#Amines Market Development

Explore tagged Tumblr posts

Text

#Amines Market Intelligence Report#Amines Market Market Research Future#Amines Market Types#Amines Market Growth Rate#Amines Market Satistics#Amines Market Development#Amines Market Application#Amines Market Forecast

0 notes

Text

A Sudanese Armed Forces (SAF) attack on a busy market in western Darfur on Monday resulted in a "horrific massacre", a war monitor said on Wednesday.

The military's shelling of the Tur'rah market, located 80km north of el-Fasher, left hundreds dead, according to Emergency Lawyers, a group of lawyers who monitor the war in Sudan. While an official death toll has yet to be confirmed, Sudanese aid groups reported that at least 54 people were killed in the attack.

Darfur Victims Support (DVS), a local group that supports victims of the conflict, cited eyewitnesses who reported that some 126 civilians were killed in the attack, with many bodies "burnt beyond recognition".

The group noted that the market serves as a commercial hub for the surrounding areas and that it would have been thronging with people at the time of the attack, at approximately 2pm.

DVS condemned the strike as "deliberate and systematic," reporting that approximately 10 barrel bombs were dropped on the market. It further cited one witness who said that white phosphorous was used in the attack. Images shared by the group appeared to show charred bodies scattered among the smouldering ruins of the market stalls.

Sudanese Armed Forces (SAF) chief Abdel Fattah al-Burhan arrived by plane in Sudan’s capital Khartoum after his troops recaptured the airport on Wednesday from the Rapid Support Forces (RSF).

Reuters reported on Wednesday that RSF forces had mostly withdrawn from the capital, with the army deploying throughout several neighbourhoods, in what is one of the most significant developments of the two-year war between the army and the RSF.

Last Friday, Sudan’s army took full control of the country’s presidential palace in Khartoum, two years after it was seized by the paramilitary RSF. Today, Al Jazeera aired footage showing Burhan inside the presidential palace where he declared, “Khartoum is free”.

After closing in on the building on the Blue Nile in recent days, the army-aligned government announced its capture on Friday. “Today the flag is raised, the palace is back and the journey continues until victory is complete,” Khaled al-Aiser, Sudan’s information minister, wrote on X when the palace was captured.

The streets of Khartoum erupted in celebration on Tuesday after the Sudanese Armed Forces (SAF) declared the city free from the Rapid Support Forces (RSF) militia.

Following intense street battles, the SAF officially announced its control over Khartoum, sparking jubilant scenes among those who remained in the city. Mohamed Obaid, 40, from Nile East - a former RSF stronghold - described the terror of survival under occupation. “I stayed indoors for days without food, too afraid to step outside,” he recounted to Middle East Eye. “I don’t even want to remember those days.

You could die at any moment for no reason. “If you managed to reach a Starlink shop to exchange money, you’d find RSF fighters running the place, seizing 30 percent of your cash for no reason.

They controlled all supplies and sold them at outrageous prices.” Emad Hassan, who fled to Cairo when the conflict erupted, told MEE: “I never thought I’d use this key again,” waving the key to his long-abandoned home in Khartoum. Hassan compared his experience to that of Palestinian refugees, forced from their homes but never giving up the hope of return.

���They still carry the keys to their houses wherever they go. We Sudanese love our land. We will return. The RSF expelled us in the most humiliating way, but we will come back.”

Despite the jubilant scenes, for many displaced Sudanese, the situation remains too volatile to risk returning home.

Once a symbol of beauty at the confluence of the White and Blue Nile, the capital now bears the scars of war - widespread destruction, streets littered with debris, and homes filled with tragic stories.

Dead bodies of civilians and soldiers alike serve as grim reminders of the suffering endured.

✍️ MEE / Mohammed Amin

17 notes

·

View notes

Text

Snacking heavyweight Pladis has announced the departure of its CEO Salman Amin with immediate effect.

In a brief statement, the McVitie’s biscuits manufacturer, owned by Turkish conglomerate Yildiz Holding, said Amin has left for “personal reasons”.

“We can confirm Sridhar Ramamurthy, chief financial officer, and Tim Brett, managing director Europe and developing markets, have assumed temporary oversight of Pladis," the statement added.

2 notes

·

View notes

Text

Let's All Eat Right Day

Let’s All Eat Right Day is celebrated on February 25 each year, as it marks the birthday of Adelle Davis, a famous nutritionist, author, and game-changer in the nutrition movement throughout the 1900s. So we’re here to put a face to some of the integral contributions in nutrition as a field. You have probably heard it said — “Eat breakfast like a king, lunch like a prince, and dinner like a pauper” — well, this wise adage can be credited to Davis herself.

History of Let's All Eat Right Day

As important to human beings as air and water, and in some ways one might argue that food tops the list because it can affect us in ways beyond just the physical. Food can change your mood, speak to your very soul, and make a difference in your self-perception. Thus on some level, we all want to eat right and are open to making changes that may bring us to good health. So it is only fitting that there be a day to celebrate eating right, which will hopefully put us all on a lifelong path of developing a healthier relationship with our food.

Nutrition itself has been around as long as humans have, however, it was not until 400 B.C. that the Greek physician Hippocrates observed the impact food has on physical health, especially when it came to the prevention and cure of illness. The ancient world foods used for medicinal properties (such as using garlic to cure stomach ailments) and the birth of nutritional science itself is fairly recent. It began with the discovery of vitamins, which were synthesized and their effects on disease studied. The name ‘vitamin’ is derived from the words ‘vital’ and ‘amine,’ coined by Dr. Casimir Funk in 1912. The onset of World War I caused widespread fear of food shortages and forced nutritional scientists to focus on food as a preventative for diseases. Hence the first Recommended Dietary Allowances (R.D.A.s) were issued around this time. Since then, nutritional science has been a burgeoning field of study, and none of us are untouched by it.

While it is not known when exactly Let’s All Eat Right Day was initially celebrated, we know it falls on the birthday of Adelle Davis as a way of honoring her work and the legacy she left. With bestselling books like “Let’s Eat Right to Keep Fit” (1954) and “Let’s Cook it Right” (1947), Davis’ research and publications had a huge impact on the everyday American consumer; even with her fair share of controversy. Her focus was on championing whole foods over processed foods with additives and advocating for the importance of taking nutritional supplements to help prevent disease and potentially other social ills. The early 1900s was a time when vitamins were introduced, and the concept of their value as dietary supplements was on the rise. It created a new niche in the market for health products backed by science. In October 1994 Congress approved the Dietary and Supplement Health and Education Act to regulate standards of nutritional supplements.

Let's All Eat Right Day timeline

400 B.C. Hippocrates Connects Food with Health

The Greek ‘Father of Medicine’ establishes a connection between food and its health impact.

1747 Discovery of Citrus Fruits’ Impact on Scurvy

Scottish physician Dr. James Lind finds that sailors who eat citrus fruits don’t contract scurvy.

1770 Metabolism is Discovered

‘Father of Nutrition and Chemistry,’ Antoine Lavoisier discovers the function of metabolism.

1912 The First Department of Nutrition

The University of California, Berkeley sets up the first Department of Nutrition in the U.S.

1947 Adelle Davis Becomes a Bestseller

Davis’ “Let’s…” series of books on nutrition sell over 10 million copies.

