#Aluminium Market Challenges

Text

Aluminium Electrolytic Capacitors Market May Set New Growth Story

Advance Market Analytics added research publication document on Worldwide Aluminium Electrolytic Capacitors Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide Aluminium Electrolytic Capacitors market. The study provides valuable market size data for historical (Volume** & Value) from 2018 to 2022 which is estimated and forecasted till 2028*. Some are the key & emerging players that are part of coverage and have being profiled are Nippon Chemi-Con Corporation (Japan), Panasonic Corp. (Japan), KEMET Corporation (United States), Capxon International Electronic Co. Ltd. (Hong Kong), Hunan Aihua Group (China), Barker Microfarads, Inc. (United States), Capacitor Industries (United States), Cornell Dubilier Electronics, Inc. (United States), DuraCap International Inc. (Canada).

Get free access to Sample Report in PDF Version along with Graphs and Figures @ https://www.advancemarketanalytics.com/sample-report/80131-global-aluminium-electrolytic-capacitors-market

Aluminium electrolytic capacitors is a polarized capacitors owing to their anodization principle. It is made of a pure aluminium foil with an etched surface. It is widely used in various industries such as communication and technology, energy and power, automotive, and consumer electronics among many others. Increasing automotive production coupled with the increasing adoption of various consumer electronic devices including televisions, smartphone, tablets, among others are likely to drive the aluminium electrolytic capacitor market in the upcoming years. The market for the aluminium electrolytic capacitors is anticipated to register a CAGR of over 3.2% during the forecast period.

Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Impact and Economic Slowdown globally. Maintain a competitive edge by sizing up with available business opportunity in Aluminium Electrolytic Capacitors Market various segments and emerging territory.

Influencing Market Trend

Technology Advancement in Aluminium Electrolytic Capacitors Products

Market Drivers

Rising Disposable Income Worldwide

High Spending Propensity of Consumers Pertaining to Electronic Goods

Opportunities:

Growing Demand from Emerging Economics such as India, China, and others

Challenges:

Issue Related to Some High Prices of Products

Have Any Questions Regarding Global Aluminium Electrolytic Capacitors Market Report, Ask Our Experts@ https://www.advancemarketanalytics.com/enquiry-before-buy/80131-global-aluminium-electrolytic-capacitors-market

Analysis by Type (Non-Solid Aluminium Electrolytic Capacitors, Solid Aluminium Electrolytic Capacitors), Configuration (Radial Leaded Aluminium Capacitors, Vertical Chip Capacitors, Horizontal Chip Capacitors, Axial Leaded Aluminium Capacitors, Screw Terminal, Snap-In/Snap-Mount Aluminium Capacitors, Specialty Aluminium Capacitors), Voltage (Low Voltage, High Voltage), End User (Consumer Electronics, Industrial Sector, Computer and Peripherals, Telecommunications, Automotive)

Competitive landscape highlighting important parameters that players are gaining along with the Market Development/evolution

• % Market Share, Segment Revenue, Swot Analysis for each profiled company [Nippon Chemi-Con Corporation (Japan), Panasonic Corp. (Japan), KEMET Corporation (United States), Capxon International Electronic Co. Ltd. (Hong Kong), Hunan Aihua Group (China), Barker Microfarads, Inc. (United States), Capacitor Industries (United States), Cornell Dubilier Electronics, Inc. (United States), DuraCap International Inc. (Canada),]

• Business overview and Product/Service classification

• Product/Service Matrix [Players by Product/Service comparative analysis]

• Recent Developments (Technology advancement, Product Launch or Expansion plan, Manufacturing and R&D etc)

• Consumption, Capacity & Production by Players

The regional analysis of Global Aluminium Electrolytic Capacitors Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2023-2028.

Table of Content

Chapter One: Industry Overview

Chapter Two: Major Segmentation (Classification, Application and etc.) Analysis

Chapter Three: Production Market Analysis

Chapter Four: Sales Market Analysis

Chapter Five: Consumption Market Analysis

Chapter Six: Production, Sales and Consumption Market Comparison Analysis

Chapter Seven: Major Manufacturers Production and Sales Market Comparison Analysis

Chapter Eight: Competition Analysis by Players

Chapter Nine: Marketing Channel Analysis

Chapter Ten: New Project Investment Feasibility Analysis

Chapter Eleven: Manufacturing Cost Analysis

Chapter Twelve: Industrial Chain, Sourcing Strategy and Downstream Buyers

Read Executive Summary and Detailed Index of full Research Study @ https://www.advancemarketanalytics.com/reports/80131-global-aluminium-electrolytic-capacitors-market

Highlights of the Report

• The future prospects of the global Aluminium Electrolytic Capacitors market during the forecast period 2023-2028 are given in the report.

• The major developmental strategies integrated by the leading players to sustain a competitive market position in the market are included in the report.

• The emerging technologies that are driving the growth of the market are highlighted in the report.

• The market value of the segments that are leading the market and the sub-segments are mentioned in the report.

• The report studies the leading manufacturers and other players entering the global Aluminium Electrolytic Capacitors market. Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

#Global Aluminium Electrolytic Capacitors Market#Aluminium Electrolytic Capacitors Market Demand#Aluminium Electrolytic Capacitors Market Trends#Aluminium Electrolytic Capacitors Market Analysis#Aluminium Electrolytic Capacitors Market Growth#Aluminium Electrolytic Capacitors Market Share#Aluminium Electrolytic Capacitors Market Forecast#Aluminium Electrolytic Capacitors Market Challenges

0 notes

Text

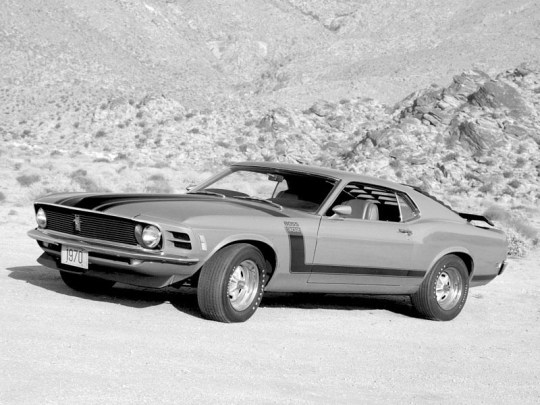

FORD MUSTANG BOSS 302

BOSS-A-NOVA!

They called it The Boss and for two short years it ruled the muscle car scene in the US, establishing itself as one of the greatest road and race cars of the era. Now, it’s one of the most collectible.

In 1960s US street lingo, if something was ‘boss’ it was cool, tough, the best. And the 1969 Boss 302 Mustang wore its badge with pride. It launched just four and a half years after the first Mustang was revealed to critical acclaim and record sales. Yearly updates to keep Mustang fresh in the face of tough new challengers from General Motors and Chrysler (particularly the Camaro) resulted in the once lean and pretty ’Stang muscling up, both in body shape and under-bonnet brawn, and the 1969-70 Boss models were the zenith of Mustang styling.

Thereafter, Mustangs became increasingly bloated and anaemic as the 1970s fuel crisis and stricter pollution laws cut horsepower and stylists lost their way; the rippling flanks and thrusting nose of the late 60s/early 70s cars gave way to boxy, bland designs. That early look would not be recaptured until 2005, when new Mustangs were given retro styling.

The Boss 302 was launched at the same time as its big-block brother, the Boss 429. Both were positioned as competition specials; Ford wanted to homologate its 302-cuber for Trans-Am and the 429ci monster for NASCAR. In fact, Ford went wild with engines between 1969-70, offering nine V8s – the ‘economy’ 302, 351 Windsor, 351 Cleveland, 390, 428 Cobra Jet, 428 Super Cobra Jet, 429 ‘wedge’, Boss 302 and Boss 429.

For the Boss 302, Ford’s high-compression 302ci small-block V8 was beefed up with four-bolt main bearing caps and redesigned ‘Cleveland’ cylinder heads with bigger inlet and exhaust valves, and ports that allowed the engine to breathe more efficiently.

