#CAN2.0

Explore tagged Tumblr posts

Text

Can 2.0 and Can Fd: Controller Area Network

May 31, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction: Can 2.0 and Can FD.

The Controller Area Network (CAN) protocol has long been the standard method for exchanging data between electronic control units (ECUs) in automotive and industrial communication systems. This technology has evolved to meet the increasing demands of modern automobiles and industrial automation. The transition from CAN 2.0 (Controller Area Network 2.0) to CAN FD (CAN with Flexible Data Rate) is a watershed moment in this history.

In this blog post, we’ll look at the differences between CAN 2.0 and CAN FD, as well as the advantages they provide in terms of data speed, dependability, and adaptability. We will also investigate the causes that led to this decision.

1. Understanding CAN 2.0:

For many years, Controller Area Network 2.0, also known as Classical CAN, was the primary communication protocol used in the industrial and automotive sectors. CAN 2.0 was developed by Bosch in the 1980s to improve communication amongst vehicle ECUs. It was suited for scenarios requiring security and real-time data sharing since it provided a consistent and predictable communication channel.

2. Key Features of the CAN 2.0:

Fixed Data Rate: The fixed data rate of CAN 2.0 is undoubtedly its most significant disadvantage. It has a maximum speed of 1 Mbps, which was sufficient for early industrial and automotive applications but has subsequently become a bottleneck as data requirements have increased over time.

Message Length: CAN 2.0 allows a maximum message length of eight bytes per frame. While this was adequate for sharing simple data, as increasingly complex data, such as high-definition video and sensor data, needed to be conveyed, it became inadequate.

Deterministic and Reliable: One of the advantages of CAN 2.0 is its deterministic nature. Critical information always takes precedence since communications are sent in a precise order with priority. CAN 2.0 has error-checking tools to improve data dependability.

Why CAN FD Is Required: As technology advanced, the limitations of CAN 2.0 became increasingly obvious. The design of CAN FD was motivated by the need for higher data speeds, larger message payloads, and more adaptive communications.

Presenting CAN FD: The advent of CAN FD, or CAN with Flexible Data Rate, intended to address the shortcomings of CAN 2.0 while retaining its primary virtues of dependability and determinism. This new protocol represents significant progress in terms of data transport capabilities and applicability to modern applications.

3. Key Advantages of CAN-FD

Flexible Data Rates: The main advantage is already evident in the name: CAN FD offers flexible data rates. This means that it has a variety of working speeds, including a maximum data rate of 5 Mbps. The ever-increasing data requirements in today’s automobiles and industrial systems must be met, and adaptability is critical.

Extended Message Length: CAN FD allows for longer message payloads because frames can carry up to 64 bytes of data. This greater message length is required for sending complex data over the network, such as high-definition video.

Backward compatibility with CAN 2.0 is one of CAN FD’s brilliant design choices. This enables a smooth transition to the new protocol by allowing older ECUs that use CAN 2.0 to share the same network as newer CAN FD devices.

Increased Network Efficiency: By boosting data transmission rates and message sizes, CAN FD allows networks to be used more effectively, reducing latency and enhancing overall system performance.

4. Implementations of CAN-FD

The introduction of CAN FD has opened up new prospects in a variety of enterprises. Here are some examples of the impact this technology is having:

Can FD be a game changer in the auto industry? Modern automobiles contain a variety of sensors and electrical control units, all of which require a fast and reliable connection. Advanced driver assistance systems (ADAS) and autonomous driving features can send critical data thanks to CAN FD’s adjustable data rates and lengthy message lengths.

Commercial Automation: Can FD provide a dependable industrial automation solution where real-time data transfer is critical? Robots and manufacturing equipment can easily communicate, allowing for accurate control and monitoring of production processes. The protocol’s flexibility allows it to suit the diverse data needs of numerous industrial applications.

Aviation and Defense: Aerospace and defense applications require high levels of dependability and data integrity. CAN FD is an excellent choice for avionics and military systems because of its better error-checking methods and ability to handle large data payloads.

