#Automatic Edge Banding Machine

Explore tagged Tumblr posts

Text

Fully Automatic Edge Banding Machines | Umaboy

Shree Umiya provides a diverse range of automatic edge banding machines, including the entry-level UEB 310 C, UEB 640 PCGD & more. Perfect for all your needs.

1 note

·

View note

Text

Automatic Edge Banding Machine Supplier in India: Golden Machinery

Golden Machinery offers top-quality automatic edge banding machines in India, perfect for enhancing the durability and aesthetics of wood panels. These machines are equipped with advanced features like high-speed performance, durable construction, and the ability to handle materials such as PVC, ABS, wood veneer, and melamine. With competitive automatic edge banding machine prices in India, Golden Machinery ensures efficient and cost-effective solutions for woodworking professionals. From precise edge feeding to seamless gluing and buffing, these machines deliver superior results while maintaining energy efficiency.

#industrial machine tool suppliers#machine tool suppliers in india#automatic edge banding machine#automatic edge banding machine price in india

0 notes

Text

Automatic Edge Bander & Banding Machine for Furniture Making

Edge banding machine

An edge banding machine is an automated woodworking machine that carries out pre-milling, gluing, end trimming, rough trimming, fine trimming, corner trimming, scraping, cleaning separation for cabinets and furniture making. The automatic edge bander is designed for straight edge banding and trimming of MDF (medium density fiberboard), blockboard, solid wood board, particle board, polymer door panel, melamine, and plywood.

Semi-Automatic Edge Bander

The semi-automatic edge banding machine is suitable for straight edge banding of MDF, blockboard and particleboard. Its capabilities include gluing, sealing, upper and lower trimming, and polishing. It is an automatic production line that can complete the conveying of panel, edge banding, upper & lower milling, and polishing at one time.

Automatic Edge Bander

The automatic edge banding machine is suitable for straight banding & trimming of solid wood, fiberboard, particleboard, MDF, plywood. The materials can be solid wood strips, PVC, melamine, and veneer. Its capabilities include pre-milling, gluing, banding, leveling, roughing, finishing, profiling, scraping, polishing, grooving.

Portable Handheld Edge Bander

The portable handheld edge bander can be applied to the operation of plate straight and curved irregular borders. When the machine is installed with the fixed bracket accessories, its use method is similar to that of the traditional curved line manual edge bander. It is suitable for banding of various materials, including melamine (impregnated) paper, veneer, plastic (PVC or ABS).

What Can An Automatic Edge Banding Machine Do?

Automatic edge banding machine is the traditional manual operation process with highly automated machinery to complete, can be a one-time double-sided glue sealing, head, chamfering, rough repair, fine repair, scraping polishing and other functions, edge sealing fine, smooth, feel good, flat and straight. Suitable for medium density fiberboard, joinery board, solid wood board, particleboard, polymer door panel, plywood and other linear edge trimming, the equipment is stable, reliable and durable, moderate price, especially suitable for large and medium-sized furniture, cabinets and other panel furniture manufacturers use.

Pre-milling

When the edge sealing surface of the plate is not smooth, it can be milled first, and it can be coated with glue and pressed.

Glue pot

Non-stick pan, uniform sol, cylinder control pressure wheel, better tape effect.

End cutting

Through the mold automatic tracking and high-frequency high-speed motor and other structures, cut off the front and back of the excess edge sealing strip to ensure smooth section.

Rough trim and Fine trim

Rough trim:The rough trimming knife is a flat knife, which is used to repair the excess sealing material on the upper and lower parts of the edge sealing belt of the processing plate, so that the upper and lower parts of the trimming plate are smooth and smooth.Fine trim:The finishing knife is a diagonal repair, which is used to repair the excess sealing material after rough repair of the upper and lower parts of the processed plate sealing strip, and make the natural transition between the plate and the sealing strip with an arc.

Corner trim

Contour trimming, trimming the chamfer effect, the edge sealing effect is more rounded and smooth.

Scraping

It is used to eliminate the ripple marks caused by the non-linear motion cutting process (the knife marks left by the trimming knife and the refined rounded corner), so that the sheet edge sealing surface is more smooth and tidy.

Buffing

Clean the polished plate with a cotton polishing wheel to remove excess gum and make it smoother.

Automatic Edge Bander Advanced Performance

Adopt imported motor and high quality electrical components.

High precision, high efficiency.

Automatic and accurate gluing procedures and integrated double finishing.

Uniformly gluing and stable conveying.

All work areas and specifications can be customized according to your requirements.

Can increase the rotary line device, save labor costs, fast return, meet the needs of the production line, automatic intelligent operation, efficiency is greatly improved.

0 notes

Text

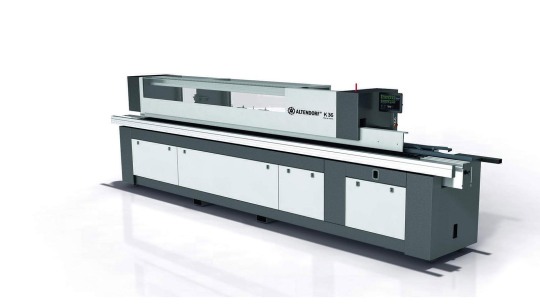

Solving Woodworking Challenges with Altendorf's Edge Banding Technology

From uneven edges to chipped veneers, every woodworker has encountered challenges with edge banding. But fear not, for the evolution of edge banding machines, and specifically Altendorf's innovative solutions, have transformed this once-laborious task into a streamlined and efficient process. Let's delve into how Altendorf's technology tackles common woodworking hurdles, empowering you to create flawless, professional-looking projects.

Uneven Edges: A Thing of the Past:

Manually applying edge banding often leads to inconsistencies in thickness and alignment. Enter automatic edge banding machines like Altendorf's K37. These marvels utilize advanced feeding and trimming systems, ensuring precise material application and a seamless finish, regardless of project complexity. For smaller workshops, manual machines like the WA 6 offer adjustable guides and pressure rollers, minimizing human error and delivering consistent results.

Chipped Veneers: No More Nightmares:

Chipped veneers can leave unsightly blemishes on your masterpiece. Altendorf's machines combat this issue with features like temperature control and pressure regulation. The WA 8, for instance, boasts pre-heating capabilities that ensure optimal adhesive activation, preventing veneer tearing during trimming. Additionally, dust extraction systems minimize chip accumulation, guaranteeing a clean and precise cut every time.

Time Constraints? Conquer Them with Speed:

Meeting deadlines can be stressful, especially with traditional edge banding methods. Thankfully, automatic edge banding machines like the WA 9 come to the rescue. With features like automatic feeding and high-speed trimming, these machines significantly enhance production speed, enabling you to complete projects faster without compromising quality. Even manual machines like the WA 6 offer improvements over handwork, allowing for quicker application and trimming, ideal for hobbyists and smaller workshops.

Material Versatility: Unleash Your Creativity:

Limited by material options? Think again! Altendorf provides a vast array of edgebanding materials, from classic wood veneers to cutting-edge laminates and functional edgebands. Whether you desire a timeless aesthetic or a modern touch, you'll find the perfect material to complement your vision. This versatility allows you to tackle diverse projects, pushing the boundaries of your creativity and catering to your unique design preferences.

Budgetary Concerns? Find Your Fit:

Investing in the right edge banding machine is crucial, but budget constraints are a reality. Altendorf understands this. They offer a diverse range of machines, from cost-effective manual options like the WA 6 to high-performance automatic solutions like the WA 9. By analyzing your project needs, workshop size, and budget, you can select the perfect machine that delivers optimal value and performance.

Beyond Technology: Expert Support at Your Fingertips:

Altendorf doesn't just sell machines; they offer a comprehensive support system. Their knowledgeable team provides invaluable training and resources, ensuring you maximize your machine's potential and overcome any challenges. Additionally, their commitment to seamless integration allows their machines to work harmoniously with other tools in your workshop, creating an efficient and productive workflow.

Conclusion: Embrace Efficiency and Excellence:

Edge banding no longer needs to be a source of frustration. With Altendorf's cutting-edge technology, diverse material options, and dedicated support system, you can conquer common woodworking challenges, elevate your efficiency, and achieve professional-looking results on every project. So, embrace the evolution of edge banding and unlock the full potential of your woodworking journey with Altendorf's innovative solutions.

