#Ammonia Market Growth

Text

Exploring the Global Ammonia Market: Insights and Trends

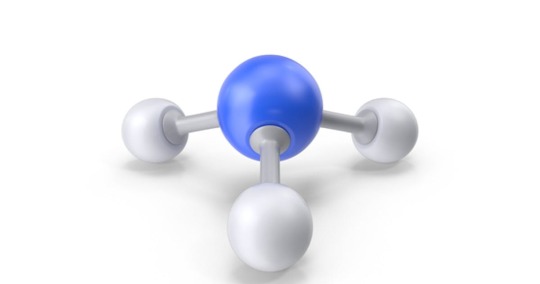

Ammonia is an inorganic compound with the formula NH3. It is a colourless gas with a characteristic pungent smell. It is mainly used as a fertilizer in agriculture and also found its applications in various other industries like chemicals, pharmaceuticals, textiles, refrigerants etc. Ammonia is produced on an industrial scale using the Haber-Bosch process.Ammonia provides nitrogen to plants which is an essential nutrient for crop growth. Rising global population and need for food security has increased the demand for fertilizers significantly over the past few decades. Ammonia being a key fertilizer ingredient has benefitted from this growing demand.

The Global ammonia market is estimated to be valued at US$ 114 billion in 2031 and is expected to exhibit a CAGR of 6.5% over the forecast period 2024-2031.

Key Takeaways

Key players operating in the ammonia market are Yara International ASA, BASF SE, CF Industries Holdings, Inc., Nutrien Ltd., Potash Corporation of Saskatchewan Inc., Dangyang Huaqiang Chemical Co., Ltd., Shanxi Jinfeng Coal Chemical Co Ltd., GTS Chemical Holdings plc.,Togliattiazot, OCI Nitrogen B.V., Agrium Inc., Sabic, and Koch Fertilizer, LLC among others.

The rising global population has increased the demand for food significantly. As per UN estimates, the global population is expected to reach around 9.7 billion by 2050 which will further drive the demand for ammonia as fertilizer.

New technologies like methane pyrolysis are being developed which helps in more efficient production of ammonia. This would help boost its supply and meet the growing demand cost effectively.

Market Trends

Growing preference for nitrogen-based fertilizers - Nitrogenous fertilizers like ammonia, urea etc. see higher demand over other fertilizers due to their high nitrogen content and economic viability. This trend is expected to drive ammonia consumption.

Increase in natural gas based capacity additions - Many new ammonia plants are being set up based on natural gas due to abundant availability and relatively lower prices vis-à-vis other feedstocks. This is expected to boost ammonia output.

Market Opportunities

Rising biofuel production - Ammonia is used as a key ingredient in biodiesel production. Increasing global targets for biofuel blending is expected to generate more demand for ammonia.

Use in hydrogen economy - Ammonia is emerging as a potential carrier and storage medium for hydrogen. Its use in hydrogen-based transportation and power generation systems can open new avenues.

Impact of COVID-19 on Ammonia Market Growth

The COVID-19 outbreak has severely impacted the global ammonia market in 2020. The imposition of lockdowns led to the closure of many manufacturing facilities, disrupting the entire supply chain. With decline in industrial activity, the demand for ammonia fell drastically across major end-use industries like fertilizers, textiles, refrigeration, pharmaceuticals etc. This led to oversupply situations in North America and Europe. Some of the projects planned for capacity expansion were also stalled during this period owing to labor shortages and financial constraints faced by the companies.

However, with gradual lifting of restrictions and restarting of industries from mid-2021, the market started recovering. The demand is steadily rising from agricultural sector to meet the increasing food demand of the growing global population. Fertilizer plants are ramping up their productions to pre-COVID levels. Manufacturers are focusing on developing innovative and cost-effective production technologies to cater to the reviving demands. Project expansion activities have also resumed. The market is anticipated to get back on the growth trajectory and surpass its pre-pandemic size by 2024. Continuous investments in agricultural sector will be crucial for the sustainable growth of ammonia market in the coming years.

Europe remains the largest regional market for ammonia, accounting for over 30% of the global supply in 2023. Availability of raw materials, technical expertise and widespread fertilizer manufacturing facilities contribute to its dominance. However, Asia Pacific is identified as the fastest growing regional market, expanding at a CAGR of around 8% during the forecast period. Increased agricultural activities and growth of allied industries like textiles are driving the demands in countries like China, India and Indonesia. Governments in the emerging economies are promoting urea fertilizer production to improve farm outputs. This makes the Asia Pacific region most lucrative for ammonia producers seeking new investment avenues.

0 notes

Text

#Green Ammonia Market#Green Ammonia Size#Green Ammonia Growth#Green Ammonia Trend#Green Ammonia segment#Green Ammonia Opportunity#Green Ammonia Analysis 2024#Green Ammonia Forecast

0 notes

Text

Australia Ammonia Market: Key Players and Dynamics

The Australia ammonia market is a critical component of the country's agriculture sector, with ammonia being a key ingredient in the production of various fertilizers needed to maximize crop yields. As one of the largest exporters of agricultural commodities globally, Australia relies on efficient fertilizer production using ammonia to support the domestic food production and meet global demand. Ammonia is produced through the Haber-Bosch process involving nitrogen from air and hydrogen from natural gas, providing nitrogen compounds essential for plant nutrition. The adoption of green production technologies is helping lower carbon footprint and meet emission reduction targets.

Australia ammonia market is estimated to be valued at US$ 934.85 Million in 2024 and is expected to exhibit a CAGR of 6.4% over the forecast period 2023 to 2030.

Ammonia serves as a crucial raw material for synthesizing various nitrogen fertilizers used to enrich soil nutrients and boost agricultural productivity. It helps bridge the gap between demand and domestic supply of agricultural produce.

Key Takeaway

Key players operating in the Australia ammonia market are Incitec Pivot Limited, Yara International ASA, Orica Limited, and Wesfarmers Chemicals, Energy & Fertilisers. Incitec Pivot and Wesfarmers together account for over 50% of domestic ammonia production capacity.

The growing demand for agricultural commodities from export markets is driving consumption of ammonia-based fertilizers in Australia. There is increased focus on utilizing advanced production technologies and renewable energy sources to manufacture 'green' ammonia for sustainable agriculture.

Major ammonia producers are undertaking capacity expansion and global expansion initiatives to capitalize on the growing export demand. For instance, Incitec Pivot is investing $200 million to increase ammonia production capacity by 40% at its Phosphate Hill operations to supply both domestic and overseas markets.

Market key trends

The adoption of renewable energy-powered green ammonia production methods using solar and wind energy is gaining traction. Green ammonia produced without carbon emissions can help reduce reliance on fossil fuels and achieve emission reduction commitments. Companies are conducting trials and feasibility studies for green ammonia projects with the support of government incentives and policies. This emerging trend of low-carbon ammonia production will likely shape the future outlook of the Australia ammonia industry.