5. Challenges and Things to Consider

Even though CAN-FD has various advantages, there are some issues and factors to consider:

Cost: Updating hardware and software may be required for CAN FD deployment, which can be costly, particularly in industries with large installations.

Complexity: Because of CAN FD’s increased flexibility, network management may become more complicated. For optimal performance, adequate setup and monitoring are required.

Transition Period: For sectors that currently have CAN 2.0 networks in place, the transition to CAN FD may necessitate careful planning to avoid interruptions and ensure backward compatibility.

Conclusion:

Can FD become a crucial invention in the ever-changing realm of automotive and industrial communications? It addresses the drawbacks of its predecessor, CAN 2.0, by allowing for configurable data speeds, larger message durations, and enhanced error detection.

CAN FD’s adaptability and durability make it a critical technology for the future as data transfer demands in both automotive and industrial systems increase? Although the transition from Can 2.0 and Can Fd may be tough, the benefits in terms of speed, efficiency, and adaptability make the investment worthwhile for industries seeking to stay on the cutting edge of technology.

Get to know more about Can 2.0 and Can FD. Checkout for best VCU Products and Services for further details mail us at [email protected] or visit our website, Dorleco.com

#CAN2.0#CANFD#Autonomousdriving#AWD#Motorcontrolstrategies#emobilitycontrols#Dorleco#VCUProducts#Sensorfusion#Programablevcu

0 notes

Text

Profesyonel Arıza Tespiti: Tactrix Openport 2.0 Arıza Tespit Cihazı (J2534)

Günümüzde araçların elektronik sistemleri, her geçen gün daha karmaşık hale geliyor. Bu da doğru teşhis ve programlama için daha gelişmiş arıza tespit cihazlarını zorunlu kılıyor. İşte bu noktada, Tactrix Openport 2.0 Arıza Tespit Cihazı (J2534) devreye giriyor. Geniş araç desteği, yüksek hızlı veri aktarımı ve kolay kullanımı ile bu cihaz, hem profesyonel servisler hem de bireysel kullanıcılar için ideal bir çözüm sunuyor.

Neden Tactrix Openport 2.0?

Tactrix Openport 2.0, araçların Elektronik Kontrol Ünitesi (ECU) ile doğrudan iletişim kurarak arıza kodlarını okuma, sıfırlama, yazılım güncelleme ve canlı veri izleme işlemlerini kusursuz bir şekilde yerine getirir. Özellikle ECU programlama desteği sayesinde, motor performansını artırma veya fabrika ayarlarına geri dönme gibi işlemler kolayca yapılabilir.

Bu cihaz, 72Mhz 32 Bit İşlemcisi, USB 2.0 Tam Hızlı Adaptörü ve CAN2.0 (CAN/ISO15765) gibi üstün donanım özellikleriyle fark yaratır. Ayrıca, J1850 (PWM/VPW) ve K-Line (ISO9141/ISO14230) desteği sayesinde eski ve yeni nesil araçlarla tam uyum sağlar.

Chip Tuning Destekleriyle Sınırları Kaldırın

Tactrix Openport 2.0, yalnızca arıza tespiti ile sınırlı kalmaz; aynı zamanda popüler chip tuning yazılımlarını da destekler. Özellikle;

PCMFlash

BitBox

MMCFlash

OpenBox

CombiLoader

ChipLoader

EcuFlash

gibi yazılımlarla uyumlu çalışarak, aracınızın performansını bir üst seviyeye taşır. Bu yazılımlar sayesinde, motor kontrol ünitelerine doğrudan müdahale edebilir, fabrika ayarlarını optimize edebilir veya özel yazılımlar yükleyebilirsiniz.

Tactrix Openport 2.0 İle Neler Yapabilirsiniz?

Arıza Kodu Okuma ve Sıfırlama: Aracınızda oluşan hata kodlarını anında tespit edebilir ve gerektiğinde sıfırlayabilirsiniz.

ECU Programlama: Motor ve şanzıman kontrol ünitelerine yazılım güncellemeleri yapabilirsiniz.