0 notes

Text

Shay’s Sudden Arrest

The automatic doors hissed open, letting in a pair of paramedics. Between them rolled a stretcher bearing a young woman with sun-kissed skin, tangled blonde hair matted slightly to one side, and piercing blue eyes that blinked against the bright hospital lighting. She looked more like someone headed to a weigh-in than someone checking into an emergency room.

“Name’s Shay Strong, twenty-six year old female.” one of the medics called out as they proceeded towards Trauma Bay One. “Passed out cold during light sparring- she’s a pro MMA fighter. Trainer said she looked a little off just before she hit the mat. Tachycardic on scene, BP’s a little soft. No trauma. No drugs or alcohol on board as far as we can tell.” The second medic rattled off.

Dr Lindsay approached and glanced up from the chart she’d been reviewing and nodded for them to bring her in. She was already tugging on gloves as she stepped into the bay, with Dr Jen the resident trailing behind her and Nurse Heather circling around.

“Hey Shay, I’m Dr Lindsay. I heard you fainted today?” she said as the stretcher clicked into place beside the trauma room table. Shay nodded, her voice low and a little hoarse as they transferred her over to the table. “Yeah. Just felt… weird, ya know? Like, a little dizzy I guess.”

She didn’t look like the type to go down easy. Even lying flat, she carried herself like someone used to getting hit and getting back up. Her toned arms were a canvas of bold, dark ink- coiled serpents on one bicep, a geometric tiger on the other, the edges of color disappearing under the bands of muscle. A glint caught the light where a nose ring curved through her right nostril, and as Heather snipped her sports bra to attach monitor leads, Lindsay caught the flash of a piercing through her nipples. Some cursive ink framed the sides of her ribs and curved along her right thigh was a floral tattoo, all intricate.

Heather worked quickly, pressing leads to Shay’s chest and murmuring quietly. “HR’s 132. BP’s 92 over 58.”

“Got PVCs on the monitor. Could be nothing. Could be something.” Dr Jen chimed in, already pulling up a blank EKG strip.

Lindsay leaned over to meet Shay’s eyes. “Any chest pain? Shortness of breath? Dizziness before you went down?” the doctor asked. “Not really. Just… I don’t know. I’ve been feeling off the last couple days. Figured it was overtraining or something.” Answered Shay. She didn’t look panicked. Just slightly dazed, maybe a little too quiet for someone her age in that kind of shape. That in itself was a red flag.

Lindsay exchanged a glance with Heather. “Let’s get labs, full cardiac panel. EKG, portable chest X-ray. And let’s call cardiology early- I don’t want to wait on this one.” Ordered Lindsay. Jen scribbled notes while Heather gently guided Shay’s arm to insert an IV. The tattoo of a phoenix flared up from her forearm, its wings half swallowed by gauze and tape. Shay looked up at the ceiling, blinking slowly. “This is probably nothing, right?” Shay asked. Lindsay hesitated before answering. “We’ll know soon. But your heart’s throwing out some signals we don’t want to ignore.” Answered Lindsay, her tone neutral and calm.

By the time the EKG machine spat out its second strip, Dr Jen was already frowning. “Frequent PVCs.” she muttered, holding the paper up toward the overhead light. “This isn’t just stress or dehydration. Something’s messing with her conduction.” Added the resident. Lindsay leaned in, scanning the sharp, jagged rhythms marching across the strip. “It’s diffuse. Not localized. And look- ST depressions in the lateral leads.” Dr Lindsay pointed out. Heather appeared from the hallway with a tray of labeled tubes. “Cardiac panel’s off to the lab. I rushed it- told them we’d owe them coffee.” Nurse Heather informed them.

Jen was already pulling up the portable chest X-ray on the trauma room computer. It took a moment for the image to load, but when it did, Lindsay narrowed her eyes at the screen. “Mild cardiomegaly. You see it?” Dr Lindsay noticed. “Yep.” Jen answered. “Heart’s too big for someone her age, especially with this kind of conditioning.” The resident continued.

Shay, still lying flat on the table with a light sheen of sweat forming on her collarbone, blinked over at them. “I take it this isn’t just a pulled muscle?” Shay chimed in, sensing something was off. Lindsay offered a tight smile. “We’re just being thorough. Something’s irritating your heart- could be an infection, could be something else. We’re running some tests to find out exactly what’s going on.” Explained Lindsay. Shay gave a small nod, unfazed. “Good. I’ve got a fight scheduled in eight weeks.”

Heather shot Lindsay a glance over the top of the monitor. Troponin’s already popped in the system: elevated significantly. “Alright. Let’s get a stat echo. I want to see her heart up close.” Lindsay said, tone shifting. Jen paused. “Should we call cardio back? We haven’t heard anything.” asked the resident. Lindsay nodded. “And book her a CT angio chest just in case. If this is myocarditis or worse, we don’t want to wait. Something’s going on here.” Responded Lindsay.

Heather slipped a BP cuff around Shay’s arm again. “Still tachy. 140s. BP 91/56.” Updated Nurse Heather.

Shay looked at all of them, calm but now visibly more alert. “You guys keep looking at each other like something’s wrong.” Shay chimed in. Lindsay didn’t sugarcoat it. “We’re seeing some strain on your heart. The kind we don’t normally see in healthy twenty-somethings.” Lindsay told Shay, succinct and to the point.

There was a beat of silence. Shay’s eyes dropped to the edge of the table. Her shoulders stayed still, but something in her expression flickered. Heather raised her brows slightly, exchanging a quiet glance with Jen behind her. Lindsay didn’t press it yet. “Let’s get that echo first. We’ll talk more when we’ve got a clearer picture.” Lindsay told the two of them.

Lindsay turned and stepped out towards the hallway just as the cardiologist on call, Dr Weiss, arrived with a rolling echo cart and a resting skepticism in her tone. “You called me for a young athlete with some PVCs?”

Lindsay crossed her arms. “Elevated troponin. PVCs, mild cardiomegaly on X-ray. And a gut feeling.”

“Alright, I need to work with a little more than a gut feeling, Dr Lindsay.” Dr Weiss responded, pushing the echo machine into the trauma bay. Dr Lindsay rolled her eyes “yeah, what do I know.” She thought to herself.

Shay remained still as cold gel was spread across her chest, the ultrasound probe tracing between tattoos and muscle. On the screen, her heart came into view, beating fast. The walls thickened. Movement reduced. Echoes of fibrosis scattered like shadows across the septum. Dr Weiss’s jaw tightened. “That’s not what I hoped to see.” She thought out loud. “Alright, make sure she gets a CT angio of the chest. Call me back when you get the results.” Dr Weiss stated, before getting the echo equipment and leaving the room.

Jen and Heather worked quickly and got Shay over to radiology. The radiology wing was quiet, insulated from the steady buzz of the ER. The fluorescent lights shined faintly overhead, casting a sterile glow across the white floors. A lone CT tech tapped at the console as Dr Jen walked alongside the stretcher, Shay lying supine. Nurse Heather hovered nearby, keeping an eye on the monitor attached to the portable stand.

Shay hadn’t said much on the way over, just muttered something about her chest feeling “weird.” Still calm. Still out of it.

“Alright, Shay, We’re gonna get a scan of your chest. You’ll hear some mechanical noises. Just stay still for us, okay?” the tech explained softly. Shay nodded.

With practiced efficiency, Heather and Jen helped guide Shay off the stretcher and onto the scanner table. She moved like someone weighed down by lead. Her arms were positioned overhead, palms relaxed, fingers curled slightly. Her blonde hair spilled behind her head like a golden halo, the tattoos on her arms displayed on her skin like stories written in ink. Something coiled and dark sat on her ribcage, rising and falling with each slow breath. The tech returned to the control booth. The scanner whirred to life.

Jen folded her arms, watching through the glass of the observation room. The lights within the CT room glowed around Shay’s still form. It was almost peaceful.

Then, without warning, Shay’s body twitched. Her chest rose awkwardly- then fell flat. Her fingers curled into loose fists. Alarms erupted. One sharp, continuous tone. Inside the control booth, the tech’s eyes went wide. “She’s coding!”

Heather was already moving. “She’s in v-tach!” Heather eyed the monitor. Jen burst through the door, grabbing the crash cart parked just outside the suite. Shay’s body was still on the scanner table, her arms still overhead, eyes wide open now, staring at nothing. Her lips parted slightly, unmoving. “Pads on!” Heather shouted. Her hands moved quickly. “Charging to 200!” Jen shouted. Heather climbed halfway onto the CT table, hovering over Shay’s torso. “Ready!” Heather nodded.

“CLEAR!”

