#CFDAnalysis

Explore tagged Tumblr posts

Text

youtube

What You’ll Learn:

✅ Basics of motor power estimation for EVs. ✅ Key forces acting on an electric vehicle: rolling resistance, aerodynamic drag, hill climbing, and acceleration. ✅ Step-by-step motor sizing calculations using Excel. ✅ Factors influencing the choice of EV motors. ✅ Overview of drive cycles and their significance in EV design.

💡Check out the previous episodes of this series here: https://www.youtube.com/playlist?list=PL9-f9hWLZS61I2GoQAXCVwwYLclPNZZwA

If you’re interested in speaking with our experts and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4fKRkYV

0 notes

Text

Inorder to reduce higher cooling demands for buildings or industries, passive cooling by night-time flushing can be seen as a promising option.CFD simulations is performed for 24 hours in a peak summer day. During the day time operation, the internal loads coupled with solar heat gain is simulated. Choose the best CFD consulting services providers for high standard quality works.

0 notes

Text

Multi-objective optimization of inlet and outlet in a circular culture fish tank using the GBDT-NSGAII algorithm and computational fluid dynamic.

New Scientists Awards

Nomination Link: https://newscientists.net/award-nomination/?ecategory=Awards&rcategory=Awardee

Web Visitors: https://newscientists.net/

For Enquiry: [email protected]

#sciencefather #scientificexcellence #scientist #PublicHealthResearcher #Anthropologist #Ecologist #Geologist #MaterialsScientist #VisitingResearcher #ScienceCommunicator #RegulatoryAffairsSpecialist #ResearchFellow #MultiObjectiveOptimization #CFDAnalysis #GBDT #NSGAII #ComputationalFluidDynamics #AquacultureEngineering #GeneticAlgorithm #Hydrodynamics #AIOptimization #SustainableAquaculture

Get Connected Here:

=================

Twitter: https://x.com/awards67811

Pinterest: https://in.pinterest.com/scienceawards/

Instagram: https://www.instagram.com/afreen202564/

blogger: https://www.blogger.com/blog/posts/8014336030053733629?hl=en&tab=jj

0 notes

Text

CFD for Marine Solutions — Flowturb Solutions

Conducting practical experiments to improvise the design can be time and resource-consuming, in many cases, it is impossible to perform. CFD tools can accurately predict and analyze the performance of vessel/equipment with low cost and time.

The following are some of the marine and aerodynamic design optimization

Optimization of marine vessel hull design

Optimization of wind turbine

Evaluation of aerodynamic design for vehicles

Visit us: https://flowturb.com/cfd-services-agency/maritime-services/

1 note

·

View note

Photo

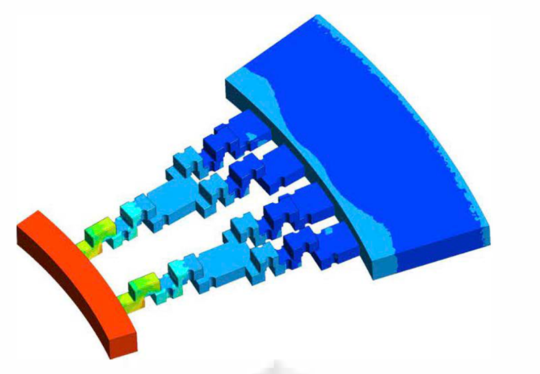

Design and Analysis of Mixed Flow Pump Impeller

by B. Naresh | P. Krishna | N. Sunny Deepak | P. Laxmi Prasanna ""Design and Analysis of Mixed Flow Pump Impeller""

Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-3 | Issue-3 , April 2019,

URL: https://www.ijtsrd.com/papers/ijtsrd23305.pdf

Paper URL: https://www.ijtsrd.com/engineering/mechanical-engineering/23305/design-and-analysis-of-mixed-flow-pump-impeller/b-naresh

call for paper engineering, paper publication for engineering, engineering journal

Mixed flow pump impeller is a centrifugal pump device where the transition of fluid flow takes place in both axial and radial direction. In this work a mixed flow pump impeller has been designed using CATIA V5 software tool and analyzed using the fundamentals of fluid mechanics and turbo machinery. As per many researchers there are many methods are used to design the impeller but still the optimized design of the mixed flow pump impeller blade has been a cumbersome work. The impeller blades have been designed by varying the semi cone angle. The CFD analysis is the advanced tool used in pump industry to improve the efficiency hence the CFD analysis is carried over the model to predict analytical values and to solve problems the problems that involves the fluid flow using ANSYS workbench 16.0. Because of its anti corrosive property stainless steel is used as material for impeller and water liquid used as a fluent which flow around the impeller. From the CFD analysis the velocity and pressure in the outlet is predicted. The outlet values will be useful for calculating the efficiency of the pump.

