#BOPP Films For Packaging Market application

Explore tagged Tumblr posts

Text

Thick growth in thin packaging: Ceresana Report on the World Market for Bioplastic Films

Wafer-thin films, often less than 1 millimeter thick, are one of the first areas of application in which bioplastics are able to establish themselves. Although casings made from petroleum products are still usually sold cheaper and in larger quantities, biobased materials such as starch or polylactic acid do not only offer a better public image regarding environmental awareness, but often also tangible advantages: Food packaging made from biodegradable plastics does not have to be disposed of at high cost, but can be composted; organic mulch films can simply be left on the field and plowed under. Ceresana has studied the global market for films made from bioplastics: The new market report forecasts that revenues will increase to around USD 14.2 billion by 2032.

Further information about the new market study “Bioplastic Films”: https://ceresana.com/en/produkt/bioplastic-films-market-report-world

#plastics#films#foils#packaging#import#export#manufacturers#production#producers#demand#consumption#polyethylene#PET#polypropylene#applications#bags#sacks#markets#bioplastics#BOPP#construction#agriculture#market study#market data

0 notes

Text

Transparent Label Sticker Printing: Enhancing Product Appeal with Clarity and Elegance

In today’s competitive market, branding and presentation play a vital role in consumer purchasing decisions. Among the many packaging solutions available, transparent label sticker printing has emerged as a favorite for businesses across various industries. From cosmetics and food products to health supplements and luxury goods, transparent labels offer a sleek, modern, and clean appearance that enhances product visibility and reinforces brand identity.

What is Transparent Label Sticker Printing?

Transparent label sticker printing refers to the process of printing labels on clear film materials such as polypropylene (BOPP) or polyester (PET). These labels are see-through, allowing the product or container to remain partially or completely visible. They are often referred to as “no-label look” stickers because when applied, they appear to be directly printed on the container, giving it a seamless and professional finish.

This type of label printing is ideal for products packaged in glass or clear plastic containers, as it allows customers to see the contents inside while still displaying essential information like branding, ingredients, and barcodes.

Key Benefits of Transparent Label Sticker Printing

Clean and Premium Look Transparent labels lend a minimalist and upscale look to any product. Their clarity makes them perfect for high-end items where aesthetics play a significant role in buyer perception.

Versatility Across Industries Whether you're in the beauty, beverage, food, or pharmaceutical industry, transparent label sticker printing offers unmatched adaptability. These labels work well on a wide variety of surfaces including plastic, glass, and metal.

Durability and Resistance Most transparent labels are water-resistant and can withstand exposure to oils, moisture, and chemicals. This makes them ideal for products that will be refrigerated or used in humid environments.

Cost-Effective Branding By eliminating the need for custom-colored containers, transparent labels allow brands to use standardized packaging while still achieving a distinct appearance. It helps lower production expenses while still maintaining a stylish, high-quality look.

Eco-Friendly Options With growing demand for sustainable packaging, many transparent label sticker materials are now available in recyclable and biodegradable options, helping brands meet eco-conscious consumer expectations.

The Transparent Label Printing Process

The process of transparent label sticker printing typically involves several steps:

Design Creation: The label is designed using specialized software, keeping in mind the transparency of the material. Special attention is given to color contrast and legibility.

Material Selection: Clear films such as polypropylene or polyester are chosen for their transparency, strength, and adhesion qualities.

Printing Method: Digital printing is widely used for its precision and cost-efficiency, especially for small to medium print runs. For larger batches, flexographic printing may be employed.

Finishing Touches: Labels can be laminated or varnished for added durability and shine. You can also add custom die-cuts to create distinctive shapes and designs that suit your brand.

Applications of Transparent Label Stickers

Cosmetics & Personal Care: Products like shampoos, lotions, and serums benefit from transparent labels as they allow the customer to view the color and texture of the product inside.

Food & Beverages: Transparent labels on glass jars, wine bottles, and gourmet sauces offer a clean and artisan-style presentation.

Household Cleaners: Many cleaning product manufacturers use transparent labels for a clinical, no-frills appearance that suggests effectiveness and purity.

Luxury Products: Perfume bottles and premium oils often feature minimalist transparent labels for a high-end, elegant feel.

Tips for Effective Transparent Label Sticker Printing

Use Opaque Inks: To ensure readability, use white ink or other opaque colors underneath text and images. This helps the design stand out against the transparent background.

Avoid Overcrowding: Minimalist designs with clear fonts and sufficient spacing look best on transparent labels.

Choose the Right Adhesive: Ensure the adhesive works well with your container’s surface and doesn’t show bubbles or hazing.

Test Before Final Run: Always conduct a sample print and apply it to the actual product to ensure the final look meets expectations.

Why Businesses Choose Transparent Label Printing

Transparent label sticker printing allows brands to communicate sophistication, simplicity, and purity. It’s especially effective when transparency itself aligns with a brand’s values—such as honesty, cleanliness, or premium quality. Moreover, the rise of clear packaging trends has pushed more businesses to explore transparent labeling as a means to connect with modern, design-conscious consumers.

As e-commerce continues to grow, first impressions count more than ever. Transparent labels not only help products stand out on physical shelves but also look appealing in online product photography, giving businesses a competitive edge.

Final Thoughts

Investing in high-quality transparent label sticker printing can be a game-changer for your brand. With their sleek look, durability, and ability to highlight your product’s best features, transparent labels are an excellent choice for modern packaging. Whether introducing a fresh product or refreshing an existing range, these transparent labels provide the flexibility and visual appeal to truly stand out.

0 notes

Text

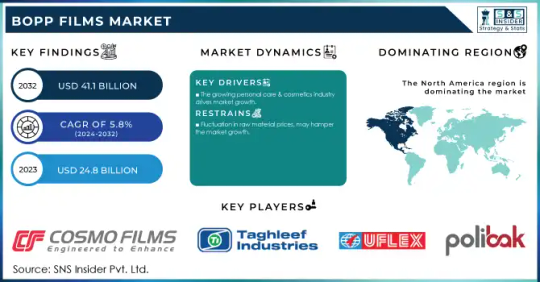

BOPP Films Market, Global Outlook and Forecast 2025-2032

Global BOPP (Biaxially Oriented Polypropylene) Films market continues to show robust expansion, projected to grow from USD 16.9 billion in 2024 to USD 23.4 billion by 2032, advancing at a CAGR of 4.9% during the forecast period.

This sustained growth trajectory reflects the material's crucial role in modern packaging solutions, offering manufacturers an optimal balance between performance characteristics and cost efficiency.

BOPP films have become indispensable across industries due to their superior moisture barrier properties, high tensile strength, and excellent printability. The material's versatility enables applications ranging from snack food packaging to pharmaceutical blister packs, with recent innovations addressing sustainability concerns through recyclable mono-material structures. As regulatory pressures increase globally, producers are investing heavily in next-generation BOPP technologies that maintain performance while meeting stringent environmental standards.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/291036/bopp-films-forecast-market

0 notes

Text

BOPP Film Market Growth Accelerates Due to Sustainability Trends and Technological Advancements

The BOPP film market has witnessed substantial growth in recent years, fueled by rising demand across multiple industries including food and beverage, personal care, pharmaceuticals, and industrial packaging. Known for its superior properties such as clarity, high tensile strength, barrier resistance, and printability, BOPP film is a preferred material in flexible packaging solutions worldwide.

