#Aluminum Nitride Pcb

Text

Aluminum Nitride PCB (AlN PCB)

Aluminum Nitride PCB stands out for its best thermal conductivity, exceeding 170 W/mK. This exceptional ability to dissipate heat makes it the go-to choice for high-power electronics that generate significant thermal loads. Key applications of Aluminum Nitride PCB include.

0 notes

Text

Special PCB Tailor-Made Solutions for Unique Applications

PCB has been well known that is printed circuit board, It is the support of electronic components and the carrier of electrical connection of electronic components, also it is of the important components, but what is special PCB

the first need know the PCB material

normal PCB material is FR4, FR4 is glass fiber epoxy resin copper clad plate, so we can say other material is special PCB, such as

FR-1 -- phenolic cotton paper, the base material is commonly known as electric board (higher economic efficiency than FR-2)

FR-2 -- phenolic cotton paper

Fr-3 - cotton paper, epoxy resin

FR-5 -- glass cloth, epoxy resin

Fr-6 -- ground glass, polyester

G-10 - Woven glass, epoxy resin

CEM-1 -- cotton paper, epoxy resin (flame retardant)

Cem-2 -- cotton paper, epoxy resin (non flame retardant)

CEM-3 -- Woven glass, epoxy resin

Cem-4 -- Woven glass, epoxy resin

Cem-5 -- Woven glass, polyesters

Ain -- aluminum nitride

SiC -- silicon carbide

also High Tg, High frequency, Rigid-Flex, Aluminum base, copper base, Thermo electric separation, and so on

#customize pcb#pcb manufacturing#business#flex pcb#pcb manufacturers#advertising#rigid flex pcb#Special PCB

0 notes

Text

What is a ceramic PCB and what are the benefits of ceramic PCBs?

Ceramic Printed Circuit Boards (PCBs) are advanced circuit boards that offer superior performance and reliability, especially in demanding high-performance electronic applications. Unlike conventional circuit boards made from organic materials such as fiberglass or epoxy, ceramic PCBs are manufactured using ceramic materials, which gives them unique properties and features. These boards are designed to excel where high thermal conductivity, excellent electrical performance at high frequencies, and robustness in harsh environments are critical.

Comprehensive Introduction to Ceramic PCBs

The foundation of a ceramic circuit board lies in its ceramic substrate, which has many advantages that distinguish it from conventional circuit boards. One of its outstanding features is its excellent thermal conductivity, which enables it to efficiently dissipate the heat generated by components. This makes ceramic PCBs the first choice for applications that generate large amounts of heat and require efficient thermal management.

The excellent electrical properties of ceramic materials, especially at high frequencies, make ceramic PCBs particularly suitable for radio frequency (RF) and microwave applications. These boards maintain signal integrity and minimize signal loss, making them indispensable in industries such as telecommunications, aerospace and satellite communications.

In addition, ceramic PCBs have impressive mechanical strength and durability, allowing them to withstand challenging mechanical stresses and vibrations. Their chemical resistance and ability to withstand harsh environments make them ideal for applications that require exposure to corrosive substances.

What are the advantages of ceramic PCBs?

Ceramic Printed Circuit Boards (PCBs) offer a variety of advantages that make them well suited for a wide range of applications, especially those requiring high performance, reliability and efficiency. Here are some of the key benefits of ceramic PCBs:

-High Thermal Conductivity: Ceramic materials such as Aluminum Oxide (Al2O3), Aluminum Nitride (AlN), and Silicon Carbide (SiC) have excellent thermal conductivity. This means that ceramic PCBs can effectively dissipate heat generated by components, preventing overheating and ensuring reliable operation of high-power electronic devices.

-Excellent electrical properties: Ceramic materials have low dielectric loss and excellent electrical properties, especially at high frequencies. This makes ceramic PCBs ideal for applications in radio frequency (RF), microwave and high-speed digital circuits where signal integrity and low signal loss are critical.

-Mechanical strength and durability: Ceramic PCBs have higher mechanical strength and rigidity than organic PCBs. This robustness allows them to withstand mechanical stress, vibration and shock, making them suitable for applications in challenging environments.

-Chemical Resistance: Ceramics are highly resistant to chemicals, solvents, acids and bases. This resistance makes ceramic PCBs ideal for applications in industries such as automotive, aerospace, and industrial where harsh chemicals are frequently encountered.

-High Temperature Resistance: Ceramic PCBs can withstand higher temperatures than traditional organic PCBs. This ability is critical for industries such as automotive and aerospace, where electronics must operate reliably at high temperatures.

Miniaturization: Ceramic PCBs can accommodate fine alignments, smaller components, and high-density interconnects, allowing for the design of compact electronic devices. This feature is critical for applications that require miniaturization without sacrificing performance.

-Signal Integrity: Ceramic PCBs provide excellent signal integrity due to their low loss angle tangent and high dielectric constant, especially at high frequencies. This makes them suitable for high-speed data transmission and communication systems.

-Harsh Environment Compatibility: Because of their thermal, mechanical, and chemical resistance, ceramic PCBs are well suited for applications in harsh environments such as oil and gas exploration, aerospace, and military applications.

Reliability and longevity: The combination of high thermal performance, ruggedness and chemical resistance contributes to the long-term reliability of ceramic PCBs, reducing the risk of failure and extending the life of electronic devices.

-Customization: Ceramic PCBs can be customized to meet specific design requirements, including substrate materials, layer configurations, alignment layouts and component placement. This flexibility allows engineers to optimize board performance for a given application.

-EMI/EMC Performance: Ceramic materials inherently provide better electromagnetic interference (EMI) and electromagnetic compatibility (EMC) performance due to their electrical properties and shielding capabilities.

0 notes

Text

Aluminum Nitride Ceramic PCB

Aluminum Nitride (AlN) is currently the best ceramic substrate material accessible. Its properties of high thermal conductivity (170 W/mK) combined with being a strong dielectric and a low expansion rate (CTE) make it the material of choice today as a substrate or package for high-power LEDs, ICs, sensors and many other components and circuits.