Canlı Veri Akışı İzleme: Motor devri, yakıt basıncı ve hava-yakıt karışımı gibi verileri anlık olarak takip edebilirsiniz.

Veri Kaydı ve Analiz: Sürüş esnasında toplanan verileri kaydedip, daha sonra detaylı analiz yapabilirsiniz.

Nasıl Satın Alabilirim?

Eğer sen de aracının performansını artırmak ve arıza tespitlerini profesyonel seviyeye taşımak istiyorsan, Tactrix Openport 2.0 ürün sayfasını ziyaret ederek hemen sahip olabilirsin.

Tactrix Openport 2.0, sunduğu geniş uyumluluk, hızlı teşhis ve programlama kabiliyeti ile araç sahipleri ve servisler için vazgeçilmez bir çözüm sunuyor. Özellikle, chip tuning desteği ile aracınızın sınırlarını yeniden belirlemek artık çok daha kolay.

Aracınızın performansını yükseltmek ve doğru teşhisler yapmak istiyorsanız, Tactrix Openport 2.0 tam da ihtiyacınız olan cihaz!

0 notes

Text

How to choose Launch X431 PRO3S+ V5.0 vs X431 PRO5?

Newest X431 PRO5 with Smartlink 2.0 VCI, and X431 PRO3S+ V5.0 is new released too, how to choose Launch X431 PRO3S+ V5.0 vs X431 PRO5?What functions do I get with Smartlink that I don't get with DBScar VII?

Launch X431 Pro3S+ vs X431 Pro5Item

X431 PRO3S+ V5.0

Launch X431 Pro5

Guided

FunctionYesYes

Offline

ProgrammingYesYesFlash Hidden FunctionYesYesTSGUN TPMS moduleYes, with i-TPMS( or TSGUN)Yes, with i-TPMS( or TSGUN)X-prog3 IMMO programmerYes, with X-Prog3Yes, with X-prog3Battery TestYes, with BST360 battery testerYes with BST360 battery testerADASYesYesVideoscopeYes with VSP600Yes with VSP600Heavy duty moduleYes with HDIII or Smartlink C V2.0 Truck ModuleYes, buy with License+Adapter is OKDiagnostic Protocols: D-PDU/J2534/RP1210 YesBus Protocols:DoIP/CAN FD YesFCA AutoAuthYesYesTesla softwareYes, purchase from MallYes, purchase from MallUpdate2 Years Free Update, after 2 years, 429EUR 2 years update2 Years Free Update, after 2 years, 429EUR 2 years updateSuper remote diagnosisNoYes, but need activation

In Sum:

1. Launch X431 Pro3S+ V5.0 and Launch X431 Pro5 have many similarities, they have the same diagnostic functions, support online coding and FCA Autoauth. All come with 2 years free update. They all supports x-prog3, itpms, bst-360, vsp600, ADAS calibration, ev diagnosis kit.

2. The main difference is that Pro3s+ V5.0 and Pro5 have different VCI. Pro3s+ V5.0 has DBscar VII Bluetooth connector while Pro5 has SmartLink 2.0 VCI. Smartlink VCI can do CAN2.0/J2534/D-PDU, CAN FD DoIP protocols for newer vehicles. And X431 PRO5 can do Benz and BMW online programming, Pro3s+ V5.0 cannot. Smartlink 2.0 can also be used as j2534 passthru for official brand software.

3. They use different heavy-duty module, pro3s+ V5.0 uses Smartlink C V2.0 while PRO5 uses truck cables set with license.

4. PRO3S+ V5.0 don't support the Super Remote function, NEW PRO5 with Smartlink C can support it, old PRO5 doesn't, if you have old PRO5 and want to add the Super Remote function please order Launch X431 SmartLink C SmartLink B Remote Diagnostic device.

0 notes

Text

Introducing the OK7110-C RISC-V Single Board Computer(SBC)/Development Board - Your Gateway to Enhanced Connectivity and Innovation. With versatile peripheral interfaces including HDMI, MIPI-DSI, camera, Ethernet, USB3.0, PCIe2.0, UART, RS485, CAN2.0, SPI, audio, TF card slot, 4G/5G, and more, this board empowers you to unleash the full potential of your projects.