These ‘semi-hemi’ heads were based on the Ford 427ci racing engine’s combustion chambers, and a balanced forged steel crankshaft and forged steel conrods allowed the engine to handle high rpms for sustained periods. A single 780cfm four-barrel Holley carburettor sat atop a high-rise aluminium inlet manifold, while a dual-point distributor, high-pressure oil pump, windage tray and screw-in welch plugs were further indications of its competition intent.

A rev limiter was fitted, progressively cutting spark from 5800rpm to 6150, but it was easily bypassed and the Boss 302 could reportedly keep making power up to 8000rpm with minor mods. In the muscle car marketing war, Ford claimed a peak horsepower figure of 290bhp at 5800rpm (the same as the Camaro Z/28), but that was extremely conservative.

Two four-speed manual Top Loader transmissions were available: a wide-ratio ’box with Hurst shifter more suited to street and strip use, and a close-ratio unit for racing. Adding to the race or road options list were four diffs: the stock 3.5:1 nine-inch, Traction-Lok 3.5:1 and 3.91:1 and the No-Spin 4.30:1 built by Detroit Automotive. Axles and diff centres were also strengthened to take the loads.

Suspension was also race-inspired with heavy-duty springs, shocks and sway bar up front, and Hotchkiss-style rear suspension with heavy-duty leaf springs, sway bar and staggered shock absorbers. The left-hand shock absorber was bolted behind the axle and the right in front, to reduce axle tramp under acceleration. Amazingly for such a high-performance car, braking was still only discs and drums with power assistance.

Ironically, the Boss 302’s sexy shape was styled by former General Motors designer Larry Shinoda, who is often credited with coming up with the Boss moniker. When asked what he was working on, he replied, "The boss’s car", a reference to new Ford president ‘Bunkie’ Knudson, who was also ex-GM and had recruited Shinoda to Ford.

While the wheelbase remained unchanged at 2740mm, the ’69 Mustang was 96.5mm longer overall to accommodate all the V8s offered, although the big-blocks still had to be shoe-horned under the bonnet. Shinoda’s ’69 Boss 302 was also one of the first production cars to offer an optional front air dam and adjustable rear wing, and his use of high-contrast black panels, rear window SportsSlats, and go-faster stripes made the Boss a real attention-grabber. The ’69 was also the only quad-headlight Mustang, a feature that was dropped for 1970 models.

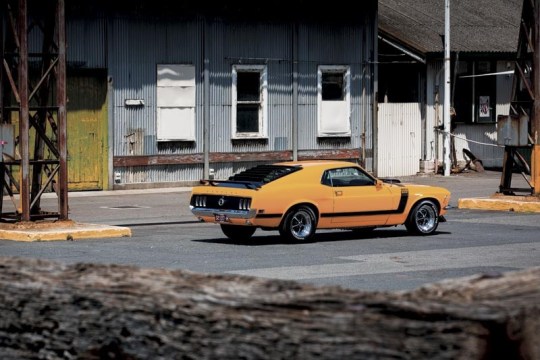

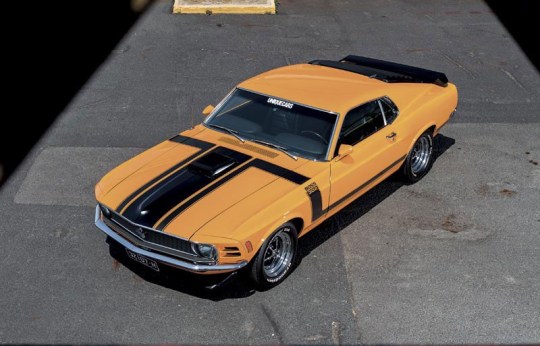

In 1970, American Hot Rod magazine dubbed the 1970 Boss 302 as "definitely the best handling car Ford has ever built", while the conservative Consumer Guide called it "uncomfortable at any speed over anything but the smoothest surface". Unique Cars resident Mustang maniac, ‘Uncle’ Phil Walker, never read the Consumer Guide review, but even if he had it wouldn’t have stopped him buying the immaculate 1970 Grabber Orange Boss 302 you see here.

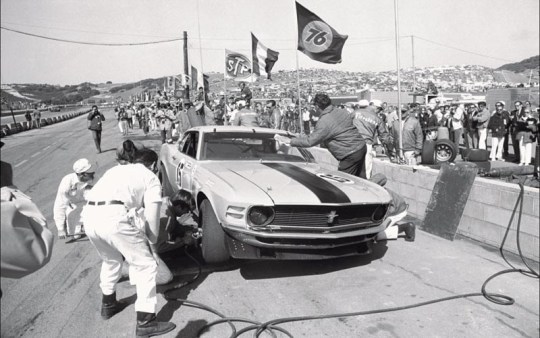

Phil already has his beloved 1966 Shelby GT350H, but the Boss 302 really got his Mustang juices percolating. And he wasn’t alone, because the first Boss he saw, some 43 years ago, is still one of Australia’s most iconic race cars: Allan Moffat’s Trans-Am racer. Phil remembers it clearly.

"I saw Moff race it Calder and I was inspired to own one," Phil recalls. "It was the most aggressive-looking car; its stance was something you had to see to believe. It looked like it was doing a million miles per hour when it was parked.

"My Boss was originally a one-owner car and I bought it from a friend of mine in California, Dave, who I also bought my Shelby GT350H from 19 years ago. Dave found it in a barn with a blown engine, but in otherwise pretty good condition.

"The lady who owned it from new didn’t realise it had a high-compression engine and had run it on standard fuel. When it blew up she just parked it.

"Dave did a nut-and-bolt restoration over two years, then put it up on his hoist. He didn’t want to sell it, but I got my way in the end – unfortunately he had the last say on the price (laughs). I didn’t even bother to test drive it; I knew it was a good car. It had 21 (new) miles on the odo when I picked it up and only 54,000 miles in total."

Since then, Phil has only put a couple of hundred miles on the car, but that’s enough for him to have bonded with it.

"I’ve only had the Boss since January and it’s growing on me. It’s different to the Shelby. It’s bigger and very low.

"The engine is incredible. Dave is one of the best engine builders in California and when he rebuilt the 302 he changed the cam spec. US camshaft technology was okay in the 60s and 70s, but if you had a big-cam muscle car they wouldn’t idle and they were terrible for driving in cities.

"A proper Boss engine can rev to 8500rpm all day and for a V8 that’s pretty serious. But they’re not renowned for low-down torque; it starts coming on from 3500rpm. My car still has a solid-lifter cam, but it pulls like a train from 1200rpm in top gear and I can drive it around at 1500rpm in top all day.

"It’s got the four-speed close-ratio Top Loader with the long first gear and with a 3.7:1 rear end it does about 55-60mph (89-97km/h) in first gear. It bloody goes!"

Phil is a fussy bugger and his cars have to look just right, so Russell Stuckey from Stuckey Tyres has ordered him a set of genuine 15 x 8 Minilites from England to replace the standard Magnum 500s.

"I want it to look like the Parnelli Jones race car, and to get the stance I want it’s going to have 275/60s on the rear and 255/60s on the front. At the moment it’s a pretty car that is tough, but I want a tough car that looks tough. And that’s all I’m going to do to it."

After his first real fang in the Boss, Phil felt that his Shelby would be half a lap in front at the end of a 10-lap sprint at Sandown, but now thinks the Boss would be quicker. We might have to put both to the acid test one day. What do you mean "no way", Phil?

It was a nervous Phil who turned up at a Melbourne storage facility in January to pick up his new Boss 302. So nervous, in fact, that he took along Unique Cars art director Ange and a sturdy tow rope – just in case.

The storage people were even more apprehensive – they had been warned about just how anal he is with his cars, as he explains: "The lady there said, ‘You must be pretty fanatical because we’ve been given strict instructions that no one is to touch the car except you’." Fortunately, the car arrived in pristine condition.

"I was pretty excited, I’d been waiting for seven weeks," Phil laughs. "I took the car cover off it, fired it up, and it drove home like a brand new car. It was as good as I thought it would be. I spent the next three hours washing it."

Sounds like our Phil.

PARNELLI AND ME

Three years ago, my mate Dave and I were invited to a Trans-Am dinner at Portland International Raceway where Dave was racing his 1970 Trans-Am Boss 302 and I was crewing for him.

