#Automatic Glass Forming Machine Market

Explore tagged Tumblr posts

Text

How to Choose the Best Pre Roll Packaging for Your Brand

In today’s cannabis market, being unique goes beyond your product. One of the key factors that affects customer perception and brand success is pre roll packaging. Whether you’re a dispensary owner, cannabis processor, or startup brand, knowing how to choose the right pre roll tubes, pre roll cones in bulk and other packaging solutions can make a big difference in presentation, compliance and shelf life. In this blog we’ll walk you through how to choose the best pre roll cones and packaging for your business.

What Is Pre Roll Packaging?

Pre roll packaging refers to any container or wrapping that holds a pre-rolled joint. The main goals are to keep it fresh, safe and good-looking. With higher consumer expectations and stricter regulations, businesses have to find the balance between form and function.

Types of pre roll packaging include:

Pre roll tubes (plastic or glass)

Child-resistant pop tops

Glass jars

Custom-printed boxes

Pre roll cones (bulk or individual)

Why Pre Roll Packaging Matters for Your Brand

Your packaging is often your customer’s first impression of your product. High-quality, functional pre roll packaging shows professionalism, improves user experience and builds brand trust. Here are a few reasons why:

Freshness & Aroma Control: Airtight containers like pre roll tubes preserve the flavor and smell of the cannabis.

Compliance: Packaging must meet state-specific laws such as child resistance and labeling.

Protection: Prevents breakage, crushing, or contamination.

Brand Identity: Creative design and customization set you apart on dispensary shelves.

Sustainability: Eco-conscious options can boost appeal among environmentally aware consumers.

How to Choose the Right Pre Roll Tubes

Pre roll tubes are the most popular packaging solution due to their durability, affordability and child resistant features. Here’s how to choose the right one:

Material Matters:

Plastic pre roll tubes are cheap, light and great for large orders.

Glass pre roll tubes are premium, reusable and show quality and sustainability.

Both are available with child-resistant features to comply with legal standards.

Size and Fit:Tubes come in sizes 98mm, 116mm or 120mm. Always match the tube to your pre roll cone size to prevent movement and breakage.

Customization OptionsWant to stand out? Choose from color options, custom labeling, foil accents and logo printing. Turn basic pre roll tubes into a brand asset.

How to Source Pre Roll Cones in Bulk

Whether you’re rolling by hand or using an automatic rolling machine, buying pre roll cones in bulk is the way to go for scale. Here’s what to consider:

Cone Material

Refined white paper cones burn clean with minimal taste.

Unbleached brown cones are natural and appeal to the eco-conscious.

Hemp paper cones are smooth and organic for premium products.

Sizes AvailableCones come in various sizes such as 84mm, 98mm, and king size (109mm). Always align the size with your packaging and branding needs.

Filter TipsQuality pre roll cones include filter tips to enhance airflow and structure. These can be spiral, flat, or customizable based on your preference.

Buying in BulkOrdering pre roll cones bulk ensures cost savings, inventory readiness, and consistent quality across batches.

How to Pick the Best Pre Roll Cones:

Not all cones are created equal. Choosing the best pre roll cones can elevate your product experience and reduce operational headaches. Here’s what to look for:

Consistent Shape & Size: Ensures uniform fill and burn.

Minimal Paper Taste: High-quality cones enhance the flower’s flavor rather than masking it.

Slow Burn: Ideal cones burn evenly and slowly for a smooth experience.

Machine Compatibility: For high-volume producers, machine-compatible cones streamline the filling process.

At Innovative Sourcing, we provide top-tier pre roll cones in bulk, offering custom branding options and premium paper choices to align with your vision.

Benefits of Investing in Premium Pre Roll Packaging:

Boosts Brand Recognition

Improves Customer Retention

Complies with Regulatory Laws

Protects Product Quality

Supports Marketing and Promotions

A well-packaged pre roll isn’t just a product—it’s an experience. From the unboxing to the final puff, every detail matters.

The Benefits of Working with a Trusted Supplier:

Selecting the right pre-roll packaging is just half the battle. From concept to delivery, a smooth experience is guaranteed when you work with a supplier who shares your business goals, compliance needs, and artistic vision.

At Innovative Sourcing, we specialize in custom pre roll packaging solutions tailored for cannabis professionals. Whether you need branded pre roll tubes, pre roll cones bulk, or eco-friendly options, we offer fast turnaround, competitive pricing, and consistent quality.

Ready to add premium pre-roll packaging to your cannabis brand? See our entire selection of cones, pre-roll tubes, and customized packaging at Innovative Sourcing.

Contact us today to request a free quote or sample pack and see why we’re the trusted supplier for leading cannabis brands across the U.S.

2 notes

·

View notes

Text

From Manual to Automatic: The Evolution of Packaging Technology

In today's fast-paced global economy, packaging plays a pivotal role in product safety, logistics, branding, and consumer experience. What began as a purely manual task centuries ago has transformed into an advanced, automated process that enables mass production, efficiency, and consistency. The journey from manual packaging to cutting-edge automated systems is not only a tale of technological evolution but also a testament to human ingenuity and innovation. In this blog, we’ll explore how packaging has evolved over the years, the milestones in automation, and the impact of this transformation on various industries.

The Beginnings: Manual Packaging

Before the industrial revolution, packaging was a labor-intensive process. Artisans, merchants, and small-scale manufacturers manually wrapped products in paper, cloth, leaves, or glass jars. granule packaging machines The main focus was to protect the product and provide a minimal aesthetic appeal.

For example, apothecaries would wrap herbs in parchment and tie them with string, while farmers used burlap sacks and wooden crates for transportation. Manual packaging required significant labor, had inconsistencies, and could not keep up with growing demand.

The Industrial Revolution: Birth of Mechanized Packaging

The 18th and 19th centuries ushered in the Industrial Revolution, fundamentally changing how goods were produced—and packaged. As manufacturing lines became more advanced, the need for faster and more efficient packaging processes grew.

This period saw the invention of basic packaging machinery like:

Filling machines to dispense powders or liquids into containers

Sealing machines for paper and tin containers

Wrapping machines for candies and small items

Although many of these machines still required human operation, they significantly reduced manual labor and improved production speed and consistency. The packaging industry began its transition from handcrafted methods to machine-assisted workflows.

Mid-20th Century: The Rise of Semi-Automation

With the advent of electricity, electronics, and pneumatics, the mid-1900s marked a dramatic leap in packaging efficiency. Semi-automatic machines emerged, allowing human workers to focus on supervision and quality control rather than manual packing.

Industries like food, pharmaceuticals, and cosmetics began investing in semi-automatic lines capable of:

Form-fill-seal processes

Labeling and coding

Cartoning and palletizing

During World War II, the need for mass production led to innovations in packaging materials such as plastics and vacuum sealing, sauce packaging machines which offered better shelf life and protection. These technological advancements laid the groundwork for full automation.

Late 20th Century: Automation Gains Momentum

By the 1970s and 1980s, the rise of microprocessors, sensors, and programmable logic controllers (PLCs) paved the way for fully automated packaging systems. This marked a turning point in industrial packaging.

Fully automatic machines could now:

Form containers from rolls of film or flat cartons

Fill with precise accuracy

Seal, code, label, and stack—without manual intervention

Industries witnessed a surge in productivity, reduced human error, and higher hygiene standards. Consumer packaged goods (CPG) companies began to adopt automation to meet rising market demands while maintaining quality and efficiency.

21st Century: Smart Packaging and Industry 4.0

The last two decades have brought forth revolutionary changes driven by Industry 4.0—a fusion of automation, data exchange, and smart technology. Today’s packaging machines are more than mechanical systems—they are intelligent, connected, and adaptable.

