#CNC components

Text

How do CNC components differ from traditional machining parts?

CNC (Computer Numerical Control) components differ from traditional machining parts primarily in precision, automation, and complexity handling. CNC machining employs computer-controlled systems, ensuring higher accuracy and consistency in part dimensions compared to traditional methods reliant on manual operation. CNC machinery can tackle intricate geometries efficiently, thanks to its multi-axis control, whereas traditional machining may struggle with complex designs due to operator limitations. Moreover, CNC processes are more automated, reducing manual intervention, minimizing errors, and enabling faster production rates. Overall, CNC components offer superior precision, automation, and versatility, making them preferred for various manufacturing applications.

0 notes

Text

#Stainless Steel Pin Manufacturer in Delhi#Stainless Steel Pins Manufacturer#Hinge Pins Manufacturer#Dowel Pins Manufacturer#KNURLED PINS Manufacturer#Precision CNC Turned Component Manufacturer#Precision Turned Component Manufacturer

2 notes

·

View notes

Text

The Importance of CNC Turned Components in Manufacturing

Manufacturing has been around for hundreds of years, but the advancements made by CNC machine manufacturers today are changing the world as we know it. As a manufacturer, you can benefit from these advancements in many ways. In this article, we'll explore some of them:

Precisions

CNC machining is used to manufacture components that require high precision. The most common types of components are those used in aerospace, medical and automotive industries such as aircraft engines and gears. CNC machined parts undergo rigorous testing at the factory before they're shipped out to customers.

The importance of precisions can also be seen in consumer products such as beer taps or wine glasses where a small deviation from the desired dimensions would result in unacceptable product quality.

Less Waste

CNC machines are more precise and they can produce parts with less waste. This is because they use a machine vision system that guides the cutting process, ensuring that only the desired material is cut. The computer also calculates how many times each part should be machined before it gets out of tolerance, so you don't have to worry about running into problems because of over-machining or under-machining your parts.

These benefits come at an expense though — CNC machines require more space than manual operations do, which means your manufacturing environment will need to accommodate them as well. In addition, there's always some risk involved when using computers in manufacturing processes: if something goes wrong during operation (e.g., power failure), your entire production line could shut down for hours at a time until repairs are made!

Higher Volume

A CNC machine is a tool that can be used to make many parts at once, which means that it can save time and money. In addition, CNC machines can produce parts with the same dimensions. This means that you won’t have to waste time or money on making parts again if they aren't the same as the other ones already in production.

Manufacturers rely on CNC turning for many reasons

CNC turning is a highly precise process that cuts the material directly into the desired shape and size. The machine can be programmed to perform any number of operations, such as cutting holes and slots or engraving text or images onto the finished product.

CNC turning allows manufacturers to produce complex shapes quickly and cost-effectively because it uses computer-aided design (CAD), which makes it possible for workers who don't have advanced training in engineering technology but possess basic knowledge of computer programming languages like SolidWorks or AutoCad to create intricate designs using specialized software programs running on their computers.

About CNC Manufacturing

Computer numerical control (CNC) machines are used in the manufacturing industry to make components. They are also used by aerospace and defense industries, as well as automotive manufacturers.

Benefits of CNC Turned Components in Manufacturing

CNC turning is a process that uses a computer to control the movement of a cutting tool. It's used in a wide range of industries, including aerospace, automotive, and medical. This type of manufacturing can produce components with complex shapes and dimensions as well as complex geometries. For CNC turntables to run efficiently, they need high-quality components made from materials such as steel or aluminum. These materials are often used because they have high hardness levels which allow them to withstand repeated operations without bending or warping under pressure while remaining strong enough not only withstands vibrations but also to resist wear over time due to their resistance against corrosion caused by water moisture ingress due to air humidity levels change during operation cycle etc.

CNC machines are changing the way we manufacture, and more importantly, they're changing the way we work. They have become so powerful that they can now be used for almost any type of manufacturing process. This opens up many opportunities for small businesses that want to expand their operations with cutting-edge technologies.

The first thing you should know about CNC machines is that they aren't just for manufacturing anymore—they're also being used in other industries such as aerospace and automotive manufacturing. The reason why this happens is that these companies know how much faster it takes to use CNC technology versus traditional methods like manual machining or lathe turning.

Another benefit of using a CNC machine instead? You'll save money! Not only does it cost less money upfront than traditional methods like manual machining but also once things get going – since there's no learning curve involved – your time spent producing parts will decrease significantly over time due to fewer errors caused by human error during production stages compared with those done manually by someone else.