Porter’s Analysis

Threat of new entrants: There are few capital requirements to enter the market as technology is mature, but established players hold large market share and economies of scale.

Bargaining power of buyers: Buyers have moderate bargaining power as there are few substitutes for ammonia in industrial processes like refrigeration and fertilizer production.

Bargaining power of suppliers: Suppliers have moderate bargaining power as raw materials for ammonia production like natural gas are available from few suppliers globally.

Threat of new substitutes: There is no close substitute for ammonia in large scale industrial applications like fertilizers currently.

Competitive rivalry: Market is dominated by few large players and competition is based on pricing, product quality and reliability of supply.

Geographically, Australia market is currently concentrated in regions of Queensland and New South Wales where large fertilizer plants and chemical industries are located. These regions account for over 60% of the domestic demand for ammonia. The fastest growing region in the forecast period is expected to be Western Australia led by expansion of mining and resource industries in the region. Mining industries use ammonia for industrial refrigeration and energy generation.

0 notes

Text

Understanding the Significance of Green Ammonia

Agriculture is a major contributor to environmental pollution. Moreover, it is a very hard sector to decarbonize. In the meantime, emissions from maritime transport are surging all over the world. Though, there is a somewhat surprising method to reduce the climate impacts of both agriculture and shipping, the good old ammonia, produced in an innovative sustainable technique.

Ammonia is a chemical compound formed with hydrogen and nitrogen. Not only it is widely utilized in making agricultural fertilizers, but it is also an important chemical for different sectors. The production of hydrogen, and therefore, of ammonia, is generally grounded on natural gas.

Ammonia produced with traditional approaches is known as grey ammonia. Green ammonia, in order, is the ammonia made with zero emissions from renewable energy sources such as solar or wind energy. The outcome is a compound with an exact composition and utilized as grey ammonia.

A Sustainable Alternative for Different Energy Necessities

Ammonia is carbon-free. As a result, combusting it doesn’t lead to carbon dioxide emissions, only water vapor and nitrogen. This makes ammonia a favorable alternative for energy production as its large-scale application can have substantial advantageous climate impacts by reducing the need for fossil fuels.

Now, let’s explore some major applications of green ammonia.

As An Energy Carrier

One major benefit of ammonia is its capacity to store energy. Moving hydrogen for wide distances can be challenging, however, ammonia can be utilized as a hydrogen carrier. On a molecular level, hydrogen is bound in ammonia, and hence ammonia can be employed in transporting as well as storing hydrogen.

In Agriculture

At least 80% of industrially produced ammonia is utilized to produce nitrogen fertilizers. Such fertilizers improve the quantity of nitrogen in the soil since nitrogen is a key nutrient for the growth of plant. Ammonia is and will remain to be an irreplaceable raw material for producing food.

Moreover, different countries are now dependent on imported ammonia. Producing green ammonia via renewable power will be a footstep toward becoming entirely self-sufficient in fertilizers. Also, domestic production can lead to fresh export opportunities.

In Shipping

Green ammonia potentials have been discussed mostly based on the idea of shipping as the maritime industry is constantly looking for novel approaches to allow carbon-neutral transportation. Maritime transport accounts for nearly 3% of world greenhouse gas releases.

Green ammonia, in the maritime industry, is considered an alternative to replace diesel fuel. Before this becomes possible, clean energy production as well as innovative technology is essential for refueling stations & ships.

Fuel must be widely accessible, mainly at detailed locations and later in each port across all countries. This is necessary to guarantee the solution's efficiency as well as the working of long-distance vessels.

To Wrap It All Up

With the growing count of industrial projects for making green ammonia and the advancement in the agriculture sector, the demand for green ammonia will reach USD 6,559.1 million by the end of this decade.

#Green Ammonia Market Share#Green Ammonia Market Size#Green Ammonia Market Growth#Green Ammonia Market Applications#Green Ammonia Market Trends

1 note

·

View note

Text

Australia Ammonia Market Insights: Trends, Challenges, and Future Outlook

Market Overview:

Ammonia is an important nitrogen source used to produce nitrogen-containing fertilizers such as urea, ammonium nitrate and ammonium phosphate. It is also used in fibers, plastics, explosives and cleaning products.

Market Dynamics:

Ammonia is mostly used in Australia for nitrogen fertilizers production due to the high demand from agricultural industry. According to recent reports, Australian agricultural sector has seen significant growth over past few years and is estimated to grow at over 3% annually during forecast period owing to rising food demand from growing population and demand for Australian agricultural exports globally. This rise in agricultural outputs will positively influence the demand for nitrogen fertilizers and subsequently ammonia market in Australia. In addition, growing demand for industrial use of ammonia like cleaning products manufacturing will also drive its market. However, stringent environmental regulations around CO2 emissions from ammonia production plants may slightly hamper the market growth during forecast period.

Major Drivers of the Australia Ammonia Market: Increased Fertilizer Demand Boosting Ammonia Consumption

The agricultural sector in Australia has been expanding significantly over the past few years. As the nation seeks to boost its agricultural output and meet the growing global food demand, the consumption of fertilizers has increased substantially. Ammonia is a key ingredient that is used in the production of nitrogen-based fertilizers such as urea, ammonium nitrate, and ammonium sulfate. With the rise in fertilizer usage, the demand for ammonia from the fertilizer industry has surged as well.

Stringent Regulations on Nitrogen Oxide Emissions Favoring Ammonia Production Shift

The Australian government has introduced stringent regulations to curb nitrogen oxide emissions from industries including power generation and waste incineration. As ammonia production and processing contributes significantly lower NOx emissions compared to other sources, many companies are shifting towards ammonia. The favorable policy environment is encouraging investments in ammonia facilities and infrastructure to replace conventional technologies. This transition is expected to boost ammonia consumption volumes in the coming years.

Major Restraint of the Australia Ammonia Market: Transportation Issues Hindering Market Expansion

While ammonia demand is rising steadily across various end-use sectors, transportation of ammonia poses unique safety challenges due to its corrosive and toxic nature. There is a lack of dedicated pipeline infrastructure for long-distance ammonia transportation within Australia. Reliance on road and sea shipments makes distribution difficult and cost-intensive. Remote locations witness supply disruptions as setting up storage and handling facilities is a major undertaking. These transportation barriers restrict the market from reaching its true potential and expanding across all geographical regions.

Major Opportunity for the Australia Ammonia Market: Green Ammonia Production Opening New Growth Avenues

With the world accelerating energy transition, green ammonia is emerging as a promising carbon-free solution. Australia is well-positioned to tap the vast potential of green ammonia due to its abundance of renewable energy resources like solar and wind. Several projects are being planned and established to produce green ammonia through electrolysis using renewable power. This provides an opportunity for Australia to export green ammonia to high demand markets in Asia and become a globally significant supplier. It can also facilitate the decarbonization of domestic shipping, fertilizer manufacturing and other industries.