When we were driving there we noticed this black Mercedes following us. When we stopped it did too and this bloke got out and said, "I noticed you guys back at the hotel. You’re going to the Trans-Am dinner aren’t you? I’m lost." It was Parnelli Jones!

I jumped in with him and when we got there I ‘invited’ myself onto Parnelli’s table, which also included Pete Brock – the guy who designed the Shelby Daytona Coupe. There was I, Mr Nobody, with all these US racing heavies, but Parnelli was a real gentleman, not up himself in any way.

The next day they had free lap time at Portland and, when I saw Parnelli there with Ford’s new ‘Parnelli Jones’ Boss 302 tribute Mustang, I asked if there was any chance of a ride and he said jump in. We did 10 laps and the guy hadn’t lost any of his ability; my eyes were getting bigger and bigger coming into the corners.

It was a great experience that I’ll never forget. – PW

IT's MINE...

Moff’s Mustang is probably the most iconic Australian racecar and after seeing it I was inspired to own a Boss Mustang.

Then, about 25 years ago, I went to Pebble Beach in Monterey for the first time and saw a 1970 Grabber Orange Boss 302, which was the colour Parnelli Jones raced in Trans-Am. That day I knew I had to own a Boss. It was the car I’d always wanted after my Shelby, which was my lifelong dream car.

My Boss 302 is fully optioned, including the Shaker, extra side mirror, tacho and rear louvres, and it’s got a lot of wow factor. When you drive down the freeway, you get the thumbs-up from all sorts of different people. I think it’s the colour.

It’s closer to show standard than my Shelby. It’s got the paint marks on the tailshaft and all the little concours details, but I’m never going to show it; I’m not into that.

The 1969/70 body shape is still the best. Ford got it right then, but lost the plot after that and it’s reflected in their collectibility today. – PW

#car#cars#muscle car#american muscle#ford#FORD MUSTANG BOSS 302#ford mustang#boss 302#MUSTANG BOSS 302#mustang

161 notes

·

View notes

Text

Relevance of sanctions against Russian aluminium

The European Union is considering a ban on primary aluminium imports as part of a new 15th package of sanctions against Russia, EU Reporter informs.

However, according to Chris Weafer, CEO of Macro-Advisory, such sanctions could significantly increase aluminium prices for European processors and consumers. Meanwhile, the restrictions will hardly put pressure on Russia.

The taxes that the aluminium industry contributes to the country’s budget are quite small. Moreover, Russia’s aluminium producer Rusal could redirect its exports to markets in China and Asia, Weafer said.

As previous trade restrictions against Russia showed, they often had unpleasant consequences for the EU itself. At the same time, real household incomes in Europe are declining due to inflation caused by the rejection of Russian raw materials. European refiners of oil, metals and polymers are forced to switch to more expensive raw materials, facing challenges.

Industrial production in the EU, heavily dependent on Russian energy, fell by 3.2 per cent year-on-year in the first half of 2024. Production of chemicals, fertilisers, metals, cars and other goods also declined.

Double-edged sword

The sanctions policy proved ineffective. Russia’s GDP grew by 3.6 per cent in 2023 and continued to grow steadily, while major Russian companies refocused their sales on the domestic market and so-called “friendly” countries.

If sanctions are imposed, Russian aluminium will have to be replaced by more expensive and environmentally harmful products. As Macro Advisory notes, the carbon footprint of Russian primary aluminium is only 2.1 tonnes of CO2 compared to the global average of 15 tonnes of CO2 per tonne of this metal.

Last December, when the EU restricted imports of aluminium wire from Russia, the Federation of Aluminum Consumers in Europe (FACE) warned that a further extension of the ban on primary aluminium would have devastating consequences for European small businesses. It would lead to higher prices and job losses.

Read more HERE

#world news#news#world politics#europe#european news#european union#eu politics#eu news#usa#usa news#usa politics#us politics#united states#politics#russia#russian news#russian sanctions#aluminium

0 notes

Text

China Automotive Parts Aluminium Die Casting Industry: Key Trends and Market Outlook

The China automotive parts aluminium die casting industry is undergoing significant growth as demand for lightweight, durable, and high-performance materials continues to rise in the automotive sector. Aluminium die casting is a crucial manufacturing process used to produce complex automotive components, offering key benefits such as reduced weight, high strength, and cost efficiency. The China Automotive Parts Aluminum Die Casting Market Size is projected to be valued at USD 10.41 billion in 2024 and is expected to grow to USD 15.49 billion by 2029, with a compound annual growth rate (CAGR) of 8.26% over the forecast period (2024-2029).

Market Overview

The market for automotive parts aluminium die casting in China is growing at a rapid pace. The shift towards electric vehicles (EVs) and the increasing production of lightweight vehicles to meet regulatory emission standards are driving demand. As of 2024, the market is estimated to be worth billions, with significant growth expected through 2029 due to rising investments in advanced die casting technologies and the expansion of China's automotive industry.

Key Trends Shaping the Industry

Growing Demand for Lightweight Vehicles

In response to strict environmental regulations, the automotive industry is increasingly focusing on lightweight materials to reduce vehicle emissions and improve fuel efficiency. Aluminium die casting offers an effective solution, providing lightweight components without compromising strength and durability. The demand for aluminium parts, such as engine blocks, transmission cases, and structural components, continues to rise in China.

Electric Vehicle (EV) Boom

China’s rapid adoption of electric vehicles is a major driver for the aluminium die casting market. As EVs require lightweight components to extend driving range and improve energy efficiency, aluminium die casting is becoming a preferred process for producing parts like battery enclosures and motor housings. With China being the world’s largest EV market, the demand for aluminium die cast parts is expected to soar.

Technological Advancements

Advanced die casting technologies, such as high-pressure die casting (HPDC), are gaining traction in China’s automotive industry. These technologies enable the production of more complex and precise components with reduced lead times and lower costs. The integration of Industry 4.0 technologies, including automation and robotics, is further improving the efficiency and quality of aluminium die casting processes.

Expansion of the Automotive Industry

China remains one of the world’s largest automotive markets, with continuous growth in vehicle production and sales. This expansion is fueling demand for automotive parts, including aluminium die cast components. Additionally, many global automotive manufacturers are establishing partnerships and production facilities in China, further driving market growth.

Sustainability and Recycling Initiatives

Aluminium is highly recyclable, and the automotive industry in China is increasingly prioritizing sustainability. Aluminium die casting plays a key role in reducing the environmental footprint of vehicle manufacturing, as it allows for the reuse of aluminium scrap in production. This trend is expected to support the long-term growth of the aluminium die casting market.

Challenges Facing the Industry

Despite the strong growth outlook, the aluminium die casting industry faces challenges, such as fluctuating raw material prices and the need for substantial capital investment in advanced machinery and technology. Additionally, competition from other lightweight materials, like magnesium alloys, could impact the market dynamics in the future.

Conclusion

The China automotive parts aluminium die casting industry is poised for substantial growth, driven by the increasing demand for lightweight materials, the rapid adoption of electric vehicles, and technological advancements. As China continues to strengthen its position as a global automotive manufacturing hub, the aluminium die casting sector is expected to play a pivotal role in shaping the future of vehicle production.

For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence https://www.mordorintelligence.com/industry-reports/china-automotive-parts-aluminium-die-casting-market

#china automotive parts aluminium die casting market#china automotive parts aluminium die casting market size#china automotive parts aluminium die casting market share#china automotive parts aluminium die casting market trends#china automotive parts aluminium die casting market forecast

0 notes

Text

Highflyer | Premier LED Fabric Light Box Manufacturer in Bangalore

Introduction to Highflyer:

Highflyer has established itself as a leading LED Fabric Light Box Manufacturer in Bangalore, renowned for delivering cutting-edge, high-quality signage solutions. The company specializes in LED fabric light boxes and combines innovative technology with superior craftsmanship to create visually striking and highly effective advertising displays. Its dedication to excellence and customer satisfaction makes it a top choice for businesses seeking impactful, modern signage solutions.

What are LED fabric light boxes, and what are their benefits?