Shay’s body jumped. Her shoulders shrugged forward. Her head lolled slightly to the side, eyes wide and unblinking. No change. “Still pulseless.” Jen shook her head, eyes locked on the monitor. “Charging again to 300!”

The second shock caused the young MMA fighter’s body to jolt sharply. And then, the monitor beeped. One beat. Then another. “She’s got a rhythm!” Heather shouted. A carotid pulse returned beneath Jen’s gloved fingers. Weak. Thready. But there. The silence that followed was no longer peaceful. It was hollow.

Shay remained unconscious, still laid out on the CT table, chest rising and falling with ghostlike shallowness. Her nose ring glinted beneath the fluorescent light. A single drop of sweat slid down her temple.

Jen swallowed hard, voice low. “Sinus tach. Let’s get her back to the trauma bay, now. Let’s keep Dr Lindsay in the loop.”

Back in trauma room one, Dr Lindsay was gloving up as Dr Jen and Nurse Heather wheeled the young fighter in, the monitors above her head still blinking erratically. Shay was conscious (barely) but she looked far worse than she had thirty minutes ago. Sweat clung to her skin in a thin sheen, her breathing fast and shallow, chest rising and falling like she’d just run ten miles.

“She coded in the CT scanner- pulseless v-tach. We got her back after two shocks, but she was down for about a minute.” Dr Jen rattled off quickly. “Jeez…” Dr Lindsay muttered under her breath, moving beside the gurney. “Get her back on the table. Full workup. Get cardio back down here just in case.” Ordered Dr Lindsay.

Heather worked fast, placing leads back onto Shay’s bare chest. The pro fight laid there, barefoot, down to just her compression shorts. Patches of electrode adhesive still stuck to her sweat-damp skin. Her ribcage rose and fell quickly, tattoos stretching and shifting, black and gray roses climbing her right side, inked vines curling around her hips. Her arms, marked with fierce script, coiled dragons, and edgy ink, lay still at her sides, fingers curling slightly with each shallow breath.

“Shay? Can you hear me?” Dr Lindsay leaned over her. Shay’s eyes fluttered open, barely focused. “Mm… yeah. What… happened?” she mumbled. “You passed out during your scan, but you’re back. You’re okay.” Lindsay answered gently.

But she wasn’t. The heart monitor beeped rapidly- perhaps too rapidly. Nurse Heather glanced at it, then turned toward the others. “Guys, she’s running hot again. 160 and climbing.” Heather shook her head. “Let’s push some mag and prep for another round of epi if needed.” Dr Lindsay barked. Then the monitor’s tone changed. Heather’s voice cut through the room like a blade. “V-tach. Pulseless.”

Alarms began to blare again. “She’s coding!” Jen shouted. “Start compressions!” Dr Lindsay ordered. Heather jumped onto the stool and began rhythmic chest compressions. Shay’s body jolted with each one, her bare chest rising and falling unnaturally. Her tattoos danced under Heather’s gloved hands- one hand pressing just over the roses coiling across her ribs, where her heart was supposed to be working. Her chest caved in, recoiling hard, her toned belly with abs rippling out.

“Charging to 200 joules, everyone CLEAR!” Lindsay called out, taking charge. Shay’s body flopped hard on the gurney when the shock hit, pierced nipples twitching slightly, her arms limp at her sides.

“Still v-tach. No carotid pulse.” Heather called after a glance at the screen. “Back on compressions, Heather. Push one of epi and one of amio.” Dr Lindsay ordered. Jen moved fast, syringes sliding into the IV line. Shay’s skin was growing cool under their hands. Her breathing had stopped altogether. Her jaw slackened.

“I’ll take over for a cycle or two” Lindsay said, moving in to relieve Heather on compressions. Lindsay’s long arms pumped with sharp, trained force. “Come on, Shay. Come on.” Lindsay said under her breath, pumping away at Shay’s chest. “meds in!” Dr Jen called out.

After a cycle of compressions and a little time for the meds to kick in, the next defib shock was administered. Another shock. Another jolt. Shay’s body twitched sharply in response to the dose of electricity. Still no pulse afterwards. Heather rechecked the monitor. “Now it’s v-fib.”

“Keep going, charge again. Let’s hit her at 300.” Dr. Lindsay said, panting now from compressions. The next shock caused Shay’s feet to kick up above the table and drop back with a thud, showing off the deep, wavy wrinkles in the soles of her size 8 feet. “Still no change.” Jen eyed the monitor, checking the rhythm. Dr Lindsay shook her head. “Keep going.”

The room stayed locked in resuscitation mode. Every move crisp, controlled, coordinated. But behind the monitors and meds, a silent current was beginning to build. 26 year old Shay Strong- healthy, undefeated in the ring, fierce as hell, was slipping further away with each failed shock. Now, she lay sprawled across the trauma bay table, her blonde hair a total mess, her arms limp at her sides. The chaotic beeps of the monitors gave way to chaos in an instant.

“She’s still in v-fib, no pulse!” Jen called out, eyes locked on the EKG rhythm twisting across the screen like a coiled snake.

“Alright, let’s run through a cycle or two of compressions and go from there.” Dr Lindsay barked. “Heather, swap with me and start compressions.” Lindsay directed. Heather launched into CPR, pressing hard and fast into Shay’s chest, her tattooed ribcage rising and falling unnaturally with each deep compression. The motion caused her small perky breasts to jiggle slightly.

“Charging to 200!” Lindsay called after the cycle of compressions were finished, the machine emitting a rising, high pitched whir. Everyone stepped back when the shock was delivered. KA-THUNK! The MMA fighter’s toned, athletic body was tossed around effortlessly on the table by the defib’s electricity. Unfortunately, there was no change.

At the head of the bed, Jen kept an eye on the ambu bag and airway, squeezing rhythmically, watching the monitors like a hawk. Her gloved hands trembled just slightly. “Still no pulse.” the young resident murmured. “Next epi’s in.” Nurse Heather confirmed between cycles of CPR, her arms visibly tiring but steady. The flat, wet thud of her palms against Shay’s bare chest punctuated the room like a grim metronome.

“Let’s go again, charge to 300. Everyone… CLEAR.” Lindsay’s voice was firm, her blue eyes scanning around the room. Shay’s toes scrunched up involuntarily in response to the shock, wrinkling the soles of her feet once more, showing off the black nail polish on her toes. A high pitched tone screamed through the room. “Come on…” Jen whispered under her breath. Still no change.

“Push another 150 of amiodarone. Let’s tube her. 7.0 ET.” Lindsay signaled to Jen, who was already sliding the laryngoscope in. Shay’s mouth hung slack, jaw open, eyes half lidded. Despite everything- the tattoos, the muscle tone, the toughness- her body looked terribly vulnerable now.

The resident quickly slid the tube in place, securing it with some tape. “Tube’s in. Still no rhythm change.” Jen confirmed, voice tight. Heather didn’t stop. Her hands pounded against Shay’s sternum repeatedly, sending ripples through the inked skin of her torso. The nose ring caught a glint of light with each compression. Her chest looked raw and bruised. “Hold compressions. Charge to 360. Everyone CLEAR.” Lindsay ordered. Shay’s body tensed up hard, almost shivering for a second or two. Still v-fib.

The room was quieter than before. The thud of compressions, the hiss of oxygen through the ambu bag, the alarms on the heart monitor silenced. A minute passed. Then another. Dr Lindsay’s hand slowly came up. “That’s twenty-five minutes down.” she informed the team sternly. Her gaze moved across the room, catching Heather’s tired face, Jen’s white knuckled grip on the ambu bag. “She’s not coming back, is she?” Jen thought to herself. Her eyes flicked to the monitor one more time. Still v-fib. Dr Lindsay gave it a moment longer. Then softly, “Heather, hold compressions. Time of death… 13:42.” Announced Lindsay. Nurse Heather stopped compressions. The room seemed to exhale all at once. The monitor, now silent, showed the jagged, erratic waveforms of refractory v-fib.

No one moved right away. Shay lay motionless on the table, her chest rising faintly from the final puffs from the ambu bag, her body glistening under the harsh, bright overhead light. For someone so strong, she looked impossibly fragile now. Lindsay peeled off her latex gloves slowly. “Let’s clean her up.” she said softly, more to the room than to anyone in particular. No one spoke. They just moved. Careful, efficient, and quiet. The fighter had gone down, and not even the best resuscitation could bring her back.