Let's All Eat Right Day FAQs

What is meant by eating right?

The official dictionary definition of the phrase ‘to eat right’ means to ‘eat healthy foods.’ However, this can vary with cultural context, dietary type, and various sociological factors like access to food. Essentially the aim of eating right is to ensure that the body receives all the nutrition it requires, in the right proportions, in order to promote good health and longevity of life.

Who is the best nutritionist in the world?

Harvard University expert, Dr. Walter Willett, is often referred to as the “most-cited nutritionist in the world,” owing to the fact that he spent around five decades researching different aspects of diet and their impact on health— more specifically, researching the cause and prevention of diseases.

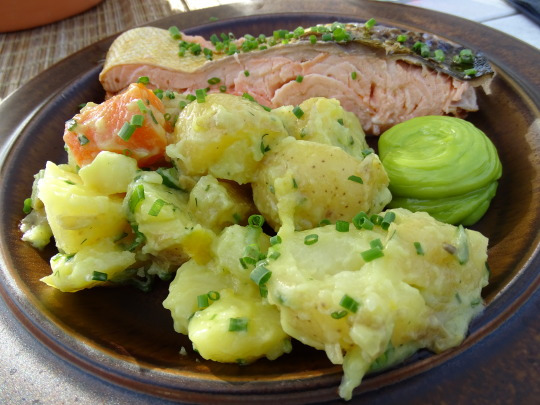

What is the most perfect food?

While there is no such thing as ‘the perfect food’, there are some foods that are termed ‘nutrient-dense foods.’ They include salmon, kale, seaweed, garlic, shellfish, potatoes, liver, sardines, blueberries, egg yolk, and dark chocolate/cocoa.

Let's All Eat Right Day Activities

Check out some fresh produce

Contribute to research

Make a dietary change

Whether you have or have not always read the labels on your groceries on this day we urge you to start. Also, we encourage you to shop for an entire meal from your nearest Farmer’s Market or fresh produce center. The results will be worth the effort but don’t blame us if your chef skills aren’t up to scratch!

Let’s face it, the internet is our go-to place for researching anything and everything. It makes sense that the information on nutrition that we consume comes from legitimate research and sources. Donating to nonprofits like the Adelle Davis Foundation can help provide university grants that support various educational programs and endeavors related to nutrition.

While this may be easier said than done, the change can be a small one to begin with. And if you don’t like the word ‘diet’ because it does have ‘die’ in it, there are plenty of more pleasant options, like clean eating (for instance).

5 Facts About Healthy Eating Which May Surprise You

Low-fat products mean more sugar

Almonds are not nuts

Lemons vs. strawberries

White chocolate is a misnomer

Cabbage is mostly water

Don’t be fooled; many low-fat food options contain added sugar.

Almonds are classified as seeds and belong to the peach family.

#Fried Green Tomatos with Corn Relish#Eggplant Albondigas with tomato sauce and roasted garlic#Grilled Peaches with Balsami glazed smoked Pork Belly#BBQ Korean Bowl#Lemongrass Chicken Bowl#Brix Restaurant & Gardens#flora#Let's All Eat Right Day#Napa Valley#Yountville#California#USA#travel#summer 2024#vacation#Canada#25 February#LetsAllEatRightDay

2 notes

·

View notes

Text

Sustainability Trends Reshaping the Epoxy Curing Agent Landscape

Introduction: Enabling the Future of High-Performance Materials

The global epoxy curing agent market is undergoing a dynamic transformation fueled by increasing demand across a variety of end-use industries such as construction, automotive, aerospace, marine, and renewable energy. These curing agents play a critical role in enhancing the performance of epoxy resins used in coatings, adhesives, sealants, and composites—offering benefits such as corrosion resistance, high durability, and mechanical strength.

As sustainability becomes a central concern, manufacturers are actively investing in low-VOC, solvent-free, and bio-based epoxy formulations. This shift is not only driven by tightening regulatory standards but also by customer demand for safer and environmentally responsible materials.

Get Ahead with Our Report: Request Your Sample Now! https://www.futuremarketinsights.com/reports/sample/rep-gb-611

Key Market Drivers

Growth in Low-VOC and Waterborne Coatings: Increased emphasis on eco-friendly and compliant solutions in construction and infrastructure sectors.

Expansion in Aerospace and Automotive Applications: Epoxy curing agents are essential for lightweight structural components, high-strength adhesives, and advanced coatings.

Rising Use of Amine-Based Curing Agents: Known for fast curing and superior chemical resistance, these formulations dominate industrial applications.

Innovation in Hybrid and Bio-Based Technologies: Technological advancements are enabling more flexible and sustainable epoxy solutions.

Notable Market Trends

Smart and Self-Healing Epoxies: Increasing research into self-healing technologies is enabling coatings that can automatically repair surface damage, improving longevity and reducing maintenance costs.

Growth in UV-Curable Systems: Rapid-curing, UV-activated epoxy systems are gaining ground, particularly in electronics and automotive applications.

3D Printing Integration: Epoxy curing agents are now playing a role in additive manufacturing, offering structural strength and precision in printed parts.

Nanotechnology Enhancement: Nanoparticles are being integrated to improve thermal conductivity, strength, and chemical resistance of epoxy composites.

Rise in Renewable Energy Applications: Epoxy systems are critical in wind turbine blade manufacturing and other renewable infrastructure due to their strength and weather resistance.

Exhaustive Market Report: A Complete Study! https://www.futuremarketinsights.com/reports/epoxy-curing-agents-market

Market Insights and Regional Outlook

The global market is witnessing a CAGR of over 3.4%, driven by strong industrial adoption of high-performance epoxy systems.

Asia-Pacific dominates the global landscape, led by countries like China and India, where epoxy usage in construction and electronics is surging.

North America and Western Europe continue to lead innovation, particularly in sustainable and regulatory-compliant formulations.

Competitive Landscape

Key industry players are focusing on R&D, partnerships, and geographic expansion to maintain competitiveness. Some of the leading companies include:

Evonik Industries AG – Pioneering bio-based epoxy curing technologies.

Huntsman Corporation – Dominant in industrial, aerospace, and marine-grade epoxy systems.

Cardolite Corporation – Specializes in renewable, cashew-based epoxy curing agents.

Gabriel Performance Products – Expanding portfolio with amine-based high-performance formulations.

Olin Corporation – Investing in solvent-free and hybrid epoxy technologies.

Recent Industry Developments

Companies are expanding waterborne epoxy technologies for safer, high-durability coatings.

Strategic mergers and acquisitions are reshaping the market, with specialty chemical firms being integrated to broaden capabilities.

Bio-based and recycled materials are seeing increased R&D interest, in line with global sustainability goals.

Leading firms are forming collaborations with automotive and infrastructure companies to deliver application-specific innovations.

0 notes

Text

Antifrogen N Clariant Heat Transfer Fluids

In today’s demanding industrial and commercial environments, reliable heat transfer is critical. That’s where Clariant Antifrogen® N heat transfer fluids come into play. Developed by Clariant, a globally recognized chemical manufacturer, the Antifrogen Clariant range delivers outstanding thermal stability, corrosion protection, and freeze resistance—making it a top choice for HVAC, refrigeration, and industrial process systems.

