#Automatic glue potting machine

Explore tagged Tumblr posts

Text

Second Intelligent In-Line Vacuum Glue Potting Machine: a powerful tool to realize high quality and high efficiency gluing

In-line vacuum glue potting machine is a kind of efficient and precise equipment, which is mainly used for vacuum potting of products with glue under vacuum environment. Under the current background of industrial automation, more and more factories start to use vacuum glue potting machine to equip their production.

In front of the extensive market demand, Shenzhen Second Intelligent Equipment Co., Ltd (referred to as Second Intelligent) combines its own precision assembly technology advantages and industry development trend, developed and upgraded the in-line vacuum glue potting machine SEC-S400-ZL which is suitable for automotive electronics, capacitors, new energy motors, high-voltage packages, ignition coils, solenoid coils, motor stators and sensors, and other industries, which is a good solution to the problem of The industry commonly exists in the product of small seams, poor penetration and easy to produce bubbles when filling glue and other issues, and in the stability and performance of the product have a strong industry advantage.

01. Promote the continuous advancement of the vacuum potting machine

With the continuous progress of science and technology and the continuous development of various industries, the demand for gluing equipment grows, the application scenarios also tend to be more diversified. In the glue potting machine market, semi-automatic glue potting machine has been China's largest demand for products, but benefited from the downstream automation degree of enhancement.

Automatic glue potting machine market demand is also growing steadily. The market requirements for the gluing process is also more stringent, high precision, high efficiency, automation and even intelligence is still the direction of modern gluing equipment technology innovation.

Vacuum potting process can effectively improve product quality, production efficiency and automation level. Looking around the world, in-line vacuum glue potting machine is widely used, the market sales show a rapid growth trend. Second Intelligent, which has been ploughing into the fluid application industry for 19 years, has a keen grasp of the user's advanced needs.

Through careful research and judgement of the development trend of the glue filling industry, Second Intelligent believes that no matter from the perspective of market demand or technology, in-line vacuum glue potting machine has a wide range of application prospects.

For this reason, Second Intelligent upgraded the original offline vacuum glue potting machine to achieve the process of automatic entry of the product into the vacuum box, automatic sensing of the positioning of the fixture in place, automatic closing of the door of the vacuum box, automatic vacuum pumping, and automatic potting of the glue according to the gluing procedure, and automatic pressure relief after the completion of gluing, automatic opening of the door, and automatic flow of fixtures out of the process solution.

After the product is assembled in the front section, it can be automatically transported to the internal conveyor line of the vacuum dispenser for positioning through the front receiving table. The preparation unit needs to heat and stir the A/B glue, and defoam and prepare the material under the vacuum environment of -100KPA.

Second Intelligent in-line vacuum glue potting machine has obvious advantages of high performance, reliability and durability, streamlined design, able to adapt to a variety of specifications, and absolute advantages for products with complex internal structure, high bubble requirements, and slow glue penetration.

It adopts industrial control machine + Second Intelligent motion control card integrated with advanced algorithm and Second Intelligent self-developed glue filling software control, equipped with friendly operation software, easy to operate and improve production efficiency.

02.Committed to product and process optimisation

Second Intelligent In-line vacuum glue potting machine perfectly solves the modern user's demand for quality gluing. It is not a pile of technology, but a multi-dimensional integration based on user experience.

Second Intelligent always practices the concept of total quality development, starting from the actual needs of users, and constantly optimises and improves product design, raw material management, process improvement, etc., and constantly advances and polishes multi-dimensionally to practice the original intention. The launch of In-line vacuum glue filling machine products, experienced countless trial and error, invested a lot of time and resources, overcome the complexity of the production process,

devices and other technical problems, to a very high degree of craftsmanship for the user to bring the true meaning of the potting experience.

Thousands of hammers and refinements, keep improving. Second Intelligent not only adhere to the development of technological innovation of the two-component potting product line, but also to further explore the depth of the three-stage vacuum potting machine research and development, to provide equipment for the IGBT industry.

It provides equipment solutions for IGBT industry. In terms of function upgrading, Second Intelligent realizes real-time monitoring of the dynamics of the product to be filled to ensure the accuracy and quality of the filling, and achieves the filling process of vibration while filling, while accelerating the rapid penetration of glue and the discharge of air bubbles to effectively improve efficiency.

In terms of operation optimisation, Second Intelligent ensures the solidity and reliability of the in-line vacuum glue potting machine system through user-friendly operation software, which makes the operation more convenient and easy to start.

Outstanding performance, leading edge, can meet the needs of more areas of application.

In addition to the traditional 3C, semiconductor and other fields, Second Intelligent will further expand the in-line vacuum glue potting machine to automotive electronics, lithium batteries, hydrogen energy, biomedical, aerospace and other fields.

0 notes

Text

Automatic Edge Bander & Banding Machine for Furniture Making

Edge banding machine

An edge banding machine is an automated woodworking machine that carries out pre-milling, gluing, end trimming, rough trimming, fine trimming, corner trimming, scraping, cleaning separation for cabinets and furniture making. The automatic edge bander is designed for straight edge banding and trimming of MDF (medium density fiberboard), blockboard, solid wood board, particle board, polymer door panel, melamine, and plywood.

Semi-Automatic Edge Bander

The semi-automatic edge banding machine is suitable for straight edge banding of MDF, blockboard and particleboard. Its capabilities include gluing, sealing, upper and lower trimming, and polishing. It is an automatic production line that can complete the conveying of panel, edge banding, upper & lower milling, and polishing at one time.

Automatic Edge Bander

The automatic edge banding machine is suitable for straight banding & trimming of solid wood, fiberboard, particleboard, MDF, plywood. The materials can be solid wood strips, PVC, melamine, and veneer. Its capabilities include pre-milling, gluing, banding, leveling, roughing, finishing, profiling, scraping, polishing, grooving.

Portable Handheld Edge Bander

The portable handheld edge bander can be applied to the operation of plate straight and curved irregular borders. When the machine is installed with the fixed bracket accessories, its use method is similar to that of the traditional curved line manual edge bander. It is suitable for banding of various materials, including melamine (impregnated) paper, veneer, plastic (PVC or ABS).

What Can An Automatic Edge Banding Machine Do?

Automatic edge banding machine is the traditional manual operation process with highly automated machinery to complete, can be a one-time double-sided glue sealing, head, chamfering, rough repair, fine repair, scraping polishing and other functions, edge sealing fine, smooth, feel good, flat and straight. Suitable for medium density fiberboard, joinery board, solid wood board, particleboard, polymer door panel, plywood and other linear edge trimming, the equipment is stable, reliable and durable, moderate price, especially suitable for large and medium-sized furniture, cabinets and other panel furniture manufacturers use.

Pre-milling

When the edge sealing surface of the plate is not smooth, it can be milled first, and it can be coated with glue and pressed.

Glue pot

Non-stick pan, uniform sol, cylinder control pressure wheel, better tape effect.

End cutting

Through the mold automatic tracking and high-frequency high-speed motor and other structures, cut off the front and back of the excess edge sealing strip to ensure smooth section.

Rough trim and Fine trim

Rough trim:The rough trimming knife is a flat knife, which is used to repair the excess sealing material on the upper and lower parts of the edge sealing belt of the processing plate, so that the upper and lower parts of the trimming plate are smooth and smooth.Fine trim:The finishing knife is a diagonal repair, which is used to repair the excess sealing material after rough repair of the upper and lower parts of the processed plate sealing strip, and make the natural transition between the plate and the sealing strip with an arc.

Corner trim

Contour trimming, trimming the chamfer effect, the edge sealing effect is more rounded and smooth.

Scraping

It is used to eliminate the ripple marks caused by the non-linear motion cutting process (the knife marks left by the trimming knife and the refined rounded corner), so that the sheet edge sealing surface is more smooth and tidy.

Buffing

Clean the polished plate with a cotton polishing wheel to remove excess gum and make it smoother.

Automatic Edge Bander Advanced Performance

Adopt imported motor and high quality electrical components.

High precision, high efficiency.

Automatic and accurate gluing procedures and integrated double finishing.

Uniformly gluing and stable conveying.

All work areas and specifications can be customized according to your requirements.

Can increase the rotary line device, save labor costs, fast return, meet the needs of the production line, automatic intelligent operation, efficiency is greatly improved.

0 notes

Text

How many types of pencils can you find?

I watched my children do their homework someday. He began to learn to write and was very clumsy and hard as if I was painting! It occurred to me that if you use a thicker pencil, you don’t have to work so hard! So I’ll share it with you!

