#Automatic Glass Forming Machine Industry

Text

10.

⚠️ SPOILER ALERT! ⚠️

Click here to read Neon Blessing from the beginning!

Club RED was a labor of love. A cyclopean eye of neon tubes stared down at the street from the facade of a beautiful temple to excess, bathing the darkening street in bloodred light which played through the mist kicked up by a nearby waterfall. The building was dark glass and darker stone, three stories tall and culminating in a domed roof. It wasn’t even 5 pm, but the line was pouring out the door and onto the sidewalk, foreign raincoats and umbrellas standing side by side with wet-haired Diluvian partygoers.

Shiv had never entered a nightclub through the front before. There’d been one club, the Magpie, that she’d frequented with her friends, but the owner was one of Ornarch’s devout and always let them skip the lines. Huh. She hadn’t been to the Magpie in years. She wasn’t even sure if it was still in business.

The line moved quickly, and before long, she was at the door. “Let’s see some ID.” There were two bouncers, identically dour and militaristic-looking men who loomed over her like a pair of sunglasses-clad statues, their suits custom-made to fit over the bulky structure of a mil-spec exocloak. Thin seams in the skin of their faces suggested the presence of subdermal armor plating to protect what the mechanized armor didn’t. One of them handled a scanner with the practiced care of a guy whose grip could crush a human skull.

Shiv showed them the card. “Kooler sent me.” The one with the scanner stared her down while the other barked a few quick words into a headset. If shit went south, the only viable exit was ducking the rope to the left, but Headset would make a grab for her and if those huge hands got a grip it was over. She’d need to distract him first, maybe blind him. Throw her coat in his face? She started to shrug it off her shoulder, just in case. Scanner continued to glower at her in a prolific display of disdain. He should be too far away to do anything, but just in case-

Headset spoke, snapping her out of her planning.

“Hm?” She’d missed what he’d actually said.

“Go on in. The boss is on the second floor.” Shiv pulled her coat back over her shoulder and brushed past the bouncers and into the club. She pushed her way past a heavy curtain of soundproof fabric and replaced the endless roar of the streets with the endless roar of Club RED’s speakers.

Water poured down gilded fountain walls and colored lights arced and scattered through thick smoke, produced by a mix of sweet-scented cigarettes and industrial fog machines. Waiters and waitresses wearing practically nothing served a very peculiar clientele: half of the patrons were exactly what she’d expected, the sort of wealthy-looking folks willing to spend fifteen credits on a can of beer; and the other half were all grizzled paramilitary types. The burning coal glow of their cybernetic eyes stared out at her through the fog, automatically seeking out her vital organs before flicking back to their drinks.

Shiv scaled the stairs to the second floor, taking a moment to look out on the dance floor from the balcony. The band’s frontwoman was more work of art than human, her limbs all formed from sweeping lines of carbon fiber and steel. Her guitar plugged into a port on the back of her neck, her quicksilver fingers dancing over the strings with surreal grace. She had a voice like an angel with a smoking habit.

“She’s quite something, ain’t she?” A woman’s voice came from behind Shiv. She turned to see Kurtz, for who else could it be? The owner of Club RED was maybe forty years old, a little shorter than Shiv, and built like a brick. Her head was clean-shaven, revealing dozens of tally mark tattoos, in sets of five, spreading from near her temple and across half of her head. Unlike everyone else, she was dressed simply and practically, in sturdy black pants and a tank top, and unlike everyone else, she had a gun at her hip, an antique revolver. Both of her eyes were red: one eye was flesh, with an iris that had either been dyed or transplanted. The other eye was metal, the iris glowing the exact same shade as the vast eye on the front of the building. She carried herself with an easy confidence, bordering on arrogance. “Are you the one Kooler mentioned?”

“Yeah.”

“I’m Joan Kurtz, owner of Club RED and REDEYE PMSC. What brings you to my door?”

First Page – Previous Page – Next Page

32 notes

·

View notes

Text

IMAGES: Modernized T-27 aircraft arrives at DCTA

Aircraft will compose a fleet of the Institute of Research and Flight Testing (IPEV), located in São José dos Campos (SP).

Fernando Valduga By Fernando Valduga 09/24/2022 - 3:00 PM in the Brazilian Air Force, Military

The Director General of the Department of Aerospace Science and Technology (DCTA), Lieutenant Air Officer Maurício Augusto Silveira de Medeiros, led, on September 15, the modernized T-27 aircraft (T-27M) from Lagoa Santa (MG) to the Institute of Research and Flight Testing (IPEV), in São José dos Campos (SP).

After landing, firefighters from the Brazilian Airport Infrastructure Company (INFRAERO) welcomed with the traditional baptism bath, which was attended by the Director of the Institute of Development and Industrial Coordination (IFI), Colonel Aviador Luiz Marcelo Terdulino de Brito. Soon after, Lieutenant-Brigadeiro Medeiros passed into the hands of the Director of the IPEV, Colonel Aviador José Ricardo Silva Scarpari, the record book of the plane, to the sound of songs sung by the Music Band and in front of the troop of the Institute, composed of pilots, engineers, mechanics and technicians who have participated in the project since the development of the prototype

The flight represented the delivery of the modernized aircraft, after a synergistic work carried out between the IPEV and the IFI, started in 2020. The Organizations contribute to the process of modernization of the T-27 with tests that evaluate the functionality, performance and reliability of the new systems, which are now presented in Glass Cockpit, based on aeronautical regulations and specialized techniques.

The Glass Cockpit concept made possible, in this aircraft, flights and approaches to landing based on satellite position and performance, that is, more direct and accurate, in addition to sending and receiving information for air traffic control through the Automatic Radiation Dependent Air Surveillance System (ADS-B), which consists of a surveillance technology in which an aircraft determines its position via satellite navigation and transmits it periodically to ground stations

Thus, using the knowledge acquired at the School of Training of Flight Tests (EFEV), IPEV professionals support the improvement of the Brazilian Air Force (FAB), either in the incorporation of new capabilities, or in the improvement of existing ones, contributing to flight safety, as well as to the fulfillment of the institutional mission.

"This modernization of the T-27M contributes to raising the level of the training of our cadets and highlights the high degree of competence of the members of the Lagoa Santa Aeronautical Material Park (PAMALS), IPEV and IFI. It also ratifies the excellence we seek as an institution, providing state-of-the-art equipment, aligned with the demands of the 21st century. In a remarkable way, the T-27M returns to the DCTA, where it was designed and developed to gain a prominent position as an instruction aircraft," said the Director General of the DCTA.

In total, 42 aircraft must be modernized, with the aim of introducing or changing technical and logistical characteristics in the systems or materials in use in Aeronautics, both to update them and to adjust their performance to the specific needs of today.

"At IPEV this magnificent machine also accompanied several generations of pilots and engineers who shared moments of tension and very high workload in the noble mission of forging the crews that today test the modern and newly arrived FAB aircraft, such as the Gripens and the KC-390. T-27M: Welcome to IPEV and DCTA. Know that our connection is prior to your first flight and that we will still have many hours to share together in the immensity of the sky, predicting, forming and testing the Air Force of tomorrow," said the Director of IPEV, Colonel Scarpari.

The T-27 Tucano was born from a FAB need to replace the T-37C, which was used in the advanced instruction of pilot training at the Air Force Academy (AFA). With an advanced design for the time it was developed and with differentiated characteristics for coaches of this type, the Tucano has become a reference in performance and established a new standard. Not by chance, the aircraft was chosen to be used in demonstrations of the Smoke Squadron and, in a short time, became a Brazilian symbol that conquered the world.

Review: DCTA, by Lieutenant Carolina Redlich - Photos: Cabo J. Alves / DCTA

Source: IPEV, by Captain Guilherme

Tags: Military AviationFAB - Brazilian Air ForceT-27 Tucano

Previous news

Heart Aerospace will establish new electric aircraft industry in Gothenburg, Sweden

Next news

Tropical storm cancels next attempt to launch Artemis I

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. It has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

Illustrative image of the arrival of the fighters in April this year.