Whether you're operating in cold regions or managing high-temperature systems, Antifrogen Clariant N offers consistent, long-term performance. It's trusted not only for its technical excellence but also for its environmental safety and versatility.

What Is Clariant Antifrogen® N?

Clariant Antifrogen® N is a premium-grade, monoethylene glycol-based heat transfer fluid specially designed for use in closed-loop heating and cooling systems. This advanced formulation includes an effective mix of organic and inorganic inhibitors, ensuring exceptional protection against corrosion, scaling, and freezing.

Its blue-green color allows for easy identification, and it's free from harmful additives such as nitrites, phosphates, and amines—making it safer for both systems and the environment.

Advantages of Antifrogen Clariant N

High Corrosion Resistance

Antifrogen N Clariant offers excellent protection for all standard metals used in cooling systems, including aluminum, steel, copper, and cast iron. This minimizes the risk of damage and ensures extended equipment life.

Freeze Protection

This fluid effectively lowers the freezing point of water, safeguarding pipes and systems even in sub-zero temperatures. Depending on dilution, it can protect down to -50°C.

Thermal Stability

With a stable composition and low degradation rate, Clariant Antifrogen maintains its thermal properties over long periods, even in high-heat applications.

Environmentally Responsible

Antifrogen Clariant is formulated with non-toxic, biodegradable ingredients. It's one of the most environmentally responsible heat transfer fluids on the global market.

Versatility Across Industries

From HVAC to geothermal systems, Clariant Antifrogen® N is suited for various industries. Its compatibility with multiple system designs and materials makes it the go-to choice worldwide.

Best Antifrogen N in India: Why It’s in High Demand

The Indian market is experiencing growing demand for high-efficiency and sustainable thermal management solutions. The best Antifrogen N in India is now widely used in applications such as:

Data centers

Cold storage units

Pharmaceutical manufacturing

Food processing industries

Solar thermal and geothermal systems

Indian industries prefer Clariant Antifrogen N for its international quality, consistent performance, and availability through a network of global suppliers of Antifrogen N heat transfer fluids. For businesses looking to upgrade their systems with reliable and eco-friendly fluids, Antifrogen Clariant is an ideal option.

Available Packaging Options

To suit diverse industrial needs, Clariant Antifrogen N is available in multiple packaging formats:

25 kg jerry cans

210-liter drums

1000-liter IBC tanks

Bulk delivery for large industrial systems

This flexibility ensures seamless integration across projects of any scale, from small commercial HVAC units to extensive district cooling systems.

How to Use Antifrogen Clariant N

To maximize its effectiveness, Antifrogen Clariant N must be diluted with demineralized water according to the required frost protection level. Recommended mixing ratios include:

30% solution for protection down to -15°C

40% solution for -25°C

50% solution for -35°C

It is crucial not to mix Antifrogen N with other brands or glycol types, as this may impair the corrosion inhibition properties.

Global Supply Network

Clariant has established a robust global supply network for Antifrogen N, with distribution centers and technical support available in Europe, Asia, North America, and the Middle East. Indian customers can easily source the best Clariant Antifrogen N in India through local distributors aligned with Clariant’s quality assurance programs.

This ensures genuine product supply, technical assistance, and timely delivery—all essential for time-sensitive industrial projects.

Why Choose Clariant Antifrogen N?

Here are key reasons why engineers, system integrators, and facility managers choose Antifrogen Clariant:

Trusted global brand with a reputation for reliability

Environmentally friendly and compliant with international standards

Long service life, reducing fluid change intervals

Compatible with various system materials

Locally available in India, making it easy to procure and maintain

From food-grade refrigeration systems to complex HVAC applications, Antifrogen Clariant N continues to be a top-tier solution for industries worldwide.

Email::[email protected]

For More information click on the link:-www.antifrogen.in

0 notes

Text

M-Toluidine Market Growth Analysis 2025

The global M-Toluidine market was valued at US$ 44.28 million in 2023 and is anticipated to reach US$ 52.43 million by 2030, witnessing a CAGR of 3.57% during the forecast period 2024-2030.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/414/m-toluidine-market

Europe market for M-Toluidine is estimated to increase from $ 10.01 million in 2023 to reach $ 11.96 million by 2030, at a CAGR of 2.14% during the forecast period of 2024 through 2030.

China market for M-Toluidine is estimated to increase from $ 23.23 million in 2023 to reach $ 25.82 million by 2030, at a CAGR of 4.87 % during the forecast period of 2024 through 2030.

M-Toluidine, also known as meta-toluidine, is an aromatic amine compound with the chemical formula C7H9N. It is a colorless liquid with a pungent odor and is used in a variety of industrial and chemical applications, including the production of dyes, pesticides, pharmaceuticals, and other organic compounds.

The major global manufacturers of M-Toluidine include Lanxess, Deepak Nitrite, Aarti Industries, Jiangsu Huaihe Chemicals, Shandong Tsaker Dongao Chemical, Hubei Kecy Chemical, Jiangsu John Kei Chemical, etc. in 2023, the world's top three vendors accounted for approximately 45.18% of the revenue.

This report aims to provide a comprehensive presentation of the global market for M-Toluidine, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding M-Toluidine.

The M-Toluidine market size, estimations, and forecasts are provided in terms of output/shipments (K MT) and revenue ($ millions), considering 2023 as the base year, with history and forecast data for the period from 2019 to 2030. This report segments the global M-Toluidine market comprehensively. Regional market sizes, concerning products by Type, by Application, and by players, are also provided.

For a more in-depth understanding of the market, the report provides profiles of the competitive landscape, key competitors, and their respective market ranks. The report also discusses technological trends and new product developments.

The report will help the M-Toluidine manufacturers, new entrants, and industry chain related companies in this market with information on the revenues, production, and average price for the overall market and the sub-segments across the different segments, by company, by Type, by Application, and by regions.

Market Segmentation By Company

Lanxess

Deepak Nitrite

Aarti Industries

Jiangsu Huaihe Chemicals

Shandong Tsaker Dongao Chemical

Hubei Kecy Chemical

Jiangsu John Kei Chemical

Segment by Type

Pharmaceutical Grade

Industrial Grade

Others

Segment by Application

Dye Intermediate

Pesticide Intermediate

Pharmaceutical Intermediate

Others

Production by Region

Europe

China

India

Consumption by Region

Europe

Germany

France

U.K.

Italy

Russia

Rest of Europe

Asia

China

India

Drivers

Rising Demand in Packaging ApplicationsEBA copolymers are widely used in the packaging industry due to their excellent flexibility, impact resistance, and sealing properties. With the growing demand for flexible and durable packaging solutions, especially in the food and beverage sector, the market for EBA is expanding.

Growing Use in Construction and Building MaterialsEBA’s strong adhesive properties and chemical resistance make it an essential material in construction, particularly for adhesives, sealants, and waterproofing membranes. The increasing focus on infrastructure development globally is driving its adoption in this sector.

Surge in Renewable Energy ApplicationsEBA is used as an encapsulant material in photovoltaic (PV) solar modules due to its durability and resistance to environmental factors. The global shift towards renewable energy sources has boosted the demand for solar energy, creating a significant market for EBA.

