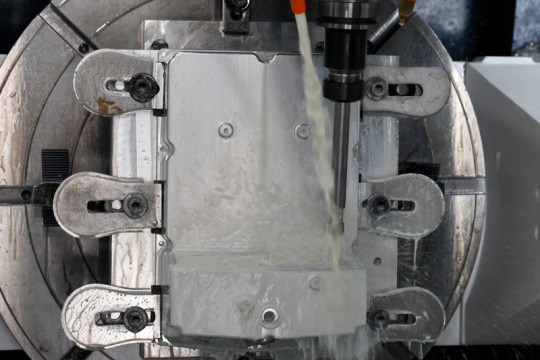

#5 axis machining services

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

PAC: 🥀

Fuck it heres why ur ass is single

Im in a mood today

Disclaimer: please take what I say with a grain of salt and not as the gospel. I just want to share some ideas of practicing and giving advice using the medium as often as I can with school, work, and my own personal studies and practice Started a Podcast draft today! Liking and sharing does a lot 🥰

Socials: TipJar/services | Follow me!

Pick a meme

1 2

3

The cards

Knight of disks 🛷

21° Leo to 20° Virgo, Earth of Assiah, Chokmah

You strive for a lot of material success and that at times makes you greedy and jealous. You want a relationship to LOOK a certain way but while people can change people rarely change in the way you want and you shouldn’t force people to be something they are not. You have a personal stubbornness about your idea of a relationship and it’s keeping you where you are

Defeat ⛸️

Venus 1. In Aquarius , Geburah in Air, 5 of swords

You are going through it lmao. Your world view will soon be shaped from pain and at times always taking fat Ls can have an impact on who you are as a person. You’re having many intellectual crisis and struggles against fate however you did sign the letter to your fate. Things only manifest because you did things to cause it. You’re single rn bc you are going through so much shit and your world view is changing so rapidly you deadass have no time and have no concept of what it would even look like.

The Tower 🥊

Saturn and Uranus, Mars, The Axis Netzach - Hod, fire

You’re single girlie bc you are straight up self destructing lmao. You’ve made a shocking realization about your current world view and since everything has been violently crumbling down around you. This is what happens when you wanna be so delulu that shit hits the absolute shit fuck fan. While there is good in destruction and we all have it your blind destruction is scaring the hoes. No one wants to be collateral.

Extras:

Story/vent:

I love you guys I am just eepy

#suitlifeofgerm#askgerm#pick a card#daily card#pick a picture#germ reads#shadow work#tarotoftheday#pac#cartomancy#thoth tarot#tarot deck#tarot blog#tarot witch#free tarot#tarot spread#daily tarot#tarot reading#tarot cards#tarot#tarot community#tarot reader#tarot spreads#tarotblr#tarotcommunity#divination#pick a reading#pick a image#pick a deck#pick a pile reading

72 notes

·

View notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

Electric Bike Winter Maintenance Guide!

The weather is getting colder and colder, presumably many friends are still rain or shine, and can't bear to close the car. If a worker wants to do a good job, he must first sharpen his tools. Electric bicycles can be said to be sports machines. To make this machine exert its maximum power, you must pay attention to the maintenance of your car when riding in winter. A comprehensive inspection of your car after leaving the car can not only prolong the service life of the car. It can eliminate many hidden dangers and improve safety! Let's take a look at the winter maintenance guide for electric bike!

Maintenance description and purpose of each part of the bicycle:

1. Head

Maintenance description: Check whether the bearings at the upper and lower ends of the head tube can be used normally, clean and oil the bearings.

Maintenance purpose: to clean the dust and sludge of the bearings in the head tube, to prevent bearing damage, rust and abnormal noise.

2. Axis

Maintenance description: Check whether the center shaft can be used normally, clean and oil the bearings.

Maintenance purpose: to clean the dust and sludge in the bottom bracket and bottom bracket to prevent damage, rust and abnormal noise of the bottom bracket.

3. Wheel front and rear hubs

Maintenance description: Check whether the hub can be used normally, clean and oil the balls in the hub.

Maintenance purpose: Check whether the hub can be used normally, clean and oil the balls in the hub.

4. Wheel set adjustment (front and rear wheels)

Maintenance description: Put the wheel set on the ring adjustment table to check whether it is deflected, and adjust it according to the situation (Nalong)

Maintenance purpose: to reduce the deflection of the wheel set to make the handling better.