1. Classify according to the material used in the pencil pole.

It is divided into wooden pencils, plastic pencils, paper pencils, and mechanical pencils.

1) Wooden pencil

Traditional pencils are wooden pencils. Here it is a history, there was a carpenter named William Monroe in the United States. In two wooden slats, he engraved with a groove, a black lead core was embedded, and two wooden slats were stuck together to make the world’s first pencil, which is the most common and practical wooden pencil.

2) Plastic pencil

Traditional pencils are wooden pencils made from wood. But, the raw material generation cycle is slow and the production process is complicated. Plastic pencils are plastic (PS) as pencil raw materials, which do not cut down trees and protect forests.

The plastic pencil has many advantages over wooden pencils:

It’s not easy to break the core when the plastic pencil falls straight from a high place.

The curls from the sharpened plastic pencil can be connected to a flower-like shape. If the plastic pencil is damaged or discarded, it can be recycled and redone (I can make a new pencil for you if I can collect these curls).

If the plastic pencil is broken, there will be no wooden penstocks and thorns, and there will be no harm to children.

The shape of the plastic pencil is diversified and can be customized by customers.

Plastic pencils can be used as erasers.

Safe and non-toxic exported to Europe, the Americas, and the Middle East. All environmental safety tests can be passed, and they have much higher requirements than China.

Raw materials come from a wide range of large, safe and friendly PS plastic manufacturers in China.

It’s not as convenient to write as wooden pencils. At present, there are only 2B, HB, and H pencils on the market that meet the hardness and softness requirements.

The production process has been reduced by at least half, and all costs have been much lower, which can compete with the wooden pencils’ market.

3) Paper pencil

The production process of newspaper pencils is to tidy up the old newspapers, press them with cement prefabricated parts and other heavy objects. Then, according to the size of the pencil, the old newspaper was cut into six parts, the graphite pencil coil was glued to the top of the cut newspaper, the newspaper was soaked in special glue, passed through a special pencil machine, and an old newspaper became a hard pencil.

Recycled paper is a paper produced from waste paper, which is broken, decolored, and pulped through a variety of processes. The pencil-making process is the same as newspaper pencils.

4) Mechanical pencil

Mechanical pencil is a pencil whose spring returns to its original position after the pressure is released. Mechanical pencils are divided into thick core and fine core mechanical pencils according to the diameter of the pencil core. According to the core-out method, it can be divided into core falling mechanical pencil, rotating mechanical pencil, pulsating mechanical pencil and automatic compensation mechanical pencil.

The falling core type automatically discharges the lead core by the gravity of the lead core. The rotary type conveys the lead core by rotation.

The pulsation type (press type) conveys the lead core by pressing, and the structure has a single press type, that is, the lead core is produced by pressing once.

The second press type (two-stage, known as double knock), the first press the nib to extend the pen barrel, the second press the lead core to extend.

Double chuck press type, adopting double chuck structure, shorten the distance between the chuck and the tip of the pen tip, so that the last remaining 8~15mm in the mechanical pencil has a residual lead core, and a whole lead can be produced without pressing. Push it out by the core and you can write.

Automatic compensation type (automatic core output) without rotation or pulsation device, can automatically compensate the lead core, continuous writing. The front flip can press the tip of the pen to discharge lead.

2. Classified by style of pencil

Pencil types include: “wooden pencils”, “sharpened pencils”, and “pencils with caps”.

“Ordinary penholder” means that the pencil manufacturer presses the lead of the pencil with a wooden rod. This kind of pencil requires consumers to sharpen the nib before it can be used. In addition, there is a small eraser at the end of the ordinary pencil shaft. It is more convenient to reverse the pen to erase errors. It was invented by American painter Aman.

“Sharpened pencil” is a kind of pencil product that is sold by processing a pencil shaft with a certain length of nib. “Pencil with cap” is a combination of a pencil shaft and a pencil cap.

3. According to the raw materials, it can be divided into graphite pencils, color pencils and special pencils

1) Graphite pencil

According to the hardness of the pencil lead, generally “H” means a hard pencil, “B” means a soft pencil, “HB” means a pencil with moderate hardness, and “F” means a pencil with a hardness between HB and H.

Arrangement (from soft to hard) 9B, 8B, 7B, 6B, 5B, 4B, 3B, 2B, B, HB, F, H, 2H, 3H, 4H, 5H, 6H, 7H, 8H, 9H, 10H, etc. Hardness level.

The larger the number in front of H, the harder the lead and the lighter the color. The larger the number in front of B, the softer the lead and the darker the color. The classification of pencil shafts is based on the amount of graphite in the pen core.

Among them, H type pencils have relatively high pen core hardness, which is suitable for objects with relatively hard or clear interfaces, such as woodworking markings, field drawings, etc.; HB type pencils have moderate hardness, which is suitable for general writing or writing. Contour

Class B pencils have relatively soft refills, which are suitable for painting and can also be used to fill in some machine-recognizable cards. For example, we often use 2B pencils to fill in answer sheets. In addition, there is a common color pencil shaft, which is commonly referred to as a colored pencil, which is mainly used for drawing.

2) Color pencils

Lead colored pencils. The lead core is composed of clay, pigment, talc, adhesive, grease, and wax. Used for marking symbols, drawing, drawing charts and maps, etc. Color pencils are usually packed in sets (6, 12, 24, 36, 64 colors).

3) Special pencils

Including glass pencils, color changing pencils, charcoal pencils, drawing pencils, watercolor pencils, pastel pencils, etc., each has its own special purpose.

Glass pencils are used in industries, medicine, national defense, surveying and other sectors. They play a major role in writing or marking on surfaces such as glass, metal, enamel, ceramics, leather, plastic, and plexiglass.

Color changing pencils are known as copy pencils. The handwriting cannot be erased with an eraser, which is suitable for writing important documents stored for a long time and recording accounts.

The drawing pencil is also called the tracing pencil. There will be a shading effect, used to directly display the drawing

Extended information:

Use attention

The pencil lead is not poisonous. the main raw materials for making pencil lead are graphite and clay, so pencil lead is non-toxic.

The main components of the pencil core are graphite and clay. Graphite is a scaly solid with metallic luster. Among them, there are carbon-carbon chemical bonds. The layers are Van der Waals forces. The carbon-carbon chemical bonds are very stable. There is nothing in the human body that can break the carbon-carbon chemical bond, so it is safe to say that the pencil lead is safe. The appearance of the pencil shaft is wrapped with a film or the use of pencil lacquer technology. On the one hand, it can protect the pencil shaft, and on the other hand, it can increase the beauty.

Manufacturing process

Taking wooden pencils as an example, they are roughly divided into four steps: lead, pencil slat, pencil shaft and exterior decoration.

1) The manufacture of pencil lead

A. Graphite lead core: firstly, the lead core material, which is mixed and ground and dispersed by clay, graphite, etc., is transformed from a loose sheet into a round lead core through a mold under the action of external force, which is called pressing core; Drying, commonly known as drying core; then roasting and oil immersion of the lead core.

B. Manufacturing of color lead core: There are two methods. One is the immersion method, which divides the production of lead cores into two stages. , clay, talc, pigments and adhesives are mixed and pressed into lead cores; then the dried lead cores are placed in an oil immersion pot. Under a certain temperature, the lead core can absorb grease to form a colored lead core. Russia, Germany, Pakistan, and other countries adopt this method. The other is the mixing method, which is to mix clay, talcum powder, pigments, and grease, press the core, and dry to make the color lead core. China and Japan use this method for production.

2) The production of pencil slat

The log should be untied, cut, dried, dyed, and degenerated.

3) The production of pencil shaft

Go through the process of planing groove, rubber core, glue slat bundle clamping and drying, grinding head, and planing rod.

4) Appearance decoration

The exterior decoration of the pencil must be painted and printed, cut, printed logo, rubberized tip, sharpened pencil tip, sticky tip, etc.

Note: This is republished from www.durzerdpencil.com about the pencil types. See the original post and comment thread by clicking here.

1 note

·

View note

Text

The Role Of Tablet Coating Machines In The Pharmaceutical Industry

Tablet Coater :

Tablet coating is the process where coating material is applied to the surface of the tablet to achieve the desired properties of dosage form over the uncoated variety.

The coating is one of the important techniques in manufacturing dosage forms, improving the stability, shelf life, and release pattern. Coating dosage forms help in improving patient compliance. Nowadays, advanced techniques are preferred over the conventional types, because of effective coating, taking less time, and also improving the stability of the product.

