#Bcomp

Link

#Apple#Bcomp#contextualuserexperience#denimrecycling#ECARX#ElectricVehicle#EV#EX30#Futurride#Geely#Google#HaleyTek#HarmanKardon#Nordico#QualcommTechnologies#sustainablemobility#VolvoCars#VolvoCarsTechFund#VolvoEX30#VolvoEX30CrossCountry

0 notes

Note

Hi Hazel I’m not sure how much you know about Extreme E but do you know what happens with the broken bodywork?? Do they have a way of recycling it??

so in XE the bodywork is a weird thing because it's not made of carbonfibre, it's made of a hemp composite called BComp.

that has a bunch of advantages, including being more sustainable but also it doesn't shatter, it just tears. it can't replace carbon fibre in all contexts yet but the fact it's good enough for racing bodywork is pretty cool.

at the end of its life it can be burned in a way that's carbon neutral or composted (which might actually be worse because it creates methane in decomposition) so it doesn't recycle but does create a non-pollutant thing to drop into landscapes and can be carbon neutral. when I stop hating myself enough I'm doing a video about composites that'll have a big bit about BComp.

15 notes

·

View notes

Text

Eco Fiber Market Trends and Forecasts: Harnessing Sustainable Textile Innovations

The eco fiber market refers to the segment of the textile industry that focuses on the production and use of sustainable and environmentally friendly fibers. Eco fibers are derived from renewable sources, such as organic plants, recycled materials, and bio-based polymers, and are manufactured using processes that minimize environmental impact.

The growing awareness of environmental issues and the desire for more sustainable products have driven the demand for eco fibers in various industries, including fashion, textiles, automotive, home furnishings, and personal care. Eco fibers Market offer several benefits compared to traditional fibers, including reduced carbon footprint, lower water and energy consumption, and the ability to biodegrade or recycle at the end of their life cycle.

Types of Eco Fibers:

Organic Cotton: Cotton grown without the use of synthetic pesticides and fertilizers, promoting soil health and biodiversity.

Bamboo Fiber: Derived from bamboo plants, this fiber is known for its rapid growth and low water and pesticide requirements.

Hemp Fiber: Produced from the cannabis plant, hemp fiber is highly durable and requires minimal chemical inputs.

Recycled Polyester: Made from recycled plastic bottles and other post-consumer waste, this fiber helps reduce landfill waste and dependence on fossil fuels.

Lyocell/Tencel: Derived from wood pulp sourced from sustainably managed forests, this fiber has a closed-loop production process, minimizing waste and chemical usage.

Soy Fiber: Made from the by-products of soybean oil extraction, this fiber is biodegradable and renewable.

Wool: A natural fiber produced by sheep, wool is biodegradable and renewable, and can be sustainably sourced through responsible farming practices.

Key Market Drivers:

Increasing consumer awareness and demand for sustainable and eco-friendly products.

Stringent government regulations promoting sustainable practices in the textile industry.

Growing adoption of circular economy principles, emphasizing the use of renewable resources and minimizing waste.

Advancements in technology, leading to the development of innovative and eco-friendly fiber production methods.

Collaborations and partnerships between industry players, research institutions, and organizations to drive sustainability initiatives.

Challenges:

Higher production costs associated with eco fibers compared to conventional fibers.

Limited availability of certain eco fibers due to factors like geographical constraints or low production volumes.

Education and awareness gaps among consumers and businesses regarding the benefits and availability of eco fibers.

Balancing sustainability with performance requirements, such as durability, comfort, and functionality.

Ensuring transparency and authenticity in the eco fiber supply chain to prevent greenwashing.

Key Players: The eco fiber market includes a wide range of companies involved in the production, processing, and distribution of eco fibers. Some prominent players in the market include: Enkev Bv, Esprit Global, Envirotextiles, European Industrial Hemp Association, Flexform Technologies, Foss Manufacturing, Hayleys Fibers, Aditya Birla Management, Ananafit, Aquafi, Greenfibres, Bcomp, David C. Poole, Ecofibre, Ecological Fibers. Lenzing AG, Grasim Industries Limited, Teijin Ltd., and US Fibers.

Overall, the eco fiber market is witnessing significant growth as consumers and industries increasingly prioritize sustainability and environmental responsibility. The development and adoption of eco fibers contribute to a more sustainable and circular economy by reducing the environmental impact of the textile industry.