5. Transmission system (front and rear derailleurs, flywheels, chains, cranksets)

Maintenance description: Check the transmission system: whether the front and rear derailleurs, flywheels, chains, and chainrings can be used normally, clean the dust and sludge, replace with new oil, and adjust the gear.

Maintenance purpose: reduce excessive wear caused by sludge and other sundries, and prolong the service life of flywheel and chain.

6. Frame

Care Description: Clean the body and remove stains.

Electric bike maintenance process

Step 1: Clean the Dirt

If the body is not very dirty, just wipe it with a damp soft cloth; if there are many mud spots, you can wash it with a water hose. It should be noted that the pressure of the water column should not be too high. At the same time, the rotating parts such as triaxial and headset cannot be washed directly with water. A toothbrush can be used for places that cannot be wiped by a rag, and the upper tube of the front fork should also be removed with a toothbrush to avoid scratches during shock absorbers. Both the rim and the brakes need to be cleaned to remove the impurities embedded in the brakes and reduce unnecessary wear and tear. Brakes and shift cables should also be wiped clean. If there is a lot of mud and sand, the wire tube can be removed and the internal chain can be cleaned with the spray pressure of the anti-rust agent. The most dust-absorbing place on the whole car, wipe off the stains with a rag. If it is very dirty, you can use an anti-rust agent to clean it. Remember to dry the chain after completion to facilitate subsequent chain oiling.

Step 2: Lubricate

Brake and shifting line pipes need to be re-oiled after cleaning, and grease lubricating oil with weak fluidity is suitable for use on the line pipes. The chain is an important part of the transmission, and it also has high requirements for oiling. Generally, 5-6 drops can be added at a time. After adding, let the chain fully rotate, and at the same time bring lubricating oil to each tooth piece, and dry the chain with a rag after adding. After cleaning the upper tube of the front fork, special lubricating oil should be used to keep the front fork moving smoothly in winter.

Step 3: Prevent Rust

After riding, it is recommended to apply some anti-rust agent to the various screws and transfer points on the bicycle. Firstly, it is anti-rust, and secondly, it is also good for future disassembly.

Electric Bike Winter Maintenance Guide!

3 notes

·

View notes

Text

Precision CNC Machine Job Work — CNC Machining Components Manufacturer

Pitrukrupa Engineering is ISO 9001:2015 certified Manufacturer, Exporter and Supplier of high performing CNC machine Components. Pitrukrupa Engineering is engaged in Service Providing in providing CNC Machine Job Work, VMC Machine Job Work, EDM Wire Cut Work and CNC Lathe Machine Job Work since its inception in 2009. We provide CNC Machining Components and Services job Work in India, USA, Canada, Brazil, UAE, Australia, Oman, South Africa, Vietnam, Afghanistan, Israel, UK.

CNC Machining Components & Parts

CNC Machine Components

VMC Machine Components

CNC Turn Mill Components

5 Axis Milling Components

4 Axis Milling Components

CNC Lathe Machine Components

CNC EDM Components

CNC Turn Mill Components

Aluminium Extrusion

Aluminium High Pressure Die Casting

Aluminium And Steel Precision Welding Fabrication

CNC Machining Job Work Services

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

For More Details

Click Here : https://www.pitrukrupaengineering.com/

0 notes

Text

youtube

Cnc machining milling parts

We make cnc lathe machining service parts, 3/4/5 axis precision cnc machining part, precision machined cnc machining parts, cnc milling machining rapid prototyping aluminum, stainless steel cnc machining parts, cnc aluminum machining parts, precision cnc machining service, cnc precision machining parts.

----------------------------------

0 notes

Text

Top Boons of 5-axis CNC Machining

5 axis machining is now the most feasible choice for all types of machining jobs, not only the most difficult ones that require longer tool reach. 5-axis CNC machining is widely utilized for the most complex and precise jobs. This manufacturing approach is expected to provide significantly improved precision.

5-axis custom machining services provide a variety of advantages

Higher speed

5-axis machining allows the use of shorter cutting tools since the head may be lowered and the cutter is directed to the surface. You might expect better outcomes by increasing cutting speed and tool vibration.

Increased productivity

One of the most time-consuming parts of 3-axis machining is setting up a workpiece many times because it needs to be reoriented. This is required if an item needs to be machined on all or multiple sides, as the cutting tool remains at a fixed angle. A machinist must be physically present to rotate the component once machining on one side is completed for these 3-axis operations, and this human need can be a significant bottleneck in production.

