#Automated Barcode Scanning

Explore tagged Tumblr posts

Text

How Automated Barcode Scanning is Revolutionizing Inventory Management.

To meet these demands, automated barcode scanning technology has emerged as a revolutionary tool, transforming how businesses manage their inventory. This blog explores the impact of automated barcode scanning on inventory management, its benefits, and its implications for the future of logistics.

The Evolution of Barcode Scanning

Barcode scanning has been a staple in inventory management for decades, providing a simple and effective way to track items throughout the supply chain. Traditionally, handheld scanners were used by warehouse workers to scan barcodes manually. While effective, this method was labor-intensive and prone to human error.

Automated barcode scanning represents the next evolution in this technology. It leverages advancements in artificial intelligence (AI), machine learning, and robotics to automate the scanning process. Automated systems can scan barcodes on items as they move through conveyor belts or storage areas, significantly speeding up the inventory process.

How Automated Barcode Scanning Works

Automated barcode scanning systems use a combination of hardware and software to scan and process barcodes. Here's a basic overview of how these systems work:

Barcode Reading: Automated scanners use high-speed cameras and sensors to detect and read barcodes on items.

Data Processing: The scanned barcode data is processed in real-time by software algorithms. AI and machine learning technologies help in interpreting the data accurately.

Integration: The scanned data is integrated with the warehouse management system (WMS) or enterprise resource planning (ERP) system, providing real-time visibility of inventory levels.

Benefits of Automated Barcode Scanning

The adoption of automated barcode scanning technology offers several key benefits for businesses:

Improved Accuracy: Automated systems significantly reduce human errors associated with manual scanning, ensuring more accurate inventory records.

Increased Efficiency: By automating the scanning process, businesses can process inventory faster and more efficiently, reducing the time and labor required.

Real-time Visibility: Automated barcode scanning provides real-time visibility into inventory levels and locations, enabling better decision-making and inventory planning.

Cost Savings: Increased efficiency and accuracy lead to cost savings by minimizing inventory discrepancies and reducing labor costs.

Scalability: Automated systems are scalable and can handle large volumes of inventory, supporting business growth without significant additional investment. Use Cases of Automated Barcode Scanning

Automated barcode scanning is being adopted across various industries, including:

Retail: Streamlining inventory management in retail stores and warehouses.

Manufacturing: Improving material tracking and inventory control on production lines.

Logistics and Distribution: Enhancing order fulfillment and shipment accuracy in distribution centers.

Healthcare: Managing medical supplies and inventory in hospitals and clinics.

Challenges and Considerations

While automated barcode scanning offers numerous benefits, there are some challenges to consider:

Initial Investment: Implementing automated systems requires a significant upfront investment in technology and infrastructure.

Integration Complexity: Integrating automated systems with existing WMS or ERP systems can be complex and time-consuming.

Maintenance and Support: Automated systems require regular maintenance and technical support to ensure optimal performance.

Future Trends in Automated Barcode Scanning

Looking ahead, several trends are shaping the future of automated barcode scanning:

Advancements in AI and Machine Learning: Continued advancements will improve the accuracy and speed of barcode reading.

IoT Integration: Integration with Internet of Things (IoT) devices will enable more seamless tracking and monitoring of inventory.

Robotics: Robots equipped with barcode scanners will further automate the process of inventory management.

Cloud-based Solutions: Cloud-based barcode scanning solutions will provide greater flexibility and accessibility.

Conclusion

Automated barcode scanning is revolutionizing inventory management by enhancing accuracy, efficiency, and real-time visibility. Businesses that adopt this technology can improve their operational processes, reduce costs, and better serve their customers. While there are challenges to overcome, the benefits of automated barcode scanning far outweigh the initial investment. As technology continues to advance, the future of inventory management looks increasingly automated and efficient.

In summary, automated barcode scanning is not just a tool for today—it's a glimpse into the future of logistics and inventory management.

#Automated Barcode Scanning#Inventory Management With Scanner#Inventory Software And Scanner#Scanning System For Inventory#Warehouse Barcode Scanner

1 note

·

View note

Text

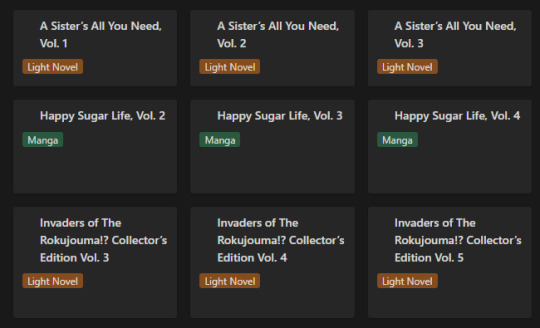

How I'm Tracking My Manga Reading Backlog

I'm bad at keeping up with reading sometimes. I'll read newer releases while still forgetting about some, want to re-read something even though I haven't started on another series, and leave droves of titles sitting on my shelves staring at me.

I got tired of that, and also tired of all these different tracking websites and apps that don't do what I want. So, with Notion and a few other tools, I've set out to make my own, and I like it! So I thought, hey, why not share how I'm doing it and see how other people keep track of their lists, so that's why I'm here. Enough rambling though, let me lead you through why I decided to make my own.

So, the number 1 challenge: Automation. In truth, it's far from perfect and is the price I pay for being lazy. But, I can automate a significant chunk of the adding process. I've yet to find a proper way to go from barcode scanning on my phone to my reading list, but I can go pretty easily from an amazon listing to the reading list. With it I grab: title, author, publisher, page count, and cover image.

So what do I use?

Well, it's a funky and interesting thing called 'Bardeen' that allows you to scrape webpages (among other things), collect and properly structure the desired information, and then feed it right into your Notion database. It's a little odd to try and figure out at first, but it's surprisingly intuitive in how it works! Once you have your template setup, you just head to the webpage (I've found Amazon the best option) and hit the button for the scraper you've built, and it puts it into Notion.

It saves an inordinate amount of time in populating fields by hand, and with the help of templates from Notion, means that the only fields left "empty" are the dated fields for tracking reading.

Thanks to Bardeen, the hardest (and really only) challenge is basically solved. Not "as" simple as a barcode, but still impressively close. Now, since the challenge is out of the way, how about some fun stuff?

Data visualization is incredibly fun for all sorts of people. Getting to see a breakdown of all the little pieces that make up your reading habits is very interesting. Sadly, Notion doesn't have the ability to build charts from your own databases, so you need a tool.

The one I ended up settling on was 'Grid.is', as it has a "direct" integration/embed with Notion.