Experience seamless integration, high-speed data transfer, and reliable communication, all in one compact and powerful development board.

Contact us for price

0 notes

Text

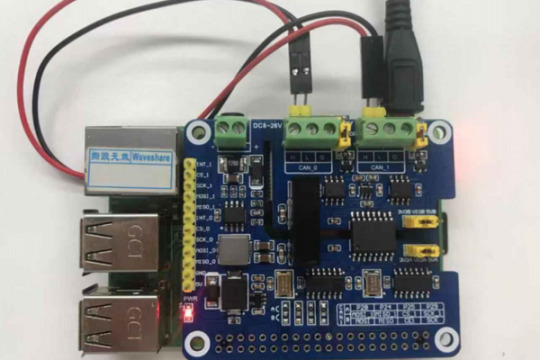

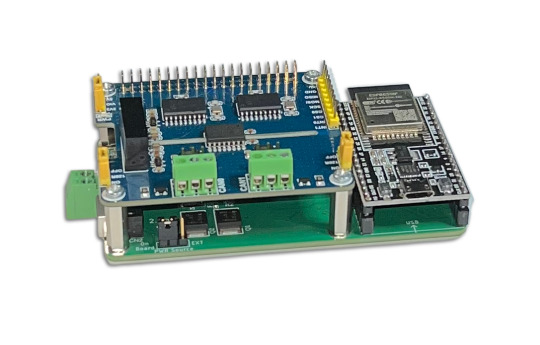

espBerry - ESP32 Development Board with Dual Isolated CAN Bus HAT

The espBerry DevBoard combines the ESP32-DevKitC development board with any Raspberry Pi HAT by connecting to the onboard RPi-compatible 40-pin GPIO header. The Dual Channel CAN Bus expansion HAT, designed for the Raspberry Pi, supports the full CAN2.0 Standard, and it features multi onboard protection circuits, high anti-interference capability, and reliable operation.

6 notes

·

View notes

Text

Ebyte Cloud Platform - Construction of Smart Farm

With the popularization of IoT technology, various IoT application cases can be seen everywhere in our lives unconsciously. Such as shared bicycles neatly parked on the roadside, shared mopeds, smart sockets and smart appliances in the home; smart irrigation systems in agriculture; smart parking systems in cities are all classic Single serial port server cases of IoT applications. It is foreseeable that the emergence and implementation of a large number of high-quality IoT solutions in the near future will bring a better experience and more convenience to our lives.

In this article, we build a smart farm application scheme based on the Ebyte cloud platform and E870-D1G as the network IO controller.

First of all, we need to clarify what is a "smart farm": it is a kind of Internet of Things as the core foundation, through the materialization of various functional parts in the farm, combined with wireless technology, automatic control technology and database to achieve intelligent management farm.

The development of smart farms is mainly divided into three stages:

Traditional labor or manpower liberation, no need to enter the farm, only manpower is required for remote control on the console;

The farm is controlled by the host computer system, and the manager can directly control the host computer to complete all farm operations, and the host computer issues all control instructions;

Artificial intelligence is highly intelligent, and all operations do not need personnel CAN2.0 Communication Module to make decisions, and are all scheduled by unmanned systems.

Of course, what we can do here is only the second stage, using the Ebyte cloud platform to build a smart farm scene, with E870-D1G as the farm worker or executor. In general, the cloud platform can be regarded as the brain of the smart farm, which is used for information collection, information storage, information processing, event triggering, task and instruction scheduling, etc. Ebyte IoT management platform, because of its simplicity, easy operation and stable operation

Starting today ! Get a free lora sample. One id(only companny & institute) is limited to 2 pieces, and the activity ends on 15th Nov. Quantities are limited, rush to buy now! https://youtu.be/YpbjGZ1mRMY

1 note

·

View note

Text

WHY CHOOSE THE LIFEPO4 BATTERY OF THE MERITSUN RACK MODULE

● Packed with LFP single cell for high performance, long life, safety and wide temperature range

● High energy density, small size, light weight, no pollution;