Key innovations in modern packaging automation include:

Robotics: Robotic arms for pick-and-place, sorting, and palletizing

Artificial Intelligence (AI): Real-time decision-making and predictive maintenance

Internet of Things (IoT): Smart sensors and data analytics for performance tracking

Vision systems: Quality inspection using cameras and pattern recognition

These technologies ensure that modern packaging lines are faster, more flexible, and capable of handling a wider variety of SKUs, packaging sizes, and materials.

Benefits of Automation in Packaging

The transition from manual to automated packaging has brought significant benefits:

Speed and Productivity Automated lines can operate continuously, producing thousands of units per hour—impossible with manual labor alone.

Consistency and Quality Machines provide uniform filling, sealing, and labeling, ensuring every package meets strict standards.

Cost Efficiency While initial investment may be high, automation reduces long-term labor costs, waste, and downtime.

Worker Safety Automation reduces the risk of repetitive strain injuries and accidents associated with manual labor.

Data-Driven Decision Making With integrated sensors and analytics, manufacturers can monitor machine performance, identify bottlenecks, and optimize operations in real-time.

Challenges and Considerations

Despite its advantages, transitioning to automation isn’t without challenges:

High Initial Costs: Small businesses may struggle with the capital needed for advanced systems.

Complex Maintenance: Automated systems require skilled technicians for setup and maintenance.

Customization Needs: Packaging machines must often be tailored for specific product types or materials.

Workforce Upskilling: As machines take over manual tasks, workers must be retrained for technical and supervisory roles.

Nonetheless, these challenges are being addressed by modular, user-friendly machines and scalable automation solutions designed for companies of all sizes.

The Future of Packaging Technology

Looking ahead, packaging technology will continue to evolve alongside advancements in AI, robotics, sustainability, and machine learning. Future trends include:

Sustainable Automation: Machines that handle recyclable or biodegradable materials efficiently

Adaptive Manufacturing: Systems that auto-adjust based on product variation or order customization

Digital Twins: Virtual simulations of packaging lines for testing and optimization

Collaborative Robots (Cobots): Safe robots that work alongside human operators

In a world where consumer demands, environmental regulations, and global logistics are constantly shifting, the role of intelligent packaging automation will become even more critical.

Conclusion

The evolution from manual packaging to fully automated systems illustrates the powerful synergy between human innovation and machine precision. What began as a slow, labor-intensive process has now become a streamlined, high-tech operation capable of meeting the demands of a global market.

For businesses looking to stay competitive, embracing modern packaging automation is no longer optional—it’s essential. Whether you're a small brand or a large manufacturer, investing in the right technology can enhance your productivity, ensure product quality, and pave the way for long-term growth.

From manual hands to robotic arms, packaging technology has come a long way—and it’s only getting smarter.

0 notes

Text

Innovations in Dairy Product Packaging Machines: Enhancing Shelf Life and Hygiene for Africa’s Dairy Sector

The Dairy industry in Africa is milking every opportunity to expand, driven by the rising population, increasing health and wellness awareness, and growing urbanisation. This has been stemming from the increasing demand for safe, fresh, and longer-lasting dairy products, be it milk, yogurt, and margarine, to flavoured milk, cream or even dairy powders.

However, how can you ensure a higher-quality product from farm to fridge in a continent where climate, infrastructure, and logistics can pose significant challenges? The answer to this problem is “Smart Dairy Packaging” with Nichrome. With 40+ years of pioneering experience in dairy packaging machines, we at Nichrome are at the frontlines of delivering innovative, efficient, and hygienic dairy solutions that are at par with the unique needs of the African markets.

With our smart and high-performing milk packaging machines and yogurt packaging machines, we, as the leading milk pouch packing machine manufacturers, are empowering African dairy producers to overcome bottlenecks in every segment.

Ready to pour into the details? Let’s dive into the creamy layers of dairy packaging innovation.

Types of Dairy Products and Their Packaging Needs

From farm-fresh milk to creamy yogurts and margarine, and powdered dairy goodness, every dairy product comes with its packaging personality. The key to delivering high-quality dairy products lies in understanding the unique packaging required and then tailoring packaging machines to handle them with precision, care, and hygiene. Our specialised range of dairy packaging machines caters to the entire dairy spectrum.

Let’s unpack the packaging needs of different dairy products and how Nichrome has been rising to the challenge:

Milk: Pouches and bottles that preserve liquid purity

Milk needs airtight, leak-proof and contamination-free packaging as it is highly perishable. Whether it’s pouches for rural markets or bottles for the urban retail, our milk packaging machines offer unmatched speed, precision, and hygiene.

Sprint 250 Plus and Excel Plus milk pouch packing machines – Ideal for small to large-scale milk packing needs.

Automatic lines with milk bottle filling machines - milk bottling in glass or PET bottles

Pouches are formed, filled, and sealed with minimal human contact, with hygienic processing.

Flavoured Milk: Keeping it Tasty & Cool

The delicious flavoured milk is a growing category among African youth. The products require tamper-evident packaging that preserves flavour and nutrients.

Our viscous liquid filling machines ensure accurate filling of flavoured milk varieties.

Multi-purpose milk filling machines can accept pouches, PET bottles, and Tetra Pak substitutes.

Advanced packaging maintains shelf stability without requiring preservatives.

Yogurt & Curd: Thick, Creamy, and Contained

Viscous and semi-solid, curd, and yogurt need extra care. We provide yogurt packaging machines with soft filling technology that prevents air pockets or spoilage.

Servo-driven filling provides hygiene and consistency.

Suitable for cups, pouches, or sachets.

Tamper-proof sealing ensures freshness and trust.

Ghee, Margarine, & Cream: The Rich Delights

For more viscous milk products such as cream, margarine, and ghee, accuracy and hygiene are important. Our milk products packaging machines provide heat-sealed, aseptic packaging that provides maximum shelf life.

Thicker consistencies with specific nozzles.

Perfect for pouch, jar, and cup packaging.

High-temperature packaging films prolong freshness.

Dairy Powders: Light but Strong

Milk powder, whey, and baby formula need protective packaging that is oxygen and moisture-proof.

Dry powder filling machines provide vacuum sealing and nitrogen flushing for extended shelf life.

Case packaging and retail-ready SKUs available.

Assists dairy processors in meeting export requirements.

Whatever your product pours, scoops, flows, or sprinkles, Nichrome has a dairy and milk packaging machine that can do it fast, hygienically, and accurately. From optimizing shelf life to optimizing operational efficiency, Nichrome's flexible packaging machines have Africa's dairy treats ever ready to serve, fresh and fabulous.

Major Packaging Challenges for Dairy Products

With the growth of the dairy business in Africa comes the need to keep packaging at the level required to meet demand, sanitation, and sustainability requirements. Dairy packaging is not a matter of simply covering milk—it's about purity, preventing loss, and defending brand reputation. But for the vast majority of dairy farmers on the continent, the path from cow to consumer is not without its complications.

The following are the biggest challenges that African dairies face, and how we help solve those:

Hygiene Maintenance - Milk and milk products are nutrient-rich but prone to bacterial contamination. Our milk filling machines are equipped with Clean-In-Place (CIP) facilities and stainless-steel construction to provide utmost sanitation.

Spoilage Prevention - Temperature fluctuation during storage and transport is prevalent throughout Africa. Nichrome battles this with air-tight, leak-proof pouches and high-barrier packaging films.

Handling Different Consistencies - From thin milk to thick ghee, yogurt, or margarine, every single product has a special flow. Our milk packaging machines feature speciality nozzles and programmable filling logic to accommodate any viscosity.

Affordability & Flexibility - Small dairies require scalable solutions. We provide milk packing machines and semi-automatic lines that are affordable to tight budgets without sacrificing performance.

It's obvious, dairy packaging in Africa is not a mass market phenomenon. It takes flexibility, dependability, and creativity. We at Nichrome not only get these issues, but we also address them. With a range of dairy packaging machines that are ideally suited to African conditions, we provide producers with the equipment they need to succeed in a competitive, fast-moving market. Because at Nichrome, we don't merely package dairy—we empower it.