CNC Turned Components Manufacturers today are changing the world as we know it. The evolution of the industry has led to a new era in manufacturing, where precision is at the forefront and turn times have been cut down substantially. With this technology becoming more accessible, many people can now experience what it's like to work in this kind of environment which offers so many benefits over traditional manufacturing methods such as cutting steel by hand or using hand tools on an assembly line with no automation involved at all. Ganeshprecision.com manufactures and supplies CNC Turned Components in India with high Accuracy & Good quality.

4 notes

·

View notes

Video

youtube

DY cast & forge a forging is a manufacturing company based on India & Se...

#youtube#www.dycastandforge.com#steelforging#Steel casting#steel machinery#Dy Impex manufactures Precision Machined components & Assemblies through the CNC VMC and Conventional Machines. And having the well known a

2 notes

·

View notes

Text

Fadal Parts Online

ITSCNC specializes in providing top-quality Fadal CNC parts online, including glentek amplifiers, fadal cnc spindles, motors, and more. With years of expertise in Fadal parts repairs, we offer new, used, and rebuilt parts to enhance your CNC machine's performance. Our extensive inventory ensures you'll find the right component for improved productivity and precision. Trust ITSCNC for reliable Fadal parts and technical support.

#fadal machine parts#fadal cnc parts#fadal parts#fadal parts online#fadal parts for cnc machine#fadal cnc replacement parts#fadal parts manual#fadal cnc machines#replacement parts for fadal#fadal machine and control technical documentation#Fadal CNC Parts#Fadal Circuit Components#Fadal Ballscrews#Fadal Spindle#Fadal CNC Motors#Fadal CNC Ballscrews#Fadal Machine - Replacement Parts for Fadal#Replacement Parts for Fadal

0 notes

Text

Precision CNC Machine Job Work — CNC Machining Components Manufacturer

Pitrukrupa Engineering is ISO 9001:2015 certified Manufacturer, Exporter and Supplier of high performing CNC machine Components. Pitrukrupa Engineering is engaged in Service Providing in providing CNC Machine Job Work, VMC Machine Job Work, EDM Wire Cut Work and CNC Lathe Machine Job Work since its inception in 2009. We provide CNC Machining Components and Services job Work in India, USA, Canada, Brazil, UAE, Australia, Oman, South Africa, Vietnam, Afghanistan, Israel, UK.

CNC Machining Components & Parts

CNC Machine Components

VMC Machine Components

CNC Turn Mill Components

5 Axis Milling Components

4 Axis Milling Components

CNC Lathe Machine Components

CNC EDM Components

CNC Turn Mill Components

Aluminium Extrusion

Aluminium High Pressure Die Casting

Aluminium And Steel Precision Welding Fabrication

CNC Machining Job Work Services

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

For More Details

Click Here : https://www.pitrukrupaengineering.com/

0 notes

Text

Elevating Precision: How a CNC Machined Components Supplier Drives Innovation

In today's technologically advanced world, precision and efficiency are paramount, especially in manufacturing. The role of a CNC machined components supplier has become indispensable, fostering innovation and ensuring the seamless production of high-quality parts. The synergy between a CNC machined components supplier and a CNC manufacturing company exemplifies the advancements and collaborative efforts that drive the industry forward.

The Backbone of Modern Manufacturing

A CNC machined components supplier specializes in producing parts with extreme precision using Computer Numerical Control (CNC) machinery. These suppliers provide critical components to various industries, including aerospace, automotive, medical, and electronics. The ability to produce intricate designs with tight tolerances makes CNC machined components suppliers the backbone of modern manufacturing.

The relationship between a CNC machined components supplier and a CNC manufacturing company is symbiotic. While the supplier focuses on producing high-quality parts, the manufacturing company integrates these components into their products, ensuring overall excellence and functionality.

Precision and Quality: The Hallmarks of CNC Machining

Precision is the cornerstone of CNC machining. A CNC machined components supplier utilizes advanced machinery and software to produce parts that meet exact specifications. This level of accuracy is crucial in industries where even the slightest deviation can lead to significant issues. For instance, in the aerospace industry, a minor flaw in a component can compromise safety and performance.

Quality control is another critical aspect that sets a reputable CNC machined components supplier apart. Rigorous inspection processes and adherence to industry standards ensure that each component meets the highest quality benchmarks. This commitment to quality not only enhances the supplier's reputation but also strengthens the CNC manufacturing company’s product reliability.

Innovation through Collaboration

The collaboration between a CNC machined components supplier and a CNC manufacturing company drives innovation. Suppliers often work closely with manufacturers to understand their specific needs and challenges. This collaborative approach leads to the development of custom solutions that address unique requirements, ultimately pushing the boundaries of what is possible in manufacturing.

For example, a CNC machined components supplier might develop a new alloy or machining technique that improves the durability and performance of a component. This innovation, in turn, allows the CNC manufacturing company to offer superior products to its customers, gaining a competitive edge in the market.

