#CNC Turned Aluminium Parts

Text

https://www.mxmparts.com China CNC Turning Service customize stainless steel turned parts, Aluminium turned parts, Copper and Brass turned parts.

#China CNC Turning#China Turned Parts#China Turning Service#China CNC Turned Parts#Stainless Steel parts#Steel Turned Parts#Aluminium Turned Parts#Brass Turned Parts#CNC Turned Aluminium Parts#Turned Brass Parts#mxmparts

1 note

·

View note

Text

Best CNC Laser Cutting, Aluminium Welding & Bending Services

Pitrukrupa Engineering provides CNC laser Cutting Work, CNC Bending Work, Aluminum Welding Work in India, USA, Canada, Brazil, UAE, Australia, Oman, South Africa, Vietnam, Afghanistan, Israel, UK.

CNC Laser Cutting Work

Our laser cutting machines can produce highly accurate and intricate cuts in various materials, including metals, plastics, and composites. We can handle complex geometries and patterns, ensuring precise and efficient component fabrication.

CNC Bending Work

Our CNC bending machines can bend materials with exceptional precision and consistency. We can handle complex bends and angles to meet your specific requirements. Bend a variety of materials, including metals and plastics.

Aluminum Welding Work

Our skilled welders specialize in various aluminum welding methods, including TIG, MIG, and FCAW. We can handle a wide range of aluminum alloys and welding applications. Aluminum welds using advanced techniques and equipment.

CNC Machining Components & Parts

CNC Machine Components

VMC Machine Components

CNC Turn Mill Components

5 Axis Milling Components

4 Axis Milling Components

CNC Lathe Machine Components

CNC EDM Components

CNC Turn Mill Components

Aluminium Extrusion

Aluminium High Pressure Die Casting

Aluminium And Steel Precision Welding Fabrication

CNC Machining Job Work Services

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

For More Details

Click Here : https://www.pitrukrupaengineering.com/

0 notes

Text

youtube

High precision cnc machining aluminum parts

We make aluminium cnc machining parts, cnc machining services parts, cnc turning and milling machining parts, brass cnc machining parts, machining service plastic cnc peek milling parts, cnc precision machining custom stainless steel parts, custom cnc machining service, 3d printing aluminum cnc machining parts.

-----------------------------------------------------

https://mxymachining.com

0 notes

Text

Custom Precision Aluminium CNC Turning parts

Hsmolds.net offers custom precision aluminum CNC turning parts, tailored to meet diverse industry needs. With advanced machining technology, they ensure exact specifications and high-quality finishes. From prototypes to large-scale production, their expertise guarantees precision and reliability. Explore their range of services for innovative solutions in aerospace, automotive, and beyond. Experience efficiency and excellence with Hsmolds.net for your CNC turning requirements.

0 notes

Text

youtube

Precision mold parts machining cnc

We make parts machining cnc custom machined turning parts, cnc precision machining parts, cnc machining aluminium alloy parts, aluminum cnc machining parts, cnc precision machining custom stainless steel parts, cnc alumimum stainless steel turning part, cnc turning milling parts, high precision cnc machining aluminum parts.

--------------------------------------------------

0 notes

Text

Understanding the Manufacturing Steps for CNC Machining Parts

A variety of parts and components may be produced using the flexible and accurate CNC machining method. It includes removing material from a workpiece and shaping it into the required form using computer-controlled machinery. Numerous sectors, including aerospace, automotive, medical, and electronics, employ this technique extensively. Let's examine the main production processes that go into creating CNC-machined items in order to better grasp how CNC machining operates.

Step 1: Design and CAD Modeling

The design of the item or component is the initial stage in the CNC machining process. CAD (Computer-Aided Design) software is used by designers and engineers to produce intricate 3D models of the component. This model functions as a machining process plan. With the use of CAD software, exact specifications, measurements, and tolerances can be set, guaranteeing that the finished product satisfies all necessary requirements.

Step 2: Converting CAD to CAM

After CAD modelling is finished, it must be translated into a format that the CNC machine can read. Computer-Aided Manufacturing, or CAM, software is used for this. The toolpath, or collection of instructions that tells the CNC machine how to move and cut the material, is created by CAM software. The toolpath contains details on feed rates, cutting speeds, and other parameters in addition to the type of tool that will be utilised.