Versatility in Polymer ModificationEBA copolymers are increasingly used as modifiers to enhance the flexibility, toughness, and impact strength of other polymers, such as polyolefins. This versatility has driven its adoption across various industries, including automotive and electronics.

Environmental Advantages over Traditional PolymersEBA copolymers exhibit better recyclability and lower emissions during production compared to other polymers. This aligns with global initiatives to adopt eco-friendly materials, further enhancing market growth.

Increased Demand for High-Performance AdhesivesEBA copolymers are gaining traction in the adhesives industry due to their strong adhesion to a wide range of substrates. Their application in industries such as automotive, electronics, and consumer goods is contributing to market growth.

Restraints

Fluctuating Raw Material PricesThe production of EBA relies on ethylene and butyl acrylate, both of which are derived from crude oil and natural gas. Price volatility in these raw materials can impact production costs and market stability.

Competition from Alternative MaterialsEBA faces competition from other copolymers and resins, such as ethylene-vinyl acetate (EVA) and low-density polyethylene (LDPE), which may offer similar properties at a lower cost. This competition could limit its market growth in price-sensitive applications.

Regulatory ChallengesThe production and use of acrylates are subject to stringent environmental regulations due to potential health and safety concerns. Compliance with these regulations can increase production costs and complicate market entry.

Limited Awareness in Emerging MarketsIn some developing regions, the benefits and applications of EBA copolymers are not well-known, limiting their adoption in industries that could otherwise benefit from their properties.

Opportunities

Expansion in Emerging EconomiesRapid industrialization and urbanization in regions like Asia-Pacific, Latin America, and Africa present untapped opportunities for EBA applications in packaging, construction, and energy sectors.

Innovation in Renewable Energy ApplicationsWith increasing investment in renewable energy, there is significant potential for EBA as a critical material in solar panel encapsulation. Continuous advancements in solar technology could further boost its demand.

Development of Bio-Based EBAThe development of bio-based EBA copolymers can address environmental concerns associated with petrochemical-based production. Bio-based variants can open new avenues for growth, particularly among eco-conscious consumers and industries.

Growing Automotive IndustryThe use of EBA as a modifier for polymers in automotive applications, such as bumpers, interior components, and protective coatings, is expanding. With the growth of electric vehicles (EVs), the demand for lightweight and durable materials is expected to rise.

Increased Focus on Sustainable PackagingAs industries prioritize sustainable packaging solutions, EBA’s recyclable properties make it an attractive material. Innovations in flexible packaging designs and eco-friendly laminates provide opportunities for market expansion.

Advancements in Polymer Blending TechnologiesNew blending technologies that enhance the performance characteristics of EBA copolymers are creating opportunities for their application in high-performance products across multiple industries.

Challenges

Technological Barriers to AdoptionSome industries may face challenges in adapting their production processes to utilize EBA copolymers effectively, especially in regions lacking advanced manufacturing infrastructure.

Environmental Concerns Related to AcrylatesDespite being more sustainable than some alternatives, the environmental impact of butyl acrylate production and its potential emissions remain concerns for stakeholders advocating for stricter regulations.

Economic Instability in Key MarketsEconomic fluctuations in regions heavily dependent on industries like construction or automotive could impact the demand for EBA copolymers, leading to market uncertainties.

High Initial Costs for AdoptionThe transition from traditional materials to EBA copolymers may involve higher upfront costs for manufacturers, including equipment upgrades and process modifications, deterring some potential adopters.

Competition from Emerging AlternativesWith the rise of new materials and polymers offering similar or superior properties, maintaining a competitive edge will require continuous innovation and marketing efforts.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/414/m-toluidine-market

https://imimmigrant.ca//read-blog/13764

https://imimmigrant.ca//read-blog/13765

https://imimmigrant.ca//read-blog/13767

https://imimmigrant.ca//read-blog/13768

0 notes

Text

Ultraviolet Stabilizers Market Future Scope Driven by Rising UV-Resistant Material Applications

The market for UV stabilizers is expected to be worth US$1.4 billion in 2023. The demand for ultraviolet stabilizers is predicted to grow at a compound annual growth rate (CAGR) of 5.3% over the following ten years, reaching an industry value of US$ 2.4 billion by the end of 2033.

Product/Technology Overview

Ultraviolet stabilizers are additives that help protect materials—especially plastics, coatings, and fibers—from the harmful effects of UV radiation. These stabilizers are commonly used in the automotive, packaging, agriculture, and construction industries to prevent photo-degradation. Three primary types of UV stabilizers dominate the market: UV absorbers, hindered amine light stabilizers (HALS), and quenchers. While UV absorbers physically absorb harmful rays, HALS act by neutralizing the free radicals generated from UV exposure. These additives play a vital role in ensuring that materials maintain their mechanical integrity, color, and aesthetic appeal over time.

As industries demand higher product performance and lifecycle sustainability, UV stabilizers have become integral to manufacturing processes involving polymers, textiles, paints, and coatings. The growing need to combat environmental wear and tear is fueling their global adoption.

Historical Growth & Market Trends

Over the past decade, the UV stabilizers market has seen consistent growth, driven largely by the increasing production of plastic-based materials used in outdoor environments. In recent years, demand has surged due to growing regulations around plastic waste and increasing expectations around material resilience. Between 2019 and 2023, the market showed stable expansion, backed by rising consumer preferences for high-performance materials, especially in construction, packaging, and automotive components. This upward trend is projected to continue as more industries adopt UV-resistant solutions in response to rising temperatures and longer sunlight exposure periods, largely driven by climate change.

Key Market Segments

The UV stabilizers market is segmented based on product type, application, and end-use industries. Among the different types, HALS dominate the market due to their long-term effectiveness in preserving material integrity. UV absorbers also hold a significant market share, especially in coatings and packaging applications.

By application, plastics take the lead, accounting for the largest portion of the market, as UV stabilizers are widely used to extend the life of plastic products exposed to sunlight. Packaging materials, especially those used for food and beverages, are a significant contributor due to rising concerns over product safety and shelf life. Construction and automotive are also fast-growing segments, as both industries require weather-resistant materials to maintain structural and aesthetic standards.

Regionally, North America and Europe have been mature markets with strict regulatory guidelines and high consumer awareness, while Asia Pacific is emerging as the fastest-growing region due to rapid industrialization, infrastructure development, and expanding manufacturing activities.

Growth Drivers

Several key factors are propelling the growth of the ultraviolet stabilizers market. One of the primary drivers is the increasing use of plastics across various sectors—particularly in packaging, construction, and automotive. Since most polymers degrade under UV exposure, the need for stabilizers to extend product lifespan has become critical. With global efforts pushing toward reducing waste and increasing recyclability, UV stabilizers help in improving product longevity, which aligns well with sustainability goals.

The construction industry’s rapid growth, especially in developing countries, is creating new demand for UV-resistant roofing, siding, and outdoor furnishings. Additionally, the agricultural sector’s use of plastic films for greenhouses and irrigation systems further supports the demand for UV stabilizers. Another significant growth driver is the increase in automotive production, where UV protection is essential for both interior and exterior plastic components.

Furthermore, regulatory guidelines aimed at reducing the environmental impact of materials encourage manufacturers to adopt UV stabilizers to ensure compliance with product durability and safety standards.