The Impact on Various Industries

The influence of CNC machined components suppliers extends across multiple industries. In the medical field, precision-machined components are essential for devices like surgical instruments and implants. The automotive industry relies on these suppliers for parts that ensure vehicle safety and performance. In electronics, CNC machined components are integral to producing devices with intricate and compact designs.

Future Prospects and Technological Advancements

As technology continues to evolve, the role of CNC machined components suppliers will only become more critical. The advent of Industry 4.0 and the Internet of Things (IoT) is driving further advancements in CNC machining. Suppliers are adopting smart manufacturing techniques, such as real-time monitoring and predictive maintenance, to enhance efficiency and reduce downtime.

Additionally, the integration of artificial intelligence (AI) and machine learning in CNC machining processes is set to revolutionize the industry. These technologies enable suppliers to optimize production, predict potential issues, and continuously improve the quality of their components.

Conclusion

In conclusion, the partnership between a CNC machined components supplier and a CNC manufacturing company is a testament to the power of collaboration and innovation. By prioritizing precision, quality, and continuous improvement, these entities play a crucial role in advancing modern manufacturing. As technological advancements continue to shape the industry, the contributions of CNC machined components suppliers will remain vital, driving progress and excellence across various sectors.

0 notes

Text

#cnc-machined-components-manufacturers#CNC-machining-parts-manufacturer#CNC-precision-machining-company#precision-CNC-machining#precision-CNC-machining-shops

0 notes

Text

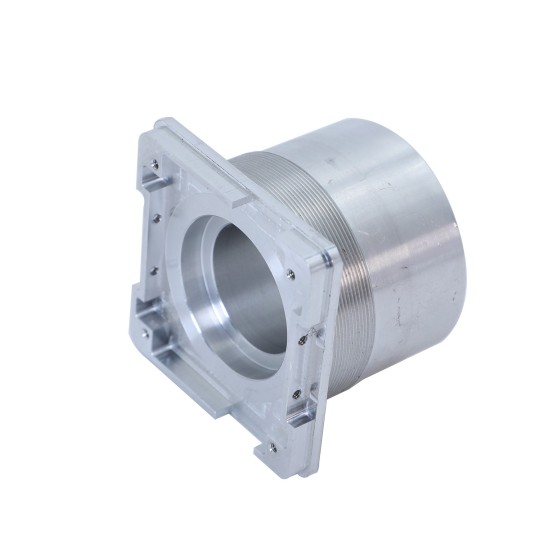

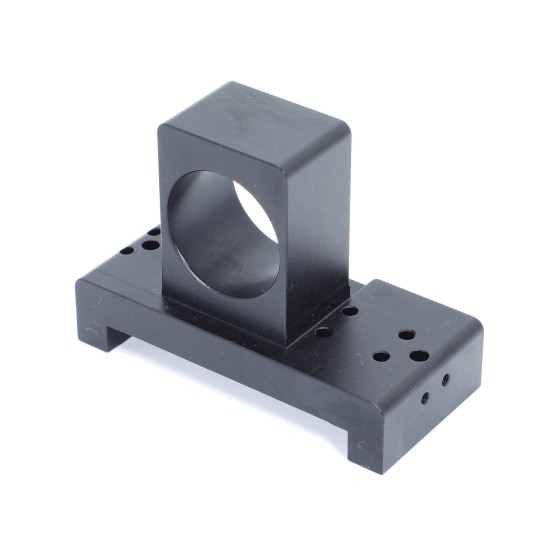

Global Precision - leading CNC machined components manufacturers. Get high-quality CNC custom machined parts, and customized solutions for your needs.

#global precision#CNC machined components#CNC machined components manufacturers#CNC components manufacturer delhi

1 note

·

View note

Text

The Complete Guide to CNC Machined Components

Brief Overview of CNC machined components

CNC components are parts made using machines controlled by computers. These machines can cut, drill, and shape materials with high precision. This technology is used to make many different parts, from tiny screws to large engine blocks. Let's look at the key features that make CNC components so valuable.

Key Features of CNC Machined Components

CNC-machined components have several key features that make them highly desirable in many industries.

1. Accuracy

CNC-machined components are known for their high accuracy. These machines can make parts with very tight tolerances, ensuring that each piece fits perfectly. This level of precision is essential for components that must work together seamlessly.

2. Complex Geometries

CNC machining can create parts with intricate shapes. This means components can have twists, turns, and curves that fit perfectly. With CNC technology, even the most complicated designs can be brought to life accurately.

3. Wide Range of Materials

CNC machining can work with many different materials like metals, plastics, and wood. This versatility makes it useful for various industries, from automotive to electronics. With CNC machining, you can create parts that meet specific needs without compromising on quality.

