#Battery state estimation techniques

Explore tagged Tumblr posts

Text

Exploring SOC-OCV Curves in Lithium-ion Battery Management

In the rapidly evolving world of lithium-ion battery technology, understanding the SOC-OCV Curve (State of Charge - Open Circuit Voltage) is crucial for optimizing battery management systems (BMS) and enhancing battery performance. This blog delves into the significance of SOC estimation, the relationship between Open Circuit Voltage (OCV) and State of Charge (SOC), and how these concepts play a pivotal role in the effective management of lithium-ion batteries.

Unraveling the SOC-OCV Mystery

The SOC-OCV curve is a fundamental tool for estimating the state of charge in lithium-ion batteries. By analyzing this curve, we can gain insights into how voltage changes with varying levels of charge. This relationship is essential for accurate battery state estimation techniques and informs the development of advanced battery management systems.

Our research highlights that precise SOC-OCV calibration is vital to understanding battery behavior, especially around critical SOC levels like 60%. Factors such as active materials, capacity attenuation, and silicon doping can significantly influence the curve's shape and behavior.

Dynamic Factors Influencing SOC-OCV Curves

Several dynamic factors impact the SOC-OCV curves, including:

Active Materials: The type of materials used in the battery, such as lithium iron phosphate and graphite, significantly affects voltage characteristics and overall performance.

Battery Types: Different battery chemistries exhibit unique SOC-OCV relationships. Understanding these differences is crucial for effective performance analysis.

SOC Adjustment Parameters: The direction in which SOC is adjusted during charging or discharging can alter the OCV readings, making it essential to consider these parameters in battery management algorithms.

Negative Silicon Doping: This innovative approach can enhance battery performance but also complicates the SOC-OCV relationship, particularly during phase transformations.

Challenges and Solutions

The complexity of the SOC-OCV curve, especially near 60% SOC, presents challenges for accurate voltage measurements. The voltage step observed in this region is primarily due to phase transformations in negative graphite. Our research addresses these challenges by providing insights into how various factors contribute to the curve's behavior, ultimately leading to improved battery health monitoring and degradation analysis.

Key Insights from Our Research

Our findings reveal that while the full battery OCV is determined by material properties, the shape of the SOC-OCV curve is influenced by several factors:

Active Material Differences: Variations in active materials can lead to distinct voltage characteristics.

SOC Regulation Direction: The method of adjusting SOC impacts OCV readings and must be carefully managed.

Charge and Discharge Cycles: These cycles affect battery capacity over time, influencing both SOC estimation and OCV measurements.

Role of Negative Electrode: The negative electrode's composition, particularly concerning silicon doping, plays a crucial role in shaping the SOC-OCV curve.

Future Frontiers in Battery Management

As we continue to explore lithium-ion battery technology, our research paves the way for future advancements in battery management systems. By enhancing our understanding of SOC-OCV mapping for energy storage systems, we can optimize battery performance and contribute to cleaner, more efficient energy solutions. In conclusion, comprehending the intricacies of SOC-OCV curves is essential for anyone involved in lithium-ion battery technology. As we push forward into a future powered by sustainable energy solutions, mastering these concepts will be key to ensuring that our batteries perform optimally throughout their lifecycle. Whether you are a researcher, engineer, or enthusiast, staying informed about these developments will empower you to contribute meaningfully to this dynamic field.

#SOC and OCV relationship#Battery health monitoring#SOC-OCV modeling for lithium-ion batteries#Advanced battery management#systems (BMS)#Lithium-ion battery performance analysis#Battery state estimation techniques#Voltage-based SOC estimation#SOC-OCV calibration#Battery degradation analysis using SOC-OCV#Lithium-ion battery voltage characteristics#OCV measurement for lithium batteries#SOC prediction methods#Battery management algorithms#Battery voltage vs SOC curve#SOC-OCV mapping for energy storage systems

0 notes

Text

The Rise of 3D Printing in Prosthetics and Orthotics Market

The global prosthetics and orthotics market plays a vital role in improving quality of life for millions worldwide. Worth an estimated $7.2 billion in 2024, the market facilitates mobility for those with limb differences or injuries through highly customized external limb replacements and braces. The market introduces prosthetics and orthotics—Medical devices that enhance or assist impaired body parts and mobility. Orthotics are braces or supports for joints, spine, and limbs; prosthetics externally replace missing limbs. Together they improve functionality and quality of life for users. Major players in the prosthetics and orthotics space utilizing advanced manufacturing include Ossur, Steeper Group, Blatchford, Fillauer, Ottobock, and WillowWood Global. These industry leaders increasingly deploy cutting-edge 3D printing and customized design software to produce state-of-the-art prosthetics and braces. Current trends in the prosthetics and orthotics market include growing utilization of 3D printing and advanced manufacturing techniques. 3D printing enables on-demand production of complex, customized devices. It reduces manufacturing costs and wait times while improving fit and comfort. Expanding material options also allow more lifelike prosthetics. As technology evolves, the market is positioned for continued growth through 2031 in facilitating mobility worldwide. Future Outlook The prosthetics and orthotics market is expected to witness significant advancements in the coming years. Manufacturers are constantly focusing on developing innovative technologies such as 3D printed prosthetics that provide a better fit, enhanced comfort, and unrestricted movement. There is also a rising trend of using lightweight, highly durable and comfortable materials like carbon fiber and thermoplastics to manufacture prosthetic devices. Advancements in myoelectric prosthetics with touch and motion sensors are making them more dexterous and responsive. Using pattern recognition and machine learning techniques, next-gen prosthetics could gain functionality approaching that of natural limbs.

PEST Analysis Political: Regulations regarding clinical trials and approvals of new prosthetic technologies may affect market growth. Favorable reimbursement policies for prosthetic devices can boost adoption. Economic: Rising disposable incomes allow more individuals to opt for higher-end prosthetics. Emerging markets present abundant opportunities for growth. Inflation and economic slowdowns can hinder market profitability. Social: Increasing incidence of amputations and disabilities due to aging population, accidents, war injuries etc. drive market demand. Growing awareness regarding prosthetics and orthotics aids adoption. Stigma associated with limb loss poses challenges. Technological: Advancements in materials, manufacturing techniques like 3D printing, sensors, computing power and battery technologies are enhancing functionality and usability of prosthetics/orthotics. Myoelectric and robotic prosthetics have vastly improved in recent years. Opportunity Rising aging population presents a huge opportunity for prosthetics and orthotics targeting mobility issues and disabilities. Over 630,000 amputations occur annually in the U.S. due to dysvascular conditions like diabetes, presenting a sizable patient pool. Expanding applications of prosthetics and orthotics beyond mobility impairment into sports and military could drive significant growth. Growing incidence of trauma and injuries globally increases the number of patients relying on these devices. Emerging markets like Asia Pacific and Latin America offer immense opportunities owing to increasing disposable incomes, expanding healthcare infrastructure and rising medical tourism. Technological advancements are constantly improving functionality and usability of prosthetic devices, fueling adoption rates. The lightweight, durable and comfortable characteristics of newer materials expand addressable indications and patient acceptance. Key Takeaways Growing demand from aging population: The rapid increase in aging population worldwide who are prone to mobility issues, disabilities and chronic diseases like diabetes is a key driver spurring sales of orthotic and prosthetic devices. Global expansion into emerging markets: Emerging markets like Asia Pacific, Latin America, Eastern Europe and the Middle East offer immense opportunities owing to their large population bases and improving healthcare penetration. Technological advancements: Constant R&D bringing advancements in areas such as 3D printing, lightweight materials,

4 notes

·

View notes

Text

Maintenance Tips for Optimal EV Battery Health

The battery is the heart of an electric vehicle (EV), and maintaining its health is crucial for ensuring the longevity and efficiency of your ride. Electric vehicles are reshaping the automotive landscape with their eco-friendly credentials and low operational costs. As an EV owner, one of your top priorities should be battery maintenance. Here's how you can ensure your EV's battery remains in tip-top shape.