Trauma Room One was quiet now. Shay laid motionless on the trauma bay table, her athletic frame still positioned how they’d left her- flat on her back, arms at her sides, a faint sheen of sweat clinging to her skin. The harsh rhythm of CPR had ended moments ago. What remained was eerie stillness.

Dr Lindsay stood at the foot of the bed, her eyes fixed on Shay’s pale face. Her mouth was slightly parted, her chest unmoving. The bruising from the chest compressions was already starting to show- deep purples and dark reds spreading across the middle of her chest. The endotracheal tube remained in place, protruding from her pale lips. Nurse Heather stepped to Shay’s side and gently detached the ambu bag from the ET tube, setting it on the nearby cart. The heart monitor, still showing v-fib, let out a soft, continuous tone that filled the room with a hollow kind of finality. Dr Jen reached over and silenced it with a tap of her gloved finger.

Heather leaned in again, her hands methodical and respectful as she disconnected the EKG leads from Shay’s chest. One by one, the stickers peeled away, leaving behind faint impressions on her pale, clammy skin. Dr Jen removed the IV lines from her arms and coiled the tubing neatly before tossing it into the biohazard bin.

Lindsay took a toe tag from the tray and filled it out in quiet pen strokes. She looped the string gently around Shay’s left big toe, the tag dangling against the wrinkled soles of her foot. Dr Jen found a clean white sheet at the end of the gurney and pulled it up slowly, covering Shay’s legs, her torso, then finally her face.

Dr Lindsay stepped closer, gently placing her fingertips beneath Shay’s chin and tilting her head just enough to shut her half-lidded eyes. One last glimpse of life, now gone. The faint line of a nose ring caught the light again.

The room was still. The chaos from earlier felt like a distant memory, something that had happened in another place, to another person. Now, there was only the quiet presence of the three clinicians standing beside a body that had, just a little while ago, been fighting to stay alive.

Dr Lindsay gave a single nod, then turned and stepped toward the door. Heather and Jen remained a moment longer, hands at their sides, saying nothing, each taking one last look at Shay’s covered, toe tagged form before exiting the room.

#resus community#resus writing#resus#cpr#cpr female#cpr resus#dark cardiophilia#medfet#defib#defibs#defibrillator

76 notes

·

View notes

Text

Severance S2E4. bro what the fuck:

–Kier Eagan’s fake-ass made-up twin brother……….

–flipping from claustrophobia to agoraphobia on a dime in a frozen doppelganger fever dream. you want to see the fallout from reintegration? well fuck you, it's a slow process, and you have wait for it. you want to see the outside world? well here it is. in the most disorienting way and place possible. a mirror to S2E1 - not letting the audience get any solid footing or sense of direction, experiencing the same disorientation that the innies do. a rat-in-a-maze bottle episode where you don't see the outside world, except they ARE outside, and yet they're not. Lumon trying to absorb and rewrite the narrative - you're outside but on our terms.

–once again obsessed with the pacing. a growing uncomfortable tension, Lumon trying to drive a wedge between MDR (intentionally AND unintentionally…. Helena…..), something that could have stretched out for several more episodes or even a season, but Irving said “nah” and ripped the band-aid clean off to clear the way. like Mark abruptly accelerating via reintegration at the end of the previous episode. has a metatextual feeling to it…. if Lumon is trying to tug the narrative in a certain direction, then MDR, inside and out, is grabbing it and YANKING it in another.

–Helena having sex with Mark…. fucked up, in many ways rape by deception using Helly’s identity, taking advantage of not one but TWO people, but the second person is the same person as Helena with the same brain and body, but also NOT the same, but yes the same, but-..… Helena perpetuating what is expected of her by her family/company, the Board saying to give Mark “what he wants, including Helly R” because Helena is another kind of cog in the machine to be taken advantage of as the company sees fit. cycles upon cycles, cruelty begetting cruelty. ethical violations in the workplace the likes of which have never been seen.

(and the quiet part getting real loud now, with the implication that the waffle party ends with sex.)

but also. deeply funny that they listened to a campfire horror story/morality tale about how sexual urges are bad, made fun of it, and went “anyway……” comedy/tragedy two sides of the same coin etc.

–Helena isn't happy! everything she says is double-edged - playing a role (for Lumon, for MDR) and yet completely sincere (she hated reciting the nine principles - sorry dad!, she doesn't like who she is on the outside, she thinks the Kier mythology is ridiculous, etc - expressing herself only through performance). she questions and doubts but has buried it so deep that it only comes out in Helly R, except now it's starting to come out in Helena too. I wonder if Irving trying to kill Helena is going to do 90% of the work in radicalizing her, because she's playacting at love and friendship, and the cracks in the Eagan conditioning are starting to show (lying and obfuscating and yet! sincere in her own demented way), but her little overtures into affection are still deeply off and wrong and causing strife (even when she doesn't mean to) and perpetuating what she knows - smiling violence and power struggle is the language she grew up with, and Irving is speaking that language to tell her that her methods aren't working, that she can't keep pretending to have the life she wants, that it's going to take more than that. and the fact that Helena and Irving Bailiff are the same, sending their innies down to the severed floor with a purpose, while “Helly” and Irving B are being cagey about what they saw on the outside….. doppelgangers and foils.

–WOE! I wonder if Irving B connecting the dots through a dream is more of Irving Bailiff leaking through, since he would know who Helena Eagan is. just like his automatic military response to being stranded in the wilderness - survival-focused, on the defensive, much more physical and violent. reintegration but a second secret kind (taking sleep deprivation to new heights).

–the doppelganger animatronic (?) of Helly had a crooked neck, calling back to her attempt to hang herself, but it was a message directed at Helena…. and we didn't see Irving's doppelganger pointing the way on its own, just as part of the group…. much to think about.

–Miss Huang’s little “pretty cool, right?” made me sad….. so childlike for a second, like she should be. girl we're getting you out of there.

–the fact that Mark and Dylan and Irving have never seen fire, and barely seen the sky (and Helly still hasn't seen any of it). let alone all of the other weird shit going on…. the behind the scenes bit talked about Lumon wanting to scare the hell out of MDR, and yeah…. yeah.

–the fact that we don't see the immediate aftermath of Mark reintegrating but do see Mark S having Mark Scout hair here and there, and one crazy flash to his other self. something to be said about how Mark S exists because Mark doesn't give a shit about himself, and he's never really thought of his severed self as someone separate (and they're not, really, except they are, and aren't, and are, and aren't, and-). and Mark S doing something for himself, not for his outie, something that distinguishes him from Mark Scout, but it turns out to be awful in the end…… oof ouch. MUCH to think about.

–I think I’ll need to see the follow-up before I decide how I feel about this episode. it did a LOT, and it needs the fallout to contextualize it. leaning pretty hard on making the story fit the idea to have the corporate retreat, but I can forgive that because it was gorgeous to look at, and I'm obsessed with the idea of a disorienting switch to an agoraphobic vista that nevertheless remains a claustrophobic trap, and team-building retreat that leaves the team in shambles is really good.

–"I'm on the ice," Gemma, "Chikhai Bardo" as an episode title, etc.... they're building up to some real undead and rebirth shit, and I'm starting to think Kier Eagan's frozen fucking Disney head isn't a joke.....

59 notes

·

View notes

Text

Cruel Irony // Part IV

Pairing | Chain x Reader

⚠️ Warnings | f!reader, Y/N used, mentions of ghoul hunting, Felix and Cowbell used interchangeably, Liam and Chain used interchangeably

Wordcount | 1.7 K

Chapter Summary: With help from Sunshine, you sneak into the catacombs, prepared to give Chain a gift, what you're not prepared for is who is there. And what Chain's not prepared for? Well everything his brother has to say

Sunshine woke you up early. So early it was still dark out, and Mountain was still fast asleep. You snuck downstairs with the tattoo kit in your hands, and headed towards the catacombs, moving as silently as possible. An edge of excitement surrounded you. Cowbell had told you he’d been wanting a tattoo and this was the perfect way to cure some of his boredom. A small smile crept onto your face as you hurried down the steps, your steps echoing in the damp air. Your fingers brushed over the walls every now and then as you kept a hand out to steady yourself against the uneven stairs.

You were so focused on what you had for him and trying not to fall that you didn’t even hear the voices drifting down the hall as you reached the last corner to round to get to Chain’s cell. But you saw it soon enough.

Lake sat in front of Chain’s cell, legs crossed as he sat on the floor, Chain’s hands reaching out between the bars, expertly braiding his hair. He’s the only one in the entire Abbey who can braid it the way Lake likes it.