Reasons why you should choose Aluminum Nitride PCB for your project

Aluminum Nitride (AlN) PCBs offers several compelling reasons, especially in applications where thermal management, high-frequency performance, and reliability are critical. Here are some key reasons to consider using AlN PCBs:

·Exceptional Thermal Conductivity: AlN ceramics have excellent thermal conductivity properties, making them highly effective at dissipating heat generated by electronic components. This property is crucial for maintaining component reliability, extending the lifespan of electronics, and preventing overheating-related failures.

·High-Frequency Performance: AlN PCBs exhibit low signal loss and minimal signal distortion, making them well-suited for high-frequency and microwave applications. They provide reliable signal transmission and are ideal for RF (Radio Frequency) circuits, microwave antennas, and advanced communication systems.

·Electrical Insulation: AlN ceramics possess excellent electrical insulation properties. They have a high dielectric strength, preventing electrical leakage and ensuring the isolation of electrical components and signals. This insulation is essential for maintaining signal integrity and preventing unintended electrical connections.

·Mechanical Strength: AlN ceramic substrates have good mechanical strength, with the ability to withstand mechanical stresses during manufacturing, assembly, and operation. This mechanical robustness contributes to the overall reliability of electronic systems.

·Compatibility with Semiconductor Devices: The thermal expansion coefficient of AlN is relatively close to that of silicon, a common material used in semiconductor devices. This compatibility allows for efficient heat transfer from semiconductor components, reducing the risk of thermal stress and enhancing their performance and longevity.

·High-Power and High-Temperature Applications: AlN PCBs are well-suited for high-power electronic components and high-temperature environments. They can efficiently dissipate heat from power amplifiers, voltage regulators, LEDs, and other heat-generating devices.

·Longevity and Reliability: The superior thermal management provided by AlN PCBs contributes to the longevity and reliability of electronic systems, reducing the risk of premature component failures due to overheating.

·Wide Range of Applications: AlN PCBs find application in various industries, including aerospace and defense, telecommunications, medical devices, automotive, and industrial electronics. They are versatile and suitable for demanding electronic applications.

·Customization: AlN PCBs can be customized to meet specific design requirements, including layer count, dimensions, and design layout, ensuring that they are tailored to the needs of the application.

·Efficient Heat Dissipation: The exceptional heat dissipation properties of AlN PCBs allow for the effective management of thermal issues without the need for additional cooling mechanisms, such as heat sinks or fans.

In conclusion, choosing Aluminum Nitride (AlN) PCBs offers lots of advantages, including superior thermal conductivity, high-frequency performance, electrical insulation, and mechanical strength. These properties make them a preferred choice in applications where traditional PCB materials may not meet the stringent requirements for thermal management and reliability. At Hitech Circuits, we supply both Aluminium Nitride PCB (AlN) processed by thick film process (Silver/silver palladium metalization) as well as Direct Plated Copper Technologies (DPC), with copper tracks and pads.

#AINPCB #ceramicpcb

0 notes

Text

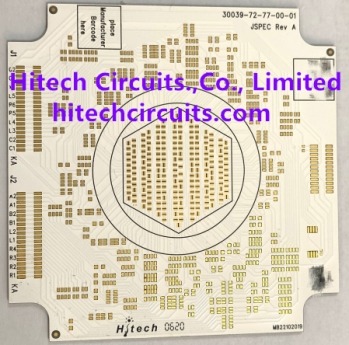

Aluminum Nitride Ceramic PCB

Aluminum Nitride Ceramic PCB have good high-frequency and electrical performance, and have high thermal conductivity, excellent chemical and thermal stability. Excellent corrosion resistance, it widely used in semiconductor and microelectronic circuit packaging pcb, High-brightness Led chip carrier board, automotive electronics and lighting components, high-power electronic component heat dissipation materials, etc.

Technical Parameters

Aluminium Nitride (ALN) material

0.5mm Ceramic thickness

1 Oz Coppper thickness

ENEPIG suitable for gold wirebonding

Solder mask: White, Legend: Black

Laser Scribed

Application: Semi-Conductor

If you want to know ceramic PCBs, please feel freely to contact Cynthia at [email protected]

0 notes

Text

What is Ceramic PCB?

Ceramic PCB board is also called ceramic substrate, ceramic circuit board, ceramic copper coated plate, ceramic substrate refers to the copper foil directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate or other ceramic substrate surface (single or double) on the special process board.

The ceramic pcb can be described as an organic binder and ceramic powder that conducts heat. The thermal conductivity at which this PCB is prepared is between 9 to 20W/m.

To explain further, ceramic PCBs are printed circuit boards, with ceramic as its base material. This base material is highly thermally conductive like aluminum nitride, alumina, and beryllium oxide. These are very effective in the transfer of heat from hot spots and then dissipating this heat over the entire surface.

Asides from this, the fabrication of ceramic PCB is done with the LAM technology. This technology is a laser quick activation metallization type. Therefore, ceramic PCBs are highly versatile and can easily substitute the whole traditional PCBs. This PCB will achieve this with even more enhanced performance and involving less complicated construction.

1. The difference between ceramic substrate and pcb board

Ceramic substrate is that we say ceramic circuit board, ceramic pcb and printed circuit board have the same circuit interconnection, through hole conduction characteristics. So what are the differences between ceramic substrate and pcb board?

(1)The thermal conductivity of PCB board and ceramic substrate is different

Ceramic substrate is made of ceramic substrate, that is, the medium is ceramic material, including alumina ceramic base, aluminum nitride ceramic base, silicon nitride ceramic base, ceramic heat dissipation performance is very good, the thermal conductivity of ceramic substrate from 25w to 230w, different ceramic medium thermal conductivity is different. The thermal conductivity of alumina ceramic substrate is 25w~30w, the thermal conductivity of aluminum nitride ceramic substrate is above 170w, and the thermal conductivity of silicon nitride ceramic substrate is 80w~90w. Then pcb board is usually the use of medium is fr4 or metal substrate, thermal conductivity is less than 3w, and the gap is too large compared with ceramic substrate, especially the need for high heat dissipation performance of the product field, ceramic substrate has become a very popular medium material.

2. Ceramic substrate and pcb board insulation is different

Ceramic substrate is generally line layer - ceramic base - line layer structure, ceramic substrate insulation is very good, is also determined by the ceramic material itself, no need to add insulation layer. pcb board needs to add an insulating layer to play a mobile insulation role, but the insulation effect is far less than ceramic substrate.