Understanding Your EV Battery

Before diving into maintenance tips, it's essential to understand what your EV battery is made of and how it functions. Most EVs use lithium-ion batteries, similar to those in your smartphone but on a much larger scale. These batteries are preferred for their high energy density and long life span. They consist of cells grouped into modules, which together make up the battery pack. A Battery Management System (BMS) monitors and regulates the battery's temperature, voltage, and current.

Regular Use and Driving Habits

One of the simplest ways to maintain your EV's battery is by using your vehicle regularly. Long periods of inactivity can negatively affect battery health. When driving, it's wise to avoid pushing your EV to its limits too often. Frequent high-speed driving and rapid acceleration can strain the battery, reducing its lifespan. Data suggests that EVs driven smoothly and at consistent speeds can see battery life extended by up to 10%.

Optimal Charging Practices

Charging habits significantly impact your EV's battery health. Although it may seem convenient to charge your battery to 100% every time, it's better to keep it between 20% and 80% most of the time. This practice, known as 'shallow charging,' can extend your battery's life. According to a study by Battery University, lithium-ion batteries kept at a 100% charge level at all times can lose up to 20% capacity in a year, while those kept at 80% showed only a 4% loss.

Temperature Management

Extreme temperatures are the enemy of EV batteries. Exposure to high temperatures can lead to faster chemical reactions within the battery, potentially reducing its capacity and life span. Conversely, cold temperatures can decrease the battery's efficiency and range. While you can't control the weather, you can minimize exposure to extreme temperatures by parking in the shade or a garage. Using your EV's pre-conditioning function, if available, can bring the battery to an optimal operating temperature before you set off, without taxing the battery itself.

Software Updates and Professional Servicing

Keeping your EV's software up to date is a vital part of battery maintenance. Automakers frequently release software updates that can improve battery management and efficiency. Additionally, periodic professional check-ups can catch potential issues before they become serious problems. Battery systems are complex and can benefit from a diagnostic eye. Manufacturers often provide detailed guidance on maintenance intervals, and following these can prolong the life of your battery.

Long-Term Storage

If you plan to store your EV for an extended period, it's important to prepare the battery properly. The ideal charge level for long-term storage is around 50%. Additionally, it's best to store your EV in a cool, dry place and to check the charge level every few months, topping it up if necessary.

Recalibration and Balance

Over time, an EV battery can lose its calibration, meaning the car's estimate of the charge level may become less accurate. To recalibrate, you should fully charge and then fully discharge the battery once every few months. This process helps maintain cell balance and ensures that the BMS accurately reads the battery's state of charge.

Your electric vehicle's battery health is paramount to its performance and longevity. By following these maintenance tips and keeping abreast of the latest care techniques, you can help ensure that your EV remains a reliable and efficient mode of transportation for years to come. With more manufacturers investing in battery technology and longevity, we can anticipate even more robust batteries in the future. However, for now, these tips serve as a foundation for responsible EV ownership and battery care.

4 notes

·

View notes

Text

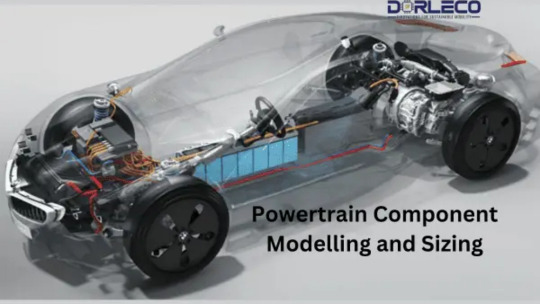

Powertrain Component Modelling and Sizing

Introduction

The dynamic automotive sector is depending more and more on virtual engineering and digital simulations to satisfy strict performance, efficiency, and regulatory requirements. The core of a vehicle’s design is the powertrain, which is the collection of elements that are accountable for generating and distributing power to the wheels. In order to achieve the best possible balance between performance, fuel efficiency, cost, and emissions, powertrain component modelling and size are crucial, regardless of the powertrain’s configuration — internal combustion engine (ICE), hybrid, or entirely electric. The systematic technique, advantages, difficulties, and prospects for powertrain component modelling and sizing in the automotive engineering process are all examined in this blog.

1. Understanding the Powertrain Component

Determining the vehicle’s intended use and performance goals is the first step in any powertrain development cycle. This fundamental stage lays the groundwork for component-level specifications and architectural choices.

Vehicle Type: EV, hybrid, commercial vehicle, sports car, or passenger car.

Performance metrics: include top speed, gradeability, towing capacity, and desired acceleration (0–100 km/h).

Compliance goals include safety regulations, fuel economy requirements, pollution regulations, and sustainability goals.

A thorough comprehension of these factors guarantees that the finished powertrain design complies with regulatory standards and market expectations.

2. Powertrain Architecture Selection

The type of vehicle and its intended use have an impact on the strategic choice of powerplant layout. Among the primary categories are:

Engine Internal Combustion (ICE)

Powertrain Hybrid (PHEV, HEV)

Electric Vehicles with Batteries (BEV)

Electric Vehicles using Fuel Cells (FCEV)

Core elements such the engine, electric motor, battery, gearbox, and control units must interact differently in each architecture. For downstream modelling, it is crucial to map the component interaction and energy flow paths at this point.

3. Modelling at the Component Level

Modelling engines

Modelling for ICE-based systems includes:

Creation of torque-speed curves

Mapping of fuel consumption

Emissions modelling and thermal behaviour

To model operating circumstances, assess combustion efficiency, and investigate transient responses, advanced programs such as GT-Power, AVL Cruise, or MATLAB/Simulink are used.

1.Modelling Transmissions

In this context, the gearbox connects wheel torque and engine power, while modelling helps determine:

Ideal gear ratios

Timing and logic for gear changing

Losses brought caused by inertia and friction

Reactivity and driveability

Single-speed gearboxes are frequently used in electric vehicles; nonetheless, efficiency and thermal considerations are still crucial.

2. Modelling Electric Motors and Batteries

In systems that are electrified:

Electric Motor: Efficiency mapping, torque-speed characteristics, inverter management, and the possibility of regenerative braking are all included in the simulations.

State of charge (SOC), voltage-current profiles, thermal performance, capacity decline, and charging/discharging behaviour are all included in the models of batteries.

Consequently, these components play a vital role in enabling accurate range estimation and supporting effective hybrid control schemes.

3. Control System Modelling

To that end, modern cars use intelligent control algorithms to regulate the flow of torque and energy. Key elements include:

Distribution of power in hybrid automobiles

Energy management systems for batteries (BMS)

Control of traction and stability

Regenerative braking and torque vectoring

Furthermore, control system modelling optimises real-time responses by ensuring smooth interaction between physical components.

4. Component sizing and optimisation

Each component is guaranteed to be neither overdesigned nor underutilised with proper dimensions. Engineers optimise variables like

Engine displacement and output torque

Maximum power and continuous motor rating

C-rate and battery capacity

Gear ratios for transmissions

The proper trade-offs between performance, efficiency, cost, and packing can be achieved with the aid of optimisation technologies (such as genetic algorithms and experiment design).

5. Compatibility and System Integration

The powertrain must function as a cohesive system in addition to its individual performance. Important integration factors consist of:

Thermal control of the battery, inverter, and engine.

Packaging and weight distribution to maintain vehicle dynamics

Features of NVH (Noise, Vibration, Harshness)

Compatibility of mechanical and electrical interfaces

Therefore, ignoring these elements may lead to inefficiencies, reliability issues, or dissatisfied clients.