BRAZILIAN AIR FORCE

Two more F-39E Gripen fighters arrive in Brazil for FAB

09/25/2022 - 16:37

THE U.S. Air Force aviator assigned to the 77th Fighter Generation Squadron reveals the name of the late 1st Lieutenant David Schmitz during a celebration of life at Shaw Air Base, South Carolina, on July 10, 2020. (Photo: U.S. Air Force by 1st class Aviator Destani K. Matheny)

AERONAUTICAL ACCIDENTS

'fake' parts in ejection seat may have contributed to the death of an F-16 pilot in the USA

25/09/2022 - 16:17

HISTORY

The secret U.S. aircraft you may never have heard of

09/24/2022 - 22:49

BRAZILIAN AIR FORCE

FAB Remotely Piloted Aircraft performs first transfer flight

09/24/2022 - 12:30

MILITARY

IMAGES: KAI displays Boramae's KF-21N model for operation on aircraft carriers

09/24/2022 - 11:00

BRAZILIAN AIR FORCE

FAB commander meets with representatives of Boeing and SAAB

09/24/2022 - 10:27

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

3 notes

·

View notes

Text

Best Digital Weighing Scale To Buy In India Online

It was a time not much way back when you and I had to go to the railway stations, hospitals, and hotels, to possess the bodyweight checked. Why? What’s the reason? We all know what it is. Even in recent times, people are more concerned about the way to remain healthy by losing weight.

So the weighing scale is going to be the most effective ever friend during this effort. Keep track of your weight, on a weekly or on a monthly basis by buying the right quality weighing scale.

A personal weighing scale will become a health monitor not just for you but also for your whole family. We’ve got n number of weighing scales available within the market.

Here we discuss something which is more beneficial to purchase and what we'd like to think about while buying.

Accuracy

If you select an analog machine, then it'll most likely give inaccurate over time due to their spring responsiveness. Here comes the digital weighing scale which plays a significant role in terms of accuracy.

Display

The most weighing scale needs a user to face up straight to report the accuracy of the weight. Choose the weighing scale with a clear and visible display.

Capacity

If you see most general bathroom scales have a typical weight capacity of 120 kg to 150 kgs. If you select high weight capacity scales which will give accurate results up to 250 kgs.

Material

Consider the overall quality and material of the scale in order to serve the consistent weight. Most of the digital weighing scale is formed from durable tempered glass, stainless steel and MS they can't be broken easily, easy to clean and maintain.

Automatic Feature

The most digital weighing scale has a feature that it automatically turns off the machine when it’s not used for some time. It helps to save lots of battery and run an extended time at usage times.

If you belong to an industry, then you must need to consider the following

Know Your Application

What will be the weighing scale going to be used for and where it is going to be used? Will this be compatible with other equipment? Few examples are,

Quality Assurance

Manufacturer

Parts Counting

Shipping

Research Laboratory Testing

Personal Scale

EQUAL offers the best personal scale in India to measure body weight. A slim and sleek weight machine that provides accurate measurement every time you are taking a reading. It’s a user-friendly scale with auto-step on technology to provide you quick results. The scale LCD reflects clear readings and the maximum load capacity of this weighing machine is 150 kg.

The machine is able to detect the lowest weight accurately is 100 grams. It has a lithium battery and is powered by 3 volts.

Digital Table Top Weighing Scale

A digital table top weighing scale is especially focused on medium-sized retail shops. This scale is extremely successful for retail weighing things with a solid body, excellent quality, and accuracy. This is often an ideal choice for all grocery shops, meat shops, bakery shops, and supermarkets.

Environment

The weighing scale comes with a range of features like waterproof and shockproof. Before you opt for a weighing scale, consider as to where you're going to place this device, if an area with high humidity and moisture then buy a water-proof machine. Suppose if you have got kids in your home, then prefer a shockproof device.

Skid-Proof

This is the main part to consider while purchasing the weight machine. Some scales don’t meet the skid-proof feature. Some old ones and youngsters may use the device to weigh themselves. So it’s important to get the device with skid-proof design.

Conclusion

Considering all these things EQUAL is the leading weighing scale manufacturer that offers a number of the most effective digital weighing scales in India. During this contemporary world, people have no time to spend and check their weight, but personal weighing machines are the one that helps to examine your weight more frequently, and this keeps you healthy forever.

#Scale Solutions#Precision Weighing#Digital Scale#Weight Management#Smart Scale#Balance And Beyond#Digital Precision#Scale It Right#Weight Check#Measure Your Success#Precision Weight#Skid-Proof#Environment#Digital Table Top Weighing Scale#Weighing Scale#Digital Weighing Scale#Personal Scale#Application#Quality Assurance#Manufacturer#Parts Counting#Shipping#Research Laboratory Testing#Automatic Feature#Material#Display#Capacity#Accuracy#Best Digital Weighing Scale#Buy In India Online

0 notes

Text

What is an Injection Molding Machine? Get to know everything about it!

Injection molding is an important industrial technique. Although it is somewhat similar to die casting, but the raw material used in this case are different. Die casting uses metals that melt at extremely high temperatures, whereas injection molding mostly uses glasses, elastomers, and most frequently thermoplastic and thermosetting polymers. Nevertheless, this process is commonly used to create thermoplastic materials. In this method, raw materials are heated to a certain temperature and then injected under pressure into the mould cavity without changing their composition.

What are the main parts of injection molding machine?

The material hopper, barrel, an injection ram/rotating screw type plunger, heating element (heater), adjustable pattern, ejectors, and a mould inside mould cavity are the key components of an injection molding machine.

Injection molding machines typically operate horizontally. A barrel is part of an injection molding machine (cylindrical pipe). At one end of the barrel, there is a hopper. Inside the barrel is a revolving screw or hydraulic ram powered by an electric motor that provides force. The barrel has a heating element (warmer) attached to it that is used to melt the molding compound when it exits the hopper.

Mold cavity linked to the barrel's opposite side. During the entire production process, a movable pattern is used and the mould is situated inside the mould cavity. Typically, copper, aluminum, and tool steels are used to make mould. Distinct types of material moulds have different life cycles. This can be chosen based on your needs.

How does the injection moulding machine works?

Extrusion and injection molding both function similarly, as implied by their names. Using a feeding apparatus, molding material and raw materials are poured into the hopper. Following that, the molding material falls into the cylinder (barrel) as depicted in the diagram due to gravity. The material is melted using a circumferential heater that is mounted on the barrel. When molding compound in powder form enters the barrel from the hopper, it begins to melt, and a revolving screw or hydraulic ram applies pressure to advance the compound into the mould.

In this split mould, which is attached to the other side of the barrel, molten plastic material is pumped into a closed mould. The revolving screw constantly advances the molding material. The hydraulic system exerts pressure. Normal injection pressure ranges from 100 to 150 MPa. Following injection, pressure is exerted for a while or held in place with some force.

The pieces produced when the entire procedure is complete are appropriately cooled. The mould is then opened, and a few ejectors are utilized to remove the part properly and damage-free. The portion mould is reopened after removal. This process is very fast and automatically repeated. Here, it is simple to make pieces with complex shapes. The injection molding process may produce 12–16,000 components every cycle.

The Procedure

- The process parameter fluctuates based on the circumstances and demands.

- The components made with this method typically weigh between 100 and 500 g.

- A single part's cycle time ranges from 5 to 60 seconds, depending on how the item is made.

- The heating range for molding material is 150 to 350 degrees Celsius.

- The molding machine has an injection capacity of 12,000 to 2.2 106 mm3.

- 100 to 150 MPa is the injection pressure.

- From 0.1 to 8.0 MN is the locking force.

What are the advantages of Injection molding machine?

- The fundamental benefit of this method is that intricately shaped components with thin walls (5–15 mm) may be molded with ease and retrieved from the die without being harmed.

- Injection-molded components offer good dimensional tolerance.

- The main benefit of this method is that it produces far less scrap than certain other methods.

- Investment cast iron and intricately machined pieces compete with parts produced through the Injection Moulding Method.

- In comparison to other procedures, this process has a high production rate.

What are the various types of injection molding machines?