5-axis machining by 5 axis machining manufacturer significantly minimizes the need for repeated setups since the movement of the table or spindle allows the cutting tool to approach the workpiece from various angles without removing it from the machine and resetting it. This leads to higher productivity throughout the whole process.

Hiring a dependable 5-axis machining services

Make sure your production team has been in operation for a significant amount of time. They should be highly experienced and qualified to ensure the quality of the job and timely completion. A corporation should be dependable and trustworthy.

Before selecting a firm, do not be afraid to ask questions regarding their 5-axis machining capabilities. A machine must also be of superior quality and capable of doing this task within a certain timeframe.

Inquire about the pricing of their services. Make sure you pay for what you get, and that the price matches the quality of the goods. Also, be informed of the materials they will be employing.

Main Source: https://bolesolutions.mystrikingly.com/

#5 axis machining manufacturer#5 Axis Machining Supplier#5 axis machining services China#5 Axis Machining Center

2 notes

·

View notes

Text

Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex part. Every part will be perfectly splendid machined by 5 axis milling.

0 notes

Text

youtube

Custom cnc machining parts

We make aluminium cnc machining parts, cusotom cnc machining parts, cnc machining parts stainless steel, cnc metal machining part, 5 axis cnc milling machining services, cnc machining custom aluminum parts, cnc oem machining parts, 5 axis cnc machining parts service parts, cnc milling lathing parts.

----------------------------------

https://mxymachining.com

0 notes

Text

Ensuring Precise Dimensions: The Art of Custom Plastic Profile Extrusion

Whether it’s creating components for machinery or crafting intricate parts for consumer products, the ability to achieve precise dimensions is crucial. One technology that excels in this arena is custom plastic profile extrusion. In this article, we’ll explore the art of custom plastic profile extrusion and how it revolutionizes manufacturing processes by ensuring precise dimensions.

Channels Ready for Immediate Use

Flexibility in Application

Custom plastic profiles are designed to be ready for immediate use, offering unparalleled flexibility in application. These profiles can be seamlessly integrated into existing systems without the need for extensive modifications, saving time and resources.

Rapid Adaptation to Specifications

One of the key advantages of custom plastic profile extrusion is its ability to rapidly adapt to specific requirements. Manufacturers can easily tailor profiles to meet the exact dimensions and specifications of each application, ensuring a perfect fit every time.

Seamless Integration with Existing Systems

Custom plastic profiles are engineered to integrate seamlessly with existing systems, minimizing downtime and disruption during installation. This allows manufacturers to upgrade their equipment and processes without costly delays or production interruptions.

Capacity for Diverse Orders

Prototype Trials

Custom plastic profile extrusion offers the flexibility to accommodate small-scale prototype trials, allowing manufacturers to test new designs and concepts with minimal investment. This enables rapid iteration and refinement, leading to faster time-to-market for new products.

Large Production Runs

In addition to prototype trials, custom plastic profile extrusion has the capacity to handle large production runs with ease. With nine primary production lines and four co-extrusion lines, manufacturers can scale up production to meet high-volume demands without sacrificing quality or precision.

State-of-the-Art Production Lines

Primary Production Lines

The state-of-the-art production lines are equipped with the latest technology to ensure consistent quality and high throughput rates. This helps to meet tight deadlines and deliver superior products to our customers.

Co-Extrusion Lines

The co-extrusion lines allow the production of complex profiles with multiple layers, expanding design possibilities and enhancing product performance. This advanced technology creates custom solutions for even the most demanding applications.

Plastic Extrusion Design Engineering

Precision Design Capabilities

Experienced engineers have the expertise to design custom profiles with precision and accuracy. Using advanced CAD software and simulation tools, It optimizes profiles for performance, durability, and cost-effectiveness.

Innovation in Profile Development

Experienced engineers are constantly exploring new materials, processes, and techniques to push the boundaries of what’s possible in custom plastic profile extrusion.

Plastic Extrusion Tooling

Advanced Tool Room Facilities

The room is equipped with cutting-edge machining technologies, including 5-axis wire EDM and CNC machining centers. This allows high-quality tooling with precision and efficiency.

Tailored Tooling Solutions

It also offers customized tooling solutions to meet the unique requirements of each project. Whether it’s rapid prototyping or iterative design processes, tooling capabilities ensure the delivery of perfect solutions for your needs.

Plastic Extrusion Fabrication

Comprehensive Fabrication Services

In addition to extrusion, Fabrication services add value to your products. From punching and routering to drilling and printing, It has the expertise and equipment to handle all aspects of production.