Challenges & Market Limitations

Despite strong growth, the UV stabilizers market is not without its challenges. One of the major limitations is the high cost associated with advanced stabilizer technologies, which can be a barrier for small and mid-sized manufacturers. The complexity of formulating UV stabilizers that are both effective and compatible with a wide variety of materials also presents technical challenges.

Moreover, environmental concerns around chemical additives in consumer products are leading to stricter regulations, particularly in Europe. Compliance with these evolving standards can increase production costs and slow down market penetration. Raw material price volatility, especially in petrochemical derivatives, also creates uncertainty in the supply chain, impacting pricing and availability for end-users.

Technological Innovations

To overcome these hurdles and meet growing demands, manufacturers are increasingly focusing on innovation. The development of bio-based and environmentally friendly UV stabilizers is gaining attention, aligning with global sustainability efforts. Companies are also working on multifunctional stabilizers that combine UV resistance with anti-oxidative or flame-retardant properties, offering more value in a single additive.

Nanotechnology is another promising frontier, with nano-UV stabilizers showing enhanced dispersion, better transparency, and superior UV resistance. These advancements not only improve performance but also reduce the quantity of additive needed, lowering costs and environmental impact. Additionally, smart stabilizers that adapt their activity based on UV intensity are being explored for advanced applications.

Regional Insights

Asia Pacific is the standout region in terms of growth rate, driven by strong industrial development in countries like China, India, and Southeast Asia. The increasing use of UV stabilizers in the packaging, construction, and automotive

0 notes

Text

Here’s how companies can ensure they’re in compliance with new requirements that go into effect in August. Nitrosamine contamination has become one of the most pressing issues facing the pharmaceutical industry today. In the past few years, these potentially cancer-causing substances have grabbed the public’s attention and become a major focus of regulators, prompting the adoption of rigorous new FDA guidelines that will go into effect this summer. Since 2018, the FDA has issued more than 500 recalls because of unacceptable levels of nitrosamines in active pharmaceutical ingredients (APIs). As executive director of analytical at SK Pharmteco, I work with pharmaceutical clients to provide comprehensive testing services for a broad range of compounds, including impurities such as nitrosamines. Based on what we’re seeing, it’s clear that the spotlight on nitrosamines will only get brighter with manufacturers having to meet new FDA guidelines for these compounds by August. The new FDA guidelines, issued last year, are both comprehensive and complex. They cover more than 250 nitrosamine compounds and apply to every drug on the market or in development. These guidelines require detecting minute levels—down to the parts per billion—with limits that vary depending on the specific nitrosamine. The stakes are high for getting it right. Noncompliance triggers an FDA Class II recall, which means drugs have to be immediately pulled from shelves. The FDA will not approve new drugs unless they meet the guidelines. Compliance may necessitate reformulation of products with different excipients and inputs. Additionally, it could require redesigning production processes, as nitrosamines can form through chemical reactions between precursors that are otherwise not hazardous on their own. In light of these stakes, pharma executives must ensure they have a robust testing program in place now and are proactively addressing any issues with noncompliant nitrosamine levels. A Fast-Developing Issue Nitrosamines can be found in a wide range of products, from foods and beverages to cosmetics and pharmaceuticals. These compounds are created when amines react with nitrosating agents such as nitrous acid, nitrogen oxides and nitrites. Nitrosamines were observed by chemists in the late 1800s, but the dangers were not understood at the time. In the 1970s, William Lijinsky, laboratory director at the National Cancer Institute’s Frederick Cancer Research and Development Facility, became a leading voice in raising concerns about their link to cancer. Initial concerns focused on tobacco products and foods, such as processed meats, where smoking or curing can introduce nitrites to trigger the chemical reaction. In the following decades, concerns grew as more studies indicated a link between different nitrosamines and cancer. Studies also showed that even small amounts of nitrosamines could be dangerous, leading regulators and experts to place greater scrutiny on their presence in products such as pharmaceuticals. In 2018, the FDA began an investigation into nitrosamine impurities in drugs that led to high-profile recalls for heartburn medicines. In 2020, the FDA issued its first guidance on the compounds, making nitrosamines an issue for the entire pharmaceutical industry for the first time. The FDA’s actions corresponded with increasing public concern about potential carcinogens in everything from food to toys and even water. While deaths from cancer have declined in the U.S., the number of new cases continues to climb each year, according to the American Cancer Society. The existence of nitrosamines in prescription drugs is particularly troubling because the medications are intended to treat illnesses, not cause them. They’re also intended to be taken on a regular basis. The FDA’s rapid and comprehensive response to the nitrosamine issue signals that it has taken a place among the agency’s top priorities in protecting the public. SK Pharmteco has seen pharma’s quick response to this change. ...

0 notes

Text

Manufacturing Nilotinib API: Key Process Considerations and Quality Challenges

Nilotinib is a second-generation tyrosine kinase inhibitor (TKI) primarily used in the treatment of chronic myeloid leukemia (CML). As an active pharmaceutical ingredient (API), nilotinib plays a crucial role in inhibiting the BCR-ABL protein that causes the uncontrolled proliferation of leukemic cells. Given its therapeutic importance and stringent safety requirements, manufacturing nilotinib API demands meticulous planning, process control, and regulatory compliance.

This article explores the key considerations in the production of nilotinib API, along with the major quality challenges that manufacturers must navigate to ensure safe and effective delivery to end-users.

1. Synthetic Route Development

The manufacturing of nilotinib begins with route selection, which directly impacts yield, cost-efficiency, and impurity formation. The synthesis process typically involves multiple steps, including heterocyclic coupling, amine protection/deprotection, and amide bond formation.

Process developers must evaluate several critical parameters during route design:

Reagent selection and cost

Reaction efficiency and scalability

Environmental and safety factors

Control of side reactions and by-products

Establishing a high-purity intermediate pathway is essential to minimize downstream purification load and reduce the risk of impurities exceeding ICH limits.

2. Impurity Profiling and Control

One of the most complex aspects of nilotinib API production is impurity identification and control. Because the molecule contains sensitive functional groups and multiple chiral centers, it is prone to the formation of related substances, isomers, and degradation products.

To address this, manufacturers must:

Implement robust analytical methods (e.g., HPLC, LC-MS) for detection and quantification

Set strict specification limits based on toxicological thresholds

Perform comprehensive forced degradation studies to anticipate and control impurities under various storage and processing conditions

Impurities must be classified and qualified according to ICH Q3A/B guidelines to ensure product safety.

3. Process Validation and GMP Compliance

Nilotinib API falls under high-value, regulated pharmaceutical ingredients, and as such, requires full Good Manufacturing Practice (GMP) compliance. The entire process—from raw material sourcing to final API crystallization—must be thoroughly validated.

Key areas of focus during validation include:

Critical Process Parameters (CPPs): Temperature, pH, solvent ratios

Critical Quality Attributes (CQAs): Assay, purity, residual solvents, particle size

Equipment qualification and cleanroom standards to prevent contamination

Manufacturers are required to maintain detailed batch manufacturing records (BMRs) and validation master plans (VMPs), especially if the API is intended for regulated markets like the US, EU, or Japan.

4. Polymorphism and Crystallization Control

The solid-state properties of nilotinib play a critical role in its bioavailability, solubility, and stability. During final crystallization, controlling polymorphic form is essential to maintain consistency in performance and comply with regulatory filings.