Market Overview and Size

As of 2024, the global BOPP film market is estimated to be valued at over USD 25 billion, with steady growth projections over the next decade. Analysts forecast a compound annual growth rate (CAGR) of 5–6% through 2030, driven largely by rising consumer goods consumption, urbanization, and a growing preference for lightweight, recyclable packaging alternatives.

Asia-Pacific dominates the market, accounting for more than 40% of global demand, with China and India leading due to their large manufacturing bases and expanding consumer sectors. North America and Europe follow, benefiting from technological innovations and sustainable packaging mandates.

Key Drivers of Market Growth

Expanding Food & Beverage Industry One of the primary drivers of BOPP film demand is its widespread use in food packaging. The film’s excellent moisture resistance and aesthetic appeal make it ideal for snack foods, confectionery, fresh produce, and frozen items. BOPP film's ability to extend shelf life and improve product visibility enhances its value in retail.

Rising Sustainability Awareness With growing concern for environmental sustainability, BOPP films have gained favor for their recyclability. As brand owners and packaging companies seek eco-friendly options, BOPP's low environmental footprint and compatibility with mono-material recycling streams make it a strategic choice.

Technological Advancements in Film Manufacturing Advances in film extrusion, metallization, and coating technologies have improved the performance characteristics of BOPP films. Modern films offer better barrier properties, heat resistance, and compatibility with digital printing—broadening their application scope and driving innovation in packaging design.

Growth in E-commerce and Flexible Packaging The rapid expansion of e-commerce has led to increased demand for protective and functional packaging. BOPP films, due to their durability and cost-effectiveness, are being increasingly used in labels, overwraps, and parcel packaging.

Challenges Facing the Market

Despite its promising growth, the BOPP film market faces several challenges. Fluctuations in raw material prices, particularly polypropylene, can affect production costs and profit margins. Additionally, competition from alternative films such as polyethylene terephthalate (PET) and polyethylene (PE) may hinder market penetration in certain segments.

Moreover, while BOPP is recyclable, recycling infrastructure remains inconsistent across regions. Without proper collection and processing systems, the material’s sustainability benefits cannot be fully realized, potentially limiting its adoption in countries with weak recycling ecosystems.

Opportunities and Future Outlook

The future of the BOPP film market appears positive, bolstered by expanding industrial applications and heightened demand for high-performance packaging. Opportunities exist in developing barrier-coated BOPP films for high-moisture or high-oxygen sensitive products. Additionally, demand is growing for ultra-thin and multilayer BOPP films that offer improved functionality without increasing weight.

Collaborations between manufacturers and packaging innovators will also play a pivotal role in expanding product capabilities. Custom-engineered BOPP films with smart features—such as antimicrobial properties, temperature sensitivity, or enhanced tamper resistance—represent a lucrative growth avenue.

Sustainability initiatives are expected to drive the development of bio-based BOPP films, made from renewable feedstocks. As regulations tighten around single-use plastics, these greener alternatives will likely gain traction, especially in regions like the European Union.

Conclusion

The BOPP film market is poised for continued growth, propelled by its versatility, cost-effectiveness, and alignment with sustainable packaging trends. As industries seek packaging solutions that balance performance, cost, and environmental impact, BOPP film is set to remain a key material. Strategic investments in innovation and recycling infrastructure will be crucial to unlocking the market’s full potential and meeting the demands of a circular economy.

0 notes

Text

Extrusion Coating Market Key Players Growth Strategies and Business Models to 2033

Introduction

The extrusion coating market has witnessed significant growth over the last decade, driven by rising demands across diverse industries such as packaging, automotive, construction, and electronics. As sustainability, innovation, and cost-efficiency continue to shape industrial practices, extrusion coating emerges as a pivotal technology that delivers versatile, durable, and environmentally friendly solutions.

This article delves into the key trends, market dynamics, growth factors, competitive landscape, and forecast of the global extrusion coating market from 2024 to 2032.

Understanding Extrusion Coating

Extrusion coating is a process where molten resin is applied onto a substrate (usually paper, foil, or film) to create a layered structure that enhances the substrate's physical and chemical properties. This coating enhances moisture resistance, improves printability, and adds strength and durability. Key materials used in this process include polyethylene (PE), ethylene-vinyl acetate (EVA), polypropylene (PP), and ethylene-methacrylic acid copolymer (EMAA).

Market Overview

As of 2024, the global extrusion coating market is valued at approximately USD 4.8 billion and is expected to reach USD 7.3 billion by 2032, growing at a CAGR of 5.3% during the forecast period.

Download a Free Sample Report:- https://tinyurl.com/5h5385z9

Key Drivers

Boom in Flexible Packaging Industry The rise in demand for convenient, lightweight, and eco-friendly packaging solutions is a major driver. Extrusion coating is extensively used in flexible packaging for food, pharmaceuticals, and consumer goods.

Urbanization and Infrastructure Growth Developing nations are witnessing a surge in urban infrastructure development. Extrusion-coated materials are used in construction applications for insulation and vapor barriers.

Automotive Applications The automotive industry uses coated films for wiring harnesses, protective shields, and under-the-hood components due to their high durability and resistance to heat and chemicals.

Rise of E-commerce Online retailing has led to a surge in protective and sustainable packaging, giving further momentum to the extrusion coating industry.

Sustainability and Recyclability Growing environmental regulations and consumer awareness are pushing companies toward extrusion coatings that use bio-based and recyclable materials.

Market Segmentation

By Material Type

Low-Density Polyethylene (LDPE): LDPE dominates due to its excellent moisture barrier, low cost, and flexibility.

Ethylene Vinyl Acetate (EVA): Used for enhanced adhesion and flexibility in high-end applications.

Polypropylene (PP): Increasingly used due to its high melting point and better mechanical properties.

Others (EAA, EMAA, etc.): Specialty resins for applications demanding higher performance.

By Substrate Type

Paper & Paperboard: Widely used in food packaging, beverage cartons, and industrial wraps.

Films: PET, BOPP, and other films used in flexible packaging formats.

Aluminum Foil: For high-barrier packaging applications, especially in pharmaceuticals and dairy.

By Application

Packaging (Food, Beverage, Personal Care): Accounts for the largest market share due to demand for protective, shelf-stable packaging.

Industrial Applications: Used for corrosion-resistant wraps, insulation, and protective barriers.

Medical & Healthcare: High hygiene standards and safe storage of pharmaceuticals create demand for high-performance coatings.

Others (Textile, Agriculture): Growing niche applications in crop covers and protective clothing.

Regional Insights

Asia-Pacific (APAC):

The largest and fastest-growing region, fueled by industrialization, urban development, and a robust packaging sector in China, India, and Southeast Asia.