Sure, it has its own "limitations", but they pose absolutely zero concern as to how I want to set up my own data visualization. You can have (as far as I know) an unlimited number of graphs/charts on a single page, and you can choose to embed that page as a single entity, or go along and embed them as independent links. Either way, the graphs are really great and there's a lot of customization and options in regards to them. Also, incredibly thankful for the fact that there's an AI assistant to create the charts for you. The way that Notion data's read in is horrendous, so the AI makes it infinitely easier than what it appears as at first.

And yes, all those little popups and hover behaviors are preserved in the embeds.

Well, I suppose rather than talking about the tertiary tools, I should talk about what I'm doing with Notion itself, no?

Alright, so, like all Notion pages it starts with a database. It's the central core to keeping track of data and you can't do without it. Of course, data is no good if you can't have it properly organized, so how do I organize it?

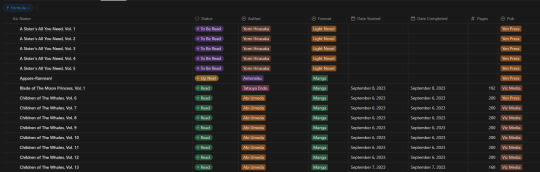

With tags, of course! I don't have a massive amount of tags in place for the database, but I am considering adding more in terms of genre and whatnot. Regardless, what I have for the entries currently is: Title, Reading Status (TBR, Reading, Read, etc.), Author, Format (manga or LN), Date Started, Date Completed, Pages, and Publisher.

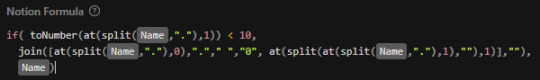

In addition to those "displayed" tags, I have two tertiary fields. The first is an image link so that entries can display an image in the appropriate view. The second, and a bit more of a pain, is a formula field used to create a proper "title" field so that Notion can sort effectively (they use lexicographic, so numbers end up sorted as letters instead). This is the poorly optimized Notion formula I used, as I don't have much experience with how they approach stuff like this. It just adds a leading zero to numbers less than 10 so that it can be properly sorted.

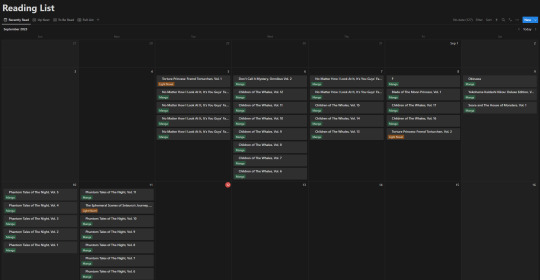

Of course this list view isn't my default view though, the calendar from the top of this post is. Most of the time though, I don't have it set to the monthly view, but rather weekly. Following up that view though, I've got my "up next" tab. This tab's meant to track all the titles/entries that I'm about to read. Things I'm planning to read today, tomorrow, or the day after. Sorta a three day sliding window to help me keep on top of the larger backlog and avoid being paralyzed by choice. It's also the only view that uses images currently.

Following that, I've got my "To Be Read" gallery. I wanted to use a kanban board but notion will only display each category as a single column, so I chose this view instead, which makes it much easier to get a better grasp of what's in the list. I've been considering adding images to this view, but I need to toy around with it some more. Either way, the point is to be able to take a wider look at what I've got left in my TBR and where I might go next.

So overall, I've ordered these views (though the list view I touch on "first" is actually the last of the views) in order from "most recent" to "least recent", if that makes any sense. Starting with where I've finished, moving to where I go next, what I have left, and then a grouping of everything for just in case.

It's certainly far from a perfect execution on a reading list/catalogue, but I think personally speaking that it checks off basically all of the boxes I required it to, and it gives me all the freedom that I could ever want - even if it means I have to put in a bit of elbow grease to make things work.

#anime and manga#manga#manga reader#manga list#reading list#reading backlog#light novel#notion#notion template

11 notes

·

View notes

Text

5 ways to make your fulfillment center run more efficiently

Running a fulfillment center can be extremely challenging in today’s complex and challenging business environment. As an online seller, it's important to ensure that your fulfillment center runs efficiently to meet the demands of your customers. In this blog, we will explore the best five ways to make your fulfillment center run more efficiently.

Optimize your inventory management system

Managing your inventory is one of the most important aspects of running a fulfillment center efficiently. An effective inventory management system can help you track your stock levels and ensure that you have enough products on hand to meet customer demand. Use inventory management software that integrates with your order management system to help you track inventory in real time and avoid stockouts. Utilize demand forecasting to make sure you have enough inventory to fulfill orders during peak demand periods.

Implement efficient picking and packing processes

Picking and packing are the two most critical processes in the order fulfillment cycle. Optimize your picking and packing processes by grouping orders by proximity, picking in batches, and using barcode scanning to avoid errors. Use automation and packing materials that are appropriate for the product being shipped to ensure that items arrive in good condition. You can also implement a quality control process to ensure accuracy and minimize errors.

Invest in automation

Automation can help you improve efficiency and reduce labor costs. Consider investing in automation tools such as conveyor belts, sortation systems, and robots to streamline your fulfillment process. Automation can also help you increase throughput and accuracy, reduce manual labor, and minimize errors. On the other hand, instead of installing all these tools, you can simply partner with NimbusPost, a tech-enabled shipping aggregator that already has 540 fully-equipped facilities and several types of warehouses to provide easy order fulfillment.

Streamline your shipping process

Shipping is a crucial aspect of fulfillment. To make your shipping process more efficient, use shipping software that integrates with your order management system. This can help you automate shipping label generation and reduce manual data entry. Choose a reliable courier service in India or a global shipping partner to ensure timely delivery and track your shipments in real time.

Train and empower your staff

Your employees are the backbone of your fulfillment center. To improve efficiency, provide regular training to ensure that they understand their roles and responsibilities. Empower your staff by giving them the tools and resources they need to succeed, such as mobile devices for picking and packing or access to real-time inventory information. Encourage open communication and solicit feedback to identify opportunities for improvement.

Conclusion

There are several ways to make your fulfillment center run more efficiently. You can follow the mentioned ways to improve your fulfillment center’s efficiency or just hire a solid shipping aggregator to get everything handled without stress at the best rates

2 notes

·

View notes

Text

Inventory Tracking Challenges Faced by Dubai Businesses and How Software Can Help

In Dubai’s fast-paced and competitive business environment, effective inventory tracking is essential for success. Whether you're in retail, wholesale, manufacturing, or distribution, poor inventory management can lead to stockouts, overstocking, lost sales, and financial inefficiencies. Despite the advanced infrastructure in Dubai, many businesses still struggle with inventory tracking challenges that impact their bottom line.

Let’s explore the key inventory tracking issues faced by businesses in Dubai and how modern inventory management software can provide much-needed solutions.

