#ACMotorDrives

Explore tagged Tumblr posts

Text

When Should You Not Use a Frequency Drive?

A frequency drive, also known as a variable frequency drive (VFD), is widely used in modern motor control systems. It adjusts the speed and torque of electric motors by varying the frequency and voltage supplied. But while a frequency drive offers many advantages, there are certain conditions where using one may not be ideal. Understanding these conditions is crucial for engineers, technicians, and plant managers. Let’s explore the scenarios where a frequency drive should be avoided.

When Should You Not Use a Frequency Drive

What is a Variable Frequency Drive?

A variable frequency drive (VFD) is an electronic device that controls the rotational speed of an alternating current (AC) motor. It does this by adjusting the motor input frequency and voltage. Most commonly, a frequency drive is used in HVAC systems, conveyors, pumps, and fans to improve energy efficiency. The key components of a frequency drive include: - Rectifier - DC link - Inverter - Controller These components work together to convert fixed-frequency AC into variable-frequency AC, which in turn controls motor speed. The ability to adjust speed on demand helps reduce energy consumption and wear on mechanical parts. Despite these benefits, a frequency drive is not suitable in all situations.

When Load Torque Requirements Are Constant

If your application demands constant torque across all operating speeds, a frequency drive may not offer the best performance. Some equipment, like positive displacement pumps or compressors, require full torque even at low speeds. A VFD in such cases can cause motor overheating or poor torque control. Instead, a soft starter or direct-on-line (DOL) starter may be a better choice in these applications. These alternatives provide full torque from the start and are simpler in design.

When Precise Speed Is Not Needed

There are many industrial setups where motor speed is fixed and does not require adjustment. Using a frequency drive in such scenarios can be unnecessary and adds cost, complexity, and maintenance. For example: - Simple water pumps running at constant speed - Exhaust fans in static ventilation systems - Conveyor belts with uniform product flow In such cases, a basic contactor-starter system or a mechanical speed reducer is more practical. Read the full article

#ACMotorDrives#ControlSystems#DriveApplications#Electricaldesign#ElectricalEngineering#IndustrialAutomation#MotorProtection#powerquality#VariableSpeedDrives#VFDSafety

0 notes

Text

Lubi Electroncis one of the best solution providers in all over india. We are a leading manufacturer and supplier of VFD panels that are used in various industrial applications. Our VFD panels are designed to meet the requirements of modern industrial automation and control systems. We offer a wide range of VFD panels that are suitable for various applications such as pumps, fans, compressors, conveyors, and more. Our VFD panels are designed to improve the efficiency and reliability of your industrial processes.

Contact [email protected] for any of your requirements. Experience innovation, efficiency, and excellence with Lubi Electronics.

#VFD #ACDrive #VariableSpeedMotorDrives #ACMotorDrive #AdjustableSpeedDrive #EddyCurrentDrive #manufacturers #suppliers #exporters #traders #dealers #manufacturingcompanies #retailers #producers #Ahmedabad #वैरिएबलफ्रीक्वेंसीड्राइव #अहमदाबाद #Gujarat #India #controlpanel #controlpanelsolution #controlpanelmanufacturersinindia

#VFD#ACDrive#VariableSpeedMotorDrives#ACMotorDrive#AdjustableSpeedDrive#EddyCurrentDrive#manufacturers#suppliers#exporters#traders#dealers#manufacturingcompanies#retailers#producers#Ahmedabad#वैरिएबलफ्रीक्वेंसीड्राइव#अहमदाबाद#Gujarat#India#controlpanel#controlpanelsolution#controlpanelmanufacturersinindia