North America:

Steady growth driven by innovations in biodegradable coatings, regulatory compliance, and advancements in food safety.

Europe:

Sustainability trends dominate the market, with stringent EU regulations promoting recyclable and bio-based coatings.

Latin America and Middle East & Africa (MEA):

Emerging markets showing potential due to rising demand for infrastructure, healthcare, and packaged goods.

Market Trends and Innovations

1. Shift Toward Sustainable Materials

With growing emphasis on a circular economy, manufacturers are developing bio-based and recyclable polymers for extrusion coating. This aligns with global efforts to reduce plastic waste and carbon emissions.

2. Multi-layer Coatings

Advanced multilayer extrusion techniques allow manufacturers to combine the properties of different resins in a single pass, enhancing barrier protection, mechanical strength, and printability.

3. Digitalization and Smart Manufacturing

Automation, IoT-enabled production lines, and AI-driven quality control are being integrated into extrusion coating processes to boost efficiency and consistency.

4. High-Performance Barrier Films

The food and pharmaceutical industries are demanding ultra-high barrier coatings that can prevent oxygen, aroma, and moisture ingress, increasing shelf life and product safety.

5. Lightweighting and Downgauging

Efforts to reduce material usage without compromising performance are pushing manufacturers to develop thinner, stronger coatings.

Challenges Facing the Market

Fluctuating Raw Material Prices: Prices of resins such as LDPE and PP are tied to the volatility of crude oil, creating cost unpredictability.

Environmental Regulations: Tightening rules around plastic usage and recycling mandates may increase operational costs for non-compliant manufacturers.

Competition from Alternative Coating Technologies: Technologies like solvent-based, aqueous, and UV-curable coatings pose a threat to extrusion coatings in specific niche applications.

Limited Recycling Infrastructure: Especially in emerging markets, lack of proper recycling channels impedes the adoption of recyclable coatings.

Competitive Landscape

The extrusion coating market is moderately consolidated with a mix of global giants and regional players.

Key Players Include:

Dow Inc.

Mondi Group

Chevron Phillips Chemical

ExxonMobil Chemical

DuPont de Nemours Inc.

Borealis AG

Mitsui Chemicals

SABIC

LyondellBasell

Jindal Poly Films

These companies focus on product innovation, strategic partnerships, geographic expansion, and sustainable offerings to stay competitive.

Future Outlook

The extrusion coating market is expected to evolve rapidly over the next decade. By 2032, the market will not only grow in size but also in complexity, driven by the convergence of sustainability, automation, and consumer preferences. As packaging requirements become more demanding and diversified, the role of extrusion coating will expand into new sectors and novel applications.

Key focus areas moving forward:

Adoption of bio-resins and circular economy models.

Integration of Industry 4.0 practices to improve process efficiency.

Development of coatings compatible with compostable and recyclable substrates.

Expansion in emerging markets with increasing industrialization and urban growth.

Conclusion

The extrusion coating market presents a promising opportunity for stakeholders across the value chain. With strong growth projected through 2032, companies that invest in sustainable innovation, advanced processing technology, and customer-centric product development are poised to lead the industry forward. While challenges persist, particularly around environmental impact and raw material volatility, the overarching trends favor long-term expansion, making extrusion coating a critical player in the future of advanced material solutions.

Read Full Report:-https://www.uniprismmarketresearch.com/verticals/chemicals-materials/extrusion-coating.html

0 notes

Text

Plastic Films & Sheets Market Analysis: Key Players and Competitive Landscape

Innovations in Sustainable Materials and Packaging Propel Growth in the Plastic Films & Sheets Market.

The Plastic Films & Sheets market size was valued at USD 135 billion in 2023 and is expected to reach USD 212.3 billion by 2032 and grow at a CAGR of 5.20% over the forecast period 2024-2032.

The global plastic films & sheets market is witnessing significant growth due to increasing demand across industries such as packaging, agriculture, construction, healthcare, and automotive. Plastic films and sheets offer versatility, durability, and cost-effectiveness, making them an essential material in various applications, including food packaging, greenhouse coverings, medical packaging, and protective barriers. Advancements in material science and manufacturing processes are further propelling market expansion.

Key Players

Novolex (Eco-Products, Shields Poly Films)

Saudi Basic Industries Corporation (SABIC) (LLDPE Films, BOPP Films)

Toyobo Co. Ltd (HINOMARU Film, COSMOSHINE SRF)

British Polythene Industries Plc (Silage Films, Pallet Wrap)

The Dow Company (ELITE Polyethylene, INNATE Precision Packaging Resins)

DuPont (Mylar Polyester Films, Tedlar PVF Films)

Toray Industries, Inc. (LUMIRROR Polyester Film, TORAYFAN™ PP Films)

Berry Global, Inc. (FormiFor Films, AgriSeal Films)

Plastic Film Corporation of America (PVC Films, PETG Films)

Bemis Company, Inc. (PerfecTear Films, SmartTack Films)

Future Scope

The plastic films & sheets market is expected to grow steadily due to rising demand for sustainable and high-performance materials. Innovations in biodegradable and recyclable plastics are gaining momentum, driven by stringent environmental regulations and consumer preferences for eco-friendly products. Additionally, advancements in nanotechnology are leading to the development of films with enhanced barrier properties, extending the shelf life of packaged goods and improving durability in industrial applications.

Emerging Trends

The market is shifting towards sustainable and eco-friendly plastics, with an increasing focus on biodegradable and compostable films made from plant-based materials. Recyclable polyethylene and polypropylene films are gaining popularity, reducing plastic waste and meeting global sustainability goals. Additionally, smart films with anti-microbial, UV-resistant, and self-healing properties are revolutionizing applications in food packaging and healthcare. The rise of flexible and lightweight packaging solutions is further driving demand, particularly in the e-commerce and food industries.

Key Points

Growing demand from packaging, agriculture, healthcare, and automotive industries.

Sustainability initiatives are driving the development of biodegradable and recyclable films.

Advancements in nanotechnology are enhancing film performance and durability.

Smart films with UV resistance, antimicrobial properties, and self-healing capabilities are gaining traction.

Flexible and lightweight packaging is boosting demand, especially in e-commerce and food sectors.

Conclusion

The plastic films & sheets market is on a strong growth trajectory, fueled by technological advancements, sustainability efforts, and expanding industrial applications. As leading companies continue to invest in eco-friendly innovations and high-performance materials, the industry is expected to play a crucial role in shaping the future of packaging, healthcare, and construction.

Read Full Report: https://www.snsinsider.com/reports/plastic-films-and-sheets-market-1723

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Plastic Films & Sheets Market#Plastic Films & Sheets Market Size#Plastic Films & Sheets Market Share#Plastic Films & Sheets Market Report#Plastic Films & Sheets Market Forecast

0 notes

Text

Advanced IML Die Cutting Machine for Precision and Efficiency

Introduction to IML Die Cutting Machine

An IML Die Cutting Machine is a crucial tool in the in-mold labeling (IML) industry, designed to deliver high-speed, precise cutting for various label applications. It enhances production efficiency, ensures accurate cutting, and provides high-quality finished labels for industries such as food packaging, beverages, and consumer goods. By utilizing advanced automation, an IML Die Cutting Machine optimizes workflow, reduces material waste, and ensures seamless label application.