6. Performance Validation Through Simulation

Subsequently, once components are designed and scaled, system-level simulations are conducted to validate the full powertrain component across real-world scenarios.

Urban driving cycles, such as the FTP-75 and WLTP

Profiles of highway loads

Simulations of hill climbing or towing

Conditions for idle-stop and regenerative braking

Engineers can create control methods and identify bottlenecks early in the process with the help of simulation technologies (such as MATLAB, dSPACE, and IPG Carmaker).

7. Physical Testing and Prototyping

Although simulation offers a theoretical starting point, physical testing is still necessary:

Prototype vehicle builds

Engine test beds and dynamometers for the chassis

Tests of endurance and durability

Prior to mass production, these tests ensure system robustness by validating predictions and identifying unforeseen mechanical, thermal, or ergonomic concerns.

8. Cost Analysis and Compromises

Additionally, a high-performance Powertrain Component needs to be profitable. Cost modelling includes:

Complexity of manufacturing and material selection

Tooling expenses and supplier availability

Implications for warranty and maintenance

In addition, simulations help identify cost-effective solutions without sacrificing critical performance parameters.

9. Iterative Refinement

In practice, the development process is rarely linear; instead, several design iterations are driven by insights gained from simulation, testing, and consumer feedback.

Modifying component specifications

Control logic revision

Power split or thermal load rebalancing

Consequently, this iterative loop ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

10. Records and Adherence

As a result, this iterative loop not only streamlines development but also ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

Logs from simulations and technical reports

Design specifications and the bill of materials

Safety requirements and emissions certifications

Design decision traceability

Proof of due diligence throughout the development process is necessary to comply with international rules (such as those set forth by the EPA, CARB, and UNECE).

Benefits of Powertrain Component Modelling and Sizing:

✔ Performance Enhancement

Fine-tuning for certain objectives, such as high torque, quick acceleration, or fuel economy, is possible through simulation.

✔Enhanced Productivity

Appropriate size improves energy efficiency on both ICE and EV platforms by preventing overdesign and lowering internal losses.

✔ Saving Money

Furthermore, by avoiding needless overspecification, manufacturers can effectively reduce manufacturing and material costs without compromising quality.

✔ Emissions Management

As a result of precise engine mapping and electric system optimisation, CO₂ and NOₓ emissions are significantly reduced.

✔ Predictive Knowledge

Prior to costly tooling and prototyping, simulations identify possible failure areas or inefficiencies.

✔ Personalisation

The architecture and Powertrain Component flexibility made possible by early modelling is advantageous for a variety of vehicle types, including haul trucks and two-wheelers.

✔ Superior Energy Organisation

Reliability and range are directly impacted by efficient battery and power management systems, particularly in EVs and hybrids.

✔ Reduced Market Time

Virtual iterations make faster development cycles possible as opposed to conventional build-and-test loops.

✔ Dependability

Moreover, stress analysis and thermal modelling ensure durability, which in turn lowers warranty claims and enhances brand recognition.

✔ Attention to Regulations

By ensuring early compliance with international safety and emissions standards, manufacturers can significantly reduce the need for costly redesigns later in the development cycle.

Difficulties with Powertrain Component Sizing and Modelling

Despite its strength, this strategy has drawbacks: Model Complexity: It takes knowledge and computing power to accurately simulate multi physics systems. Data Reliability: Reliable input data is necessary for model accuracy, which frequently necessitates rigorous physical testing for calibration. Integration Difficulties: Maintaining balance between electrical, mechanical, and control systems is difficult. Dynamic Operation Limits: Unexpected real-world circumstances are not always taken into account by models. Cost of Software Tools: Smaller businesses cannot afford the sophisticated simulation suites. Rapid Technological Changes: As EVs advance quickly, current models may become outdated. Real-World Parameter Uncertainty: It is challenging to accurately forecast traffic, temperature, and driver behaviour.

Conclusion

At the forefront of contemporary vehicle engineering is the modelling and sizing of powertrain components. In a cutthroat market, they enable automakers and suppliers to create vehicles that are effective, legal, and perform well. Engineers may unlock better ideas while cutting down on time, expense, and environmental effect by combining virtual simulations with actual testing. Modelling techniques will only become more crucial as the sector continues its transition to electrification and autonomous systems. Experts anticipate that future developments in digital twins, AI-driven simulations, and cloud-based co-simulation platforms will further push the limits of accuracy and effectiveness. Powertrain modelling and sizing are essentially strategic enablers of innovation, performance, and sustainability in mobility when used with insight and rigour.

#Dorleco#EVEngineering#PowertrainModelling#AutomotiveInnovation#VCU#CANDisplay#BatteryManagement#SimulationDrivenDesign#ElectricVehicles#MobilitySolutions#FutureOfTransport#EngineeringExcellence#DigitalEngineering

0 notes

Text

Exploring Tesla's Schedule of Sustainable Houses: Which One is Right for You?

Introduction

In a globe significantly focused on sustainability and cutting-edge living services, Tesla has become a leader, not simply in electric cars yet additionally in sustainable real estate. With Elon Musk at the helm, the firm has actually made headings with where to find elon musk $10,000 house its ambitious vision of creating cost effective and green homes. This short article discovers Tesla's schedule of sustainable homes, including their unique features, pricing information, and schedule. Whether you're interested by the idea of a Tesla small house or considering purchasing an extra standard Tesla home, we'll assist you determine which alternative lines up finest with your way of living needs.

Exploring Tesla's Schedule of Lasting Houses: Which One is Right for You? A Peek right into Tesla's Vision for Sustainable Living

Tesla's technique to sustainable living incorporates renewable energy modern technologies perfectly integrated right into architectural designs. The business pictures homes that are not just eco-friendly yet additionally technically progressed, making use of solar energy, battery storage space systems, and energy-efficient appliances.

What Makes Tesla Homes Unique? Integration with Solar Technology Every Tesla home comes equipped with solar panels. These panels produce tidy energy that can power the home. Powerwall Battery Systems Homes consist of Tesla's Powerwall technology. This enables home owners to save excess energy produced throughout the day for nighttime use. Smart Home Features Advanced innovation regulates home heating, air conditioning, and lighting. Integration with mobile applications ensures convenience and efficiency. Understanding Tesla's Home Offerings

Tesla uses numerous models that satisfy various way of livings and budget plans. Right here's a breakdown:

The Affordable Alternative: Elon Musk's $10,000 House Often referred to as the Elon Musk $10,000 house, this design has actually gathered tremendous interest. It represents an attempt to make homeownership available to everyone. Where Can You Get It?

If you're wondering about where to acquire this home, it's important to remain upgraded via Tesla's official channels or relied on real estate systems because specific listings might differ based on availability.

Tesla Tiny House: A Minimalist Approach The Tesla tiny house personifies minimalist living without compromising modern conveniences. Ideal for individuals or pairs seeking budget-friendly yet elegant accommodations. Comparing Costs: What Can You Expect?

|Model|Estimated Rate|| --------------------------|-----------------|| Elon Musk $10,000 House|$10,000|| Tesla Tiny Home|$15,000|| Requirement Tesla Home|Varies (check neighborhood listings)|

Are Tesla Homes Available in the U.S.?

Yes! Already, are Tesla homes available in the US? The answer is affirmative however differs by state because of regional guidelines and schedule. It's advisable

0 notes

Text

Building a Sustainable Future: How LOHUM is Leading the Charge in Lithium-Ion Battery Recycling

As global electric vehicle (EV) sales are projected to surge by 35% in 2023 alone, the demand for lithium-ion batteries is set to skyrocket. Not only are these batteries powering our electric cars, but they are also central to clean energy storage solutions for solar power systems, electric scooters, motorcycles, and even planes. However, with this surge comes a new challenge: managing the massive influx of retired batteries. This is where LOHUM, a BWMR Registered Partner, is leading the way with its innovative recycling and repurposing technologies.