Advanced Features in Nichrome's Dairy Packaging Machines

When it comes to packaging milk in a tough and dynamic market such as Africa, efficiency is not sufficient; you require smart, flexible, and forward-looking machines. At Nichrome, innovation is infused in each nut and bolt. Our milk & dairy packaging machines raise the bar on automation to deliver smarter, more efficient solutions that meet real-world requirements.

Here’s the breakdown of the features that set Nichrome's milk packing machines apart:

Automatic Pouch Filling & Sealing

Automatically operated models are the Sprint 250 Plus, Filpack Servo 12K, and Filpack CMD.

Provide uniform pouch sealing with minimal operator interference.

Servo-based operations produce fault-free sealing at high speeds.

Bottle & Jar Filling Lines

From bottling milk to curd in jars, we champion all the varied formats.

Modular systems allow easy integration into existing plants.

General-purpose for flavoured milk, yogurt, and margarine.

Hygienic CIP Systems

Equipments have Clean-In-Place capability for sanitary processing.

Conserves time, water, and detergent compared to hand washing.

Proper Filling for Viscous & Liquid Products

The milk filling machines employ piston and servo-based technology.

Oversees everything from raw milk to cream, yogurt, and margarine.

Reduces overfill loss and is cost-effective.

Packaging Material Compatibility

It accommodates high-barrier laminates, mono-material films, and recyclable ones.

Ensures safety without compromising on sustainability.

Compatible with all standard widths and thicknesses of film rolls.

In brief, our dairy products packaging machines do not just process your product; they process your problems. Whether it is keeping things clean, making things more precise, or making things more efficient, our machines are designed to keep pace with today and expand for tomorrow.

From small regional African dairy farmers to large-scale cooperatives, we offer precision, flexibility, and innovation in an amalgamation that makes packaging not only a process, but a source of differentiation.

Advantages of Applying Contemporary Dairy Packaging Machines

With Africa's dairy industry going into high gear to respond to growing demand, traditional methods no longer cut it. Outdated packaging technology not only keeps your production on ice but also amplifies the chances of spoilage and contamination, delivering a blow to your bottom line and consumer trust.

That is where Nichrome's second-generation dairy packaging solutions step in. Designed to combine hygiene with high-speed functionality, our machines are made to serve African dairies of all sizes, whether packaging raw milk in pouches or flavoured yogurt and margarine in cups.

Here's why it's a cream-of-the-crop choice to upgrade to Nichrome:

Long Shelf Life - Whether milk pouch packaging, yogurt cups, or margarine packs, Nichrome provides packaging that holds spoilage at bay.

Consistent Quality - Each packet is sealed, filled, and trimmed with machine accuracy.

Speed & Efficiency – Our automatic packaging machines produce thousands of pouches an hour, achieving a high throughput rate.

Fewer Wastages - Precise filling results in less wastage and higher output from your material.

Multi-SKU management - Convert SKUs on the fly. One milk packaging machine will switch between SKUs with minimal downtime.

Compliance & Certifications – Our packaging solutions enable compliance with FSSAI, ISO, and international standards of hygiene.

Energy-Efficient Operations - New drives and smart control panels lower energy use and boost plant ROI.

These advantages extend far beyond the pack—they enable your dairy plant to become a wise, forward-looking facility. In a business where margins count and quality sells, Nichrome puts you ahead of the competition. You need to grow efficiently, safely, and intelligently. Whether you're supplying urban supermarkets or rural cooperatives, with Nichrome, your packaging line is a productivity powerhouse.

Conclusion: Channelling Innovation into Africa's Dairy Future

Africa's milk industry is poised for a packaging revolution. With growing urbanization, cold chains, and dairy consumption, the demand for milk product packaging that is innovative, efficient, and hygienic also increases.

With state-of-the-art dairy packaging machines, we at Nichrome haven’t just kept pace but forged ahead. Whether it's milk pouch solutions or milk filling machines, our machines empower African dairies to dispense quality, safe products with speed and panache.

So, are you also looking to upgrade your milk packaging line or introduce a new dairy brand? As a new entrant or legacy co-op, Nichrome Africa offers the best of Indian technology for African conditions.

Call us today to discover a full range of dairy products packaging machines and experience the intelligent packaging first-hand.

Let's change the way Africa consumes milk. Pouch by pouch.

#dairy packaging machines#milk packaging machines#yogurt packaging machines#milk pouch packing machine manufacturers#dairy packaging#dairy packaging machine#milk packaging machine#milk pouch packing machines#milk bottle filling machines#liquid filling machines#milk filling machines#yogurt packaging machine#milk products packaging machines#Dry powder filling machines#nichrome dairy packaging machines#automatic packaging machines#milk packaging line

0 notes

Text

Why Investing in a Packaging Machine is a Game Changer

In today’s fast-paced manufacturing and logistics industry, efficiency is key. Businesses looking to scale operations and improve product presentation can significantly benefit from industrial packaging machines. Whether for food, pharmaceuticals, or consumer goods, automating your packaging process ensures consistency, enhances product safety, and reduces labor costs.

If you're in the market for Industrial Packaging Machines, understanding what to look for and how to choose the right model is essential. This guide explores everything you need to know before making a purchase.

Types of Packaging Machines

Depending on your industry, various industrial packaging machines cater to specific needs. Some of the most popular options include:

1. Filling Machines

Ideal for liquid, powder, or granule-based products, filling machines ensure accurate portioning and prevent wastage.

2. Sealing Machines

Perfect for ensuring airtight packaging, these machines come in various forms, including vacuum sealers and heat sealers.

3. Wrapping Machines

From stretch wrappers to shrink-wrapping machines, these units protect and bundle products for transportation.

4. Labeling Machines

Consistency in branding is crucial, and labeling machines ensure every package is professionally marked with the necessary information.

5. Cartoning Machines

If your business involves boxing products, cartoning machines simplify the process, ensuring efficiency and precision.

Key Considerations When Buying a Packaging Machine

Purchasing a packaging machine for sale is a significant investment. Here are the crucial factors to consider:

1. Production Volume

Determine whether a semi-automatic or fully automated machine suits your business needs based on your daily production capacity.

2. Material Compatibility

Not all packaging machines work with every material. Ensure the machine you choose supports your packaging materials, whether plastic, glass, or cardboard.

3. Space Requirements

Consider the available space in your facility. Some industrial packaging machines require substantial floor space, while others are compact and adaptable.

4. Maintenance & Durability

Choose a machine that is easy to maintain, with readily available spare parts and reliable customer support in Australia.

5. Compliance & Safety Standards

Ensure the machine meets Australian industry regulations, including food safety and environmental guidelines.

Customer Testimonials

"Upgrading to an automatic sealing machine transformed our packaging efficiency. What used to take hours now gets done in minutes! Highly recommend investing in quality packaging machines in Australia." – Jason M., Food Manufacturer

"We switched to a fully automated filling and labeling machine, and the accuracy has improved tremendously. No more spillage or labeling errors!" – Linda S., Pharmaceutical Industry

FAQs About Packaging Machines

1. What is the lifespan of an industrial packaging machine?

With proper maintenance, most industrial packaging machines last 10-15 years, making them a long-term investment for your business.

2. Are used packaging machines a good option?

Second-hand machines can be cost-effective but ensure they are in good working condition and meet industry standards before purchasing.

3. How much does a packaging machine cost?

The price varies based on the type and automation level. Entry-level models start at a few thousand dollars, while advanced machines can go up to six figures.

4. Can packaging machines be customized?

Yes! Many suppliers offer customization to fit specific business needs, including speed, materials, and additional features.

Where to Find the Best Packaging Machines in Australia

Finding the right Bubble Wrap For Packing involves researching reputable suppliers who offer high-quality equipment, excellent after-sales service, and industry compliance. Many businesses opt for local distributors to ensure faster delivery, technical support, and compliance with Australian standards.