Enhanced Product Finishing

The finishing services include surface treatments, coatings, and quality assurance measures to ensure that your products meet the highest standards of quality and performance. With attention to detail and commitment to excellence, you can trust Custom Plastic Profile Extrusion to deliver superior results every time.

Incorporating 3D Printing

Prototyping Capabilities

Our 3D printing capabilities enable rapid prototyping and iteration, allowing you to test new designs and concepts quickly and cost-effectively.

Customization and Personalization

With 3D printing, it can create custom profiles with unique features and designs, allowing you to differentiate your products and stand out in the market.

FAQs

Are custom plastic profiles suitable for small-scale projects?

Yes, custom plastic profiles are highly adaptable and can be tailored to meet the requirements of small prototype trials.

How quickly can custom plastic profiles be produced?

Production times vary depending on the complexity and volume of the order. However, manufacturers often offer rapid turnaround times to meet tight deadlines.

What materials can be used for custom plastic profile extrusion?

A wide range of thermoplastic materials can be used for custom profile extrusion, including PVC, ABS, HDPE, and more.

Are custom plastic profiles suitable for outdoor applications?

Yes, custom plastic profiles can be engineered to withstand harsh environmental conditions, making them ideal for outdoor use.

Can custom plastic profiles be recycled?

Yes, many thermoplastic materials used in custom profile extrusion are recyclable, contributing to sustainability efforts.

Conclusion

In conclusion, custom plastic profile extrusion is a versatile and efficient manufacturing process that revolutionizes the way we produce components and products. With its ability to ensure precise dimensions and tailor-made solutions, custom plastic profile extrusion offers numerous benefits for various industries. From flexible application to seamless integration with existing systems, this technology provides manufacturers with the tools they need to stay competitive in today’s market.

Ready to experience the benefits of custom plastic profile extrusion for your next project? Contact Lakeland Plastics today to bring your vision to reality with precision and excellence.

0 notes

Text

Shenzhen Rapid Direct Co., Ltd. Unveils Cutting-Edge 5 Axis CNC Machining Services, revolutionizing precision engineering

0 notes

Text

5-Axis CNC Machining Services at BOEN – Precision for Complex Designs

At BOEN, we’ve been delivering cutting-edge 5-axis CNC machining services since 2014, using advanced German-imported DMG machines. Whether it’s for aerospace components, robotics parts, automotive, or medical devices, our high-speed precision equipment ensures every part meets your exact specifications.

What is 5-Axis CNC Machining?

Unlike traditional 3-axis machining (which operates on the X, Y, and Z axes), 5-axis CNC machining introduces two more axes – A and B. These extra axes allow for multi-directional cutting capabilities that make producing intricate designs easier, faster, and more efficient.

Benefits of 5-Axis CNC Machining:

Machining Complex Surfaces: Allows work on every surface apart from the clamping area.

Rotational Accuracy: Essential for precision designs.

Faster Material Removal: Reduces waste and saves time.

Improved Surface Finish: Enhances part quality.

Single Setup for Complex Shapes: Increases productivity, saving on labor costs.

Our service is ideal for prototypes, small production runs, or larger-quantity orders across multiple industries. With over 40 certified materials available (including plastics and metals), we offer on-demand machining to bring your designs to life. Whether it’s intricate medical devices or robust automotive parts, BOEN ensures quality and precision at every step.

Why Choose BOEN?

We combine advanced technology with expert craftsmanship. Our fully equipped facility handles both 3-axis and 5-axis machining, providing you with customized results for your unique projects.

Our experienced machinists and programmers can handle complex geometries, undercuts, and angles all in a single setup, minimizing errors and ensuring efficiency. By reducing setup times, overhead, and tooling costs, we deliver high-precision parts at the lowest possible cost per part.

Explore how our 5-axis CNC machining can elevate your project to the next level!

#CNCmachining#5AxisMachining#PrecisionEngineering#Aerospace#Robotics#Automotive#BOEN#ComplexDesigns#Manufacturing#Prototyping

0 notes

Text

Precision at Your Fingertips: Inline Engineering’s CNC Machining Services in Perth

In today’s world of demanding engineering projects, precision and efficiency are paramount. At Inline Engineering, we understand this need. That’s why we offer a comprehensive suite of CNC machining services in Perth, utilizing cutting-edge technology to bring your designs to life with unmatched accuracy and speed.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where computer-controlled machines perform precise cutting and shaping of various materials. This allows for the creation of complex and intricate components with incredible detail and consistency.