Major Trend in the Australia Ammonia Market: Rising Investments in Large-Scale Import Terminals

To cater to the increasing fertilizer demand and ensure steady ammonia supply, major players in the Australian market are investing heavily in setting up import terminals with large capacities. For instance, Incitec Pivot recently completed expansion of its ammonia import facility at Kwinana, Perth to achieve a handling capacity of 1 million tonnes per year. Yara is constructing a new ammonia import terminal near Brisbane which is expected to receive 800,000 tonnes annually once completed in 2024. These import hubs will strengthen Australia's position as a key ammonia importing and distribution center to support the agricultural growth momentum.

#Australia Ammonia Market Share#Australia Ammonia Market Growth#Australia Ammonia Market Demand#Australia Ammonia Market Trend#Australia Ammonia Market Analysis

0 notes

Text

The Global Clean (Blue & Green) Ammonia Market is projected to grow at a CAGR of around 23.56% during the forecast period, i.e., 2025-30. The Global Clean (Blue & Green) Ammonia Market is in its embryonic stage since the historical period, owing to the major focus on research & development & not much commercial application of clean ammonia among end-user industries. However, with the increasing investment by the companies towards the setup of clean ammonia production facilities, the market is expected to witness significant growth during the forecast years.

#Global Clean (Blue & Green) Ammonia Market#Global Clean (Blue & Green) Ammonia Market News#Global Clean (Blue & Green) Ammonia Market growth#Global Clean (Blue & Green) Ammonia Market industry#Global Clean (Blue & Green) Ammonia Market report#Global Clean (Blue & Green) Ammonia Market Share#Global Clean (Blue & Green) Ammonia Market Size#Global Clean (Blue & Green) Ammonia Market Industry#Global Clean (Blue & Green) Ammonia Market price

0 notes

Text

The downside of ammonia is that it is a toxic refrigerant. It can also be flammable at certain concentrations. For this reason, all ammonia systems need to be designed with safety. Ammonia does not burn without a supporting flame since it has ignition energy 50 times higher than natural gas.

#Ammonia Refrigerants Market#Ammonia Refrigerants#Ammonia Refrigerants Market size#Ammonia Refrigerants Manufacture#Ammonia Refrigerants Market Report#Ammonia Refrigerants Market Overview#Ammonia Refrigerants Market Outlook#Ammonia Refrigerants Market Trends#Ammonia Refrigerants Market Share#Ammonia Refrigerants Market Driver#Ammonia Refrigerants Market Demand#Ammonia Refrigerants Market growth#Ammonia Refrigerants Market insights#Ammonia Refrigerants Industry#Ammonia Refrigerants Market Forecast#Ammonia Refrigerants Market Analysis#Global Ammonia Refrigerants Market#Ammonia Refrigerants Industry Trends#Ammonia Refrigerants Market Growth#Ammonia Refrigerants Market CAGR#Ammonia Refrigerants Market in Europe#Ammonia Refrigerants Market in USA#Ammonia Refrigerants Market in Asia Pacific#Refrigerants Market#Refrigerants

0 notes

Text

1. Nearly All U.S. Turkeys Are Raised on Factory Farms

Each year, more than 200 million turkeys are slaughtered for food in the U.S. [over 46 million of those solely for the holidays] — and over 99 percent of U.S. turkeys are raised on industrial farms and kept in severely crowded and unsanitary conditions. They are given little or no care and denied the chance to engage in many natural behaviors, like nesting, rooting in the grass for food, or perching. Sheds are filled with ammonia and animal waste, which is harmful to both birds and human workers and puts both at risk for respiratory conditions.

2. Turkeys Are Bred for Painful Rapid Growth

Factory-farmed turkeys are selectively bred to grow to an unnatural size quickly, reaching market weight in just four months. By that age, today’s factory-farmed males are roughly triple the weight of adult wild male turkeys. This breeding for maximal production and profit leaves many birds suffering from deformities and heart conditions and too large to fly, roost, or mate naturally. Burdened by their body weight, some cannot stand or reach their water and food.

3. Turkeys Are Subjected to Painful Mutilations

Many consumers may be shocked that some excruciating procedures are considered standard practice in the poultry industry. Turkeys and chickens alike are routinely detoed (the tips of their toes are severed) and “debeaked” (the tips of their beaks are burned or cut off) — all with no form of pain relief. This is an attempt to prevent injuries caused by the stress of extreme crowding, caused by factory farming itself. While the American Veterinary Medical Association has not condemned debeaking, it has acknowledged that “acute and chronic pain are associated with this procedure.”

4. Birds Are Excluded From the Humane Methods of Slaughter Act

While other land animals — including pigs, cows, and sheep — are offered basic protections under the Humane Methods of Slaughter Act, birds (including turkeys, chickens, ducks, and geese) are excluded. This leaves the treatment of these birds at slaughter largely up to meat and egg producers, who most often put profit above animal welfare. While turkeys and chickens are lowered into electrified water in an attempt to stun them, this often fails, leaving many birds conscious when their throats are cut.

5. Animal Agriculture Is a Major Driver of Our Climate Crisis

Many factors affect human-induced climate change, but farming billions of animals yearly is widely considered a leading driver of our environmental crisis. Animal agriculture accounts for at least 14.5 percent of global greenhouse gas emissions. The industry also uses 80 percent of U.S. agricultural land — and according to the University of Minnesota, the U.S. could feed almost three times more people by providing major crops directly to humans rather than livestock. One of the easiest and most effective ways an individual can do their part in helping to fight climate change is by choosing a plant-based diet.

3 notes

·

View notes

Text

The Commercial Refrigeration System Market is projected to grow from USD 54766 million in 2024 to USD 75239.81 million by 2032, expanding at a CAGR of 4.05% from 2024 to 2032.The global commercial refrigeration system market is witnessing rapid growth, driven by several key factors such as rising demand from the food and beverage industry, technological advancements, and an increasing emphasis on energy efficiency. Commercial refrigeration systems are essential for preserving perishable goods, maintaining food safety, and ensuring product quality across various industries. This market encompasses various types of equipment, including refrigerators, freezers, walk-in coolers, display cases, and ice-making machines, used in sectors such as supermarkets, convenience stores, restaurants, and food processing facilities.

Browse the full report at https://www.credenceresearch.com/report/commercial-refrigeration-system-market

Market Overview

The commercial refrigeration system market has seen substantial growth in recent years, driven primarily by increasing urbanization, rising disposable incomes, and changing consumer preferences towards ready-to-eat and frozen food products. In addition, the expansion of the foodservice industry, including restaurants, cafes, and hotels, has spurred demand for efficient and advanced refrigeration solutions.