● Use CBMS-BMU design, protect voltage, current and temperature in the whole process

● Integrated communication interface, #CAN2.0 and #RS485 communicate with UPS or PC

● Integrated LED indicator, shows SOC and operating status

● Balance between cells, balance between racks

● LCD displays battery system information (custom)

● Packed in a standard 19-inch container, easy to install and expand capacity

● can customize battery system with neutral line

● 15 years of service life, stable performance, maintenance free

Official website: www.meritsunpower.com

0 notes

Text

Can 2.0 Vs. Can Fd: The Evolution of Controller Area Network

Introduction:

The Controller Area Network, or CAN, has long been the preferred protocol for transferring data between electronic control units (ECUs) in the world of automotive and industrial communication systems. This technology has advanced over time to satisfy the rising demands of contemporary cars and industrial automation. The change from CAN 2.0 (Controller Area Network 2.0) to CAN FD (CAN with Flexible Data Rate) is a crucial turning point in this history.

In this blog post, we will examine the distinctions between CAN 2.0 and CAN FD, as well as the benefits it offers in terms of data speed, dependability, and adaptability. We will also examine the factors that led to this move.

1. Understanding CAN 2.0:

2. Key Features of CAN 2.0:

Fixed Data Rate: The fixed data rate of CAN 2.0 is arguably its biggest drawback. It runs at a top speed of 1 Mbps, which was adequate for early industrial and automotive applications but has since become a bottleneck as data requirements have grown over time.

Message Length: The maximum message length allowed by CAN 2.0 is 8 bytes per frame. While this was appropriate for exchanging simple data, as more complicated data, such as high-definition video and sensor data, needed to be communicated, it became insufficient.

Deterministic and Reliable: One of CAN 2.0’s advantages is that it is deterministic. Critical information always takes precedence since messages are transmitted in a specific order with priority. Error-checking features are also included in CAN 2.0 to improve data dependability.

Why CAN FD Is Required: The limits of CAN 2.0 became more and clearer as technology developed. The creation of CAN FD was prompted by the need for faster data rates, bigger message payloads, and more adaptable communication.

Presenting CAN FD

The introduction of CAN FD, or CAN with Flexible Data Rate, sought to improve upon the drawbacks of CAN 2.0 while preserving its main strengths of dependability and determinism. In terms of data transfer capabilities and applicability to contemporary applications, this new protocol offers considerable advancement.

3. Key Benefits of CAN FD

Flexible Data Rate: The biggest benefit is already implied in the name: CAN FD provides flexible data rates. This indicates that it has a range of operating speeds, with a top data rate of up to 5 Mbps. The ever-increasing data requirements in today’s cars and industrial systems must be accommodated, and this flexibility is essential.

Extended Message Length: Thanks to frames that can hold up to 64 bytes of data, CAN FD supports longer message payloads. This longer message length is essential for transferring complicated data over the network, such as high-definition video.

Backward compatibility with CAN 2.0 is one of CAN FD’s clever design decisions. This permits a smooth transition to the new protocol by allowing older ECUs utilizing CAN 2.0 to live on the same network as newer CAN FD devices.

CAN FD improve error detection and reporting processes, offering a more thorough and trustworthy way to guarantee data integrity?

Increased Network Efficiency: By improving data transmission rates and message sizes, CAN FD helps networks be used more effectively, cutting down on latency and improving system performance as a whole.

4. Implementations of CAN FD

The automotive sector: CAN FD be a game-changer for the automobile industry? There are several sensors and electrical control units in modern automobiles, and they all demand fast and dependable connection. Advanced driver assistance systems (ADAS) and autonomous driving features can transmit vital data thanks to CAN FD’s flexible data rates and long message durations.

Commercial Automation: CAN FD provide a reliable industrial automation option, where real-time data interchange is crucial? Robots and manufacturing equipment can easily communicate with one another, allowing for precise production process control and monitoring. The protocol’s flexibility enables it to meet the various data requirements of many industrial applications.

Aviation and Defence: High degrees of dependability and data integrity are required for aerospace and defense applications. CAN FD is a good option for avionics and military systems due to its improved error-checking procedures and capacity for handling huge data payloads.