Step 3: Material Selection

One of the most important aspects of CNC machining is selecting the appropriate material. In addition to being compatible with the machining process, the material must be appropriate for the intended use. Metals like steel, titanium, and aluminium, as well as polymers like ABS, nylon, and PEEK, are frequently utilised in CNC machining. Composites are also frequently utilised. Strongness, longevity, weight, and cost are among the considerations that go into choosing a material.

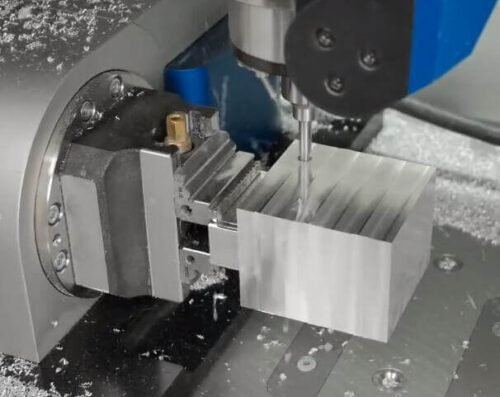

Step 4: Setting Up the CNC Machine

Before machining can begin, the CNC machine needs to be set up. This involves installing the appropriate cutting tools and securing the workpiece in place. The machine operator ensures that the workpiece is properly aligned and that the cutting tools are correctly positioned. Calibration is also performed to ensure that the machine's movements are accurate and precise.

Step 5: Programming the CNC Machine

With the machine set up, the next step is to program it using the toolpath generated by the CAM software. The program is loaded into the CNC machine's controller, which interprets the instructions and executes the machining process. The operator may perform a dry run or simulation to verify that the program is correct and to identify any potential issues before actual machining begins.

Step 6: Machining the Part

The machining process has different steps to create specific shapes and sizes. Common CNC machining operations include:

Milling: A rotating cutting tool removes material to make flat surfaces, slots, and pockets.

Turning: The workpiece spins while a cutting tool shapes it into cylinders.

Drilling: A rotating drill bit makes holes in the workpiece.

Tapping: Threads are cut into pre-drilled holes for screws.

Grinding: A grinding wheel smooths the surface for fine finishes and tight tolerances.

During machining, the CNC machine follows the programmed toolpath, precisely removing material to create the desired part. The process is highly automated, allowing for consistent and repeatable results.

Step 7: Quality Control and Inspection

The part is subjected to stringent quality control and inspection following machining to make sure it satisfies the necessary tolerances and requirements. Numerous measurement instruments and methods are employed, including optical inspection systems, coordinate measuring machines (CMM), micrometres, and callipers. Before the part moves on to the following step, any deviations or flaws are found and fixed.

Step 8: Post-Processing

Post-processing procedures could be required, depending on the specifications of the component. These procedures can involve heat treatment (increasing material qualities), deburring (removing burrs and sharp edges), polishing (getting a smooth surface finish), and coating or painting (improving appearance and protection). Making ensuring the part is prepared for its intended application is the goal of post-processing.

Step 9: Assembly and Integration

The CNC-machined part might need to be merged with other parts if it's a part of a bigger assembly. This entails positioning, fitting, and fastening the component. Depending on the complexity and volume of manufacturing, assembly can be completed manually or with the aid of automated equipment.

Step 10: Final Inspection and Testing

The completed product goes through one more round of testing and inspection before being dispatched to the customer. This guarantees that the component satisfies all functional and performance specifications. Depending on the part's intended use, testing may involve stress, load, functional, and environmental tests. The component is cleared for shipping after passing every test.

Conclusion

Each step is critical to ensuring that the final product meets the required specifications and standards. By understanding the manufacturing steps involved in CNC machining, Manufacturers can produce high-quality parts and components with precision and efficiency. Whether for prototyping or mass production, CNC machining continues to be a vital technology in modern manufacturing.

Do you want to start your next CNC project with us? Upload your file here and get an Instant Quote in minutes! For more information, send us an email at [email protected]

#cnc_machining #rapid_prototyping #manufacturer

0 notes

Text

The Guide to CNC-Machined Aluminum Parts

The Guide to CNC-Machined Aluminum Parts

Introduction

CNC machining is a versatile process used to create precise parts from various materials. Among these materials, aluminum stands out for its cost-effectiveness, abundant availability, and ease of machining. In this guide, we’ll explore the benefits of CNC-machined aluminum parts and why it’s a popular choice for both large-scale production and small-batch projects.Get more news about aluminium cnc machining parts discount,you can vist our website!