According to industry reports, the global commercial refrigeration market was valued at approximately USD 30 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of around 5% between 2021 and 2027. This growth is further boosted by the ongoing developments in cooling technologies, the need for greener refrigeration solutions, and the increasing awareness of food safety regulations.

Key Drivers of Growth

1. Rising Demand in the Food and Beverage Industry

The food and beverage industry is one of the largest end-users of commercial refrigeration systems. The increasing demand for frozen and chilled food products has resulted in a heightened need for efficient refrigeration solutions. Supermarkets, grocery stores, and food processing facilities rely heavily on these systems to store perishable products, maintain their quality, and extend their shelf life. The growth of e-commerce and online grocery delivery services has also driven the adoption of commercial refrigeration systems to meet the requirements of cold chain logistics.

2. Technological Advancements

Technological innovations in the commercial refrigeration sector have led to the development of energy-efficient and environmentally friendly systems. New refrigeration units with advanced features such as digital temperature control, smart monitoring systems, and energy-efficient compressors have gained significant traction in the market. The adoption of natural refrigerants such as ammonia, CO2, and hydrocarbons, which have low global warming potential (GWP), is another major trend, in line with global efforts to reduce greenhouse gas emissions and meet environmental standards.

3. Stringent Food Safety Regulations

Regulatory bodies across the globe have introduced stringent food safety standards to ensure the quality and safety of food products. These regulations require businesses to maintain proper refrigeration and storage practices to prevent contamination and spoilage. As a result, companies in the foodservice, retail, and hospitality industries are increasingly investing in commercial refrigeration systems that comply with these regulations, further driving market growth.

4. Growth of the Hospitality Industry

The global hospitality industry, encompassing hotels, restaurants, and cafes, has experienced steady growth due to increasing tourism and consumer spending on dining out. These establishments require reliable refrigeration systems to store food and beverages safely. The trend of cloud kitchens and ghost kitchens, which are food delivery-only operations, has also contributed to the demand for commercial refrigeration systems to maintain operational efficiency.

Challenges Facing the Market

Despite the positive growth trajectory, the commercial refrigeration market faces certain challenges. The high initial investment required for purchasing and installing advanced refrigeration systems is a significant barrier for small and medium-sized enterprises (SMEs). Additionally, the rising cost of energy and the need for regular maintenance and repairs add to the overall operational expenses.

Moreover, environmental concerns regarding the use of refrigerants with high GWP have led to stricter regulations on traditional cooling technologies. Businesses are now required to phase out older systems and adopt more eco-friendly alternatives, which can be cost-prohibitive.

Future Outlook

The future of the commercial refrigeration system market looks promising, with continued growth anticipated over the next decade. The increasing focus on energy efficiency and sustainability will drive the development of innovative refrigeration solutions. Companies are expected to invest in research and development to create systems that not only reduce energy consumption but also comply with environmental regulations.

Moreover, the growing trend of smart and connected refrigeration systems, which enable real-time monitoring and predictive maintenance, will further revolutionize the industry. As businesses seek to enhance operational efficiency and reduce downtime, the adoption of these advanced technologies will become more prevalent.

Key Players:

Daikin

Johnson Controls

Carrier

Dover

Baltimore Aircoil Company

Blue Star Limited

De Rigo Refrigeration

Fogel

Hussmann

Imbera

Segmentation:

Based on Product Type

Refrigerator & Freezer

Transportation Refrigeration

Refrigerated Display Cases

Beverage Refrigeration

Ice Cream Merchandiser

Refrigerated Vending Machine

Based on Refrigerant Type

Fluorocarbons

Hydrocarbons

Inorganics

Based on Application

Hotels & Restaurants

Supermarkets & Hypermarkets

Convenience

Based on Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/commercial-refrigeration-system-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Examining the Competitive Landscape of Australia Ammonia Market

Ammonia has wide industrial applications including use as a fertilizer in agriculture. As the raw material for the production of nitrogen fertilizers like urea and DAP, ammonia provides nitrogen which is an essential nutrient for plants. Australia has a well-established agricultural industry and is one of the world's largest exporters of wheat, barley and wool. The demand for fertilizers is increasing steadily with the need to boost agricultural yields to meet the rising global food demand.

The global Australia Ammonia Market is estimated to be valued at US$ 934.85 million in 2023 and is expected to exhibit a CAGR of 6.4% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity

Opportunities in agriculture production: The rising population has increased pressures on the agricultural sector to produce more food while efficient utilization of resources like land and water. Ammonia based fertilizers help increase the productivity of farmlands thus supporting growth in agriculture. The Australia Ammonia Market is anticipated to benefit from government initiatives and investments towards boosting agricultural output through sustainable means like fertilizer usage. This presents lucrative opportunities for ammonia producers and distributors to cater to the rising demand from farmers.

Porter's Analysis

Threat of new entrants: The threat of new entrants in the Australia ammonia market is moderate. Significant capital investments are required to build ammonia production facilities acting as a barrier. However, growing demand and high profit margins attract new players.

Bargaining power of buyers: The bargaining power of buyers is high due to the fragmented nature of buyers and existence of many domestic and global suppliers. Buyers can negotiate on price and quality standards.

Bargaining power of suppliers: The bargaining power of suppliers is moderate. Supply is dependent on few raw material suppliers and fluctuations in their prices can impact overall production cost. However, long term contracts balance their influence.

Threat of new substitutes: The threat of new substitutes is low as ammonia has few substitutes that offer similar economic and productive benefits in agricultural and industrial applications.

Competitive rivalry: The competition is high among the existing players to increase market share. Players compete on pricing, product differentiation, reliability of supply and customer service.

SWOT Analysis

Strengths: Large domestic market with increasing food production and industrialization. Presence of major fertilizer producers with established infrastructure and distribution network.

Weaknesses: High dependency on imports for raw materials increases operational costs. Stringent environmental regulations raise compliance costs.

Opportunities: Growing consumption in applications such as refrigerants, cleaning products, plastics offers new avenues. Investments in renewable energy projects will boost fertilizer demand.

Threats: Volatility in natural gas prices is a major threat. Supply constraints can adversely impact buyers. Stringent safety norms during production and transport poses challenges.

Key Takeaways

The Australia ammonia market size reached US$ 934.85 million in 2024 and is forecast to grow at a CAGR of 6.4% during 2023-2030.

Key players operating in the Australia ammonia market are Incitec Pivot Limited, Yara International ASA, Orica Limited, and Wesfarmers Chemicals, Energy & Fertilisers. Incitec Pivot Limited is the leading producer with integrated operations and supply chain network across the key farming regions. Yara International offers comprehensive product portfolio and technical expertise.

Regional analysis suggests southern region will continue to dominate the ammonia consumption driven by high agricultural productivity. Queensland is emerging as a high growth market backed by government investments promoting sustainable agriculture and expansion of mining industry. Consumption in western region is also rising on account of increasing food exports and mineral mining activities.