The Growing Demand for Lithium-Ion Batteries

The lithium-ion battery market is expanding at an unprecedented rate, driven by the global shift towards electric mobility and sustainable energy storage. According to estimates, the number of retired EV batteries alone could exceed half a million vehicles annually by 2030, translating to over 2 million metric tonnes of batteries per year. But while the demand for these batteries rises, so does the critical need for sustainable disposal and recycling solutions.

Recycling lithium-ion batteries isn't just about waste management—it’s about creating a sustainable supply of lithium-ion battery precursors. Currently, only about 5% of lithium-ion batteries are recycled worldwide, compared to an impressive 99% recycling rate for lead-acid batteries. This disparity highlights the urgent need for advanced recycling infrastructures to recover valuable minerals such as lithium, cobalt, nickel, and manganese.

LOHUM is stepping up to meet this need with state-of-the-art recycling technologies that not only recover these critical materials but also do so in a cost-effective and environmentally friendly manner.

LOHUM's Commitment to Sustainable Battery Recycling

LOHUM has established itself as a BWMR Registered Partner, aligning its recycling practices with global best standards. The company’s mission is to close the loop on lithium-ion battery materials, ensuring that the critical minerals used in these batteries are reclaimed and reintroduced into the supply chain efficiently. This commitment not only reduces dependency on newly mined materials but also significantly lessens the environmental impact associated with battery disposal.

The company's multi-layered recycling approach involves:

Discharging and Shredding: Batteries are safely discharged to minimize fire risk, then shredded to break down their components.

Materials Recovery: Through hydrometallurgy and pyrometallurgy processes, LOHUM extracts valuable minerals from the shredded materials. Unlike traditional methods, which often lose lithium during recovery, LOHUM's proprietary technology maximizes lithium extraction, ensuring even the finest particles are salvaged.

Direct Recycling Techniques: LOHUM employs advanced direct recycling methods that preserve the cathode's structure, maintaining the integrity of lithium-ion battery precursors. This innovation not only enhances the purity of recovered materials but also reduces the energy required for reprocessing.

Why Recycling Lithium-Ion Batteries is Essential for the Future

The global market for lithium-ion battery precursors is projected to grow exponentially, and recycling will be a cornerstone in meeting this demand sustainably. Here’s why:

Resource Conservation: Lithium, cobalt, and nickel are not infinite. Mining these materials depletes natural resources, disturbs ecosystems, and creates geopolitical dependencies. Recycling provides a sustainable supply chain alternative.

Environmental Impact: Traditional mining operations have severe environmental impacts, including water depletion and pollution. Recycling reduces the need for mining and lowers carbon emissions by repurposing existing materials.

Cost Efficiency: As the costs of raw materials fluctuate—sometimes by as much as 300% in a single year—recycled materials offer a stable, cost-effective alternative. In fact, the value of recovered battery material could reach $600 per ton by 2025, according to McKinsey.

Energy Security: By reclaiming critical minerals domestically, LOHUM is helping to build a more resilient and self-sufficient energy grid.

The Future of Lithium-Ion Battery Recycling with LOHUM

As part of its long-term vision, LOHUM is investing heavily in cutting-edge recycling technologies that promise to reshape the battery industry. One of the standout innovations is direct cathode recycling, which allows the cathode material to be rejuvenated and refunctionalized without the need for energy-intensive re-synthesis. This not only enhances battery performance but also reduces the carbon footprint of manufacturing new batteries.

Moreover, LOHUM is expanding its global footprint, with a focus on sustainable practices that align with international standards. As a BWMR Registered Partner, the company is not just keeping pace with industry demands—it is setting the standard for sustainable battery recycling.

Closing the Loop: A Sustainable Vision for Tomorrow

In a world rapidly moving towards electrified mobility and renewable energy, LOHUM is at the forefront of a crucial industry shift. By pioneering sustainable recycling methods and reintroducing lithium-ion battery precursors into the market, the company is closing the loop on battery production and redefining how we think about energy storage.

As electric vehicles, solar storage, and grid applications continue to grow, LOHUM is committed to powering the future responsibly—one recycled battery at a time.

LOHUM: Powering a Sustainable Future, One Battery at a Time.

Would you like me to make it even more impactful with an engaging opening story or a call to action at the end?

Visit us at: lithium-ion battery repurposing companies

#lohum#critical minerals#li-ion battery waste management#lithium battery reusing and recycling#3 wheeler ev battery#battery waste management#lithium battery waste recycling#reverse logistics for lithium-ion batteries

0 notes

Text

Why You Should Always Call the Best Towing Company in Gulfport, FL for Emergencies

Emergencies on the road can happen at any time, leaving drivers stranded, frustrated, and unsure of what to do next. Whether you’re dealing with a flat tire, a dead battery, or a vehicle breakdown, having a reliable towing service on call can make all the difference. When facing roadside emergencies, calling the best towing company in Gulfport, FL ensures you receive prompt, professional, and efficient assistance. Here’s why relying on the best towing service is always the smartest choice.

Fast Response Times for Urgent Situations

During an emergency, every minute counts. The best towing company in Gulfport, FL understands the importance of quick response times and is available 24/7 to assist you. Whether you’re stranded in the middle of the night or stuck on the side of the road during rush hour, a professional towing service ensures that help arrives as quickly as possible. This fast response reduces the stress and danger of being stranded on the road.

Professional Expertise and Equipment

Towing is not just about hooking a car to a truck and driving off. It requires expertise, precision, and the right equipment to ensure the safety of your vehicle. Professional towing companies have trained technicians who know how to handle different types of vehicles, including motorcycles, sedans, SUVs, and even large trucks. With state-of-the-art equipment and skilled operators, your vehicle is in safe hands.

Safety and Damage Prevention

Attempting to tow a vehicle yourself or relying on an inexperienced service can lead to further damage. Improper towing techniques can harm your vehicle’s transmission, brakes, or suspension. By choosing the best towing company in Gulfport, FL, you ensure that your car is handled with care, using the correct towing methods and equipment to prevent unnecessary damage.

24/7 Availability for Peace of Mind

Car trouble doesn’t follow a schedule. Whether it’s early in the morning or late at night, breakdowns and accidents can happen when you least expect them. A reliable towing company operates around the clock, ensuring that you’re never left without help when you need it most. No matter the time or location, professional tow truck drivers are ready to assist.

Wide Range of Services

The best towing company in Gulfport, FL offers more than just towing. Many top-rated towing services provide roadside assistance, including jump-starts, tire changes, lockout services, and fuel delivery. This means that even if your car doesn’t need to be towed, you can still rely on professionals to get you back on the road quickly.

Affordable and Transparent Pricing

One concern many drivers have when calling a towing service is the cost. The best towing companies provide fair and transparent pricing with no hidden fees. Reliable towing services will provide an estimate upfront, so you know exactly what to expect. Choosing a reputable towing company ensures that you receive high-quality service at a reasonable price.

Local Expertise and Trustworthiness

Hiring a local towing company means working with professionals who know the Gulfport, FL area well. They understand the local roads, traffic patterns, and potential hazards, which allows them to navigate quickly and efficiently to your location. Additionally, local businesses rely on their reputation, meaning they are more likely to provide top-notch service to maintain customer trust and satisfaction.

Emergency Roadside Assistance Reduces Stress

Breaking down in an unfamiliar or unsafe area can be a stressful and even dangerous experience. Knowing that help is just a phone call away provides peace of mind. The best towing company in Gulfport, FL takes the stress out of roadside emergencies by offering reliable and professional assistance whenever you need it.

