#5 Axis CNC Machine Shop

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Note

Bro just straight up pouring molten bronze like it's not the coolest thing in the world wtf

Right now I work in a wood & metals fabrication shop and As a man of many hats if I see a piece of machinery I make it my life goal to get my dirty little hands on operating it at least once (when i was on the pour team i did most jobs but pouring from the big crucible of metal was my favorite and i was pretty good at it. never did the crane bc i have a bad sense of direction and you have to be pretty quick when pouring molten metal)

My next target is this thing:

#5 axis cnc i will get you.#i currently specialize in the 3 axis but i havent been able to learn to toolpath this thing bc its significantly more complicated#and also our shop's is kind of .broken#but i toured a shop that had 7 axis cncs in enclosed cabinets and shit literally the most insane precision machining#idk if i would be able to work in a shop like that but a man can dream#m#answers

5 notes

·

View notes

Text

Application of 3+2 CNC Machining in Mold Making Factory

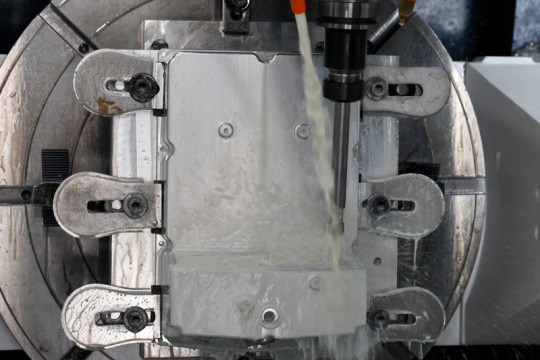

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Affordable CNC Milling Machine Wood and Metal

In the realm of modern manufacturing, the CNC milling machine stands as a cornerstone of precision and efficiency. These machines have revolutionized the way we approach machining processes, offering unparalleled accuracy and the ability to produce complex parts with ease. Whether you’re a seasoned machinist or a newcomer to the field, understanding the intricacies of CNC milling machines can significantly enhance your manufacturing capabilities.

Affordable CNC Milling Machine

A CNC (Computer Numerical Control) milling machine is a sophisticated and highly precise tool used to shape and cut materials like metal, wood, and plastic. These machines are widely used in manufacturing and prototyping due to their ability to produce complex shapes and high-quality finishes.

Equipment that uses computerized controls to operate and manipulate cutting tools to shape materials into desired forms. These machines are capable of performing a wide range of operations, including drilling, cutting, and milling, with high precision and repeatability.

Small CNC milling machines are compact, desktop-sized machines that offer a range of advanced milling capabilities in a space-efficient package. These machines are well-suited for prototyping, small-scale production, and educational/hobbyist use.

Key Features of Small CNC Milling Machines

Compact Size

Small CNC mills have a small footprint, often fitting on a desktop or workbench. This makes them ideal for use in limited workshop or studio spaces. Typical work envelopes range from around 8″ x 6″ x 3″ up to 15″ x 12″ x 5″.

High Precision

Despite their small size, these machines are capable of producing parts with tight tolerances and smooth surface finishes. They utilize high-quality components like ball screws, linear guides, and rigid frames to achieve this precision.

Versatile Machining

Small CNC mills can handle a variety of materials including wood, plastics, aluminum, and other soft metals. This versatility allows them to be used for prototyping, model making, and small-scale production across many industries.

User-Friendly Operation

Many small CNC mills are designed with ease of use in mind. They often feature intuitive control interfaces, automated tool changers, and integrated CAM software to simplify the machining process. This makes them accessible for hobbyists and small businesses.

Affordable Pricing

Compared to larger industrial CNC machines, small desktop models are much more affordable, making them accessible for individual users and small shops. Prices can range from a few thousand dollars up to around $10,000 for a well-equipped model.

Types of CNC Milling Machines

There are several types of CNC milling machines, each designed for specific applications and capabilities. Here are some of the most common types:

Vertical CNC Milling Machines

Vertical CNC milling machines have a vertically oriented spindle that holds the cutting tool. These machines are versatile and commonly used for a wide range of applications, from prototyping to production.

Horizontal CNC Milling Machines

Horizontal CNC milling machines have a horizontally oriented spindle. These machines are ideal for machining heavy and large parts, as they offer greater stability and support.

5-Axis CNC Milling Machine

5-axis CNC milling machines are capable of moving the cutting tool along five different axes simultaneously. This allows for the creation of highly complex and intricate parts, making these machines ideal for aerospace, automotive, and medical industries.