LED fabric light boxes are illuminated displays designed to showcase graphics or advertisements on fabric panels, providing a vibrant and engaging visual experience. These light boxes are famous for their sleek, modern appearance and versatility. The LED lighting ensures uniform brightness and energy efficiency, making them ideal for indoor and outdoor applications. Highflyer's LED fabric light boxes are designed to offer optimal visibility and aesthetic appeal, enhancing the overall impact of any advertising campaign.

Innovative Design and Technology

Highflyer's success as an LED fabric light-box manufacturer in Bangalore is driven by its commitment to innovative design and technology. The company utilizes advanced design software and state-of-the-art manufacturing techniques to create visually stunning and highly functional lightboxes. Incorporating the latest LED technology, Highflyer ensures its fabric light boxes provide consistent illumination, high colour accuracy, and long-lasting performance.

High Quality and Durability

Quality and durability are central to Highflyer's approach as a leading LED Fabric Light Box Manufacturer in Bangalore. Each lightbox is crafted using premium materials, including high-grade aluminium frames and weather-resistant fabrics, to ensure longevity and robustness. Highflyer's rigorous quality control processes guarantee that every LED fabric light box meets high standards and performs reliably over time, even in challenging environmental conditions.

Customization for Unique Branding Needs

One of Highflyer's key strengths is its ability to offer customized LED fabric light box solutions tailored to each client's needs. Highflyer's team works closely with clients to develop light boxes that align perfectly with their branding and marketing objectives, whether a unique design, specific dimensions, or custom features. This personalized approach ensures that each LED fabric light box serves its functional purpose and reflects the client's brand identity and messaging.

Sustainability and Eco-Friendly Practices

Sustainability is a core value for Highflyer, reflected in its manufacturing practices for LED fabric light boxes. The company incorporates eco-friendly practices by using recyclable materials and energy-efficient LED lighting. This commitment to sustainability helps reduce the environmental impact and aligns with modern eco-conscious values, offering clients signage solutions that are both environmentally responsible and effective.

Versatility of LED Fabric Light Boxes

From its expertise as a leading LED Fabric Light Box Manufacturer in Bangalore, Highflyer's LED fabric light boxes are highly versatile and suitable for various applications. Whether for retail stores, trade shows, corporate offices, or public spaces, these light boxes provide excellent illumination and enhance visual appeal in diverse settings. Their adaptability makes them ideal for numerous industries, enabling businesses to utilize LED fabric light boxes as powerful tools for improving visibility and attracting attention.

Expert Installation and Maintenance Services

In addition to manufacturing, Highflyer offers expert installation and maintenance services for its LED fabric light boxes. The company's skilled technicians ensure that each lightbox is installed precisely and optimally. Regular maintenance services are also available to address any issues and ensure the continued performance and longevity of the light boxes. This comprehensive approach guarantees clients a complete signage solution with ongoing support.

Client-Centric Approach and Exceptional Service

Highflyer's client-centric approach is a significant factor in its reputation as a top LED fabric light-box manufacturer in Bangalore. The company prioritizes understanding each client's unique needs and goals, offering tailored solutions and exceptional customer support. This focus on service excellence fosters solid relationships and ensures clients receive signage solutions exceeding their expectations.

Recognition and Industry Impact

Highflyer's contributions to the LED fabric light box industry have been recognized through various awards and accolades. These honours highlight the company's commitment to quality, innovation, and customer satisfaction. Such recognition reinforces Highflyer's position as a leading LED Fabric Light Box Manufacturer in Bangalore and underscores its impact on the signage industry. These achievements validate the company's dedication to excellence and its role in shaping the future of visual communication.

FAQs (Frequently Asked Questions)

Why is Highflyer one of Bangalore's top producers of LED fabric light boxes?

Highflyer excels in innovative design, high-quality materials, and customization, making it a top choice for impactful LED fabric light boxes.

What types of LED fabric light boxes does Highflyer offer?

Highflyer offers a range of LED fabric light boxes, including custom designs for retail environments, trade shows, corporate offices, and public spaces.

How does Highflyer ensure the durability of its LED fabric light boxes?

Highflyer uses premium materials and rigorous quality control processes to ensure its LED fabric light boxes are durable and reliable.

Does Highflyer provide installation and maintenance services for LED fabric light boxes?

Yes, Highflyer offers expert installation and maintenance services to ensure that LED fabric light boxes are installed correctly and maintained for optimal performance.

What is Highflyer's approach to sustainability in manufacturing LED fabric light boxes?

Highflyer integrates eco-friendly practices using recyclable materials and energy-efficient LED lighting to minimize environmental impact.

Conclusion: Highflyer's Leadership in LED Fabric Light Box Manufacturing

In conclusion, Highflyer stands out as the premier LED Fabric Light Box Manufacturer in Bangalore due to its commitment to innovative design, high-quality production, and client satisfaction. The company's use of advanced technology, dedication to customization, and focus on sustainability make it a top choice for businesses seeking practical and visually appealing signage solutions. With a strong emphasis on exceptional service and ongoing support, Highflyer continues to lead the way in the LED fabric light box industry, driving success for its clients and advancing the field of visual communication.

#fabricledboardmanufacturerinbangalore, #ledbacklitsignboardsmanufacturerinbangalore, #ledfabricboxmanufacturerinbangalore, #ledfabriclightboxmanufacturerinbangalore,

#fabricledboardmanufacturerinbangalore#ledbacklitsignboardsmanufacturerinbangalore#ledfabricboxmanufacturerinbangalore#ledfabriclightboxmanufacturerinbangalore

0 notes

Text

Enhanced Oil Recovery Market Shows Magnificent Growth During Forecasted Years 2024-2031| Exclusive Research Report

The recently released Enhanced Oil Recovery Market Report 2024, delivers an in-depth analysis of the market. This comprehensive evaluation includes size, product specifications, cost structures, industry connections, and an overview of the market landscape. Additionally, the report offers detailed insights into the Enhanced Oil Recovery market's size, volume, and forecasts across various product types, applications, and end-users. With its expert insights, the report serves as a crucial guide for enterprises seeking a strategic comprehension of the constantly evolving technology sector.

Who are the Largest Manufacturers of Enhanced Oil Recovery Market Globally?

BP plc

Cenovus Energy, Inc.

Equinor ASA

ExxonMobil Corporation

LUKOIL

Petróleo Brasileiro S.A.

Total SA

Royal Dutch Shell plc

TechnipFMC plc

National Aluminium Company Limited

China National Petroleum Corporation

Titan Oil Recovery

Occidental Petroleum

Statoil

British Petroleum

Kinder Morgan

Denbury Resources

Husky Energy

Praxair Technology

Wintershall

Canadian Natural Resources

ADNOC

Enhanced Oil Recovery Market’s Drivers and Restraints:

The report delves into crucial aspects of the Enhanced Oil Recovery market, including production costs, supply chain dynamics, and raw material dependencies. It offers an analysis of how the COVID-19 pandemic has affected the industry and provides actionable recommendations for businesses to navigate evolving market conditions effectively. Key market restraints, such as economic challenges in emerging nations and obstacles within the business landscape, are identified and explored in detail. Understanding these risks enables businesses to devise strategies aimed at mitigating challenges and ensuring sustained success in this dynamic industry.

Get Sample Report Copy of Enhanced Oil Recovery Market Report

Enhanced Oil Recovery Market Size And Scope

The Enhanced Oil Recovery market has experienced notable growth in recent years, propelled by the rising demand for power electronics across various sectors, including automotive, telecommunications, and renewable energy. This market is poised for further expansion as the global adoption of electric vehicles and renewable energy sources accelerates. Enhanced Oil Recovery s are highly valued for their exceptional thermal conductivity, electrical insulation, and mechanical strength, making them indispensable in power modules and electronic components. With ongoing advancements in technology and manufacturing, the applications of Enhanced Oil Recovery s are expected to broaden, extending their reach into an even wider array of uses in the near future.

Regional Segmentation:

North America: U.S., Canada and Mexico

Europe: Germany, France, U.K., Italy, Spain, and Rest of Europe

Asia Pacific: China, India, Japan, South Korea, Southeast Asia, and Rest of Asia Pacific

South America: Brazil, Argentina, and Rest of Latin America

Middle East & Africa: GCC Countries, South Africa, and Rest of Middle East & Africa

Why You Should Purchase This Report:

Discovering Valuable Connections: Uncover potential suppliers and partnership opportunities highlighted in the report.