Avoiding Further Damage to Your Vehicle

Inexperienced or unprofessional tow operators can cause additional harm to your car by using incorrect towing techniques. A reputable towing company follows industry best practices to ensure your vehicle is transported without scratches, dents, or mechanical stress. This is especially important for modern cars with complex electronics and sensitive components.

Comprehensive Roadside Assistance Services

The best towing companies in Gulfport, FL, don’t just tow—they offer full roadside assistance, including:

Jump starts (for dead batteries)

Tire changes (for flats or blowouts)

Lockout services (if you’re locked out of your car)

Fuel delivery (if you run out of gas)

Winching and recovery (for stuck or off-road vehicles)

Having a single company that can handle multiple issues saves you time and stress.

Final Thoughts

When faced with a roadside emergency, calling the best towing company in Gulfport, FL is the safest and most reliable choice. With fast response times, expert handling, 24/7 availability, and a wide range of services, professional towing companies ensure that you receive the help you need without unnecessary delays or risks. Whether you need a tow, a battery jump-start, or other roadside assistance, trusting the best in the business guarantees safety, efficiency, and peace of mind.

0 notes

Text

Battery Management System in Electric Vehicles: A Complete Guide

Introduction

Electric vehicles (EVs) are revolutionizing the automotive industry with their eco-friendly nature and efficient performance. At the core of every EV is its battery pack, which requires a sophisticated Battery Management System (BMS) to ensure safety, efficiency, and longevity. This guide explores what a BMS is, its components, functions, and why it is essential for electric vehicles.

What is a Battery Management System (BMS)?

A Battery Management System (BMS) is an electronic system that monitors and manages a rechargeable battery pack. It ensures optimal performance, prevents overcharging and deep discharging, balances cell voltages, and enhances battery life. Without a BMS, an EV battery could suffer from degradation, overheating, or even failure.

Key Functions of a BMS in EVs

1. Battery Monitoring

Measures key parameters such as voltage, current, and temperature.

Monitors the State of Charge (SoC) to estimate the remaining energy.

Tracks the State of Health (SoH) to assess battery longevity.

2. Cell Balancing

Ensures equal charging and discharging of all battery cells.

Prevents weaker cells from degrading faster than others.

Uses passive or active balancing techniques for uniform performance.

3. Thermal Management

Prevents overheating by managing cooling and heating systems.

Uses temperature sensors to detect abnormal heat levels.

Optimizes battery performance under various weather conditions.

4. Overcharge and Over-Discharge Protection

Prevents overcharging, which can cause thermal runaway.

Stops deep discharging to avoid battery damage.

Ensures each cell operates within safe voltage limits.

5. Fault Detection and Safety Management

Detects issues like short circuits, internal faults, and cell failures.

Triggers safety mechanisms such as shutdown or isolation.

Communicates warnings to the vehicle’s main control unit.

Components of a BMS

A BMS consists of multiple hardware and software components, including:

Battery Control Unit (BCU): The central processor that manages battery operations.

Voltage and Current Sensors: Measure real-time parameters of the battery pack.

Temperature Sensors: Monitor heat levels to prevent overheating.

Cell Balancing Circuit: Maintains uniform charge distribution.

Communication Interface: Connects to the vehicle’s control system for data exchange.

Types of BMS Architectures

1. Centralized BMS

Single control unit for the entire battery pack.

Simple design but less scalable for larger packs.

2. Distributed BMS

Multiple smaller units handling different battery sections.

Offers better scalability and redundancy.

3. Modular BMS

Combination of centralized and distributed architectures.

Provides flexibility for different battery pack sizes.

Importance of BMS in Electric Vehicles

Enhances Battery Life: Proper charge management reduces wear and tear.

Improves Safety: Detects and prevents potential hazards.

Increases Efficiency: Optimizes energy usage for better mileage.

Provides Real-Time Data: Helps with predictive maintenance and monitoring.

Future of Battery Management Systems

As EV technology advances, BMS is evolving with features like:

AI-Powered Predictive Maintenance

Wireless BMS for Simplified Design

Integration with Smart Grids for Enhanced Charging

Conclusion

A Battery Management System is the backbone of an electric vehicle’s battery pack, ensuring safety, efficiency, and reliability. As EV adoption grows, advancements in BMS technology will play a crucial role in making electric mobility more sustainable and efficient.

For more information battery management system for electric vehicle

#bms#battery management system#lithion#lithium battery#lithion power#batterymanagementsystem#electricvehicle#ev#lithionpower

0 notes

Text

Battery Charging IC Market to Witness Comprehensive Growth by 2032

Battery charging ICs are devices that regulate current and voltage within a battery. They are commonly used in portable devices such as cell phones, tablets, and laptops. Among various types of batteries, Li-ion battery charger ICs have emerged as the promising ones because of their unique characteristics. These batteries have greater energy densities, offering higher voltage per cell and tolerating higher currents. In the past few years, battery charging IC technology has undergone a huge transformation, offering new applications across diverse industries. Continuous advancements in this field focus on enhancing the efficiency, flexibility, and thermal management of batteries. Soft switching has evolved as a new technique in the domain that offers greater efficiency and enables lower heat generation. By minimizing energy losses and electromagnetic interference, these switching models boost the performance of battery chargers. Moreover, in traditional battery charging ICs, diodes are used to provide fixed forward voltage losses which act as essential components in charging designs. However, in today’s ICs, diodes are replaced with active semiconductor switches, offering a bridgeless converter topology. On the other hand, the rapid integration of Gallium Nitride and Silicon Carbide enables faster switching and reduces energy losses. This development reduces the use of passive magnetic components and minimizes heatsinks, rendering a more compact charging system. Many leading manufacturers have started integrating DC-DC converters in these devices to decrease system cost and complexity by eliminating additional components, interconnections, and assembly steps. The configuration of offboard DC fast charging stations simplifies the overall charging process and supports the functionalities of onboard chargers with a hybrid of AC and DC charging.

These charging ICs have penetrated various industries, including consumer electronics, automotive, and the power industry for potential applications. This diverse applicability of the systems has boosted the growth of the battery charging IC market. According to Allied Market Research, the industry is projected to manifest a CAGR of 9.2% from 2024 to 2032. In consumer electronics, these devices manage charging for gadgets such as smartphones and laptops, ensuring enhanced battery performance. In the automotive sector, they are deployed in EVs to optimize power delivery and vehicle safety. Also, many power businesses have started implementing these ICs in energy storage systems to enhance grid management. In July 2024, Eatron Technologies, a renowned technology company offering advanced battery solutions, announced the launch of its cutting-edge battery management technology. The firm introduced a next-generation AI-powered Battery Management System on Chip in partnership with Syntiant, a leader in delivering end-to-end deep learning solutions. This technology is developed with the integration of Eatron’s intelligent software layer and Syntiant’s ultra-low-power NDP120 neural decision processor. This product is designed to deliver unparalleled battery performance, safety, and longevity. AI-BMS-on-chip has represented a notable advancement in battery management, providing energy-efficient systems with an additional 10% battery capacity and extending battery life by up to 25%. This advanced solution improves battery power by offering precise state-of-charge and health estimations. Additionally, by providing early detection of potential issues through predictive diagnostics, this system provides operational safety and prevents failures. Furthermore, the solution incorporates the processing capabilities of Syntiant’s NDP120, which enables it to operate efficiently in the cloud infrastructure. This further results in lower latency, reduced power consumption, and overall system costs. Nonetheless, because of its seamless integration, AI-BMS-on-chip is beneficial for a wide range of battery-powered applications, which include consumer electronics, mobility, and industrial purposes. The solution also offers customization capabilities through a toolchain that allows users to adapt functionalities to suit specific applications. It also provides cost-effective alternatives for businesses seeking advanced battery technologies to gain a competitive edge. Battery charging ICs have become essential components in modern electronics, meeting the emerging demands of modern businesses. Moreover, the rising adoption of EVs and the rapid advancements in charging technologies are expected to create new avenues for the landscape in the coming years.