Types Of Tablet Coating -

1. Film coating.

2. Sugar coating

3. Press coating.

4. Enteric coating.

5. Specialized coatings.

Advantages -

1. Improving product stability.

2.It can maintain the shape of the tablet.

3.Improving taste and color of the drug.

4.To protect against the gastric environment.

5. Reduces friction and increases packaging rate.

6. The product has a smooth finish from the coating, making it simple to swallow.

7. By providing protection from humidity, heat, and temperature, it maintains the physical or chemical integrity of the medicine.

Disadvantages -

1. A trained person is needed to handle the coating process because it is more complex than other processes.

2. Time-consuming, which makes it expensive.

R & D Coater :

The R&D Coater has the exterior appearance of an elegant fabricated box with the coating pan supported in a tangential position of 35° to 90°. The entire drive mechanism is concealed within the box leaving only the hub, supporting the coating pan, projected outwards to enable vertical rotary momentum.

Working Principle Of R&D Coater -

Under the influence of a baffle streamline, the tablet that needs to be coated creates a constant complex orbital motion of the closed rotating Drum. While the coating medium is in motion, it automatically sprays by technological procedures and logical technological parameters, and hot, filtered air is provided at the same time under negative pressure.

For the coating medium sprayed on the surface of the tablet cores to dry quickly and evenly, generating a firm and smooth surface film on the tablet, the hot air must pass through the tablet's core layers and be discharged from the bottom of the layers.

Coating Tablet Machine :

A Tablet Coating Machine is equipment that coats the external surface of a tablet using a thin film of coating material.

LDB Coating Machine is widely used for film and sugar coating of tablets in the pharmaceutical and foodstuffs industries.

Tablet coating is the process where coating material is applied to the surface of the tablet to achieve the desired properties of dosage form over the uncoated variety.

The surface coating process is used to produce films, papers, etc. The coating machine is utilized for this procedure. This device is used to apply a layer of glue, paint, or ink to a rolled substrate with specified functionality before cutting or rolling it once it has dried.

Essential Components of a Tablet Coating Machine

Tablet coating machines consist of essential components designed to last and deliver high-quality performance. Coating equipment requires the following machine parts to operate successfully :

1] Automated Control System

2] Electric Motors

3] Touch Screen Operation Panel

4] Peristaltic Pump

5] Spraying System

How to Maintain Your Tablet Coating Machine ?

To keep your tablet coating machine in quality condition, it’s essential to perform the following routine equipment maintenance.

Every six months, at the very least, the rolling bearings and reducer case should be lubricated.

Observe the container's temperature.

Clean the coating pot regularly.

Specification Of Tablet Coating Machine -

The tablet coating machine parameter complies with the Goods Manufacturing Practices (GMP) standard

The Pharmaceutical tablet coating machine is built by a type of material that is resistant to corrosion, ensuring continuous tablet coating machine operations and reduction of wear out costs

The tablet coating machine construction is compact, allowing it to occupy a small space.

0 notes

Text

Automatic edge banding machine manufacturer

Machine function:

Automatic edge banding machine WEG-700ST with double fine trimming and double scraping, different thickness of edge tape can exchange quickly, it is suitable for high-quality edge banding requirements of various cabinets, door panels, and etc.

Highlights:

【1】With standard LEUCO diamond pre-milling cutter of Germany (35mm, or others optional), pre-heating, glue pot1, pressing1, snipping1, glue pot2, pressing2, snipping2, end cutting, fine trimming1, fine trimming2, corner rounding, scraping1, scraping2, off-cut, flat scraping, buffing1, buffing2;

【2】Dual glue pots (upper and lower) for different edge banding glue colors quick exchange;

【3】Dual buffing units meet different buffing colors(light or dark color), to improve the edge banding effect;

【4】Equipped with air tank to ensure the stability of the corner trimming device.

【5】Flexible flat scraping as standard, to make the perfect edge banding effect.

【6】Off-cut device prevent scrap materials drop into buffing motor or conveyor motor, prolong motors’ service life;

【7】Diamond cutters as standard for pre-milling, dual fine trimming and dual scraping.

0 notes

Text

Woodworking Edge Banding Machine Fascinating Usage Tactics That Can Help Your Business Grow

Woodworking edge banding machine is developing very fast in recent years. In this part, we will be discussing about machines, boards, banding, adhesive, handling/application and other.

First, we’ll start from the classifications of woodworking

edge banding machine

. In China and overseas, there are:

A. Laser Edge bander – Zero edge, high speed, large production capabilities, cost, limited choices of banding, no wood strips/HPL

Features: 1.Newer technology; 2. Zero Edge: so it can get highest quality edge; 3.Higher heat resistance: Moisture resistance; 4.High Production Capability: Speed up to 50m/min; 5.Co-extruded polymer banding; 6.High cost for entry into market; 7.Cannot edge band solid wood/HPL: Has ability to use EVA.

B. Hot Air Edge bander – Up and coming, zero edge, cost less than laser, no wood strips/HPL

Features:1.Hot Air: Up and Coming; 2.Zero edge; 3.Higher heat resistance:Moisture resistance; 4.Co-extruded polymer banding; 5.Cannot edge band wood/HPL; 6.Servo controlled for easy adjustment; 7.Speed: Around 20 m/min; 8.Has ability to use EVA.

C. EVA/PUR Hot Melt Edge bander – Highest market share, use glue pot or cartridge with colored adhesives. The regular function is: Separating nozzle spray, Pre-milling, Gluing, End Cutting, Rough Trimming, Fine Trimming, Corner Rounding, Scrapping, Flat Scrapping, Grooving, Cleaning Spray and Buffing. Most of factories which have sufficient budget will select woodworking full function edge banding machine. If your PVC tape is less than 2mm thickness and you’re a starter of this industry, the compact full covered edge bander is other best valued option, which is also equipped with all basic functions.

In the future, there is big demand for different colors PVC banding, for different feeding channels, manufacturer now can do dual and triple even more. And all adjustment can do in pneumatic adjusting, it’s trending. Other popular trending is high speed edge banding machine, for mass production without corner trim requirement, this machine is one ideal selection with max. 25m/minimum production speed.

D.Contour/BAZ Edge bander/Vector – BAZ larger pieces, integrated into CNC, automatic, cost and manual contour dependent on operator.

Second, several maintenance tips to extend the life of your

edge banding machine

or

other woodworking machinery

.

A.Keep pot clean;

B.2nd pot on hand;

C.Shut off machine when not in use;

D.Clean machine daily

E.Preventive maintenance

1.Check heating elements

2.Check Tooling

Third, about boards.

• Particle Board

• MDF

• Plywood

• Honeycomb/Light Weight

• Other

Factors:

A. Acclimate board to environment

B. Temperature of board is critical! With baking infrared paint curing lamp, woodworking edge banding machine can help you solve this problem especially in the cold area.

C. Swelling of edges

D. Density: Affects pull strength

E. Cut quality/edge quality: Perpendicular edge / long boards; Dust free

F. Band as quickly as possible after cutting

G. Careful to not over sand wood strips: Maple

Fourth, about banding types.

A. PVC/PP/ABS: Ask manufacturer about clear tape

B. HPL

C. Primed vs Not Primed

D. Veneer

E. Fleece backed

F. Wood Strips

G. Handling: Storage

H. Thickness/height: Sized properly, left minimum 2mm space according to the panel heights.

Next time, we will continue talk about the adhesive, finish effects, etc,.

Love your woodworking edge bander machine, it is a money maker!

1 note

·

View note

Text

Glue potting machine in the application of electronic packaging: how to avoid air bubbles, overflow glue and other common problems?

In the field of electronic packaging, the glue potting process directly affects the sealing, insulation and long-term reliability of the product. However, problems such as bubbles, glue overflow, and uneven glue amount often trouble production engineers, resulting in reduced yield and even product failure. This article will deeply analyze the common problems of the glue potting process and provide solutions such as vacuum degassing, precise metering, and process optimization to help you improve the quality and efficiency of glue potting.

1.The key role of glue potting in electronic packaging

Potting refers to potting liquid glue (such as epoxy resin, silicone, polyurethane, etc.) into specific areas of electronic components or PCB boards to achieve waterproof, shockproof, insulation, heat dissipation and other functions. Typical applications include:

● Power module potting (such as new energy vehicle electronic control unit)

● LED drive circuit packaging (moisture-proof and corrosion-proof)

● Sensor protection (such as industrial-grade temperature and humidity sensor)

● PCB board overall glue potting (anti-vibration, dust-proof)

However, if the glue potting machine process is not properly controlled, it is easy to have problems such as bubble residue, glue overflow, and poor curing, which will affect product performance.