4. Superior Surface Finish

CNC machining ensures parts have a smooth surface finish. This means they feel sleek and fit together snugly. With a superior surface finish, components work efficiently and look polished. In conclusion, CNC-machined components offer precision and quality.

5. Customization

Customization is key in CNC machining. It allows for making parts tailored to specific needs. Whether it's adjusting dimensions or adding unique features, CNC machines can handle it. This flexibility ensures that every component meets exact requirements.

Read the full article

0 notes

Text

CNC Machined Parts in Ahmedabad

Scharf Precision Engineering is a leading provider of CNC machined parts and components in Ahmedabad. We specialize in CNC machined parts as per customer requirements with international standards. We have been serving clients from different industries including aerospace, military, energy and electronics.

#CNC Machined Parts#Precision Turned Components#CNC Machined Components#Custom Machined Parts#CNC Machined Parts Production#Ahmedabad

1 note

·

View note

Text

Unitritech Leading the Way in Aerospace Machined Components Manufacturing

In the highly specialized field of aerospace manufacturing, precision and reliability are paramount. Among the key players in this industry, Unitritech stands out as the premier manufacturer of aerospace machined components. With a steadfast commitment to quality, innovation, and customer satisfaction, Unitritech has earned its reputation as the best in the business.

Unitritech's expertise in producing high-precision machined components ensures that every part meets the stringent standards required for aerospace applications. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing for unparalleled accuracy and consistency. This dedication to excellence extends to their rigorous quality control processes, which guarantee that every component is meticulously inspected and tested before it reaches the customer.

One of the key factors that set Unitritech apart is their ability to handle complex and challenging projects. Whether it's producing intricate parts for commercial aircraft or custom components for military applications, Unitritech's skilled team of engineers and technicians possess the knowledge and experience to deliver exceptional results. Their innovative approach to problem-solving and continuous improvement ensures that they remain at the forefront of the industry.

In conclusion, Unitritech's commitment to precision, quality, and innovation makes them the best choice for aerospace machined components manufacturing. Their dedication to exceeding customer expectations and their proven track record of excellence solidify their position as industry leaders.

#High Precision Aerospace Machined Components#Advanced Aerospace Component Manufacturing#Custom Aerospace Machining Services#Leading Aerospace Machined Parts Supplier#Top Aerospace CNC Machining Company#Aerospace Precision Machining Experts#Quality Aerospace Manufacturing Solutions#Reliable Aerospace Machined Parts Manufacturer

0 notes

Text

Upgrades, Fadal Machine - Replacement Parts for Fadal

Upgrade your Fadal CNC machine with high-quality replacement parts designed to enhance performance and reliability. Whether you're looking to boost precision or extend the lifespan of your equipment, our selection of Fadal replacement parts, including amplifiers, motors, and controllers, offers the perfect solution. Optimize your CNC machine's efficiency with parts that meet or exceed OEM standards, ensuring seamless integration and minimal downtime. Trust our expertise to keep your CNC machine running at its best with top-notch upgrades tailored to your specific needs.

#Replacement Parts for Fadal#Fadal CNC machine#CNC machine#cnc machine repair#fadal cnc parts#fadal machine parts#fadal parts#fadal parts online#fadal parts for cnc machine#fadal cnc replacement parts#fadal parts manual#fadal cnc machines#fadal machine and control technical documentation#cnc machined parts#cnc machined components#fadal machine#Fadal Machine Parts#Fadal Parts Manual#Fadal Parts For CNC Machine#Fadal CNC Parts#Fadal Axis Amplifier#Fadal CNC Motors#Fadal CNC Ballscrews#Fadal CNC Keyboards#Fadal Parts

0 notes

Text

CNC / VMC Machining Job Work & CNC Machining Components in India— Pitrukrupa Engineering

Pitrukrupa Engineering is country’s leading Manufacturer, Exporter and Supplier firm offering high performing CNC Milling and Turning Components since its inception in 2009.

Our CNC Machining Work

We are offering CNC Machining job Work to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

CNC Machining Components & Parts

We are offering CNC Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Lathe Machining Component

5 Axis Milling Components

4 Axis Milling Components

CNC Turn Mill Components

CNC Turn Mill Machining Parts

Aerospace and Defence Machining Parts Manufacturing

Aluminium And Steel Precision Welding Fabrication

Aluminium High Pressure Die Casting

Aluminium Extrusion

For More Details

Click Here : https://www.pitrukrupaengineering.com/

#Machining Job Work#CNC Machining Work#CNC Job Work#5 Axis Milling Components#4 Axis Milling Components#CNC Turn Mill Machining Parts

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

Precision CNC machining service for defence, automotive, medical, government, mining, aerospace, electronics and telecommunication industries.

#machinery#cnc machined components#electronic components#spareparts#manufacturer#factory#cnc machining#machining parts#precision machining#machinist

0 notes