You skid to a stop at the sight. “Oh, I’m sorry… I didn’t realize someone else was down here.”

Lake’s hackles rise and he practically spits out, “What is she doing here?”

“Lake, manners,” Chain chides automatically, brows furrowing at the younger water ghouls reaction to your presence. “What’s wrong?”

“That’s Mountain’s sister.”

Chains hands still their work as he tense. “Why did you withhold that from me?” His words, cold as they are, are directed at you.

You flinch at the harsh tone, your heart shattering a bit at the reaction and stammering over your words, ““I- I- didn’t re- realize it was im- important.”

You place the tattoo machine down on the floor near Lake, not wanting to get closer to the hostile ghoul than necessary and spin around. Your hand scratches at the skin over your heart as you rush back towards the stairs. Your eyes sting with tears that you refuse to let fall. Not yet, not until you were out of there. Maybe the whispers were right. In that spilt second of harshness, what you’ve heard about Liam killing people suddenly felt real.

Chain sighs and runs a hand through his hair, eyeing the kit warily. “Lake what is that… contraption?”

“A tattoo kit, a machine, ink, the needles, everything,” the younger water ghoul shrugs, picking it up, turning it over in his hands. His eyebrows furrow, and he looks up at Chain. “Why’d she bring you a tattoo kit?”

The smallest of smiles spread over his lips as he turns Lake’s head back around, hiding the twitch of his lips under the guise of braiding Lake’s hair. He didn’t want the other ghoul to see even the slightest softening in his expression. “She certainly isn’t her brother.”

Lake huffs out a breath and tries to turn again to look at the older water ghoul, but Chain tugs on the braid that he had yet to finish. “Ah, I haven’t finished.”

“You’re going to ignore the fact that she is Mountains sister?” Lake questions, a hint of a frown in his tone.

“Mountain was the one to cause me harm. She’s innocent in the grand scheme of things,” Chain says smoothly. “She was in the pit when everything happened.”

“She’s still Mountain’s blood!”

“Has she been around him much since coming up topside?” Chain asked. “Because I can barely even smell the faintest hints of Mountain on her.”

“There’s something you’re not telling me,” Lake grumbles under his breath.

“Have you even talked to her?”

Lake fell silent. He hadn’t.

Chain hummed. “Thought so.”

The two sat in silence as Chain finished braiding the younger ghouls hair. “Band.” He held a hand out and Lake dropped his hairband into the older ghouls hand. It wasn’t long after that Lake was heading back upstairs with Chain calling after him, “Maybe give her a chance.”

A chuckle, that Chain would recognize anywhere, sounded from the slight crack in the foundation near the ceiling of his cell. A crack that had gotten bigger when Cowbell had chipped at it so Chain could see the moon from his cold, dark, damp cell.

“Got a new toy, there Liam?” Cowbell drawled. He was sitting outside on the damp dirt by the wall so he could talk to his brother.

“Y/N brought it to me.”

“Ah, seems like the girl to.”

“You know her?” Liam scoffs.

“She came by the forest last night, looking for answers. Wanted to know why you are locked up down there.”

“What did you tell her?”

A beat. “My truth.”

“Your truth?” Liam scoffs.

“I don’t know what happened, just the little bits and pieces of what you’ve told me and what I’ve heard whispered around the grounds,” Cowbell shrugged.

“You could have checked my memories, then told her.”

“Rather not. Feels wrong.”

Another pause. The chains clink together as Liam shifts, leaning against the wall.

“You’re a demon of hell, and that feels wrong?”

“Must have picked up some morals along the way.”

Liam snorted. “There’s a higher chance of Iffrit growing a third tit.”

Cowbell laughs, ignoring the jab at his expense and smirks. “That’s an image.”

Liam hums quietly, falling silent for a few moments before falling back on the last topic of conversation. You.

“Were you aware of her lineage?”

Cowbell rolls his eyes. “Yes, I knew she was Mountain’s sister.”

“And you withheld that information for what reason?”

“Didn’t want your stubbornness getting in the way of seeing your mate.”

“Mate?”

“You didn’t realize?” A mocking laugh. “You’re mates, Chain. Your hearts beat as one. Hers is a soft, gentle echo of yours.”

“You can’t know that for sure.”

“I heard it,” Cowbell said flatly.

“But not when I was around. You can’t possibly compare the two!”

A huff of air. “Here’s what I do know. You’re soft around her. Hard with most other people, which is ironic; if anything, you should be hard for her and soft for everyone else.”

A deep groan came from Liam’s chest at his brothers words. No matter how much time he had spent with and away from Felix, he would never get used to the crude jokes that would come out.

“She was not frazzled when she came out of the catacombs. A little embarrassed, perhaps, but then Lake came up after her, so I imagine she wasn’t expecting you to have friends. You are a demon locked away after all.”

Chain rolls his eyes. “Real sweet of you to spy.”

“Just looking out for my favourite brother.”

A snort emanates from Chain and Cowbell smirks at the sound. “For the brother who can see, you sure are blind, Liam.”

“Shut up,” he huffs, earning a chuckle from his other half. “Don’t see you wandering around with a mate.”

“You don’t see anyone wandering around. You’re underneath them all. Literally.”

“I could break out of here.”

“I don’t know why you haven’t.”

“It’ll prove that I’m a monster to Sister Imperator.”

“Fuck what that bitch thinks.”

“I don’t want to scare-”

“Ahhhh, so you are soft for her.”

“She shouldn’t keep visiting me.”

“She feels the tug.”

“Figure out how to stop it then.”

“I can’t. You can’t. Hell, not even Dad can. He chose her for you. Deal with it and stop being a sorry ass. You’re one of the devil’s bodyguards, for fucks sake. Act like it.”

“Wise words from the banished one.”

“Never played by the rules, still don’t. It’s why I’m here giving you a lecture because your dumbass won’t accept what rightfully belongs to you.”

“And if Imperator finds out I have a mate?”

“Let her try to keep her from you.”

“She could be punished for my-”

“You’re wrongfully punished, and from what I see-”

“You can’t see.”

A huff. “From what I can see Dad favors her. No one can hear your singing from the catacombs all the way to the bloody rooms. But she did. Fucking followed it down here to you. If sister tried to hurt her, pretty sure dad would unleash all of hell on her. And I’d want a front-row seat to that spectacle.”

“I’m sure Special would join you with a bucket of popcorn,” Chain grumbles.

“Ah, what a time to be alive.” The words are teasing, and Liam can’t help the smile that creeps onto his face.

“You’d enjoy watching me fight Sister on that a little too much.”

“I need some form of entertainment since I’ve been isolated for so long.”

“You’re hopeless.”

“I should hope so. Demons aren’t meant to spread hope around, Liam. We’re meant to wreak havoc and cause chaos. With Sister Imperator in charge, we’re doing less and less of that. I mean look at Copia for fucks sake! When was the last time anyone was even allowed to hunt?”

“I can’t look at Copia, remember?” Liam mutters dryly. “And the younger ghouls don’t feel the need to hunt. You know this. Plus, after what happened last time we hunted, it’s better off this way.”

“What did happen? You refuse to even explain the events of that night. Not even Lake or River will tell me.”

“It was bad,” Liam admitted quietly. His voice was softer than Felix had ever heard it. “We, water ghouls at least, were hunted for sport in the forest. It got worse after you were banished from the ministry, and I guess I was just more on edge because of that, so… I hunted back. Snapped the neck of any of the hunters that had even but a scratch on anyone, especially Lake and River. Mountain turned me in. Told Sister some factless lie, hid bones in my room, framed me to look like a monster.”

The two fell silent. The words hitting harder than either of them expected them to.

“Maybe I am a monster.” The words were soft and whispered, so quiet that Felix almost didn’t catch them.

“You’re a demon from hell. We all are,” Felix reminded him.

“But-”

“No. You were just braiding Lake’s hair. Does a monster really do something like that?”

A pause. Liam tilts his head back and the chains rattle a bit.

“Tell her.”

Liam jerks up right. “What? No.”

“Why not?”

“I don’t want her to know that side of me.”

“Y’know, some girls find that side hot.”

Liam chokes on the air he just took in, coughing and sputtering. By the time he caught his breath again, Felix had slipped off.

[Prev] [Next]

#ghost band#ghost ghouls#nameless ghouls#the band ghost#mountain ghoul#sunshine ghoulette#chain ghoul#chain ghost#chain x reader#lake ghoul#cowbell ghost#cowbell ghoul

13 notes

·

View notes

Text

Post Round 2 [Pt. 2] - Tov’s Log

————————————————————

A moment of silence passed.