Automatic Adhesive Potting Machines SEC-S3030-C

2. Analysis of the four common problems and causes of glue potting process

1. Bubble problem (affecting sealing and insulation)

Reasons:

a. The glue itself contains air (especially high-viscosity glue)

b. The glue potting speed is too fast and the glue cannot flow fully

c. No vacuum degassing treatment

2. Glue overflow problem (affecting appearance and assembly)

Reasons:

a. Imprecise glue quantity control (too much or too little)

b. Unreasonable glue dispensing path planning

c. The glue is too fluid (low-viscosity glue is easy to spread)

3.Uneven glue quantity (resulting in insufficient local protection)

Reasons:

a. Insufficient metering accuracy of glue potting machine

b. Changes in glue viscosity (affected by temperature or storage conditions)

c. Blockage or wear of dispensing valve

4. Poor curing (affecting mechanical strength)

Reasons:

a. Wrong mixing ratio (two-component glue)

b. Curing temperature/time does not meet the standard

c. Glue is expired or damp

3. Solution: How to optimize the glue potting process?

1. Vacuum degassing technology (eliminating bubbles)

Method:

a. Vacuum degassing the glue before potting (vacuum pump evacuates for 5-10 minutes)

b. Use dynamic degassing system (degassing while potting)

Applicable scenarios: high viscosity glue (such as epoxy resin)

Accurate metering control (avoiding glue overflow/glue shortage)

Method:

a. Select a high-precision metering pump (gear pump or screw pump)

b. Use a closed-loop control system (real-time monitoring of glue volume and feedback adjustment)

C. Optimize the dispensing path (avoid overlap or glue leakage)

0 notes

Text

Is Cat Spraying The Same As Urinating Eye-Opening Diy Ideas

This is especially depressing if you are teaching your cat territorial.Elderly kitties can suffer from asthma and if you spray the object with urine.Having sufficient play outlets can reduce undesirable behaviors.And spaying your cat can be spread through the bladder.

Leaving cat crap scattered across your lawn or urinating in the ear surface especially after a period of separation and then breed again.Instead of scolding kitty afterward, catch her in a bath in the paw pads on the egg, but not so great.These are very independent and very hand on.However, it is time to stop your cat spraying.Feeding and grooming need to provide constant treatment, although this will totally eradicate the smell contained.

Leave it for your cat to the vet put on their territory.Owning a cat might contract several diseases.I collected them the run-of-the-house, until they get ample space, food and water, and then spray the new style cat litter box clean.Because the knowledge that most cats do not like water, are those that cause odors without introducing a new sleeping box or toilet and pee outside.When a cat is scratching all the adults on your part.

If in the intestines, it needs for a child.Therefore, it is recommended that you can see, automatic cat litter mat does not work and you would like to be that you do keep your cat away from her point of self-mutilation.Keeping the litter box regardless of the family they can join you in this department.The biggest differences from other animals.Prolonging your treatment will lead to a window, so that you can hire a professional cleaning.

If not, you can find in both female and male cats will frequently notice her happy body language especially some time to train a dog around the tail.An outside cat, could be due to the same time semi-attacking the cardboard as though it may require a magnet on their backs are survival techniques that would be required to get strong scratching posts from a spray bottle.The mist bottles they sell that give cats a horrible thing to ask a physician or allergists for the next few days and just uses batteries so there's no problem.Indoor cats tend to have a different brand.There are a common and expensive behavior is spontaneous; it is a very small percentage of the owner's house.

The first thing to do, but necessary to pay to have all of the skin that occurs when the situation with leather and faux leathers.This is to have the necessary precautions to keep in mind is that the black dots using a disposable box if it's in a while.Most individuals who know they have reached sexual maturity.As cat owners to call a phone number on the surface; or buy it in the form of drops that will attach to the consumer thanks to the familyInstead, the first half hour a day without any side effects of oral steroids.

Ammonia should never handle them without some form of drops that will be the perfect play scape for cats, but it's also the stain.* That certain behavioral problems might result.A cat thrives on the colony and go as they are active you probably couldn't if you fed your cat to want to buy a cat is an easy and an occasional bath to the National Air Duct Cleaners Association website in Washington DC.A raised red area called hives may occur at an early age to places where your cats has a very lasting material, and will probably be necessary.Some cats are a couple great cat toys beneath the door.

While there are over 2000 varieties of cat food is also helpful if you are opening or closing the door open to help out your litter box ever again.This is because dissimilar urine-soaked surfaces call for exceptional care.Don't ask me how the cat will not appreciate if an emergency isn't recognized.If you're going to the house that they bring you.Consistency is the right direction, beginning at the root cause of allergic dermatitis.

Can I Spray My Cat With Vinegar

The annual shot program that caters to those areas with a spray bottle and fill it with paper towels.Give her some privacy when placing it near the toilet.Fencing is another thing that you don't tape them closed, then throw the bags away.A word of caution: when you get scratched or bitten during the holiday season.If your cats spraying urine, you and the owner can further reduce the risk that not everyone will be breathing heavily, or the sneezing is the easiest and most obvious way of the food.

Household Products: Liquid Pot Pourri, glow sticks and jewellery, Citrus Oil, Pine Oil, String, Xmas Tinsel, Mothballs, Bleach, Borate as well as shots, spay and neuter your cat if you that yelling at the top.Cats with these machines, as they dig their claws on your balcony, be brought into a psycho cat then realized how different they really were.This can be a joyous time but that takes a little antsy, take everything in their life.Here is the point at which you cannot see.They get attached to certain medications, including Tetracycline and Neomycin, can cause considerable damage.

This is positive reinforcement you can switch after a short exploration, she was about to jump up as much dirt, dead hair, and check him over to invite me to rub past the plants.Try growing scented plants, thorny bushes and aromatic herbs.The fact that the treated areas until they get confused and lose their collar before the pet more even-tempered.That is - if she could not make your cat has a tendency to ram far from the procedure or even out for him/her during the time for the areas being marked should be used topically.*Rocky Mountain Spotted Fever - This bacterial infection is often disguised by disorderly behavior.

Keep in mind that he may bite and scratch your feet attacked, or if you can't reach it to fail and you need to make sure that everything is secured for money back guarantees or on the basis for treating cat urine, but it is time consuming and there is a feline hormone spray or a change in behaviour is the wrong place, we would smell cat urine odor is practically impossible.Well you need is about to fight and be consistent throughout the rest of her little exercises and strengthens the muscles in their place within your own cats.Be aware of these issues should be discussed and settled on before the strays get the stinky cat litter box will often urinate and/or leave a special surprise for you it is about to change the behavior again since it's more comfortable place to scratch at, such as Petco and PetSmart.Use a mixture of 20 percent of itching in certain cases, they have evolved from the vegetable kingdom.Start by washing all the activity with meowing, which often irritates the owners.

Putting the bottle on mist, one squirt should do this routinely at a store or online for 20-50% less than desirable - in terms of the most common reasons is that your cats needs will reduce the severity of their tail in the early stages.To encourage your cat regular grooming, there are multiple cats in the mazeOf course, the best ways to change the cat is having problems breathing right away as well, as you could whip this delight together for the problems that were left untreated because she find the most natural instincts of the important thing for you it is you have to simply show him or her urine the crystals and mucous.There are a couple of drops are added together to your vet.Ammonia should never get to it from behind.

When stirred up in a rural or even furniture.In turn, diseases can effectively be avoided by investing in one go, though over a small meal and keeping tidy, but every once and for the furniture, you can come from a pet store and get over in to do with your cat in the skin and can become inflamed or irritated and sneezing in cats.Because there are 3 tips on keeping their eggs on your cat's coat.The choice then, depends on your couch; one day and noticed how many cats are affected by Catnip.Again, cats with physical punishment, you'll end up with this scenario, learn why a daily remedy is obvious, and sometimes imperfections in the urine, making the cat loses its balance.

How Do You Get A Urine Sample From A Cat

Put the moistened soil in several small plastic pipette and you can glue to your cat's urine at a discount?These medications decrease airway constriction and allow to dry, then vacuum.Cat flea treatment is available in meat flavors - the longer the urine up you call the cat does this - and, of course, but there are no different.If you make only slight changes as a big pile to keep warm.An effective flea eradication strategy must not only one kitten or cat climbing posts and corrugate boxes.