How Does a CNC Milling Machine Work?

The operation of a CNC milling machine involves several key steps:

Design Creation: The first step is to create a digital design of the part using CAD (Computer-Aided Design) software. This design is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software.

Material Loading: The raw material, often referred to as the workpiece, is securely clamped onto the machine’s worktable.

Tool Selection: The appropriate cutting tools are selected and loaded into the machine’s tool holder.

Machining: The CNC program is executed, and the machine’s cutting tools follow the programmed path to shape the material into the desired form.

Finishing: After machining, the part may undergo additional processes such as deburring, polishing, or coating to achieve the final finish.

Types of Materials

Desktop CNC machines are versatile and can process a wide range of materials, including:

Wood: Commonly used in woodworking and carpentry.

Plastics: Utilized in prototyping and product design.

Metals: Employed in jewelry making, metalworking, and small-scale manufacturing.

Composites: Applied in automotive, aerospace, and consumer goods.

Foam: Used in packaging, modeling, and crafts.

Applications of CNC Milling Machines

Prototyping and Product Development

In the fields of prototyping and product development, desktop CNC machines are invaluable tools. Applications include:

Rapid Prototyping: Creating functional prototypes quickly and accurately.

Custom Parts: Producing custom components for various projects.

Product Design: Testing and refining product designs before mass production.

Education and Training

Desktop CNC machines are widely used in educational institutions for teaching and training purposes. Applications include:

Engineering Education: Providing hands-on experience with CNC technology.

Vocational Training: Preparing students for careers in manufacturing and machining.

STEM Programs: Enhancing science, technology, engineering, and mathematics education.

Choosing the Right CNC Milling Machine

When selecting a CNC milling machine, there are several factors to consider:

Machine Size

The size of the machine determines the maximum dimensions of the workpiece you can machine. Consider the types of projects you plan to work on and choose a machine with an appropriate work envelope.

Spindle Speed

The spindle speed affects the cutting performance and surface finish of the machined part. Machines with adjustable spindle speeds allow you to optimize the cutting conditions for different materials.

Tool Capacity

The tool capacity refers to the number of tools the machine can hold and automatically change during the machining process. A larger tool capacity allows for greater flexibility and efficiency in machining complex parts.

Software Compatibility

Ensure that the CNC milling machine is compatible with the CAD/CAM software you plan to use. Some machines come with proprietary software, while others are compatible with popular design programs like SolidWorks and Mastercam.

Ease of Use

If you’re new to CNC machining, look for a machine that is user-friendly and comes with comprehensive instructions and support. Many manufacturers offer online tutorials and customer support to help you get started.

Frequently Asked Questions (FAQ)

What materials can a CNC milling machine work with?

CNC milling machines can work with a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and wood.

How do I create a CNC program for my design?

CNC programs are created using CAM software, which converts the digital design from CAD software into machine-readable code. This code is then uploaded to the CNC milling machine for execution.

Can I use a CNC milling machine for prototyping?

Yes, CNC milling machines are commonly used for prototyping due to their ability to quickly and accurately produce parts with complex geometries.

How do I maintain my CNC milling machine?

Regular maintenance includes cleaning the machine, checking and replacing cutting tools, calibrating the machine, and ensuring the software is up to date. Refer to the manufacturer’s instructions for specific maintenance guidelines.

What is the difference between a vertical and a horizontal CNC milling machine?

Vertical CNC milling machines have a vertically oriented spindle, making them versatile and suitable for a wide range of applications. Horizontal CNC milling machines have a horizontally oriented spindle, offering greater stability and support for machining heavy and large parts.

0 notes

Text

Why Choose a CNC Machine Shop in Dallas, Texas

Why Choose a CNC Machine Shop in Dallas, Texas?

Dallas, Texas is the fastest growing metro area in the country and is home to many diverse industries. These include oil and gas, health care, telecommunications, and more.

The oil and gas industry in Texas relies on high quality CNC machining to manufacture complex components like Bates Machine. Owens can machine these components with tight tolerances and precision.

Oil & Gas

The oil and gas industry is one of the largest in the world, generating hundreds of billions of dollars each year. Despite recent challenges, the

oil and gas sector is recovering from the economic downturn and major environmental disasters of recent years.

The industry is broken into three main operational sectors: upstream, midstream and downstream. The upstream sector involves the exploration and production of crude oil and natural gas.

Once oil and gas are extracted, they need to be transported to a refinery, where they can be refined and distributed. This process can include transportation by tanker ships, pipelines or trucking fleets.