(3)The heat dissipation structure of ceramic substrate is different from that of pcb board

The heat dissipation structure of the ceramic substrate is the structure of the circuit layer - ceramic base - circuit board layer. Because there is no insulating layer in the middle, the heat of the device is transferred directly from the ceramic base to the circuit layer and the heat dissipation is out, the heat dissipation is fast and the effect is good. pcb board is the need for heat from the medium layer - insulation layer - line layer, separated by an insulation layer at the same time, the dielectric layer itself of the thermal conductivity is poor, then add heat conduction adhesive, heat conduction effect is still not improved, often can not achieve the purpose of rapid heat dissipation device. In particular, some high-power devices need to use ceramic substrate as a cooling substrate in the product field where the heat dissipation and temperature change is relatively large.

(4)Ceramic substrate and pcb board application is different

Ceramic substrate and pcb board application is different, mainly the performance of the two is different, ceramic substrate is used in high thermal conductivity, high heat dissipation, high insulation, product field, such as high power LED lighting, high power module, high-frequency communication, track power supply; Ordinary pcb board is used in some more extensive, heat dissipation, insulation and other requirements are not strict, used in private commercial commodities.

(5) The price of ceramic substrate is different from that of pcb board

The material and performance of ceramic substrate and pcb board are different, and the final decision is that their prices are different. The board of ceramic substrate is very high and the production cost is high.

Ceramic substrate has outstanding advantages, but the ceramic substrate is fragile and has a high scrap rate, which requires a high level of production technology. However, you can't make a circuit board with the size of more than one meter like ordinary pcb boards. Hitech Circuits has more than 10 years of experience in the ceramic circuit board industry, and many universities and R & D institutions are in cooperation, welcome to inquiry.

2.Ceramic substrate and high-frequency plate difference

The material is different. The ceramic substrate is made of aluminum oxide or aluminum nitride, and the high frequency plate is made of Rogers, Yaron, PTFE, etc., with low dielectric constant and high frequency communication speed.

Performance is different. Ceramic substrate is widely used in refrigeration and systems, high power modules, automotive electronics and other fields. High frequency board is mainly used in high frequency communication field, aviation, high-end consumer electronics and so on. High-frequency communication field involves heat dissipation requirements, usually need to be combined with the ceramic base and high frequency plate, such as high frequency ceramic pcb.

1. Application of ceramic substrate

Ceramic substrates are used in led chips to achieve better thermal conductivity. In addition, ceramic substrate is also used to make ceramic chips in the following electronic devices:

◆High power semiconductor module

◆Semiconductor cooler, electronic heater; Power control circuit, power mixing circuit

◆Intelligent power module; High frequency switching power supply, solid state relay

◆Automotive electronics, aerospace and military electronics components

◆Solar panel module; Telecommunications private exchange, receiving system; Laser and other industrial electronics

Application of ceramic substrate in third generation semiconductor

The mainstream power devices represented by MOSFET, IGBT and transistor occupy a place in their own frequency and power supply segments. Due to the comprehensive excellent performance of IGBT, it has replaced GTR, become the inverter, UPS, frequency converter, motor drive, high-power switching power supply, especially now the hot electric vehicle, high-speed rail and other power electronic devices in the mainstream devices.

Application of alumina ceramic substrate in electronic power field

In the field of power electronics, such as power switching power supply, electric drive, etc., dielectric ceramic substrate is needed to achieve better thermal conductivity, prevent current burn out and short circuit.

Application of alumina ceramic co-fired plate in lithium battery industry

With the recommendation of artificial intelligence and environmental protection, the automobile industry has also launched electric cars, mainly through battery storage. Lithium batteries made of ceramic substrate can achieve better current and heat dissipation functions, promoting the market demand for new energy vehicles.

2. Advantages of ceramic substrate

A. The thermal expansion coefficient of ceramic substrate is close to that of silicon chip, which can save Mo sheet of transition layer, save labor, save material and reduce cost;

B. Reduce the welding layer, reduce the thermal resistance, reduce the cavity;

C. Under the same load flow, the wire width of copper foil 0.3mm thick is only 10% of that of ordinary printed circuit board;

D. Excellent thermal conductivity, so that the chip packaging is very compact, so that the power density is greatly increased, improve the reliability of the system and device;

E. Ultra-thin (0.25mm) ceramic substrate can replace BeO, without environmental toxicity problems;

F. Large load capacity, 100A current continuously through 1mm wide 0.3mm thick copper body, temperature rise about 17℃; With 100A current continuously passing through a 2mm wide 0.3mm thick copper body, the temperature rise is only about 5℃.

G. Low thermal resistance, 10×10mm ceramic substrate 'thermal resistance of 0.63mm thickness of ceramic substrate is 0.31K/W, 0.38mm thickness of ceramic substrate is 0.19K/W, 0.25mm thickness of ceramic substrate is 0.14K/W.

H. High insulation and high pressure resistance to ensure personal safety and equipment protection.

I. New packaging and assembly methods can be realized, so that the product is highly integrated and the size is reduced.

3. Ceramic substrate technology

At present, the common types of ceramic heat dissipation substrate include HTCC, LTCC, DBC and DPC. DBC and DPC for the domestic in recent years to develop mature, and energy production of professional technology, DBC is the use of high temperature heating Al2O3 and Cu plate combination, its technical bottleneck is not easy to solve the problem of micro-pores between Al2O3 and Cu plate, which makes the mass production energy and yield of the product by the greater challenge. DPC technology is the use of direct copper plating technology, Cu deposition on the Al2O3 substrate, its process combined with the material and film technology, its product is the most commonly used ceramic cooling substrate in recent years. However, its material control and process technology integration ability requirements are high, which makes the technical threshold of entering the DPC industry and stable production is relatively high.

(1) HTCC (High-Temperature Co-fired Ceramic)

The manufacturing process of HTCC is very similar to that of LTCC. The main difference is that the ceramic powder of HTCC is not added with glass material. Therefore, the ceramic powder of HTCC must be dried and hardened into embryonic form at a high temperature of 1300~1600℃. Due to its high co-firing temperature, the choice of metal conductor materials is limited, its main materials for high melting point but poor conductivity tungsten, molybdenum, manganese... Such as metal, and finally laminated sintering molding.