Following are the different types of injection molding machines. Have a look:

Hydraulic Injection Molding Machine

Hydraulic injection molding machine were the only types of machine at start. It is the oldest one in the industry. Following are the benefits of this machine-

1. Economical price

These machines cost far less at the base level than comparable models.

2. Cheap parts

If a machine component needs to be replaced because it has been damaged or has reached the end of its useful life, the replacement parts are less expensive and more readily available.

3. Robust components

The machine's hydraulic components are longer-lasting and more resistant to deterioration.

4. Easy to use and maintain

High-pressure clamping forces are typically simple to adjust on hydraulic injection devices.

5. Powerful

The gripping force on hydraulic molding machines is outstanding.

Electric Injection Molding Machines

In the 1980s, electric injection molding machines were made available and soon gained popularity in the high precision plastic parts production sector. The positioning accuracy of today's full electric servo drive injection molding machines is exceptionally precise (of 0.0001 in), but at a very high cost.

1. Less idle time

There is no possibility of oil leaking. Additionally, since no oil is used, there is no need to replace filters, which lowers consumable costs.

2. Efficiency while using energy

Electric Injection Molding Machines only consume energy when they are in use, thus their output is limited to what is necessary to support the load.

3. Fast procedure

Since these machines are digitally controlled, the procedure can be completely repeated without any oversight.

4. Highly reproducible

The injection device can be accurately controlled, the molding conditions can be stabilized, the injection control (such as pressure and speed) can be regulated in fine units, and there is a highly accurate control and monitoring system. It can handle challenging tasks like multi-stage hydraulic system extension and control the extension.

Injection Molding Machine Price

There are various types of machines. The Injection Molding Machine Price will also vary according to the complexity of the machine.

Costs for large industrial injection molding equipment can range from $50,000 to $200,000 or more. Additionally, the facilities needed to operate, maintain, and monitor these equipment are more demanding and call for expert staff.

Who are the best injection molding machine manufacturers?

There are many Injection Molding Machine Manufacturers in India; however, some of them offer the exception quality products that last longer. Here is the list of some trusted manufacturer in India-

Milacron

Yizumi Injection Molding Machine

Primex Plastics Pvt. Ltd

Windsor Machines Limited

Haitian

Hikon

ENGEL Global

Indo-MIM

Micro Plastic

Kruger

Vikas Industries

Jagmohan PlaMech Pvt. Ltd

Neelgiri Machinery

These are some of the leading manufacturers offering the best quality Injection Molding Products. If you are looking for someone in your region, you can try to search on Google and write Injection Molding Machine near me. This way, you will find the list of top-rated manufacturers offering top-notch services in your area.

Types of products made with injection molding machine

There are various types of products that can be made with injection molding machines.

Some of them are listed below-

Toys

Plastic bottles

Machinery and automotive components

Household products like molded closures, containers, etc.

Healthcare industry

Agricultural products

Conclusion

Injection moulding may appear to be a complicated procedure, yet it is the most popular manufacturing technique because it can manufacture a wide range of everyday things quickly and effectively. One of the most economical methods for producing both working prototypes and finished goods is injection molding.

#Injection Molding Machine#molding material#raw materials#injection molding process#Injection-molded components#Injection Moulding Method.#hydraulic molding machines#Injection Molding Machine Price#Injection Molding Machine Manufacturers#Injection Molding Products

0 notes

Text

Brutal beauty: How a Russian master makes unique art from steel and crude iron

CULTURE

NOV 14 2017 OLEG YEGOROV

"Lamberjack's rest", a mini-bar made by Nik Faber studioSergey Gaydenkov / Nik Faber

Today gold or jewels will barely raise an eyebrow – these materials are everywhere and each item made of them costs a lot, no matter if it’s worth it. Nikolay Savinkov, a self-employed entrepreneur from Moscow, challenges this approach. His works are made of cheap materials but demonstrate real craftsmanship.

“I used to sell such trash while working in jewelry sales!” Nikolay Savinkov, the founder and the only full-time employee of the Nik Faber studio, recalls with a laugh. “Every item made of gold or other precious metal costs a lot, no matter how primitive it is. You can simply put a hole in a gold brick – wow, it’s already a treasure. It was pissing me off.”

One day, long after leaving his job in jewelry sales, Savinkov decided to shake things up and prove that real art depends on the mastery of the artist, not on the material. So he launched his own small enterprise, Nik Faber.

“My aim is to prove that art can be created not only with cheap materials, like black steel or crude iron, but also without fine jewelry tools,” Savinkov explains. He works predominantly with semi-automatic welding machines, angle grinders and screwdrivers. The result is impressive, with tiny details worked through scrupulously.

"Steampunk" clocks.Sergey Gaydenkov / Nik Faber

Usually this small business runs as follows: Savinkov invents a concept and makes a sample which attracts buyers (through social nets and adverts). Sometimes people ask him to create something specific, but most just like to repeat an existing pattern. “Few people are creative,” Savinkov notes with regret.

"Mosquito" lamp.Sergey Gaydenkov / Nik Faber

At least his own mind is creative. Nik Faber’s works range widely: lamps in the form of giant insects, sword or pistol-shaped shoe horns, giant hookahs-lamps-clocks (yes, three in one). Not to mention corkscrews and glass-holders of all possible shapes and sizes – these are among the most popular orders.

"Pistol" shoehorn.Sergey Gaydenkov / Nik Faber

Savinkov’s approach is very individual as he doesn’t use molds or copying tools. “Even when I’m trying to make an exact replica of an item I made before, it will turn out unique,” he explains. “It’s manual labor, so the details will differ anyway.”

youtube

Nik Faber

Making different items out of metal has been Savinkov’s main source of income for about seven years. He doesn’t always work alone, outsourcing to several people, including a constructor, a woodman and a logistics specialist. But they don’t work with him all the time: when Savinkov is in the workshop with metal, he is alone.

"Moon-rover" ashtray.Sergey Gaydenkov / Nik Faber

Sometimes the job can be pretty rough. The artist recalls that one of the most difficult items in his career was an ashtray in the shape of a moon-rover: there were eight small wheels each consisting of three discs, with ten tiny spokes in each. “I had to weld 0.8 mm wires, lots of small dots. A slip of the hand or a bit too much heat, and everything would have melted.” Nor was creating a lamp in the shape of Snork’s head (a fictional creature from the S.T.A.L.K.E.R. universe) a piece of cake, but it turned out well.

"Snork's head" lamp.Sergey Gaydenkov / Nik Faber

Savinkov works in different styles (loft, techno art), but most of his creations recall good old steampunk. That’s no coincidence – the artist respects this style for its combination of heaviness and elegance.

“We live in an époque of plastic, when things are replicated in their millions and break quickly. This is why steampunk is popular, I guess – it represents a time when people were building something to last for centuries with its brutal Victorian-age beauty.” According to Savinkov, steampunk contrasts the modern industry, replaceable and vulgar, that’s why he uses it.

youtube

Nik Faber

As Nik Faber’s work is unique, people have to pay a reasonable price for it, Savinkov supposes. Pricewise, his items basically range from 3,000 to 15,000 rubles ($50 to $253). Some can be more expensive, but it’s difficult to sell them, especially through shops which tend to double or triple the price.

“I’d be happy to expand production,” Savinkov says, but the economic situation is dire and demand in the premium segment is sluggish. So far, the artist keeps on working alone. He compares it to cutting stone: a bit too much force and the whole work is ruined. Any way out? Always stay focused.

Steam-boat by Nik Faber.Sergey Gaydenkov / Nik Faber

If using any of Russia Beyond's content, partly or in full, always provide an active hyperlink to the original material.

ARTMOSCOWBUSINESS IN RUSSIA

Dymka: The secrets of making a medieval North Russian toy

From Gzhel to Matryoshkas: How Russian designers are revisiting folk art

7 very unusual 20th century avant-garde buildings in Moscow

10 Soviet buildings inspired by Le Corbusier

How a Soviet colonel created the first musical synthesizer

0 notes

Text

Fully Automatic Compact Blood Collection Tube Production Line

Radiant Industries:

Radiant Industries introduces a state-of-the-art Fully Automatic Compact Blood Collection Tube Production Line, characterized by its compact design and adherence to current Good Manufacturing Practices (cGMP).