Common Inventory Tracking Challenges in Dubai

1. Manual Inventory Processes

Many small and medium-sized enterprises (SMEs) in Dubai still rely on spreadsheets or manual logs. These methods are prone to human error and often lead to inaccurate stock records, duplication, or missing items.

2. Lack of Real-Time Data

Without real-time inventory data, businesses can’t make informed decisions. This leads to delays in order processing, stock mismatches, and poor customer experiences.

3. Multi-Location Stock Management

Companies with multiple warehouses or retail outlets across Dubai often struggle to maintain consistent stock levels. Transferring goods between locations becomes a logistical nightmare without centralized tracking.

4. Limited Visibility into Stock Movements

Businesses find it hard to trace items from suppliers to shelves or from warehouses to customers. This lack of transparency affects accountability and creates difficulties in managing returns, shrinkage, or theft.

5. Non-Integrated Systems

Disjointed systems for sales, purchasing, and inventory lead to data silos. Without integration, it becomes difficult to track inventory levels accurately or synchronize them with customer demand.

6. Regulatory and VAT Compliance

Since the introduction of VAT in the UAE, businesses must maintain precise records of inventory movements for tax reporting. Non-compliance can result in penalties or legal issues.

How Inventory Management Software Solves These Problems

1. Automation and Accuracy

Inventory management software automates stock tracking, reducing human error and saving time. Automated systems ensure real-time updates, which help businesses maintain accurate records and make quicker decisions.

2. Real-Time Inventory Visibility

With cloud-based solutions, Dubai businesses gain instant access to inventory levels across all locations. This enables better planning, faster order fulfillment, and improved customer satisfaction.

3. Centralized Multi-Location Management

Modern software allows centralized control of inventory across multiple warehouses and branches. It helps monitor transfers, manage reorders, and maintain optimal stock levels without duplication.

4. Barcode and RFID Integration

Many inventory solutions support barcode scanning and RFID tagging, providing full traceability. This boosts transparency and minimizes loss due to errors, theft, or misplacement.

5. Seamless Integration with Other Systems

Advanced inventory software integrates with accounting, POS, e-commerce, and ERP systems. This improves workflow efficiency and ensures all departments have access to updated inventory data.

6. VAT-Ready and Regulatory Compliance

Dubai-specific inventory software includes features to generate VAT reports and maintain compliance with UAE Federal Tax Authority (FTA) regulations. This ensures accurate documentation and simplifies audits.

Conclusion

Dubai’s business landscape demands precision, speed, and adaptability—qualities that manual inventory tracking simply cannot provide. By adopting Inventory Management Software Dubai companies can overcome the most common challenges, gain better control over their stock, and position themselves for growth.

Investing in the right inventory solution isn’t just about technology—it’s about empowering your business to make smarter decisions, reduce costs, and improve customer service in one of the most dynamic markets in the world.

0 notes

Text

Why Real-Time Inventory Tracking is Essential for Modern Business Success

In today's hyper-competitive marketplace, businesses must embrace tools that optimize operational workflows while enhancing responsiveness. An Inventory Management System (IMS) with real-time inventory tracking capabilities is no longer a luxury—it's a strategic necessity. Real-time visibility into stock movement not only mitigates the risk of stockouts and overstocking but also strengthens the supply chain and drives profitability.

The Critical Need for Real-Time Inventory Tracking

Manual inventory methods, spreadsheets, and periodic stocktaking are outdated practices that often lead to errors, delays, and misinformed decisions. In contrast, real-time inventory tracking automates stock monitoring by continuously updating inventory levels as goods are received, moved, or sold. This dynamic system ensures that businesses always have an accurate snapshot of their inventory, empowering them to make informed decisions at lightning speed.

The agility afforded by real-time tracking is essential for businesses dealing with fast-moving goods, omnichannel retail, and complex logistics. It allows teams to forecast demand, optimize reordering, and minimize the holding cost of inventory. Moreover, with precise data at their fingertips, companies can swiftly identify discrepancies and prevent costly inventory shrinkage.

Key Components of a Real-Time Inventory Management System

A robust real-time IMS is an integrated solution that unifies multiple functions across procurement, warehousing, order fulfillment, and sales. Core components include:

Barcode Scanning and RFID: Automated identification technologies allow for accurate tracking of product movement throughout the supply chain.

Cloud-Based Software: Enables seamless access to inventory data across locations and departments, ensuring transparency and cross-functional collaboration.

Analytics and Reporting Tools: Provide actionable insights into stock turnover rates, deadstock, seasonal demand trends, and supplier performance.

Inventory Alerts and Automation: Customizable notifications signal low stock levels or abnormal activity, prompting immediate action.

Enhancing Business Efficiency Through Integration

An advanced IMS integrates effortlessly with eCommerce platforms, ERP systems, and point-of-sale (POS) software. This synergy eliminates data silos, accelerates order processing, and supports omnichannel operations. When orders are placed, the system automatically adjusts inventory levels, notifies warehouse staff, and updates financial records—without human intervention.

The real-time nature of the system enables just-in-time (JIT) inventory practices, where businesses hold minimal stock while fulfilling orders efficiently. JIT strategies reduce carrying costs and free up capital for other operational needs. This lean approach is especially beneficial for small and mid-sized enterprises looking to scale without bloated inventories.

The Role of Inventory Management Services

Adopting a sophisticated IMS is only part of the equation. Businesses must also invest in specialized inventory management services to maximize the system’s potential. These services include strategic consulting, process audits, software implementation, and ongoing support.

Partnering with a provider of inventory management services ensures that the system is customized to the unique needs of the business. Experts analyze inventory flow, identify inefficiencies, and design scalable solutions tailored to current and future growth. Additionally, they offer training programs that empower staff to use the system effectively, minimizing errors and enhancing productivity.

Furthermore, outsourced inventory management services offer real-time monitoring and analytics support, helping businesses track KPIs and continuously improve inventory strategies. This proactive approach ensures long-term sustainability and competitive edge.

Benefits of Real-Time Inventory Tracking

The advantages of real-time inventory tracking are multifaceted:

Enhanced Accuracy: Reduces data entry errors and provides precise inventory counts at all times.

Improved Customer Satisfaction: Prevents stockouts and backorders, enabling timely deliveries and better service.

Cost Reduction: Eliminates excess inventory and associated storage costs.

Scalability: Supports business expansion by handling complex inventory structures and multiple warehouses.

Data-Driven Decisions: Offers deep insights that inform purchasing, pricing, and merchandising strategies.

Preparing for the Future of Inventory Management

As industries shift towards automation and digital transformation, real-time inventory tracking will become the standard rather than the exception. Businesses that fail to upgrade their systems risk falling behind. The future will demand more from inventory systems—greater integration with AI, machine learning, and IoT for predictive analytics and autonomous inventory control.