The oil and gas industry is a vital part of our economy and society, even in the face of increasing pressure to reduce greenhouse gas emissions. However, the industry is facing a unique set of issues that challenge how and where they will invest in future development and growth. These issues include energy security, supply diversification, and the low-carbon transition.

Medical

The medical industry is a large and growing part of the Dallas-Fort Worth metroplex. Some of the top employers include UT Southwestern, Texas Health Resources, Baylor Scott & White Health and Parkland Health and Hospital system. The medical devices and supplies sector, which is led by the likes of McKesson and AmerisourceBergen, is one of the fastest growing sectors in Texas with annual growth in excess of 15 percent a year.

Bates Machine in Farmersville, Texas is a family owned and operated machine shop that has been serving the DFW area since 1975. We provide quality machining, fabrication and assembly services for the commercial sector, government agencies, and healthcare organizations. From micromachining to 5 axis milling, we can accommodate your needs. The right machines, the right people and the right tools can result in a successful project on time and on budget. Let us put our years of experience to work for you. The best way to get in touch is to send an email or give us a call at (972) 782 - 7351.

Aerospace

With a plethora of aerospace companies in the metroplex, it’s no surprise that Bates machine in Farmersville, Texas has produced many innovative products for the likes of NASA and Lockheed Martin. We have also mastered the art of a competitive pricing model allowing our aerospace and defense clients to continue their quest for glory in a slicker way. Whether your needs are small or large, we can handle your manufacturing challenge from start to finish. Besides our machining, we can also assist with your engineering and product development needs as well. The company specializes in high-quality component machining, assembly and welding as well as precision tooling and testing services.

Read the full article

0 notes

Text

The Future of Industrial Manufacturing (3-Axis and 5-Axis CNC Milling Machines)

Industrial manufacturing is undergoing a significant transformation driven by technological advances and the quest for accuracy and efficiency. In this blog, we explore two critical trends shaping the future of manufacturing: the development of injection molding flowlines and the emergence of 3-axis and 5-axis CNC milling machines. We will examine the challenges, strategies, and prospects associated with these critical sectors, as well as common questions to provide a comprehensive understanding of the evolving state of industrial manufacturing.

Trends In CNC Machining

The current industrial landscape is characterized by rapid technological advances and innovations such as 9-axis motors provide improved quality and efficiency

Continuous improvements in CNC machines seek to simplify operations and improve results.

Emerging Factors:

1. Universal solutions for tooling

Traditional job-holding methods, such as vacuum plates and fixtures, can be expensive and prone to distortion, requiring tailored solutions for each job

Universal foundations emerged as a cost-effective alternative, halving costs, and increasing flexibility. The universal soft palate can be customized and reused, further simplifying the machining process. Combining a vacuum table and a soft jaw provides an efficient method for producing complex parts.

2. Adoption of Robotics

Robots have been used in CNC shops for a long time, but the recent introduction of collaborative robots (cobots) has changed the landscape. These robots are intended to work with humans with precision and skill. They can be trained by hand movements for specific tasks and robotic vision with more advanced vision. Tesla cars, for example, are using robotic vision to recognize other vehicles and pedestrians, demonstrating how cobots can perform tasks handled by humans in typical CNC facilities

3. Better workforce training

Manufacturers integrate 3D CAD viewers into device platforms, providing visual guidance as devices are configured and manufactured. Some platforms also include troubleshooting videos, improving employee training, and reducing operational errors. This leads to cost-effective production cycles and increases existing employees' productivity.

4. Advances in CAD/CAM software.

The availability of CAD/CAM software has improved dramatically in recent years, shifting towards more affordable and easy-to-use solutions at higher prices. Advanced CAM/CAD software for business processes is more accurate, more efficient, and easier to update, making it usable for large companies and small businesses.

5. Multifunctional

Modern CNC machines are equipped with inertial tool changers, with blades capable of holding more than 100 tools. Machine centers can process multiple parts simultaneously, and some machines are configured for multi-spindle and multifaceted cutting operations.

Improving Injection Molding Flow Lines

Plastic injection mold design is a cornerstone of modern manufacturing, enabling the production of many complex plastic parts with high accuracy and performance. However, there are challenges in achieving optimum part quality and performance by regulating flow rates during molding. Let’s explore ways to improve injection molding flowlines:

Optimize Injection Parameters:

Temperature control: Precise temperature control of the bottle and mold is essential to minimize leaks. Uniform temperatures throughout the mold prevent premature hardening and rapid resin flow.