How an IML Die Cutting Machine Works

An IML Die Cutting Machine operates by cutting labels from printed sheets or rolls with extreme accuracy. The die-cutting process ensures that labels fit perfectly onto plastic containers, maintaining high adhesion and durability during molding. The machine is equipped with servo-controlled technology, digital cutting features, and high-speed rotary or flatbed cutting systems to ensure efficiency and precision in mass production.

Key Features of an IML Die Cutting Machine

High Precision Cutting – The IML Die Cutting Machine ensures that each label is cut to exact specifications, avoiding misalignment or inconsistencies.

Speed and Efficiency – With automated functions and high-speed operations, it significantly reduces production time.

Versatile Application – Supports a variety of label materials, including PP, PET, and BOPP films.

Automated Adjustments – Advanced sensors and control systems adjust settings in real time for maximum accuracy.

Minimal Material Waste – Optimized cutting processes ensure efficient material usage, reducing production costs.

Advantages of Using an IML Die Cutting Machine

Increased Production Efficiency

An IML Die Cutting Machine is designed for high-volume production, enabling manufacturers to meet market demands efficiently. The automation minimizes manual intervention, improving workflow consistency and overall productivity.

Enhanced Label Quality

Precision cutting ensures that labels maintain their shape and dimensions, resulting in flawless integration during the molding process. This enhances the final product’s aesthetic appeal and durability.

Cost-Effective Solution

By reducing label wastage and minimizing errors, an IML Die Cutting Machine helps in cost savings for manufacturers. The high-speed operation also reduces labor costs, making the process more economical.

Compatibility with Various Molding Processes

An IML Die Cutting Machine supports injection molding, blow molding, and thermoforming processes, making it a versatile choice for different packaging applications.

Industries That Benefit from an IML Die Cutting Machine

Food and Beverage Packaging – Ensures durable and visually appealing labels for dairy, beverage, and snack packaging.

Consumer Goods – Used for household and personal care product labeling.

Pharmaceutical Industry – Ensures labels remain intact and resistant to external factors.

Conclusion

An IML Die Cutting Machine is essential for businesses looking to enhance production quality and efficiency. Its advanced features, precision cutting, and automation make it a valuable investment for manufacturers in the IML industry.

0 notes

Text

BOPP Films Market Barriers Competition from Biodegradable and Alternative Packaging Materials

BOPP Films Market Barriers: Environmental Concerns and Sustainability Challenges

The growing demand for sustainable packaging has put BOPP films under scrutiny. While they offer durability and barrier properties, their non-biodegradable nature raises environmental concerns. Many brands and consumers are shifting towards eco-friendly alternatives, limiting the adoption of BOPP films in industries focused on sustainability goals.

BOPP Films Market Barriers: Recycling Limitations and Waste Management Issues

Although BOPP films are recyclable, the lack of efficient recycling infrastructure limits their sustainable disposal. Many recycling facilities struggle with sorting and processing BOPP films due to their multilayer structures, leading to low recycling rates. This challenge increases plastic waste accumulation, further restricting market growth.

BOPP Films Market Barriers: Stringent Government Regulations and Compliance Challenges

Government policies and regulations surrounding plastic packaging have created significant hurdles for BOPP film manufacturers. Many countries are imposing bans and restrictions on single-use plastics, leading to reduced demand for BOPP films in certain applications. Compliance with evolving regulations increases operational costs and complicates market expansion strategies.

BOPP Films Market Barriers: Competition from Biodegradable and Alternative Packaging Materials

The rise of biodegradable and compostable packaging materials poses a major challenge to the BOPP films market. Innovations in sustainable packaging, such as paper-based and biopolymer alternatives, are gaining traction among environmentally conscious consumers and businesses. This competition reduces the growth potential of BOPP films in various sectors.

BOPP Films Market Barriers: Supply Chain Disruptions and Logistics Challenges

Supply chain inefficiencies, including transportation delays and raw material shortages, significantly impact the production and distribution of BOPP films. Global trade restrictions, labor shortages, and increased freight costs further exacerbate these challenges, leading to inconsistent supply and higher costs for manufacturers and end-users.

BOPP Films Market Barriers: Fluctuating Demand in End-User Industries

The demand for BOPP films varies across industries such as food packaging, pharmaceuticals, and consumer goods. Economic downturns, changing consumer preferences, and industry-specific regulations affect the consumption of BOPP films. The unpredictability of demand makes it difficult for manufacturers to plan production and inventory management effectively.

BOPP Films Market Barriers: Limited Awareness and Adoption in Emerging Markets

While BOPP films are widely used in developed markets, their adoption in emerging economies remains limited. Lack of awareness about their benefits, high initial investment costs, and inadequate processing facilities hinder their widespread use in developing countries. Market education and infrastructure development are necessary to expand adoption.

BOPP Films Market Barriers: Performance Constraints and Material Limitations

Despite their advantages, BOPP films have certain performance limitations that restrict their applications. They exhibit lower heat resistance compared to other polymer films, making them unsuitable for high-temperature applications. Additionally, issues related to printability and adhesion affect their usability in specialized packaging solutions.

BOPP Films Market Barriers: Strategies to Overcome Growth Challenges

To overcome these barriers, industry players must invest in research and development to improve the recyclability and sustainability of BOPP films. Collaborations with regulatory bodies can help create policies that support responsible plastic usage. Enhancing supply chain efficiency and exploring cost-effective raw material alternatives will also play a crucial role in ensuring long-term market growth.

Conclusion

The BOPP films market faces multiple barriers that challenge its growth and expansion. High production costs, environmental concerns, recycling limitations, and competition from alternative packaging materials restrict market potential. However, with advancements in technology, regulatory collaboration, and sustainability-focused innovations, the industry can address these challenges and create new opportunities for growth.

0 notes

Text

BOPP Film Prices, News, Trend, Graph, Chart, Monitor and Forecast

BOPP (Biaxially Oriented Polypropylene) film prices are influenced by a variety of factors, including raw material costs, supply chain dynamics, global demand, and regional market trends. The BOPP film industry plays a crucial role in packaging, labeling, and lamination applications, making its pricing trends essential for manufacturers, suppliers, and end-users. Understanding the key drivers behind BOPP film prices helps businesses strategize effectively and manage procurement costs efficiently.

The primary determinant of BOPP film prices is the cost of polypropylene, the essential raw material used in production. Polypropylene is derived from crude oil and natural gas, making its price highly susceptible to fluctuations in global energy markets. When crude oil prices rise, polypropylene production costs increase, directly impacting BOPP film prices. Additionally, supply chain disruptions, refinery shutdowns, and geopolitical tensions can contribute to volatility in raw material costs, leading to unpredictable price movements in the BOPP film market.