(2) LTCC (Low-Temperature Co-fired Ceramic)

LTCC is also known as low-temperature co-fired multilayer ceramic substrate. In this technology, inorganic aluminum oxide powder and about 30%~50% glass material are combined with organic binder to make it evenly mixed into mud slurry. Then, the slurry is scraped into sheets with a scraper, and then through a drying process, the sheet slurry is formed into a thin piece of raw blank. As the transmission of signals at all levels

For the internal lines of LTCC, the screen printing technology is used to fill holes and print lines on the raw embryos, and the internal and external electrodes can be used respectively of silver, copper, gold and other metals. Finally, the layers are stacked and sintered in the sintering furnace at 850~900℃.

(3) Direct Bonded Copper (DBC)

Direct copper coating technology is the use of copper oxygen eutectic liquid directly on the ceramic coating, the basic principle is to introduce an appropriate amount of oxygen between copper and ceramic before or during the coating process, in the range of 1065℃~1083℃, copper and oxygen form Cu-O eutectic liquid, DBC technology uses the eutectic solution to chemically react with the ceramic substrate to form CuAlO2 or CuAl2O4 phase on the one hand, and to infiltrate the copper foil to realize the combination of the ceramic substrate and copper plate on the other hand.

(4) DPC (Direct Plate Copper)

DPC is also known as direct copper-plated substrate. Take DPC substrate process as an example: First of all, the ceramic substrate is pre-treated and cleaned, and the ceramic substrate is sputtered on the ceramic substrate and combined with the copper composite layer by using the vacuum coating technology of thin film manufacturing. Then the circuit is made by the re-exposure, development, etching and film removal process with the yellow light microshadow photoresistance. Finally, the thickness of the circuit is increased by electroplating/electroless plating deposition, and the metallized circuit is made after the photoresistance is removed.

3. Production process of ceramic substrate

1. Drilling

Ceramic substrate is generally used by laser punching, compared with the traditional punching technology, laser punching technology has the advantages of high precision, fast speed, high efficiency, large-scale mass punching, suitable for the vast majority of hard and soft materials, no loss to tools, in line with the printed circuit board high density interconnection, fine development.

Through the laser drilling process of ceramic substrate has high bonding force of ceramic and metal, no falling off, foaming phenomenon, to achieve the effect of growth together, high surface smoothness, roughness in 0.1μm ~ 0.3μm, laser drilling aperture in 0.15mm-0.5mm, even can reach 0.06mm.

2、Copper-clad

Copper coating refers to the area without wiring on the circuit board covered with copper foil, connected with the ground wire, in order to increase the ground wire area, reduce the loop area, reduce voltage drop, improve power efficiency and anti-interference ability. Copper coating can not only reduce the ground impedance, but also reduce the cross-sectional area of the loop and enhance the mirror loop of the signal. Therefore, the copper coating process plays a very key role in the ceramic substrate PCB process, incomplete, truncated mirror loop or incorrect position of the copper layer often lead to new interference, have a negative impact on the use of the board.

3. Etching

Ceramic substrates also need to be etched, with the circuit pattern pre-coated with a lead-tin resist layer, and then chemically etched away the unprotected, non-conductive copper to form the circuit. Etching is divided into inner layer etching and outer layer etching, inner layer etching using acid etching, with wet film or dry film as corrosion resistance; The outer etching is alkaline etching with tin and lead as resist.

There are many kinds of manufacturing process of ceramic products in circuit board factory. It is said that there are more than 30 kinds of manufacturing processes, such as dry pressing, grouting, extrusion, injection, casting and isostatic pressing. Because the electronic ceramic substrate is a "flat" type, the shape is not complicated, the manufacturing process of dry forming and processing is simple and the cost is low, so most of them use dry pressing forming method. The manufacturing process of dry press PCB electronic ceramics mainly includes blank forming, blank sintering and finishing, forming circuit on the substrate.

1. Green manufacturing of ceramic substrate (forming)

Use high purity alumina (content ≥95% Al2O3) powder (different particle sizes are required depending on the purpose and manufacturing method. For example, from a few illiterates to tens of microns) and additives (mainly adhesives, dispersants, etc.). Form a "paste" or processed material.

(1) Dry pressing of ceramic substrate to produce green parts (or "green").

Dry pressing billet is the use of high purity alumina (electronic ceramics with alumina content greater than 92%, most of the use of 99%) powder (dry pressing particles shall not exceed 60μm, for extrusion, rolling, injection and other powder particles should be controlled within 1μm) add the appropriate amount of plasticizer and binder, mixed evenly after dry pressing billet. At present, the offspring of square or round pieces can reach 0.50mm, or even ≤0.3mm (depending on plate size). Dry pressed billets can be processed before sintering, such as dimensioning and drilling. Machining, but be careful to compensate for the size shrinkage caused by sintering (magnify the size of the shrinkage).

(2) Production of green billet by ceramic substrate spreading method.

Flow glue liquid (aluminum oxide powder + solvent + dispersant + adhesive + plasticizer mixed evenly + screening) manufacturing + flow casting (in the flow casting machine glue on metal or heat-resistant polyester belt) + drying + trimming (can also be other processing) + degreasing + sintering and other processes. It can realize automation and scale production.

2. Sintering and finishing of green billet after sintering. The raw parts of ceramic substrate often need to be "sintered" and finished after sintering.

(1) Sintering of raw ceramic substrate.

Ceramic billet "sintering" refers to the process of "sintering", the billet (volume) in the cavity, air, impurities and organic matter such as dry pressure removal, so that its volatilization, combustion, extrusion, and removal of alumina particles. Achieve close contact or combined growth process, so after sintering of ceramic green billet, there will be weight loss, size shrinkage, shape deformation, compressive strength increase and porosity reduction and other changes.