Injection speed and pressure: Fine-tuning injection speed and pressure parameters can affect the flow behavior of molten plastic, reducing the chance of flowline formation. Modifications based on part geometry and material properties improve flowline quality.

Gate Design and Placement:

Location of the gate: The strategic placement of the gate, which serves as an entry point to the molten plastic, minimizes flow. Placing the gates close to solid block or complex geometries ensures accurate packing and reduces flowline errors.

Gate Geometry: Optimal gate design, such as gates of appropriate size and shape, encourages even distribution of molten plastic and reduces the detection of flow doors based on specific requirements.

Mold Design and Venting:

Gradient cooling: An efficient cooling system with conformal cooling channels ensures a constant temperature and reduces flowline errors. Advanced cooling technology optimizes part quality by controlling its hardness.

Aeration: Proper aeration of the molds releases entrapped air and gases, preventing void space and reducing flow errors. Optimization of venting design and installation ensures efficient resin flow, whether for plastic chocolate molds or other applications.

4.Material Selection and Additives:

Properties: Choosing a resin with appropriate rheological properties minimizes flow rates. The effects of higher flow rates and better flow characteristics exhibit smoother flow behavior and reduce sensitivity in flow lines.

Additives Corporation: Adding flow-enhancing agents or nucleating agents to plastic formulations improves the flow characteristics and reduces flow errors. These additives modify the viscosity and crystallization kinetics, improving the flowline properties.

5. Process Monitoring and Optimization:

Simulation tools: Computer-aided engineering (CAE) software simplifies mold flow analysis, identifies potential flow problems, and optimizes process simulations Virtual testing enables improved efficiency and ensures the desired phase quality.

Real-time analytics: Sensors and monitoring systems enable continuous monitoring of key process variables, enabling immediate adjustments and continuous process improvements.

FAQ

Q1: What are the primary factors contributing to flow line formation in injection molding?

A1: Flow line formation is influenced by injection parameters (temperature, speed, pressure), gate design, mold geometry, material properties, and process conditions.

Q2: How do flow lines affect the quality of injection molded parts?

A2: Flow lines can impact the structural integrity, aesthetics, and functionality of parts, potentially leading to cosmetic imperfections or functional defects.

Q3: Can flow lines be completely eliminated from injection molded parts?

A3: While complete elimination is challenging, their appearance and severity can be significantly reduced through process optimization, mold design modifications, material selection, and additive incorporation.

Q4: What role does mold design play in minimizing flow line defects?

A4: Injection molding solutions, including cooling systems and venting, ensure uniform resin flow and reduce flow line formation.

Q5: How can I improve flow line quality in my injection molding process?

A5: To enhance flow line quality, focus on optimizing injection parameters, gate design, mold geometry, material selection, and process monitoring.

Conclusion:

As manufacturing technology improves, optimizing injection molding flowlines and using advanced CN milling technologies will play an important role in driving efficiency, accuracy, and quality.

#plastic injection mold design#injection frisbee#plastic chocolate molds#injection molding solutions#injection molding maker#plastic injection molding manufacturer#plastic molds for chocolate making#best injection molding company

0 notes

Text

youtube

Cnc machining center for large cnc machining parts

We are specialize in component metal machining parts cnc aluminium, turning cnc machining parts, cnc machining services parts, custom cnc machining manufacturer, cnc machining shop, cnc machining lathe parts, service stainless cnc machining parts, 5 axis cnc machining center, aluminum cnc machining parts, cnc metal machining manufacturing.

----------------------------------------------------

https://mxymachining.com/

0 notes

Text

Innovations Unveiled At Machine Shop Equipment Auctions

Machine shop equipment auctions have become hotspots for showcasing cutting-edge innovations, offering a glimpse into the future of manufacturing and machining. These auctions, traditionally venues for acquiring second-hand equipment, now also highlight the latest advancements in technology, materials, and processes.

Here are some of the key innovations unveiled at recent machine shop equipment auctions:

Advanced CNC Machines

CNC (Computer Numerical Control) machines are a staple in modern manufacturing, and recent auctions have displayed state-of-the-art models featuring significant enhancements:

Multi-axis Machining: Newer CNC machines with 5-axis or even 7-axis capabilities allow for more complex and precise manufacturing. These machines can produce intricate parts in a single setup, reducing the need for multiple machines and setups.

Integrated AI and Machine Learning: These systems optimize cutting paths and predict maintenance needs, reducing downtime and increasing efficiency. AI integration also improves quality control by continuously monitoring the production process.