For companies seeking efficiency, consistency, and a competitive edge, investing in an industrial packaging machine is a smart move. Whether automating an existing process or scaling production, the right machine will make all the difference.

Final Thoughts

As demand for precision and speed in manufacturing continues to grow, investing in packaging machines in Australia can elevate your business. By understanding the types of machines available and evaluating key factors before purchasing, you can find the ideal packaging solution to enhance productivity and streamline operations.

0 notes

Text

Aerogel Market Forecast: Emerging Technologies and Growth in 2024

Aerogel Industry Overview

The global aerogel market size is expected to reach USD 3.49 billion by 2030, registering a CAGR of 17.0% from 2025 to 2030, according to a new report by Grand View Research, Inc. Aerogel has a wide application portfolio due to its unique qualities and ongoing research & development regarding its usage in new and advanced applications. Its properties including superior thermal resistance, lightweight, very low density, fire resistance, and excellent thermal insulation are likely to boost its demand across varied applications.

Aerogels can provide innovative and environment-friendly solutions for high-performance insulation and light-diffusing in a wide range of architectural daylighting applications. Major players offer advanced and innovative solutions for architectural applications. For instance, Cabot Corporation provides LUMIRA aerogel an innovative high-performance insulation for architectural daylighting. The key benefits offered by the LUMIRA aerogel include natural light diffusing insulated glass units, structural composite panels, structural polycarbonate systems, U-channel glass, unit skylights, smoke vents, tensile structures, and fabric roofing.

Moreover, the development of advanced aerogels from waste is likely to create potential growth opportunities over the forecast period as the concerns associated with waste management are increasing among private as well as public organizations. The governments are making possible efforts for proper management of continuously increasing amounts of waste. Additionally, awareness about the usage of environment-friendly materials is rising among the end-users, this is another factor projected to generate potential growth in the near future.

Gather more insights about the market drivers, restrains and growth of the Aerogel Market

Aerogels can be molded into thin films or monoliths and used in thermal insulation, acoustic, thin-film coatings, vibration damping, or any place where structural foam is required such as the automotive industry. The automotive industry is shifting from internal combustion engines (ICEs) to fully electric and automatic moving machines. Earlier, companies focused on specified parameters, including efficiency, comfort, performance, or safety. However, with the help of aerogels, all these requirements can be clubbed together, thus, making aerogels an ideal raw material in the automotive industry.

The manufacturers in the market have agreements with suppliers, distributors, exporters, or online sellers for the disbursal of the product in the end-use market. Efficient distribution is one of the major challenging factors responsible for the slow expansion of manufacturers in foreign markets. The high production cost involved in the manufacturing of aerogel as well as its fragility and delicacy associated with the transportation in distant locations involved in the final delivery is likely to restrict its growth to an extent over the forecast timeframe.

The market is moderately competitive in nature owing to the presence of a few manufacturers which are consolidated in North America and Middle East & Africa. The strong presence of major players along with the presence of opportunities in developing countries with huge investing power for continuous development exhibits highly competitive rivalry among the players.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The Americas stone paper market sizewas estimated at USD 220.4 million in 2024 and is expected to grow at a CAGR of 5.4% from 2025 to 2030.

The global cobalt market sizewas estimated at USD 16.96 billion in 2024 and is expected to grow at a CAGR of 6.7% from 2025 to 2030.

Aerogel Market Segmentation

Grand View Research has segmented the global aerogel market on the basis of on product, technology, form, end-use, and region:

Aerogel Product Outlook (Revenue, USD Million, 2018 - 2030)

Silica

Polymers

Carbon

Others

Aerogel Technology Outlook (Revenue, USD Million, 2018 - 2030)

Supercritical Drying

Other Drying

Aerogel Form Outlook (Revenue, USD Million, 2018 - 2030)

Blanket

Particle

Panel

Monolith

Aerogel End-use Outlook (Revenue, USD Million, 2018 - 2030)

Oil & Gas

Building & Construction

Automotive, Aerospace & Marine

Performance Coatings

Others

Aerogel Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Italy

Belgium

Poland

Asia Pacific

China

India

Japan

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

UAE

Key Companies profiled:

Aspen Aerogels, Inc.

Cabot Corporation

Aerogel Technologies, LLC

Active Aerogels, LDA

BASF

JIOS Aerogel Corporation

Nano Technology Co., Ltd.

Dow

Enersens

Key Aerogel Company Insights

Some of the key players operating in the market include Aspen Aerogels, Inc., Cabot Corporation, Aerogel Technologies, LLC, and others:

Aspen Aerogels, Inc. provides advanced aerogel materials renowned for their exceptional thermal insulation properties and lightweight design. The company specializes in developing high-performance aerogel products for various industries, including oil and gas, construction, automotive, and aerospace. Aspen’s flagship product, Pyrogel, is used for industrial insulation, while Cryogel caters to cryogenic applications. These innovative materials offer significant energy savings and safety benefits, making Aspen Aerogels a key player in promoting sustainability and efficiency across multiple sectors.

Cabot Corporation is a global specialty chemicals and performance materials company recognized for its innovative solutions across various industries, including electronics, energy, and transportation. The company offers diverse products, including carbon blacks, fumed silica, and aerogels. Its aerogel products, particularly in aerogel-based insulation materials, are designed to provide outstanding thermal performance, lightweight characteristics, and versatility for applications in oil and gas, building and construction, and automotive sectors.

Order a free sample PDF of the Aerogel Market Intelligence Study, published by Grand View Research.

0 notes

Text

"From Costs to Sustainability: Why PET is a Game-Changer for Packaging"

As global markets expand, the demand for efficient, cost-effective packaging solutions has skyrocketed. This raises a crucial question: how can industries meet these growing needs while ensuring product safety and sustainability? Enter PET (Polyethylene Terephthalate), a material that is rapidly replacing glass in packaging. Why is PET the ultimate choice for modern packaging, and what are its key benefits? Now let's explore PET's transformational potential and how it will influence packaging going forward.

The Rise of PET: A New Era in Packaging

In recent years, PET has emerged as a game-changer in the packaging industry. But what exactly makes PET stand out from traditional materials like glass? PET is extremely lightweight, durable, and indestructible in contrast to glass.It is a more affordable option for packing food and drinks because of these features.For example, PET’s high barrier properties ensure that products remain fresh longer, which is a significant advantage in the competitive market of packaged goods.

Strength and Durability: PET vs. Glass

When comparing PET to glass, strength and durability are where PET truly shines. Glass, while classic, is heavy and prone to breakage, which can lead to costly losses during transportation. PET, on the other hand, drastically reduces transportation costs due to its lightweight nature. The almost zero breakage rate of PET ensures that products arrive at their destination intact, making it a reliable choice for manufacturers and distributors alike.

Economy of Cost and Adaptability

PET's cost-effectiveness is one of its greatest benefits. PET is not only reasonably priced but also pliable in a broad range of forms and dimensions because of its durability and resilience to chemicals. The product's visual attractiveness is improved by adaptability, which fosters greater creativity in packaging design. PET is also reasonably priced for its production method, which makes it a cost-effective option for packaging requirements involving large volumes.

Environmental Advantages: PET's Recyclability

PET's recyclability is a big plus at a time when environmental sustainability is a major concern. In contrast to glass, which may be recycled but needs a lot of energy to do so, PET is easily recycled into new products. In addition to having zero environmental impact, this 100% recyclable product also satisfies consumer demand for environmentally responsible goods. PET's capacity to be made in a variety of colors and transparency makes it suitable for use in a variety of industries.