Then another.

Elias’s arms were still tense.

Finally, he sighed.

It was different sounding than Prem’s sigh. Elias sighed like he knew this confrontation was inevitable.

“Sounds like a fine name to me.” He said. His tone gave nothing else away.

The elevator stopped its descent and the doors slid open.

Tov assumed Elias would turn to the right towards the main clinic area, but instead he went to the left.

She furrowed her brow, hesitating, but continued to follow behind him.

As if he’d sensed her confusion, Elias spoke up again, “We’re going to the medical technician room. We have proper equipment to recalibrate your band there.”

Tov felt like he was speaking to more than just her.

Probably so.

She wouldn’t doubt that every inch of the dorm was covered with hidden cameras and audio recorders.

There was really no such thing as privacy in Alien Stage.

Tov took two steps for each of Elias’s long and sure strides.

He walked to a rhythm.

One. Two. One. Two. One. Two.

Her pace was a little faster.

One. Two. Three. One. Two. Three.

Something about counting steps like this felt nostalgic to her.

They came to a stop in front of a set of white doors. Elias removed one of his gloves to place his thumb on the scanner next to them.

His skin was dark like hers. A large scar stretched across the back of his hand.

The doors swung open automatically.

Inside was a sterile white room filled with medical equipment and various machines Tov could recall seeing in the hospitals she frequented; all very expensive and equally as delicate.

Elias gestured for her to enter first and manually pulled the doors shut until a heavy lock clicked in place.

There were a few medical beds lined up in a row against the left wall. Tov sat on the edge of the nearest bed.

“We’ll be able to talk freely in here,” he said, forgoing a chair to lean against the counters across from her. “All of the equipment frequencies interfere with the audio listening devices used throughout the complex.”

Tov briefly glanced around the corners of the room, “What about cameras?”

“There’s a lot of proprietary medical technology down here. Cameras are forbidden in case of a breach.”

Huh. Good to know.

Elias tugged off his helmet, revealing black, tightly coiled hair cut close to the scalp. His jawline was sharp, but his eyes were sharper; ink black and stone cold.

He crossed his arms, meeting her gaze head on. “So,” he started. “Prem?”

Tov nodded once, “Prem.”

He sighed again and pinched the bridge of his nose.

Tov imagined that it was close to how she looked whenever she found out Nyx or Dian did something stupid, usually in the other’s company.

Elias muttered something under his breath before clearing his throat and addressing her, “Okay then. How much did he tell you?”

“He said you’re the one who wrote the notes and that you told him not to tell me. Then he gave me your name, the shift you work, and the code word.”

“Great, so, basically everything I told him.” Elias huffed. “Damn it, Prem.”

Probably should’ve worked alone.

Tov didn’t say that aloud.

“I’m sure you have a lot of questions. I’ll answer as much as I can before we need to go back upstairs to avoid suspicion.”

The openness was… odd.

She wasn’t expecting Elias to be so forthcoming. She thought she’d have to pry information out of him like she had to with Prem.

But this time, she didn’t have any leverage. It was for the best that she didn’t run into any resistance.

“You’re the original author of the notes?” She asked.

Elias nodded once, “I am.”

“Did every contestant get a note?”

“No. Only you.”

Tov frowned, “Why?”

“Because the information was only relevant to you.”

On its face, the answer made sense. Tov was close to Solei, Aurien, and Nyx. Of course she’d want to know they were alive and safe.

But Lang was also close to Nyx. Why was the information about him given to her and not Lang?

There had to be another reason.

“Why did you chose me specifically?” She asked.

Elias hesitated. Tov wanted to seize the moment by the throat.

“I— did it as a favor.” He said stiltedly.

She wanted to groan long and suffering in that way Tallis always hated to hear.

You’ve got to be kidding me…

“So you’re another middleman.” It was a statement, not a question.

“No, I’m the primary source.” He countered. “I’m the one who took the risk of gathering the information and writing the notes.”

“And you risked your position just to fulfill a favor? You don’t even get anything out of it?”

He looked away, rubbing the back of his neck, “Well, no. I do get something out of the agreement.”

Tov leveled him with a look that she could tell he was pointedly ignoring.

“If you’re getting something out of the agreement then it’s not a favor. It’s a transaction.” She said, voice flat.

“I don’t think I could put a price on what I’m getting.” He said.

Tov was getting really tired of everyone being so fucking cryptic all the time.

“Who asked you to write those notes and give them to me?”

“I can’t say.”

Oh fuck no—

Elias cut Tov off before she could even open her mouth to argue.

“—And no, I’m not as easy to crack as Prem. You can’t blackmail me into telling you who they are.” He spoke with such finality it made Tov want to draw blood.

“I made a promise and I plan to keep it.” He said. “A soldier’s word is his bond.”

By the way his set his jaw and narrowed his eyes, she knew he wasn’t going to yield. Normally, Tov wouldn’t either.

But there was still more she could learn from him, even if this was a dead end.

She relented with a sigh, breaking eye contact. “Fine.”

“Good.”

There was no way that ‘good’ wasn’t patronizing. But Tov let it go.

She needed answers about Lark.

“Do you know anything about the investigation into Lark’s poisoning?”

Elias’s expression turned grim.

“Unfortunately, no. But not for a lack of trying.” He sounded as disappointed as Tov felt. “As soon as the preliminary autopsy suggested poisoning, the AREPH swooped in and took over the whole case. They iced everyone out and pissed off some of the higher ranking guards.”

Tov mulled the new information over as she worried her bottom lip between her teeth.

Why would the AREPH get involved in a poisoning case?

There was nothing to suggest Lark’s death was connected to any of the security breaches or escapes.

It was a question that had been bothering her since she was interrogated by those AREPH agents the morning after Round 17.

Now it was gnawing.

“Have they made any official statements?”

Elias scoffed, “That’s not part of their operating procedure.” He said. “If guards lack transparency, then the AREPH is completely opaque by comparison. We know next to nothing about the extent of what they do and how they do it. Even their facility locations are classified.”

“No leaks, I assume?”

He shakes his head, “None that I know of. Medics tend to catch wind of most rumors.”

Tov knew she was coming up on yet another dead end.

“Is there anything else you can tell me about the AREPH?”

Elias thought it over for a moment, furrowing his eyebrows, “Well, there is one thing. But I don’t know if it’s relevant.”

I’ve got nothing to lose.

Tov gestured for him to continue.

“When the security breach during Round 6 happened, I got caught in the chaos with some other guards doing crowd control. We ended up crossing paths with a group of AREPH agents heading in the opposite direction, and there was a human with them.”

She blinked.

Wait.

What?

“A pet-human?” She asked.

“Maybe? I’m not sure.” Elias shook his head, “All I know is that they were wearing an AREPH uniform and badge.”

Tov couldn’t stop thinking of the possibility that the human was one of her classmates.

She tried to think all the way back to Round 6. Who was alive and who was dead?

Azure. Moran. Stasya. Min. Rose was still alive.

It couldn’t have been any of them… right?

“What did they look like?”

“Young, grey hair, black face mask, really fucking tall. You can’t miss them.”

The only person she knew close to that description was Nyx, and he was definitely not helping the AREPH.

Tov hoped he was somewhere resting peacefully, but still very much alive.

“Could the AREPH be recruiting humans now?” She asked.

“They could be, for all we know.” He muttered. “No clue why a human would work for those ghouls, though.”

Tov raised an eyebrow. “People probably say the same about you working as a guard.”

“I didn’t have a choice.” He said.

“Maybe they don’t either.”

Maybe as humans — no matter where they ended up in this system — would never have a choice.

Somewhere off to their right, a tone chimed.

Elias pushed away from the counter, sidestepping her loaded statement.

It was for the best.

“We should probably start heading back now. Any last questions?”

Tov shook her head, “None that can be answered right now.”

“Alright, do you mind if I ask you one then?”

“Sure, why not.”

“How did you get Prem to confess?”

“I faked a medical emergency to lure him into my room.” She said. “Once he was inside, I locked us both in and threatened to report him for writing the notes if he didn’t tell me who actually wrote them.”

Elias stopped halfway through putting his helmet back on.

He blinked.

Once.

Twice.

Then he doubled over laughing.

The joy ringing in his voice was so incongruous with his appearance and demeanor that it caught her completely off guard.

It reminded Tov of her own giddy, uncontrollable laughter after Nyx was rescued.