0 notes

Text

youtube

💡 What You’ll Learn: Setting up a BTMS simulation in Ansys Fluent. Understanding volumetric heat sources and material properties. Using the density-based solver with turbulence models. Analyzing results and running parametric studies.

🔍 Key Highlights: Geometry and meshing overview. Creating named selections and applying boundary conditions. Viewing results using CFD-Post. Running parametric analysis for optimization.

🚀 Take your first step into simulating Battery Thermal Management Systems with confidence. Perfect for students, engineers, and EV enthusiasts! Don't forget to like, subscribe, and hit the bell icon for updates on more simulation tutorials.

💡Check out the previous episodes of this series here: https://www.youtube.com/playlist?list=PL9-f9hWLZS61I2GoQAXCVwwYLclPNZZwA

If you’re interested in speaking with our experts and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3Zm5B8Z

#youtube#skilllync#mechanicalengineering#cfd#engineering#cfdanalysis#cfd simulation#electricvehicle#ansysfluent#ansys#turbulence

0 notes

Text

High Velocity Oxygen Fuel Nozzle Spray CFD ANALYSIS

Uncover the secrets of HVOF nozzle spray with CFD analysis. Explore internal flow, particle behavior, and optimize coating formation for superior results.

The best way for you to get the necessary information is by contacting a reputable CFD Consulting Services or a Structural Analysis Services provider.

#CFDAnalysis#CFDConsultingServices#DiscretePhaseModelling#flowrate#graphlertech#HighVelocityOxy-Fuel#HVOF

0 notes

Text

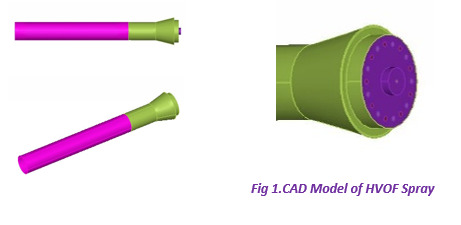

High Velocity Oxygen Fuel Nozzle Spray CFD ANALYSIS

INTRODUCTION

High Velocity Oxy-Fuel(HVOF) Spray is used to coat corrodible components with resistive materials. It utilizes highly compressed fuel that combust with oxygen to accelerate the momentum and temperature of the particle and also to make the flow supersonic.

Supersonic nature of flow in an atmospheric condition producing sequential pressure expansion and contraction letting out a phenomenon called Shock Diamonds. These Shock Diamonds a.k.a pressure pulsations produced due to hyper pressure gradient with respect to atmospheric pressure.

With the aid of the CFD technology, the complex Pressure Gradient of supersonic flow nature can be vividly captured and the design progress can be accelerated. Thus, CFD is an important tool for Flow physics as it will reduce the time consuming and expensive experimental procedures.

SCOPE OF THIS RESEARCH WORK

To model the combustion of fuel and oxygen in a compressed chamber.

Get a higher temperature and velocity pulsation proportional to pressure pulsation.

Injection of spray material using Discrete Phase Modelling (DPM).

MODEL ACQUISITION PROCESS

The HVOF Setup is experimentally analysed in Annamalai University, Chidambaram. From the resource the component is manually measured and the model is generated in CAD software package Pro-E Wildfire 5.0.

CFD ANALYSIS

With a goal of capturing shock diamonds of the supersonic flow of HVOF Spray, CFD is utilized in a following systematic way.

The best way for you to get the necessary information is by contacting a reputable CFD Consulting Services or a Structural Analysis Services provider.

VALIDATION STUDY

CFD procedure has lot of variables such as grid count, turbulence model, and discretization scheme, so it is important for a CFD engineer to play between those variables without affecting the solution accuracy. A commercial Computational Fluid Dynamics (CFD) code, ANSYS CFX V14.5 with a k-ε Standard turbulence model with Eddy Dissipation Model for combustion was used and the impact of supersonic flow in an atmospheric pressure and the Pressure pulsation was obtained.

The numerical results are compared with the experimental data to arrive at the best computational procedure (BCP) and Discrete Phase Modelling (DPM) is proceeded to introduce the surface coat material into the domain.

INFLUENCE OF CFD TECHNIQUE IN THIS PROBLEM

The Shock Diamond occurrence mainly depends on the hyper pressure difference between the atmosphere and combustion chamber. It depends on the flow rate of fuel, oxygen and volume of the combustion chamber.