Another significant factor influencing BOPP film pricing is the balance between supply and demand. Over the years, the demand for flexible packaging solutions has surged due to the growing food and beverage, pharmaceutical, and consumer goods industries. The increasing preference for lightweight, durable, and eco-friendly packaging has further driven the adoption of BOPP films. When demand outpaces supply, prices tend to rise as manufacturers struggle to meet market requirements. Conversely, an oversupply of BOPP films can lead to price reductions as producers seek to clear excess inventory.

Get Real time Prices for BOPP (Biaxially Oriented Polypropylene) film: https://www.chemanalyst.com/Pricing-data/bopp-film-1209

Regional market dynamics also play a crucial role in shaping BOPP film prices. Asia-Pacific, particularly China and India, dominates the global BOPP film production landscape due to the presence of large-scale manufacturing facilities and an abundance of raw materials. As a result, price fluctuations in these regions often have a ripple effect on the global market. Additionally, trade policies, import-export regulations, and tariffs can impact the cost of BOPP films in different regions. For instance, restrictions on polypropylene exports from major producing countries can lead to supply shortages, pushing up prices in import-dependent markets.

The impact of technological advancements on BOPP film prices cannot be overlooked. Innovations in film manufacturing, such as multi-layer extrusion technology and the development of high-barrier films, have enhanced the quality and functionality of BOPP films. While these advancements improve performance, they also add to production costs, influencing overall pricing trends. Additionally, investments in sustainable packaging solutions, including recyclable and biodegradable BOPP films, are driving price variations as companies incorporate eco-friendly materials and production techniques.

Economic conditions and inflationary pressures further contribute to fluctuations in BOPP film prices. Inflation affects the cost of raw materials, labor, transportation, and energy, all of which are crucial components of the production process. Rising inflation leads to higher manufacturing costs, which are eventually passed on to consumers in the form of increased BOPP film prices. Conversely, during economic downturns, reduced consumer spending and lower industrial activity can lead to weakened demand, causing prices to decline.

Seasonal trends also have an impact on the BOPP film market. Demand for flexible packaging films, including BOPP, typically increases during peak holiday seasons when the need for food and beverage packaging surges. This seasonal demand boost often results in price hikes as manufacturers ramp up production to meet orders. Similarly, disruptions caused by extreme weather conditions, such as hurricanes or winter storms, can affect supply chains, leading to temporary price spikes.

Sustainability and environmental regulations are emerging as key factors affecting BOPP film prices. Governments and regulatory bodies worldwide are implementing stringent policies to reduce plastic waste and promote recyclable packaging materials. Compliance with these regulations often requires manufacturers to invest in new technologies and modify production processes, leading to higher costs. Additionally, the growing consumer preference for sustainable packaging options is encouraging companies to develop innovative BOPP film solutions, which may come at a premium price.

The competitive landscape of the BOPP film industry also plays a crucial role in determining prices. The market is characterized by the presence of numerous global and regional players competing to gain market share. Price competition among manufacturers often leads to aggressive pricing strategies, impacting overall market rates. Additionally, strategic collaborations, mergers, and acquisitions among key industry players influence price trends by altering market dynamics and supply capabilities.

Future projections for BOPP film prices suggest a complex interplay of factors that will shape market trends. The rising demand for flexible packaging, especially in emerging economies, is expected to sustain market growth. However, raw material price volatility, regulatory changes, and shifting consumer preferences toward sustainable packaging could introduce new pricing challenges. Companies in the BOPP film market must remain adaptable and proactive in responding to these evolving trends to maintain competitiveness and profitability.

As the BOPP film market continues to evolve, stakeholders must closely monitor key price influencers, including raw material costs, technological advancements, regulatory policies, and supply-demand dynamics. Strategic procurement planning, investment in research and development, and a strong focus on sustainability will be essential for businesses aiming to navigate price fluctuations effectively. By staying informed about market trends and adopting innovative approaches, companies can optimize costs and capitalize on growth opportunities in the dynamic BOPP film industry.

Get Real time Prices for BOPP (Biaxially Oriented Polypropylene) film: https://www.chemanalyst.com/Pricing-data/bopp-film-1209

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#BOPP Film Price#BOPP Film Prices#BOPP Film Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

1 note

·

View note

Text

Flexure Print N Pack to commission new blown film extrusion line in 2024-25

Ahmedabad-based flexible packaging converter Flexure Print N Pack is set to expand its capabilities with significant new investments. The company plans to commission a multilayer blown film extrusion line within the financial year 2024-25, aiming to strengthen its vertical integration. Flexure Print N Pack is also gearing up to install converting machinery for both monolayer and multilayer packaging in the next few months, according to Jainam Shah, managing partner at Flexure Print N Pack.

“We are also exploring collaborations with industry suppliers to add value to our wide-web flexographic printed products through offline processes,” Shah said in an exclusive interview with Packaging South Asia.

Current capabilities and machinery

Flexure at present operates four flexographic printing presses, including one central impression press and three stack-type configured presses. The facility is equipped with an advanced photopolymer plate mounting machine along with anilox sleeves and photopolymer plate cleaning machines to ensure quality and durability. In the lamination department, the company utilizes both solvent-free and solvent-based lamination machines.

The slitting department boasts drum-type and cantilever differential slitting machines. For conversion, Flexure Print N Pack runs a variety of machines, including bottom seal bag-making machines, side seal bag-making machines, slit-seal plus gusset machines, and multiple pouch-making machines.

A milestone year in 2024

Reflecting on 2024, Shah described the year as "busy, challenging, and eventful," marked by significant achievements. Flexure Print N Pack reached a notable milestone by successfully printing 208 LPI print resolution jobs on its flexographic press. The company also conducted trials with hybrid screening, water-based inks, and extended color gamut, which are set to transition into full-scale production in the coming months.

Established in 2001, the Asian Packaging Excellence Awards recognize outstanding achievements, innovation, and contributions to packaging production across the Asia region, celebrating the pinnacle of excellence in the Asian packaging industry.

“These awards underscore our commitment to excellence in packaging production,” Shah said.

Production capacity and solutions

Flexure Print N Pack currently converts between 175 and 200 metric tonnes of material per month. The company’s product portfolio spans a range of exclusive flexographic-printed solutions, including LDPE, CPP, TQPP, BOPP, PET, coated paper, and compostable films as substrates. These materials are supplied in monolayer and multilayer roll forms, as well as in converted pouch formats.

Flexure Print N Pack specializes in manufacturing a variety of packaging solutions, including bakery bags, shopping bags, hygiene application pouches, vacuum pouches, zipper pouches, quad seal pouches, and stand-up pouches, among others.

A vision for the future

With its new investments and a focus on innovation, Flexure Print N Pack is poised to strengthen its position in the flexible packaging industry, Shah said. The addition of the blown film line and enhanced converting capabilities will enable the company to meet evolving market demands and reinforce its reputation for quality and innovation.