To thrive in this evolving landscape, companies must not only invest in cutting-edge systems but also collaborate with experienced inventory management services providers. These partnerships bridge the gap between technology and execution, ensuring businesses remain agile, responsive, and competitive.

Conclusion

Real-time inventory tracking is revolutionizing how companies manage their stock, enhancing visibility, reducing waste, and enabling rapid response to market demands. By implementing a powerful IMS and leveraging expert inventory management services, businesses can build a resilient supply chain, improve customer experiences, and drive sustainable growth.

0 notes

Text

Track And Trace System

At Padhya Software Technologies, we provide advanced Track and Trace solutions to help businesses monitor and manage their assets, inventory, and shipments with accuracy and efficiency. Our solutions integrate real-time tracking, barcode scanning, GPS, IoT, and automated notifications to enhance visibility and streamline operations across various industries.

0 notes

Text

Enhance Your Business Operations with Expert Stocktaking in Perth, WA

Introduction

In at the moment’s swift-paced trade environment, successful stock management is primary for fulfillment. One of the optimal ways to make sure your industrial runs smoothly is through professional stocktaking prone. In Perth, WA, agencies can gain immensely from reliable https://connermueb429.iamarrows.com/efficient-and-accurate-the-hallmarks-of-top-notch-perth-stocktaking-services stocktaking that now not merely streamlines operations but also complements accuracy in stock administration. This article will delve into a lot of sides of stocktaking in Perth, offering insights into how those features can develop into your enterprise operations.

youtube

What is Stocktaking?

Stocktaking refers to the method of counting and verifying the stock stages in a commercial enterprise. It enables name discrepancies between physical inventory and recorded inventory ranges, making certain that firms maintain appropriate statistics.

The Importance of Accurate Stocktaking

Accurate stocktaking performs a very important function in:

Financial Accuracy: Ensuring fiscal statements mirror actual asset values. Operational Efficiency: Identifying slow-moving units enables organisations to strategize better. Customer Satisfaction: Accurate inventory guarantees product availability for clientele. Types of Stocktaking Services Available in Perth

When it involves stocktaking functions in Perth, you have got numerous alternatives obtainable:

1. Manual Stocktaking

Manual stocktaking comprises physically counting products and recording them by means of hand or by using spreadsheets. While this means is cost-successful, it is going to be time-ingesting and likely to human errors.

2. Automated Stocktaking

Automated structures make use of generation resembling barcode scanning or RFID tags to observe inventory extra successfully. This approach particularly reduces mistakes and saves time.

three. Professional Stocktaking Services Perth

Hiring a trusted stocktaking supplier in Perth can provide tailored strategies situated to your industrial demands. These specialists convey talents and technologies to streamline the strategy.

Why Choose a Professional Stocktaking Company in Perth? Expertise Matters

When you engage a pro stocktaking provider in Perth, you profit from their intensive enjoy:

They apprehend regional industry dynamics. They are accepted with top practices for varied industries. Efficiency and Accuracy Guaranteed

Professional offerings make use of systematic methods that beef up both performance and accuracy all over the stocktake activity:

Use of progressed equipment for details series. Trained group of workers who diminish mistakes. How to Find Trusted Stocktaking Services Near Me in Perth?

Finding official stocktaking services is usually daunting, yet factor in these steps:

Online Research: Look for comments and testimonials about local establishments. Ask for Recommendations: Connect with other companies which have used these features. Request Quotes: Comparing quotes between unique companie

0 notes

Text

Exploring the Latest Trends in Brisbane's Stocktaking Industry

Introduction

In an ever-evolving economic landscape, stocktaking stays a relevant but characteristically ignored facet of commercial enterprise operations. In Brisbane, the stocktaking business just isn't with reference to counting gadgets; it’s about leveraging technology, enhancing accuracy, and offering magnitude to organisations seeking nontoxic inventory administration recommendations. As we delve into “Exploring the Latest Trends in Brisbane's Stocktaking Industry,” we are going to discover how regional enterprises are adapting and thriving amidst exchanging market calls for.

Stocktaking Brisbane: An Overview What is Stocktaking?

At its core, stocktaking refers back to the approach of counting and recording inventory units in a industry. It’s main for affirming precise data, combating loss, and making certain that grant meets call for.

youtube

The Importance of Stocktaking in Brisbane

In Queensland's bustling capital, effectual stocktaking could make or spoil a institution's economic future health. With industries ranging from retail to warehousing, understanding native traits is necessary.

The Evolution of Stocktaking Services in Brisbane Historical Context of Stocktaking in Brisbane

Historically, stocktaking interested handbook counts and hard work-in depth strategies. However, with technological advancements, this has remodeled dramatically over the last decade.

Modern Techniques for Accurate Stocktaking

Today’s https://www.google.com/maps/d/edit?mid=1VqiH_k1M0GQazcxnVVaSfT_IWUcTwGg&usp=sharing groups appoint several techniques consisting of barcode scanning programs and RFID expertise to enrich accuracy. These tricks diminish human blunders and streamline operations.

Emerging Technologies in Stocktaking Automation: The Future of Stocktaking Services in Brisbane

Automation is reshaping how companies mindset stock handle. Automated systems not only store time yet also offer precise-time statistics evaluation that supports managers make expert choices.

Artificial Intelligence and Machine Learning Integration

AI is revolutionizing stock control with the aid of predicting traits based on historic knowledge. This predictive diagnosis lets in establishments to dwell beforehand by means of optimizing stock degrees as a result.

Affordable Stocktaking Solutions for Small Businesses Understanding Budget Constraints

Small organisations as a rule operate within tight budgets, which makes discovering good value stocktaking offerings important for their survival.

How to Find Best Affordable Stocktaking Brisbane Options?

Researching local organisations focusing on budget-friendly treatments can lead you to perceive height-notch capabilities with out breaking the bank.

Reliable Stocktaking Professionals in Brisbane What Defines Reliability in Stocktaking?

Reliability in stocktaking method having secure execs who give consistent consequences although minimizing discrepancies for the period of counts.

Choosing the Right Professionals for Your Business Needs

When making a choice on a stocktaking visitors in Brisbane, inspect credentials, knowledge level, an

0 notes

Text

Warehouse Management System (WMS): The Backbone of Efficient Logistics

Managing a warehouse today isn’t just about stacking boxes and printing shipping labels. It’s about speed, precision, and visibility. That’s where a Warehouse Management System, or WMS, becomes a game-changer for businesses of all sizes.

If you're wondering how a WMS can transform your operations, you're in the right place.