The sintering methods of ceramic billet are as follows: ① atmospheric sintering, non-pressure sintering will bring large deformation; ② pressure (hot pressing) sintering, pressure sintering, can get good flat products is the most commonly used method; ③ Hot isostatic sintering is the use of high pressure hot gas sintering. Its characteristic products are finished at the same temperature and pressure. All kinds of performance balance, the cost is relatively high. In the added value of products, or aerospace, national defense and military products in the use of this sintering method, such as the military field of mirrors, nuclear fuel, barrel and other products. The sintering temperature of dry pressed alumina green billets is mostly between 1200℃ and 1600℃ (depending on composition and flux).

(2) Finishing of ceramic substrate after sintering (cooked) blank.

Most sintered ceramic billets require finishing. The purpose is: ① to obtain a flat surface. In the process of high temperature sintering of green billet, due to the imbalance of particle distribution, voids, impurities and organic matter in the green billet, it will cause deformation, unevenness or excessive roughness and difference. These defects can be solved by surface finishing; ② Obtain high finish surface, such as specular reflection, or improve lubricity (wear resistance).

Surface polishing treatment is to use polishing materials (such as silicon carbide, B4C) or diamond sand paste to gradually polish the surface from coarse to fine abrasive. Generally speaking, the use of AlO powder or diamond paste ≤1μm, or laser or ultrasonic processing to achieve.

(3) strong (steel) treatment.

After surface polishing, in order to improve the mechanical strength (such as bending strength, etc.), electronic ray vacuum coating, sputtering vacuum coating, chemical vapor evaporation and other methods can be used to plating a layer of silicon compound film, through 1200℃ ~ 1600℃ heat treatment, can significantly improve the mechanical strength of ceramic parts!

3. Form a conductive pattern (circuit) on the substrate

To process conductive graphics (circuits) on ceramic substrates, it is necessary to manufacture copper-coated ceramic substrates first, and then to manufacture ceramic printed circuit boards according to PCB technology.

(1) Forming a copper-covered ceramic substrate. There are currently two methods of forming copper-coated ceramic substrates.

① Laminating method. It is formed by hot pressing one side of oxidized copper foil and alumina ceramic substrate. That is, the ceramic surface is treated (such as laser, plasma, etc.), get activated or rough surface, and then according to the "copper foil + heat-resistant binder layer + ceramic + heat-resistant binder layer + copper foil" laminate together, after 1020℃ ~ 1060℃ sintering, the formation of double-sided copper coated ceramic laminate. ② Electroplating method. After plasma treatment, the ceramic substrate is "sputtered titanium film + sputtered nickel film + sputtered copper film", and then conventional electroplating copper to the required copper thickness, that is, the formation of double-sided copper-coated ceramic substrate.

(2) Single and double sided ceramic PCB board manufacturing. According to traditional PCB manufacturing techniques, single - and double-sided copper-coated ceramic substrates are used.

(3) ceramic multilayer plate manufacturing.

① In single and double panels repeatedly coated insulation layer (alumina), sintering, wiring, sintering to form PCB multilayer board, or the use of casting manufacturing technology to complete. ② Ceramic multilayer plate is manufactured by casting method. The raw tape is formed on the casting machine, then drilling, plugging (conductive glue, etc.), printing (conductive circuit, etc.), cutting, laminating, isostatic pressing to form ceramic multilayer plate. Hitech Circuits has more than 10 years of experience in manufacturing ceramic substrates, so feel free to consult them if you need to know more technical questions.

1 note

·

View note

Text

Uses and Characteristics of Ceramic Substrate

Ceramic substrate refers to copper foil directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single or double sided) at high temperature on a special process plate. The ultrathin composite substrate has excellent electrical insulation performance, high thermal conductivity, excellent soft brazing and high adhesion strength, and can be etched into a variety of graphics like PCB board, with great current-carrying capacity. Therefore, ceramic substrate has become the basic material of high power electronic circuit structure technology and interconnection technology.

Purpose:

High-power semiconductor module; Semiconductor cooler, electronic heater; Power control circuit, power mixing circuit.

Intelligent power module; High frequency switching power supply, solid state relay.

Automotive electronics, aerospace and military electronics components.

Solar panel module; Telecommunications private exchange, receiving system; Laser and other industrial electronics.

Features:

Strong mechanical stress, stable shape; High strength, high thermal conductivity, high insulation; Strong binding force, anti-corrosion.

Excellent thermal cycle performance, cycle times up to 50,000, high reliability.

And PCB board (or IMS substrate) can be etched out of a variety of graphic structure; No pollution, no pollution.

Ceramic Substrate Use temperature range -55℃ ~ 850℃; Thermal expansion coefficient is close to silicon, simplifying the production process of power module.

Aluminum Nitride Ceramic Substrate

Read the full article

#996AluminaCeramicSubstrates#AlNCeramicSubstrate#AluminaCeramicSubstrate#AluminumNitrideCeramicSubstrate#CeramicSubstrate

0 notes

Text

What are different types of aluminum nitride substrates?

Aluminum nitrides substrates have multiple categories that are highly compatible with advanced circuit board designs. In terms of applications and specifications, AlN substrates offer a wide variety.

Therefore, manufacturers prefer these materials over other traditional ceramic substrates for their PCB applications. The most striking AlN substrate types for PCB applications are-

High power AlN substrate

AlN PCB substrates used in powerful electronics support various PCB materials such as ceramic PCBs. They have made the best use of thermally conductive materials in powerful PCB applications.

In addition, these substrates help integrated circuits and LED-based devices to function properly.

LED AlN substrate

Do you struggle with your LED control in electronic devices?

LED AlN substrates are the most effective solution to solve these kinds of problems in power electronics.

In addition, LED-based aluminum nitride substrates provide heat conductivity functions for sensitive devices. Therefore, the designer can improvise the PCB scheme according to the requirements of applications.

Read More - Cable and Wire Harness Assembly

Laser AlN substrate

This type of AlN substrate brings forward newer opportunities in PCB-based projects. Laser aluminum nitride supports the use of laser engraving during the manufacture of PCBs. It helps the designer to guarantee optimal precision when designing and manufacturing PCBs.

High current AlN substrate

The main advantage of high-current AlN PCB substrates is their thermal conductivity. Usually their thermal conductivity ranges from 170-320 W / mK, which is impressive compared to other substrates.