0 notes

Text

Everything You Need to Know About BOPP Woven Bags and Laminated Sacks

BOPP woven bags are one of the most versatile, durable, and cost-effective packaging solutions available today. These bags are commonly used in industries like agriculture, food processing, construction, and chemicals. Let’s dive into what makes them indispensable and how businesses can benefit from them.

What Are BOPP Woven Bags?

BOPP woven bags are made by laminating BOPP (Biaxially Oriented Polypropylene) film onto woven polypropylene fabric. This process creates a packaging material that combines the strength of woven polypropylene with the aesthetic appeal of a printed BOPP film.

These bags are available in multiple variations, including:

BOPP Laminated Woven Bags: Enhanced with a laminated layer for added strength and moisture resistance.

BOPP Laminated PP Woven Bags: Designed for heavier loads while maintaining customization options.

Woven Polypropylene Sacks: Commonly used in industrial and agricultural applications due to their tear resistance.

Key Benefits of BOPP Woven Bags

1. Strength and Durability BOPP woven bags can withstand heavy loads, making them suitable for transporting bulky products like fertilizers, grains, and chemicals. Their woven structure resists tearing and punctures.

2. Moisture Resistance The laminated BOPP Bag film protects contents from humidity, ensuring that moisture-sensitive products remain intact during transit and storage.

3. Customization and Branding These bags offer excellent printing capabilities. Businesses can display high-resolution images, logos, and text on the bags, helping with brand recognition and marketing.

4. Eco-Friendliness Made from recyclable materials, BOPP bags provide a sustainable alternative to traditional plastic packaging, aligning with growing environmental concerns.

5. Cost-Effective Despite their premium features, BOPP laminated bags are cost-efficient. Their durability reduces replacement costs, while their customizability serves both functional and promotional purposes.

Applications of BOPP Laminated Bags

Agriculture

Packaging for rice, grains, seeds, and animal feed.

Protection against pests and moisture.

Food Industry

Used for storing sugar, flour, and other dry goods.

Keeps food fresh with moisture and UV protection.

Construction Materials

Ideal for products like cement and sand.

Heavy-duty strength ensures safe handling during transport.

Retail and Branding

Eye-catching designs help attract customers and reinforce brand identity.

How Are BOPP Bags Manufactured?

The production of BOPP bags involves several steps:

Lamination: A layer of BOPP film is laminated onto woven polypropylene fabric.

Printing: High-quality reverse printing techniques create vibrant, long-lasting designs.

Cutting and Stitching: The laminated fabric is cut and stitched into the desired bag shape and size.

Testing: Bags are tested for strength, water resistance, and durability before shipment.

How to Choose the Right BOPP Laminated Bags Manufacturer

When sourcing BOPP laminated woven bags, it’s important to select a reliable manufacturer. Look for these key attributes:

Customization Options: Ability to provide tailored designs and sizes.

Quality Assurance: Adherence to industry standards for strength, durability, and eco-friendliness.

Eco-Friendly Practices: Manufacturers that use sustainable materials and processes.

Competitive Pricing: Affordable solutions without compromising quality.

Future Trends in BOPP Laminated Bags

As industries shift towards sustainable and innovative packaging, BOPP laminated bags are poised for further growth. Upcoming trends include:

Increased Use of Recyclable Materials: More manufacturers are focusing on fully recyclable designs to reduce environmental impact.

Smart Packaging Features: Incorporation of tamper-evident seals and QR codes for product tracking.

Enhanced Printing Techniques: Offering even more customization for brand differentiation.

0 notes

Text

Cold Seal Packaging Market Expansion Fueled by Demand in Food, Pharma, and Eco-Friendly Sectors

The cold seal packaging market has seen significant growth in recent years, driven by rising demand for efficient, consumer-friendly, and eco-conscious packaging solutions. This form of packaging, which uses pressure-sensitive adhesives instead of heat to seal materials, is widely utilized in industries such as food and confectionery, pharmaceuticals, and personal care. With increasing awareness about sustainability and food safety, cold seal packaging is becoming a preferred choice across the globe.

What is Cold Seal Packaging?

Cold seal packaging refers to a packaging process that uses a pressure-sensitive coating to bond two substrates together without the need for heat. Typically, one substrate is coated with a cold seal adhesive, which adheres only to itself under pressure. This is especially useful for heat-sensitive products, as it prevents damage and maintains product integrity. The most common materials used include paper, film, and foil substrates.

Market Drivers

1. Demand for Convenience and Speed

One of the main advantages of cold seal packaging is the speed of packaging. It is significantly faster than traditional heat sealing, allowing for higher throughput and improved productivity. This benefit is particularly valuable in the food and beverage sector, where efficiency and volume are key operational drivers.

2. Rising Demand in Confectionery and Snack Industry

Cold seal packaging is heavily used in wrapping chocolate bars, granola bars, candies, and bakery items. These products are sensitive to heat and can lose quality if subjected to high temperatures during packaging. Cold sealing preserves product freshness, improves shelf life, and enhances visual appeal through high-quality printing and design compatibility.

3. Eco-Friendly and Energy-Efficient

Since no heat is required, cold seal packaging uses less energy compared to heat-sealing processes. This aligns well with global trends toward sustainability and energy conservation. Additionally, manufacturers are increasingly using recyclable and biodegradable substrates to further reduce the environmental impact.

4. Pharmaceutical and Medical Applications

The pharmaceutical industry requires packaging that ensures product safety, tamper resistance, and hygiene. Cold seal packaging meets these requirements without exposing drugs or medical devices to heat. It’s also suitable for high-speed automated packaging lines, which are essential in large-scale pharmaceutical production.

Market Segmentation

The cold seal packaging market can be segmented by material type, end-user industry, and geography.

By Material Type: The most common materials are paper, aluminum foil, BOPP (biaxially oriented polypropylene), and PET (polyethylene terephthalate). Paper and foil laminates dominate the market due to their excellent barrier properties and printability.

By End-Use Industry: Major end-users include food and beverage, pharmaceuticals, cosmetics, and personal care. The food sector remains the largest consumer, followed by pharmaceuticals and health-related products.

By Region: North America and Europe are the largest markets, driven by high consumption of packaged foods and pharmaceuticals. However, Asia-Pacific is witnessing the fastest growth, especially in emerging economies like India and China, where urbanization and middle-class expansion are fueling demand.

Challenges

Despite its advantages, cold seal packaging faces certain limitations:

Cost: Cold seal adhesives and the application process can be more expensive than traditional methods, especially for small-scale manufacturers.

Limited Adhesive Lifespan: The adhesive layer in cold seal materials has a limited shelf life, requiring careful inventory management and faster turnover.

Specialized Equipment: Not all packaging lines are compatible with cold seal technology. Companies may need to invest in specialized equipment, which can be a barrier to adoption.

Technological Innovations

Innovation in adhesive technology and substrate development continues to drive the market forward. Manufacturers are developing cold seal coatings that offer improved performance, wider sealing windows, and compatibility with more substrates. In addition, digital printing technologies have enabled customization and shorter production runs, catering to brand-specific packaging needs.