1 note

·

View note

Photo

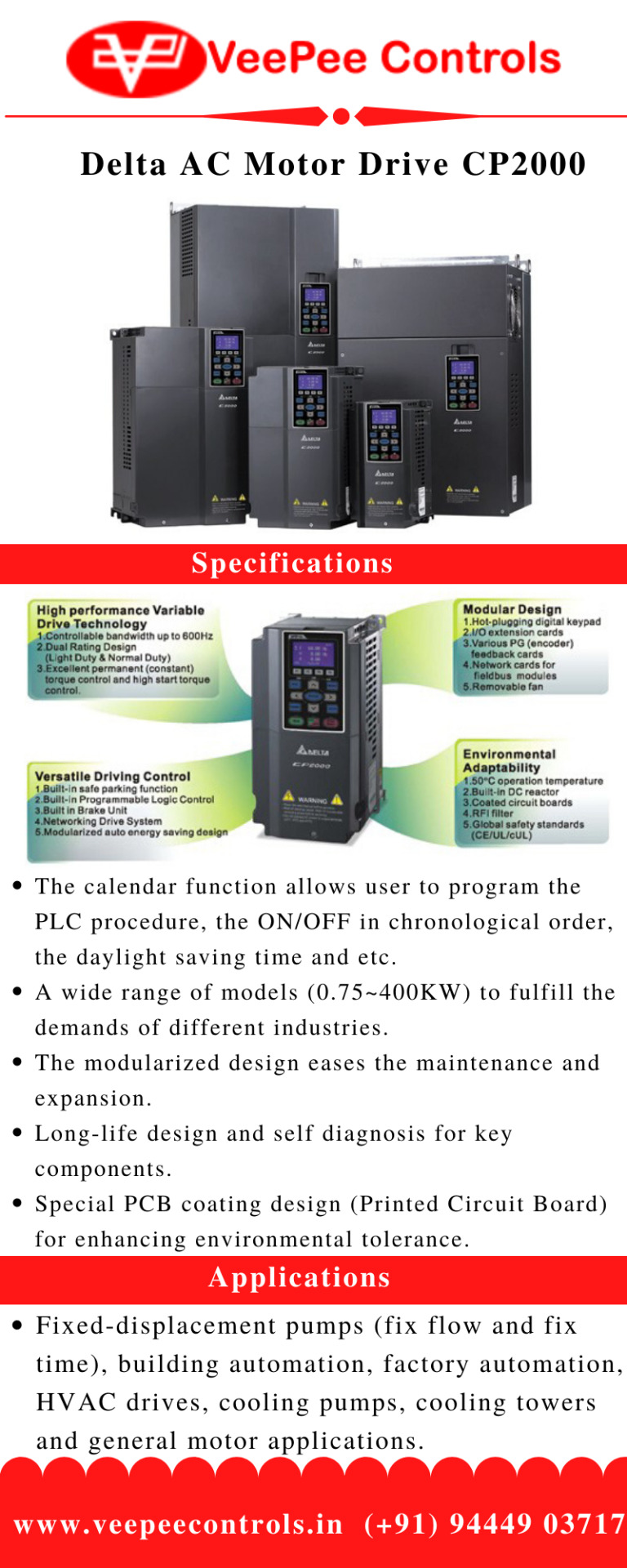

If you are Looking for Delta AC Motor Drive CP2000 Series in Chennai? Then this is the correct place for you. Veepee Controls offers all types of Delta VFD Products with reasonable prices than compared to authorized Delta VFD Dealers in Chennai, India.

Delta's Sensorless Vector Control Drive CP2000 Series has broadened the idea of energy saving and utilizes this principal as the basis of its design. The CP2000 is specifically designed for applications, for example, air blowers, pumps and HVAC drives with its intelligent PID control giving the best efficiency.

Specifications:-

· The calendar function allows user to program the PLC procedure, the ON/OFF in chronological order, the daylight saving time and etc.

· A wide range of models (0.75~400KW) to fulfill the demands of different industries.

· The modularized design eases the maintenance and expansion.

· Long-life design and self diagnosis for key components.

· Special PCB coating design (Printed Circuit Board) for enhancing environmental tolerance.

· Complied with global safety standards: CE, UL and cUL

· Standard LCD model (IP20/NEMA1) with built-in PLC to support up to 10K steps

Applications:-

Fixed-displacement pumps (fix flow and fix time), building automation, factory automation, HVAC drives, cooling pumps, cooling towers and general motor applications.

Visit: http://veepeecontrols.in/vfd.php

Contact: 7401113717

0 notes