What is a Warehouse Management System?

A Warehouse Management System (WMS) is a software solution that helps control and streamline all warehouse operations—from inventory tracking and order picking to receiving, packing, and shipping. In simple terms, it acts as the brain of your warehouse, ensuring everything runs efficiently and with fewer errors.

Why is WMS Important?

A warehouse without a WMS is like a city without traffic lights—chaotic and unpredictable. A good WMS helps:

Minimize picking and packing errors

Increase inventory visibility

Improve space utilization

Optimize workforce efficiency

Accelerate order fulfillment

These improvements aren’t just for show—they lead to better customer satisfaction, reduced costs, and higher profitability.

Key Features of a WMS

Today’s WMS platforms are built to handle complex workflows while being easy to use. Some core features include:

Real-time inventory updates

Barcode and RFID scanning

Automated replenishment alerts

Zone-based picking and wave picking

Returns and reverse logistics processing

Integrated shipping label generation

These tools give warehouse teams the ability to work faster and with far more accuracy.

Types of Warehouse Management Systems

There isn’t a one-size-fits-all when it comes to WMS. The four most common types include:

Standalone WMS – Installed locally and used exclusively for warehouse functions

Cloud-Based WMS – Hosted on the cloud, accessible from anywhere with internet

ERP-Integrated WMS – Embedded into enterprise software like SAP or Oracle

Supply Chain Execution Suites – Part of a larger supply chain management platform

Each has its strengths. Smaller businesses might favor cloud-based WMS tools, while large corporations may opt for robust ERP-integrated solutions.

How Does WMS Work Inside a Warehouse?

Here’s a simple walkthrough of how a WMS improves everyday operations:

A shipment arrives → WMS records incoming inventory

Goods are scanned and stored → WMS tracks their exact location

An order comes in → WMS tells workers the fastest way to pick it

Order is packed → WMS prints the shipping label and updates inventory

Item is shipped → WMS closes the transaction and logs the update

This seamless workflow drastically reduces manual errors and improves order cycle times.

Is SAP a WMS?

Yes. SAP offers a Warehouse Management module called SAP EWM (Extended Warehouse Management). It's a highly configurable system that supports complex warehouse processes, real-time tracking, and deep integration with SAP’s broader ERP and logistics tools.

What Are the Core Functions of a WMS?

A modern WMS typically handles:

Inventory tracking

Order fulfillment

Goods receiving and put-away

Picking and packing optimization

Labor and task management

Returns and restocking

Reporting and analytics

These functions help businesses stay competitive by creating faster, more accurate warehouse environments.

Benefits of Implementing a WMS

The return on investment for WMS software can be enormous. Here’s what businesses gain:

99%+ inventory accuracy

25–50% faster order processing

Reduced labor costs

Improved customer satisfaction

Greater warehouse transparency

Whether you manage one small storage facility or multiple distribution centers, a WMS can be scaled to fit your business model.

FAQs About WMS

🔹 What are the 4 types of WMS? Standalone, Cloud-Based, ERP-Integrated, and Supply Chain Execution Suites.

🔹 What is WMS in a warehouse? It’s the system that manages and automates key warehouse tasks—inventory, picking, packing, and shipping.

🔹 Is SAP a WMS system? Yes, SAP offers a warehouse solution called SAP EWM, designed for complex logistics operations.

🔹 What are the functions of WMS? Core functions include real-time inventory tracking, order fulfillment, returns processing, labor management, and analytics.

Final Thoughts

A Warehouse Management System is no longer a “nice-to-have”—it’s a “must-have” for businesses looking to scale efficiently and deliver consistently. In a world where customers expect next-day delivery and perfect accuracy, a robust WMS ensures your warehouse meets those expectations with ease.

If your business is growing and you’re still tracking inventory on spreadsheets, it might be time to level up with a smart WMS. It’s not just about keeping up—it’s about staying ahead.

#Warehouse Management System (WMS)#ERP-integrated solutions#Extended Warehouse Management#supply chain#supply chain management platform#ERP and logistics#SAP EWM#WMS

0 notes

Text

Business Operations with Field Service Management Apps by FieldEZ Technologies

In today’s fast-paced, digitally connected world, businesses that rely on field operations — such as service providers, retailers, and sales teams — need powerful, integrated tools to manage their mobile workforce efficiently. This is where field service management apps play a critical role. FieldEZ Technologies, a leader in this domain, offers innovative solutions like ServiceEZ, SalesEZ, and RetailEZ, designed to automate workflows, improve customer experience, and streamline field operations.

The Growing Need for Field Service Management Software:

As customer expectations continue to rise, companies must provide fast, efficient, and error-free services. Traditional methods of managing field teams with spreadsheets or manual dispatching no longer suffice. Businesses require modern field service management software that integrates scheduling, tracking, reporting, and communication in a single platform.

FieldEZ Technologies addresses this need with advanced, customizable apps tailored to industry-specific requirements. Whether it’s managing service technicians, retail staff, or sales agents, FieldEZ’s platform ensures improved visibility, performance, and customer engagement.

1. ServiceEZ: Powering Field Service Operations

ServiceEZ by FieldEZ is a comprehensive field service management app built to optimize technician dispatch, automate job assignments, and ensure real-time updates from the field. With intelligent scheduling and route optimization, businesses can reduce downtime, cut travel costs, and increase the number of daily service calls.

The app supports barcode scanning, digital forms, offline functionality, and customer feedback collection — ensuring seamless service delivery and enhanced productivity. Businesses across utilities, telecom, HVAC, and other industries use ServiceEZ to automate workflows and improve SLA adherence.

2. SalesEZ: Field Sales Automation at Its Best

Managing a mobile sales force comes with its own set of challenges — from lead tracking to sales reporting. SalesEZ is FieldEZ’s answer to these challenges. This intuitive field service management software enables sales reps to update CRM data on the go, plan their schedules, record customer interactions, and generate instant quotations.

SalesEZ empowers sales teams with real-time insights, GPS-based tracking, and analytics dashboards, helping managers make data-driven decisions. The app is particularly valuable for FMCG, pharma, and B2B service industries where fast response and relationship management are key.

3. RetailEZ: Revolutionizing Field Retail Execution

FieldEZ’s RetailEZ app focuses on improving the efficiency of field retail operations such as merchandising, stock audits, and planogram compliance. It allows retail field agents to capture real-time data, monitor retail shelf conditions, and sync reports instantly with backend systems.

RetailEZ promotes workflow automation by digitizing retail audits and eliminating paperwork. With configurable task checklists, geo-tagging, and photo capture capabilities, it helps retail brands gain full visibility into store-level execution and brand compliance.