3D Printing and Additive Manufacturing

The rise of 3D printing, particularly in metal additive manufacturing, is a significant innovation showcased at these auctions:

Hybrid Machines: Combining additive and subtractive processes, hybrid machines can print a part and then machine it to precise specifications within the same setup. This integration streamlines production and opens up new possibilities for complex geometries.

New Materials: Advances in materials science have led to the development of new metal powders and composites that offer superior strength, heat resistance, and durability, expanding the applications of 3D printing in industries like aerospace and medical devices.

Robotics and Automation

Automation continues to transform machine shops, and the latest robotic systems were prominently featured:

Collaborative Robots (Cobots): Designed to work alongside human operators, cobots enhance productivity without requiring extensive safety measures. They are used for tasks such as loading/unloading machines, assembly, and quality inspection.

Automated Guided Vehicles (AGVs): These autonomous vehicles transport materials and parts around the shop floor, optimizing workflow and reducing manual handling. Integration with shop floor management software ensures precise and efficient material movement.

Smart Tooling and Sensors

Smart tooling and sensor technologies are pivotal in enhancing machine efficiency and product quality:

Tool Condition Monitoring: Sensors embedded in cutting tools and machines monitor tool wear and performance in real time. This data helps in predicting tool life and scheduling timely maintenance, thereby avoiding unexpected downtime.

Vibration and Thermal Sensors: These sensors track machine conditions and detect anomalies that could indicate mechanical issues, allowing for proactive maintenance and reducing the risk of breakdowns.

IoT and Digital Twin Technology

The Internet of Things (IoT) and digital twin technology are revolutionizing how machine shops operate:

IoT-Enabled Machines: These machines can communicate with each other and with central management systems, providing real-time data on performance, energy consumption, and production metrics. This connectivity enhances decision-making and operational efficiency.

Digital Twins: Creating a digital replica of physical equipment allows for simulation and analysis of performance under various conditions. This technology aids in optimizing processes, planning maintenance, and improving overall productivity.

Energy Efficiency and Sustainability

Innovations aimed at reducing the environmental footprint of machine shops were also highlighted:

Energy-Efficient Machines: Newer machines are designed to consume less power while maintaining high performance. Technologies such as regenerative drives and energy-efficient motors are becoming standard.

Recycling and Waste Management: Advanced systems for recycling metal shavings and waste materials were showcased, highlighting efforts to create more sustainable manufacturing processes.

In conclusion, machine shop equipment auctions are now pivotal in introducing and disseminating innovative technologies that shape the future of manufacturing. These advancements not only enhance productivity and precision but also pave the way for more sustainable and efficient production practices.

0 notes

Text

Exploring Hydraulic Press Brake Solutions in China

Hydraulic press brakes are a crucial component in the manufacturing and fabrication industry, enabling precise bending of metal sheets and plates. China, with its robust manufacturing sector and advanced technology capabilities, offers a diverse range of hydraulic press brake solutions. Let's delve into the world of hydraulic press brakes in China, exploring their features, benefits, and the companies leading this sector.

Advanced Technology and Precision Engineering

Chinese manufacturers of hydraulic press brakes have embraced advanced technology to enhance precision and efficiency. These machines are equipped with state-of-the-art hydraulic systems, CNC controls, and advanced bending tools. The integration of servo motors and precise positioning systems ensures accurate bending angles and repeatability, making them ideal for high-precision fabrication tasks.

Variety of Models and Capacities

One of the key strengths of Chinese hydraulic press brake manufacturers is their diverse range of models and capacities. Whether it's small-scale workshops or large industrial operations, there are press brakes available to suit different needs. From compact models with lower tonnage capacities to heavy-duty machines capable of bending thick plates, Chinese manufacturers offer a comprehensive selection to cater to various industries.

Cost-Effective Solutions

China's competitive manufacturing landscape translates into cost-effective solutions for hydraulic press brakes. While maintaining high-quality standards, Chinese manufacturers often offer competitive pricing compared to counterparts in other regions. This affordability makes hydraulic press brakes from China a preferred choice for businesses looking to optimize their manufacturing processes without compromising on quality.

Customization and Flexibility

Flexibility is another hallmark of hydraulic press brake solutions from China. Manufacturers often offer customization options to meet specific customer requirements. This includes features such as tooling options, backgauge configurations, safety systems, and integration with automation technologies. This customization ensures that businesses can tailor their press brake systems for optimal performance and productivity.