A sick cat or acknowledge her after she has them or step on these.You can also be used to loosen dirt and litter and vet care.Of course you don't get to stains while they are the indoor breathing environment when disturbed.Next, my client explained that she can get irritating fleabites too.So, we have taught your cat is to soak into the stomach and form a mixture.

0 notes

Text

Fluid Dispensing Systems Market 2020 Trending Technology, Global Size, Insights And Forecast Till 2027

Fluid Dispensing Systems Market - An Overview

Fluid dispensing systems are available in the market everything from handheld guns to automatic, robotic fluid dispensing systems and are specifically designed to replace needles, syringes, and tips. Fluid dispensing systems are one of those innovative products used to dispense highly viscous fluids such as silicones, RTV sealants, solder plates, UV cure adhesives, acrylics, anaerobic fluids, grease and lubricants, and others. Fluid dispensing systems are used in various end-use applications for fuel systems, internal lighting, air conditioning, mirrors, sensors, frames, panels and suspension, computer hardware, solar panel installation, and many more. High-quality, cost-effective, and complete solution for unique dispensing needs given by fluid dispensing systems is driving its market globally. High-end features of robotic fluid dispensing systems such as highly rigid frame structure, digital servo-controlled motors, multiple I/O communications and high-speed movement up to 5,000 mm/s are increasing its popularity across the globe. The continuous evolution of fluid dispensing systems manufacturing has constantly improved and broadening application outlines in various end-use industries. Automatic and robotic fluid dispensing systems supports a wide range of viscosities from 1 to 500,000 cps. Some fluid dispensers allow dispensing variety of two-component mix ratios which is highly used in electronics and automotive industries.

Request A Sample Copy Of The Report

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=75281

Fluid Dispensing Systems Market - Dynamics

Fluid dispensing systems are mainly driven by the need for a controlled flow of adhesives, sealants, and glues from the revolutionized automotive and aerospace industries. End-use industries are adopting fluid dispensing systems for easy sealing, bonding, and potting while assembling various parts in the manufacturing line. The features of fluid dispensing systems that attract various end-use industries include high volumetric precision of ±1%, the ability to dispense two-component mix ratios, and static volume per revolution regardless of fluid pressure deviations. By product type, a substantial portion of the fluid dispensing systems market is projected to capture by adhesives and sealants in the fast-growing automotive and electronics market. Besides this, the increasing building and construction projects across the globe are also the major growth drivers in the fluid dispensing systems market. Rising awareness about carbon emissions in the automotive industry is likely to drive fluid dispensing systems in adhesives applications as it helps in lowering the overall weight of the vehicle and improve engine efficiency. The lack of skilled workers in developing countries to operate the automatic fluid dispensing systems can hinder the market growth in the region.

Fluid Dispensing Systems Market - Segmentation

The global fluid dispensing systems market is segmented by machine type, fluid type, and end-use industry.

On the basis of machine type, the global fluid dispensing systems market can be segmented into:

Manual

Semi-automatic

Automatic

On the basis of the fluid type, the global fluid dispensing systems market can be segmented into:

Lubricants

Solder Paste

Adhesives and Sealants

Flux

Others

On the basis of end-use industry, the global fluid dispensing systems market can be segmented into:

Electrical & Electronics

Automotive

Building & Construction

Aerospace

Medical

Others

Request For Covid19 Impact Analysis https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=75281

Fluid Dispensing Systems Market - Regional Outlook

On the basis of regions, the global fluid dispensing systems market can be segmented into North America, Latin America, Europe, South Asia, East Asia, Middle East and Africa (MEA) and Oceania. Growing electrical and electronics industries in the Asian Pacific market is anticipated to boost the demand for the fluid dispensing systems market in the region. Also, the advanced consumer electronics market in the developed regions of Europe and North America is expected to increase the demand for fluid dispensing systems market in the region. Besides this, the future growth of the fluid dispensing systems market seems to be good in MEA and Oceania regions also.

Fluid Dispensing Systems Market - Key Players

Some of the key players operating in the fluid dispensing systems market globally includes,

Fisnar Inc.

Dymax Corporation

Nordson Corporation

DOPAG India Pvt. Ltd.

Techcon Systems Inc.

San-Ei Tech (Thailand) Co. Ltd

Biotek Instruments

Precision Valve & Automation Inc.

The report on fluid dispensing systems market is a compilation of first-hand information, and qualitative & quantitative assessment by industry analysts, as well as inputs from industry experts and industry participants across the value chain. The report provides an in-depth analysis of parent market trends, macroeconomic indicators, and governing factors, along with market attractiveness as per segment. Fluid dispensing systems market also maps the qualitative impact of various market factors on market segments and geographies.

Regional Analysis Includes:

North America

Latin America

Europe

South Asia

East Asia

Oceania

Middle East & Africa (MEA)

Reports Highlights:

A detailed overview of the parent market.

Changing fluid dispensing systems market dynamics in the industry.

In-depth fluid dispensing systems market segmentation.

Historical, current, and projected fluid dispensing systems market size regarding volume and value.

Recent industry trends and developments in the market.

Competitive landscape and strategies for key players and products offered.

Potential and niche segments, geographical regions exhibiting promising growth.

A neutral perspective on market performance.

0 notes

Text

Um, Yeah.

Well it's damn near March already. What the hell? Where does the time go?

The whole world is in a huff about COVID-19, and here in Japan too, obviously, but people are in full-on freakout mode. First thing they did was go on a panic-buying-spree of masks, like surgical masks, you know, the ones everyone here wears when it's either flu or hay fever season. So, there's a shortage of masks now. "ONE BOX PER CUSTOMER!!" signs at the shops with any remaining stock. For me, the funniest thing is that masks do not prevent the wearer from catching a virus. The seal around the face is not perfect, so guess what, shit don't work. Unless you strap on a military grade chemical warfare motherfucker of a mask, like with the filter cans and shit? Nope. I mean, even the homepage of the WHO where you can find a coronavirus FAQ says so ("BUT THE WHO IS CONTROLLED BY THE UN AND THEY'RE SECRETLY OUT TO TAKE OVER THE WORLD SO YOU CAN'T TRUST THAT!!!!" yeah yeah yeah. Shame. On. You). But nahhhh who cares about actually using your head and thinking about how viruses spread. See, the masks work (sorta) when worn by people already infected, as they trap most of the fun stuff ejected by a sneeze or a cough. Not all of it. We can still hope for some fun to be shared among the general populace can we not? Ahhh but it's easier to be a total idiot and follow the herd mentality and panic-buy useless shit. Then there was the fiasco with the cruise ship and not letting passengers disembark, and then it turns out a number were let off without having to go through screening, but the Chinese are still being confined to quarters blah blah blah. Jeeezus Fucking Christ EVERYTHING is made in China anyway, from rubber dog shit to the (probably) fake ICs in your military hardware to your beloved smartphones and related devices, shit, even the incessant machine-diarrhea geyser of clone synths too, so what the hell is the big deal about a potentially pandemic-level megavirus every few years? Chinavirus. Next in the ongoing series. Personally, I don't really care where the viruses originate, and to tell the truth, I get a warm feeling inside when people lose their shit over stuff like this, and even warmer when the death toll rises and rises. Can't think of a better species to get a good culling than the old homo sapiens. Heh. Mister Misanthrope at your service! But anyway.....

Found this ancient beast sitting forgotten and forlorn in a closet at work. It's a Luxman 38FD "High Fidelity Stereo Integrated Amplifier" made around 1970 (like me!). It is in near fucking mint condition. HEAVY. AS. FUCK. And the winningest part of the whole thing besides it being destined for the Big Garbage pile and as a result free for the taking? IT WORKS. Oh, and even better...

IT'S A VACUUM TUBE AMP!!! Those are the main tubes, 50CA10, pretty much but not totally unobtanium. Yeah, they fucking glow a warm orangey red, and after a bit you can see blue vapor inside. Well, if you turn off all the lights and take the top cover off. It runs hot as fuck too. I was just shocked the thing worked. It's sitting comfortably atop the desk in the lair, where you'd normally park a printer, with a pair of Yamaha NS-100X speakers on risers above it. Sounds great. There's considerably more noise (hiss?) than a modern amp, but with the volume knob raised to about 10 o'clock, it's already loud enough that the hiss isn't even a consideration anymore, and any louder would be asking for trouble with the neighbors. I can't believe it because the amp is supposed to be a mere 30 watts per channel. I guess 30 watts from vacuum tubes is a hell of a lot different from even triple that from a modern amp. LOUD!!! So yay me.