SEPPA SOLUTIONS: Leading the Charge in PET Packaging Solutions

For those seeking advanced PET packaging solutions, SEPPA stands at the forefront. SEPPA offers a comprehensive range of PET blowing machines, from semi-automatic to fully automatic models. Whether your needs are for low-speed or high-speed production lines, Seppa equipment caters to various industries, including water, sparkling water, CSD (carbonated soft drinks), juice, milk, beer, liquor, and wine. Seppa Solutions offers full line solutions for PET bottles and jars in addition to PET blowing equipment.

This includes rinser fillers, cappers, labelers, date and batch coders, shrink/carton packaging equipment, palletizers, and stretch wrappers. Selecting Seppa Solutions means investing in a strong and adaptable packaging solution that satisfies market demands.

Why PET is the Best Option for Contemporary Packaging

To summarize, PET is not only a fad but a revolution in the packaging sector. It is the best option for many different items because of its durability, affordability, adaptability, and environmental advantages. PET plays an increasingly important role in providing effective, sustainable packaging solutions as the world's markets continue to expand. A more efficient and environmentally responsible future is only a few steps away for companies that embrace PET and invest in cutting-edge solutions like those provided by Seppa Solutions.

#automatic pet bottle blowing machine#pet blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#pet bottle blow machine#pet blower machine#pet blowing machine manufacturer in india#automatic pet blowing machine#bottle blower machine#bottle blow machine#pet blowing machine manufacturer

0 notes

Text

Application of Acrylic Material in Thermoforming

With the demand for diversified designs and the wide application of new materials, plastic materials are favored by designers and users because of their unique characteristics. There are many types of plastic materials, with obvious characteristics and wide applications, acrylic materials are undoubtedly the ones.

Ⅰ. Thermoforming

With the continuous development of science and technology, the manufacturing industry is also constantly innovating and progressing. Among them, thermoforming process, as an emerging manufacturing technology, is gradually becoming a new trend in the future manufacturing industry.

Thermoforming is divided into thin gauge thermoforming and heavy gauge thermoforming according to the thickness of the sheets.

Thermoforming is a plastic processing technology. The main principle is to heat a flat hard plastic sheet to soften it, then use vacuum to adsorb it to the surface of the mold, and then cool it into shape. It is widely used in plastic packaging, lighting, advertising, decoration and other industries.

Heavy gauge thermoforming refers to the use of materials with a thickness exceeding 2mm, which cannot be vacuum formed on fully automatic tools. A semi-automatic vacuum forming machine dedicated to thick gauge thermoforming must be used for processing and production.

To optimize the sheet forming process, it is crucial to consider various factors. Begin by carefully managing stress concentration heat sheet, ensuring that ambient air temperature is controlled. Achieve uniform temperature distribution across the sheet, paying particular attention to the sheet interior's cooling time. Use a proper mold covering to maintain forming temperature low. Employ a blowing mold consists of optical light sensors for precise monitoring. Alternatively, a jig or soft material can be utilized to enhance the cooling process. Implementing a horizontal heating system further contributes to the overall efficiency and effectiveness of the sheet forming operation.

Vacuum forming can be used for product design and manufacturing of rear-projection TV back covers, displays, medical equipment, textile machinery, automotive accessories, and product design and manufacturing in precision electronics, medical equipment, and cosmetics industries.

The main advantage of pressure forming is that it can produce complex shapes and sizes, while also providing supporting services during the manufacturing process, such as printing and assembly, to meet vacuum forming requires of different customers.

Ⅱ. Acrylic Sheet

Acrylic

Acrylic (PMMA) particles are colorless or transparent material with a specific gravity of 1.19 g/cm3 and low surface hardness. They are easily scratched by hard objects and difficult to catch fire. The melting point of PMMA is about 130–140°C, which is much lower than the high temperature of glass, which is about 1000 degrees.

The panel is coated with a high concentration of ultraviolet absorber. Acrylic has high transparency, can be weathered for a long time, never fade, has a service life of 5 to 8 years, and has good light transmittance, up to 93%, with excellent light transmittance and light soft.

Acrylic sheet is a plexiglass processed through a special process. It has strong hardness, good material, radiation protection, and good light absorption effect. With the development and widespread application of optical technology, it has gradually been widely used in industrial manufacturing and modern home life. middle. Moreover, acrylic materials have large sales volume and high recognition in the market.

PMMA has the advantages of being light, cheap, and easy to form. Its forming methods include casting, injection molding, machining, vacuum forming, etc. Injection molding, in particular, can be produced in large quantities with simple process and low cost. Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

Why is Acrylic Sheet Suitable for Thermoforming?

Appearance

From the appearance point of view, acrylic sheets have the same transparency as crystal, with good light transmission effect, which can reach more than 93%. In the design and manufacturing process, many different colors can be customized according to requirements.

The dye effect is good. After a long period of There is no possibility of color fading after use. Only with good quality can it be widely promoted and used in the decoration process.

Good Processing Performance

It has excellent heat resistance. Generally speaking, the surface of its acrylic sheet has the advantage of very good resistance to high temperatures after encountering high temperatures. Of course, for different size ranges, they all need to be processed before they can be installed.

Its processing performance is relatively strong, and the quality and performance are the same as before processing. At the same time, it has good toughness and no defects will appear during the processing, the outdoor service life is about 5-10 years, and the color remains as new during use.

Production Process

In terms of the production process of acrylic sheets, there are mainly two types: casting type and extrusion type. The hardness and toughness of the sheet are improved through hot processing technology. This is why at the current stage, acrylic panels installed outdoors will not have any quality problems after a long period of weathering.

Therefore, the emergence of this new sheet material can have unique technical advantages from this process and form its own characteristics at the current stage.

Cast Plate: Higher molecular weight, excellent stiffness, strength and excellent chemical resistance. Therefore, it is more suitable for processing large-sized sign plaques, and the softening process takes a relatively long time.

This sheet is characterized by small batch processing, unmatched flexibility in color system and surface texture effects by other products, and complete product specifications, suitable for different needs.

Extruded plate: Compared with cast plate, extruded plate has lower molecular weight and weaker mechanical properties, but has higher flexibility, which is beneficial to bending and thermoforming processing, and its softening time is shorter. When processing larger-sized sheets, it is beneficial to various rapid vacuum forming.

At the same time, the thickness tolerance of extruded plates is smaller than that of cast plates. Since extruded boards are produced automatically in large batches, the colors and specifications are difficult to adjust, so the diversity of product specifications is subject to certain restrictions.

Translucency

In terms of appearance light transmission effect, there are mainly types such as transparent, translucent, milky white, etc. The colors are different, and the surface effects will also be different, and the visual impact is very strong.

Excellent Material

Acrylic sheet is a new green and environmentally friendly material in the 21st century. It has a high recycling rate and can be reused to make simple sheets. It has strong light transmittance. These characteristics make it play a key role in the decoration process.

Ⅲ. Application of Acrylic Thermoforming Products

In terms of engraving, decoration, handicraft production, advertising signs, light boxes, etc. PMMA has the advantages of being light, cheap, and easy to form.

Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

In construction, it is mainly used in lighting bodies, roofs, sheds, stairs and interior wall panels. The application of acrylic in lighting lampshades and automotive lamps on highways and high-end roads is also quite rapid.

With the construction of hotels, guesthouses and high-end residences in big cities, lighting bodies have developed rapidly. Lighting bodies made of extruded plexiglass panels have the characteristics of high overall structural strength, light weight, high light transmittance and good safety performance. Compared with inorganic glass lighting devices, it has great advantages.

In terms of sanitary ware, acrylic can be used to make bathtubs, washbasins, dressing tables and other products. Acrylic bathtubs have been widely used due to their luxurious appearance, depth, easy cleaning, high strength, light weight and comfortable use.

Acrylic is the best new material for manufacturing sanitary ware after ceramics. Compared with traditional ceramic materials, in addition to its unparalleled high brightness, acrylic also has the following advantages:

It has good toughness and is not easy to be damaged, it has strong repairability. Just use soft foam and a little toothpaste to wipe the sanitary ware as new.