5. Challenges and Things to Think About

Even if CAN FD has several benefits, there are some difficulties and things to take into account:

Cost: Updating hardware and software may be necessary for CAN FD implementation, which can be expensive, especially for sectors with extensive installations.

Complexity: Due to CAN FD’s greater flexibility, network management may become more difficult. For best performance, proper setting and monitoring are necessary.

Transition Period: For sectors that already have CAN 2.0 networks in place, the switch to CAN FD may need careful planning in order to prevent interruptions and guarantee backward compatibility.

Conclusion:

CAN FD become a key invention in the constantly changing world of automotive and industrial communications? By providing adjustable data speeds, longer message durations, and improved error detection systems, it solves the shortcomings of its forerunner, CAN 2.0. The versatility and dependability of CAN FD make it a crucial technology for the future as the demands for data transfer in both automotive and industrial systems continue to rise. Although switching from CAN 2.0 to CAN FD may be difficult, the advantages in terms of speed, efficiency, and adaptability make the investment worthwhile for sectors looking to stay on the cutting edge of technology.

#CAN FD#ECUs#CAN2.0#Controlareanetwork#Dorleco#ADAS#automotive#adjustabledataspeed#automobileindustry

0 notes

Text

Can 2.0 and Can Fd: Controller Area Network

Introduction: Can 2.0 and Can FD.

Electronic control units (ECUs) in industrial and automotive communication systems have long exchanged data via the Controller Area Network (CAN) protocol. This technology has developed to satisfy the growing needs of industrial automation and contemporary cars. A turning point in this history was the switch from CAN 2.0 (Controller Area Network 2.0) to CAN FD (CAN with Flexible Data Rate) (Can 2.0 and Can Fd).

We’ll examine the distinctions between CAN 2.0 and CAN FD in this blog post, along with the benefits they offer in terms of data speed, reliability, and flexibility. We will also look into the reasons behind this choice.

1. Comprehending CAN 2.0:

For many years, the main communication protocol utilized in the automotive and industrial industries was Controller Area Network 2.0, also referred to as Classical CAN. In the 1980s, Bosch created CAN 2.0 to enhance communication amongst car ECUs. Because it offered a reliable and consistent communication channel, it was appropriate for security and real-time data-sharing scenarios.

2. CAN 2.0’s salient features:

Fixed Data Rate: Without a doubt, CAN 2.0’s biggest drawback is its fixed data rate. Its 1 Mbps top speed was adequate for early industrial and automotive applications, but as data demands have grown over time, it has since become a bottleneck. Message Length: Eight bytes per frame is the maximum message length permitted by CAN 2.0. This was sufficient for transmitting basic data, but it proved insufficient when more complicated data had to be shared, like sensor data and high-definition video.

Deterministic and Reliable: CAN 2.0’s deterministic nature is one of its benefits. Since messages are provided in a precise order with priority, critical information always comes first. Error-checking features in CAN 2.0 increase the reliability of the data.

Why CAN FD Is Required: The Need for CAN FD The shortcomings of CAN 2.0 became more apparent as technology developed. The requirement for more adaptable communications, larger message payloads, and faster data rates drove the construction of CAN FD.

Introducing CAN FD: The introduction of CAN FD, or CAN with Flexible Data Rate, aims to rectify the issues with CAN 2.0 while maintaining its main advantages of determinism and reliability. When it comes to data transfer capabilities and suitability for contemporary applications, this new protocol is a major advancement.

3. Key Advantages of CAN-FD

Flexible Data Rates: CAN FD provides flexible data rates, which is the primary benefit that is immediately apparent from the name. This indicates that it has a range of operating speeds, up to a 5 Mbps maximum data rate. Adaptability is essential to meeting the ever-increasing data requirements in today’s industrial systems and autos.

Extended Message Length: Because frames may hold up to 64 bytes of data, may FD enable longer message payloads. Sending complicated data over the network, such as HD video, requires this longer message length.