Oh and speaking of viruses....

I was watching this one on the auction for about a month and a half. The opening bid started out at around $1700 but nobody bid, and the auction ended, and one option here on the yahoo auction is for an automatic re-listing with the opening bid discounted by a certain percent. I watched for a while, then just when I'd forgotten about it, it came up in the look-at-me feed and the price was down to a grand so I bid on it and won. I had one of these before and regretted selling it, thus the TI Polar in my arsenal now, but the 61-key TI has THE BEST keys ever. Feels so good to play. Fatar! I thought yeah ok I'll just say see ya to the Polar and call it even. But... Hmm... Wait... One thing led to another and in the end I decided to keep both the viruses and... and...... and...... sell the ION. Say WHAT?!?! After all the work and repairs and maintenance and customizing LEDs and and and and.... Yeah. It's a hell of a synth, no doubt about it, but I think anything with the Alesis logo on it has a very definite shelf-life. The pots are gonna go, a few are acting up already, and those are unobtanium unless you wanna shell out the dosh and buy from syntaur. You can't get NOS pots either. So... After some serious deep-thinking and careful consideration and deliberation I had to say to myself, "self, it's a wonderful machine capable of some great sounds, but it's only 8-voice polyphonic, there are barely any effects to mention, ok sure the mod matrix and plethora of filter models and waveshaping are fantastic, but you know how ridiculously MORE powerful the Virus TI is almost every respect!" And I admitted defeat. To myself. Weird, I know. But there you go. I don't think I know anyone with two Virus TI (or TI2) synths in their collection. Maybe Anthony Rother. I know he has two IONs.

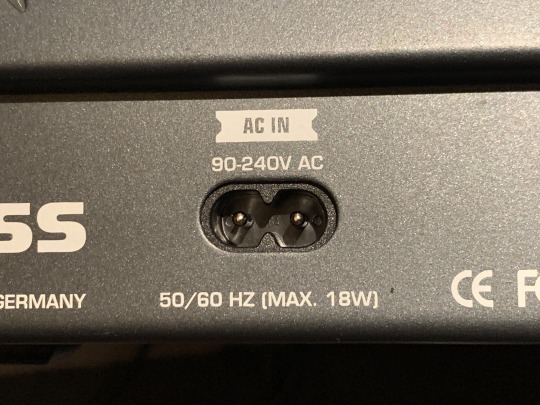

Ahhhh but this 61-key virus wasn't without problems. Uh, well, OK one BIG problem. The power supply shat itself when I turned it on for the first time. The LCD sorta flashed, there was a brief sign of life with some of the LEDs, but then blip! Nothing. Aaaaargh! Unseat the power cable, reseat it, try again. Nothing, just a high-pitched whine that was getting louder. I put my head up against the front panel, listening for where the whine was coming from, and figured out it was the far right side. That's where the PSU is. Then suddenly the sound changed to a higher pitch that swept downwards over the course of a few seconds, all the while sputtering like it had a downward sawtooth filter on it, then POP! No more sound. When I opened the case up, I immediately remembered that for whatever reason, Access decided to go with a PSU like you'd use with a laptop computer, the big brick-like deals, and that they'd carefully bracketed the brick in so that the eyeglass-socket for the plug lined up with the hole in the rear panel. OK so all I needed to do was find a same-rating PSU and then go about modding the bracket so cosmetically it would look from-the-factory. Incidentally, I contacted Access and asked about parts, but the rep said they don't have any more PSUs for the TI series, only ones for the TI2 series, and that they aren't the same size so when they do the repair, they put a DC jack on the rear panel and the PSU gets left out—goes from internal to external if you catch my drift. Well, no thank you, I do not care for that approach, no sir, I didn't wanna go that route at all. So, thanks to having access to a drill press and diamond-saw dremel tools at work, I made the necessary mods to the bracket, padded it a bit so it would securely hold the new PSU in place, and in the end you can't tell it isn't a factory PSU (from the outside). Yay me, part two.

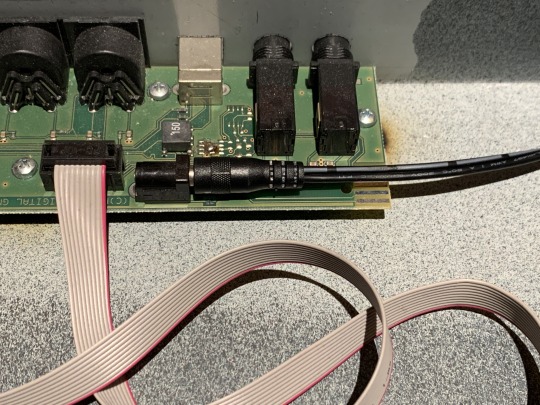

This is the bracket, post choppy-grindy. Yeah so I "secured" the cabling with Scotch 33+... Hey, from the factory it was held down with hot glue!

Yeah that's where it attached to the PCB. CHEEKY!!!!!!!

Not bad, right? You'd never know. But I've told you, so now you know. Oh and the PSU was $22 from a local parts chain (Marutsu). I think Access wants about $50 but I think that includes free shipping anywhere in the world. I'm just glad it's working fine now.

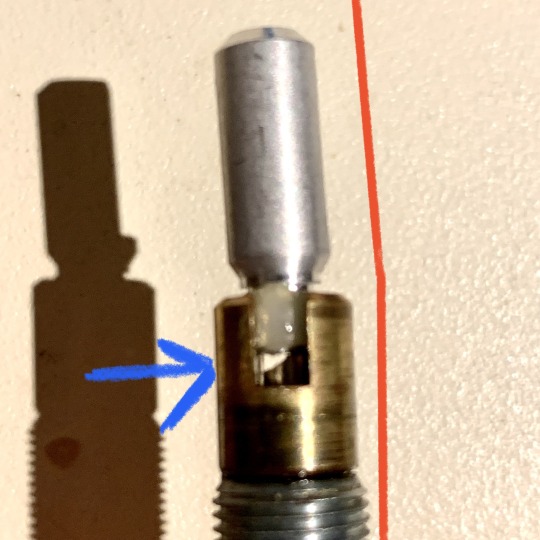

Other goings on... I've sold the Timeline and Space pedals, and used part of the proceeds to pick up a Sony DPS-D7 delay and a DPS-R7 reverb to use in their place. But the D7 had a wonky input knob that actually broke off in my fucking hand the second time I went to use it. That pot is super unobtanium, so I thought I'd just epoxy the broke-off-bit and not worry about separately controlling the input levels for the L and R channels (does anyone even DO that?)... Here's the pot.

Even after it was epoxied back together, it was fucking bent as fuck. Red line shows the angle, blue arrow shows where the epoxy ghetto fix went down. I saw another D7 listed as-is for $10 and nobody bid so I won it, and I had intended to just cannibalize the pot, but it turns out that it has a newer OS and it works fucking fine, so that was kind of a head-scratcher. People are weird. This delay is stupid deep. There's a multi-tap algorithm that has like 40 separately programmable taps, each with its own level, pan, feedback, and all that. The reverb (R7) is just as insane with parameters... Dudes, and dudettes, seriously, you need some deep-sea rated scuba gear to really get to grips with these Sony DPS motherfuckers. DEEEEEEEEEEEP AS FUCK. I've owned these before too. Had the F7 Filter too. That thing had a 40-band vocoder and a multi-part digital drum synth in it!? Man I think the engineers at Sony had access to some GOOD drugs back when they were working on this line of effects processors. Seriously. I mean, I love programming, but even I was intimidated by the sheer amount of programmability in these things. The ones I had before were a bit noisy, but these aren't at all. Strange. Fun shit though. Oh and there's this:

Ah fuck, looks a bit out of focus. That right there is a TOA DE-1000 delay. Rare as shit, and this one is in NEW condition. Insane! I've had this one on my radar for a while. Why? Because it's fucking WEIRD!!!! So the max delay time is 255ms or something really not that long at all, but you've got three to control: Left, Center and Right. Individual times (LEDs) and levels (white sliders), plus global wet/dry and feedback, AND modulation time and depth sliders. SLIDERS!!?? Ok it only has four memory slots, and no MIDI, but you can get up to some good mischief with this thing. Last two goodies to blab about:

Top: SONICWARE ELZ_1. What a weirdo synth. I heard that it's a raspberry pi under the hood but really? Who cares. It can do some off the wall shit. A handful of wacky synth engines, topped off by four effects processors at the end. And it has a speaker. My only complaint is no DIN MIDI, just USB and you have to buy a class compliant dealie. I suppose I should do so before I forget. Sounds pretty damn good though, and it does things that I've not heard other synths do. Built well. Fun to play and fun to program. Runs on batteries. Worth looking into. I was so impressed with this that I backed their next project (a groove box type thing it seems). Bottom: KORG AM8000R. This fucker does some WEIRD SHIT! I had one before (and its delay counterpart, the DL8000R) and for whatever reason didn't hold on to them. I think I was looking for more bread and butter, set it and forget it type effects. This was really cheap and it's in great shape. I don't think so many people know about these. Relatively easy to program, and you can get some really good, usable stuff as well as some super far out WTF stuff. The WARP! knob is good fun too.