Benefits of FieldEZ Field Service Management Apps:

What sets FieldEZ’s solutions apart is their scalability, ease of integration, and industry-specific features. Some key benefits include:

Real-time Visibility: Track job status, employee location, and customer interactions instantly.

Workflow Automation: Eliminate manual processes and streamline field operations with automated task assignments and notifications.

Improved Customer Experience: Faster response times and real-time communication lead to higher satisfaction.

Data-Driven Insights: Dashboards and reports provide managers with actionable insights for continuous improvement.

Cost Efficiency: Reduce fuel costs, idle time, and unproductive hours by optimizing routes and schedules.

Why Choose FieldEZ?

FieldEZ Technologies has established itself as a trusted provider of field service management software with a strong client base across industries and geographies. Their solutions are backed by robust technology, mobile-first design, and strong customer support. With a modular and API-ready architecture, FieldEZ apps can integrate easily with existing CRMs, ERPs, and legacy systems, making the transition smooth and effective.

Conclusion:

The future of field operations lies in intelligent, mobile-first solutions that drive efficiency and customer satisfaction. FieldEZ’s suite of field service management apps — ServiceEZ, SalesEZ, and RetailEZ — offers just that. By embracing these solutions, businesses can automate workflows, empower their workforce, and stay ahead in a competitive landscape.

#field service#fieldez#services#apps#management software#field management#field service software#field force management

0 notes

Text

RFID Library Management Solution: Streamline your library operations

Libraries are a valuable Place for learning and sharing knowledge. But running a library, particularly a big one, can be time-consuming and demanding. As libraries grow, so do problems of inventory management, security, and high-level service. That's where RFID (Radio Frequency Identification) technology steps in. Poxo's RFID Library Management System provides a clever solution to assist.

What is an RFID LMS?

RFID refers to Radio Frequency Identification, an electromagnetic field-based technology to identify and monitor tags placed on objects—libraries' books and library materials in this context. An RFID LMS (Library Management Solution) is the entire configuration of RFID technology incorporated into library operations such as tracking books, managing users, inventorying, and security.

How Poxo RFID System work?

Poxo, RFID Automation is a trusted name in India’s RFID space, known for providing simplified, scalable, and cost-effective automation solutions tailored to institutional needs. Poxo's RFID LMS employs new technology to simplify library operations, speed them up, and make them more precise. It assists libraries in enhancing their services to staff and users.

Here’s how Poxo’s RFID solution helps a library:

Easy Book Check-In and Check-Out With Poxo's RFID system, patrons can check books in and out automatically at a self-service kiosk. The system reads the RFID tag instantly—no scanning barcodes one at a time necessary. This saves time and eliminates lines at the desk. Fast and Precise Inventory Librarians can utilize a portable RFID scanner to browse through shelves and scan books instantly. This keeps all items in check and locates any missing or misplaced books with ease. Anti-Theft Security RFID gates at the entrance of the library identify whether an individual attempts to remove a book without checking it out. If a tag has not been deactivated, the gates will notify the staff. This prevents loss and theft. User-Friendly Software Poxo’s system includes a simple dashboard for staff to manage records, see reports, and check which books are borrowed. It is easy to learn and use, even for beginners. Customizable and Scalable Regardless of the size of the library, the RFID LMS can be scaled to accommodate its increasing needs. It can be simply expanded as the collection of the library expands, and it continues to be efficient and effective in the long term. As the RFID solution accommodates greater volumes of materials and users, the library expands along with it, providing flexibility for future expansion and upgrades

Key Elements of an RFID Library System-

1. RFID Tags: Small chips are mounted on each book. They keep track of the book's unique ID, title, and status. Each tag contains a unique ID that stores the book’s information, such as title and status.

2. RFID Readers: Machines mounted at circulation counters, self-service kiosks, or shelves to read books without touching them.

3. Antennae and Security Gates: Positioned at the entrance/exit of the library to identify any book removal without permission

4. Library Management Software: The "brain" of the system, this software manage all RFID data with the library database, facilitating management of inventory, user activity, and circulation records.

5. Self-Service Stations: Permit users to check out and return books on their own, avoiding queues and employee workload, enhance service and minimize staff workload.

Conclusion

The RFID Library Management Solution is not just a technology upgrade—its a revolution in the way libraries operate and serve their communities. RFID allows libraries to focus on what they do best: bringing people and knowledge together by speeding up processes, improving accuracy, and offering greater security and convenience. Regardless of whether you are running a school, college, or public library, Poxo has an easy and effective solution for upgrading your library system and making it future-proof.

0 notes

Text

The Smart Way to Streamline Your Business: A Guide to Inventory Management Solutions

Managing stock efficiently is one of the most critical aspects of running a successful business. Whether you deal in retail, wholesale, or manufacturing, the right inventory management approach can dramatically reduce costs, boost accuracy, and improve customer satisfaction.

Why You Need Inventory Management Software

In today’s fast-paced business environment, relying on manual tracking systems is no longer sustainable. Modern inventory management software offers automated solutions for tracking stock levels, managing orders, and syncing sales channels in real-time. With the right software, businesses can minimize stockouts and overstocking, saving both time and money.

Choosing the Right Inventory Management Programs

The market is full of various inventory management programs, each offering unique features like barcode scanning, warehouse integration, and multi-location tracking. Choosing a program that fits your business size and operational needs is essential to scale efficiently.

Get Ahead with Inventory Planning Software

Predicting future demand is just as important as tracking current stock. Inventory planning software helps businesses forecast sales trends, plan replenishment cycles, and reduce waste. By aligning purchasing decisions with actual demand data, businesses can maintain optimal inventory levels year-round.

Final Thoughts

Efficient inventory systems are no longer optional—they're essential. From basic tracking to advanced forecasting, the right tools empower businesses to make smarter decisions and grow sustainably. Start optimizing your stock operations today with industry-leading inventory solutions

0 notes

Text

Case Study: Successful Inventory Optimization with ERP Integration in Dubai

In the fast-paced and highly competitive business landscape of Dubai, efficient inventory management is a crucial element of operational success. For many companies, the solution lies in integrating inventory systems with a comprehensive Enterprise Resource Planning (ERP) platform. In this case study, we explore how a mid-sized distribution company in Dubai transformed its inventory operations through ERP integration—leading to increased efficiency, cost savings, and better decision-making.

Background

Company: Al Noor Distributors Industry: FMCG (Fast-Moving Consumer Goods) Location: Dubai, UAE Employees: 150+ Previous System: Standalone inventory software and manual Excel-based tracking Challenge: Frequent stockouts, overstocking, lack of real-time data, and poor demand forecasting

The Challenge

Al Noor Distributors faced several challenges due to disconnected systems and manual processes:

Inventory inconsistencies due to human error

Difficulty in tracking expiry dates and batch numbers

Inefficient procurement due to lack of visibility into stock levels

High holding costs from overstocked slow-moving items

Stockouts that led to customer dissatisfaction and lost sales

Management realized that these inefficiencies were not only hampering operational productivity but also directly impacting profitability.