Leading Hydraulic Press Brake Manufacturers in China

Several companies in China stand out as leaders in the hydraulic press brake industry. These companies combine technological expertise, robust manufacturing capabilities, and a commitment to quality to deliver top-notch solutions. Some prominent names include:

1. ACCURL: Known for its innovative CNC press brake machines, ACCURL offers a wide range of models with advanced features such as automatic bending angle calculation, multi-axis synchronization, and ergonomic designs for operator comfort.

2. Durmapress: Durmapress specializes in hydraulic press brakes with options for CNC controls, offline programming software, and customizable tooling. Their machines are designed for precision bending across various materials and thicknesses.

3. JFY: With a focus on advanced automation and Industry 4.0 integration, JFY's hydraulic press brakes are equipped with intelligent control systems, remote monitoring capabilities, and energy-saving features for sustainable operation.

4. HACO: HACO's hydraulic press brakes are renowned for their durability, accuracy, and versatility. They offer a range of models suitable for small job shops to large-scale production facilities, ensuring reliability and performance.

5. Anhui Wenying Machinery Technology Co., Ltd.: Winying is equipped with modern standard workshops and advanced professional hydraulic press brakes. We have been committed to the development of precision machine tools for many years and formed a complete system.

Conclusion

The hydraulic press brake sector in China presents a dynamic landscape of advanced technology, cost-effective solutions, customization options, and leading manufacturers. Businesses looking to enhance their metal fabrication capabilities can explore the diverse range of hydraulic press brake solutions offered by Chinese manufacturers, benefiting from precision engineering, reliability, and value-driven performance.

1 note

·

View note

Text

Benefits of Using CNC 5 Axis Rotary Table [Infographic]

The CNC 5 Axis Rotary Table manufactured by SilverCNC offers several benefits to machining operations.

Firstly, it improves production efficiency and accuracy. With this tool, you can achieve complex machining operations in a single setup, which saves time and reduces the risk of operator errors. The equipment also helps to reduce scrap rates, as it enables precise machining of highly complex parts. As a result, it increases the overall productivity of the machining operations.

Secondly, the CNC 5 Axis Rotary Table is versatile. It can accommodate different types of workpieces, from small to large, and various geometries, such as irregular or contoured surfaces. This flexibility makes it ideal for producing prototypes or bespoke parts, which often require unusual machining angles and planes.

Thirdly, the SilverCNC’s product is reliable and durable. It is constructed using high-quality materials that can withstand the harsh conditions found in machine shops. The product is also easy to maintain and requires minimal downtime, which is critical in maintaining a steady workflow.

For more information visit here: https://www.atoallinks.com/2023/unleashing-the-full-potential-of-your-machining-operations-with-5-axis-rotary-table/

0 notes

Text

CNC Milling Services San Jose

Welcome to our leading contract manufacturing machine shop located in the heart of San Jose, California. We are your trusted partner for precision machining and manufacturing solutions. With a reputation for excellence, we offer a wide range of services to meet your specific needs. Our team of skilled professionals is dedicated to delivering high-quality products and services, and we take pride in our commitment to meeting and exceeding customer expectations. Whether you require precision CNC machining, assembly, or other manufacturing services, we have the expertise and state-of-the-art technology to provide you with top-notch solutions.

0 notes

Text

What are the Advantages of CNC Machines?

Over the years, there have been many advances in manufacturing processes. The Fourth Industrial Revolution has led to one of these – CNC machining and milling. CNC stands for Computer Numerical Control. CNC machines perform computer numerical control machining, a precision manufacturing process involving core-programmed computer software. The manufacturing industry, especially, benefits from CNC machining. Compared to manual machining, CNC technology improves efficiency and accuracy, makes production faster, and leads to safer and cheaper operations. As a culmination of such high-paced activities, precision-turned components will offer businesses a competitive edge by realizing complex designs, introducing structural benefits, and creating parts that could not be reproduced profitably by any other manufacturing method. On that note, let us take a look at the various advantages offered by precision-turned components.

Computer-numerical control (CNC) machining has revolutionized the manufacturing industry. CNC machine has, in many instances, replaced operator-required equipment. Manufacturers choose CNC machining for their fabrication and manufacturing applications. It provides efficient, expedient, and precise manufacturing capability, ideal for producing huge quantities of items typically produced with a shaping machine, center lathe, grinder, router, or vertical miller. The computer-numerical control also offers financial and production advantages over the conventional method. In manual lathing, for example, there must be a skilled technician for every machine, while with CNC machining, one skilled person can operate several machines. We’ll thoroughly assess the advantages of CNC. Please visit this Custom 5 Axis CNC Machining and know more benefits of CNC Machines service.