0 notes

Text

Natural-Fiber Super Formula Bodywork Makes European Debut

Bcomp is unveiling the flax fiber–based bodywork for Japan’s Super Formula race series at JEC World 2023 in Paris this week.

from plasticstoday.com - Community for Plastics Professionals https://ift.tt/ZwTCR4o

0 notes

Text

Eco Fiber Market Size with Global Industry Pandemic Analysis, Growth Rate, Latest Trend and Forecast to 2030

Eco fiber refers to fibers that are environmentally friendly and sustainable. These fibers are produced using methods that have a minimal impact on the environment and use fewer resources compared to traditional fibers. Some examples of eco fibers include:

Organic cotton: Cotton grown without the use of synthetic pesticides and fertilizers.

Hemp: A fast-growing plant that requires less water and pesticides than cotton.

Bamboo: A fast-growing grass that requires no pesticides and little water to grow.

Recycled polyester: Made from recycled plastic bottles, reducing waste and energy consumption.

Tencel: Made from sustainably harvested eucalyptus trees, using a closed-loop production process that recycles water and solvents.

Eco fibers are becoming increasingly popular as people become more aware of the environmental impact of fashion and textiles. They offer a more sustainable alternative to traditional fibers and help to reduce the environmental impact of clothing production.

The eco fiber market is growing rapidly as more consumers become aware of the environmental impact of fashion and textiles. The market for eco fibers includes a wide range of products such as clothing, home textiles, and industrial textiles.

The Asia Pacific region is expected to be the fastest-growing market for eco fibers, driven by increasing consumer awareness and government initiatives promoting sustainable textile production. North America and Europe are also expected to see significant growth in the eco fiber market due to the increasing demand for sustainable fashion and textiles.

Some of the key players operating in the global eco fiber market are Enkev Bv, Esprit Global, Envirotextiles, European Industrial Hemp Association, Flexform Technologies, Foss Manufacturing, Hayleys Fibers, Aditya Birla Management, Ananafit, Aquafi, Greenfibres, Bcomp, David C. Poole, Ecofibre, Ecological Fibers. Lenzing AG, Grasim Industries Limited, Teijin Ltd., and US Fibers.

The demand for eco fibers in the market is increasing as more consumers become aware of the environmental impact of fashion and textiles. The demand is being driven by various factors, such as:

Growing Environmental Awareness: Consumers are becoming more aware of the environmental impact of fashion and textiles, and they are actively seeking out eco-friendly and sustainable options. This is driving demand for eco fibers in the market.

Government Regulations: Governments around the world are implementing regulations and policies to promote sustainable production and reduce the environmental impact of the textile industry. This is increasing the demand for eco fibers, as textile manufacturers are looking for more sustainable alternatives to traditional fibers.

Corporate Social Responsibility (CSR): Companies are increasingly adopting sustainable business practices as part of their CSR initiatives. This includes using eco fibers in their products, which is driving demand for these fibers in the market.

Innovation in Fiber Production: Advances in technology have made it possible to produce eco fibers more efficiently and cost-effectively, making them a more attractive option for textile manufacturers.

The eco fiber market is experiencing significant growth as more consumers and companies prioritize sustainability and environmental responsibility. According to various market reports, the global eco fiber market is expected to grow at a compound annual growth rate (CAGR) of 9-10% from 2021 to 2028.

Several factors are driving the growth of the eco fiber market, including:

Increasing Consumer Awareness: Consumers are becoming more aware of the environmental impact of fashion and textiles, and they are looking for more sustainable options. This increased demand is driving growth in the eco fiber market.

Government Regulations: Governments around the world are implementing regulations and policies to promote sustainable production and reduce the environmental impact of the textile industry. This is driving growth in the eco fiber market as textile manufacturers look for more sustainable alternatives to traditional fibers.

Innovation in Fiber Production: Advances in technology have made it possible to produce eco fibers more efficiently and cost-effectively, making them a more attractive option for textile manufacturers. This has led to increased investment in eco fiber production and further growth in the market.

Corporate Social Responsibility (CSR): Companies are increasingly adopting sustainable business practices as part of their CSR initiatives. This includes using eco fibers in their products, which is driving growth in the eco fiber market.