The Solution: ERP Integration

To address these issues, Al Noor partnered with a local ERP provider specializing in inventory and distribution solutions in the UAE. The company implemented a cloud-based ERP system with full inventory, purchasing, and sales modules, customized to meet local VAT compliance and multilingual support requirements.

Key Modules Implemented:

Inventory Management

Procurement & Supplier Management

Sales & Order Management

Real-Time Reporting & Analytics

Mobile App for Warehouse Operations

Implementation Process

The ERP implementation followed a structured roadmap:

Needs Assessment: Detailed analysis of existing workflows and pain points

Customization: Tailoring the ERP to support barcode scanning, batch tracking, and expiry management

Data Migration: Consolidation and cleaning of existing data from Excel and old systems

Training: User training sessions for warehouse, procurement, and sales teams

Go-Live & Support: Live deployment with 24/7 post-implementation support

Results Achieved

Within six months of implementation, Al Noor Distributors experienced significant improvements:

Metric

Before ERP

After ERP

Inventory Accuracy

~70%

98%

Stockouts

Frequent

Rare

Overstock Levels

High

Reduced by 35%

Procurement Time

Manual & Delayed

Automated & Timely

Reporting

Delayed & Inaccurate

Real-Time & Accurate

Key Benefits:

Real-time inventory tracking reduced errors and improved accountability

Automated reorder alerts ensured timely procurement

Detailed analytics improved demand forecasting

Mobile app enabled faster warehouse operations and barcode scanning

Integration with VAT-compliant invoicing streamlined financial reporting

Conclusion

The successful integration of ERP and Inventory Management System UAE allowed Al Noor Distributors to transform its inventory challenges into competitive strengths. By investing in a unified ERP solution tailored to the UAE market, the company not only optimized its stock management but also positioned itself for scalable growth.

For businesses in Dubai and across the UAE, this case study is a clear example of how digital transformation in inventory management can lead to tangible, measurable results. Whether you’re in retail, distribution, or manufacturing, ERP-integrated inventory systems are no longer a luxury—they’re a necessity for staying competitive in 2025 and beyond.

0 notes

Text

Physical Document Management vs Digital: What Works Best in 2025?

In an age where digital transformation dominates the narrative, many organizations—especially in highly regulated sectors like BFSI, healthcare, and legal—still grapple with the decision between physical document management and digital solutions. So what really works best in 2025?

This article compares both methods across critical factors, helping you make the right choice for your enterprise.

🏢 What is Physical Document Management?

Physical document management involves the storage, retrieval, and protection of paper-based records. This includes:

Warehousing documents in secure storage facilities

Barcode tracking and indexing

Manual or semi-automated retrieval

Controlled access and destruction (e.g., shredding)

At Stockholding Document Management Services (SDMS), we manage millions of physical files for top BFSI and legal clients across India.

💻 What is Digital Document Management?

Digital document management involves converting paper records into electronic files and managing them through software systems. Core features include:

Digital scanning and indexing

Cloud-based storage and access

Workflow automation and version control

Compliance tracking and e-signatures

SDMS offers robust Document Management System (DMS) solutions that meet industry-grade compliance and security standards.

📊 Comparison: Physical vs Digital Document Management

FeaturePhysical Document ManagementDigital Document ManagementStoragePhysical space (warehouse)Cloud/server-basedAccess TimeHours to daysInstantSecurityPhysical locks, guardsEncryption, role-based accessCostLower initial costHigher initial, lower long-termComplianceManual trackingAutomated audit trailsDisaster RecoveryVulnerable to fire/floodBackups, geo-redundancyEnvironmental ImpactHigh (paper, printing)Low (sustainable)

🔍 Use Case 1: BFSI Sector

Challenge: High volume of loan documents, KYC, transaction forms. Need: Secure, long-term storage + easy retrieval for audits.

Solution: A hybrid approach where documents are stored physically for 5–10 years and digitally archived for instant access.

SDMS Benefit: Seamless physical + digital integration, barcode tracking, and secure VDR access for regulators.

⚖️ Use Case 2: Legal & Compliance

Challenge: Legal firms deal with sensitive case files and contracts. Need: Long-term storage + chain of custody documentation.

Solution: Physical records managed with strict access control; digitized copies with timestamped workflows.

SDMS Benefit: Tamper-proof physical storage + digital document trails with e-signature logs.

📈 What Should You Choose in 2025?

Here’s a quick guide: Business TypeRecommended ApproachBanks & NBFCsHybrid (Physical + Digital)InsuranceDigital-first, physical for legacy recordsHealthcareDigital with secure physical backupsLaw FirmsPhysical for originals, digital for case accessSMEsFully digital (cost-efficient)

✅ Final Verdict

There is no one-size-fits-all answer. Physical document management offers unmatched legal security and compliance in certain sectors, while digital solutions bring agility, speed, and cost efficiency.

In 2025, the best approach is often a hybrid one—leveraging the strengths of both.

📞 Need Help Choosing?

At Stockholding Document Management Services, we specialize in both physical and digital document solutions tailored to your industry.

🔗 Explore Our Services 📩 Contact us today to get a customized solution.

1 note

·

View note

Text

Importance of a WMS in Modern Warehousing

If you’ve ever dealt with delayed inventory updates or mysterious stock discrepancies, then real-time inventory visibility might just be your warehouse’s new best friend. A WMS system provides a live view into your inventory at any given moment. It tracks every item from the time it enters the facility to when it leaves, automatically updating your database with every transaction.

Why is this such a big deal? Because in warehousing, timing is everything. Real-time data means you’re not relying on outdated spreadsheets or delayed reporting. You’ll know instantly if a product is out of stock, which locations have excess, and whether it's time to reorder. It drastically reduces the chances of overstocking or understocking, helping maintain just-in-time inventory levels.

This level of visibility also enhances trust with customers. When your system says a product is in stock, you can confidently fulfill that order. No more canceled shipments or embarrassing emails about backorders. You become more reliable and trustworthy—which customers notice.

Moreover, it empowers your team. Instead of spending time hunting down items or double-checking quantities, they can focus on fulfillment and efficiency. In essence, real-time visibility turns your warehouse from reactive to proactive—and that’s a game-changer in competitive industries.