0 notes

Text

Natural & Organic Henna: Best Mehendi Products

Introduction

Natural & Organic Henna: Best Mehendi Products are the way to go They offer rich, vibrant colors and are gentle on your skin. Whether you’re an artist creating intricate patterns or someone who loves a touch of henna, these top-quality options give you beautiful results and peace of mind.

1. Why Choose Natural & Organic Henna?

When it comes to henna, choosing natural and organic is a smart move for both your skin and your designs.

Harmful Effects of Chemical-Based Henna: Many henna products on the market use synthetic dyes and preservatives, which can cause skin irritations, rashes, or even allergic reactions. These chemicals might give you a quick color, but they often come with unpleasant side effects.

Benefits of Organic Mehendi: Organic mehendi, on the other hand, is made from pure henna leaves and natural ingredients. It’s free from synthetic additives, making it much gentler on your skin. With organic henna, you get beautiful, vibrant designs without worrying about harmful chemicals.

2. Benefits of Using Organic Mehendi for Hair

Nourishment and Conditioning: Natural mehendi (henna) isn’t just for decorating your skin — it’s also a fantastic treat for your hair! Unlike chemical dyes that can strip your hair of its natural oils, natural mehendi nourishes and conditions your locks. It’s packed with natural goodness that strengthens your hair and makes it healthier, all without any harsh chemicals.

Why Organic Henna Is Great for Hair Coloring:

Strengthens Hair Follicles: Organic henna boosts your hair from the roots, helping reduce breakage and making your hair stronger overall. It’s like a mini workout for your hair follicles!

Adds Shine: Forget dull, lifeless hair. Organic henna gives your hair a gorgeous, natural shine, making it look vibrant and glossy.

Promotes Hair Growth: Applying henna can help stimulate your scalp and promote healthy hair growth. It keeps your scalp nourished and balanced, which is key for growing strong, healthy hair.

Tips for Applying Natural Henna:

Mix It Up: Create a smooth paste by mixing henna powder with water. For extra conditioning, try adding a bit of yogurt or lemon juice.

Get to Applying: Apply the paste evenly to clean, damp hair. Make sure you cover every strand from root to tip. Don’t forget to wear gloves to keep your hands stain-free!

Let It Sit: Leave the henna on your hair for at least 1–2 hours. If you’re looking for a deeper color, you can keep it on a bit longer. Just check on it now and then.

Rinse Well: Rinse out the henna with lukewarm water until it runs clear. Avoid shampooing right away; let the color settle for a day or two before washing with shampoo.

3. Best Organic Henna Products for Skin & Hair

Best Organic Henna Product: Amina Natural Henna Powder

Ingredients: 100% pure henna leaves, no additives or chemicals.

Benefits: Provides a deep, rich color with excellent coverage.

User Feedback: Users appreciate its smooth application and natural-looking color. It’s praised for being gentle on the scalp and delivering consistent, long-lasting results.

Amina Natural Henna Powder is a top choice for those seeking a pure, vibrant, and effective henna product.

Read this :- Best Natural Mehendi Products

4. Why Amina Henna is the Top Choice for Natural Henna

Amina Henna is a brand that takes pride in delivering 100% natural henna. Their products are completely free from harmful chemicals like PPD (para-phenylenediamine), ammonia, or any artificial dyes that can irritate the skin or damage your hair. Instead, Amina focuses on using pure henna leaves, which gives you rich, vibrant color while also caring for your hair.

Safe and Effective Coloring

Amina Henna offers an authentic henna experience, perfect for those who want a natural and safe alternative to chemical-laden products. The brand’s henna not only provides a deep and beautiful shade but also conditions the hair, leaving it soft and shiny. If you’re looking to give your hair a natural boost without exposing it to harsh chemicals, Amina is your go-to choice.

Pure Organic Ingredients

One of the biggest reasons why Amina Henna stands out is its commitment to purity. The henna is sourced from high-quality henna plants and processed without any additives. This ensures that what you’re getting is nothing but the best of nature’s ingredients, making it one of the most trusted options for organic mehendi products.

5.Why You Should Choose Amina Henna

When buying henna, especially for your skin or hair, it’s important to choose a brand that prioritizes both quality and safety. Here’s why Amina Henna should be at the top of your list:

No harmful chemicals: Amina Henna is free from synthetic additives that can cause allergic reactions or skin problems. It’s a natural, safe option for people who want pure henna without the risk of irritation.

Vibrant color and shine: The rich color Amina Henna provides lasts longer and looks more vibrant than other chemical-based products. Plus, its natural conditioning properties leave your hair looking healthier and more radiant.

Trusted brand: With Amina Henna, you know you’re getting a product that’s been carefully sourced and tested. It’s a brand that stands for quality and consistency in the world of natural henna.

The Importance of Choosing a Reputable Henna Brand

When it comes to henna, quality matters. Many cheap or low-quality henna products on the market are mixed with harmful chemicals that can cause damage in the long run. Amina Henna avoids these pitfalls by sticking to a pure, all-natural formula. By choosing a trusted brand like Amina, you can enjoy beautiful color and designs without worrying about skin irritations or hair damage.

6. How to Identify Genuine Organic Henna

When buying henna, it’s important to make sure it’s natural and safe. Here’s how to spot authentic organic mehendi:

Check the Label: Look for “100% pure henna” and avoid chemicals like PPD or ammonia.

Certifications: Choose products with organic certifications like USDA or India Organic.

Simple Ingredients: The best henna will only list Lawsonia Inermis. Avoid chemical additives.

Beware of Misleading Words: Words like “herbal” or “instant henna” may hide harmful ingredients.

Look at Color & Smell: Real henna is green or olive and has an earthy smell.

Trusted Brands: Stick to reliable names like Amina Henna for quality products.

Avoid Cheap Prices: Super low prices may mean fake or chemical-filled henna.

Avoid “Instant” Henna: Organic henna takes time to develop color naturally.

Conclusion

Choosing natural and organic henna is a smart choice for your hair and skin because it’s safer and healthier than chemical-based products. Organic henna doesn’t contain harmful chemicals like PPD or ammonia, which can damage your hair or irritate your skin. Instead, it provides rich color and shine while also keeping your hair soft and healthy.

Organic mehendi is gentle on your skin, giving you beautiful color without any risk of allergic reactions. Trusted brands like Amina Henna offer pure, chemical-free henna, so you can be sure you’re getting a safe product.

You May like This:- The Best Organic Henna Mehendi Powder for Hair

FAQs

1. Is natural henna safe for sensitive skin?

Yes, natural henna is chemical-free and gentle on sensitive skin, but it’s always best to do a patch test.

2. Can organic henna be used on hair?

Yes, organic henna is great for hair, adding color, shine, and nourishment without harsh chemicals.