In particular, they perform better than alumina PCBs in most PCB devices where high-current management is an urgent need. Again, AlN substrates offer versatility in terms of usage due to their compatibility with high current loads.

Stiff AlN substrate

In most cases, commercial electronic products suffer from durability and are sensitive to wear. But stiff AlN substrates improve the robustness of commercial items and make them tolerant of external hazards.

Rigid aluminum nitrides are worthwhile for aerospace equipment and communication equipment with complicated functions.

Multi-layer AlN substrate

AlN substrates enable PCB designers to provide 12-32 layers. These substrates are very suitable for multi-layered designs. Multi-layer AlN substrates greatly improve the functionality of PCBs with a high TG.

0 notes

Text

Features of High Precision Fiber Laser Cutting Machine

High precision fiber laser cutting machine adopts quick cutting 3.0 system independently developed by QUICK LASER, which has the functions of full closed-loop control, gantry double drive flexible algorithm, CCD visual positioning and automatic height adjustment. It adopts quasi continuous fiber laser. The equipment has the advantages of high speed, high precision and no thermal deformation in cutting.

Power: 150W/800W/1000W/1200W/1500W/ 2000W

Features:

Laser high-precision cutting technology can be used for laser cutting, drilling, engraving, scribing, heat penetration, welding, etc. in equipment manufacturing, automobile and aviation precision manufacturing and various micro-processing industries, such as mobile phone PCB circuit board precision cutting, Processing such as perforation; processing of ink jet ports of ink jet printers with a size of more than 20 microns.

Nowadays, precision micromachining technology is mainly used in consumer electronics, MEMS, LED chip manufacturing, touch screen, LCD, medical and other high-end fields, as well as aerospace and other high-end fields, and can process a variety of alloys, semiconductors, ceramics, various transparent materials, thin films and polymers.

1. The machine body is made of marble, and the CAE finite element analysis and calculation are used to ensure that the strength of each part of the machine tool meets the change of load and the dynamic and static accuracy of the machine tool;

2. Optical fiber transmission, flexible processing, suitable for precision cutting of stainless steel thin metal plates, micro-hole processing, metal parts cutting; alumina, aluminum nitride, zirconia and other materials;

3. High-precision machine tools, imported fiber lasers, cutting heads, etc. are guaranteed, which can cut out higher positional accuracy and dimensional accuracy, better roundness, and better corner effect;

4. Stable walking and energy control enable the machine to cut the edge of the product with a smaller heat-affected zone, smoother edge-cutting effect, and good effect consistency.

Suzhou Quick Laser Technology Co., Ltd. is a professional laser equipment manufacturer. We have advanced technology and excellent product quality, QUICK LASER is committed to the research and development, production, sales and service of intelligent laser systems and industrial solutions. If you need a laser cutting machine, please contact us. We look forward to working with you.

0 notes

Text

LED Lighting Modules: Taking the Heat Out of the Situation

The appeal of using LEDs in lighting applications is growing rapidly. The numerous and significant benefits of using modules that incorporate a matrix of LEDs are being recognized by design engineers in several key industry sectors, including aerospace, architectural lighting, and the "golden egg" automotive market.

Attributes such as design flexibility, low power consumption, even and reliable light, and long lifetime distinguish LED modules from designs based on traditional filament lamps and fluorescent tubes. LEDs can also have knock-on benefits, such as greatly reducing the size and complexity of the module and simplifying the lens design.

A good example of some other benefits of LED lighting is demonstrated by an application in the cabin of a passenger aircraft. A retrofit LED unit that replaced a fluorescent-tube lighting module enabled finely controlled dimming and also provided mood lighting through the use of differently coloured LEDs.

Thermal management

Perhaps the most challenging issue when realizing a module design that uses LEDs is to manage the temperature of individual device junctions during normal operation. If the considerable amount of heat produced by all the devices in a module is not managed correctly then the junction temperatures may reach a level where the LEDs' expected life is shortened and reliability is compromised (see Links).

LED modules typically comprise a matrix of many surface mount devices. These LEDs are soldered to an etched copper layer that provides the interconnects between the individual LEDs as well as other passive and active components that are required to complete the circuit. The small size of the LEDs and the close proximity with which they can be mounted means that designers have a huge amount of design freedom and can achieve complex lighting patterns with high levels of brightness.

The etched copper circuit is separated from a base plate - usually made of aluminum - by a thermally efficient, electrically isolating dielectric material. The characteristics and capabilities of the dielectric layer are key to the design flexibility and performance of the overall module.

Dielectric materials are made by blending thermally efficient materials such as alumina and boron nitride with other ingredients, to provide a flexible yet resilient coating on the base plate. An important characteristic of the dielectric layer is the amount of electrical isolation it provides between the copper on the topside and the metallic base plate on the underside. This is known as its dielectric strength. A typical dielectric material may possess a dielectric strength of around 800 V/mil and be coated onto the base plate to a thickness of 8-12 mils (1 mil = 1 inch-3 = 25.4 µm).

Flexible PCB

2 notes

·

View notes

Text

What is Ceramic PCB?

Ceramic PCB refers to a special process board in which copper foil is directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single-sided or double-sided) at high temperature. The made ultra-thin composite substrate has excellent electrical insulation properties, high thermal conductivity, excellent solderability and high adhesion strength, and can be etched into various patterns like a PCB board, and has a large current carrying capacity. ability. Therefore, ceramic PCB has become the basic material of high-power power electronic circuit structure technology and interconnection technology.

Manufacturing method of ceramic PCB board

1. Thick film ceramic PCB

These circuit boards consist of gold and dielectric paste printed on a ceramic substrate and baked at a temperature slightly below 1000°C. Thick-film ceramic PCBs can use gold or copper, and copper is most used because of its lower cost. To prevent oxidation, the board is baked in nitrogen.

2. Low Temperature Co-fired Ceramic (LTCC) PCB

LTCC uses co-firing while burning non-glass, glass composite materials or glass crystals and other materials at the same time. The traces are usually gold to achieve high thermal conductivity, and the circuit board is baked at 900°C.