0 notes

Text

Quantum Computing and Green Tech: The Next Leap in Energy Efficiency

The urgency to transition towards sustainable energy solutions has never been greater. With global energy consumption skyrocketing and climate change concerns mounting, businesses are looking to cutting-edge technologies to drive efficiency and sustainability. One of the most promising advancements in this space is quantum computing. While still in its early stages, quantum computing has the potential to revolutionize green tech by optimizing energy consumption, reducing emissions, and accelerating the development of cleaner alternatives.

The Energy Challenge in a Data-Driven World

In the digital age, businesses and economies are increasingly dependent on vast computational power. Traditional data centers, which support everything from cloud computing to artificial intelligence, consume enormous amounts of energy. According to recent estimates, data centers alone account for nearly 1% of global electricity demand. With the continued expansion of artificial intelligence, blockchain, and big data, this energy footprint is expected to grow significantly.

This is where quantum computing enters the picture. Unlike classical computers, which process information in binary (0s and 1s), quantum computers leverage quantum bits (qubits) that can exist in multiple states simultaneously. This capability allows quantum systems to process complex computations exponentially faster than classical counterparts, reducing energy usage for large-scale computational tasks.

Quantum Computing: The Catalyst for Energy Efficiency

1.Optimizing Energy Grids

Green tech initiatives, particularly in renewable energy, require sophisticated grid management systems. Quantum computing can enhance grid optimization by rapidly analyzing massive datasets related to power consumption, weather patterns, and energy storage. This results in more efficient energy distribution and reduced waste, enabling a more resilient and sustainable power infrastructure.

2.Revolutionizing Battery Technology

One of the biggest challenges in the renewable energy sector is efficient energy storage. Traditional lithium-ion batteries have limitations in longevity and efficiency. Quantum computing can accelerate the discovery of new battery materials by simulating complex molecular structures at an unprecedented speed. This could lead to the development of next-generation batteries that are not only more efficient but also more environmentally friendly.

3.Enhancing Carbon Capture and Climate Modeling

Carbon capture and storage (CCS) technologies are crucial in mitigating climate change, but they require immense computational power to model and optimize capture processes. Quantum computing can dramatically improve the efficiency of these models, enabling faster development of techniques to remove carbon dioxide from the atmosphere. Additionally, quantum-driven climate simulations can provide more accurate predictions, helping policymakers and businesses develop better sustainability strategies.

4.Material Science for Green Manufacturing

Green tech depends heavily on the discovery of sustainable materials, whether for solar panels, energy-efficient construction, or biodegradable electronics. Quantum computing can significantly accelerate material science research, uncovering new compounds that can make green manufacturing more viable and cost-effective.

Expanding Quantum’s Role in Sustainability

1.Accelerating Drug Discovery for Eco-Friendly Solutions

The pharmaceutical industry is another area where quantum computing can contribute to sustainability. By rapidly simulating molecular interactions, quantum computers can facilitate the discovery of eco-friendly drugs and biodegradable medical materials, reducing waste and pollution.

2.Improving Logistics and Supply Chain Management

Efficient supply chains play a crucial role in sustainability. Quantum algorithms can optimize transportation routes, reduce fuel consumption, and minimize waste in global supply chains, making them more sustainable and cost-effective.

3.Quantum Cryptography for Secure Green Energy Transactions

With the rise of decentralized energy systems and smart grids, cybersecurity is a growing concern. Quantum cryptography can enhance security in energy transactions, ensuring that green tech initiatives operate safely and efficiently.

Challenges and the Road Ahead

While the potential of quantum computing in green tech is vast, several challenges remain. Quantum computers are still in their infancy, with hardware constraints and error rates that limit their immediate applicability. Additionally, these systems require extremely low temperatures to function, which poses energy consumption concerns of their own. However, with major tech players such as IBM, Google, and startups like IonQ investing heavily in quantum research, breakthroughs are expected within the next decade.

For businesses and investors, now is the time to explore quantum computing’s potential impact on sustainability. Early adopters who integrate quantum-driven solutions into their green tech strategies will likely gain a competitive edge as the technology matures.

The Role of Governments and Regulations

Governments around the world have recognized the potential of quantum computing and are investing billions into research and development. Policymakers are also looking at regulatory frameworks that ensure quantum technologies align with green tech objectives. By fostering public-private collaborations, governments can drive quantum innovations that directly benefit sustainability efforts.

Preparing for a Quantum Future

To harness the full potential of quantum computing in green tech, businesses must start preparing now. Companies should invest in workforce training, research partnerships, and pilot projects to understand how quantum algorithms can be integrated into their existing systems. As quantum hardware becomes more accessible, early adopters will have a distinct advantage in developing sustainable, energy-efficient solutions.

Conclusion

Quantum computing represents a paradigm shift in computing, with profound implications for energy efficiency and sustainability. As green tech continues to evolve, integrating quantum computing into areas such as energy grids, battery storage, carbon capture, and material science could redefine how we tackle climate change.

For C-suite leaders, startup entrepreneurs, and managers, the intersection of quantum computing and green tech is not just a futuristic concept—it’s an imminent revolution. Those who position themselves at the forefront of this technological leap will not only drive sustainability but also unlock new business opportunities in a rapidly shifting economic landscape.

Uncover the latest trends and insights with our articles on Visionary Vogues

0 notes

Text

iphone 11 pro max screen replacement

Welcome to the Best Apple Service Center – Your Trusted Partner for Device Repairs

In today’s digital world, our devices have become an integral part of our daily lives. Whether it’s an iPhone, MacBook, or Apple Watch, having a reliable service center to handle repairs is essential. If you are looking for the Best AppleCare Service Center, look no further. We specialize in professional repair services for all Apple devices, ensuring that your gadgets are restored to their optimal condition.

Why Choose Our Apple Service Center?

Choosing the right service center for your Apple devices is crucial. Here’s why we stand out:

Certified Technicians: Our team consists of experienced professionals trained in Apple device repairs.

Genuine Parts: We use only authentic Apple parts to ensure the longevity and performance of your device.

Quick Turnaround: Most repairs are completed within the same day.

Affordable Pricing: We provide competitive pricing without compromising on quality.

Warranty Assurance: Our repairs come with a warranty for added peace of mind.

Services Offered

We specialize in a range of Apple device repairs, including but not limited to:

iPhone Repairs

iPhone Xs Max Screen Replacement

iPhone 11 Pro Max Screen Replacement

iPhone 13 Pro Max Screen Replacement

Apple Watch Repairs

Best Apple Watch Repair Near Me – Whether your watch has a cracked screen or battery issues, we can fix it.

MacBook Repairs

MacBook Service Center – We handle logic board issues, screen replacements, and battery replacements for MacBooks.

General Mobile Repair Services

Best Mobile Repair Indore

iPhone Repair Indore

Best iPhone Shop Near Me

Benefits of Using Our Apple Service Center

Expert Repairs: Our team has extensive experience in handling complex Apple device issues.

Cost-Effective Solutions: We provide budget-friendly repair services with no hidden charges.

Convenient Location: Easily accessible service center for all your Apple repair needs.

Customer-Centric Approach: We prioritize customer satisfaction and strive to exceed expectations.

Why Choose Us?

With numerous service centers available, why should you trust us?

Industry Experience: Years of experience in repairing Apple devices.

Customer Trust: Thousands of satisfied customers and positive reviews.