The eco fiber market has a wide range of applications across various industries. Some of the key applications of eco fibers include:

Clothing and Apparel: Eco fibers are used in the production of clothing and apparel, including t-shirts, jeans, jackets, and other garments. Organic cotton, hemp, bamboo, and recycled polyester are some of the popular eco fibers used in the clothing industry.

Home Textiles: Eco fibers are also used in the production of home textiles, such as towels, bedding, and curtains. Tencel and organic cotton are popular eco fibers used in the home textiles industry.

Industrial Textiles: Eco fibers are increasingly being used in industrial textiles, such as packaging materials, geotextiles, and automotive textiles. Recycled polyester and bamboo fibers are popular eco fibers used in industrial applications.

Non-Woven Products: Eco fibers are also used in the production of non-woven products, such as wet wipes, diapers, and feminine hygiene products. Tencel and bamboo fibers are popular eco fibers used in the production of non-woven products.

Medical Textiles: Eco fibers are used in the production of medical textiles, such as bandages, wound dressings, and surgical gowns. Tencel and bamboo fibers are popular eco fibers used in medical textiles due to their antibacterial and moisture-wicking properties.

Overall, the eco fiber market has a diverse range of applications across various industries, and this is expected to continue to grow as more companies and consumers prioritize sustainability and environmental responsibility.

0 notes

Text

Super Formula confirms introduction of new bio-composite chassis for 2023 | Super Formula

Super Formula, Japan’s top-line single-seater series, has completed development of its innovative new spec chassis and confirmed it will be introduced in 2023.

Announced in October 2021, the joint development project between the series and its two engine suppliers Honda and Toyota has utilised several technologies that are new to top-level motorsport with the aim of having cars that are more sustainably manufactured and operated.

Dubbed the ‘SF23’, the updated Dallara chassis will use new bodywork supplied by Swiss firm Bcomp that is made of a bio-composite material that maintains “the same rigidity and weight as the conventional carbon materials but focused completely on the application of natural substances such as hemp-derived materials,” according to the series.

By switching from carbon fibre to bio-composite, the reduction in CO2 emissions from manufacturing alone is said to be 75%. Following crashes when parts have to be replaced, this will also be a more sustainable method of providing spare components.

The bodywork is also being revised for 2023 to change the aerodynamic profile of the cars. This is being done with the goal of having close racing, and includes a radical reshaping of the front and rear wings and additional aerodynamic appendages on the sidepods.

Tyre supplier Yokohama has also worked on creating a more sustainable product. Its single-specification slick compounds will be made from “approximately 33% recycled and renewable raw materials” in 2023, it says. Yokohama claims it is its first “carbon neutral racing tyre”, which follows Super Formula’s ambition to become a carbon neutral series, a target shared by F1.

Over 10,000km of testing has been completed at multiple circuits in Japan with the new bodywork and tyres.

The technical overhaul for the series is accompanied by a revamped digital media approach that includes introducing an F1 TV-style live streaming and archive video service with features such as being able to listen to team radio and viewing live telemetry.

The full grid for Super Formula’s 2023 season has already been announced, with three rookies arriving in the series. Red Bull junior Liam Lawson will step up from Formula 2 to race for Team Mugen, Formula Regional Americas champion Raoul Hyman has landed a seat at B-MAX Racing thanks to a scholarship from Honda and Super Formula Lights runner-up Kakunoshin Ohta has been given a chance at Dandelion Racing.

Advert | Become a RaceFans supporter and go ad-free

Other motorsport

Browse all other motorsport articles

via RaceFans - Independent Motorsport Coverage https://www.racefans.net/

#F1#Super Formula confirms introduction of new bio-composite chassis for 2023 | Super Formula#Formula 1

0 notes

Link

UK supercar maker McLaren Automotive is beginning its shift towards electric vehicles (EVs). It plans to launch its first hybrid in 2021 and stop developing internal combustion (petrol) engines by 2030. McLaren’s CEO, Mike Flewitt, told the Financial Times that the company would focus on hybrid supercars until it transitions...