3. High temperature co-fired ceramic (HTCC) PCB

HTCC uses alumina and binders as well as plasticizers, solvents and lubricants. Circuit traces can be metals, such as tungsten and molybdenum, and the baking temperature can be as high as 1600°C to 1700°C. This method is most suitable for small circuit boards and carrier circuits.

Advantages of ceramic pcb board

1. High resistance.

2. Outstanding high frequency characteristics.

3. High thermal conductivity: It is related to the material itself, ceramics are compared to metals. Both resins have advantages.

4. Good chemical stability, anti-vibration, heat resistance, pressure resistance, internal circuits, MARK points, etc. are better than general circuit substrates.

5. It is more accurate in printing, patching and welding.

Disadvantages of ceramic pcb board

1. Fragile

This is one of the main shortcomings. At present, only small-area circuit boards can be produced.

2. The price is expensive

There are more and more requirements for electronic products. Ceramic circuit boards only meet the requirements of some relatively high-end products, and low-end products will not be used at all.

Application of ceramic PCB

Ceramic PCB enjoys its greatest realization in high-speed, high-power circuit applications. Compared with traditional circuit board materials, these circuit boards can reduce parasitic capacitance by up to 90%, and provide the greatest hope for future use in aerospace, medical equipment, industry, and automotive industries.

0 notes

Text

BSTCeramicPCB Co., LTD offers ceramic PCB (printed circuit boards) for your company's needs. We also offer Alumina Ceramic, Aluminum Nitride, Ceramic Core PCB, Ceramic Base PCB and much more. Quote & Order your ceramic PCBs online.

0 notes

Text

What is Ceramic PCB?

What is Ceramic PCB?

Ceramic PCB refers to a special process board in which copper foil is directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single-sided or double-sided) at high temperature. The made ultra-thin composite substrate has excellent electrical insulation properties, high thermal conductivity, excellent solderability and high adhesion strength, and can be etched into…

View On WordPress

0 notes

Text

Ceramic PCB Manufacturing--Hitechpcba

Ceramic PCB board is also called ceramic substrate or ceramic circuit board, ceramic copper coated plate, ceramic substrate refers to the copper foil directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate or other ceramic substrate surface (single or double) on the special process board. The ultrathin composite substrate has excellent electrical insulation performance, high thermal conductivity, excellent soft brazing and high adhesion strength, and can be etched into a variety of graphics like PCB board, with great current-carrying capacity. Therefore, Ceramic PCB board has become the basic material of high power electronic circuit structure technology and interconnection technology.

Ceramic PCB Manufacturing & Assembly – One-stop service The ceramic substrate (ceramic PCB) refers to a special process board in which a copper foil is directly bonded to a surface of an alumina (Al2O3 ) or aluminum nitride (AlN) ceramic substrate (single or double-sided) at a high temperature. The ultra-thin composite substrate produced has excellent electrical insulation properties, high thermal conductivity, excellent solderability, and high adhesion strength, and can etch various patterns like a PCB board, and has a large current carrying current ability.

The advantages and disadvantages of Ceramic PCB

(1) Ceramic PCB board has very good thermal conductivity and insulation performance. Ceramic PCB board is made of ceramic substrate, ceramic substrate itself has very good insulation and thermal conductivity, thermal conductivity of 25~230w, insulation resistivity is 10 minus 14 square, visible insulation performance is very good.

(2) The dielectric constant of ceramic PCB board is very low, the dielectric loss is small, has very good high frequency performance, the dielectric loss of alumina ceramic PCB board is less than 0.0003@1MHz, the dielectric loss of aluminum nitride ceramic PCB board is less than 0.0005@1MHz. Low dielectric loss, high frequency performance, is widely used in the field of high frequency communication.

(3) Ceramic PCB bonding force is strong, using bonding technology, copper foil will not fall off.

(4) Ceramic PCB has large on-board flow, 100A current continuously passes through 1mm0.3mm thick copper body, and the temperature rises about 17℃; when 100A current continuously passes through the 2mm0.3mm thick copper body, the temperature rises only about 5℃.

(5) Ceramic PCB board is with high temperature resistance, corrosion resistance, environmental protection, can work in a very complex environment, long-term high frequency, long service life.

Disadvantages: fragile, scrap rate is high, this is one of the main short comings of ceramic PCB board, which leads to the production of a small area of the circuit board, the general size is less than 120mm, special custom 200mm,230mm, the general price is more expensive, the board cost is higher. In addition, because ceramic PCB board is made of ceramic material, it does not have better toughness like FR4 board, so it can make more than one meter long and wide. Another point is that the price is expensive, the requirements of electronic products are more and more rules, ceramic circuit boards are still used in some relatively high-end products, low-end products will not be used.

With over 15 years of experience in the electronic industry we are committed to producing custom ceramic PCBs that meet up with the various electronic devices at hand.

0 notes

Text

What is the difference between ceramic, high frequency and ordinary PCB boards?

Ceramic substrate is a kind of special PCB board with good thermal conductivity, insulation performance, and high dielectric constant. It is widely used in terminal products in the field of heat dissipation. Commonly used ceramic-based materials include aluminum oxide, aluminum nitride, zirconium oxide, ZTA, silicon nitride, silicon carbide, etc. FR circuit board refers to a circuit with epoxy glass fiber cloth as the main material. So, what is the difference between ceramic circuit board and ordinary PCB board

The difference between ceramic substrate and PCB board

Different materials. Ceramic substrate is an inorganic material, and the core is aluminum oxide or aluminum nitride; ordinary PCB board uses FR4 glass fiber board, which is an organic material. Ordinary PCB board can be laminated in multiple layers. LTCC is the mainstream of ceramic multilayer circuit board. The ceramic multilayer process currently being developed by Hitech Circuits Co., Ltd. is different from the traditional method. It uses magnetron sputtering technology to grow a layer of ceramic medium on the ceramic circuit board that has been metallized, and then re-metallizes this layer of medium to make the second layer of circuit.

b. The performance and application of ceramic substrates are different. The thermal conductivity of ceramic substrates far exceeds that of ordinary PCB boards. The thermal conductivity of alumina ceramics is ≧25W(m·K), and the thermal conductivity of aluminum nitride ceramics is ≧170W(m·K). They are used in industries with large heat dissipation requirements, such as high-power LED lighting, high-power modules, high-frequency communications, and track power supplies. The thermal expansion coefficient of ceramic substrates is more compatible with silicon wafers, and the product stability is higher. Ordinary PCB boards are widely used, mostly in private commercial products.