Advantages of Aluminum CNC Machining

Cost-effectiveness: Aluminum’s abundant availability and ease of machining often result in competitive prices for CNC-machined parts. It’s a budget-friendly choice for various industries.

Lightweight and Strong: Aluminum combines low weight with excellent strength. This makes it ideal for aerospace, automotive, and consumer goods applications.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing good resistance to corrosion. This property is crucial for parts exposed to harsh environments.

High Machinability: Aluminum is easy to machine, allowing for efficient production of complex geometries. Tight tolerances (as tight as +/- 0.001 inches) can be achieved with CNC milling and turning processes.

Conclusion

When considering custom CNC-machined parts, aluminum is a reliable choice. Its cost-effectiveness, lightweight properties, and corrosion resistance make it suitable for a wide range of applications. Whether you’re prototyping or producing components, aluminum CNC machining delivers consistent quality and precision.

0 notes

Text

Stainless Steel Machined Parts

Usually we all think of stainless steel as being utilised for items such as home furnishings or cutlery and earlier in the early 90's beer cans!! Well, did you actually know?? Stainless steel plays a key part as a material within the precision machining industry even more so in today's CNC machinery based processes. Whether you travel on an aeroplane or a cruise-liner you can guarantee that many of the working or exposed components have been machined from a grade of stainless steel.

CAD-CAM software further enables the capability to manufacture stainless steel components to the highest specification.

Today's common methods of machining stainless steel components can be one of many including turning, milling, drilling and boring using state-of-the-art CNC Machinery. In the aerospace industry close tolerance, complex parts are required and are produced using 5-Axis milling machines along with Multi-Axis CNC mill/turning machines. CAD-CAM software further enables the capability to manufacture stainless steel components to the highest specification.

Why Stainless Steel??

Well, this material combines a number of excellent properties. Firstly, stainless steel has great corrosion resistance making it appealing for applications that are exposed to bad weather and moisture. Secondly, It offers greater strength than materials such as mild steel and aluminium and can be further enhanced with heatreatment processes. As you guessed it, it makes for a great choice for aerospace components.

Thanks for taking the time to read this article and we hope it has given you some valuable insight into stainless steel machined parts.

Thank you!!

0 notes

Text

CNC Machining Services EU - Kipacboatstands.com

At our company, we specialize in providing top-quality CNC machining services for a diverse range of industries, including automotive, construction, and manufacturing. Our state-of-the-art equipment and highly skilled team of engineers and machinists enable us to meet your most demanding project requirements with precision, efficiency, and exceptional quality. CNC Machining Services EU

Our Comprehensive CNC Machining Services:

CNC Turning: Our expert team can create intricate and complex shapes with our advanced CNC lathes, ensuring high-quality and precise results for all your turning needs, including shafts, pins, and other cylindrical components.

CNC Milling: Our cutting-edge CNC milling machines enable us to perform precision milling operations on a wide range of materials, including steel, aluminium, and other alloys. We can create custom parts, prototypes, and large-scale production runs for your specific requirements.

CNC Drilling: Our precision drilling services deliver accurate, consistent holes in a variety of materials and sizes. From simple holes to complex patterns, we have the expertise to meet your drilling needs.

Surface Grinding: We offer surface grinding services to achieve the finest finishes and tightest tolerances for your parts. Our skilled team can grind flat, parallel, and square surfaces, ensuring your components meet the highest quality standards.

Why Choose Us?

Advanced Technology: Our state-of-the-art CNC machining centres and software ensure that your projects are completed with the highest level of accuracy, efficiency, and quality. • Experienced Team: Our team of skilled engineers and machinists have extensive experience in CNC machining, allowing us to handle complex projects with ease and confidence. Vessel Support Systems

Quality Assurance: We implement rigorous quality control measures to ensure that every component we produce meets or exceeds your expectations. Our commitment to quality is reflected in our adherence to ISO 9001:2015 standards and compliance with EN ISO 2768-1, EN ISO 13920, and EN ISO 9013.