#Transport#2021#2030#automaker#automobiles#autos#battery powered#Bcomp#British#car#cars#Composites Technology Centre#COVID-19 pandemic#electric#electric car#electric cars#electric supercars#electric vehicle#electric vehicles#EV#EVs#F1#Financial Times#flax fiber#hybrid#hybrid cars#hybrid supercars#Hybrids#James Key#McLaren Automotive

21 notes

·

View notes

Text

Volvo Tech Fund Invests In Sustainable Lightweight Materials Fund Bcomp

Volvo Tech Fund Invests In Sustainable Lightweight Materials Fund Bcomp

Volvo has used materials from Bcomp in the 2021 Concept recharge vehicle

By Sahil Gupta

, Published: 05-Apr-22 03:28 PM IST

0 Views

Volvo’s tech fund has made a strategic investment in Bcomp which is a Swiss company that develops high performance lightweight materials that are based on natural fibers. Bcomp uses flax fibers which is a bio based material that offers significant savings in terms…

View On WordPress

0 notes

Photo

Our fun dysfunctional family Christmas photo. Love you all!! #bcomp #barbizon #industrypros (at Falcons Nest) https://www.instagram.com/p/B6JNHMVh66O/?igshid=2lbp956bq3ze

0 notes

Photo

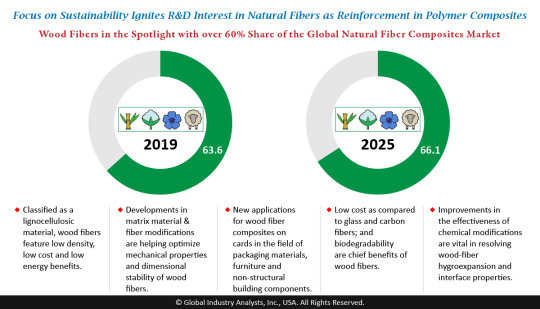

The global market for Natural Fiber Composites is projected to reach US$8.5 billion by 2025, driven by the growing focus on environmental sustainability and the ensuing search for safer and natural alternatives for traditionally engineered materials. The world is gradually moving towards a circular economy in response to the growing pressure to address pollution, global warming and climate change. The manufacturing industry as a result is coming under intense pressure to reduce its carbon footprint and develop a sustainable value chain for raw material supply, while simultaneously meet the challenges of intensifying competition. The industry has made measurable progress in the transition to bio-based products. Several natural and renewable materials have been successfully developed to replace current petroleum-derived products. As the environmental cost of manufacturing using non-renewable resources increase there will be a parallel increase in the commercial value of natural products and feedstocks given their extraordinary value-addition in preserving the environment. As demand for advanced composites in manufacturing grows, natural fiber composites (NFCs) are attractively positioned to tap into this opportunity. Defined as reinforcing fibers derived from natural origin such as wood, plants and animals, NFCs are CO2 neutral. Developments in chemical and physical treatment methods are vital to ensure the efficiency and final performance and properties of the natural fiber composites. To manipulate and customize the properties of NFCs, agro fibers are often integrated with plastics. Synthetic fibers such as glass fibers in polymer composites can be replaced by NFCs to improve their eco-friendly profile. Read More…

0 notes

Text

Textspeak is Fine

It took me 2-3 years to learn the shorthand I utilize right now and I just want to say something: there’s nothing fucking wrong with textspeak.

We have this weird perception as working professionals that textspeak is informal, and yes, okay, it is. But we, older folk who weren’t raised on texting, say that it rots your brain, that it prevents people from being able to fully form understandable sentences. But it’s not true, and the science says it’s true, and also I would say that it’s not true.

We’ve been using some kind of textspeak for eons. “Shorthand” gets a better rap because it’s designed for a professional setting, but it’s got a lot of the same characteristics as textspeak because both are designed for speed. For starters, the shorthand alphabet is phonetic. So rather than saying something like, “It might be better for you to go outside” if I were using shorthand phonetics, I would say something like, “It mite B beder 4 U to go outside.” And if I were using textspeak phonetics, it would look like “mite b better 4 u to go outside.” So there’s already a lot of similarities between textspeak and shorthand, but the similarities don’t end there. For example, let’s try “Please take out the trash, thank you.”

In shorthand, I would write this as “Pls tak out trash thx.” The only real difference is that because shorthand is so phonetic, I can drop the silent e’s which wouldn’t be done in textspeak. But superlative words like “the” are cut, common words are abbreviated, words with complicated spellings are shortened and spelled phonetically…

To be honest, knowing textspeak has made my job easier, because I use common text shortcuts to describe more complex ideas. For example: “what do.” Someone who is familiar with the phrase knows that it more or less means “what are you going to do” but it’s much shorter and much faster.