Benefits of CNC Machining:

Unmatched Precision: CNC machining guarantees consistent and accurate results, even for complex geometries.

Increased Efficiency: Automation streamlines production and reduces lead times compared to traditional machining methods.

Enhanced Design Freedom: CNC machining allows for the creation of intricate details and shapes not possible with manual methods.

Reduced Waste: Precise cutting minimizes material waste, contributing to cost-effectiveness and sustainability.

Repeatability: CNC programs ensure consistent part production, ideal for high-volume projects.

Inline Engineering: Your Perth Partner for Precision CNC Machining

Inline Engineering is a trusted provider of CNC machining services in Perth. We offer a wide range of capabilities and materials to suit your specific needs:

Multi-Axis Machining: Our advanced CNC machines handle 3, 4, and 5-axis machining for complex designs.

Diverse Material Selection: We work with a variety of materials, including steel, aluminum, stainless steel, plastics, and more.

Prototyping & Production Runs: We cater to both rapid prototyping needs and high-volume production runs.

Dedicated Project Management: We assign a dedicated project manager to ensure clear communication and on-time delivery.

Quality Control & Inspection: Our commitment to quality includes rigorous inspections throughout the process.

Why Choose Inline Engineering for Your CNC Machining Needs?

We don’t just machine parts; we partner with you to achieve your goals. Here’s what sets us apart:

Experienced Team: Our team of qualified engineers and machinists are passionate about precision and efficiency.

Advanced Technology: We invest in cutting-edge CNC machinery to deliver exceptional results.

Custom Solutions: We take the time to understand your project requirements and deliver tailored solutions.

On-Time Delivery: We prioritize meeting deadlines and keeping you informed throughout the process.

Competitive Pricing: We offer competitive rates while maintaining the highest quality standards.

Looking for a reliable and experienced CNC machining partner in Perth? Look no further than Inline Engineering. Contact us today for a free consultation and quote. Together, let’s transform your designs into reality with exceptional precision and efficiency.

0 notes

Video

youtube

Precision Engineering: 5 Axis CNC Machining Explained | KD Hardware Co., Ltd.

Discover the capabilities of 5 Axis CNC Machining with KD Hardware Co., Ltd. Our advanced machining technology allows for precise and complex part production, making us a trusted partner in various industries. Whether you're in aerospace, automotive, or any other sector, our CNC machining solutions are tailored to meet your exact specifications.

🎥 Watch this video to learn more about how KD Hardware Co., Ltd. leverages this technology to deliver top-notch machining services.

💼 Contact Us:

For inquiries, quotes, or more information, please visit our website or contact us at [email protected].

👍 Like, Share, and Subscribe to stay updated with the latest in CNC machining technology and innovations.

#youtube#5axiscncmanufacturers#simultaneous5axismachining#5axismachiningcenter#machiningcenter5axis#5axiscncmilling#5thaxismachining

0 notes

Text

Plasma Metal Cutting Machines

Plasma Metal Cutting Machines

The plasma metal cutting machines provided by our company include metal flat plasma cutting machine, metal plate and tube integrated plasma cutting machine,metal square tube plasma cutting machine, portable metal plasma cutting machine, round tube plasma cutting machine, gantry plasma cutting machine.

Do you have a thought to DIY or buy an affordable CNC Plasma Cutter? We’ll provide you with the competitive CNC Plasma Table with expert customer service to satisfied your requirements.

CNC Metal plasma table

CNC plasma tables by iGOLDEN provide a broad range of cutting solutions. Designed for top-notch cut quality, a iGOLDENCNC plasma table is durable enough to run full production for years, yet nimble enough to cut intricate shapes with ease. iGOLDEN is here to help you select the best CNC plasma cutting table to meet your specific needs.

The table cuts a 4×4 4×8 5×10 area and works well with 4×8 and 4×10 sheets. In fact, the software allows you to automatically layout and cut 4×8 or larger (up to 20 ft long) shapes.

Industrial CNC cutting table system offers all the features to get started on cutting carbon steel, stainless steel and non-ferrous metal in any 2D graphics. The included Digital Torch Height Controller maintains distance between the plasma torch and your work – producing smooth edges, sharp details and high precision.

Gantry type metal plasma cutting machine

Heavy Frame Metal Plasma Cutting Machine Sheet Tube Metal Cutting CNC Plasma Cutter Gantry Plasma Flame Cutting Machine

1. Heavy-duty gantry cutting machine adopts heavy-duty frame, heavy-duty guide rail, good stability, large span, the gauge has a width of 4 meters, 5 meters, and 6 meters, and the length can be from 8 meters to tens of meters.