Working with a leading Stress Analysis Services provider or well-known Product Design Companies will make new routes possible.

CONCLUSION

A Special phenomenon of Fluid flow is acquired in computational methodology

Surface Coat material injection and Combustion of fuel-oxygen is modelled

#CFDAnalysis#CFDConsultingServices#DiscretePhaseModelling#flowrate#graphlertech#HighVelocityOxy-Fuel#HVOF

0 notes

Text

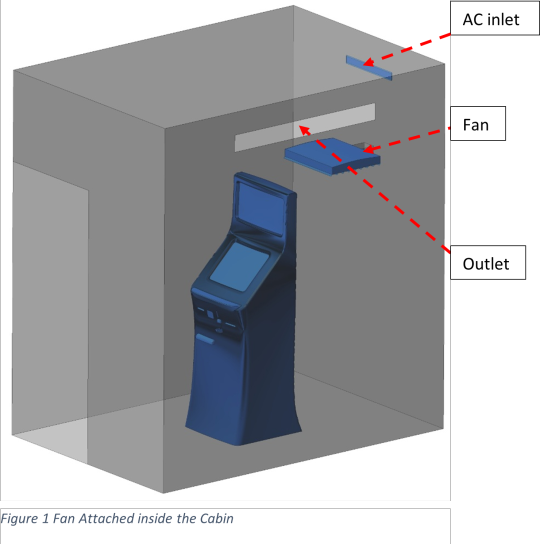

Enhancing Energy efficiency in ATM cabin and DATA centers using CFD Analysis

Discover how CFD analysis optimizes energy use in ATM cabins & DATA centers. Enhance efficiency &reduce costs. Learn more!

Contact a well-known CFD Consulting Services or a Structural Analysis Services provider to acquire the required information.

#airflowdistribution#airconditioningunits#ATM&datacenters#CFDAnalysis#CFDConsultingServices#Energyefficiency#finiteelementanalysis#StressAnalysisServices