The texture is soft and does not feel cold and biting in winter.

The colors are bright and can meet the individual pursuits of different tastes.

Using acrylic to make basins, bathtubs, and toilets is not only exquisite in style and durable, but also environmentally friendly. Its radiation is almost the same as the radiation of the human body's own bones.

Acrylic can be made into various fashionable products, such as leather bags, waist chains, watches, high heels, heels, hair accessories, brooches, bracelets, buttons, earrings, necklaces, rings, pendants, photo frames, etc. There are many types and unlimited development space for continuation.

At the same time, acrylic material has high processing plasticity and good surface hardness and transparent luster. It is often used by designers to match with various materials in the design of various exquisite containers to add texture and practicality to the containers, such as lipsticks and Delicate containers such as chemicals, and other daily necessities such as massagers, jewelry boxes, fans, etc.

Taking advantage of the cool feeling of acrylic material and combining it with creative design, acrylic material is perfectly presented in a variety of popular boutiques.

Acrylic thermoformed door panel series: European style, Chinese style doors, door frames, dado panels, ceilings, gussets, etc.

Acrylic thermoformed curtain boxes, window sill panels, window covers, etc.

Acrylic thermoformed furniture series: desktops, benches, countertops, shelves, kitchens (bookcases, wardrobes), etc.

Acrylic thermoformed series production of various speakers.

Processing and production of acrylic thermoformed vehicles and special-shaped decorative products for boats.

Ⅳ. Advantages of Thermoformed Acrylic Products

Transparency

Colorless and transparent organic glass sheet with a light transmittance of over 92%.

Excellent Weather Resistance

It has strong adaptability to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its performance will not change. It has good anti-aging performance and can be used outdoors with confidence.

Good Processing Performance

Suitable for both machining and vacuum forming, acrylic panels can be dyed, and the surface can be painted, screen-printed or vacuum coated.

Excellent Comprehensive Performance

Acrylic boards come in a wide variety of colors, and have extremely excellent comprehensive properties, providing designers with a variety of choices. Acrylic boards can be dyed, and the surface can be spray-painted, screen-printed or vacuum coated.

Non-toxic

It is harmless even if it comes into contact with people for a long time, and the gas generated when burned does not produce toxic gas.

Made of PMMA acrylic thermoforming, it has the characteristics of good light transmittance, bright and clean exterior and interior, environmental protection, and can be painted. The color can be changed to produce products of different specifications and shapes according to customer requirements.

Mainly used in plastic transparent covers of game consoles, lampshades, observation instrument covers, leisure furniture hammocks, organic handicrafts, bank signboards, advertising light boxes, etc.

Ⅴ. Precautions for Acrylic Thermoforming Production

General acrylic will undergo thermal deformation at about 100 degrees Celsius, so you must pay attention to this temperature when using it, and if it is to be used continuously, the temperature cannot be higher than 90 degrees.

When acrylic thermoformed products become blurry or unclean due to slight scratches or dust adsorption due to static electricity, you can use 1% soapy water to wipe them clean with a soft rag.

The hardness of the thermoformed surface is comparable to that of aluminum, so care should be taken to avoid scratching the surface when using or processing acrylic. If it is accidentally scratched, it will need to be restored by polishing.

When installing acrylic products, thermal expansion and contraction must be taken into consideration, and there must be a space for expansion and contraction during assembly.

If the preliminary processing work is not done well, the acrylic thermoformed product will also be deformed at the moment of demoulding, and the quality of the deformed product will inevitably be affected. In order to avoid similar problems from happening again, we must develop corresponding solutions to this problem.

In order to prevent deformation after pressure forming is demolded, the operator is first required to check the temperature of the cooling water, and at the same time adjust the water volume of the nozzle to meet the specified range. Secondly, the wind direction at each location must be adjusted to find the most suitable forming pressure for acrylic thermoforming production.

In addition, when demoulding, try to use the pressure of vibrating the upper mold to force smooth demoulding. If the air volume at the bottom can be appropriately increased, it will also be helpful to ensure the quality of acrylic thermoformed products. If these cannot solve the problem, the only way to overcome the deformation problem is to re-make the upper mold.

Conclusion

With the continuous advancement of social science and technology and the continuous improvement of process technology, acrylic thermoforming will have broader market prospects and application prospects in the future. Its future development trends include the following aspects:

1. Continuous improvement of creativity: As people pay more and more attention to personalization, acrylic thermoforming will use more creativity to create more unique products through different processes and materials.

2. More environmentally friendly and energy-saving: When making acrylic thermoforming products, low-carbon, environmentally friendly, and energy-saving methods will be increasingly used to achieve a greener production environment.

3. Upgrading of materials: As people pay more and more attention to health and environmental protection, acrylic blister materials will increasingly use healthy, environmentally friendly and safe materials, and improve the performance indicators of the materials through technical means.

0 notes

Text

Dishwashing Detergent Market Trends and Opportunities: Global Outlook (2023-2032)

The Dishwashing Detergent Market is projected to grow from USD 20,438.4 million in 2024 to USD 33,698.63 million by 2032, reflecting a compound annual growth rate of 6.45%.

Dishwashing detergent, also known as dishwashing soap, dish detergent, or dishwasher detergent, is a type of cleaning agent used to assist in dishwashing. It is usually a highly-foaming mixture of surfactants with low skin irritation, and is primarily used for hand washing of glasses, plates, cutlery, and cooking utensils in a sink or bowl. In addition to its primary use, dishwashing detergent also has various informal applications, such as for creating bubbles, cleaning oil-affected birds, and various other cleaning purposes.

The effectiveness of dishwashing detergents depends on several factors including the quality of the water being used, the amount of grease and dirt on the items to be washed, and the specific chemicals used in the formulation of the detergent. Modern dishwashing detergents contain a complex mix of ingredients that often include surfactants, enzymes, bleach, and fragrances to improve cleaning performance, reduce water hardness, and provide a pleasant scent.

The composition of these detergents can vary significantly. Surfactants are used to break up grease and dirt, enzymes are added to break down starches and proteins, and bleaching agents help remove tough stains. Each component works together to ensure effective dish cleaning. Moreover, environmental concerns have prompted the development of eco-friendly dishwashing detergents that use biodegradable ingredients and avoid phosphates that can cause algal blooms in waterways.

Dishwashing detergents are available in various forms including gels, liquids, powders, and tablets. Each form has specific advantages depending on the washing conditions and the type of dishwashing machine, if one is used. Liquid detergents are particularly popular for handwashing dishes because they dissolve quickly and are easy to control in terms of quantity. Powders and tablets are commonly used in automatic dishwashers for their convenience and controlled dosing, which helps prevent waste.

The global market for dishwashing detergents has seen steady growth, driven by rising household standards and increasing availability of automated dishwashers in homes. Manufacturers are continuously innovating and expanding their product lines to include detergents that are not only more effective but also environmentally friendly, catering to the growing consumer demand for sustainable cleaning solutions.

Key Player -

Procter & Gamble Co. (US)

Unilever NV (Netherlands)

Henkel AG & Co. KGaA (Germany)

Church & Dwight Co. Inc. (US)

Kao Corporation (Japan)

The Clorox Company (US)

SC Johnson & Son Inc. (US)

Lion Corporation (Japan)

Seventh Generation Inc. (US)

More About Report- https://www.credenceresearch.com/report/dishwashing-detergent-market

The Dishwashing Detergent Market is witnessing robust growth driven by increasing consumer awareness regarding hygiene, escalating demand for convenient cleaning solutions, and the rising trend of automatic dishwashers in households. Moreover, the market is propelled by advancements in product formulations, such as eco-friendly and biodegradable detergents, catering to environmentally conscious consumers.