Backward compatibility: One of the clever design decisions made by CAN FD is backward compatibility with CAN 2.0. Enabling older ECUs that use CAN 2.0 to share the same network as more recent CAN FD devices facilitates a seamless transition to the new protocol.

Enhanced Network Efficiency: CAN FD makes networks more efficient by increasing data transmission rates and message sizes, which lowers latency and improves system performance as a whole.

4. CAN-FD Implementations

In many different businesses, the implementation of CAN FD has created new opportunities. Here are a few instances of how this technology is affecting things:

Could FD revolutionize the automotive industry? Numerous sensors and electrical control units used in modern cars need a quick and dependable connection.

CAN FD’s long message durations and configurable data speeds allow autonomous driving features and advanced driver assistance systems (ADAS) to transmit vital data.

Commercial Automation: In situations where real-time data flow is essential, can FD offer a reliable industrial automation solution? Accurate control and monitoring of production processes are made possible by the easy communication between robots and manufacturing equipment. The adaptability of the protocol enables it to meet the various data requirements of a wide range of industrial applications.

Aviation and Defense: Applications in the aerospace and defense industries demand a high degree of data integrity and reliability. Because of its superior error-checking techniques and capacity to manage massive data payloads, CAN FD is a great option for military and avionics applications?

5. Difficulties and Considerations

CAN-FD offers several benefits, but there are also some problems and things to think about:

Cost: CAN FD deployment may necessitate updating hardware and software, which can be expensive, especially in sectors with substantial deployments.

Complexity: Network administration may become more difficult as a result of CAN FD’s enhanced flexibility. Sufficient setup and monitoring are necessary for optimum performance.

Transition Period: To prevent disruptions and guarantee backward compatibility, sectors that already have CAN 2.0 networks in place may need to carefully plan their move to CAN FD.

Conclusion:

Can FD emerge as a key innovation in the dynamic fields of industrial and automotive communications? By enabling adjustable data speeds, longer message durations, and improved error detection, it overcomes the shortcomings of its predecessor, CAN 2.0.

Can FD’s endurance and versatility make it a vital technology for the future as industrial and automotive systems require more data transfer? For enterprises looking to stay on the bleeding edge of technology, the advantages in terms of speed, efficiency, and adaptability make the investment worthwhile, despite the potential difficulties of the shift from Can 2.0 and Can Fd.

Learn more about Can 2.0 and Can Fd Check out the top VCU services and VCU products, CAN Keypads, CAN Display. For further information, you can visit our website at Dorleco.com or send us an email at [email protected].

0 notes

Text

RISC-V: An open, Flexible, and Innovative Processor Architecture Leading the Future

As technology develops rapidly, smart devices play an increasingly important role in our lives. Have you ever wondered why your smartphone, computer, and other smart devices can run various complex software and applications? This is all thanks to the powerful processor architecture. Today, we will take you into an eagerly anticipated processor architecture - RISC-V.

RISC-V originated from the University of California, Berkeley, and was created by a group of researchers including Andrew Waterman, Krste Asanović, and Yunsup Lee. Their vision is to break the closed design pattern of computer processors and provide an open and flexible instruction set architecture. Since its release RISC-V has received widespread attention in various fields and has become a highly praised architecture.

Advantages of RISC-V:

1. Openness and freedom: RISC-V’s open-source allows anyone to use and customize it for free, without paying patent royalties.

2. Modularity and customization: RISC-V’s design allows developers to choose different modules and create custom instruction sets that meet specific needs.

3. Technological innovation: RISC-V’s openness encourages technological innovation and attracts the participation of many companies and research institutions.

4. Wide range of application fields: RISC-V can be used for embedded systems, IoT devices, servers, high-performance computing and other fields.