0 notes

Text

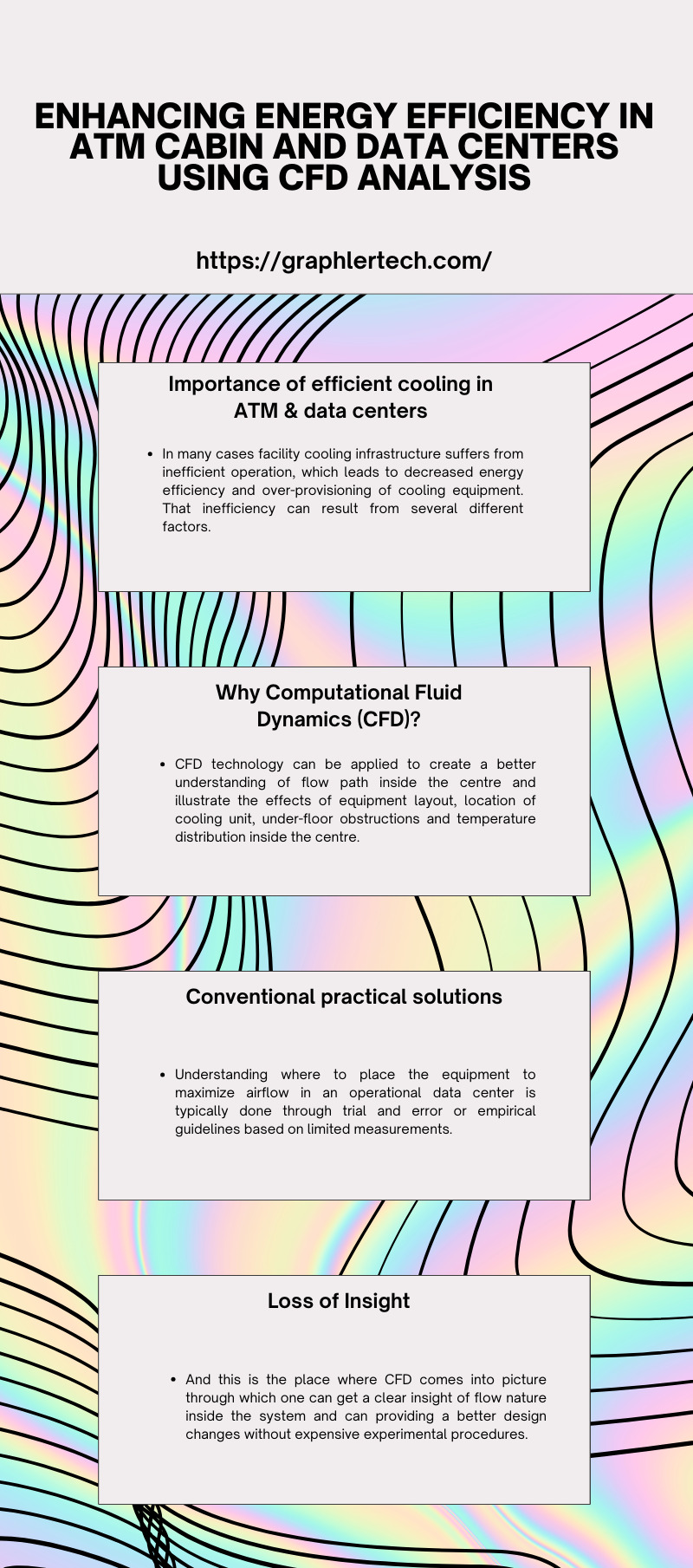

Enhancing Energy efficiency in ATM cabin and DATA centers using CFD Analysis

Introduction

Banks and other entities are continued to be challenged by the increase in demand for energy utilization of commercial made air-conditioning units for cooling of ATM centers & data centers. In operational perspective, this means more energy is utilized and thus more the running over-head cost per year.

In this case, the existing cooling infrastructure may not be suitable or efficient which make those involved in ATM and data center must integrate design and operational priorities to ensure long term viability of their facilities.

Importance of efficient cooling in ATM & data centers

However, in many cases facility cooling infrastructure suffers from inefficient operation, which leads to decreased energy efficiency and over-provisioning of cooling equipment. That inefficiency can result from several different factors. For example, the cooling airflow is not distributed according to the demands of the equipment, or the discharged hot air is not properly contained or vented.

With continuing increases of heat generation in ATM & data centres, plus dramatically rising energy costs, banks and other entities are coming under greater pressure to improve the efficiency of cooling systems and reduce power consumption.

Why Computational Fluid Dynamics (CFD)?

CFD modelling would enable data centre mangers to accurately depict and understand the use of cooling resources and allow for appropriate infrastructure right-sizing. This could significantly help prevent organizations from under- or over-provisioning the infrastructure. Instead of buying cooling equipment they do not need, they might discover that they can simply reposition what they have.

Contact a well-known CFD Consulting Services or a Structural Analysis Services provider to acquire the required information.

Conventional practical solutions

It’s currently estimated that, on average, 5-10 percent of company’s budgets are dedicated to energy costs. This percentage will rise, inevitably. It seems that government mandates will soon force facilities operators to reduce energy consumption. Many companies are already evaluating and/or implementing alternative solutions to reduce their energy use and make data centre cooling processes more efficient.

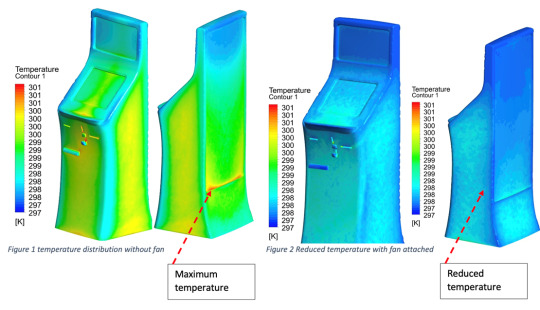

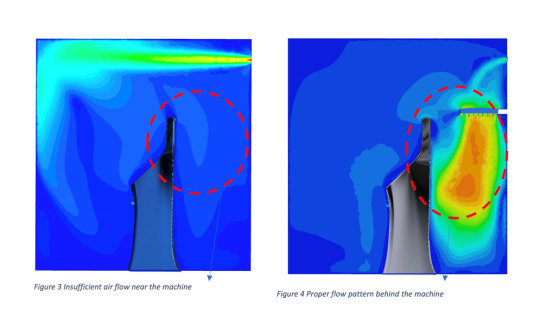

Flow pattern inside a general ATM cabin is studied using CFD technique. In this study, air flow from AC duct is applied into the cabin to study the flow nature and the operating temperature range over the ATM machine.

In order to have a good air circulation a fan is introduced under the AC duct as shown in figure 2. And the suction through the fan is found to have a good flow pattern and reduced temperature distribution over the machine as shown in figure 6.

Loss of Insight

These methods often do not consider the complex fluid dynamics that govern air flow distribution, and consequently do not produce the expected flow rates. An adjustment in one section of the data center will affect flow rates throughout the other areas. This kind of design procedure is labor-intensive, time-consuming and expensive –and still seldom yields an optimal, efficient solution.

