping the future this year.

1. AI-Driven Drafting Is No Longer a Dream

AI is not just a buzzword anymore — it's becoming a practical tool inside CAD environments. Leading software platforms like AutoCAD, SolidWorks, and Fusion 360 have started embedding AI features that help drafters automate repetitive tasks, catch design errors early, and even suggest optimizations.

Imagine this: You’re drafting a building layout, and your CAD software flags potential structural issues before you even finish. Or you start drawing piping layouts, and AI automatically routes them based on best practices. That’s already happening!

In 2025, expect AI assistance to become your new best drafting buddy — saving time, boosting accuracy, and making complex projects easier to manage.

2. Cloud-Based CAD Collaboration Is the New Normal

Remember the days of endless email attachments and “version 17_final_FINAL.dwg” file names? Thankfully, they’re behind us.

With cloud-based CAD platforms like Onshape, Autodesk Construction Cloud, and even AutoCAD Web, teams can work together in real time, from anywhere. Changes are synced instantly, and multiple users can review or edit designs simultaneously.

In today's remote and hybrid work era, cloud collaboration isn’t optional — it’s expected. Teams that adopt cloud-based CAD are not just faster; they’re more connected, more secure, and much better positioned for global projects.

3. Integration of AR and VR in CAD Drafting

If you haven't tried slipping on a VR headset to walk through your CAD model yet, you're missing out. Augmented Reality (AR) and Virtual Reality (VR) are changing the game for how we experience drafted designs.

Instead of looking at 2D drawings or rotating 3D models on a screen, clients and stakeholders can walk through a design — whether it’s a new home, a manufacturing plant, or a complex mechanical system.

In 2025, more firms are investing in AR/VR integration to help with design validation, client presentations, and training. Not only does this boost wow-factor, but it also reduces errors that would otherwise be caught late (and cost a lot more to fix).

4. More Emphasis on Sustainability in Drafting

Green building isn’t just a trend — it’s a responsibility. And sustainability is making its way deep into CAD workflows.

Today’s drafters are being asked to think beyond just "how it looks" or "how it functions" to how it impacts the environment. Modern CAD tools now offer features like energy analysis, material lifecycle tracking, and carbon footprint estimations directly inside drafting environments.

This shift means drafting sustainably is no longer a niche skill. It’s becoming an expectation across architecture, engineering, and manufacturing industries.

5. Rise of Automation and Parametric Design

Manual drafting? Sure, it still happens. But more often, automation and parametric design are taking over.

Parametric design lets you create models where one change automatically updates related components. For example, resize a window, and the wall adjusts to fit — no manual tweaks needed.

In 2025, CAD software continues pushing toward smarter, automated drafting workflows. This doesn’t just make projects faster; it drastically reduces human error and gives drafters more time to focus on creativity and problem-solving rather than manual grunt work.

6. Cross-Platform CAD Skills Are in Demand

Gone are the days when knowing just AutoCAD was enough. Employers and clients now expect CAD professionals to work across multiple platforms — from Revit to Rhino, SolidWorks to Inventor — depending on the project’s needs.

Learning multiple CAD environments gives you a serious edge in today's competitive market. It also makes collaboration smoother when different teams use different tools but need to work together.

In short, Adaptability is the new specialization.

7. Better Access to Learning and Certification

The barriers to learning CAD drafting have never been lower.

From online certifications on Coursera and LinkedIn Learning to free YouTube tutorials, anyone can start building CAD skills today — and many employers now value certifications from recognized online courses just as much as traditional degrees.

In 2025, we're seeing a huge surge in micro-credentials, skill bootcamps, and remote internships focused on CAD drafting. Whether you’re a seasoned pro or just getting started, there’s never been a better time to level up.

Final Thoughts

CAD drafting is stepping into an exciting new era — one where AI, cloud collaboration, AR/VR, and sustainability aren’t futuristic ideas, but everyday realities.

If you're already in the drafting world, embrace these trends to stay ahead of the curve. And if you're just starting? There's no better time to dive in and build a future-ready career.

One thing’s for sure: In 2025 and beyond, CAD drafters won’t just draw designs — they'll design the future.

#cad drafting services#outsource cad drafting services#cad outsourcing services#outsource autocad drafting#outsource drafting services#cad drafting company#cad design and drafting services#cad drafting outsourcing services#cad outsourcing#cad drafting outsourcing#outsourced cad services#cad outsourcing companies#autodesk drafting outsourcing#outsource cad services#drafting services in india#cad drafting contractor#autocad design outsourcing#outsource autocad 3d services#cad outsourcing company

0 notes