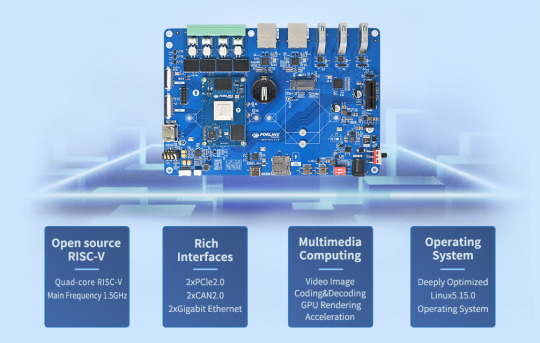

RISC-V is an eagerly anticipated open-source instruction set architecture, with a wide range of application prospects. It represents the future direction of computer processor design, and its openness, freedom, and technological innovation make it have potential in multiple fields. To boost the development of RISC-V, Forlinx Embedded launched a new product - FET7110-C System on Module, which is the first product based on RISC-V architecture.

FET7110-C SoM is based on StarFive’s 64-bit high-performance quad-core RISC-V JH7110 processor design and development, with high performance, multi-function, low power consumption characteristics, CPU stable working frequency 1.5GHz, Coremark score of 5.09 CoreMark/MHz, performance better than Cortex-A55. 7110 uses IMG BXE-4-32 MC1 architecture, provides powerful GPU processing capability, supports multi-channel video encoding and decoding, and supports rich functional interfaces such as 2 PCIe2.0, 2 Gigabit Ethernet, and 2 CAN2.0, making its application scenarios more extensive.

In terms of power consumption, the FET7110-C SoM is divided into eight power domains that can be switched independently. By using software, the CPU frequency can be adjusted, allowing customers to dynamically control the power consumption according to different application scenarios.

FET7110-C SoM is a versatile board for all industries and can be used in many industries such as industrial intelligence, smart surveillance, commercial electronics, smart home and power and energy. After rigorous testing, the FET7110-C SoM can provide stable performance support for customers' high-end applications.

The emergence of RISC-V provides a new option. In the future, with the increasing demand for openness and customization, RISC-V is expected to continue to grow in different application fields. In particular, RISC-V is expected to gain more market share in embedded systems, IoT, education and research.

0 notes

Text

Forlinx Embedded plans to launch its first RISC-V system module FET7110-C SoM.

This high-performance processor is based on the open-source RISC-V architecture, integrating 4-core U74 with a frequency of 1.5 GHz and a speed of up to 5.09 CoreMark/MHz.

It has powerful GPU processing capabilities, multiple video codecs, 2 PCIe2.0, 2 Gigabit Ethernet, 2 CAN2.0 and other commonly used interfaces, supports Linux5.15 operating system, and is perfect for industrial control, human-machine interaction, machine vision, edge computing and other fields.

Stay tuned for more updates!

Learn More: https://www.forlinx.net/company-news/481.html

0 notes

Text

Dual Isolated CAN Bus HAT for Raspberry Pi

The Dual Channel CAN Bus expansion HAT, designed for the Raspberry Pi, supports the full CAN2.0 Standard, and it features multi onboard protection circuits, high anti-interference capability, and reliable operation. As a result, it suits applications such as automotive devices or industrial automation.

https://copperhilltech.com/dual-isolated-can-bus-hat-for-raspberry-pi/

0 notes

Text

Dual Isolated CAN Bus HAT for Raspberry Pi

The Dual Channel CAN Bus expansion HAT, designed for the Raspberry Pi, supports the full CAN2.0 Standard, and it features multi onboard protection circuits, high anti-interference capability, and reliable operation. As a result, it suits applications such as automotive devices or industrial automation.

https://copperhilltech.com/dual-isolated-can-bus-hat-for-raspberry-pi/

0 notes

Photo

Arduino-Compatible Teensy 4.0 Classic CAN, CAN FD Board with 480x320 3.5" Touch LCD

The Teensy 4.0 (installed) board comes with a CAN2.0 (Classic CAN) or CAN FD port. It includes a 480x320 3.5" capacitive touch screen with ILI9488 LCD controller. Connection to the Teensy is via SPI running at 60MHz. The board can be powered through the Teensy's USB port or via an external 7 to 24 VDC power supply connected to the onboard SMPS (Switch Mode Power Supply).

https://copperhilltech.com/teensy-4-0-classic-can-can-fd-board-with-480x320-3-5-touch-lcd/

0 notes