Furthermore, the burgeoning urban population and their hectic lifestyles are fueling the demand for time-saving cleaning products, further stimulating market expansion. Additionally, innovations in packaging and marketing strategies, coupled with the growing e-commerce sector, are providing significant opportunities for market players to expand their reach and enhance their market presence.

Competitive Analysis-

Procter & Gamble, for instance, offers a variety of dishwashing products under its well-known brands such as Dawn and Cascade. These products are popular for their cleaning efficiency and are marketed through various channels, including extensive advertising and promotional strategies.

Unilever, another giant in the market, competes with its array of brands like Sunlight and Seventh Generation, focusing on eco-friendly and sustainable products, which appeal to a segment of consumers increasingly concerned about environmental impact.

Reckitt Benckiser with its Finish brand, emphasizes innovation in the automatic dishwashing market segment, offering products that promise superior cleaning power and convenience.

Henkel markets its dishwashing products under the Persil and Pril brands, known for their effectiveness and the company's commitment to sustainability.

These companies often engage in competitive strategies such as mergers, acquisitions, and partnerships to expand their market footprint and enhance their product lines.

Segments:

Based on Type:

Liquids

Powder

Cakes

Others

Based on End-User:

Residential

Commercial

Institutional

Browse the full report – https://www.credenceresearch.com/report/dishwashing-detergent-market

Browse Our Blog- https://www.linkedin.com/pulse/dishwashing-detergent-market-overview-growth-factors-future-singh-xuwzf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Best Digital Weighing Scale To Buy In India Online

It was a time not much way back when you and I had to go to the railway stations, hospitals, and hotels, to possess the bodyweight checked. Why? What’s the reason? We all know what it is. Even in recent times, people are more concerned about the way to remain healthy by losing weight.

So the weighing scale is going to be the most effective ever friend during this effort. Keep track of your weight, on a weekly or on a monthly basis by buying the right quality weighing scale.

A personal weighing scale will become a health monitor not just for you but also for your whole family. We’ve got n number of weighing scales available within the market.

Here we discuss something which is more beneficial to purchase and what we'd like to think about while buying.

Accuracy

If you select an analog machine, then it'll most likely give inaccurate over time due to their spring responsiveness. Here comes the digital weighing scale which plays a significant role in terms of accuracy.

Display

The most weighing scale needs a user to face up straight to report the accuracy of the weight. Choose the weighing scale with a clear and visible display.

Capacity

If you see most general bathroom scales have a typical weight capacity of 120 kg to 150 kgs. If you select high weight capacity scales which will give accurate results up to 250 kgs.

Material

Consider the overall quality and material of the scale in order to serve the consistent weight. Most of the digital weighing scale is formed from durable tempered glass, stainless steel and MS they can't be broken easily, easy to clean and maintain.

Automatic Feature

The most digital weighing scale has a feature that it automatically turns off the machine when it’s not used for some time. It helps to save lots of battery and run an extended time at usage times.

If you belong to an industry, then you must need to consider the following

Know Your Application

What will be the weighing scale going to be used for and where it is going to be used? Will this be compatible with other equipment? Few examples are,

Quality Assurance

Manufacturer

Parts Counting

Shipping

Research Laboratory Testing

Personal Scale

EQUAL offers the best personal scale in India to measure body weight. A slim and sleek weight machine that provides accurate measurement every time you are taking a reading. It’s a user-friendly scale with auto-step on technology to provide you quick results. The scale LCD reflects clear readings and the maximum load capacity of this weighing machine is 150 kg.

The machine is able to detect the lowest weight accurately is 100 grams. It has a lithium battery and is powered by 3 volts.

Digital Table Top Weighing Scale

A digital table top weighing scale is especially focused on medium-sized retail shops. This scale is extremely successful for retail weighing things with a solid body, excellent quality, and accuracy. This is often an ideal choice for all grocery shops, meat shops, bakery shops, and supermarkets.

Environment

The weighing scale comes with a range of features like waterproof and shockproof. Before you opt for a weighing scale, consider as to where you're going to place this device, if an area with high humidity and moisture then buy a water-proof machine. Suppose if you have got kids in your home, then prefer a shockproof device.

Skid-Proof

This is the main part to consider while purchasing the weight machine. Some scales don’t meet the skid-proof feature. Some old ones and youngsters may use the device to weigh themselves. So it’s important to get the device with skid-proof design.

Conclusion

Considering all these things EQUAL is the leading weighing scale manufacturer that offers a number of the most effective digital weighing scales in India. During this contemporary world, people have no time to spend and check their weight, but personal weighing machines are the one that helps to examine your weight more frequently, and this keeps you healthy forever.

#Scale Solutions#Precision Weighing#Digital Scale#Weight Management#Smart Scale#Balance And Beyond#Digital Precision#Scale It Right#Weight Check#Measure Your Success#Precision Weight#Skid-Proof#Environment#Digital Table Top Weighing Scale#Weighing Scale#Digital Weighing Scale#Personal Scale#Application#Quality Assurance#Manufacturer#Parts Counting#Shipping#Research Laboratory Testing#Automatic Feature#Material#Display#Capacity#Accuracy#Best Digital Weighing Scale#Buy In India Online

0 notes

Link

0 notes

Text

Industrial Parts Washer In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Industrial Parts Washer Market: Global opportunity analysis and industry forecast

Industrial parts washers are the cleaning equipment that are used to remove the debris or contaminants like paint, grease, oil and corrosion from the work-pieces. The industrial part washers are automatic or semi- automatic machines that uses high pressure jets to spray detergents, hot water, acids and solvents to clean the parts surfaces. Industrial parts washers are powered by gasoline or electricity and includes a wash tank that is made up of glass, plastic or stainless steel. Other components include brushes, scrubbers, water softeners and deionizers. The industrial washers are categorized into different types such as solvent based industrial parts washer and water based industrial part washer which includes degreasers, thermal washer, spray washers, fluidized bed washer, and scrub tanks. The thermal system is one of the popular type in industrial parts washers which is used heat to remove grease, oil and other contaminants from the machine parts.

Top impacting factors: Market Scenario Analysis, Trends, Drivers and Impact Analysis

The increasing demand for the cleaning of accessories of a machine during the time of packaging, surface treatment, distribution and assembling act as a growth driver for the industrial parts washer market. The growing manufacturing and automotive industries in the developing countries like India and China is expected to boost the growth of the industrial parts washer market. Further, the rising demand for the light motor vehicles and public transport vehicles in automotive industries due to rise in working population is expected to boost the growth of the industrial part washer market. The increasing importance for protecting the equipment’s from dirt, corrosion and other external factors is creating demand for industrial parts washers in the industries. However, the high initial investment and decline in the sale of automobiles in past few years can hamper the growth of the industrial parts washer market.

New product launches to flourish the market

The launch of new generation technologically advanced products can boost the growth of the industrial parts washer market. On November 2018, one of the global leader in industrial parts washer The Ecoclean Group has launched a new industrial parts washer EcoCcompact. The product EcoCcompact is a solvent-based industrial parts washer which uses hydrocarbons and alcohols for cleaning of parts and components of various machines in aerospace and automotive industry. It is also used in manufacturing units to remove the contaminants like grease, metal chips, paints and other such contaminants.

High demand form applications:

The automatic industrial parts washers is used for various applications in industries like automotive, aerospace, printing and manufacturing. In automotive industries, the industrial steam washer are used to clean the engine block, gear boxes and the fastener tools like nuts, bolts, screws and rail bearings. The oil, dirt, metal chips, abrasives and grease from these components are cleaned with hot water and detergent that is sprayed using a pressure jet. Further, in aerospace industry, the industrial parts washer are used in repairing and re-manufacturing operations of jet engine and used in cleaning of contaminants from the turbine blades. Moreover, in printing & press industry, industrial parts washers are used in cleaning and degreasing the inks, varnish and other waste lubricants that are used during the production of newspapers, magazines and others. The solvent parts washers is used in the removal of oil & grease in slicers, utensils, stoves and other food preparations equipment in food & beverages industries.