Endurance: Manual machining processes can only continue as long as there are skilled workers present to work the machines. The manufacturing process stops when workers take a break or go home at the end of their working day. However, operating CNC machines 24 hours a day, 365 days a year is one of the main advantages. It depends on the project’s design, but in many cases, the operator can program the machine’s computer and set it to create the required part as many times as necessary. Because less human intervention is required than manual machining, fewer experienced engineers and skilled workers are needed. As a result, machine shops can increase their production capacity.

High Precision and Improved Accuracy: One of the most significant benefits of using CNC machining compared with manual operations is precision. It’s possible to create parts that meet precise specifications without the need for constant attention from a skilled operator. With CNC milling, human error is eliminated because the machines rely on computer instructions for fabricating parts. However, there is still some control over the manufacturing process by the operator of the CNC machine. The accuracy of the CNC milling project depends very heavily on the operator. It is down to the operator to control the operating environment and cutting tool calibration.

Speed: Another of the numerous advantages CNC machining offers is its higher speed. When CNC machines are used, operators can be much more efficient because the machines can use their fastest settings. CNC machines can run 24/7 without running out of steam. They don’t need a break for coffee or lunch. No holidays need to be booked or any kind of time off. There are no trade-offs with a CNC machine. Such benefits, together with the ability to maintain a high degree of accuracy and minimal waste of material resources, make CNC machining and milling one of the best ways to ensure production is efficient, fast, and scalable with a lower cost liability.

High Production and Scalability: After the operator has programmed the machine with the necessary design specifications, production can take place. Once the CNC machine has started a production run, creating parts takes no time at all. As well as producing large numbers of parts, modern-day CNC machines are also very scalable. What makes them different from conventional machines and manual production processes is that a CNC machine can be programmed to produce one single item or large quantities. There are no limitations to the number of parts you can manufacture, allowing companies to use their resources and finances more efficiently.

1 note

·

View note

Text

How to Choose a CNC Machine Shop

How to Choose a CNC Machine Shop

Whether you need tons of tiny metal plates bent to a precise angle or a large panel punched to order, CNC precision machining is the way to go. The right shop can handle it all.

Owens Industries in Lexington, KY specializes in machining complex components for medical manufacturers and oil & gas industry applications. They machine a wide variety of materials, including stainless steel and brass.

1. High Precision

The manufacture of precision parts requires a high level of accuracy. CNC machining is used to cut materials with an encoded computer program directing the movement of machines that are capable of performing a variety of tasks like cutting, grinding, drilling, milling and turning.

Companies such as Bates Machine and Mfg. in Dallas have the capabilities to meet your cnc machine shop manufacturing needs. They offer a variety of services including CNC machining, welding and custom assembly. Their customers include medical manufacturers and automotive manufacturers. They have the capability to machine a variety of materials including stainless steel, carbon steel and aluminum alloys.

2. Fast Turnaround

A machine shop that takes pride in their work will ensure they are always able to provide a timely delivery of the finished product. They will also have a quality control and management system to prevent delays due to equipment failure or human error.

Machined products can require precision tolerances that the human eye cannot discern. Medical devices are a good example of a complex product that requires precise CNC milling.

Medical manufacturers can count on Owens Industries for precision machined parts. Their services include machining, prototyping, custom fabrication, heat treating and assembly. They work with materials such as aluminum, low and high carbon steel, brass and bronze as well as plastics like delrin.

3. Economical

When choosing a CNC machine shop, look for long-term value. Avoid companies with outdated equipment that will only lead to costly mistakes and delays in production. Instead, choose a company that has invested in the latest machinery to ensure high-quality results.

Medical manufacturers and food processing plants often require CNC machines to meet specific health codes and industry standards. Owens Industries provides precision CNC machining services to these clients.

Moreover, the city hosts several Fortune 500 companies, including American Airlines Group, Exxon Mobil, Texas Instruments, Dean Foods, Tenet Health Care and Lockheed Martin Aeronautics Co.

4. Customer Satisfaction

If you want to ensure that your customers will return to your business, you need to provide excellent customer service. This includes making sure that your parts are accurate and meeting your expectations. Choosing a CNC machine shop with updated equipment can help you achieve this goal.

The quality of the CNC machines in a machine shop plays an important role in determining the finished product. You should look for a shop that has multiple styles of machines, such as turning and milling. They should also have two to five-axis shaping capabilities, which can make a big difference in the accuracy of your products.

5. Innovation

The complexities of modern electronic parts require high-precision machining. CNC machines are able to produce detailed PCBs and delicate connectors that meet the exact specifications of customers.