Improved Warehouse Efficiency and Productivity

A WMS isn’t just a fancy inventory tracker—it’s a full-blown productivity booster. It takes the guesswork out of daily operations and replaces it with automation, direction, and data. Workers aren’t left wondering what task to do next or which aisle to check; the WMS tells them where to go, what to do, and how to do it faster.

Tasks that used to take hours—like cycle counting or inventory reconciliation—are completed in minutes. Routes for picking are optimized to minimize walking time and reduce fatigue. Bottlenecks are identified early, and resources can be reallocated in real-time.

And let’s not forget about performance metrics. A good WMS tracks employee productivity, identifies slow-moving inventory, and flags inefficiencies. This data is invaluable for warehouse managers aiming to streamline operations and improve KPIs.

Plus, as the workforce becomes more mobile and tech-savvy, WMS platforms now come with mobile compatibility, allowing staff to update stock or scan items right from a tablet or handheld device. This boosts both speed and accuracy, helping you do more with less.

Reduced Human Error and Enhanced Accuracy

Let’s face it—mistakes in warehousing can cost a lot. Whether it’s shipping the wrong item, misplacing stock, or inaccurate inventory records, human error can ripple through your entire supply chain. This is where a WMS becomes your warehouse’s safety net.

With barcode scanning, RFID integration, and automated workflows, a WMS significantly reduces the need for manual entry. That means fewer typos, less data duplication, and way fewer “oops” moments that lead to costly returns or unhappy customers.

Think about it: If every stock move, pick, and shipment is scanned and logged in real-time, there’s little room for miscommunication or mistakes. Workers are guided step-by-step through their tasks, ensuring they’re doing the right thing at the right time.

And when errors do happen, they’re caught early. The WMS can flag inconsistencies or alert managers when something looks off. This proactive approach doesn’t just save time—it preserves your reputation and improves customer satisfaction.

Warehouses that rely solely on manual processes are playing a dangerous game. As order volumes grow and customer expectations rise, accuracy becomes non-negotiable. A WMS helps you hit the bullseye every time.

How a WMS Transforms Warehouse Operations

Optimized Inventory Management

Inventory is the beating heart of your warehouse. But without proper management, it can also be your biggest liability. That’s why optimized inventory control is one of the standout benefits of a WMS.

With precise location tracking, automated stock rotation (like FIFO and LIFO), and low-stock alerts, a WMS gives you complete control over your inventory. You’ll know what’s in stock, where it’s stored, and how long it’s been there—all without lifting a clipboard.

It also helps reduce waste. Perishables or seasonal items can be prioritized for shipping before they expire or become obsolete. Overstocked items can be flagged and discounted before they tie up too much capital. Understocked SKUs can be reordered just in time to avoid losing sales.

And if you're running multiple warehouses or fulfillment centers? No problem. A WMS can centralize inventory data across all locations, helping you balance stock levels and fulfill orders from the most optimal source. It turns a chaotic stockroom into a well-coordinated, responsive engine that drives business forward.

Streamlined Order Fulfillment

In the world of e-commerce and omnichannel retail, order fulfillment is your brand’s handshake. It’s how you leave a lasting impression. A WMS makes sure that handshake is firm, timely, and professional—every single time.

When an order comes in, the WMS kicks into gear. It assigns the task to the appropriate picker, chooses the best picking method, and generates packing slips automatically. It can even validate the order contents before sealing the box and printing the shipping label.

The result? Orders are fulfilled faster, with fewer mistakes. Customers get exactly what they ordered, when they expect it. Returns drop, satisfaction rises, and reviews improve.

And during peak seasons, a WMS really shines. It can handle spikes in demand without the chaos. It ensures your team doesn’t get overwhelmed and helps maintain service levels even when the order volume triples overnight.

If you’ve ever missed a shipping deadline or had an angry customer complain about wrong items, you’ll appreciate the peace of mind a WMS provides. It brings order to the chaos—and that’s priceless in today’s fast-paced market.

Enhanced Shipping and Receiving Processes

Shipping and receiving are two of the most critical yet error-prone areas in warehouse management. A slip-up here can derail your entire operation—from delays to misplaced inventory to unhappy customers. Fortunately, a WMS simplifies and automates these processes, creating a seamless flow from dock to stock and stock to ship.

Let’s start with receiving. When shipments arrive, a WMS allows staff to scan barcodes or RFID tags instantly, updating inventory in real-time. It can cross-check items against purchase orders to flag discrepancies immediately—no more over-receiving or missing items that get noticed days later. It also directs putaway, suggesting optimal storage locations based on item characteristics, space availability, and demand patterns.

On the shipping end, a WMS ensures that each order is complete, accurate, and properly labeled before it leaves your facility. Integration with courier APIs enables automatic label generation, rate shopping, and real-time tracking updates. This means fewer manual steps, faster throughput, and fewer customer complaints about delivery issues.

Moreover, because everything is scanned, logged, and timestamped, you have a digital trail for every movement. This transparency helps resolve disputes, track performance, and continuously refine your processes. Whether you're shipping 50 or 5,000 orders a day, a WMS ensures they all move out smoothly and accurately.

For original post visit: https://castocus.com/blogs/13434/Importance-of-a-WMS-in-Modern-Warehousing

0 notes

Text

Mastering Inventory for Field Service Success with a Field Service Inventory Management System

For field service businesses, efficiently managing inventory is no longer optional—it’s essential for profitability and customer satisfaction. Imagine a technician arriving at a job without the right part. This scenario highlights why a robust Inventory Management System is crucial.

A Field Service Inventory Management System is specifically designed to track tools, parts, and equipment across warehouses and mobile units, ensuring technicians have what they need, when they need it. This minimizes delays and repeat visits, enhancing service delivery and cost-effectiveness. Consider how real-world examples in HVAC, telecom repairs, and medical equipment maintenance demonstrate the tangible benefits of having the right parts readily available through such a system.

Inventory management for field service presents unique challenges due to its distributed nature, lack of real-time visibility in the field, the volume of fast-moving parts, the coordination of mobile teams, and unpredictable service demands. However, a centralized, cloud-based Inventory Management System with features like barcode/RFID scanning and smart allocation tools can effectively address these complexities.

Key features of an effective Field Service Inventory Management System include real-time tracking with mobile access, seamless integration with field service software, barcode/RFID capabilities, automated alerts and restocking, comprehensive reporting, and scalability. These features empower field service operations to streamline workflows, improve accuracy, and make data-driven decisions.

In conclusion, a well-implemented Field Service Inventory Management System is a cornerstone of success in the field service industry. By ensuring the right parts and tools are available at the right time, businesses can empower their technicians, enhance productivity, improve customer satisfaction, and ultimately achieve significant cost savings. Investing in the right Inventory Management System is an investment in the future of efficient and effective field service delivery.

0 notes