I, in my work capacity, type ppl- instead of people. Here is a real, actual example of something I wrote, in shorthand, while making $20 an hour to do my job:

Sumary of wht do: of interest to lab resrs or stkhs. Genotypng, earlier ths wk gentyp cattle, do ODFWs salmon. Srv broden comm + binf serv + growng ml, dl, apprch. Machine vish syst for grass vs wheat (instd of tweezer) bcomp high perf comp needs. Act in res tng wkshps to disseminate knoldge… wld be intestng to lok @ esp PDX is dats aswng ?s w/ citzn prog, w/ AI prg, inv spec idetify in rangeland, timstmp upload, infoms models. Synergy there. Wnt to know more @ co-op proj esp in vay area. Mite b god if socio-econimc, that’s specly of VA.

If someone who didn’t know my shorthand shortcuts were to read this, they would think it was absolute nonsense. But I can read it, because I learned a way to type up notes that was quicker than what I could do by writing out full sentences.

And furthermore, I had to turn off my auto-correct settings to even type that nonsense because of course I’ve saved some of the more common abbreviations in Word.

Anyway point being, there’s nothing wrong with people using textspeak in informal situations. If they’re using it in their resume or research paper… tht’s a diff prob tht hs nthing to do w/ their ablty 2 form meaningful sntcs.

4 notes

·

View notes

Text

Eco Fiber Market Insights: 2023, Progressive Trends, Growth Opportunities | Development Companies

Eco fiber is a type of fiber that is produced using sustainable and environmentally friendly methods. It is made from natural materials that have been grown without the use of harmful pesticides or fertilizers, or from recycled materials such as plastic bottles or old clothing. Eco fibers can be used to make a wide range of products, including clothing, textiles, carpets, and packaging materials. Some common types of eco fibers include organic cotton, hemp, bamboo, and recycled polyester. The production of eco fibers aims to minimize the impact on the environment by reducing waste and pollution, conserving natural resources, and promoting sustainable agriculture practices. This can help to reduce the carbon footprint of the textile industry and promote a more sustainable approach to fashion and consumer goods.

The eco fiber market has grown significantly in recent years as consumers and businesses become more environmentally conscious and demand sustainable and eco-friendly products. The market for eco fibers is expected to continue to grow in the coming years due to increasing consumer awareness, government regulations, and the adoption of sustainable practices by companies.

Some of the key players operating in the global eco fiber market are Enkev Bv, Esprit Global, Envirotextiles, European Industrial Hemp Association, Flexform Technologies, Foss Manufacturing, Hayleys Fibers, Aditya Birla Management, Ananafit, Aquafi, Greenfibres, Bcomp, David C. Poole, Ecofibre, Ecological Fibers. Lenzing AG, Grasim Industries Limited, Teijin Ltd., and US Fibers.

The eco fiber market has been experiencing significant growth in recent years, driven by factors such as increasing consumer awareness and demand for sustainable products, government regulations, and the adoption of eco-friendly production practices by companies. The growth of the eco fiber market is expected to continue in the coming years.

The fashion industry is also a major contributor to the growth of the eco fiber market. Fashion brands are increasingly adopting sustainable practices and incorporating eco fibers into their products to meet the growing demand for sustainable fashion. This trend is expected to continue, with many brands making sustainability a key part of their business strategy.

In addition, government regulations are also driving the growth of the eco fiber market. Governments around the world are implementing regulations to promote sustainable practices in the textile industry and reduce the environmental impact of textile production.

The demand for eco fibers is increasing as consumers become more environmentally conscious and demand sustainable and eco-friendly products. The eco fiber market is driven by several factors that are contributing to the growing demand for eco fibers.

One of the key factors driving demand for eco fibers is the increasing awareness of the environmental impact of the textile industry. Consumers are becoming more conscious of the impact of their purchasing decisions on the environment and are looking for eco-friendly alternatives. This has led to a growing demand for eco fibers, which are produced using sustainable and environmentally friendly methods.

The fashion industry is also driving the demand for eco fibers. Many fashion brands are adopting sustainable practices and incorporating eco fibers into their products to meet the growing demand for sustainable fashion. This trend is expected to continue, with many brands making sustainability a key part of their business strategy.