Competitive Landscape

Key players in the global cold seal packaging market include Amcor, Mondi Group, Constantia Flexibles, Sealed Air Corporation, and Bischof + Klein. These companies are focusing on research and development to enhance adhesive formulations, reduce costs, and improve sustainability. Partnerships and acquisitions are also common strategies for market expansion.

Future Outlook

The future of the cold seal packaging market looks promising, with steady growth projected over the next decade. Market analysts forecast a compound annual growth rate (CAGR) of 5% to 7%, depending on region and industry segment. Factors such as rising consumer expectations for convenience, sustainability mandates, and technological advancements will continue to shape the market.

Emerging trends such as smart packaging, eco-friendly materials, and the growing e-commerce sector are likely to further increase the adoption of cold seal packaging. As businesses seek to balance performance with sustainability, cold seal technology will remain a vital part of the packaging industry's evolution.

In conclusion, the cold seal packaging market represents a dynamic and evolving segment of the global packaging industry. Its advantages in terms of speed, safety, and sustainability make it a compelling choice for modern manufacturers and brands. With ongoing innovation and expanding applications, cold seal packaging is well-positioned for long-term growth and relevance.

#ColdSealPackaging#PackagingIndustry#FlexiblePackaging#PackagingSolutions#PackagingTrends#SmartPackaging

0 notes

Text

Eco-Friendly Packaging Solutions for Companies: Increasing Brand Awareness

BOPP bags have gained popularity in today's quickly changing packaging industry because of their exceptional strength, clarity, and adaptability. These bags are widely used in many different industries, including consumer goods, textiles, food packaging, and agriculture. The emergence of bopp bags manufacturers has been essential in satisfying the rising need for long-lasting and environmentally responsible packaging options.

Biaxially oriented polypropylene film, which is used to make BOPP bags, is stretched in two directions, increasing the material's tensile strength and making it perfect for high-performance applications. These bags are ideal for branding because of their transparent surface, which not only makes the contents highly visible but also offers a wide range of colorful printing options. Their popularity in a variety of industries is further enhanced by their resistance to physical stress, chemicals, and moisture.

The ability of BOPP bags to preserve the quality and freshness of packaged goods is one of their key benefits. These bags provide a barrier against moisture and oxygen, extending the shelf life of food items, particularly in the snack and confectionery sectors. Similar protection from outside environmental elements is offered by BOPP bags for goods like fertilizers, seeds, and grains, guaranteeing their safety and integrity throughout storage and transit.

BOPP bags are a cost-effective packaging option because of their strength, protective qualities, ease of handling, and lightweight nature. Their adaptability also extends to customization, enabling producers to produce bags in a range of sizes, shapes, and patterns to meet particular client needs. Businesses looking for custom packaging solutions that complement their brand image and marketing objectives are now in greater demand as a result of this.

Manufacturers of BOPP bags play an increasingly important role as the market for these bags expands. These producers are in charge of making bags of the greatest caliber as well as making sure that their goods satisfy the various demands of their customers. They accomplish this by making investments in state-of-the-art technology, putting stringent quality control procedures in place, and consistently coming up with new ideas to improve the performance and functionality of their products.

Many manufacturers of BOPP bags have also adopted eco-friendly practices as a result of the global shift towards sustainability. One of BOPP material's main advantages is its ability to be recycled, which has encouraged its widespread use in sectors trying to lessen their environmental effect. In order to make BOPP bags more sustainable and assist companies in achieving their environmental objectives, manufacturers are putting more and more emphasis on using recycled polypropylene in their production.

Additionally, BOPP bags have excellent printing capabilities that let companies use them for advertising. An affordable method of raising brand awareness is to print complex patterns, logos, and messages straight onto the bags' surface. Businesses in the retail and consumer goods industries that wish to display their products with visually appealing designs and information will find this feature especially appealing.

As industries look for creative packaging solutions that combine practicality and style, the demand for BOPP bags is predicted to keep growing. One of the main reasons for these bags' increasing appeal is their capacity to offer the best possible protection while simultaneously enhancing brand identity.

A Prominent Brand in the Production of BOPP Bags

As one of the leading producers in the market, Sudarshan Add Pack is a standout choice for finding premium BOPP bags. The company has years of experience in the packaging industry and is well known for creating eco-friendly, long-lasting, and customizable packaging solutions. The use of cutting-edge machinery and strict quality control procedures demonstrate Sudarshan Add Pack's dedication to excellence, guaranteeing that every bag performs to the highest standards. Apart from their proficiency in producing BOPP bags, Sudarshan Add Pack is committed to providing their customers with individualized service. They collaborate closely with companies to provide packaging solutions that satisfy functional and branding needs, whether they are small custom runs or large industrial orders.

0 notes

Text

Synthetic And Bio-based Polypropylene Market: Detailed Insights on Size, Share, Growth Potential

The global synthetic and bio-based polypropylene market size is expected to reach USD 178.8 million by 2030, registering a CAGR of 8.8% from 2024 to 2030, according to a new report by Grand View Research, Inc. Growth of key end-use industries such as packaging and automotive in Asia Pacific is expected to drive the global polypropylene market the forecast period. In addition, increasing construction spending particularly in emerging markets of China, India, and Indonesia is also expected to have a positive influence on market growth.

Synthetic And Bio-based Polypropylene Market Report Highlights

Injection molding dominated the market and accounted for a market revenue share of 48.4% in 2023. Polypropylene's attributes, such as high impact resistance, chemical inertness, and ability to be molded into complex shapes, make it highly suitable for injection molding applications.

The Asia Pacific synthetic and bio-based polypropylene market dominated in 2023. This growth owes to significantly increasing environmental awareness and government regulations.

Bio-based polypropylene demand is more dominant in emerged markets of North America and Europe. These markets are characterized by stringent regulations and aware consumers regarding the environmental hazards caused due to petrochemical-based polypropylene.

For More Details or Sample Copy please visit link @: Synthetic And Bio-based Polypropylene Market Report

Volatile propylene prices on account of constantly fluctuating crude oil prices are expected to remain a key challenge for market participants. Stringent environmental regulations regarding the production and disposal of polypropylene are also expected to degrade the market growth over the forecast period. In order to overcome these issues, major participants have shifted their focus towards the development of sustainable polypropylene.

Injection molding emerged as the leading application segment and accounted for 46.1% of total market volume in 2014. The shift towards the replacement of the steel automotive industry in order to improve the fuel efficiency of automobiles is expected to remain a key driving factor for this segment over the forecast period. Films are expected to witness the highest growth rate of 5.7% from 2015 to 2022. Growing demand for BOPP films for a myriad of applications is expected to drive this segment over the forecast period.

List of major companies Synthetic And Bio-based Polypropylene Market

Braskem

Dow Inc.

Borealis AG

LyondellBasell Industries Holdings B.V.

Total S.A.

Trellis Bioplastics

BioAmber Inc.