And this is the place where CFD comes into picture through which one can get a clear insight of flow nature inside the system and can providing a better design changes without expensive experimental procedures.

Collaborating with the best Stress Analysis Services provider or top Product Design Companies will open up new ways.

#airflowdistribution#airconditioningunits#ATM&datacenters#CFDAnalysis#CFDConsultingServices#Energyefficiency#finiteelementanalysis#StressAnalysisServices

0 notes

Text

Enhancing Energy efficiency in ATM cabin and DATA centers using CFD Analysis

Discover how CFD analysis optimizes energy use in ATM cabins & DATA centers. Enhance efficiency & reduce costs. Learn more!

#airflowdistribution#airconditioningunits#ATM&datacenters#]#CFDAnalysis#CFDConsultingServices#Energyefficiency#finiteelementanalysis#StressAnalysisServices

0 notes

Text

Acoustic CFD Analysis in Valves

Explore how Acoustic CFD Analysis improves valve performance. Unlock efficiency and optimize your systems with this groundbreaking approach.

#AcousticCFDAnalysis#AcousticModelling#CFDAnalysis#CFDConsultingServices#controlvalve#Noisetrim#StructuralDesignServices

0 notes

Text

Acoustic CFD Analysis in Valves

Why is Acoustic Modelling important?

Acoustic waves are pressure pulses travelling through a compression medium at the speed of sound in that medium. Predicting valve acoustics is very tedious and costly for running experiments in laboratory inorder to evaluate the effectiveness of one design over the other.

Predicting valve acoustics using CFD has become possible with advanced computational capabilities and different turbulent models such as RANS & LES to evaluate the pressure sound levels with reasonable accuracy. Using CFD stands to the reason that if we could understand the turbulent time varying nature of pressure fields, we could calculate the noise generated in the valve trim with reasonable accuracy and that with just a fraction of cost and time in comparison to a physical laboratory experimention and measurements.

Role of Noise trim and CFD analysis to predict Acoustic level:

In a control valve where pressurized gas, steam or vapor is flowing contains enormous amount of potential energy. This stored potential energy is converted into other forms such as turbulent fluid motion, heat, sound waves, vibration etc.

Majority of sound generated in a control valve is due to turbulent fluid motion. Turbulence causes large pressure fluctuations due to the formation of eddies of all sizes. The size of the eddy and fluid velocity determines the frequency of pressure fluctuation. Larger eddies produce lower frequency noise and vice versa.Obtain reliable insights from an excellent CFD consulting services or an Structural Design Services company.

For this reason Noise trims are used to reduce the aerodynamically generated noise by the fast moving fluid stream. This is done by increasing the pressure drop of the fluid in the trim. This is done in Single and multi-stage noise trim by staging the pressure drop and bypassing the flow through many openings.

CFD analysis provides substantial insight on the pressure fluctuation, intensity of turbulence, pressure drop across stages and Acoustic level in the noise trim. This helps product development team to virtually validate the noise attenuation ability of that particular design.

The following observations can be made -

Pressure contour (left) and velocity vectors (right) shows supersonic flow through the low noise trim.

Calculate acoustical conversion efficiency at each stage of the noise trim.

Intensity of turbulence coming into each stage due to restrictions.

Evaluate pressure drop ratio at each stage.

Coimbatore has the best Stress analysis services, which are provided by Graphler Technology Solution. A team which is well experienced with 10 years industrial knowledge. Visit our websites or contact us for more information.

#AcousticCFDAnalysis#AcousticModelling#CFDAnalysis#CFDConsultingServices#controlvalve#Noisetrim#StructuralDesignServices

1 note

·

View note

Text

Explore how Acoustic CFD Analysis improves valve performance. Unlock efficiency and optimize your systems with this groundbreaking approach.

#AcousticCFDAnalysis#AcousticModelling#CFDAnalysis#CFDConsultingServices#controlvalve#Noisetrim#StructuralDesignServices

0 notes

Text

CFD can provide the best ventilation design by mitigating the above mentioned factors. Every building is different and variety of factors influence the effectiveness of the ventilation such as location, orientation, materials used and type of activity. Get a clear cut knowledge by consulting a well established CFD Consulting Services or an Engineering Animation Services Company

#CADConversionServices#CFDAnalysis#CFDAnalysisServices#EngineeringAnimationServices#ForcedVentilation#LargeIndustrialSheds#NaturalVentilation#ProductAnimationServices

0 notes

Text

Discover the power of CFD simulation for predicting ventilation behaviour in manufacturing units through predictive modelling and explore the benefits of using CFD simulation.

0 notes