But she was still confused.

Tov tilted her head at him, “What’s so funny?”

Elias shook his head, waving her off as his laughter subsided, “Nothing. It’s nothing.” He was smiling now.

The stone cold look in his eyes had melted into something soft like putty. “You just reminded me of someone I know.”

“I see.” Tov didn’t know what else to say in the wake of such a genuine expression of emotion from a stranger.

Luckily, Elias kept talking.

“I think you would’ve made a good soldier.” He said. “You’ve got the mind for it.”

Tov thought for a moment, before asking, “If I agree, will you tell me who you’re working with?”

He chuckled again as he fastened his helmet on.

“Look, Tov. If you really want to find out who’s behind all of this, keep going.”

————————————————————

Tov got some answers (yay!), but they only led to more questions (boo!).

All will be revealed in due time. She just has to keep going…

Anyways, new relationship dynamic just dropped: Tov and Dian worsties (besties that have constant beef) 😁

Also, Eddy was the human AREPH agent that Elias saw during Round 6, so Tov sort of knows who they are now.

The next log will be post Round 24. I’m still trying to process Himei’s death and the extent it will impact Tov’s wellbeing (spoiler alert: it’s not good), so that might be a few days? We’ll see.

And then Round 26 is like… right after that. Big oof 🫠

Tallis and Eddy belong to @lookatmysillies.

Nyx and Dian belong to @rockwgooglyeyes.

Lang belongs to @pwippy.

#alien stage#alnst#alien stage oc#alnst oc#alnst oc: tov#alnst oc: elias#alien stage fan season#alnst fan season#alien stage season 39#alnst season 39#tov’s log

13 notes

·

View notes

Text

Edge Banding Machine Manufacturer in Ahmedabad, India

Edge Banding Machine Manufacturer in Ahmedabad, India

Edge Banding Machine Manufacturer in Ahmedabad, India By Umisons Industries. Buy Automatic Edge Banders and Edge Banding Machines at Best Price in India.

Read More: https://www.umisons.com/services/edge-bander/

2 notes

·

View notes

Text

Colorimeter Market Future Trends Shaping Innovations in Quality Control and Color Measurement Technologies

The colorimeter market is poised for significant growth and transformation as future trends reshape how color measurement technologies are developed and applied across various industries. Colorimeters, essential instruments for objectively measuring color, play a critical role in quality control, product development, and color matching processes. As industries increasingly demand accurate and efficient color management, evolving technologies and shifting market needs are driving innovation and expanding the scope of colorimeter applications. This article explores the key future trends shaping the colorimeter market and their impact on the industry landscape.

Growing Demand for Portable and Handheld Colorimeters

One of the most prominent future trends in the colorimeter market is the rising demand for portable and handheld devices. Advances in miniaturization and sensor technology have enabled manufacturers to develop compact, lightweight colorimeters that deliver precise color measurements in the field.

These portable instruments offer significant advantages over traditional benchtop models, providing users with convenience, ease of use, and rapid data acquisition. Sectors such as textiles, printing, food and beverages, cosmetics, and automotive increasingly rely on handheld colorimeters for on-site quality control and color verification. The trend toward portability is expected to accelerate as more industries adopt color measurement solutions to improve operational efficiency.

Integration with Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) integration represent a cutting-edge trend that is set to revolutionize the colorimeter market. By incorporating AI algorithms, colorimeters can offer enhanced data analysis, predictive color matching, and adaptive calibration features.

AI-powered colorimeters can automatically adjust for environmental variables such as lighting and surface texture, improving measurement accuracy and consistency. Machine learning models can also analyze historical color data to optimize production processes and reduce waste. This fusion of AI and color measurement technology is opening new possibilities for smarter, more autonomous color management systems.

Expansion of Applications Across Diverse Industries

The future of the colorimeter market is marked by expanding applications beyond traditional sectors. While industries like textiles, paints and coatings, and plastics have long been major users, newer industries are increasingly recognizing the value of precise color measurement.

Healthcare and pharmaceuticals are adopting colorimeters for monitoring product quality and ensuring consistency in drug formulations. Food and beverage manufacturers use colorimeters to verify freshness, ripeness, and product appearance. Even the electronics industry applies color measurement for display calibration and manufacturing processes. This broadening of applications is fueling market growth and encouraging manufacturers to develop specialized colorimeters tailored to specific industry needs.

Advancements in Spectral and Multispectral Colorimetry

Technological advancements are driving a shift toward more sophisticated spectral and multispectral colorimeters. Unlike traditional tristimulus colorimeters that measure color based on three primary channels, spectral colorimeters capture detailed spectral data across multiple wavelengths.

This approach enables higher accuracy and better color discrimination, especially for complex or metameric colors. Multispectral colorimeters extend this capability by measuring reflectance or transmittance across even more wavelength bands, allowing precise analysis of materials under various lighting conditions. The adoption of these advanced devices is expected to increase in industries requiring the utmost color precision, such as automotive coatings, art restoration, and high-end printing.

Increasing Importance of User-Friendly Interfaces and Connectivity

The market is witnessing a shift toward user-centric design in colorimeter products, with an emphasis on intuitive interfaces, touchscreen displays, and wireless connectivity. Modern colorimeters often feature smartphone or tablet compatibility, enabling data transfer, remote operation, and cloud-based analysis.

This trend enhances user experience and facilitates seamless integration into digital quality control workflows. Wireless connectivity also supports real-time monitoring and reporting, critical for fast-paced manufacturing environments. As Industry 4.0 concepts gain traction, connected colorimeters will become integral components of smart factories and automated production lines.

Emphasis on Environmental Sustainability and Compliance

Sustainability considerations are increasingly influencing colorimeter market trends. Regulatory bodies and consumers alike are demanding environmentally responsible production processes, which include precise color control to minimize material waste and ensure compliance with eco-friendly standards.

Colorimeters help manufacturers reduce rework and defective products by enabling accurate color matching from the start. Furthermore, some newer models are designed with energy-efficient components and recyclable materials, aligning with broader sustainability goals. This focus on green manufacturing practices is expected to shape product development and marketing strategies in the colorimeter market.

Growth in Emerging Markets and Regional Adoption

Emerging markets in Asia-Pacific, Latin America, and Africa present significant opportunities for the colorimeter market’s future growth. Rapid industrialization, expanding manufacturing sectors, and rising quality standards are driving demand for color measurement instruments in these regions.

Countries like China, India, Brazil, and Mexico are investing in advanced quality control technologies, including colorimeters, to enhance their competitiveness in global markets. Regional manufacturers are also tailoring products to meet local needs, such as rugged designs for harsh environments or cost-effective models for small and medium enterprises. This geographic expansion diversifies the market and encourages innovation.

Conclusion

The colorimeter market future trends reflect a dynamic and evolving landscape characterized by technological innovation, expanding applications, and growing user demands. The rise of portable and handheld devices, integration of AI and machine learning, advances in spectral measurement, and enhanced connectivity are driving the market toward smarter, more versatile color management solutions.

Additionally, sustainability imperatives and emerging market growth provide further momentum for the industry. Companies that invest in developing user-friendly, high-precision, and environmentally conscious colorimeters will be well-positioned to capitalize on these trends. As accurate color measurement becomes increasingly vital across industries, the colorimeter market is set for sustained expansion and transformative innovation.

0 notes

Text

PET Strapping Rolls: Durable, Eco-Friendly Solutions for Secure Packaging

In today's fast-paced shipping and logistics industry, securing goods during transit is more crucial than ever. Among the various packaging solutions available, PET strapping rolls have emerged as a top choice for businesses seeking reliable, strong, and environmentally friendly strapping options. This article explores what PET strapping rolls are, their advantages, applications, and why they are becoming the preferred material in modern packaging.

What Are PET Strapping Rolls?

PET (Polyethylene Terephthalate) strapping rolls are plastic bands made from a high-performance polyester resin. These straps are produced in roll form, allowing easy handling and efficient use in automatic and manual strapping machines. PET strapping offers superior tensile strength and flexibility compared to traditional steel or polypropylene straps, making it ideal for securing heavy loads and fragile items alike.

Key Benefits of PET Strapping Rolls

1. Exceptional Strength and Durability

PET strapping rolls are designed to withstand high tension without breaking or deforming. Their high tensile strength allows them to secure heavy pallets and bulky shipments effectively. Unlike steel straps, PET straps do not rust, chip, or cause injury, ensuring safer handling.