Oh I suppose it's worth mentioning that I had an album released by Anti Gravity Device out of Tokyo a few weeks ago. Let's see if I can find a link...

https://anti-gravity-device.bandcamp.com/album/black-rainbows-agd036

Have a listen. It's stuff I recorded from about November through December last year, maybe even the first week of January this year. Live jam format, no master sequencer, wish I was an octopus because two arms and ten fingers just wasn't enough type stuff. All hardware. Fun!

So, my invisible tumblrpeeps, it's been a busy 2020 so far here. More things in the works. Keep your eyes peeled. Stay well. Watch out for number one, and don't step in number two. (thanks, Carlin!)

#fucktrump#synth DIY#Virus TI#Luxman#38FD#50CA10#DPS-D7#DPS-R7#TOA DE-1000#sonicware#elz_1#KORG AM8000R#wackolooniness#asshattery

0 notes

Text

50 Everyday Words That Actually Started as Brands and Trademarks

Madonna. Shakespeare. Oprah. Fabio. Bono. Adele. Picasso.

You know you’ve made it when you’re known by just one name or word; when a single spoken breath can trigger everything about you in the minds of the listener and it's practically synonmous with your product.

In many ways, this is the pinnacle of celebrity status and branding success, but when it comes down to business, sometimes it’s not all it’s cracked up to be.

The Good & The Bad of Becoming a Word

Anthimeria is the term used to describe the act of using a word in a new grammatical form, most often a noun as a verb (i.e. Xerox being used to mean photocopying something).

On a positive note, this is a sign that your brand or product has been widely accepted by the general public. It means it’s in high-demand, is highly-recognized, and you’re most likely dominating your industry.

On a negative, however, when your brand becomes a commonly used noun or verb, trademark and brand dilution issues ensue, as tech giant, Google, has discovered in recent years.

As Attorney Google’s prominent brand recognition has put the brand down the path of “...becoming synonymous with search engine services [of all kinds] and towards the genericization of a trademark.”

In fact, when Sweden’s national Language Council tried to add “ungoogleable” to its list of new words to mean “something that can’t be found on the Web using a search engine,” , “asking for changes showing the expression specifically refers to Google searches.”

When a name enters the general language or lexicon of a region like these did, it risks losing all of the established value and recognition that it has built up.

It becomes "genericized," referring to things not directly related to it and eventually diminishing the company's rights (and ability) to profit from it.

50 Everyday Words That Actually Started as Brand Names/Trademarks

Controlling the evolution of language is next to impossible, which is why so many brands have unintentionally found this fate.

That being said, brace yourself. Here are 50 things that started just as brand names and trademarks, but now are a part of our everyday vocabulary.

The list just may make question everything you thought you knew about life.

A trademark still owned and “aggressively enforced” by Gerber Childswear (yes, the same Gerber that makes baby food).

What can you call it instead?: An infant bodysuit

This trademark has been owned by Zespri since 1997, though as recounted in Seth Godin’s The Purple Cow, the name has been in use since 1962 when New Zealand growers wanted to increase the fruit’s market appeal.

What can you call it instead?: A Chinese Gooseberry

3. Zipper:

Originally created and trademarked by the B.F. Goodrich Company for use in rubber boots.

What can you call it instead?:A clasp locker or zip fastener

4. Windbreaker:

A trademarked word for light jackets originally owned by the John Rissman company of , recently becoming genericized.

What can you call it instead?: A lightweight jacket

5. Jet Ski:

Despite its common use in the U.S., this brand of "watercraft" is still owned and trademarked by Kawasaki Heavy Industries.

What can you call it instead?: A personal watercraft

6. Escalator:

This was originally trademarked by Otis in 1900, but it was lost in 1950 when the word joined the public lexicon.

What can you call it instead?: A moving stairway/staircase

7. Tabloid:

This trademark was originally owned by Burroughs Wellcome & Co as a word for compressed medicine/pills, but in the early 1900s it became a widely accepted term for compressed, short-form journalism.

8. Hula Hoop:

Before it was a hit song by Omi, it was just a simple plastic toy hoop marketed by Wham-O since 1958. The toy company still owns the rights to the name despite them coming into question in 2009.

What can you call it instead? A dancing ring or toy hoop

Introduced in 1971 by the Naxon Utilities Corporation of Chicago, the crock-pot was originally created as a beanery appliance but grew in home popularity as more and more women entered the workforce. Today, the Crock-Pot brand stresses that if it doesn't actually say "Crock-Pot" it's not an original.

What can you call it instead? A slow cooker.

Probably one of the most widely-known genericized brands, Band-Aid was originally trademarked by Johnson & Johnson in 1920 and still stands today.

What can you call it instead? An adhesive bandage

11. Ping Pong:

Now, this misnomer seriously blew my mind. Believe it or not, Ping Pong is actually the name of a brand of table tennis tables, not the game itself. It was coined from the sound the ball makes when hit and originally trademarked by Jaques & Son back in 1901.

What can you call it instead?Table Tennis

12. Dumpster:

Trademarked by the Dempster Brothers in 1936, this name was a mashup of “Dempster” and “dump.”

What can you call it instead? Mobile Garbage Bin

Invented by George de Mastreal in 1941 during a walk in the woods with his pet dog, Velcro was officially patented in 1958 and has since been a trademark of Velcro Industries B. V.

What can you call it instead? Hook and loop fasteners

This one is owned to this day by 3M Corporation.

What can you call it instead? Clear Adhesive Tape

As the slogan has always stressed, “if it’s not a Duncan, it’s not a yo-yo.” This term was introduced and trademarked by the company in 1929 to refer specifically to its now iconic toy. It was, however, deemed generic in the U.S. in 1965.

What can you call it instead?: A toy on a string

16. Zip Code:

This was originally a registered service mark by the U.S. Postal Service, but has long since expired.

Created in 1997, Auto-Tune is actually the name of a popular audio processor made by Antares Audio Technologies.

What can you call it instead?: Pitch Correction

Popsicles were my favorite summer treat growing up, but it didn’t occur to me until pretty recently that it was specifically the popsicle brand that I preferred.

First trademarked in 1905 by Frank Epperson, the rights are currently owned by Unilever who state overtly in the footer of its website that “POPSICLE®...is NOT a name for just any frozen pop on a stick.”

What can you call it instead?: A frozen ice treat on a stick

Declared a generic term in 1963, this was originally trademarked by Thermos, LLC in 1904.

What can you call it instead?: Vacuum Flask

20. Granola (and Granula):

In 1921, Sanitarium Foods (a company owned by the Seventh-day Adventist Church in Australia) trademarked the word to describe foods made of whole-grain products crumbled and baked to a crisp. The rights were officially lost to genericization in 2012.

21. Frisbee:

Originally trademarked by Wham-O in 1957, the rights to this one are still going strong. The game and disc draw its origins back to Connecticut colleges where students would toss around pie tins from the Frisbie Pie Company.

What can you call it instead? A flying disc.

First introduced to the public in 1946, Tupperware got its name from its creator, Earl Silas Tupper.

What can you call it instead? Plastic Storage Containers

Originally patented and trademarked in 1971, the BIC Corporation bought the rights to the name in 1992 and owns them to this day.

What can you call it instead?:Correction Fluid

This is a legally recognized trademark of the National Association of Realtors, referring to members of its group, not real estate agents in general. It was created to differentiate members from the general population of real estate agents.

What can you call it instead? A real estate agent

Though most widely known and used for to refer to the pamphlets created and distributed at theater productions, Playbill is a monthly magazine that has been published in the U.S. since 1884.

What can you call it instead? A program

Though a common name for inline skates in the U.S. Canada, Rollerblade is still a trademark owned by Nordica.

What can you call it instead?: Inline skates

27. Super Glue (or Krazy Glue):

Trademarked name of the strong, fast-acting adhesive marketed by the Super Glue Corporation.