Competitive Pricing: We strive to offer the best value for your investment by providing top-quality CNC machining services at competitive prices.

Customer Satisfaction: We work closely with you throughout the entire machining process to ensure your project is completed to your specifications and meets your unique requirements.

0 notes

Text

Welcome to the Ming Xiao Mfg YouTube channel! In this informative video, we will delve into the world of Aluminum Turned Parts. As a leading supplier in the industry, Ming Xiao Mfg is here to provide you with valuable insights and expertise on this topic.

Join us as we explore the intricacies of Aluminum Turned Parts and their applications in various industries. We will showcase our state-of-the-art manufacturing processes that ensure precision and reliability in every component we produce. With our years of experience, we are dedicated to delivering high-quality parts that meet your specific requirements.

Throughout this video, we will showcase real-life examples and testimonials from satisfied customers who have benefited from our Aluminum Turned Parts. From automotive to aerospace, electronics to machinery, our components have proven their worth in diverse applications.

So, whether you're an industry professional seeking detailed information or simply curious about Aluminum Turned Parts, this video is a must-watch. Join us on this journey as we demonstrate why Ming Xiao Mfg is the go-to supplier for top-notch Aluminum Turned Parts. Subscribe to our channel for more exciting content on precision manufacturing and stay tuned for future videos.

www.mxmparts.com

#AluminumTurnedParts #PrecisionComponents #HighQualitySuppliers #ExpertCraftsmanship

#aluminum parts cnc turning#turned parts#china metal parts#cnc turning#china supplier#cnc turned parts#custom parts#aluminum turning parts#aluminium turned parts#custom aluminum parts#cnc turned aluminum parts#china turned parts

0 notes

Text

Precision CNC Machine Job Work — CNC Machining Components Manufacturer

Pitrukrupa Engineering is ISO 9001:2015 certified Manufacturer, Exporter and Supplier of high performing CNC machine Components. Pitrukrupa Engineering is engaged in Service Providing in providing CNC Machine Job Work, VMC Machine Job Work, EDM Wire Cut Work and CNC Lathe Machine Job Work since its inception in 2009. We provide CNC Machining Components and Services job Work in India, USA, Canada, Brazil, UAE, Australia, Oman, South Africa, Vietnam, Afghanistan, Israel, UK.

CNC Machining Components & Parts

CNC Machine Components

VMC Machine Components

CNC Turn Mill Components

5 Axis Milling Components

4 Axis Milling Components

CNC Lathe Machine Components

CNC EDM Components

CNC Turn Mill Components

Aluminium Extrusion

Aluminium High Pressure Die Casting

Aluminium And Steel Precision Welding Fabrication

CNC Machining Job Work Services

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

For More Details

Click Here : https://www.pitrukrupaengineering.com/

0 notes

Text

youtube

High precision parts cnc turning machining

We make aluminium cnc machining parts, cnc machining, component metal machining parts cnc aluminium parts, cnc parts machining service, 5 axis cnc milling machining services, 5 axis cnc milling machining services, cnc machining parts manufacturers.

-----------------------------------------------

https://mxymachining.com

0 notes

Text

Custom cnc aluminium turning parts in china

At Hsmolds.net, discover precision-engineered custom CNC aluminum turning parts in china tailored to your specifications. Our China-based facility employs cutting-edge technology and skilled craftsmanship to deliver high-quality components for diverse industries. With a commitment to excellence and efficiency, we ensure prompt delivery and competitive pricing. Experience superior performance and reliability with our custom CNC aluminum turning parts, visit Hsmolds.net today.

0 notes

Text

CNC Turning: Accuracy and Effectiveness in Production

Efficiency and precision are critical in the industrial sector. Among the many machining techniques, CNC turning is a crucial method that combines these two attributes to create components of superior quality. CNC turning, whether it be in the electronics, automotive, or aerospace industries, is a vital procedure that forms the foundation of many contemporary production operations.

What is CNC Turning?

A workpiece, typically cylindrical, is rotated while a cutting tool is applied to remove material and form the required shape. This process is known as CNC (Computer Numerical Control) turning. Computer programming on the CNC lathe, the equipment utilized for this procedure, manages the workpiece's rotation and the movement of the cutting tool. Each part is machined to precise specifications in this precisely controlled environment, ensuring that there is slight variance from piece to piece.