Market Dynamics and Trends: Grasp a complete understanding of the global Enhanced Oil Recovery market's dynamics and trends.

In-Depth Market Analysis: Explore the latest market trends and thorough competitive analysis, along with other key insights about the global market.

Spotting Potential Collaborators: Learn about potential future partners, suppliers, or affiliates outlined in the report.

Strategic Mergers and Acquisitions: Strategically plan mergers and acquisitions by identifying top manufacturers in the industry.

Identifying Emerging Competitors: Recognize emerging players who have strong product offerings, allowing you to devise effective strategies to stay competitive.

Targeting New Clients or Partners: Identify potential new clients or partners within your desired audience.

Strategizing Based on Industry Leaders: Develop tactical plans by understanding the key areas of focus for leading companies.

About Us:

SkyQuest is an IP focused Research and Investment Bank and Accelerator of Technology and assets. We provide access to technologies, markets and finance across sectors viz. Life Sciences, CleanTech, AgriTech, NanoTech and Information & Communication Technology.

Our Other Reports:

5G IoT Market to Surpass USD 136.18 Billion by 2031, Witnessing 50.2% CAGR Growth.

5G IoT Market to Surpass USD 136.18 Billion by 2031, Witnessing 50.2% CAGR Growth.

Flexible Packaging Market to Reach USD 398.08 Billion by 2031 | SkyQuest

Flexible Packaging Market to Reach USD 398.08 Billion by 2031 | SkyQuest

Flexible Packaging Market to Reach USD 398.08 Billion by 2031 | SkyQuest

Flexible Packaging Market to Reach USD 398.08 Billion by 2031 | SkyQuest

Flexible Packaging Market to Reach USD 398.08 Billion by 2031 | SkyQuest

Flexible Packaging Market to Reach USD 398.08 Billion by 2031 | SkyQuest

Blockchain in Manufacturing Market is Expected to Reach USD 70058.5 Million by 2031-end, Need for Transparency and Security in Multiple Manufacturing Verticals Driving Market | SkyQuest Technology

Blockchain in Manufacturing Market is Expected to Reach USD 70058.5 Million by 2031-end, Need for Transparency and Security in Multiple Manufacturing Verticals Driving Market | SkyQuest Technology

0 notes

Text

Dynamics of Brakes Market: Global Trends and Opportunities

With the rise of electric and autonomous vehicles, the innovations in the Brakes Market are not just keeping pace but setting new benchmarks in the development of the automobile industry in general towards smarter, safer and more efficient braking systems.

Take the Tesla Model 3’s regenerative braking system, for a prime example—this technology not only recaptures kinetic energy but also boosts range by converting up to 70% of the braking energy into power. Bosch’s iBooster which integrates electronic stability control with brake actuation is another game-changer, allowing for faster response times—just 150 milliseconds—and increased safety in vehicles equipped with Advanced Driver Assistance Systems (ADAS). Meanwhile, Brembo’s Sensify braking system leverages the power of AI to offer millisecond-level precision, enhancing both performance and safety. The market is also shifting toward low-copper and ceramic brake pads which reduce particulate emissions by up to 90% and improve durability.

Brakes Market Supply Chain in 2024

The brakes market supply chain in 2024 is a complex but globally interconnected system that involves several key stages, from raw material sourcing to manufacturing, distribution and final assembly. Raw materials such as steel, aluminium and composites are sourced from various suppliers which often require precision engineering to meet strict quality standards. These materials are then processed into components like brake discs, pads and callipers, often in specialized manufacturing facilities. Tier-1 suppliers such as Bosch and Brembo play a crucial role in producing and supplying these components to automotive manufacturers. Their supply chain also includes logistics and distribution networks that ensure timely delivery to automakers and aftermarket retailers. The integration of advanced technologies, such as AI-driven inventory management and real-time tracking is increasingly important in optimizing the supply chain, minimizing delays and reducing costs. However, the industry faces challenges such as fluctuating raw material prices and the need for sustainable practices which are driving innovations in supply chain efficiency and resilience.

Key Challenges in the Global Brakes Market

Supply Chain Disruptions have been amplified by ongoing geopolitical tensions and the aftermath of the COVID-19 pandemic continues to cause material shortages and drive up costs, straining manufacturers.

Raw Material Volatility remains a critical concern, with fluctuating prices of essential components like steel, aluminium and rare earth elements introducing additional layers of risk and uncertainty, particularly for advanced braking systems.

Rigorous Environmental Regulations are further pressuring manufacturers to innovate, necessitating the development of low-emission, noise-reducing brake technologies. These regulations demand substantial investment in research and development, making compliance a costly endeavour.

The Shift to Electric Vehicles (EVs) presents another complex challenge, as traditional brake systems must be re-engineered to work alongside regenerative braking technologies thereby reducing demand for conventional components and forcing companies to rethink product portfolios.

Intense Competition has been reshaping the market landscape, with established renowned players and emerging startups pushing the boundaries of innovation. However, this fierce rivalry is now compressing profit margins, making it harder for companies to make sustainable long-term growth future plans.

Requirement for Skilled Labor is becoming increasingly critical, especially in regions facing labour shortages. The complexity of modern braking systems requires highly trained workers for both manufacturing and maintenance creating bottlenecks that could slow down the brake production.

Best-Selling and Most Popular Brakes in the Global Brakes Market

Brembo Brakes

EBC Brakes

Wagner Brakes

Raybestos Brakes

Bosch Brakes

Akebono Brakes

Brakes Market by Type

Disc Brakes: Use callipers to squeeze pads against a rotating disc for strong and reliable stopping power.

Drum Brakes: Press brake shoes outward against a drum to create friction and slow the vehicle.

Anti-lock Braking System (ABS): Prevents wheel lockup during hard braking to maintain steering control.

Regenerative Brakes: Converts braking energy into electricity, recharging the battery in EVs and hybrids.

Hydraulic Brakes: Uses brake fluid pressure to apply brakes which provides smooth and effective braking.

Electronic Braking System (EBS): Replaces hydraulic control with electronic signals for quicker and more precise braking.

Parking Brakes: Keeps the vehicle stationary when it is parked which is often operated mechanically or electronically.

Drum-in-Hat Brakes: Combines disc brakes with a small drum for the parking brake function into an all-in-one unit.

Carbon-Ceramic Brakes: High-performance brakes that resist heat and wear are ideal for sports and luxury cars.

Air Brakes: Uses compressed air to apply brakes which are commonly found in heavy trucks and buses for powerful braking.

Browse more relevant reports :

Light Duty Vehicle Market and Motorcycle Market

Learn about - Automotive Fastener Market Research

Road Bikes Market and Micro EVs Market

Car Brake Pads Market Research and Overview

Read more about - The Aerospace Cold Forgings Market

Automotive Sun Visors Market Research 2023-2030

Automotive Air Conditioning Market Overview 2024-2031

Market Research by Report Prime.

#BrakesMarket #BrakesMarketResearch #BrakesMarketSegmentation #BrakesMarketOverview #BrakeMarket #BrakesMarketSize

0 notes

Text

Global Organometallics Crosslinking Catalysts Market Size,Growth Rate,Industry Opportunities 2024-2030

Global Info Research announces the release of the report “Global Organometallics Crosslinking Catalysts Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030” . This report provides a detailed overview of the market scenario, including a thorough analysis of the market size, sales quantity, average price, revenue, gross margin and market share.The report provides an in-depth analysis of the competitive landscape, manufacturer’s profiles,regional and national market dynamics, and the opportunities and challenge that the market may be exposed to in the near future. Global Organometallics Crosslinking Catalysts market research report is a comprehensive analysis of the current market trends, future prospects, and other pivotal factors that drive the market.

According to our (Global Info Research) latest study, the global Organometallics Crosslinking Catalysts market size was valued at USD 1776 million in 2023 and is forecast to a readjusted size of USD 2585.6 million by 2030 with a CAGR of 5.5% during review period.

Metal-organic compounds are a class of chemical compounds that contain metals and organic ligands, which confer solubility in organic solvents or volatility. The series of organometallic crosslinking catalysts include organic tin, organic bismuth, organic titanium, organic zinc, organic zirconium, etc. The application fields involve polyurethane (PU, CPU, TPU, SPU, SPUR); silicone (MS, STPE); water-based paint, electrophoretic paint, cable, medicine and other industries, with very good industrialization prospects.

Major global organometallic cross-linking catalyst players include Evonik Industries, Momentive Performance Materials, Albemarle, Lanxess and Borica Co., Ltd. Etc. The top five players in the world by revenue account for almost 45 per cent. North America is the world's largest market with a market share of about 30 percent, followed by Europe with about 29 percent and China with 15 percent. In terms of product type, organotin catalysts are the largest market segment with 74% share, and in terms of application, polyurethane has the largest share with about 50%.

The Global Info Research report includes an overview of the development of the Organometallics Crosslinking Catalysts industry chain, the market status of Polyurethane (Organotin Catalysts, Organic Zirconates Catalysts), Organosilicon (Organotin Catalysts, Organic Zirconates Catalysts), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Organometallics Crosslinking Catalysts.

Regionally, the report analyzes the Organometallics Crosslinking Catalysts markets in key regions. North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Organometallics Crosslinking Catalysts market, with robust domestic demand, supportive policies, and a strong manufacturing base.

Market Segmentation

Organometallics Crosslinking Catalysts market is split by Type and by Application. For the period 2019-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value.

Market segment by Type: Organotin Catalysts、Organic Zirconates Catalysts、Organic Titanates Catalysts、Organic Aluminium Catalysts、Others

Market segment by Application:Polyurethane、Organosilicon、Others

Major players covered: Evonik Industries、Momentive Performance Materials、Albemarle、Lanxess、Borica Co., Ltd.、PMC Organometallix、Nantong MingiTai Chemical、Reaxis、Galata Chemicals、BNT Chemicals、Nantong Haotai Products&Chemicals、Jiangsu Xinlu、Dorf Ketal、Borchers Inc.

The content of the study subjects, includes a total of 15 chapters:

Chapter 1, to describe Organometallics Crosslinking Catalysts product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top manufacturers of Organometallics Crosslinking Catalysts, with price, sales, revenue and global market share of Organometallics Crosslinking Catalysts from 2019 to 2024.

Chapter 3, the Organometallics Crosslinking Catalysts competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Organometallics Crosslinking Catalysts breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030.

Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030.

Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Organometallics Crosslinking Catalysts market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030.

Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis.

Chapter 13, the key raw materials and key suppliers, and industry chain of Organometallics Crosslinking Catalysts.

Chapter 14 and 15, to describe Organometallics Crosslinking Catalysts sales channel, distributors, customers, research findings and conclusion.

Our Market Research Advantages:

Global Perspective: Our research team has a strong understanding of the company in the global Organometallics Crosslinking Catalysts market.Which offers pragmatic data to the company.

Aim And Strategy: Accelerate your business integration, provide professional market strategic plans, and promote the rapid development of enterprises.

Innovative Analytics: We have the most comprehensive database of resources , provide the largest market segments and business information.

About Us:

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provide market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Top Reasons to Consider Double Glazing Replacement in Muswell Hill: A Comprehensive Guide

Introduction

If you live in Muswell Hill, chances are you appreciate the unique charm and character of the area. The beautiful Edwardian homes, leafy streets, and vibrant community make it a highly desirable place to live. But with these older homes often comes the challenge of maintaining them, especially when it comes to energy efficiency. This is where double glazing replacement in Muswell Hill becomes a hot topic. Whether you’re looking to enhance your home’s insulation, reduce energy bills, or simply modernize your property, understanding double glazing and its benefits is crucial.

What Is Double Glazing?

Double glazing refers to windows that have two panes of glass instead of one, with a gap in between filled with air or an inert gas like argon. This design creates an insulating barrier, reducing heat loss from inside the home and keeping the cold air out. Not only does this improve energy efficiency, but it also helps with noise reduction—an important factor if you live near a busy road or in a bustling area like Muswell Hill.

Signs That You Need Double Glazing Replacement

You might be wondering when it’s time to consider replacing your double glazing. There are several tell-tale signs:

Condensation Inside the Glass: If you notice condensation or moisture trapped between the panes, it’s a sign that the seal has failed and the insulation properties are compromised.

Draughts and Cold Spots: Feeling a draught even when the windows are closed is another indicator that your windows might need replacing.

Difficulty in Opening or Closing Windows: This could be due to warping, which not only affects the window’s functionality but also its insulating properties.

Noise Reduction Ineffectiveness: If outside noise seems louder than before, it could be because your double glazing is no longer as effective.

Visible Damage to the Frames or Glass: Cracks, chips, or decaying frames are obvious signs that replacement is needed.

The Benefits of Replacing Old Double Glazing

Investing in new double glazing can offer numerous benefits:

Improved Energy Efficiency: Modern double glazing is more efficient than older versions, meaning you’ll likely see a reduction in your heating bills.

Enhanced Security: Newer windows come with better locking mechanisms, providing increased security for your home.

Increased Property Value: Double glazing is a desirable feature for potential buyers, adding to your home’s market value.

Better Noise Insulation: High-quality double glazing can significantly reduce the amount of external noise that enters your home.

Reduced Maintenance Costs: New windows are easier to maintain and less likely to suffer from issues like condensation and draughts.

Choosing the Right Double Glazing for Your Home

When it comes to selecting the right double glazing, there are several factors to consider:

Types of Double Glazing: The most common materials used for frames are uPVC, timber, and aluminium. uPVC is popular due to its affordability and low maintenance, while timber offers a classic look that suits the architectural style of Muswell Hill. Aluminium is durable and offers a sleek, modern appearance.

Energy Ratings: Windows are rated on their energy efficiency, typically from A++ to E. The higher the rating, the better the insulation.

Aesthetic Considerations: Given Muswell Hill’s unique architectural style, it’s important to choose windows that complement the period features of your home.

Cost vs. Quality: While it can be tempting to opt for the cheapest option, investing in high-quality windows will pay off in the long run with better performance and longevity.

The Double Glazing Replacement Process

Replacing double glazing involves several key steps:

Initial Consultation and Survey: A professional installer will visit your home to assess your needs and take measurements.

Selecting the Right Windows: Based on the survey, you’ll choose the type, style, and material of your new windows.

Installation Day: The old windows will be removed and the new ones installed. This process is usually straightforward but can take a few days depending on the number of windows.

Post-Installation Inspection: After installation, a thorough inspection ensures everything is in order. It’s also a good time to receive maintenance tips from the installer.

Costs Involved in Double Glazing Replacement

The cost of replacing double glazing can vary widely depending on several factors:

Material: uPVC is typically the most affordable, while timber and aluminium can be more expensive.

Size and Number of Windows: Larger homes or homes with many windows will obviously cost more.

Installer: Prices can vary depending on the installer’s experience and reputation.

Budgeting tips include getting multiple quotes, comparing not just the price but what’s included, and considering any additional costs like disposal of old windows or potential repairs to the surrounding areas.

Finding a Reliable Double Glazing Installer in Muswell Hill

To ensure a successful installation, finding a reliable installer is crucial:

Research Local Installers: Look for companies with experience in Muswell Hill, as they’ll be familiar with local regulations and the style of homes.

Check Certifications: Make sure the installer is certified by a recognized body such as FENSA or CERTASS.

Read Reviews: Online reviews and testimonials can give you insight into the quality of an installer’s work.

Ask Questions: Don’t hesitate to ask potential installers about their experience, the materials they use, and their process.

Case Study: A Successful Double Glazing Replacement in Muswell Hill

To give you a real-world example, consider the case of a family living in a typical Edwardian home in Muswell Hill. They faced high heating bills and noise from a nearby busy road. After researching, they opted for timber-framed double glazing that matched their home’s style. The installation process was smooth, and they immediately noticed a difference in both comfort and quietness. Plus, their energy bills dropped significantly, making the investment worthwhile.