3. How long does organic henna last?

On skin, it lasts 1–3 weeks, and on hair, it lasts 4–6 weeks before fading naturally.

4. What are the benefits of using organic henna?

Organic henna provides vibrant color while conditioning and strengthening your hair.

5. Where can I purchase natural and organic mehendi products?

You can buy high-quality, chemical-free mehendi products at buyamina.com.

👉 Shop Now

0 notes

Text

0 notes

Text

Japan's Energy Transition: Navigating Renewables and Ethical Supply Chains

As Japan revisits its energy plan, there is a growing demand for an increased focus on renewable sources like wind and solar power to enhance the country's clean energy transition. Currently, Japan's energy policy has been deemed "insufficient" by Climate Action Tracker regarding necessary emissions reductions to limit global warming to 1.5 degrees Celsius.

Mika Ohbayashi, director of the Renewable Energy Institute, emphasizes the need for greater incentives for solar installations on buildings and the expansion of commercial-scale solar projects. She also advocates for increasing other renewable sources, including onshore and offshore wind, hydropower, bioenergy, and geothermal energy.

Environmental organizations like REI, Kiko Network, and Climate Integrate argue that prioritizing wind and solar, the most cost-effective renewable options, is crucial. They criticize Japan's current emphasis on hydrogen and liquefied natural gas, as well as experimental technologies like ammonia co-firing with coal and carbon capture and storage (CCS).

However, the challenge lies in China's dominance over key materials and technologies for the energy transition, such as lithium and cobalt, vital for batteries and solar panels. While these materials are economically advantageous, they often come with ethical concerns, including forced labor in supply chains.

Seaver Wang from the Breakthrough Institute questions the true cost of these technologies, highlighting reports linking solar supply chains to forced labor in Xinjiang, China. He argues against supporting suppliers operating in regions with human rights abuses.

Japan's plans to co-fire ammonia with coal face criticism for not being a viable clean energy solution. Transitioning to more ethical supply chains would require significant investment and time—luxuries that the planet cannot afford amid escalating climate crises.

Collaborating with the U.S. and Europe to develop alternative technologies, such as floating offshore wind, presents another route, though it necessitates substantial policy changes. Walter James, an energy consultant, notes that while Japan acknowledges its reliance on China, it has yet to take decisive action to mitigate this dependence.

Instead, Japan seeks to bolster its domestic industry through CCS, hydrogen, and emerging technologies like perovskite solar cells and floating offshore wind.

China's state-supported industrial policies have enabled it to dominate the solar and battery markets, pushing Japan and Europe out of leadership roles. This shift raises concerns about Japan's economic security and energy transition.

Despite the challenges, climate advocacy groups recognize China's rapid advancements in renewables, suggesting that Japan could benefit from China's surplus solar capacity to reduce fossil fuel reliance. However, much of Japan's recent solar growth has been dependent on Chinese imports.

Wang asserts that maintaining domestic control of clean energy supply chains is vital for future economic development. He questions why countries like Japan would willingly surrender leadership in transformative technologies.

The human rights implications of China's production practices, particularly concerning forced labor in Xinjiang, loom large. Reports detail the oppressive conditions faced by Uyghurs in labor camps, raising ethical concerns about the supply chains for solar panels and batteries.

Japan has focused less on competing directly with China in solar and batteries and more on promoting alternative technologies through initiatives like the Asia Zero Emission Community. This approach contrasts with the U.S., which has introduced incentives to boost domestic manufacturing of renewables while imposing tariffs on Chinese imports due to human rights violations.

Despite the pressure to take a firmer stance against China, Japan's vulnerability to potential retaliation has led to a cautious approach. Current voluntary supply chain due diligence measures may need strengthening to prevent human rights abuses.

While Japan's leadership in rare earth minerals is gaining attention, the focus remains on diversifying supply chains. Opportunities lie in offshore wind technology and innovative solar solutions, positioning Japan to reduce its dependence on China and contribute to a more sustainable energy future.

#Japan#renewable energy#wind power#solar power#energy transition#supply chains#human rights#China#climate action

0 notes

Text

Dry Ice Market Analysis: Global Industry Trends and Forecast (2023-2032)

The Dry Ice Market is projected to grow from USD 2087.6 million in 2024 to an estimated USD 3739.84 million by 2032, with a compound annual growth rate (CAGR) of 7.56% from 2024 to 2032.

Dry ice, the solid form of carbon dioxide (CO2), plays a critical role across various industries due to its unique properties, particularly its ability to sublimate directly from a solid to a gas at -78.5°C (-109.3°F) without passing through a liquid phase. This characteristic makes dry ice an incredibly effective cooling agent, widely used in the food and beverage industry for transportation and storage, where maintaining low temperatures is essential for preserving perishable goods. It is also extensively used in the medical and pharmaceutical sectors for the safe shipment of temperature-sensitive materials such as vaccines, biological samples, and medical supplies, especially in situations where refrigeration is not feasible or reliable.

Beyond its role as a cooling agent, dry ice is employed in industrial cleaning through a process known as dry ice blasting. This method is valued for its effectiveness and environmental benefits, as it cleans surfaces by sublimating on impact, leaving no residue and reducing the need for harsh chemicals or water. This application is particularly beneficial in industries such as manufacturing, automotive, and aerospace, where delicate equipment or surfaces require a non-abrasive yet thorough cleaning process.

The production and supply chain of dry ice are also influenced by fluctuations in the availability of raw CO2, which is a byproduct of industrial processes such as ammonia production and ethanol fermentation. Periods of low CO2 availability, often due to disruptions in these industries, can lead to shortages of dry ice, impacting industries that rely on it for critical operations. This was notably evident during the COVID-19 pandemic, when the demand for dry ice surged to support the distribution of vaccines requiring ultra-cold storage, highlighting the vulnerability of its supply chain.

Dry ice, the solid form of carbon dioxide (CO2), has a wide range of applications across various industries due to its unique properties, particularly its ability to sublimate directly from a solid to a gas without passing through a liquid state. Here are some of the primary uses of dry ice:

1. Food Preservation and Transportation

Refrigeration During Shipping: Dry ice is commonly used to keep perishable foods like meat, seafood, and dairy products frozen during transportation. Its extremely low temperature (-78.5°C or -109.3°F) makes it more effective than traditional ice, ensuring that goods remain frozen for extended periods without the risk of melting.

Storage of Frozen Foods: In retail and commercial settings, dry ice is used to maintain the cold chain for frozen foods, especially when mechanical refrigeration is unavailable or during power outages.

Flash Freezing: Dry ice is used to flash-freeze food items, rapidly reducing their temperature to prevent the formation of large ice crystals, which can degrade the texture and quality of the food.