Government regulations are also contributing to the growing demand for eco fibers. Governments around the world are implementing regulations to promote sustainable practices in the textile industry and reduce the environmental impact of textile production. This has led to an increased demand for eco fibers, which are produced using sustainable methods and have a lower environmental impact compared to traditional fibers.

Eco fibers have a wide range of applications across various industries. They are used in the production of textiles, carpets, packaging materials, and other consumer goods. Some of the key applications of eco fibers are:

1. Textiles: Eco fibers are used in the production of clothing, bedding, and other textiles. They can be made from natural materials such as organic cotton, hemp, and bamboo, which are grown without the use of harmful pesticides or fertilizers. Eco fibers are also used in the production of recycled polyester, which is made from recycled plastic bottles and other waste materials.

2. Carpets: Eco fibers are used in the production of carpets, which are made from materials such as recycled nylon, wool, and jute. Eco-friendly carpets are becoming increasingly popular as consumers look for sustainable and environmentally friendly flooring options.

3. Packaging: Eco fibers are used in the production of packaging materials such as paper bags, cardboard boxes, and other types of packaging. Eco-friendly packaging is becoming increasingly important as companies look for ways to reduce their environmental impact and meet consumer demand for sustainable products.

4. Automotive: Eco fibers are also used in the automotive industry for the production of interior components such as seats, headliners, and carpets. Materials such as recycled polyester and natural fibers are used to create eco-friendly alternatives to traditional automotive components.

The eco fiber market offers several benefits to both consumers and the environment. Some of the key benefits of the eco fiber market are:

☛ Sustainability: Eco fibers are produced using sustainable methods and materials, which helps to reduce the environmental impact of textile production. Eco fibers are often made from natural materials such as organic cotton, bamboo, and hemp, which are grown without the use of harmful pesticides or fertilizers. This helps to protect the environment and reduce the carbon footprint of textile production.

☛ Reduced Waste: Eco fibers are often made from recycled materials, which helps to reduce waste and conserve resources. By using recycled materials, the eco fiber market helps to reduce the amount of waste that ends up in landfills and conserve natural resources such as water and energy.

☛ Health Benefits: Eco fibers are often made from natural materials, which can be beneficial for people with allergies or sensitive skin. Natural fibers such as organic cotton and bamboo are free from harmful chemicals and irritants, which can help to reduce the risk of skin irritation and other health issues.

☛ Innovation: The eco fiber market is driving innovation in the textile industry, with companies investing in research and development to create new eco-friendly fibers and production methods. This innovation is helping to create new products and solutions that are more sustainable and environmentally friendly.

Overall, the eco fiber market offers several benefits to both consumers and the environment, including sustainability, reduced waste, health benefits, and innovation. As consumers and businesses become more environmentally conscious, the demand for eco fibers is expected to continue to grow, driving further innovation and helping to reduce the environmental impact of textile production.

0 notes

Photo

#Repost @spvracing with @get_repost ・・・ Finally on rolling! Great test yesterday for the 1st time on track of our new #electricgt #tesla #p100 . Thanks to @officialalvarofontes @emmakimilainen aswell as all the team from @electricgt_holdings and @qev_tech for deliver this fantastic machine We will update you with more information about the championship and the following tests avilable #spvracing #electric #cars #official #launch #egv #hrxbespokemotorsport #dhl #bcomp #pirelli #alcon #qev

#pirelli#spvracing#egv#alcon#qev#dhl#p100#bcomp#repost#electric#cars#hrxbespokemotorsport#official#electricgt#launch#tesla

0 notes

Text

BMW i Ventures investe em compósitos de alto desempenho feitos de fibras naturais

BMW i Ventures investe em compósitos de alto desempenho feitos de fibras naturais

O BMW Group não para de inovar e está investindo na fabricação sustentável de componentes feitos de materiais naturais. A BMW i Ventures, empresa de capital de risco do grupo, adquiriu a Bcomp, fabricante Suíça líder de peças de alto desempenho feitos de fibras naturais. As peças reforçadas e naturais da Bcomp foram usadas pela primeira vez pela equipe BMW M Motorsport na Fórmula E em 2019. Em…

View On WordPress

0 notes