Latest Repair Technology: We use state-of-the-art tools and techniques.

24/7 Customer Support: Reach out to us anytime for assistance.

How to Get the Right Repair Service?

Step 1: Contact us or visit our service center.

Step 2: Discuss the issue with our experts.

Step 3: Get a free diagnosis and cost estimate.

Step 4: Approve the repair, and we’ll take care of the rest.

Step 5: Pick up your device in perfect working condition.

Customer Testimonials

John D. – “I had my iPhone Xs Max screen replacement done here, and the service was outstanding. Highly recommended!”

Emily R. – “The best Apple repair service I’ve ever experienced. Quick, professional, and affordable.”

Michael B. – “If you are looking for the best iPhone service center, this is the place to go!”

Conclusion

Your Apple devices deserve the best care. Whether it’s a cracked screen, battery replacement, or software issue, our service center ensures top-notch repairs. Trust us as your go-to Best AppleCare Service Center for all your Apple device needs. Contact us today and get your device repaired by the experts!

0 notes

Text

Advancements in Precise State of Charge (SOC) Estimation for Dry Goods Batteries

In the dynamic world of dry goods batteries, accurately determining the State of charge estimation (SOC estimation for dry goods batteries) is crucial for optimal performance and longevity. This article explores two widely used methods for SOC estimation for dry goods batteries: the Anshi integral method and the open-circuit voltage method. By examining their mechanics, strengths, and limitations, we aim to understand each method's suitability for different battery types clearly, highlighting recent advancements in SOC estimation.

I. The Anshi Integral Method

The Anshi integral method precisely calculates SOC by considering critical variables such as charge and discharge currents, time, and total capacity. This method is a cornerstone of Precise SOC estimation technology and is versatile and suitable for various battery chemistries.

Operational Mechanics

Current Measurement: Accurate measurements of charge and discharge currents using high-precision sensors are fundamental to SOC measurement for dry batteries.

Time Integration: Integrating measured currents over time to determine the total charge transferred utilizes advanced SOC algorithms for batteries.

SOC Calculation: Dividing the total charge transferred by the battery's capacity to obtain SOC ensures Accurate SOC estimation methods.

Strengths

Versatility: Applicable to different battery chemistries, enhancing Dry goods battery SOC improvement.

Robustness: Resilient to noise and parameter variations, supporting reliable Battery state of charge monitoring.

Accuracy: Provides precise SOC estimation when combined with other methods, contributing to Improving SOC estimation accuracy.

Limitations

Sensor Dependence: Accuracy relies on the quality of current sensors, affecting overall Battery management system SOC.

Temperature Sensitivity: SOC calculation can be affected by temperature variations, necessitating adaptive measures.

Computational Complexity: The integration process can be computationally expensive, impacting real-time applications.

II. The Open-Circuit Voltage Method

The open-circuit voltage method estimates SOC by measuring a battery's voltage when no load is connected. This method is particularly effective for ternary and lithium manganate batteries due to their unique voltage characteristics, representing significant Innovations in battery SOC tracking.

Operational Mechanics:

Voltage Measurement: Measuring the battery's open-circuit voltage is a fundamental aspect of State of charge estimation techniques.

SOC Lookup Table: Comparing the measured voltage to a pre-constructed lookup table utilizes Battery SOC prediction advancements.

SOC Determination: Obtaining the corresponding SOC value from the lookup table ensures reliable Real-time SOC estimation for batteries.

Strengths:

Simple Implementation: Requires minimal hardware and computational resources, making it an Accurate SOC estimation method.

High Accuracy: Provides precise SOC estimates for specific battery chemistries, enhancing SOC measurement for dry batteries.

Temperature Independence: Relatively unaffected by temperature variations, improving overall SOC estimation accuracy.

Limitations:

Limited Applicability: Effective only for batteries with well-defined voltage-SOC relationships, restricting its use.

Lookup Table Dependence: Accuracy depends on the quality and completeness of the lookup table, highlighting the need for comprehensive data.

Dynamic Voltage Fluctuations: Self-discharge and other factors can affect open-circuit voltage accuracy, challenging State of charge estimation.

III. Suitability for Different Battery Types

The open-circuit voltage method is generally applicable, but its accuracy varies depending on the battery chemistry:

Ternary Batteries: Highly suitable due to distinct voltage-SOC relationships.

Lithium Manganate Batteries: Performs well due to stable voltage profiles.

Lithium Iron Phosphate Batteries: Requires careful implementation and calibration for accurate estimation within specific SOC segments.

Lead-Acid Batteries: Less suitable due to non-linear voltage-SOC relationships.

IV. Factors Affecting State of Charge Calculation

Several factors influence SOC estimation accuracy:

Current Sensor Quality: Accuracy depends on high-precision sensors, critical for Battery state of charge monitoring.

Temperature Variations: Battery capacity changes with temperature, affecting SOC calculation.

Battery Aging: Aging reduces capacity and increases internal resistance, impacting SOC accuracy.

Self-discharge: Natural discharge over time can lead to underestimation of SOC.

Measurement Noise: Electrical noise in the system can introduce errors in SOC calculation.

V. Enhancing SOC Estimation Accuracy

To achieve accurate SOC estimation, several strategies can be employed:

Fusion of Methods: Combining the Anshi integral method with the open-circuit voltage method improves accuracy by leveraging dynamic and static information, representing key Advancements in SOC estimation.

Adaptive Algorithms: Real-time data-driven algorithms compensate for changing battery parameters and environmental conditions, enhancing SOC algorithms for batteries.

Kalman Filtering: Advanced filtering techniques reduce measurement noise, enhancing accuracy and reliability.

VI. Impact of Accurate SOC Estimation

Accurate SOC estimation has significant implications across various applications:

Optimized Battery Usage: Avoiding overcharging and deep discharging extends battery life and enhances performance, contributing to Dry goods battery SOC improvement.

Improved Safety: Reliable information on remaining capacity prevents safety hazards associated with improper charging or discharging.

Extended Battery Lifespan: Minimizing stress on batteries prolongs their lifespan, reducing costs and environmental impact.

Efficient Battery Management: Accurate SOC information enables optimized charging, discharging, and prevention of premature failure, integral to Battery management system SOC.

VII. Applications in Various Industries

Accurate SOC estimation finds applications beyond dry goods batteries:

Renewable Energy Systems: Optimizes energy storage in solar and wind power installations.

Electric Vehicles: Predicts driving range and optimizes battery performance, leveraging Battery SOC prediction advancements.

Portable Electronics: Provides reliable information on remaining battery life in smartphones and laptops.

Medical Devices: Ensures reliable operation of battery-powered medical devices for patient safety.

VIII. Future Development

Advancements in SOC estimation can be expected in the following areas:

Advanced Machine Learning Techniques: Analysing data patterns for even greater accuracy.

Battery Health Monitoring Integration: Comprehensive insights into battery performance and failure prediction.

Wireless Communication: Real-time monitoring and remote battery management, enhancing Real-time SOC estimation for batteries.

Conclusion

Accurately estimating State of charge estimation is crucial for optimizing dry goods battery performance and lifespan. Understanding the mechanics, strengths, and limitations of the Anshi integral method and the open-circuit voltage method allows informed selection and implementation for different battery types. As technology progresses, further advancements in SOC estimation techniques will enhance the efficiency and reliability of dry goods batteries across diverse applications, driving forward Innovations in battery SOC tracking and Battery SOC prediction advancements.