2. Medical and Pharmaceutical Applications

Transport of Biological Samples: Dry ice is essential for shipping temperature-sensitive biological samples, including blood, tissues, and vaccines. It ensures that these samples remain frozen, preserving their integrity until they reach their destination.

Cold Storage of Vaccines: Certain vaccines, such as those requiring ultra-cold storage (e.g., mRNA COVID-19 vaccines), are stored and transported using dry ice to maintain the necessary low temperatures.

3. Industrial Cleaning (Dry Ice Blasting)

Surface Cleaning: Dry ice is used in a process known as dry ice blasting, where small pellets of dry ice are propelled at high speed to clean surfaces. This method is effective in removing contaminants like grease, paint, and rust without damaging the underlying material or leaving any residue, as the dry ice sublimates on impact.

Environmental Benefits: Dry ice blasting is preferred in industries where the use of chemicals or water-based cleaning methods could cause contamination or damage, such as in food processing, automotive, aerospace, and manufacturing.

4. Special Effects and Entertainment

Fog Effects: Dry ice is widely used to create dense, low-lying fog effects for theater productions, concerts, movies, and haunted attractions. When combined with warm water, dry ice produces a thick, white fog that stays close to the ground, creating a dramatic visual effect without leaving any moisture behind.

Smoke and Mist in Photography: Photographers and filmmakers use dry ice to create eerie or mysterious atmospheres in still and video shoots, adding depth and interest to their work.

5. Pest Control and Agriculture

Fumigation: Dry ice is sometimes used in pest control, particularly for fumigating enclosed spaces like grain silos, as it releases CO2 gas that can suffocate insects and pests without the need for toxic chemicals.

Frost Protection: In agriculture, dry ice can be used to create a controlled frost effect for research or to protect certain crops from late-season frost by generating a cold barrier that helps prevent frost damage.

6. Laboratory and Scientific Research

Cryogenic Applications: Dry ice is used in laboratories to create cryogenic conditions, such as freezing cells or samples quickly to preserve their structure. It is also used to conduct experiments that require very low temperatures.

Controlled Chemical Reactions: Dry ice is used in various chemical processes where a low temperature is needed to control reaction rates or stabilize reactive compounds.

7. Metalworking and Manufacturing

Shrink Fitting: In metalworking, dry ice is used in a process called shrink fitting, where parts are cooled with dry ice to contract them for easy assembly into tighter fits. When the metal part warms up and expands, it creates a secure, precision fit.

Welding and Grinding: Dry ice is sometimes used to cool materials during welding or grinding processes to prevent overheating and to maintain the integrity of the metal.

8. Carbonation in Beverages

Carbonated Drinks: Dry ice is occasionally used in the production of carbonated beverages to add carbonation or to quickly chill the drinks during the bottling process.

9. Emergency Cooling

Cooling in Disasters: During power outages or natural disasters, dry ice is used to keep essential items like medications, food, and other perishables cold when refrigeration is unavailable.

Emergency Cooling of Electronics: Dry ice can be used to cool overheated electronics or machinery temporarily in situations where traditional cooling methods are not feasible.

10. Culinary Uses

Gastronomy: In molecular gastronomy, dry ice is used to create dramatic presentations, such as producing smoke effects in dishes or rapidly freezing ingredients. Chefs use dry ice to create unique dining experiences, like carbonating fruits or making instant ice creams.

11. Airline Catering

In-Flight Food Storage: Dry ice is used in airline catering to keep meals and beverages cold during flights, especially on long-haul journeys where maintaining food safety is crucial.

Key Player Analysis:

Air Liquide

ASCO CARBON DIOXIDE LTD. (U.S.)

Central McGowan (U.S.)

Chillistick Ltd. (U.K.)

Continental Carbonic Products, Inc.

CryoCarb (U.S.)

Dry Ice UK Limited

Linde plc

NEXAIR (U.S.)

Polar Ice Ltd. (Ireland)

Praxair Technology, Inc. (U.S.)

Ice Corporation

SICGIL India Limited

The Iceman (Canada)

Tripti Dry Ice Co.

More About Report- https://www.credenceresearch.com/report/dry-ice-market

The dry ice market presents several growth opportunities driven by advancements in technology, rising demand in various industries, and evolving consumer needs. Here are some key growth opportunities in the dry ice market:

1. Rising Demand in the Food and Beverage Industry

Cold Chain Logistics: As the global food and beverage industry expands, particularly with the growth of online grocery shopping and home delivery services, the need for efficient cold chain logistics is increasing. Dry ice is essential for transporting perishable goods like seafood, meat, and frozen desserts, ensuring they remain frozen during transit. The rise in demand for frozen and refrigerated foods, coupled with the expansion of e-commerce in the food sector, offers significant growth potential for the dry ice market.

Craft and Specialty Beverages: The growing popularity of craft and specialty beverages, such as artisanal ice creams and cold-brew coffees, also drives demand for dry ice in small-scale and specialty food production.

2. Expansion in the Pharmaceutical and Medical Sector

Vaccine Distribution: The COVID-19 pandemic highlighted the critical role of dry ice in the pharmaceutical supply chain, particularly for the distribution of vaccines that require ultra-cold storage. This has led to a sustained demand for dry ice in the medical sector, not only for vaccines but also for other temperature-sensitive pharmaceuticals and biological samples. As global vaccination efforts continue and new vaccines and biologics are developed, the need for reliable cold storage and transportation solutions like dry ice will remain high.

Biological Sample Transport: The ongoing growth of biotechnology and precision medicine, which often involve the transport of temperature-sensitive biological samples, further drives demand for dry ice in the healthcare industry.

3. Increased Adoption of Dry Ice Blasting

Industrial Cleaning: Dry ice blasting is gaining traction as a preferred industrial cleaning method due to its effectiveness, environmental benefits, and ability to clean without damaging surfaces. As industries such as manufacturing, automotive, aerospace, and food processing seek more sustainable and efficient cleaning solutions, the demand for dry ice blasting services is expected to grow. This presents opportunities for dry ice manufacturers to supply the growing industrial cleaning sector with high-quality dry ice pellets.

Environmental Regulations: Stricter environmental regulations are encouraging industries to adopt cleaning methods that reduce waste and chemical use, further boosting the adoption of dry ice blasting.

4. Growth in the Entertainment and Special Effects Industry

Event Production: The entertainment industry, including theater, film, concerts, and live events, continues to grow, with increasing demand for special effects. Dry ice is a popular choice for creating dramatic fog effects, especially in productions requiring a low-lying, dense fog. As the events and entertainment industry recovers and expands post-pandemic, the use of dry ice in special effects is expected to increase.

Experiential Marketing: Brands are increasingly using experiential marketing, including visually impactful elements like dry ice fog effects, to engage consumers. This trend provides additional growth opportunities in the marketing and advertising sectors.