How Double Glazing Affects Your Energy Bills

One of the biggest benefits of replacing old windows is the impact on your energy bills. Double glazing works by reducing heat loss, meaning your home stays warmer in the winter without cranking up the heating. Over time, the savings on your energy bills can help offset the initial cost of the windows.

Environmental Impact of Double Glazing Replacement

Beyond the financial benefits, double glazing also has a positive environmental impact. By reducing your home’s energy consumption, you’re lowering your carbon footprint. Additionally, many modern double glazing options are made from eco-friendly materials, making them a greener choice.

Common Misconceptions About Double Glazing Replacement

There are some common misconceptions about double glazing that might make homeowners hesitant:

“It’s Not Worth the Investment”: While the upfront cost can be high, the long-term savings and added value to your home make it a sound investment.

Aesthetic Concerns: Some fear that new windows will clash with their home’s style. However, with so many design options available, it’s possible to find windows that enhance your home’s appearance rather than detract from it.

Future-Proofing Your Home with Double Glazing

Double glazing isn’t just about immediate benefits. It’s also a way to future-proof your home. With energy regulations becoming stricter, having high-quality insulation will ensure your home meets future standards. Plus, durable windows mean less worry about repairs or replacements down the line.

Conclusion

Double glazing replacement in Muswell Hill offers homeowners numerous benefits, from improved energy efficiency and noise reduction to enhanced property value. With a variety of materials and styles to choose from, it’s possible to find an option that complements the unique character of your home. By investing in high-quality double glazing, you’re not just upgrading your windows—you’re making a long-term investment in your home’s comfort, security, and future value.

FAQs

How often should double glazing be replaced?

Typically, every 20-35 years, depending on the condition and quality of the original installation.

Will double glazing change the look of my home?

Not necessarily. With a wide range of designs available, you can choose windows that match or enhance your home’s appearance.

Does double glazing really reduce noise?

Yes, especially when using thicker glass or opting for acoustic glass options.

Are there any grants available for double glazing?

Some government schemes offer incentives for energy-efficient home improvements. Check with local authorities for the latest information.

Can I replace just one or two windows?

Yes, but for consistent energy efficiency and aesthetics, it’s often recommended to replace all windows at the same time.

0 notes

Text

Aluminium Trusses Market Set For More Growth

Advance Market Analytics added research publication document on Worldwide Aluminium Trusses Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide Aluminium Trusses market. The study provides valuable market size data for historical (Volume** & Value) from 2018 to 2022 which is estimated and forecasted till 2028*. Some are the key & emerging players that are part of coverage and have being profiled are Alutek (United Kingdom), Area Four Industries (United Kingdom), Easy Access Co. (New Zealand), Eurotruss (Netherlands), Jiangsu Shizhan Group (China), Kordz, Inc. (Australia), Layher (Germany), Peroni S.p.a. (Italy), Guangzhou Shinestage Technologies (China), Prolyte Group (Netherlands), PUHP Lumex (Netherlands), TAF USA, LLC (United States), Tower Scaffolding (United Kingdom), Truss UK (United Kingdom).

Get free access to Sample Report in PDF Version along with Graphs and Figures @ https://www.advancemarketanalytics.com/sample-report/133072-global-aluminium-trusses-market

Aluminum truss is a rigid structure made of aluminum beams. Aluminum beams form a rigid aluminum alloy binder when assembled in a certain order. Aluminum beams consist of aluminum plates. These plates are made into aluminum beams by a process known as casting. In general, aluminum plates are high-performance applications used in product manufacturing, transportation, military, aerospace, and various other industries. Aluminum truss is used for light, sound, exhibition, event, stage shows, fashion shows, decoration, DJ, club, etc. An aluminum truss is generally used for maximum load and lighting of the stage. These are available in 1060 mm x 600 mm sections with a span of 100 feet in two columns without supports.

Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Impact and Economic Slowdown globally. Maintain a competitive edge by sizing up with available business opportunity in Aluminium Trusses Market various segments and emerging territory.

Influencing Market Trend

Easy To Shape, Clean and Maintain

The Increasing Significance of Aluminum Trusses in the Construction Industry

Market Drivers

Rise In the Number of Entertainment Events Globally

High Adoption Of Aluminum In The Various Sectors Due To Its Characteristics Like Good Strength, Lightweight, Strength, Sustainability, Recyclable, And Corrosion-Free Nature

Ease of Installation and Rel

Opportunities:

Rapid Urbanization Translating to A Large Number of New Construction Projects Worldwide

Advancements in Aluminum Trusses for Interior Decorative Purposes

Growth in Infrastructure Investment and Industrialization

Challenges:

Raw Material Price Fluctuations

Have Any Questions Regarding Global Aluminium Trusses Market Report, Ask Our Experts@ https://www.advancemarketanalytics.com/enquiry-before-buy/133072-global-aluminium-trusses-market

Analysis by Type (Flat Truss, Triangular Truss, Square Truss, Circular & Oval Truss, Other), Application (Individual, Commercial), Distribution Channel (Direct Sales, Indirect Sales {Speciality Stores and E-Commerce}), End-Use (Construction, Automobile, Transportation, Aerospace, Others)

Competitive landscape highlighting important parameters that players are gaining along with the Market Development/evolution

• % Market Share, Segment Revenue, Swot Analysis for each profiled company [Alutek (United Kingdom), Area Four Industries (United Kingdom), Easy Access Co. (New Zealand), Eurotruss (Netherlands), Jiangsu Shizhan Group (China), Kordz, Inc. (Australia), Layher (Germany), Peroni S.p.a. (Italy), Guangzhou Shinestage Technologies (China), Prolyte Group (Netherlands), PUHP Lumex (Netherlands), TAF USA, LLC (United States), Tower Scaffolding (United Kingdom), Truss UK (United Kingdom)]

• Business overview and Product/Service classification

• Product/Service Matrix [Players by Product/Service comparative analysis]

• Recent Developments (Technology advancement, Product Launch or Expansion plan, Manufacturing and R&D etc)

• Consumption, Capacity & Production by Players

The regional analysis of Global Aluminium Trusses Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2023-2028.

Table of Content

Chapter One: Industry Overview

Chapter Two: Major Segmentation (Classification, Application and etc.) Analysis

Chapter Three: Production Market Analysis

Chapter Four: Sales Market Analysis

Chapter Five: Consumption Market Analysis

Chapter Six: Production, Sales and Consumption Market Comparison Analysis

Chapter Seven: Major Manufacturers Production and Sales Market Comparison Analysis

Chapter Eight: Competition Analysis by Players

Chapter Nine: Marketing Channel Analysis

Chapter Ten: New Project Investment Feasibility Analysis

Chapter Eleven: Manufacturing Cost Analysis

Chapter Twelve: Industrial Chain, Sourcing Strategy and Downstream Buyers

Read Executive Summary and Detailed Index of full Research Study @ https://www.advancemarketanalytics.com/reports/133072-global-aluminium-trusses-market

Highlights of the Report

• The future prospects of the global Aluminium Trusses market during the forecast period 2023-2028 are given in the report.

• The major developmental strategies integrated by the leading players to sustain a competitive market position in the market are included in the report.

• The emerging technologies that are driving the growth of the market are highlighted in the report.

• The market value of the segments that are leading the market and the sub-segments are mentioned in the report.

• The report studies the leading manufacturers and other players entering the global Aluminium Trusses market. Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

#Global Aluminium Trusses Market#Aluminium Trusses Market Demand#Aluminium Trusses Market Trends#Aluminium Trusses Market Analysis#Aluminium Trusses Market Growth#Aluminium Trusses Market Share#Aluminium Trusses Market Forecast#Aluminium Trusses Market Challenges

0 notes

Text

The Global Dynamics of Aluminium Scrap Imports: Insights, Trends, and Key Players

Aluminium scrap plays a crucial role in the production and recycling industries, providing significant environmental benefits by reducing the need for new raw materials and lowering carbon emissions. This article delves into the global dynamics of aluminium scrap imports, highlighting key trends, major players, and the economic and environmental impacts of this vital resource.