Elegantly designed, the machine operates fully automatically, encompassing key production stages within a compact footprint. It follows cGMP guidelines, ensuring product quality and compliance with industry standards.

The production line includes essential functions such as tube loading, chemical dosing, drying, cap adding, vacuum/non-vacuuming, cap pressing, form tray loading, and more.

Individual Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) control ensure easy and safe operation. Highlighting the efficiency of the entire line is the fact that 3-4 workers can manage it.

Compared to other manufacturers, Radiant Industries' equipment boasts unique features, including a smaller overall dimension, higher automation and stability, lower fault rates, and reduced maintenance costs.

Specifically designed for vacuum blood collection tubes, the production line showcases its specialized focus.These tubes typically feature a sterile glass or plastic design, utilizing a stopper to create a vacuum seal for precise volume depiction.

Vacuum blood collection tubes prevent needle stick damage by avoiding direct contact with needles, minimizing contamination risks.

The vacuum blood collection tube includes a double-pointed needle attached to a plastic tubular adapter, available in various gauge sizes.

Specifications:

Applicable Tube Size: Dia.: 13x75/100mm; Dia.: 16x100mm

Working Speed: 8000-10000 pcs/hour

Dosing Method and Accuracy: Various dosing methods, including FMI metering pump, ceramic pump, pinch valve, and rotary piston pump.

Drying Method: PTC heating with a high-pressure fan

Cap Specification: Downward or upward type caps based on customer requirements

Applicable Foam Tray: Interlaced or rectangular foam tray

Power: 380-415 V / 50 HZ/ 20 KW

Compressed Air: 6 to 8 bar

Space Occupation: 3510 (L) X 2600 (W) X 1800 (H) mm approx.

Service Coverage in Maharashtra:

Radiant Industries provides the Fully Automatic Compact Blood Collection Tube Production Line in Maharashtra, covering locations such as Mumbai, Pune, Nagpur, Nashik, Vasai-Virar, Solapur, Bhiwandi, Amravati, Kolhapur, Akola, Latur, Jalna, and more.

Read the full article

#Akola#Amravati#Bhiwandi#FullyAutomaticCompactBloodCollectionTubeProductionLine#India#Jalna#Kolhapur#Latur#Manufacturer#Mumbai#Nagpur#Nashik#Pune#Solapur#Supplier#Vasai-Virar

0 notes

Text

Carbon Fabric

8 characteristics of Carbon fiber material

I. Small density, light weight:

It is about 1/5 of copper and 3/5 of aluminum alloy, greatly reducing the product.

II. Good chemical resistance:

Substituting metal avoids corrosion and extends life.

III. Fatigue resistance, long service life:

No permanent deformation, greatly improving the safety and stability of product components.

IV. High strength, high modulus:

About 1.3 times of copper, 3.7 times of aluminum alloy, improve product strength, rigidity and other mechanical properties.

V. Low coefficient of thermal expansion:

It will not affect the use of products due to thermal expansion and cold contraction image products.

VI. Good electrical conductivity:

Excellent electrical conductivity in composite materials.

VII. Energy absorption and shock absorption:

It has excellent damping function to vibration, thus reducing vibration and noise.

VIII. Self-lubricating, wear resistance:

Make full use of self-lubricity to improve product smoothness and reduce component wear.

ABOUT US

We were founded in September 2015 and located in Zhijiang Industrial Park, Haining, Zhejiang, is a large scientific and technical enterprise focusing on scientific research, product development, production, sales and service in the area of fiberglass-based. Carbon Fabric Suppliers and Carbon Fabric Company.

The glass fiber products and glass fiber composite material we produce are widely used and can be used in electric appliances, electronics, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, and other high-tech fields. We use 4.6-meter automatic warping machines, 3.4-meter air-jet looms and 4.6-meter wide high-grade rapier looms, suitable for PTFE, PVA, PVC, PU, and silicone coating. Our main products are fiberglass cloth, fiberglass mesh, waterproof building material, special building material, bakeware, BBQ accessories, and sealing strip. Our products are sold to more than 30 provinces at home and several countries and regions in North America, South America, Europe, Mid East, Southeast Asia, Oceania, Africa, and so on.

We will be committed to becoming a professional fiberglass products company with China's competitive advantage and complete industry chain and forming a superior fiberglass composite material manufacturing enterprise.

0 notes

Text

Industrial Parts Washer In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Industrial Parts Washer Market: Global opportunity analysis and industry forecast

Industrial parts washers are the cleaning equipment that are used to remove the debris or contaminants like paint, grease, oil and corrosion from the work-pieces. The industrial part washers are automatic or semi- automatic machines that uses high pressure jets to spray detergents, hot water, acids and solvents to clean the parts surfaces. Industrial parts washers are powered by gasoline or electricity and includes a wash tank that is made up of glass, plastic or stainless steel. Other components include brushes, scrubbers, water softeners and deionizers. The industrial washers are categorized into different types such as solvent based industrial parts washer and water based industrial part washer which includes degreasers, thermal washer, spray washers, fluidized bed washer, and scrub tanks. The thermal system is one of the popular type in industrial parts washers which is used heat to remove grease, oil and other contaminants from the machine parts.

Top impacting factors: Market Scenario Analysis, Trends, Drivers and Impact Analysis

The increasing demand for the cleaning of accessories of a machine during the time of packaging, surface treatment, distribution and assembling act as a growth driver for the industrial parts washer market. The growing manufacturing and automotive industries in the developing countries like India and China is expected to boost the growth of the industrial parts washer market. Further, the rising demand for the light motor vehicles and public transport vehicles in automotive industries due to rise in working population is expected to boost the growth of the industrial part washer market. The increasing importance for protecting the equipment’s from dirt, corrosion and other external factors is creating demand for industrial parts washers in the industries. However, the high initial investment and decline in the sale of automobiles in past few years can hamper the growth of the industrial parts washer market.

New product launches to flourish the market

The launch of new generation technologically advanced products can boost the growth of the industrial parts washer market. On November 2018, one of the global leader in industrial parts washer The Ecoclean Group has launched a new industrial parts washer EcoCcompact. The product EcoCcompact is a solvent-based industrial parts washer which uses hydrocarbons and alcohols for cleaning of parts and components of various machines in aerospace and automotive industry. It is also used in manufacturing units to remove the contaminants like grease, metal chips, paints and other such contaminants.

High demand form applications:

The automatic industrial parts washers is used for various applications in industries like automotive, aerospace, printing and manufacturing. In automotive industries, the industrial steam washer are used to clean the engine block, gear boxes and the fastener tools like nuts, bolts, screws and rail bearings. The oil, dirt, metal chips, abrasives and grease from these components are cleaned with hot water and detergent that is sprayed using a pressure jet. Further, in aerospace industry, the industrial parts washer are used in repairing and re-manufacturing operations of jet engine and used in cleaning of contaminants from the turbine blades. Moreover, in printing & press industry, industrial parts washers are used in cleaning and degreasing the inks, varnish and other waste lubricants that are used during the production of newspapers, magazines and others. The solvent parts washers is used in the removal of oil & grease in slicers, utensils, stoves and other food preparations equipment in food & beverages industries.

Full Report With TOC:-https://www.alliedmarketresearch.com/industrial-parts-washer-market-A09999

0 notes

Text

Tea packaging in e-commerce: Ensuring product safety and freshness

Tea is a popular beverage in Bangladesh, and the packaging of tea products plays a crucial role in ensuring product safety, maintaining freshness, and attracting customers. Packaging solutions such as powder packaging machines, powder bottle filling machines, automatic sachet packing machines, and pouch sealing machines are widely used in the tea industry in Bangladesh. Choosing a reliable packaging machine supplier like Nichrome and investing in quality machines is key to the success of any tea business in Bangladesh.

Challenges in Tea Packaging in Bangladesh:

Moisture: Tea is sensitive to moisture, and exposure to humidity can affect its flavor and aroma. Packaging companies must use moisture-resistant materials and sealing techniques to prevent moisture from entering the packaging.

Aroma: The aroma of tea is an essential factor in determining its quality. Packaging companies must use materials that do not absorb the aroma of the tea, such as aluminum foil or metallized film.