5. Technological Advancements and Innovation

Sustainable Production: As industries focus more on sustainability, there is growing interest in producing dry ice using CO2 captured directly from the atmosphere or from industrial processes with a lower carbon footprint. Innovations in CO2 capture and recycling technologies can lead to more environmentally friendly dry ice production methods, appealing to eco-conscious businesses and consumers.

Advanced Dry Ice Machines: The development of more efficient and versatile dry ice production machines, capable of producing dry ice in various forms (blocks, pellets, slices) quickly and cost-effectively, presents opportunities for manufacturers to serve a broader range of industries with tailored solutions.

6. Expansion into Emerging Markets

Growth in Emerging Economies: Emerging markets in Asia, Latin America, and Africa are witnessing rapid industrialization, urbanization, and growth in sectors like food processing, pharmaceuticals, and entertainment. As these economies develop, the demand for dry ice in logistics, industrial cleaning, and special effects is likely to increase, providing significant growth opportunities for dry ice producers.

Healthcare Infrastructure Development: As emerging economies invest in healthcare infrastructure, the need for reliable cold storage solutions for vaccines, medications, and biological samples will drive demand for dry ice.

7. Environmental and Waste Management Applications

Dry Ice Blasting in Environmental Remediation: Dry ice blasting is increasingly being used in environmental remediation projects, such as the removal of asbestos, mold, and lead paint. Its ability to clean surfaces without creating secondary waste or using harmful chemicals makes it an attractive option for environmentally focused projects.

Waste Reduction Initiatives: As industries and municipalities focus on reducing waste and improving sustainability, dry ice can be used in various waste management applications, such as decontaminating equipment or cleaning sensitive machinery without generating additional waste.

8. Expanding Use in Laboratories and Research

Cryogenic Applications: The ongoing expansion of research in fields such as biotechnology, pharmaceuticals, and materials science drives demand for cryogenic applications where dry ice is used to maintain ultra-cold temperatures. This includes preserving samples, conducting low-temperature experiments, and stabilizing materials during processing.

9. Innovations in Consumer Products

Home Delivery Services: The growth of meal kit delivery services and online grocery shopping has led to an increase in the use of dry ice for home deliveries. As these services expand, there is a corresponding increase in the demand for dry ice to keep perishable products cold during transit.

DIY and Consumer Markets: The availability of dry ice for consumer use in DIY projects, science experiments, and home entertainment (e.g., creating fog effects for parties) presents an additional growth avenue. Retail outlets and online platforms offering small quantities of dry ice for personal use are becoming more common.

10. Partnerships and Collaborations

Cross-Industry Collaborations: Dry ice manufacturers can explore partnerships with companies in related industries, such as logistics, healthcare, and environmental services, to develop integrated solutions that enhance the efficiency and sustainability of cold chain logistics, industrial cleaning, and environmental management.

Segmentation:

By Type:

Pellets,

Blocks,

Other forms of dry ice.

By Application:

Food and beverage,

Healthcare,

Industrial cleaning,

Other sectors.

Browse the full report – https://www.credenceresearch.com/report/dry-ice-market

Browse Our Blog: https://www.linkedin.com/pulse/dry-ice-market-overview-growth-factors-future-qfodf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Australia Ammonia Market Dynamics: A Comprehensive Overview

Ammonia is commonly used as a nitrogen fertilizer in agriculture to enhance crop productivity. It is also used in the production of various chemicals and other nitrogen compounds used in refrigeration systems, plastics, fibers, explosives, and other industries. The agricultural sector dominates the demand for ammonia in Australia as it is a major raw material used in the production of urea and other nitrogen fertilizers. With over 60% of Australia's land area being used for agricultural purposes, the demand for ammonia from the farming industry is continually growing.

The global Australia Ammonia Market is estimated to be valued at US$ 934.85 Million in 2023 and is expected to exhibit a CAGR of 6.40% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

One of the key drivers for the growth of the Australia ammonia market is the rising agriculture industry. As mentioned earlier, around 60% of Australia's land is used for agricultural activities with farming being a major economic driver. With the population increasing, the demand for food grains and other crops is also rising. This has pushed farmers to increase crop yield through the use of nitrogen fertilizers like ammonia and urea. The growing importance of food security is also encouraging greater fertilizer use. Moreover, favorable government initiatives and subsidies for the agriculture sector promote higher fertilizer consumption. All these factors contribute to the increased demand for ammonia in Australia over the forecast period.

SWOT Analysis

Strength: Incitec Pivot Limited, Yara International ASA, Orica Limited are among the leading players in Australia with extensive production facilities and distribution network in the country. They have economies of scale and can leverage their expertise to produce ammonia at competitive costs. Australia has abundant natural gas reserves, a key raw material for ammonia production. This ensures secure feedstock supply and price stability. The agriculture industry is a major consumer of ammonia as fertilizer. Growing demand from this sector is expected to drive ammonia consumption.

Weakness: Ammonia is corrosive in nature and its production and transportation require special equipment and safety measures. This increases operating costs. Strict environmental regulations regarding emissions from fertilizer plants increase compliance costs. Fluctuations in natural gas prices can impact input costs and undermine profit margins of producers.

Opportunity: Rapid growth in population and rising food demand in Australia is boosting fertilizer usage. This will create increased demand for ammonia. Government support for agriculture through subsidies on fertilizers can spur consumption. Emerging non-fertilizer uses such as construction chemicals offer new opportunities. Import restrictions may arise which can benefit domestic manufacturers.

Threats: Stiff competition from cheaper imports can threat local producers. Trade disputes or global economic slowdown can negatively impact export opportunities. Stringent health, safety and environmental standards increase regulatory burden. Substitution threat from alternative fertilizers poses competition risks.

Key Takeaways

The Australian ammonia market is expected to witness high growth over the forecast period supported by robust demand from the agriculture sector. Australia is highly dependent on imports to meet domestic ammonia demand indicating prospects for local manufacturers. The global Australia Ammonia Market is estimated to be valued at US$ 934.85 Million in 2023 and is expected to exhibit a CAGR of 6.40% over the forecast period 2023-2030.

The agriculture industry is the major end-user of ammonia in Australia accounting for over 80% of total consumption. Queensland and New South Wales are the fastest growing regions driven by their large agriculture and mining industries. Major plants owned by Incitec Pivot and Orica are located in Queensland capitalizing on available gas reserves.

Key players operating in the Australian ammonia market are Incitec Pivot Limited, Yara International ASA, and Orica Limited. Incitec Pivot Limited is the largest producer with facilities in Queensland and Victoria. It is expanding capacity to leverage growth opportunities. Yara International ASA operates an ammonia import terminal at Port Kembla to serve the needs of industrial customers.

#Australia Ammonia Market Share#Australia Ammonia Market Growth#Australia Ammonia Market Demand#Australia Ammonia Market Trend#Australia Ammonia Market Analysis

0 notes