Challenges here include:

Identifying and maintaining the correct crystal form (e.g., Form A, Form B)

Avoiding unintended form conversion during drying or storage

Optimizing solvent selection and cooling profiles

Failure to maintain a consistent polymorphic profile can lead to regulatory rejections and batch failures in downstream formulation.

5. Environmental and Safety Considerations

The use of organic solvents, reagents like phosphorylating agents, and elevated reaction temperatures make nilotinib synthesis both environmentally and operationally sensitive. Manufacturers must ensure:

Efficient waste management and solvent recovery systems

Compliance with EHS (Environment, Health, and Safety) guidelines

Worker safety through proper PPE, closed systems, and process automation

Minimizing the ecological footprint while maximizing yield remains a balancing act in nilotinib API production.

Conclusion

The manufacturing of nilotinib API is a highly specialized process that involves a delicate interplay of synthetic chemistry, regulatory rigor, and quality assurance. From route development and impurity control to polymorphic consistency and GMP compliance, every step must be optimized for safety, scalability, and global regulatory acceptance.

As demand for high-performance oncology APIs grows, nilotinib API manufacturers that focus on innovation, quality control, and environmental responsibility will remain critical to the success of global pharmaceutical supply chains.

0 notes

Text

Non-Ionic Surfactants Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

Non-Ionic Surfactants Market - Size, Share, Demand, Industry Trends and Opportunities

Global Non-Ionic Surfactants Market, By Substrate (Synthetic Surfactants and Bio-Based Surfactants), Type (Alcohol Ethoxylates, Fatty Alkanolamides, Amine Derivatives, Glycerol Derivatives, Alkoxylates, and Others), Application (Cleaners, Emulsifiers, Foaming Agents, Wetting Agents, Additives, and Others), End-Use Industry (Paints and Coatings, Personal Care and Cosmetics, Textiles, Agrochemicals, Household Cleaners, Food and Beverage, Oil and Gas, and Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends.

Access Full 350 Pages PDF Report @

**Global Non-Ionic Surfactants Market Analysis**

The global non-ionic surfactants market is experiencing steady growth, driven by various factors such as increasing demand from end-use industries like personal care, household detergents, and industrial applications. Non-ionic surfactants are surface-active agents that are widely used for their emulsifying, dispersing, and wetting properties. The market is expected to witness significant growth in the coming years due to the rising awareness regarding hygiene and cleanliness, coupled with the growing emphasis on sustainable and eco-friendly products.

**Segments**

1. **Product Type**: The market can be segmented based on product type into alcohol ethoxylates, alkylphenol ethoxylates, fatty amine ethoxylates, glycerol esters, and others. Alcohol ethoxylates are one of the most commonly used non-ionic surfactants due to their biodegradable nature and low toxicity.

2. **Application**: Non-ionic surfactants find applications in various industries such as personal care, textiles, agriculture, paints, and coatings. The personal care segment is expected to witness significant growth owing to the increasing demand for mild and skin-friendly surfactants in products like shampoos, body washes, and skincare formulations.

3. **End-Use Industry**: The market can also be segmented based on end-use industry into household detergents, industrial & institutional cleaning, oilfield chemicals, agrochemicals, and others. The household detergents segment holds a significant market share, driven by the growing consumer preference for effective cleaning solutions.

**Market Players**

- BASF SE - Clariant - Dow - Stepan Company - Croda International Plc - Evonik Industries AG - Huntsman International LLC - Kao Corporation - Sasol - Akzo Nobel N.V.

These market players are focusing on strategic initiatives such as product launches, collaborations, and mergers & acquisitions to strengthen their market presence and expand their product portfolios.

The global non-ionic surfactants market is witnessing several trends that are shaping the industry's landscape. One prominent trend is the increasing adoption of bio-based surfactants due to growing environmental concerns and regulatory pressures. Companies are investing in research and development activities to develop innovative bio-based surfactants that offer comparable performance to traditional surfactants while being sustainable and environmentally friendly.

Moreover, the market is also witnessing a shift towards sustainable packaging solutions to reduce plastic waste and minimize the environmental impact of product packaging. This trend is driving manufacturers to explore alternative packaging materials and recyclable options to align with the growing consumer preference for eco-friendly products.

Despite the positive growth outlook, the global non-ionic surfactants market faces challenges such as fluctuating raw material prices and stringent regulations regarding the use of certain chemicals in surfactant formulations. Manufacturers need to navigate these challenges by implementing efficient supply chain strategies, exploring cost-effective sourcing options, and ensuring compliance with regulatory standards to sustain their market position.

In conclusion, the global non-ionic surfactants market is poised for significant growth driven by increasing demand from diverse end-use industries and a growing focus on sustainability. Market players need to focus on innovation, sustainability, and strategic collaborations to capitalize on emerging opportunities and overcome industry challenges.

Non-Ionic Surfactants Key Benefits over Global Competitors:

The report provides a qualitative and quantitative analysis of the Non-Ionic Surfactants Market trends, forecasts, and market size to determine new opportunities.

Porter’s Five Forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make strategic business decisions and determine the level of competition in the industry.

Top impacting factors & major investment pockets are highlighted in the research.

The major countries in each region are analyzed and their revenue contribution is mentioned.

The market player positioning segment provides an understanding of the current position of the market players active in the Personal Care Ingredients

Table of Contents: Non-Ionic Surfactants Market

1 Introduction

2 Global Non-Ionic Surfactants Market Segmentation

3 Executive Summary

4 Premium Insight

5 Market Overview

6 Non-Ionic Surfactants Market, by Product Type

7 Non-Ionic Surfactants Market, by Modality

8 Non-Ionic Surfactants Market, by Type

9 Non-Ionic Surfactants Market, by Mode

10 Non-Ionic Surfactants Market, by End User

12 Non-Ionic Surfactants Market, by Geography

12 Non-Ionic Surfactants Market, Company Landscape

13 Swot Analysis

14 Company Profiles

Critical Insights Related to the Non-Ionic Surfactants Included in the Report:

Exclusive graphics and Illustrative Porter’s Five Forces analysis of some of the leading companies in this market

Value chain analysis of prominent players in the market

Current trends influencing the dynamics of this market across various geographies

Recent mergers, acquisitions, collaborations, and partnerships

Revenue growth of this industry over the forecast period

Marketing strategy study and growth trends

Growth-driven factor analysis

Emerging recess segments and region-wise market

An empirical evaluation of the curve of this market

Ancient, Present, and Probable scope of the market from both prospect value and volume

Browse Trending Reports:

Flexible Substrates Market Data Quality Tools Market Insomnia Market Medical Image Management Market Prosopagnosia Treatment Market IVD In Cardiology and Neurology Market Automotive Number Plate Market Building Acoustics Market Local Anesthetics Market Collagen supplements Market Hypercalcemia Treatment Market Pharmaceuticals Packaging Testing Equipment Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]

0 notes

Text

0 notes

Text

Ethylene Amines Market Expands with Increased Use in Water Treatment and Personal Care Sectors

The ethylene amines market is witnessing robust growth driven by expanding industrial applications, technological advancements, and the increasing demand from end-user industries such as automotive, agriculture, pharmaceuticals, and water treatment. Ethylene amines are a group of chemicals derived from ethylene dichloride and ammonia. They include ethylenediamine (EDA), diethylenetriamine (DETA), triethylenetetramine (TETA), and other related compounds. These chemicals are valued for their versatile chemical properties, including high reactivity and the ability to form complex structures.