Shelf life: The shelf life of tea is limited, and packaging companies must ensure that their packaging can preserve the quality of the tea for as long as possible.

Environmental impact: The tea industry has a significant environmental impact, and packaging companies must consider sustainable packaging solutions that minimize waste and reduce their carbon footprint.

Cost: The packaging machine price is be a significant expense for tea companies, especially small and medium-sized businesses. Packaging companies must balance the cost of packaging with the need for quality and functionality.

Consumer preferences: Consumer preferences and trends can change quickly, and packaging companies must stay up-to-date with the latest trends and technologies to remain competitive in the market.

Nichrome’s tea packaging machines play a vital role in ensuring that tea products are protected during transport and storage. Our powder packaging machine is a popular choice for packaging loose tea leaves and powders. It is designed to fill and seal tea bags, packets, or pouches with a precise amount of tea, ensuring consistency and freshness.

The powder bottle filling machine is another option for packaging tea products. It is ideal for packaging loose tea in glass or plastic bottles, and it offers precise powder bottle filling machine capabilities to ensure consistent tea portions.

The automatic sachet packing machine and the pouch packing machine are also popular choices for packaging tea products, providing airtight and moisture-resistant packaging to maintain freshness.

Consider Nichrome as the leading packaging machine supplier in Bangladesh, which ensures quality and reliability of the tea packing machine. A filling and packaging machine by Nichrome is an investment in your business, and you need a supplier that can provide durable and efficient machines at a reasonable price.

The vertical form fill seal machines from Nichrome are a popular choice among tea packaging machines due to its versatility and speed in producing a variety of packaging options. These packaging machine prices are also affordable which makes them a preferred packaging solution for businesses. Moreover, investing in a high-quality packaging machine is critical to ensure product safety and freshness, which can ultimately impact customer satisfaction and retention.

In conclusion, tea packaging machines from Nichromeare essential in ensuring product safety and freshness, especially for e-commerce businesses. The use of Nichrome’s powder packaging machines, powder bottle filling machines, automatic sachet packing machines, and pouch sealing machines can help you maintain the quality and flavor of tea products. Choose Nichrome as your reliable

packaging machine supplier in Bangladesh and invest in quality machines like shampoo filling machine, ointment tube filling machine, silica gel packing machine, ointment filling machine, blister packaging machine, viscous liquid filling machine, soybean oil packing machine, potato chip packaging machine, chub packaging machine, spices packing machine and liquid pouch packingmachine and small packaging machine which is the key to the success of any e-commerce business. Choose Nichrome! Choose the best!

0 notes

Text

Used Filling Machine Filler For Sale

It’s mechanically weighing, filling, conveying the bottles, corresponding to jar, bucket. Manually or routinely seal the bottle is elective in accordance with your filling needs. The bottle filling machine is one of our primary packing machines that's widely used within the granules filling industry. The filling vary of all our granule filling machine is from 10~5000g.

Touch screen monitors enable the operator to input the specified output parameters and likewise to observe the efficiency of the machine during production. Automatic Overflow Filling & ROPP Cap Capping Production Line is widely applied in meals, beverage,... Bottle peak and bottle positioning adjuster make it straightforward to vary bottles. Fill level consistency, an thought of clear glass bottles filling. Cleanability should be one of the primary focuses in any machinery concerned in prescription drugs.

Sometimes the infeed starwheel may be choke fed, requiring a sensor to make sure there may be an enough backlog of bottles to forestall a random bottle from causing a jam. However in most cases the bottles are spaced and timed with an infeed screw which is one other changepart previous to the infeed starwheel. Since our founding, the AMS staff and services have continued to grow filler machines and adapt to help our clients’ needs. AMS has earned its trade reputation by manufacturing a full line of customized filling gear. With a quick tooling change, every mannequin can dispense products ranging from powders, granules, flakes, liquids, gels and pastes. XpressFill serves many shoppers within the Wine Industry around the globe.

Furthermore, the accuracy of the machines in the filling process minimizes the wastage of products. The machine is integrated with a PLC management system that allows the operator to manipulate the machine to their desired configuration. They can input the desired production fee, quantity per container, and container sort. There are merchandise that have difficulty flowing except the temperature is warm. If you cope with such merchandise, there are discharge hoppers that are outfitted with a heating mechanism that discharges hot water to encourage the flow of merchandise down the filling heads. Both with advanced technology and 20 years of expertise, Neostarpack ensures each buyer's demands are met.

While the rigidity makes them easy to run, it makes them more durable for the buyer to use since they don't collapse. After squeezing the product out, the tube returns to its authentic form, sucking air into the tube. A variation on the gravity configuration is continuous movement rotary machines generally used for milk and water filling.

Artisan Winemakers can select between the Volumetric Filler (XF260 two spout / XF460 4 spout) or the Level Filler fashions (XF2100 two spout / XF4100 4 spout). The Volumetric Filler fills to a particular volume utilizing a timer, giving flexibility with bottle measurement, accommodating very small to very giant bottles. While the Level Filler permits the liquid to fill to a particular top in the bottle using a sensor. These are open tubes and depend filler machines on capillary action brought on by the product’s floor pressure to prevent dripping. (Hold your finger over the end of a straw and withdraw it out of your drink to see this impact.) The smaller the nozzle diameter the more pronounced the impact. Some fluids do not have sufficient surface pressure to rely upon this effect.

Piston filling machines are an affordable and dependable solution to filling liquids in bottles. These filling machines measure out specific volumes of liquid merchandise from think to thick, viscous products as properly as liquids with particles, similar to soup. These fillers can be single- or multi-head machines to satisfy the wants of the given software and speed.

The nozzles have “No Bottle – No Spray System” activated only by the presence of bottles by means of an infeed sensor. Beaverton Foods has been a buyer of Horner Automation’s for over 6 years. They still use SLC500 rack PLC’s , however they should arrange the machine for future upgrades and the old control equipment won't filler machines minimize it. Beaverton’s outdated machines have to be up to date because of the hardware not being supported anymore and the price for alternative hardware and accompanying software is not cost effective.

A light plastic or metal container is in all probability not inflexible enough to resist the vacuum and can collapse. Fluid path tubing must also be sufficiently inflexible to face up to the system vacuum. For best outcomes the inlet head pressure ought to be kept constant. At the start of the job, with a full tank, there could additionally be 5-10′ of positive inlet head. At the tip of the job, with a virtually empty tank, there may be 1-2′ of adverse inlet head. A rod moves the diaphragm in and out varying the pumping chamber dimensions.

0 notes

Text

Major project

- Designers/movements

I want to make sure I'm looking at as much relevant visual information along with written sources and more, so for this I knew I had to look into more modern designers who use the topic of industrialisation as inspiration. I understand this would most likely mean looking at newer industrialisation however I still think it is very relevant to the subject, of exploring/visualising man made to machine made. However during my research I found relevant information that was closer to the time and how this industrialisation helped new art forms and medians be explored.

- Graphic Design

‘As this supply-and-demand cycle became the force behind the relentless development, graphic design played an important role in marketing factory output. It was a time of optimism and wealth, but not without it’s social costs. Long 13-hour days, unsanitary and filthy living conditions, women and children among the workforce, overproduction, economic depressions, and the loss of jobs due to new improvements in technology took their toll.’

‘Mass production of goods brought with it an overpowering need for mass communication.’

- Typographers

Robert Thorne, Vincent Figgins, Henry Caslon, among others, began experimenting with bold, heavily slabbed-serifed fonts called antiques or Egyptians. These typefaces generally had an even stroke weight, heavy, rectangular slab serifs, and short ascenders and descenders.

Robert Thorne’s Type

Henry Caslon’s Type

- Printing

Hatch Show Print, a print shop that uses wooden letter press to create typography posters, located in Nashville, Tennessee, was founded in 1879 and still produces wood type and letterpress posters for a broad range of uses.

Hatch Show Print’s Work

- Automatic Type Press

Ottmar Merganthaler

‘Ottmar Merganthaler invented and obtained the first patented Linotype machine that created type automatically. The linotype machine could do the work of seven or eight compositors at the same time.’