2. It can realize double flame or double plasma cutting at the same time, forming 2 workpieces at a time, increasing double efficiency, saving half of the time, half of labor and one piece of equipment.

3. Equipped with high-power plasma power supply, such as 200A 300A 400A, to achieve plasma thick plate cutting. The plasma cutting speed is 3-5 times that of flame cutting, which improves production efficiency.

4. Multi-head plasma or flame straight cutting can be added, multiple workpieces at the same time, saving time.

5. The heavy-duty gantry cutting machine has beautiful appearance and high-end atmosphere, demonstrating the strength of the enterprise and improving its competitiveness among competitors.

Portable metal Plasma cutting Machine

A new portable design man carried construction is applied to the mini CNC plasma cutter machine here. Although it is small in volume, it can still cut 5ft x 10ft metal sheets as the stroke for X & Y axis is 1500x3000mm. The portable design enables us to put the plasma cnc in any location as the production needs. Let us give an example to interpret this point here. Suppose we want to cut a 12-meter-long steel plate, and such a large steel plate is not easy to move. So how do we put it on the machine to cut it? Taking the portable cnc plasma cutter here, we put it on the metal plate, and then we start the equipment to cut. Therefore, it is the right solution for the giant metal materials cut. Except for the plasma torch, it has a flame cutting torch also. 5ft x 10ft Portable cnc flame plasma cutting machine for sale with unmatched service now!

Portable metal Flame/Plasma Cutting Machine

Mini portable design, Man-carried construction; Two options available on stroke: 1500x3000mm (5ft x 10ft) and 1500x2500mm (5ft x 8ft). Mini cnc plasma cutter with portable design

The default configuration coming with two torches, one plasma cut torch, and one Oxy-fuel flame cutting torch. plasma torch of mini cnc plasma cutter

The portable cnc plasma cutter is equipped with an automatic torque height controller (THC controller). auto torch height control of mini cnc plasma cutter

Professional plasma cutting controller dedicated for portable plasma cnc – STARFIRE control system with LED display in English. mini cnc plasma cutter control system

A cut drawing library with rich resources is built into the cnc system. Production cuts can be executed by simply setting the size parameters. drawing library in the mini plasma cutter system

Plug and Play design. mini cnc plasma cutter with plug and play design ● X & Y axis is adopting rack and pinion transmission. rack on mini cnc plasma cutter.

What is Plasma Cutting?

Plasma cutting is a process that involves cutting through electrically conductive materials using an accelerated jet of hot plasma. The technology harnesses the power of ionized gas to melt and expel material from the cut, resulting in clean and precise cuts.

How Does a Plasma Cutter Work?

A plasma cutter works by sending an electric arc through a gas that is passing through a constricted opening. The gas can be oxygen, nitrogen, argon, or even shop air. This elevates the temperature of the gas to the point that it enters a plasma state. The plasma is then directed at the workpiece, melting the metal and blowing it away.

Components of a Plasma Metal Cutting Machine

Power Supply

The power supply is the heart of the plasma cutter. It provides the energy required to maintain the plasma arc. Modern power supplies are designed to deliver consistent power, ensuring smooth and efficient cutting.

Plasma Torch

The plasma torch is the tool that directs the plasma arc onto the workpiece. It consists of several components, including the electrode, nozzle, and swirl ring, each playing a crucial role in the cutting process.

Control Console

The control console allows the operator to adjust the cutting parameters, such as speed, amperage, and gas flow. Advanced consoles come with digital displays and programmable settings for enhanced precision.

FAQ

What materials can a plasma cutter cut?

Plasma cutters can cut a variety of electrically conductive materials, including steel, aluminum, brass, and copper.

How thick can a plasma cutter cut?

The cutting thickness depends on the power of the plasma cutter. Some machines can cut materials up to several inches thick.

Is plasma cutting safe?

Yes, plasma cutting is safe when proper safety measures are followed, including wearing PPE and ensuring adequate ventilation.

Can plasma cutters be used for precision cutting?

Yes, plasma cutters are known for their precision and can produce clean, accurate cuts suitable for various applications.

What is the lifespan of a plasma cutter?

The lifespan of a plasma cutter depends on its usage and maintenance. Regular maintenance can extend the life of the machine significantly.

0 notes