Aluminium Scrap Import Trends in India

In 2024, India imported 135,816 metric tonnes of aluminium scrap in April, showing a slight increase from the previous month’s 128,861 metric tonnes but a decrease from the 141,894 metric tonnes imported in April 2023. This trend underscores India’s position as a major player in the global aluminium scrap market.

In 2023, India was the world’s top importer of aluminium scrap, with 506,864 shipments. Over 3,453 Indian importers sourced aluminium scrap from 14,928 suppliers worldwide, reflecting a robust and growing market.

Global Aluminium Scrap Market

Several countries dominate the global aluminium scrap market. China, India, and the United States are among the top importers, with India surpassing other major economies in recent years. China, the second-largest importer, brought in $2,030.01 billion worth of aluminium scrap in 2021.

Economic and Environmental Impact

Recycling aluminium scrap is environmentally beneficial, significantly reducing CO2 emissions and conserving energy. For instance, recycling aluminium scrap produces only 0.3 million metric tonnes of CO2 per tonne, compared to 14 tonnes of CO2 per tonne produced through traditional methods. Economically, the demand for aluminium scrap is driven by strong market dynamics and price trends, with the Asia Pacific region being the largest producer and consumer.

Challenges and Opportunities

The aluminium scrap market faces several challenges, including import duties and regional conflicts that disrupt supply chains. However, there are opportunities for growth, such as policy changes proposed by industry associations like MRAI, which advocate for the removal of import duties to support sustainability.

Aluminium Scrap HSN Codes

Understanding the correct HSN codes is essential for importers. For aluminium scrap, the primary HSN codes are:

7602: Aluminium waste and scrap

760200: Detailed categories of aluminium waste and scrap

Industry Insights and Future Outlook

The global aluminium market is projected to grow, with an expected value of USD 255.91 billion by 2029. Industry experts suggest that advancements in recycling technology and supportive policies will drive this growth, especially in regions like Asia Pacific, North America, and Europe.

Resources for Importers

Importers can access real-time aluminium scrap import data through platforms like Eximpedia, which provide comprehensive databases and market reports. New importers are encouraged to utilize these resources to stay informed and competitive.

Conclusion

Aluminium scrap imports are vital to the global aluminium industry, contributing to economic growth and environmental sustainability. By staying informed about market trends, policy changes, and technological advancements, traders can navigate the challenges and seize opportunities in this dynamic market. For further information, platforms like Eximpedia offer valuable insights and data to help importers succeed.

#globaltradedata#eximpedia#Aluminium scrap imports#Aluminium Scrap Importer Data#aluminium scrap hsn code#op aluminium scrap importers

0 notes

Text

Cyclodextrin Market Trends, Demand & Future Scope till 2032

Cyclodextrin Market provides in-depth analysis of the market state of Cyclodextrin manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Cyclodextrin in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Cyclodextrin Market Report:

The report offers a comprehensive and broad perspective on the global Cyclodextrin Market.

The market statistics represented in different Cyclodextrin segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Cyclodextrin are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Cyclodextrin.

Major stakeholders, key companies Cyclodextrin, investment feasibility and new market entrants study is offered.

Development scope of Cyclodextrin in each market segment is covered in this report. The macro and micro-economic factors affecting the Cyclodextrin Market

Advancement is elaborated in this report. The upstream and downstream components of Cyclodextrin and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/cyclodextrin-market-100564

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Blood Clot Retrieval Devices MarketMarket Growth Rate

Waste Derived Biogas MarketMarket Forecast

Global Cosmetic Lasers MarketMarket Size

Clinical Trial Patient Recruitment Services MarketMarket Growth

Geosynthetics MarketMarket Analysis

Portable Solar Charger MarketMarket Size

Global Polyolefin Elastomers (POE) MarketMarket Share

Global Wireless Gigabit MarketMarket Growth

Underwater ROV MarketMarket

Recreation Management Software MarketMarket Share

Construction Management Software MarketMarket Growth Rate

Screenless Display MarketMarket Forecast

Global Sheep Milk Soap MarketMarket Size

Healthcare Education Learning Management System MarketMarket Growth

Gastroenterology MarketMarket Analysis

Alf3 (Aluminium Fluoride) MarketMarket Size

Global Tamping Machine MarketMarket Share

Global Fixed Wing Unmanned Aerial Vehicles MarketMarket Growth

In-wheel Motors MarketMarket

Indoor Location-based Services (LBS) MarketMarket Share

Pvc Cling Film MarketMarket Growth Rate

Membrane Distillation MarketMarket Forecast

Global Defatted Wheat Germ Powder MarketMarket Size

Sequins Apparels MarketMarket Growth

Gene Sequencing MarketMarket Analysis

CNC Video Measuring MarketMarket Size

Global Hospital Commode MarketMarket Share

Global Fireproofing Material MarketMarket Growth

Microplate Reader MarketMarket

Sulfonated Melamine Formaldehyde Condensate MarketMarket Share

Comic Book MarketMarket Growth Rate

Patient Engagement Software MarketMarket Forecast

Global Ultralight and Light Aircraft MarketMarket Size

Neuropathy Screening Devices MarketMarket Growth

Panoramic Camera APP MarketMarket Analysis

Automatic Capacitor Winding Machine MarketMarket Size

Global Fin Seal Overwrapping Machine MarketMarket Share

Global Mine Escape Rescue Capsule MarketMarket Growth

Beating Heart Surgery Stabilizer MarketMarket

Ultrasonic Thickness Coating Gauge MarketMarket Share

0 notes

Text

Flexible Plastic Packaging Market worth $264.9 billion by 2030

The report "Flexible Plastic Packaging Market by Packaging Type (Pouches, bags, roll stock, films & wraps), Printing Technology (Flexography, Rotogravure, Digital Printing), End-user Industry, Material (Plastics, aluminum Foils,) and Region - Global Forecast to 2030", is approximated to be USD 182.4 billion in 2022, and it is projected to reach USD 264.9 billion by 2030, at a CAGR of 4.8%.

Download pdf- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1271

The Flexible plastic packaging market is experiencing significant growth driven by several factors, including the increasing demand for packaged and processed food and beverages, changing lifestyles, rising disposable income, and a growing awareness of sustainable packaging. Additionally, rising urbanization and a focus on hygiene are also contributing to the market's expansion. However, the high cost of raw materials and poor recycling infrastructure may limit market growth. Despite these challenges, opportunities exist in the market for sustainable packaging alternatives and as a substitute for traditional packaging materials. The Flexible plastic packaging industry also faces the challenge of adapting to rapid technological changes.

By Packaging type, Bags accounted for the 2nd largest share in 2021

Paper and plastic bags are prevalent packagings used for various purposes. Plastic bags (of the thin film) are usually made of LDPE, HDPE, and polypropylene. Common uses of plastic bags include bags for shopping, household garbage, food packaging, dry cleaning, newspapers, frozen foods, fresh produce, agricultural products, medical & biohazard waste, and antistatic bags. Plastic bags are inexpensive to mass-produce, relatively easy to transport due to their lightweight, and can be folded into small sizes. They are water-resistant and do not add weight to the goods they carry. Due to the pandemic, single-use plastic bags are one of the most preferred packaging options among consumers. Despite growing environmental concerns, the production and consumption of single-use plastic bags are increasing worldwide. In the current scenario, countries are not focusing on sustainability. In the US, New York is among the states that have postponed implementing a ban on plastic bags.

By Material, Aluminium Foils accounted for the 2nd largest share in 2021.

Aluminum foil is a thin aluminum sheet (produced from bauxite ore) and is a lightweight metal with a silvery-white appearance. It is also the world’s most abundant metal in free and combined states. The aluminum used in Flexible plastic packaging is in the form of rolled products. Aluminum foil packaging with multilayered plastics is widely used for packaging fresh and processed meat, poultry, and fish, as they provide better hygiene and increase product shelf-life. They are extensively used in the food & beverage and healthcare sectors for packaging products, such as cheese cubes and blister packs. Aluminum has high ductility, and barrier protection, making it an ideal packaging material. It increases the shelf-life of products by keeping food, drinks, and other products safe and fresh. Another factor that enhances the use of aluminum for packaging purposes is its unparalleled recyclability.

By Printing Technology, Rotogravure accounted for the 2nd largest share in 2021.