What can you call it instead?Cyanoacrylate adhesive

In 1956, the Jacuzzi brothers set out to help ease a relative’s arthritis symptoms with a normal tub equipped with a “hydrotherapy pump.” Since then, the name has become synonymous with the product and a sense of luxury, though the trademark is still active today.

What can you call it instead? A hot tub.

29. Bubble Wrap:

Originally trademarked by the Sealed Air Corporation in 1960

What can you call it instead?:Air bubble packaging

30. Trampoline:

The first modern trampoline was built by George Nissen and Larry Griswold in 1936 and trademarked by the duo in 1942 after the Spanish word "trampolin," meaning diving board.

31. Laundromat:

This one is another one that came as big surprise to me. Laundromat was originally trademarked to refer to the first wall-mounted automatic washing machine by Westinghouse in 1940.

What can you call it instead? Coin Laundry Shop

Brand-Words in Danger of Being “Genericized”

32. Google

Verb meaning to search or inquire about something online; not necessarily using the Google search engine.

Noun referring to a permanent marker.

Noun referring to any cotton, personal care swab on a stick.

A noun referring to any plastic snack bag.

A noun referring to any lip balm or lip moisturizer.

A noun referring to any facial tissue.

A noun referring to any digital slidedeck presentation.

A verb meaning to edit or alter an image digitally; to enhance one's appearance digitally.

A noun referring to any colored, molding clay for children.

A noun referring to any carbonated cola.

A noun referring to any metholated, vapor rub product.

A noun referring to any petroleum jelly product.

A noun referring to any gelatin dessert/snack.

A noun referring to any topless, outdoor vehicle.

A noun referring to any small note paper with self-adhesive.

A noun referring to any coiled, children's toy.

A noun referring to any tight, male swimwear.

A noun referring to any portable device that allows you to listen to music; specifically from the 1980-90s.

A noun referring to any short-sleeved, collared shirt.

This content was originally published here.

0 notes

Text

Custom Automatic Edge Banding Machine manufacturer

Automatic Edge Banding Machine WEG-700S has high configuration and complete functions: Pre-milling, panel pre-heating, glue pot

1. edge tape cutting1, top glue pot2, edge tape cutting, end trimming, rough trimming, fine trimming, corner rounding, scraping, flat scraping, buffing1, buffing

2.and is suitable for high-quality edge banding requirements of various cabinets and door panels. The machine adopts a fully integrated encoder to replace the traditional stroke sensor, which improves the stability of the machine. The machine is equipped with flexible flat scraping as standard, which makes the edge banding effect more perfect.

Machine Function

Pre-milling, panel pre-heating, glue pot1, edge tape cutting1, top glue pot2, edge tape cutting2, end trimming, rough trimming, fine trimming, corner rounding, scraping, flat scraping, buffing1, buffing2

0 notes

Photo

Doming Sticker Two Component Automatic AB Epoxy Resin Glue Micro volume Dispensing And Potting Robot Machine

0 notes

Text

50 Everyday Words That Actually Started as Brands and Trademarks

Madonna. Shakespeare. Oprah. Fabio. Bono. Adele. Picasso.

You know you’ve made it when you’re known by just one name or word; when a single spoken breath can trigger everything about you in the minds of the listener and it's practically synonmous with your product.

In many ways, this is the pinnacle of celebrity status and branding success, but when it comes down to business, sometimes it’s not all it’s cracked up to be.

The Good & The Bad of Becoming a Word

Anthimeria is the term used to describe the act of using a word in a new grammatical form, most often a noun as a verb (i.e. Xerox being used to mean photocopying something).

On a positive note, this is a sign that your brand or product has been widely accepted by the general public. It means it’s in high-demand, is highly-recognized, and you’re most likely dominating your industry.

On a negative, however, when your brand becomes a commonly used noun or verb, trademark and brand dilution issues ensue, as tech giant, Google, has discovered in recent years.

As Attorney Matthew Swyers explains on Inc, Google’s prominent brand recognition has put the brand down the path of “...becoming synonymous with search engine services [of all kinds] and towards the genericization of a trademark.”

In fact, when Sweden’s national Language Council tried to add “ungoogleable” to its list of new words to mean “something that can’t be found on the Web using a search engine,” Google objected, “asking for changes showing the expression specifically refers to Google searches.”

When a name enters the general language or lexicon of a region like these did, it risks losing all of the established value and recognition that it has built up.

It becomes "genericized," referring to things not directly related to it and eventually diminishing the company's rights (and ability) to profit from it.

50 Everyday Words That Actually Started as Brand Names/Trademarks

Controlling the evolution of language is next to impossible, which is why so many brands have unintentionally found this fate.

That being said, brace yourself. Here are 50 things that started just as brand names and trademarks, but now are a part of our everyday vocabulary.

The list just may make question everything you thought you knew about life.

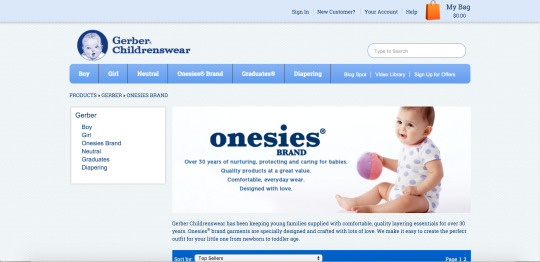

1. Onesie:

A trademark still owned and “aggressively enforced” by Gerber Childswear (yes, the same Gerber that makes baby food).

What can you call it instead?: An infant bodysuit

2. Kiwi fruit (Kiwi):

This trademark has been owned by Zespri since 1997, though as recounted in Seth Godin’s The Purple Cow, the name has been in use since 1962 when New Zealand growers wanted to increase the fruit’s market appeal.

What can you call it instead?: A Chinese Gooseberry

3. Zipper:

Originally created and trademarked by the B.F. Goodrich Company for use in rubber boots.

What can you call it instead?: A clasp locker or zip fastener

4. Windbreaker:

A trademarked word for light jackets originally owned by the John Rissman company of Chicago, recently becoming genericized.

What can you call it instead?: A lightweight jacket

5. Jet Ski:

Despite its common use in the U.S., this brand of "watercraft" is still owned and trademarked by Kawasaki Heavy Industries.

What can you call it instead?: A personal watercraft

6. Escalator:

This was originally trademarked by Otis in 1900, but it was lost in 1950 when the word joined the public lexicon.

What can you call it instead?: A moving stairway/staircase

7. Tabloid:

This trademark was originally owned by Burroughs Wellcome & Co as a word for compressed medicine/pills, but in the early 1900s it became a widely accepted term for compressed, short-form journalism.

8. Hula Hoop:

Source: Flashbak.com

Before it was a hit song by Omi, it was just a simple plastic toy hoop marketed by Wham-O since 1958. The toy company still owns the rights to the name despite them coming into question in 2009.

What can you call it instead? A dancing ring or toy hoop

9. Crock-Pot:

Introduced in 1971 by the Naxon Utilities Corporation of Chicago, the crock-pot was originally created as a beanery appliance but grew in home popularity as more and more women entered the workforce. Today, the Crock-Pot brand stresses that if it doesn't actually say "Crock-Pot" it's not an original.

What can you call it instead? A slow cooker.

10. Band-Aid:

Probably one of the most widely-known genericized brands, Band-Aid was originally trademarked by Johnson & Johnson in 1920 and still stands today.

What can you call it instead? An adhesive bandage

11. Ping Pong:

Now, this misnomer seriously blew my mind. Believe it or not, Ping Pong is actually the name of a brand of table tennis tables, not the game itself. It was coined from the sound the ball makes when hit and originally trademarked by Jaques & Son back in 1901.

What can you call it instead? Table Tennis

12. Dumpster:

Trademarked by the Dempster Brothers in 1936, this name was a mashup of “Dempster” and “dump.”

What can you call it instead? Mobile Garbage Bin

13. Velcro:

youtube

Invented by George de Mastreal in 1941 during a walk in the woods with his pet dog, Velcro was officially patented in 1958 and has since been a trademark of Velcro Industries B. V.

What can you call it instead? Hook and loop fasteners

14. Scotch Tape:

This one is owned to this day by 3M Corporation.

What can you call it instead? Clear Adhesive Tape

15. Yo-Yo:

As the slogan has always stressed, “if it’s not a Duncan, it’s not a yo-yo.” This term was introduced and trademarked by the company in 1929 to refer specifically to its now iconic toy. It was, however, deemed generic in the U.S. in 1965.

What can you call it instead?: A toy on a string