The difference between ceramic substrates and high-frequency boards

Different materials. Ceramic substrates are made of aluminum oxide or aluminum nitride, while high-frequency boards are mostly made of Rogers, Yalong, polytetrafluoroethylene, etc., with low dielectric constants and fast high-frequency communication speeds.

Different performance. Ceramic substrates are widely used in cooling sheets and systems, high-power modules, automotive electronics and other fields. High-frequency PCB boards are mainly used in high-frequency communications, aviation, high-end consumer electronics, etc.

3. In the field of high-frequency communications involving heat dissipation requirements, ceramic substrates are usually required to be combined with high-frequency PCB boards, such as high-frequency ceramic PCBs.

If you want to know ceramic PCBs, please feel freely to contact Cynthia at [email protected]

0 notes

Text

PCB Thermal Conductivity of Various Materials

The PCB thermal conductivity is its ability to conduct heat. Materials that have a lower thermal conductivity allow for a lower rate of heat transfer. On the other hand, materials with a high thermal conductivity allow for a higher rate of heat transfer. For example, metals are very effective at conducting heat because they have high thermal conductivity. That is why we frequently use them in applications where we require heat dissipation. However, materials with low thermal conductivity are suited for applications requiring thermal insulation. In this article, we will take a look at PCB thermal conductivity and how it affects their performance.

PCB Thermal Conductivity of Various Materials

In this section, we will take a look at the thermal conductivity of various PCB materials.

Epoxies and Glasses (FR4, PTFE, and Polyimide)

We mostly use FR4 for the mass production of PCB. However, in this case, PCB thermal conductivity is very low in comparison to alternative materials. Therefore, most manufacturers have to use a number of thermal management techniques and methods to maintain the temperature of PCBs and their active components with a safe operational range.

Ceramics (Alumina, Aluminum Nitride, and Beryllium Oxide)

Ceramics offer much higher thermal conductivity than epoxies and glasses. However, this higher thermal conductivity comes with higher manufacturing costs. This is because ceramics are mechanically tough and hence it is difficult to drill them mechanically or by using lasers. So, multilayer fabrication of ceramic PCB becomes difficult.

Metals (Copper and Aluminum)

We mostly use aluminum for making metal core PCB. Metals have higher thermal conductivity than epoxies & glasses and they have a reasonable manufacturing cost. Therefore, they are quite effective for applications that require exposure to thermal cycling and need heat dissipation. The metal core allows for efficient thermal relief and heat dissipation on its own and therefore we don’t need additional processes and mechanisms. So, manufacturing costs tend to decrease.

PCBs With High Thermal Conductivity vs Conventional PCB

Materials with high thermal conductivity such as ceramics and metals allow for better heat dissipation as compared to materials with low thermal conductivity such as FR4.

Materials with low thermal conductivity require vias and through plate holes for heat removal.

Therefore, the manufacturing steps tend to increase in the case of materials with low PCB thermal conductivity.

So, the manufacturing process becomes complex and the costs tend to increase.

On the other hand, materials with high PCB thermal conductivity don’t need additional processes and mechanisms for thermal relief or heat dissipations.

Hence, the manufacturing steps and costs tend to decrease for materials with low PCB thermal conductivity.

Materials with high PCB thermal conductivity don’t allow localization of thermal stresses. This is because heat moves through them easily and stresses are unable to segregate in one place.

Therefore, the structure is thermally stable and these boards tend to have a longer lifespan.

In comparison, materials with low PCB thermal conductivity hinder the flow of heat and hence they allow for stress localization.

Therefore, they have low thermal stability and hence have a shorter lifespan.

Since material with high thermal conductivity doesn’t need vias therefore there is more space for mounting components.

Hence, PCB with high thermal conductivity is more dense and smaller in size.

This allows us to make smaller and more efficient PCBs.

It is an established fact that materials with high thermal conductivity also have a high electrical conductivity. Therefore, it is more beneficial to use materials with high PCB thermal conductivity.

Materials which have high thermal conductivity also have a stable CTE. Which means that they show desirable thermal expansion properties. This allows us to make PCBs which are thermally as well as dimensionally stable.

Since materials with high thermal conductivity are thermally stable therefore we can use them in extreme application because we are certain that their thermal degradation won’t occur.

Heat Dissipation Through PCB Thermal Conductivity

We are living in an era where it is possible to perform microelectronic packaging and the integration technology is readily available. Therefore, the overall power density of electronic devices is on a steady rise. However, the physical dimensions of electronic devices and electronic components are steadily decreasing. So, the generated heat is instantly segregated which leads to dissociation or disintegration of the whole electronic system.

However, the heat flux density of electronic devices is also increasing, and the high-temperature environment affects the performance of electronic devices as well. Hence, we need a more efficient plan for establishing thermal control, and we need to tackle the problem of heat dissipation head-on in order to open new avenues of PCB manufacturing.

The Solution

Engineers have come up with some strategies for solving these problems with thermal management. These include,

Increasing the thermal conductivity of the PCB for improving the heat dissipation

Using materials that are able to withstand higher operating temperatures. We can do this by improving the Thermal Decomposition Temperature.

Improve the thermal adaption of the material to its environment and thermal cycling. We can do this by improving the CTE.

The most efficient strategy from these is to use material with high thermal conductivity for combating the heat dissipation. This is because these materials allow for a smooth heat transfer and heat never accumulates in one place. Hence, heat leaves the system as soon as it is generated and doesn’t damage the board. The problem only arises when there is a hindrance to heat flow and it starts accumulating. In this case, it will lead to thermal stresses and damage the PCB. That is why it is not recommended to use materials with low PCB thermal conductivity in high-end applications.

If you are facing problems with heat dissipation in your boards then you are in the right place. MOKO Technology is well experienced in the design and development of PCBs with high thermal conductivity. We can make customized high thermal conductivity PCBs for you which will meet your needs and allow for efficient heat dissipation. Feel free to reach out to us if you have any queries.

0 notes