#State of charge estimation#SOC estimation for dry goods batteries#Precise SOC estimation technology#Advancements in SOC estimation#SOC measurement for dry batteries#Battery state of charge monitoring#SOC algorithms for batteries#Accurate SOC estimation methods#Dry goods battery SOC improvement#State of charge estimation techniques#Battery management system SOC#Improving SOC estimation accuracy#Battery SOC prediction advancements#Real-time SOC estimation for batteries#Innovations in battery SOC tracking

0 notes

Text

Global Lithium Carbonate Market Size Is Growing With a CAGR of 19.4%(2024-2031)

According to our (Global Info Research) latest study, the global Lithium Carbonate market size was valued at US$ 26520 million in 2024 and is forecast to a readjusted size of USD 90500 million by 2031 with a CAGR of 19.4% during review period.

The world's major lithium carbonate manufacturers include SQM, Albemarle and FMC. The world's top three manufacturers together occupy about 40% of the market share. China is currently the world's largest lithium carbonate market, accounting for approximately 83% of the global sales revenue market share. In terms of product type, battery grade lithium carbonate occupies a dominant position, accounting for 82% of the total. At the same time, in terms of application, batteries are the largest application field, accounting for 82%.

"Lithium Carbonate" 2025 Breakdown, Data Source, Secondary Sources, Primary Sources, Research Report delivers leading competitors strategic analysis, with micro and macro-economic factors, market trends, future growth scenarios, with pricing analysis. This report provides a holistic overview on Market Current Situations, Key Collaborations, Merger & Acquisitions along with Trending Innovations and New Business Development Policies. A detailed professional report focusing on primary and secondary growth drivers, regional segments, growth share, and geographical analysis of top key players. Lithium Carbonate trend analysis with historical data, estimates to 2025 and Compound Annual Growth Rate (CAGR) forecast to 2031.

Top Key Players Covered in Market Report 2025-2031:SQM、Albemarle、FMC、Orocobre、Tianqi Lithium Industry、Ganfeng Lithium Industry、Ruifu Lithium Industry、Shengxin Lithium Energy、Salt Lake Industry、Yahua Industrial、Ronghuitong Lithium Industry、Zangge Mining、Zhicun Lithium Industry

Short Description of the Lithium Carbonate 2025-2031: Market Overview of Global Lithium Carbonate: According to our latest research, the global Lithium Carbonate looks promising in the next 6 years. As of 2025, the global Lithium Carbonate was estimated at USD Million, and it’s anticipated to reach USD Million in 2031, with a CAGR during the forecast years. This report covers a research time span from 2020 to 2031, and presents a deep and comprehensive analysis of the global Lithium Carbonate, with a systematical description of the status quo and trends of the whole market, a close look into the competitive landscape of the major players, and a detailed elaboration on segment markets by type, by application and by region.

Global and Regional Analysis: North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

Market Segmentation Lithium Carbonate report provides an exhaustive 360-degree analysis, by utilizing both primary and secondary research techniques. The research gained comprehensive insights into current market dynamics, pricing trends, developments, supply-demand and evolving consumer behaviors.

On the basis of product type, this report displays the production, revenue, price, market Industrial Grade Lithium Carbonate、Battery Grade Lithium Carbonate

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each Batteries、Glass and Ceramics、Medical、Lubricating Oil、Metallurgy、Other

Our method for estimating market size is holistic and multifaceted. We assess vital industry trends, regulatory landscapes, and segment-specific dynamics, evaluating their potential influence on demand projections. Key macroeconomic factors, including price fluctuations, demographic shifts, and changes in demand patterns, are integrated into our calculations. To discover market value, we not only delve deep into the profiles of prominent players and their global market shares but also rely on our frequently updated internal database, enriched with insights and announcements from pivotal market stakeholders.

Some of the Key Questions Answered in this Report:

What is the Lithium Carbonate size at the regional and country level What are the key drivers, restraints, opportunities, and challenges of the Lithium Carbonate, and how they are expected to impact the market What is the global (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa) sales value, production value, consumption value, import and export of Lithium Carbonate Who are the global key manufacturers of the Lithium Carbonate? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue) What are the Lithium Carbonate opportunities and threats faced by the vendors in the Lithium Carbonate? Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application? What focused approach and constraints are holding the Lithium Carbonate? What are the different sales, marketing, and distribution channels in the global industry? What are the key market trends impacting the growth of the Lithium Carbonate? Economic Impact on the Lithium Carbonate and development trend of the Lithium Carbonate What are the Lithium Carbonate opportunities, market risk, and market overview of the Lithium Carbonate The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Hydrogen Bromide product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Hydrogen Bromide, with price, sales, revenue and global market share of Hydrogen Bromide from 2020 to 2025. Chapter 3, the Hydrogen Bromide competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Hydrogen Bromide breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2020 to 2031. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2020 to 2031. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2020 to 2024.and Lithium Carbonate forecast, by regions, type and application, with sales and revenue, from 2026 to 2031. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Hydrogen Bromide. Chapter 14 and 15, to describe Hydrogen Bromide sales channel, distributors, customers, research findings and conclusion.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Expert Tesla Auto Body & Collision Repairs in Florida | Car Geeks Collision

Welcome to Car Geeks Collision, the leading Tesla auto body shop near you in Florida. We specialize in Tesla collision repair, providing expert services to restore your vehicle to its original condition. Our certified technicians ensure precision, quality, and efficiency in every repair.

Your One-Stop Tesla Repair Shop

As a trusted Tesla repair shop, we offer a range of specialized services, including:

Expert Paint Shop

Give your Tesla a flawless finish with our auto body paint shop. Whether you need a minor touch-up or a complete car body repair, we use advanced color-matching technology for a seamless look.

Dent Repair Services

Dents and dings can affect your Tesla’s sleek appearance. Our Tesla dent repair near you removes imperfections using state-of-the-art techniques, preserving the vehicle’s aesthetics and value.

Battery Repair & Restoration

Tesla's battery system requires expert care. Our Tesla body shop near you provides specialized battery repair and maintenance to keep your vehicle running at peak performance.

Why Choose Car Geeks Collision?

Tesla-Certified Technicians: Our specialists understand Tesla body repair inside and out.

Advanced Collision Repairs: From minor scratches to major auto collision repair, we handle it all.

Insurance-Friendly Services: We work with all insurance providers, offering a hassle-free process.

Courtesy Vehicles: Get back on the road while we restore your Tesla.

No Upfront Payments: We prioritize customer convenience.

Get a Free Collision Repair Estimate Today!

If you're searching for Tesla collision repair near you, Car Geeks Collision is your trusted partner. Contact us today for a collision repair estimate and experience expert auto body collision repair in Florida!

0 notes

Text

Comprehensive Truck Repair and Maintenance Services at Collision Truck Center

Introduction

At Collision Truck Center, we specialize in providing high-quality repair and maintenance services for all types of trucks, including semi-trucks, commercial fleets, and heavy-duty vehicles. With years of expertise in the industry, we understand the critical role trucks play in businesses, and our mission is to keep your vehicles running safely and efficiently. Whether you’re searching for a truck body shop near me or need professional semi-truck DPF filter cleaning near me, we are your trusted partner.

Body Shop Services for Trucks

At Collision Truck Center, we offer a comprehensive range of services designed to restore and maintain the structural integrity and aesthetics of your truck:

Truck Body Shop Expertise

Our body shop trucks is equipped with state-of-the-art technology and staffed by experienced technicians who specialize in truck repairs. From minor dents to significant collision damages, our truck auto body shop ensures that your vehicle is repaired to its original condition.

Structural Repairs

We handle frame straightening, welding, and alignment services to ensure your truck is road-ready. Whether it’s a commercial fleet or a semi-truck body shop requirement, our team uses advanced tools to guarantee precision in every repair.

Customization and Refinishing

For those seeking to upgrade their truck’s appearance, we provide custom painting and refinishing services. Our technicians use high-quality paints and materials, ensuring long-lasting results.

Semi-Truck Body Shop Services Near Me