2. Eco-Friendly and Recyclable

As sustainability becomes a priority, PET strapping stands out for its environmental benefits. Made from recyclable polyester, these straps reduce plastic waste and contribute to a circular economy. Many manufacturers offer PET strapping made from recycled materials, further reducing the carbon footprint.

3. Lightweight and Cost-Effective

PET strapping rolls are significantly lighter than steel straps, which helps reduce shipping costs and makes manual handling easier. Their durability ensures fewer replacements and less downtime, translating to long-term cost savings for businesses.

4. Versatility Across Industries

PET strapping is suitable for a wide range of applications, from securing boxes and cartons to bundling construction materials, steel pipes, timber, and more. Its flexibility allows it to absorb shocks during transit, protecting goods from damage.

5. Enhanced Safety Features

Unlike steel strapping, PET straps do not have sharp edges, reducing the risk of injuries to workers during packaging and unloading. Moreover, PET strapping rolls do not cause damage to delicate or sensitive products.

Applications of PET Strapping Rolls

Logistics and Shipping: Ensuring cargo stability during long-distance transportation.

Construction: Bundling heavy materials like bricks, tiles, and metal rods.

Manufacturing: Securing finished goods on pallets for warehouse storage.

Agriculture: Bundling produce or agricultural tools safely.

E-commerce: Protecting parcels and fragile shipments.

How to Choose the Right PET Strapping Roll

When selecting PET strapping rolls, consider the following factors:

Width and Thickness: Depending on the load weight and size, choose the appropriate strap dimensions.

Tensile Strength: Opt for straps that can handle the tension required for your specific application.

Core Size and Length: Ensure compatibility with your strapping equipment for efficient operation.

Color Coding: Some industries use color-coded strapping for identification or branding purposes.

Installation and Handling Tips

Use proper tensioning tools to avoid over-tightening, which can damage both the strap and the goods.

Store PET strapping rolls in a cool, dry place to maintain their integrity.

Train staff on safe handling techniques to maximize safety and efficiency.

Why PET Strapping Rolls Are the Future of Packaging

With growing demand for sustainable, reliable, and cost-effective packaging solutions, PET strapping rolls offer a smart alternative to traditional materials. Their combination of strength, flexibility, and recyclability aligns perfectly with modern supply chain needs and environmental regulations.

0 notes

Text

Innovative Solutions for Woodworking: Shree Umiya F-Tech Machines | Umaboy Group

Woodworking requires precision, efficiency, and the right equipment to deliver high-quality results. Shree Umiya F-Tech Machines, part of the esteemed Umaboy Group, stands as a trusted name in crafting advanced woodworking machinery designed to elevate production standards. From automatic edge banding machines to reliable panel saws, we provide comprehensive solutions for professionals in the woodworking industry.

Automatic Edge Banding Machines: Precision Made Easy

Edge banding is a critical step in furniture manufacturing, ensuring clean, finished edges that enhance durability and aesthetics. Shree Umiya F-Tech Machines offers cutting-edge automatic edge banding machines that streamline this process. Whether you are looking for an auto edge banding machine for high-speed production or a versatile solution for custom projects, our machines deliver unparalleled accuracy and efficiency.

Features of Our Automatic Edge Banding Machines:

Seamless application for a variety of edge materials like PVC, ABS, and wood.

Advanced automation to minimize manual intervention.

Robust build for long-lasting performance and reliability.

Panel Saw Machines: Engineered for Perfection

In the woodworking industry, precision cutting is non-negotiable, and that’s where our panel saw machines excel. Shree Umiya F-Tech Machines, a leading panel saw machine supplier and manufacturer, ensures that every product is built with the needs of modern workshops in mind.

Whether you need a panel machine for large-scale production or a compact panel saw for small-scale tasks, our offerings cater to diverse requirements.

Key Benefits of Our Panel Saw Machines:

High-speed, smooth cutting for a variety of materials.

User-friendly controls for efficient operation.

Engineered for durability to withstand heavy-duty use.

Why Choose Shree Umiya F-Tech Machines?

As part of the Umaboy Group, we prioritize innovation, quality, and customer satisfaction. Our woodworking machines are designed to deliver top-notch performance while simplifying complex processes. With a commitment to excellence, we aim to be your go-to partner for advanced woodworking solutions.

Elevate Your Woodworking with Us

Whether you’re in need of an automatic edge banding machine or a panel saw machine, Shree Umiya F-Tech Machines has you covered. Contact us today to learn more about our products and how they can transform your woodworking operations.

#automatic edge banding machine#automatic edge banding#auto edge banding machine#panel saw#panel machine#panel saw machine suppliers#panel saw machine manufacturer

1 note

·

View note

Text

Mattress Border Machine: Top 5 Advanced Systems for Edge Reinforcement in 2025

Mattress Border Machine: Top 5 Advanced Systems for Edge Reinforcement in 2025

What Is a Mattress Border Machine?

youtube

A mattress border machine is specialized equipment used in mattress manufacturing that handles the creation, quilting, and attachment of the vertical side panels (borders) of mattresses. These machines help streamline production by automating what would otherwise be labor-intensive processes.

Core Functions of Mattress Border Machines

The primary purpose of a mattress border machine is to create professionally finished edges for mattresses. These machines can perform several key functions depending on the model. Most border machines can quilt decorative patterns into the border material, adding both aesthetic appeal and structural integrity to the mattress sides.

Some advanced models like the M-4000 and M-4400 are designed for high-speed production, capable of quickly processing large volumes of mattress borders.

Border machines can also measure and cut border sections to precise specifications, ensuring consistency across production runs. This precision is crucial for creating professional-looking mattresses that meet quality standards.

Many modern border machines can also install zippers, which is essential for mattress protectors and mattresses with removable covers. This feature has become increasingly important as demand for accessible, cleanable mattress products grows.

Key Components and Structure

Border machines typically consist of several important components working together. The sewing head is one of the most crucial parts - machines like the DZ-52 feature multi-needle systems designed specifically for wider border sewing applications.

The feeding mechanism moves fabric through the machine at a controlled rate. Some advanced models include auto-feeding systems with edge-alignment technology that ensures borders remain straight and even.

Most border machines have pattern programming capabilities that allow manufacturers to create various decorative stitching patterns. These can range from simple rectangular designs to more complex triangle patterns, as seen in the CC-1A model.

Material detection sensors help prevent jams and ensure proper alignment throughout the sewing process. These sensors are particularly important when working with different fabric thicknesses or when attaching rubber bands in mattress protector production.

How Mattress Border Machines Work

The operation begins with loading the border fabric onto the machine. For roll-to-roll systems from Global Systems Group (GSG), this involves setting up continuous fabric rolls for high-volume production.

The machine then positions the fabric correctly using alignment tools and sensors. This step is crucial because even slight misalignments can result in visible defects in the finished mattress.

Next, the multi-needle sewing head creates decorative stitching patterns across the border material. This not only enhances the appearance but also reinforces the border for durability. Machines like the DZ-52 are specialized for this precise function.

For borders requiring zippers, specialized attachments on machines like the Richpeace Border Zipper Sewing Machine automatically position and attach zipper components. This automation dramatically reduces the time needed compared to manual zipper installation.

Finally, cutting mechanisms measure and cut the finished borders to the exact specifications needed for each mattress size. The precision of these cuts ensures proper fit when the borders are attached to the mattress panels.

Types of Mattress Border Machines

youtube

Mattress border machines come in several varieties, each designed to handle specific tasks in mattress manufacturing. These machines stitch designs, attach tapes, and create borders that give mattresses their finished look and structure.

Manual Mattress Border Machines

Manual border machines are the most basic type and require significant operator involvement. These machines need workers to guide the fabric through the stitching process by hand. While they're slower than other options, they offer great flexibility for custom work and small production runs.

Manual machines are usually more affordable, making them ideal for smaller mattress manufacturers or start-up operations. They typically include simple serging machines that finish the edges of the border fabric and basic stitching equipment.

The learning curve for manual machines is relatively short, but productivity depends heavily on operator skill. Most can handle various fabric types and thicknesses, though they lack the advanced pattern capabilities of automated systems.

Automatic Mattress Border Machines

Automatic border machines represent the cutting edge of mattress manufacturing technology. These sophisticated systems can create complex patterns and designs with minimal human intervention. They're programmable via touchscreens, allowing operators to select from pre-loaded designs or create custom patterns.

These machines dramatically increase production speed and consistency. Many automatic models can stitch logos, decorative patterns, and functional elements like handles or ventilation holes.