Market Drivers

One of the key drivers for the ethylene amines market is their growing application in the automotive and transportation sectors, particularly in fuel and lubricant additives. Ethylene amines improve fuel efficiency, reduce engine deposits, and enhance overall vehicle performance. The rising global automotive production and the push for improved fuel standards are creating sustained demand for these compounds.

Another major contributor is the agricultural sector, where ethylene amines are used in the production of chelating agents and pesticides. These compounds help in enhancing crop yields and improving soil nutrient balance. With the growing need to ensure food security and increase agricultural productivity, the demand for ethylene amines in agrochemicals is expected to rise steadily.

In the pharmaceutical and personal care industries, ethylene amines serve as intermediates in the production of various drugs and personal care products. Their use in the manufacture of surfactants, emulsifiers, and corrosion inhibitors makes them integral to multiple industrial processes. As these sectors continue to expand globally, especially in emerging economies, the ethylene amines market is poised for sustained growth.

Technological Advancements

Technological innovation in production processes is also influencing market dynamics. The traditional methods of producing ethylene amines via batch processing are gradually being replaced by continuous processes, which are more efficient and environmentally friendly. Advanced catalysts and process optimization techniques have enabled manufacturers to improve product yield, reduce waste, and lower operational costs.

In addition, R&D efforts focused on developing bio-based ethylene amines are gaining momentum. These sustainable alternatives are attracting attention due to the growing emphasis on reducing the carbon footprint of chemical manufacturing. While still at a nascent stage, bio-based ethylene amines could become a significant market disruptor in the future.

Regional Insights

Geographically, Asia-Pacific dominates the global ethylene amines market, with countries such as China, India, and Japan leading in both production and consumption. The region benefits from strong industrial infrastructure, lower production costs, and high demand across end-use sectors. Rapid urbanization and industrialization are expected to keep this region at the forefront of market growth.

North America and Europe also hold significant market shares, driven by technological advancements, environmental regulations, and demand from high-value industries. The presence of major manufacturers and stringent quality standards ensure a stable and mature market in these regions.

Challenges and Restraints

Despite its positive outlook, the ethylene amines market faces certain challenges. The production of ethylene amines involves toxic raw materials and complex chemical processes, which pose environmental and safety concerns. Regulatory pressures to minimize hazardous emissions and ensure worker safety can increase compliance costs for manufacturers.

Furthermore, price volatility of raw materials like ethylene and ammonia can affect profit margins. Fluctuations in oil prices also impact the cost structure of ethylene amines, making price management a crucial aspect of market strategy.

Future Outlook

The ethylene amines market is set to experience steady growth over the next decade. Emerging applications in niche segments like epoxy curing agents, textile chemicals, and water treatment will open new avenues for market expansion. Strategic investments in research, product innovation, and sustainability initiatives will be key to maintaining competitiveness.

Collaborations between chemical manufacturers and research institutions are also expected to foster innovation and create customized ethylene amine formulations tailored for specific industry needs. As environmental regulations tighten, the shift toward greener and safer chemical processes will continue to shape the future of the industry.

In conclusion, the ethylene amines market presents promising growth opportunities across a wide array of industries. With increasing global demand, technological evolution, and a rising focus on sustainability, stakeholders in this market are well-positioned to capitalize on long-term trends.

0 notes

Text

Global Triethylenetetramine (TETA) Market, Report: Trends, Opportunities, and Forecast 2025-2031

Triethylenetetramine (TETA) Market, Global Outlook and Forecast 2025-2032

The global Triethylenetetramine (TETA) Market continues to expand steadily, with its valuation reaching USD 785.1 million in 2024. According to comprehensive industry analysis, the market is projected to grow at a CAGR of 5.1%, reaching approximately USD 1.1 billion by 2032. This growth trajectory reflects increasing demand across diverse industrial applications, particularly in epoxy curing agents and specialty chemical formulations where TETA's unique properties offer distinct advantages.

Triethylenetetramine (TETA) serves as a crucial component in multiple industries due to its effectiveness as a curing agent for epoxy resins. Its versatility extends to applications in fuel additives, lubricants, and corrosion inhibitors, making it indispensable in sectors ranging from construction to automotive manufacturing. The compound's ability to enhance material performance continues to drive adoption, particularly as industries seek more durable and efficient chemical solutions.

Download FREE Sample Report: https://www.24chemicalresearch.com/admin24cr/download-sample/287976/global-triethylenetetramine-forecast-by-manufacturers-technology-application-market-2025-2032-45

Market Overview & Regional Analysis

Asia-Pacific leads the global TETA market with significant production capacity concentrated in China, Japan, and India. The region benefits from robust chemical manufacturing infrastructure and growing demand from end-use industries such as automotive and construction. North America follows closely, driven by technological advancements in polymer production and strong demand from the aerospace sector. Europe maintains a steady market presence, supported by stringent environmental regulations that favor high-performance chemical solutions.

Emerging markets in Latin America and the Middle East show promising growth potential, though infrastructure limitations and regulatory hurdles currently constrain faster expansion. Meanwhile, developed regions continue to innovate, focusing on sustainable production methods and specialized applications that leverage TETA's chemical properties more effectively.

Key Market Drivers and Opportunities

The market's upward trajectory stems from multiple factors, including increased infrastructure spending worldwide and the growing preference for high-performance epoxy systems. Industrial applications account for approximately 65% of global demand, with construction materials comprising another 20%. Emerging opportunities include:

The development of bio-based alternatives presents an exciting frontier, potentially opening new markets in eco-conscious industries. Additionally, evolving applications in renewable energy systems and advanced material sciences suggest long-term growth potential beyond TETA's traditional uses.

Challenges & Restraints

The TETA market faces several constraints including raw material price volatility and tightening environmental regulations. Supply chain complexities and the specialized handling requirements for amines also pose operational challenges for manufacturers.

Competitive pressures from alternative curing agents and the industry's need for continual innovation present additional hurdles. However, strategic investments in production efficiency and application development help mitigate these challenges.

Market Segmentation by Type

High Purity TETA

Industrial Grade TETA

Download FREE Sample Report: https://www.24chemicalresearch.com/admin24cr/download-sample/287976/global-triethylenetetramine-forecast-by-manufacturers-technology-application-market-2025-2032-45

Market Segmentation by Application

Epoxy Curing Agents

Fuel Additives

Lubricating Additives

Asphalt Additives

Other Specialty Applications

Market Segmentation and Key Players

Dow Chemical Company

BASF SE

Huntsman Corporation

Nouryon

Delamine BV

Tosoh Corporation

Mitsubishi Gas Chemical Company

Arabian Amines Company

Report Scope

This report provides a comprehensive analysis of the global Triethylenetetramine (TETA) market, covering the period from 2024 to 2032. It includes detailed examination of market dynamics, segmentation, competitive landscape, and growth prospects across key regions including:

Market size and growth projections

Application and product type analysis

Regional market developments

The report features in-depth profiles of major industry participants, including:

Business overviews and product portfolios

Production capacities and technological capabilities

Financial performance metrics

Strategic initiatives and market positioning

Additionally, the research identifies key market influencers and evaluates potential challenges that could impact future growth trajectories.