Full Report With TOC:-https://www.alliedmarketresearch.com/industrial-parts-washer-market-A09999

0 notes

Text

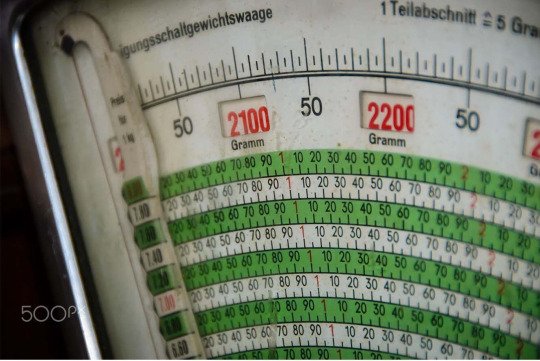

Automatic Glass Forming Machine Market Report Till 2028 | Latest Trend, Growth Opportunities & Forecast Analysis

The study on Automatic Glass Forming Machine Market with its type and application sales analysis is very essential for all the decision-makers or strategists operating in this industry. The report is made by analysts with deep industry knowledge and experience. The global, regional, and country annual sales and revenue has been studied for the historical years and estimated for the current year. With the help of analytical tools, primary interviews, and data triangulation the report is enriched with quality data. The qualitative data on the upcoming industry trends with market triggers and risks are covered as a separate section in this comprehensive report.

As understood and analyzed in the global Automatic Glass Forming Machine market report the growth CAGR in the year 2022 to 2028 is showing a promising inclination. The macro and microeconomic conditions are studied and forecast data is anticipated.

Click here to get a FREE Sample PDF Copy of the Automatic Glass Forming Machine Market Research Report @ https://www.decisiondatabases.com/contact/download-sample-59820

As per this report analysis, the Automatic Glass Forming Machine market is expected to show a CAGR (revenue) of xx% between the forecast years and the global market size can cross USD XX million by the end of 2028, growing from USD XX million in the year 2022. This report specifically covers the global market share (sales as well as revenue) of key companies in the Automatic Glass Forming Machine business, as mentioned in a separate Chapter 3.

Regionally, the Automatic Glass Forming Machine market data is studied under the below-mentioned regions and countries – Americas covering (United States, Canada, Mexico, Brazil), APAC covering (China, Japan, Korea, Southeast Asia, India, Australia), Europe covering (Germany, France, UK, Italy, Russia, Spain), Middle East & Africa covering (Egypt, South Africa, Israel, Turkey, and other GCC Countries).

This research study gives a comprehensive overview of market share and growth opportunities of the Automatic Glass Forming Machine market as per type and application. The report also covers key manufacturers’ profiles with sales and gross margin data.

The key manufacturers covered in this report: Breakdown data in Chapter 3.

Heye International GmbH

BDF Industries

Jetter AG

Sklostroj Turnov

LiSEC GmbH

JCL Engineering

Ishizuka Glass Group

BOTTERO

C&M Machinery

Chongqing Life Furnace Technology

GPS Glasproduktions-Service GmbH

Bucher Emhart Glass

Others

To inquire about report customization, feel free to reach out to our team of expert analysts @ https://www.decisiondatabases.com/contact/ask-questions-59820

This study considers the Automatic Glass Forming Machine value and volume generated from the sales of the following segments:

Segmentation by type: breakdown data from 2017 to 2022, in Section 2.3; and forecast to 2028 in section 11.7.

Blow and Blow Method

Press and Blow Method

Segmentation by application: breakdown data from 2017 to 2022, in Section 2.4; and forecast to 2028 in section 11.8.

Health Care

Chemical

Food & Beverages

Laboratories

Others

The latest developments of the industry and the sales channel, manufacturing process along with the manufacturing cost study is covered in the report.

Key Questions Answered –

What will be the Automatic Glass Forming Machine market CAGR and size between 2022-2028?

Who are the top/leading players of the Automatic Glass Forming Machine market?

What changes are expected in the Automatic Glass Forming Machine market in the next six years?

Which are the top product and leading applications of the Automatic Glass Forming Machine market?

What are the leading market drivers and major risks factors for the Automatic Glass Forming Machine market?

Which region/country leads and foresees highest growth in the next six years?

Purchase the Complete Global Automatic Glass Forming Machine Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-59820

About Us:

DecisionDatabases.com is a global business research report provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research reports, customized research reports, company profiles, and industry databases across multiple domains. Our expert research analysts have been trained to map clients’ research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise, and meaningful data at a lightning speed.

For more details: DecisionDatabases.com E-Mail: [email protected] Phone: +91-93077-28237 Website || Official Blog || Insights Analysis

#Automatic Glass Forming Machine#Automatic Glass Forming Machine Market#Automatic Glass Forming Machine Industry

0 notes

Text

Anon said: BSKSBS OK SO BEFORE REQUESTING IS CLOSED (hopefully I’m not late-) CAN I GET REINER AND HIS S/O GOING IN A PLANE TRIP SOMEWHERE WITH HIS CUSINS OR HOING TO A ARCADE???? I really love your fics and they make me go 💞💞✨

Reiner and his cousins on an airplane

{ Reiner x you | tw:air-sickness | fluff | modern }

{ "La Seine a Paris" 1915 by Henri Alphonse Barnoin 1882 - 1940 }

When arriving at the automatic glass doors, leading to the long open terminal area, Gabi and Udo were the first to run off towards the large clear windows.

Their faces smoshed against the glass, watching in awe as a plane was making a round through the runway, preparing to take off.

Following them was a very sleepy Zofia who fell into the nearest seat available, as her mother sat beside her while talking to Udo's mom.

Soon enough, an out of breath Falco was sitting near them after insisting to carry the clearly too heavy bag, that was twice his size, to the luggage area with Reiner.

Udo's mom made sure each of them had their carry on backpacks with snacks, blankets and everything they might need, while Zofia's mother made sure they behaved and didn't bother the security too much during check up.

Reiner was beside you the whole time, going with you to finish the documents and get their boarding tickets, taking a walk through the airport free market and buying something to drink from the vending machines.

It's a trip you've both been planning for months, a week alone in a far away tropical island, white sandy beach with stray coconuts and tall palm trees. The perfect getaway for you to relax and get some time for yourselves.

At least that's what it was supposed to be, wasn't it for Reiner accidentally mentioning it to Bertolt one night.

And just like fire spreading, it wasn't long before Bertolt told Annie, who mentioned it to Zeke who spoke to Pieck about it and it ended with Porco who spilled it to Zofia's mom on a Saturday's night.

Just after 24 hours of Reiner telling Bertolt, you both got a call from Udo's mother saying they've already booked tickets for them and the kids to accompany you.

"We thought you'd feel alone all by yourselves."

And with Reiner already having taken the time off work, he couldn't reschedule it.

That's how you ended up boarding and airplane with four kids and their two mothers.

Surprisingly getting them through security wasn't as hard as you thought it would be, especially with Zofia's mother keeping an eye on them.

It wad the boarding part that's almost caused a fight to happen on the airplane, you see like all kids, they too wanted to window seat.

You and Reiner looked at each other, both concerned you might get kicked off the airplane if this wasn't solved really quickly before it gets physical.

Thankfully, with some coaxing from Udo's mother and sly manipulation form Zofia's mom. The kids ended up agreeing on a seating arrangement that restored peace between them.

Gabi would sit near the window, Falco in the middle seat with Reiner near the aisle. He'd be just opposite side of where you sat next to him, Zofia near you in the middle and Udo near the window.

Apparently Zofia's and Udo's mother somehow managed to take the far away two seats that were booked for you and Reiner.

With being separated, even if it's by a small walk through aisle, Reiner's mood quickly went sour as he looked at your with a grumpy look.