- Periodicals and Illustrated Weeklies

The linotype led to a surge in the production of periodicals and illustrated weeklies, including the Saturday Evening Post.

Saturday Evening Post Covers

- Victorian Era

‘During the reign of Queen Victoria it was a time of strong moral and religious beliefs, proper social conventions, and optimism.’ ‘The Victorian love of ornate and extravagant embellishments was noted in architecture, manufactured products, and elaborate borders, text, and imagery in graphic design.’

‘Victorian graphics utilised a printing technique called chromolithography that unleashed a flood of colourful printed images.’

Victorian Era Products

Victorian chromolithography

- Art Nouveau

‘What Defines Art Nouveau? Art Nouveau was a compelling and energetic style in the visual arts which spanned from around the early 1890s to the First World War. Art Nouveau artists, inspired by plant forms and nature, took organic subjects and flattened and abstracted them into sophisticated, sinuous and flowing motifs.’

‘Art Nouveau emerged as a reaction to major world events including the Industrial Revolution which began in the eighteenth century. The Industrial Revolution was the transformation from a handicraft economy to one dominated by machine manufacturing through the rise of technology.’

‘These five elements can also be seen in the Art Nouveau movement. The industrial revolution allowed for faster and cheaper production of materials making new building materials such as glass, reinforced concrete, cast iron and steel, readily available. Art Nouveau artists embraced industrial production and the accessibility of materials to create their work.’

‘Art Nouveau was ubiquitous in Europe’s train stations, tea rooms and department stores: it belonged equally to the public and private realms. Art Nouveau flourished during a period of rapid social and technological change in Europe as industrialisation, mass production and urbanisation accelerated.’

Examples of Art Nouveau

- Art Deco

This movement also then inspired other artists and designers to express themselves further which played a part in creating Art Deco. Though this is movement has happened after the industrial boom it is a by-product of its new found opinion on mass production and accessibility to a range of once hard to come by or expensive materials.

‘In the increasingly conservative political climate, critics saw Art Nouveau as ‘decadent’ and over-elaborate. It failed to meet the demand for a modern national style.”In a time of booming industrialisation and post-war nationalism, veterans of French Art Nouveau like Maurice Dufrene and Paul Follot recognised the need to modernise tradition’

‘finding the new factory style of mass production highly effective in making its everyday objects d’ art widely available and affordable. In contrast to the whimsically flowing, heavily-ornamented style of Art Nouveau, Art Deco found relief from the curvaceous pastel “excessive decadence”’

- Art Deco Artists/Designers

Jean Dunand

Jean Dunand, ‘Despite beginning his artistic career as a sculptor who produced decorative objects, Dunand is most remembered for his lacquered works which included panels, interiors, and furniture pieces. Dunand applied lacquer to a variety of objects and even decorated the works of other famous Art Deco artists like Émile-Jacques Ruhlmann.’

Jean Dunand’s Work

Georges Lepape

Georges Lepape, Remembered as one of the most famous fashion magazine illustrators in history, Lepape’s works were seen as crucial Art Deco pieces as they were able to seamlessly blend fashion and artistic expression. As his portraits were characterized by bold colors, smooth lines, and graphic stylization, Lepape injected an air of elegance that gave his works an appealing aesthetic.

Georges Lepape Art,

- Sources

https://99designs.co.uk/blog/design-history-movements/art-nouveau-design/

https://www.europeana.eu/en/exhibitions/art-nouveau-a-universal-style/origins-of-art-nouveau

https://www.oreilly.com/library/view/understanding-industrial-design/9781491920381/ch01.html

https://vietnamnews.vn/life-style/419279/young-designers-showcase-collections-inspired-by-industrial-revolution-4-0.html

https://essayfrolic.wordpress.com/2017/05/30/art-deco-an-artistic-response-to-industrialization/

https://medium.com/@brandywilletts/how-the-industrial-revolution-impacted-graphic-design-6140fad2cca

https://artincontext.org/famous-art-deco-artists/

http://luc.devroye.org/fonts-54976.html

https://www.hatchshowprint.com/haley-gallery/restrikes

https://blog.drupa.com/en/pioneers-printing-ottmar-mergenthaler-2/

https://www.rit.edu/press/history-linotype-company-softcover

https://guides.loc.gov/american-women-prints-photographs/graphic-journalism-illustration/weeklies

https://ncna.dh.chass.ncsu.edu/imageanalytics/history.php

https://www.saturdayeveningpost.com/history-saturday-evening-post/

https://brewminate.com/mid-victorians-and-their-food/

https://visualartsdepartment.wordpress.com/the-victorian-era/

0 notes

Text

NICHROME KETCHUP PACKING SOLUTIONS ARE A NOTCH UP

Globally, and across industries, pouch filling machines are a popular choice for viscous condiments packing and viscous ready to eat foods like tomato ketchup. Tomato ketchup packing is usually done in two ways—in tear away or standee pouches, or in High Density Polyethylene (HDPE) bottles.

In either case, the tomato ketchup packaging needs to be robust and leak-proof. Hence the need for superior quality packing machinery. Pouches are flexible, lightweight bags that offer many advantages over traditional packaging such as metal cans or glass bottle packing.

Types of Ketchup Packing

There are two major types of liquid pouch filling machines: vertical form fill seal (VFFS) and horizontal form fill seal (HFFS) packing machines. The filled and sealed bag is cut away. As is evident in many tomato sauce/ketchup brands, the top seal on the first bag becomes the bottom of the next bag, and the process repeats. The cut pouch falls to a collection system, typically a belt conveyor that brings the pouch to the next packaging step.

Ketchup packing is generally referred to as ‘flexible packaging’ or ‘sachet packing’ as opposed to ‘bottle and jar packing’ which is rigid.

Flexible packaging offers several advantages: it uses less material, needs less energy during formation, and produces less greenhouse gases during manufacturing. Being lightweight & unbreakable, it is economical to pack, store, and transport.

Nichrome Ketchup Packaging

There are many pouch filling machine manufacturers offering multiple packaging machines for diverse applications. If you are looking for a ketchup pouch packing machine manufacturer--Nichrome is your best bet.

Four decades of experience worldwide, intensive inhouse R&D, state-of-art manufacturing, technology tie-ups with global majors, thousands of successful installations, strong nation-wide service network – few pouch filling machine manufacturers can match the knowhow, capabilities, and record of accomplishment of Nichrome.

HFFS for Ketchup Packing

Whether your ask is for HFFS or multitrack packing machine (for 4 side seal pouches up to 100 gm); pick fill seal machines; bottling line or standee pouch/ DOYPACK pouch packing-- explore Nichrome's offerings for packing tomato paste/ketchup. Nichrome offers special sealing technology for viscous liquids on its multitrack machines.

Cost-effectiveness

Nichrome is dedicated to offering the most advanced packaging technology for food, pharma, and other relevant industries. Nichrome can deliver top quality at competitive prices with its own R&D centre, manufacturing, and testing facilities.

High ROI

Nichrome proactively supports customers from consultation and customized packaging machine development to the production of the packaging machine, backing it up with extensive after-sales service. Some hallmarks of Nichrome’s packaging solutions are high production rates, optimum accuracy, and consistent pouch quality as per the client’s requirements.

T-110

In its T-110 ketchup packaging machine, Nichrome offers an efficient integrated system for ketchup filling and packaging that covers a turntable, UV sterilisation chamber, automatic liquid filling machine, cap feeding elevator, rotary capping machine, induction sealer, labelling machine, date & batch coding system, and packing table. SKUs range from 100 ml to 20 litres. Applications include a wide range of packing solutions for food & liquids such as ketchup.

T-140

Nichrome's HFFS packaging machines bring you next generation, linear technology from Europe. The series is versatile and can be used for packing a wide range of powders, grains, snacks, liquids, and viscous products like ketchup using different fillers. The series also offers a range of pouch formats with superior pouch aesthetics.

T-170

Nichrome’s HFFS packaging machines, especially the T-170 are PLC based with touch screen interface. The compact and versatile design offers both single and perforated chain of pouches with quick and easy changeover. Well-designed duplex modules are available for higher outputs.

Nichrome is a leading manufacturer of form-fill-seal packaging machines in India. A pioneer of flexible packaging in India, Nichrome brings four decades of experience and innovation to the table.

Nichrome’s offerings include a wide range of VFFS and HFFS packaging machines. Horizontal form fill seal machines are traditionally more flexible and versatile than vertical form fill seal ones, although the latest VFFS packaging systems are more adaptable to different products, pouch types & sizes, film types than earlier versions.

Pick and Fill Seal

Nichrome’s Pick-Fill-Seal machine provides the combined benefits of variety, productivity, and specialty packaging for ready-to-eat foods. Using versatile rotary technology, the horizontal packaging machine conveniently packs a wide variety of ready-to-eat foods in eye-catching innovative shapes while maintaining freshness of the products.

The machine is sturdy and compact, easy to clean and maintain. An advanced variant of packaging technology innovated by Nichrome enables two or three different fillers to dispense multiple types of ingredients in the same pouch.

Bottle Filling Machine

Nichrome’s Automatic Bottle Filling system is designed to handle many different types of products, from water to tomato ketchup. From products with thin watery consistency to highly viscous products like ketchup, Nichrome’s liquid food packaging system can handle them all.

Nichrome’s liquid filling machine also handles a versatile SKU range with fast changeover and no change of parts. It is equally efficient packing in glass, HDPE and PP bottles or metal tins.

Conclusion

It could be a small variation in a pouch format or customization of an existing machine; a pro-actively developed filling system or consultancy & system design for a complete packaging plant - -Nichrome has the expertise, capabilities and innovation to transform productivity and enrich customer relationships in endless ways. Call Nichrome to discuss your unique requirements and let us amaze you with our products and services.

#ketchup filling#pouch filling machines#tomato ketchup packaging#vertical form fill seal (VFFS)#horizontal form fill seal (HFFS) packing machines#pouch filling machine manufacturers#ketchup pouch packing machine manufacturer#pick fill seal machines#bottling line#ketchup packaging machine#Automatic Bottle Filling system#liquid filling machine

0 notes

Text

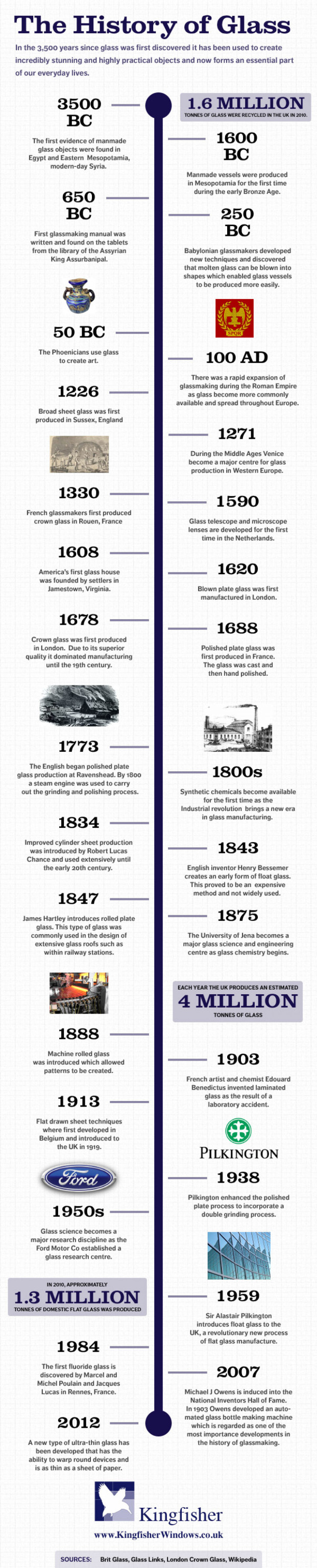

History of Glass

HISTORY

The very first glass known to stone age people which was used for making weapons and decorative objects, was obsidian, black volcanic glass.

The earliest man-made created glass dates back to around 3500BC, with finds in Egypt and Eastern Mesopotamia. Discovery of glassblowing around 1st century BC was a breakthrough in glass making.

It is believed that glassmaking was discovered 4,000 years ago, or more, in Mesopotamia. The Roman historian Pliny attributed the origin of glassmaking to Phoenician sailors.

INVENTION

Glass was first made in the ancient world, but little is known about man’s first efforts to make glass. Amulets and solid beads were made in Mesopotamia as far back as 2500BC.

Later, glass making was further developed in Egypt around 1500BC.

During 15th century Venetian glass blower, Angelo Barovier, crated cristallo, a nearly colourless, transparent glass. By the late 1500’s, many Venetians went to northern Europe seeking better life where they established factories and brought the art of Venetian glassblowing.

MANUFACTURING

In the early 1800’s, there was a great demand for window glass which was called crown glass. In the 1820s, the age of blowing individual bottles, glasses and flasks was ended by the invention of a hand-operated machine. In the 1870s, the first semi-automatic bottle machine was introduced.

After 1890, new development and manufacture of glass increased rapidly. Machinery has been developed for precise, continuous manufacture of a host of products. In 1902, Irving W. Colburn invented the sheet glass drawing machine which made possible the mass production of window glass.

HOW GLASS HAS DEVELOPED OVER THE YEARS:

Modern development:

Modern glass production is based on the float glass method. With the right glass-making information, the industry evolved in a very short time. The last few years are known as the pinnacle of glass history.

1900’s development

The main glass producing method in the 1900s was the “Sheet Glass Method”. In this method, ribbons of glass drew between the cooled rollers from a tank furnace. It was somewhat an advanced method but still imperfect.

2000’s development:

In the 2000s, the glass industry revolutionized. The credits go to the introduction of the “Float Glass Process”. In 1959, the float glass method was invented. The Float Glass Method changed the course of glass history.

This process was developed when manufacturers melt the glass at a very high temperature. It is then poured onto a large shallow bath of molten metal to cool off. The molten glass spreads on the flat surface and forms sheets. This method is inexpensive and viable as compared to all other previous methods. So it quickly became popular among the manufacturers. This method is still in-use in glass production today. More than 90 percent of the world’s glass is made through this float glass method.

0 notes

Text

How Does an Automatic Glass Beveling Machine Work?

When it comes to precision glass work, the dependability of an automatic glass beveling machine is priceless. Whether you’re a professional-grade glazier or just starting out in the hobbyist glasswork industry, these machines can make all of your projects much easier and more efficient. But how does an automatic glass beveling machine actually work?

In this blog post, we explore the inner workings of an automatic glass beveling machine so that you can get a better understanding of its capabilities. Additionally, we'll discuss some tips for selecting and using these machines for your needs. Read on to learn more about what makes these machines such essential tools!

How Does an Automatic Glass Beveling Machine Work?

1. What is an Automatic Glass Beveling Machine and What Does It Do?

2. How Does an Automatic Glass Beveling Machine Work?

3. What is Manual Glass Bevelling Machine and How Does It Work?

4. The Benefits of Using an Automatic Glass Beveling Machine

5. Some Tips on How to Use a Glass Beveling Machine Safely and Effectively

6. How to Choose the Right Glass Beveling Machine for Your Needs?

1. What is an Automatic Glass Beveling Machine and What Does It Do?

Automatic glass beveling machines are used to shape and polish the edges of glass pieces accurately. This ensures a smooth finish, greater durability, and improved safety in producing a range of items such as mirrors, furniture, and lighting fixtures. The machine performs the necessary cuts without any manual intervention while retaining maximum precision by using diamond grinding wheels that rotate at high speeds. It consists of components such as a transverse guiding section, frame support section, clamping pressure device, driving motor feeder unit and blade base assembly.

Additionally, features like a touchpad control panel with LED display can be found in some machines as it provides vital information about its operations for better efficiency and user convenience. Overall, an automatic glass beveling machine is a cost-effective solution for efficient and time-saving polishing of the edges of glass products.

FS-first Automatic Glass Beveling Machine F371C Serise

2. How Does an Automatic Glass Beveling Machine Work?

An automatic glass beveling machine combines the use of advanced motors, diamond blade cutting technology, and precision sensors to give users faster and more consistent automated beveling. It works by first sucking the sheet into the working area with a vacuum system before adjusting the angle, speed and depth of the cut. The diamond blade then rotates at high speed, cutting along preset parameters to create a perfectly finished beveled edge with no chipping.

Depending on the particular machine model, automated depth control, tool changing, multi-step processing and suction cup loading systems may also be included for added convenience and accuracy. Beveling machines take all the guesswork out of creating unique shapes for special projects and can save time over traditional hand-filing methods.

Furthermore, this whole process can take place in near silence thanks to the use of noise-canceling technology. This means that it is ideal for factory, or industrial applications where large amounts of beveled glass need to be produced efficiently and in relative silence.

3. What is Manual Glass Bevelling Machine and How Does It Work?

A manual glass bevelling machine is a process widely used in the glass industry to create rounded edges on cut pieces of glass. It provides a safe and efficient way to bevel the edges of any piece of glass. Developed for manual operations, this machine utilizes a horizontally rotating diamond wheel to create smooth and constant surfaces at predefined angular positions. Through using precision drills and water jets, the material is removed from the edge of the piece forming an angle that gradually gets larger until it reaches a desired depth.

Compared to automated processes, manual glass bevelling machines offer more flexibility when it comes to adjusting cutting parameters as well as doing detailed carving for more intricate projects such as decorative glasses or art pieces.

Additionally, because of their portability, they are preferred by many glass professionals in fields such as architecture due to their ability operate effectively without access to heavy machinery or power tools.

FS-first FYJ-80 Special Shape Grinding

4. The Benefits of Using an Automatic Glass Beveling Machine

An automatic glass beveling machine is a great addition to any company that needs to produce high-quality finished glass products. This type of machine takes the guesswork out of the process, resulting in perfectly beveled edges, saving both time and money. In this part, we will explore the benefits of using an automatic glass beveling machine and why it might be right for your business.

The Benefits of Automation

Using an automatic glass beveling machine has numerous advantages over manual processes. For example, because these machines are automated, they require less labor and are much faster than manual methods. Additionally, with an automated machine, you can set up multiple cutting operations at once, allowing you to streamline your production process and cut down on the time spent setting up each job. Finally, these machines provide consistent results every time, eliminating the need for trial and error when attempting to achieve a perfect edge.

Accuracy and Precision

Using an automatic glass beveling machine for your glass projects takes the guesswork out of cutting accurate angles and shapes. An automatic glass beveling machine uses advanced technology to make sure that each cut is precise and consistent, leaving your project with perfect angles every time. Plus, these machines can easily handle any size or shape of the material, making them versatile for all types of projects. Related Article: Use the Best Glass Beveling Machine to Save Time

Cost Savings

Using an automatic glass beveling machine also offers cost savings for businesses that need to produce large quantities of high-quality glass products. Because it requires less labor than manual methods and can handle multiple jobs at once, you can reduce costs associated with labor and materials while still producing quality work. Additionally, because these machines provide consistent results each time they are used, businesses don’t have to worry about wasting materials due to faulty cuts or incorrect angles.

Ease of Use

An automatic glass beveling machine is easy enough for anyone to use – even if they don’t have any prior experience operating one. The machines come with user-friendly interfaces that make them simple enough for novice employees to operate quickly and efficiently without needing extensive training or instruction from experienced technicians. Additionally, many models come with safety features such as emergency shutoff switches or dust extraction systems that help prevent accidents or damage during operation.

Improved Safety

One final benefit of using an automatic glass beveling machine is enhanced safety for both operators and those around them. Manual tools require the operator to use their hands close to sharp blades which increases the chance of injury or accidents happening. With an automated system, there is no need for the manual operation which eliminates this risk entirely. This not only keeps operators safe but also ensures that everyone around them remains safe as well.

An automatic glass beveling machine provides many benefits that make it ideal for those looking for precision results in the fabrication industry. These machines offer accuracy and repeatability while increasing speed and efficiency compared to manual methods – all at a lower cost than traditional solutions. If you’re looking for a more efficient way to create perfect bevels on all types of glass products then investing in an automatic glass beveling machine could provide exactly what you need!

5. Some Tips on How to Use a Glass Beveling Machine Safely and Effectively

Read More

1 note

·

View note

Text

Glass bottle beverage automatic filling machine

GST specializes in tip cartoning machines, automatic filling machines, automatic packaging machines, automatic assembly machines, automatic packaging machines for frozen tubes, serological pipette production lines, centrifuge tube production lines, syringe packaging machines, automatic hanger production equipment, automation equipment , Non-standard automation equipment, an automation equipment company integrating R&D, manufacturing and sales. And in pharmaceutical, cosmetics, biological consumables, plastics, electronic hardware and other manufacturing industries, he has rich experience in information technology development, automated high-end equipment, automated production line development and system integration.

The glass bottle beverage three-in-one automatic filling machine needs to install a spray washing device between filling and capping. Through photoelectric detection, when a bottle passes through, it will spray pure water on the bottle mouth to remove the residue left in the bottle during filling. Spray and clean the fruit juice drink at the mouth of the mouth screw to prevent bacteria from growing in the mouth of the subsequent bottle.

From a strict safety point of view, after the fruit juice drink is sealed, it needs to be sterilized by inverting the bottle and sprayed to sterilize and cool down. Spray sterilization is also called pasteurization, and then the temperature is lowered immediately. Long-term high temperature of the juice material will cause the loss of internal affecting ingredients, affecting the taste and color.

The obtained fruit juice is used for the preparation of fruit juice drinks. Some original fruit juices taste sour or have a bitter taste, so food additives should be added to make it a fruit juice drink rich in taste, so that it will not be accepted by the masses and is conducive to launching the market. In the process of blending the juice, Because the fruit juice needs to be diluted and adjusted in price, sugar is added, and a sugar pot is added during the blending process to facilitate the addition of white sugar to dissolve and form the syrup used for blending.

0 notes

Text

All About Filter Press Manufacturer

To satisfy your needs, we provide a wide range of filter press sizes. From our huge 2000mm lab filter press down to 200mm. Additionally, the filter press manufacturer may be fitted with a system for automatically washing clothes, a drop tray, a shaking system, etc.

We are able to provide the entire filter press dewatering plant along with the filter press, including the thickener and all other required plant ancillaries like the feeding pump, compressors, conveyor, and even special chemical-resistant paint.

Every piece of equipment we offer is designed to increase your production over time.The feed pump for filters is often referred to as a filter press pump. Delivering slurry to the maker of the filter press is the function of the feed pump.

The filter press's rate of filtration is determined by the feed pressure, which is affected by the power of the filter press manufacturer and the head of the feed pump.Therefore, compatibility with the filter press and slurry performance should be taken into account while selecting the feed pump.

Nearly every form of slurry can be processed using a filter press china, including slurries from the ceramics, stone, glass, mining, petrochemical, culinary, pharmaceutical, textile, leather, and municipal industries, as well as slurries from the washing of coal, sand, and minerals.

using solid carbon steel that resists corrosion, has high rigidity, meets structural stability standards, and has a long service life; Filter press china are produced using a unique, patented process and high polymer PE.

The benefits include being lightweight, resistant to corrosion, resistant to acids and bases, virulent, and tasteless;A well-known brand of component is used in the electrohydraulic integration control system.

Precision machining and dependable, long-lasting service are the benefits of hydraulic systems;high-quality production methods and tools. It is an ideal solid-liquid separation device that is easy to use, safe to operate, convenient to service; utilizing cutting-edge production methods and technology to ensure that every product is at the highest degree of advantage.

A wide range of adjustable parameters, including inlet quantity, discharge clearance, pull plate tension, pull plate speed, and other factors, allow this machine to produce any specification (chamber or membrane) of 630mm1250mm, which is nearly the same as the ordinary automatic filter press with the same filtering area. It also has a simple structure, high production efficiency, stable and reliable operation, and low maintenance costs.

In order to address the problem of the difficult-to-clean sticky muck on filter cloth, the pneumatic shaking function was carefully devised. When compared to a standard filter press, rapid filtering and one-time pull plate discharge can significantly cut labor costs, boost production capacity of a single machine, and shorten process times.

0 notes