Get Full Report Here: https://www.24chemicalresearch.com/admin24cr/reports/287976/global-triethylenetetramine-forecast-by-manufacturers-technology-application-market-2025-2032-45

FAQ

01. What are the primary applications of Triethylenetetramine (TETA)?

TETA serves primarily as an epoxy curing agent and finds significant use in fuel additives, lubricants, and corrosion inhibitors across multiple industries.

02. Which regions show the strongest growth potential for TETA?

Asia-Pacific currently leads in consumption, while North America and Europe maintain strong positions in specialized applications. Emerging markets show promising growth potential.

03. What technological advancements are shaping the TETA market?

Innovations focus on production efficiency, sustainable alternatives, and the development of specialized formulations for high-performance applications.

04. How do environmental regulations impact the TETA industry?

Regulatory frameworks influence production methods and product specifications, driving innovation toward more environmentally friendly solutions.

05. What challenges do TETA manufacturers currently face?

Key challenges include raw material price fluctuations, specialized handling requirements, and competition from alternative chemical solutions.

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

Medical Marvels: The Role of Carbon Nanotubes in Drug Delivery

The global carbon nanotubes (CNT) market is on the verge of an unprecedented expansion, projected to grow from USD 1,166.2 million in 2025 to an astounding USD 2,812.1 billion by 2035. This surge reflects a robust compound annual growth rate (CAGR) of 9.2%, driven by advancements in nanotechnology and an increasing demand for CNTs across multiple industries, particularly in energy storage, electronics, and automotive sectors. With superior mechanical, electrical, and thermal properties, CNTs are revolutionizing materials science and industrial applications.

𝐅𝐮𝐧𝐜𝐭𝐢𝐨𝐧𝐚𝐥𝐢𝐳𝐚𝐭𝐢𝐨𝐧: 𝐓𝐡𝐞 𝐊𝐞𝐲 𝐭𝐨 𝐔𝐧𝐥𝐨𝐜𝐤𝐢𝐧𝐠 𝐂𝐍𝐓 𝐕𝐞𝐫𝐬𝐚𝐭𝐢𝐥𝐢𝐭𝐲

Carbon nanotubes in their pristine form are hydrophobic, tend to bundle together due to van der Waals forces, and are difficult to integrate into most solvent systems or polymer matrices. These limitations significantly reduce their utility in real-world industrial applications. Functionalization—either through covalent or non-covalent modification—addresses these challenges at the molecular level.

Covalent functionalization alters the intrinsic structure of CNTs by attaching functional groups such as carboxyl, hydroxyl, or amine groups directly onto the tube walls. This enhances solubility and reactivity but can sometimes degrade electrical properties. Non-covalent techniques, on the other hand, involve wrapping CNTs with polymers or surfactants, preserving their core structure while improving dispersion and processability.

𝐆𝐞𝐭 𝐀𝐡𝐞𝐚𝐝 𝐰𝐢𝐭𝐡 𝐎𝐮𝐫 𝐑𝐞𝐩𝐨𝐫𝐭: 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐍𝐨𝐰! https://www.futuremarketinsights.com/reports/sample/rep-gb-78

Such molecular-level adaptations not only improve CNT performance but also allow them to be tailored to specific industries. For instance, polymer-wrapped CNTs can be seamlessly integrated into hydrophilic media for biomedical use, while carboxylated CNTs exhibit enhanced compatibility with epoxy matrices used in structural composites. These changes open doors to new application domains and mitigate regulatory concerns surrounding toxicity and bioaccumulation.

"With rapid technological advancements and growing industrial demand, the carbon nanotube market is poised for exponential growth. The integration of CNTs in energy storage, electronics, and structural materials will redefine multiple industries, creating new opportunities for innovation and commercialization," says Nikhil Kaitwade, Associate Vice President at Future Market Insights (FMI).

𝐊𝐞𝐲 𝐓𝐚𝐤𝐞𝐚𝐰𝐚𝐲𝐬 𝐟𝐫𝐨𝐦 𝐭𝐡𝐞 𝐂𝐚𝐫𝐛𝐨𝐧 𝐍𝐚𝐧𝐨𝐭𝐮𝐛𝐞𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐭𝐮𝐝𝐲:

The global carbon nanotubes market will experience a CAGR of 9.2% from 2025 to 2035, with a valuation reaching USD 2812.1 billion by the end of the forecast period.

Lithium-ion battery and supercapacitor applications will significantly contribute to market expansion due to CNTs' role in enhancing energy efficiency and storage capacity.

Asia-Pacific is expected to dominate the CNT market, with China leading the production and application of CNTs across various industries.

Companies are investing in research and development to improve CNT production efficiency and explore novel applications in healthcare, construction, and flexible electronics.

The market faces challenges such as high production costs and technical limitations in large-scale manufacturing, but ongoing research is addressing these barriers.

𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐈𝐦𝐩𝐚𝐜𝐭: 𝐅𝐮𝐧𝐜𝐭𝐢𝐨𝐧𝐚𝐥𝐢𝐳𝐞𝐝 𝐂𝐍𝐓𝐬 𝐢𝐧 𝐄𝐦𝐞𝐫𝐠𝐢𝐧𝐠 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬

As functionalization techniques mature, CNTs are entering sectors once considered inaccessible due to incompatibility or safety concerns. One noteworthy domain is biodegradable electronics, where functionalized CNTs are used as conductive inks in wearable biosensors that degrade safely in the body or environment after use. In 2023, a Japanese startup successfully launched a biodegradable patch for ECG monitoring that employed non-covalently modified CNTs within a biodegradable polymer matrix, highlighting how functionalization directly influences product viability.

The textile industry is another emerging frontier. Functionalized CNTs are being used to create anti-bacterial, conductive fabrics that can monitor temperature or humidity. These “smart textiles” are gaining traction in sportswear and military uniforms, where data collection and comfort intersect. Functionalized CNT coatings also play a role in water purification membranes, enhancing filtration rates and antimicrobial properties, especially when bonded with silver or titanium dioxide nanoparticles.

𝐄𝐱𝐡𝐚𝐮𝐬𝐭𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐩𝐨𝐫𝐭: 𝐀 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐒𝐭𝐮𝐝𝐲! https://www.futuremarketinsights.com/reports/global-carbon-nanotubes-market

Such applications are not just technically innovative—they are expanding the segmentation of the CNT market into areas that previously showed minimal interest due to integration barriers. As more companies adopt CNT-based solutions in fields like biosensing, medical imaging, and environmental tech, the market narrative around CNTs is evolving from a niche, high-tech material to a broadly applicable industrial component.

𝐂𝐚𝐫𝐛𝐨𝐧 𝐍𝐚𝐧𝐨𝐭𝐮𝐛𝐞𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Product:

Multi-walled Carbon Nanotubes (MWCNT)

Single-walled Carbon Nanotubes (SWCNT)

By Application:

Application in Polymers

Application in Energy

By Region:

North America

Latin America

Western Europe

Eastern Europe

East Asia

South Asia & Pacific

Middle East & Africa

0 notes