NatureWorks LLC

Danimer Scientific

Novamont S.p.A.

FKuR Kunststoff GmbH

For Customized reports or Special Pricing please visit @: Synthetic And Bio-based Polypropylene Market Analysis Report

We have segmented the global synthetic and bio-based polypropylene market based on application, end-use, and region.

#BioPolypropylene#SyntheticPolypropylene#Polypropylene#BioBasedMaterials#SyntheticPolymers#SustainableMaterials#GreenChemistry#PlasticsIndustry#BioPolymers#EcoFriendlyPlastics#InnovationInMaterials#PolymerScience#BioPlastics

0 notes

Text

What is Flexible Packaging and Its Importance?

Flexible packaging has revolutionized 🌍 the way products are stored, transported, and consumed. As its name suggests, flexible packaging uses materials like plastic films, foils, and papers to create lightweight and versatile packaging solutions. Unlike rigid packaging, flexible alternatives can adapt to the shape of the product, enhancing convenience for both manufacturers and consumers.

Flexible packaging uses a variety of substrates to cater to different product requirements. Common materials include: BOPP, PET, Polyethylene, Polyamide, Aluminum Foil, PVC, and Paper.

These materials are tailored for applications in food, beverages, healthcare, and more 🍔💊🍹.

Key Benefits of Flexible Packaging

1. Sustainability 🌱: Modern flexible packaging uses less material, reduces waste, and supports recyclable and biodegradable options, aligning with global sustainability goals.

2. Cost Efficiency 💰: Its lightweight nature significantly cuts transportation and storage costs.

3. Enhanced Product Protection 🛡️: Advanced barrier properties preserve product freshness, extend shelf life, and safeguard against contamination.

4. Customizable Designs 🎨: Flexible packaging is ideal for branding, enabling high-quality prints and innovative designs to capture consumer attention.

5. Versatility 🔄: It accommodates a wide range of industries, including food, pharmaceuticals, beverages, and more.

Rising Demand for Flexible Packaging

As global consumer preferences shift toward eco-friendly 🌍 and convenient solutions, the demand for flexible packaging has surged 📈. Key sectors such as food and beverage, healthcare, and e-commerce rely on flexible packaging to meet their needs for durability, safety, and efficiency.

Webtech’s Innovative Solution

Recognizing this growing demand, Webtech International Machineries proudly unveiled its latest innovation at Labelexpo 2024—a New Generation Flexographic Printing Machine with a 670 mm working width.

Designed to meet the rigorous demands of the flexible packaging industry, this state-of-the-art machine integrates cutting-edge technology to deliver exceptional print quality, reduced setup times, and increased production efficiency ⚙️.

WEBTECH has already secured several significant orders for this advanced machine, including a prestigious international order from Russia 🇷🇺. With our robust, heavy-duty, high-performance machinery, we are confident in our ability to showcase excellence and innovation, proudly representing our nation 🇮🇳 on the global stage and making our mark in every corner of the world 🌏.

Webtech’s commitment to innovation ensures that businesses remain competitive in a rapidly evolving market while addressing environmental challenges 🌱. Our latest Flexographic Printing Machine underscores our vision of empowering industries with sustainable and efficient packaging solutions.

Flexible packaging is not just a trend—it’s the future of packaging. Embrace this transformation with Webtech’s advanced machinery.

Stay connected with us for more updates from Labelexpo 2024! ✨

For more information contact us at : 099997 79973 | [email protected]

#flexiblepackaging#flexographic label printing machine#Flexo#fully servo#670 mm#Packaging Labels#pet label#BOPP Labels

0 notes

Text

BOPP Films Market Growth: Key Drivers and Emerging Opportunities

Increasing Demand for Flexible Packaging and Labeling Applications Fuels Growth in the BOPP Films Market.

The BOPP Films Market size was USD 24.8 billion in 2023 and is expected to reach USD 41.1 billion by 2032 and grow at a CAGR of 5.8% over the forecast period of 2024-2032.

The Biaxially Oriented Polypropylene (BOPP) Films Market is witnessing significant growth due to increasing demand for lightweight, durable, and cost-effective packaging solutions. BOPP films offer high tensile strength, moisture resistance, and excellent clarity, making them an ideal choice for applications in food packaging, labeling, pharmaceuticals, and industrial sectors. With the global shift toward sustainable and high-performance packaging materials, BOPP films are gaining traction as a recyclable alternative to traditional plastic films.

Key Players in the BOPP Films Market

Cosmo Films Ltd. (Cosmo Sensa, Cosmo Polyester Films)

TAGHLEEF INDUSTRIES GROUP (TALATEX, THERMOLAM)

POLİBAK PLASTİK (Polibak BOPP Films, Polibak Lidding Films)

UFlex Limited Inc. (FlexPET, UFlex BOPP Films)

SRF Limited (SRF BOPP Films, SRF Specialty Films)

NAN YA PLASTICS CORPORATION (NyFilm, NyBond BOPP Films)

Vacmet India Ltd (Vacmet BOPP Films, Vacmet Lamination Films)

Tatrafan, s.r.o (Tatrafan BOPP Films, Tatrafan Metallized Films)

ObenGroup (Oben BOPP Films, Oben Clear Films)

FlexFilms (FlexPET, FlexBOPP Films)

Future Scope of the Market

The BOPP films market is set for continued expansion, driven by:

Growing demand for flexible and cost-effective packaging solutions.

Advancements in high-barrier and metallized BOPP films for extended shelf life.

Expansion in food & beverage, personal care, and pharmaceutical packaging applications.

Rising adoption of eco-friendly and recyclable film alternatives.

Increasing investment in advanced printing technologies for BOPP film labeling.

Emerging Trends in the BOPP Films Market

The industry is seeing strong growth in the food and beverage sector, where BOPP films are widely used for snack packaging, confectionery wrapping, and frozen food applications. The demand for biodegradable and recyclable BOPP films is increasing as companies shift toward sustainable packaging solutions. Moreover, advancements in nanotechnology and multilayered BOPP films are enhancing barrier properties, heat resistance, and printability, catering to premium branding and high-performance packaging needs.

Key Points:

Increasing demand for flexible and recyclable packaging materials.

Rising adoption of BOPP films in food, pharmaceuticals, and labeling applications.

Technological advancements in high-barrier and biodegradable BOPP films.

Sustainability initiatives driving innovation in eco-friendly film alternatives.

Growing preference for digital printing solutions in BOPP labeling applications.

Conclusion

The BOPP Films Market is on a strong growth trajectory, fueled by rising consumer demand for flexible, cost-effective, and sustainable packaging solutions. As industries transition to recyclable and high-performance films, BOPP remains a key player in shaping the future of packaging and labeling technologies. Companies investing in material innovation, sustainability, and advanced printing techniques will lead the market in the years ahead.

Read Full Report: https://www.snsinsider.com/reports/bopp-films-market-1455

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#BOPP Films Market#BOPP Films Market Size#BOPP Films Market Share#BOPP Films Market Report#BOPP Films Market Forecast

0 notes