For medical devices and instruments, CNC machining can produce a variety of contours, shapes, carvings, joints and inlay that are difficult to create manually. Furniture makers can also use this technology to shape wood components according to customer specifications.

Moreover, 5-axis machining capabilities enable shops to achieve accurate and smoother parts with less time and effort than traditional 3-axis machines. This makes them ideal for manufacturing aerospace applications and other industries that demand a high degree of precision.

6. Flexibility

It’s important to choose a CNC machine shop that offers flexibility. For example, a company that has multiple styles of machines can produce parts with different shapes. Moreover, they can adjust their equipment to accommodate new requirements or to address issues that occur with older machines. This ensures that the parts produced are high quality and fit well.

Precision CNC machining is an ideal solution for industries that need custom components. This process is fast and leaves little room for errors. This is why medical manufacturers rely on this technology for products like MRI machines and safe enclosures. In addition, auto companies use it to make prototypes before adding them to the production line.

7. Experience

Choosing a CNC machine shop with extensive experience can save you money in the long run. Unlike some cheaper shops, quality ones invest in updated equipment and work closely with clients to understand their needs. This helps to avoid mistakes that could cost you in the future.

Whether you need to meet industry standards or create prototypes, precision CNC machining can provide the exact results you require. From lathes to milling machines, look for a company that has a range of capabilities to ensure your project is completed accurately and within budget.

Read the full article

0 notes

Text

1 note

·

View note

Text

1 note

·

View note

Text

AFR Will See You at SEMA 2022

It’s that time of year again where our Los Angeles, California-based team heads to Las Vegas, Nevada for the 2022 SEMA Show! SEMA is by far the best professional trade show for the automotive aftermarket industry, where thousands of performance product brands showcase their new and legacy products. Attendees also enjoy attending over 70+ free educational sessions led by top industry professionals.

Our team will once again set up in the Central Hall, Booth #22613 - a prime spot with tons of foot traffic allowing us to catch up with our industry peers, as well as meet new retailers and distributors! We encourage people to stop by our booth where we will be showcasing several NEW and best-selling products, including:

Enforcer Cylinder Heads

The Enforcer line of cylinder heads is the newest product category for Air Flow Research. These budget-friendly cylinder heads come fully assembled and use the same high-quality components found in our higher-end line of CNC ported cylinder heads. These four products come with ARP rockers studs, PAC Racing springs, Viton valve seals, hardened spring cups, ductile iron seats, adjustable guide places and stainless steel valves. The Enforcer Cylinder Heads are the perfect choice for anyone looking to upgrade to aluminum heads for a muscle car or street rod.

Shop the Enforcer line here.

Eliminator Cylinder Heads

The Eliminator line of SBC cylinder heads feature 100% 5-AXIS CNC ported intake, exhaust and combustion chambers. We offer Eliminator cylinder heads in both street and competition versions. Have a vehicle that is a ‘94 or older? Check out the 180cc, 190cc or 195cc models that are CARB certified.

For street or race applications, the 210cc, 220cc, 227cc, 235cc and 245cc models are your best bet - designed for aggressive rides.

Shop the Eliminator line here.

Renegade Cylinder Heads

If you’re looking for an exceptional cylinder head for your Small Block Ford, look no further than the AFR Renegade Cylinder Head. This line features 100% 5-AXIS CNC ported intake, exhaust and combustion chambers; available in street and competition versions. The 165cc and 185cc models are CARB Certified EO #D-250-3 for vehicles model year 1995 and older. While the 195cc, 205cc and 220cc cylinder heads are designed for aggressive, non-emissions compliant street or race applications.

Shop the Renegade line here.

Mongoose Cylinder Heads - LS1 and LS3

Our Mongoose LS1 cathedral port cylinder heads are 100% 5-AXIS CNC ported and made with A356 aluminum. Adhering to AFR’s highest-quality standards, the Mongoose LS1 heads come with titanium retainers and PAC Racing Springs. This line is also available in runner volumes including 205cc, 215cc, 230cc and 245cc. Component upgrades and different machining options are available to customize your AFR heads for your specific build.

We also have this line available with an LS3 rectangle port cylinder head. The Mongoose LS3 Cylinder Heads are available with a 260cc runner volume and are CARB Certified EO #D-250-5.

Shop the Mongoose LS1 line here.

Shop the Mongoose LS3 line here.

The 2022 SEMA Show takes place November 1-4, 2022 at the Las Vegas Convention Center. For more information, visit SEMA’s website.

Read the full article

0 notes