How CNC Turning Works

Several crucial phases are involved in the CNC turning process:

Programming: A digital design is first created using CAD (Computer-Aided Design) software. Once translated into a program, the CNC machine can follow this design. The software provides guidance on the feed rate, speed, and tool movements needed to make the item.

Setup: The workpiece is firmly fixed to the CNC lathe's spindle. The cutting tool is also adjusted, either automatically or manually, based on the part's intricacy.

Turning: As it rotates, the cutting tool moves along the workpiece's surface, removing material to form the part. To make complex geometries like grooves, threads, and tapers, the tool can travel in numerous directions, usually along the X and Z axes.

Finishing: After rough turning, the item may undergo finishing procedures like coating or polishing to obtain the required surface quality and dimensions.

Inspection: The completed part is inspected to ensure it satisfies the necessary requirements. Automated inspection systems or precise measuring equipment may be necessary for this.

Advantages of CNC Turning

High Precision: CNC turning machines can produce high-precision parts with tolerances as small as microns, which is an advantage. For sectors like aircraft and medical equipment, where even the tiniest deviation can have serious consequences, this level of precision is crucial.

Consistency: CNC machines can produce vast batches of similar items with slight variations since they operate according to preprogrammed instructions. This uniformity is essential for mass production to retain quality.

Efficiency: CNC turning's automated nature minimizes the need for human involvement, speeding up production and lowering labour expenses. It is very efficient because it can produce parts precisely and quickly.

Versatility: CNC technology can turn a wide variety of materials, including polymers and composites, as well as metals like titanium, steel, and aluminium. Because of its adaptability, producers can produce parts for a range of uses.

Complex Geometries: Manual turning would be difficult or impossible to do with CNC turning machines' ability to manufacture detailed features and elaborate shapes. This aptitude is especially helpful in fields that demand intricate patterns.

CNC Turning Applications

Several industries employ CNC turning for a variety of purposes, including:

Automotive: Producing precision parts that are essential to the operation of vehicles, such as engine and transmission parts.

Aerospace: Manufacturing lightweight, highly durable parts for spaceships and aeroplanes where accuracy is essential.

Medical Devices: Precision and biocompatibility are critical in the creation of complex components for medical devices and implants.

Electronics: Machining connections, housings, and other parts for electronic gadgets.

Industrial Equipment: Manufacturing shafts, bushings, and other parts for tools and machines are known as industrial equipment.

Frequently Asked Questions Regarding CNC Turning

1. What is turning with a CNC machine?

During the CNC turning process, a workpiece is turned to shape it by removing material with a cutting tool. Computer software controls the process, enabling the accurate and reliable manufacture of cylindrical pieces.

2. Which materials are suitable for CNC turning?

CNC turning can work with numerous materials, including plastics and composites, as well as metals like titanium, steel, and aluminium. The material selection is determined by the particular needs of the component being made.

3. What benefits does CNC turning offer?

High precision, consistency in production, cost and time efficiency, material utilization diversity, and the capacity to generate complicated shapes are just a few benefits of CNC turning.

4. What distinguishes CNC turning from CNC milling?

CNC turning produces items that are usually cylindrical since the workpiece rotates while the cutting tool stays stationary. CNC milling, on the other hand, allows for the fabrication of more complicated designs since the cutting tool rotates while the workpiece either remains stationary or moves in numerous directions.

In summary

The CNC turning process is an essential machining method that provides unparalleled accuracy, effectiveness, and adaptability. CNC turning is a vital component of contemporary production since it guarantees that every element follows strict requirements, regardless of whether it is used to make straightforward cylinder pieces or intricate geometries. CNC turning gives businesses that prioritize quality and consistency the exact and dependable outcomes they need to stay ahead of the competition.

1 note

·

View note

Text

youtube

High precision parts cnc turning machining

We are specialize in cnc precision turning parts, cnc lathe processing turning center parts, precision cnc turning milling aluminum parts, stainless steel cnc turning machining parts, oem high precision cnc machining service, precision small metal cnc machining parts, brass cnc machining parts, aluminium alloy cnc milling turning parts .

-------------------------------------------------------------

https://cncmtf.com

0 notes

Text

Top Aluminum CNC Machining Service in China

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes